Tube-sinking cast-in-situ pile and construction technology thereof

A technology of immersed tube grouting pile and construction technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of incomplete compaction, fast tube pulling speed, and reduced pile tip strength, so as to prevent stress concentration, Prevent water ingress and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Embodiments of the invention are:

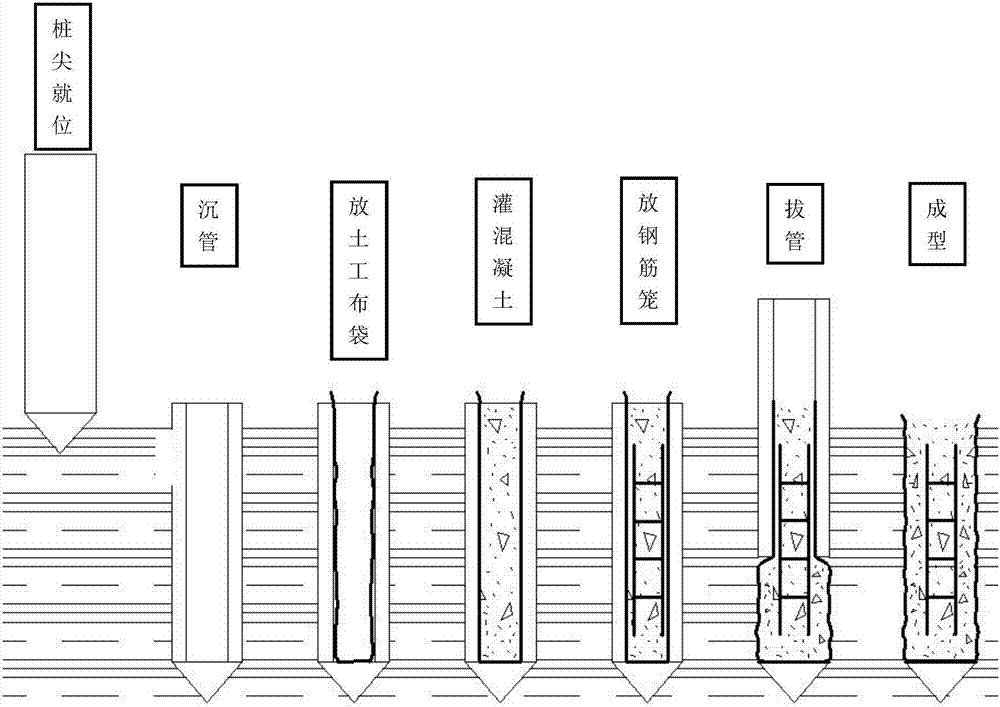

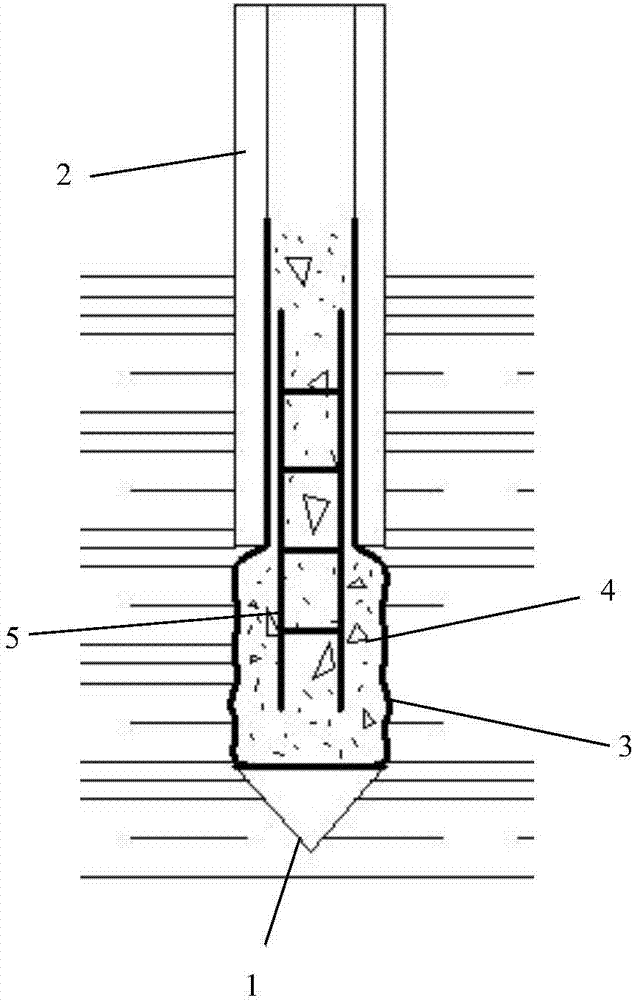

[0032] See attached figure 1 with figure 2 The invention relates to an immersed tube cast-in-situ pile, which includes a pile pipe, a pile point, a geotextile bag, a pile body and a reinforcement cage.

[0033] The pile point is a prefabricated concrete pile point.

[0034] The working process of this embodiment: a construction process of immersed pipe grouting piles, comprising the following steps:

[0035] A. The pile tip is in place: lift the pile tube to align it with the precast concrete pile tip embedded in the pile position;

[0036] B. Immersed tube: Use a pile driver to press the pile tube together with the pile tip into the soil;

[0037] C. Put in the geotextile bag: put the geotextile bag into the pile pipe;

[0038] D. Pouring concrete: pouring concrete into the geotextile bag;

[0039] E. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com