Patents

Literature

37results about How to "Guaranteed not to collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

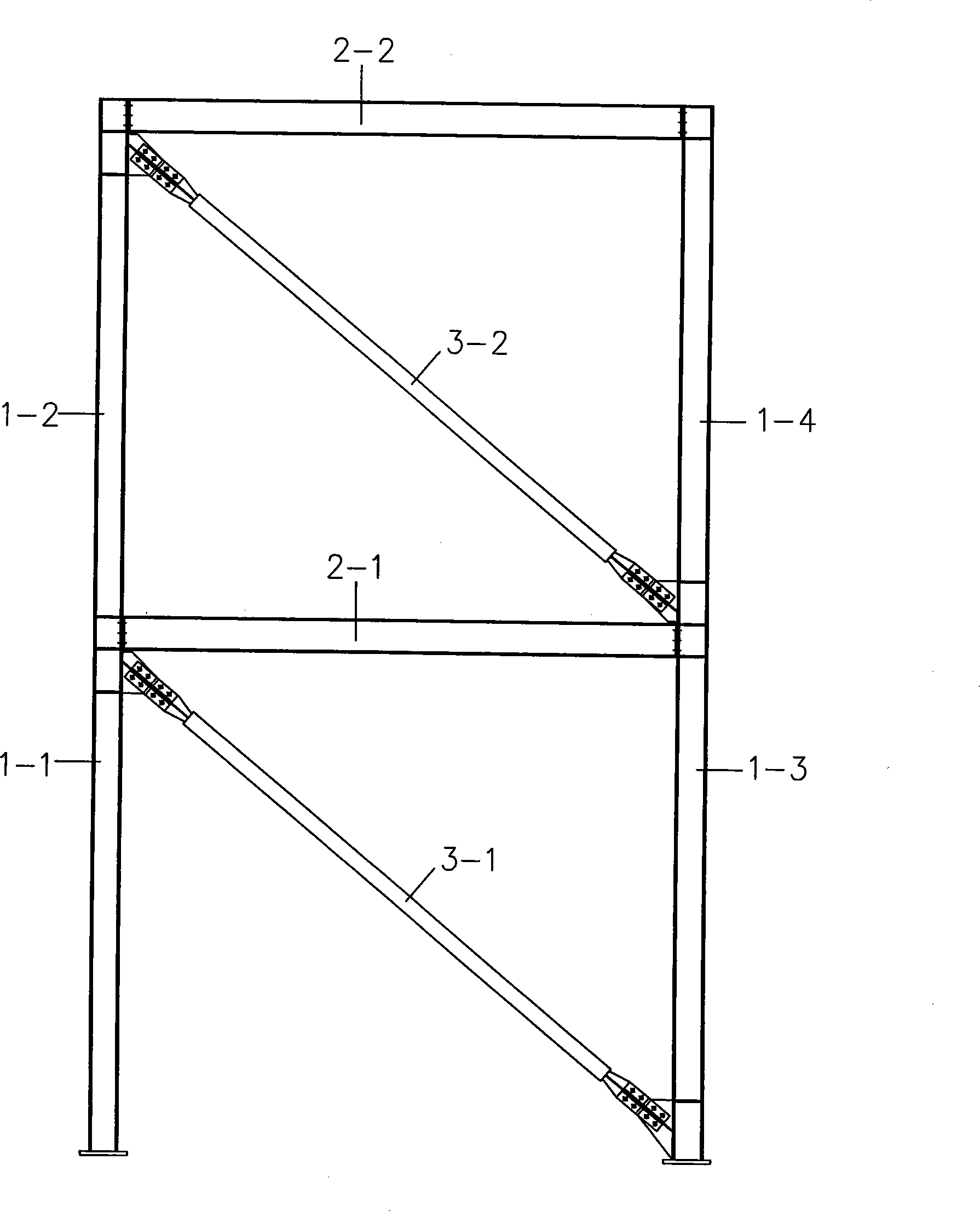

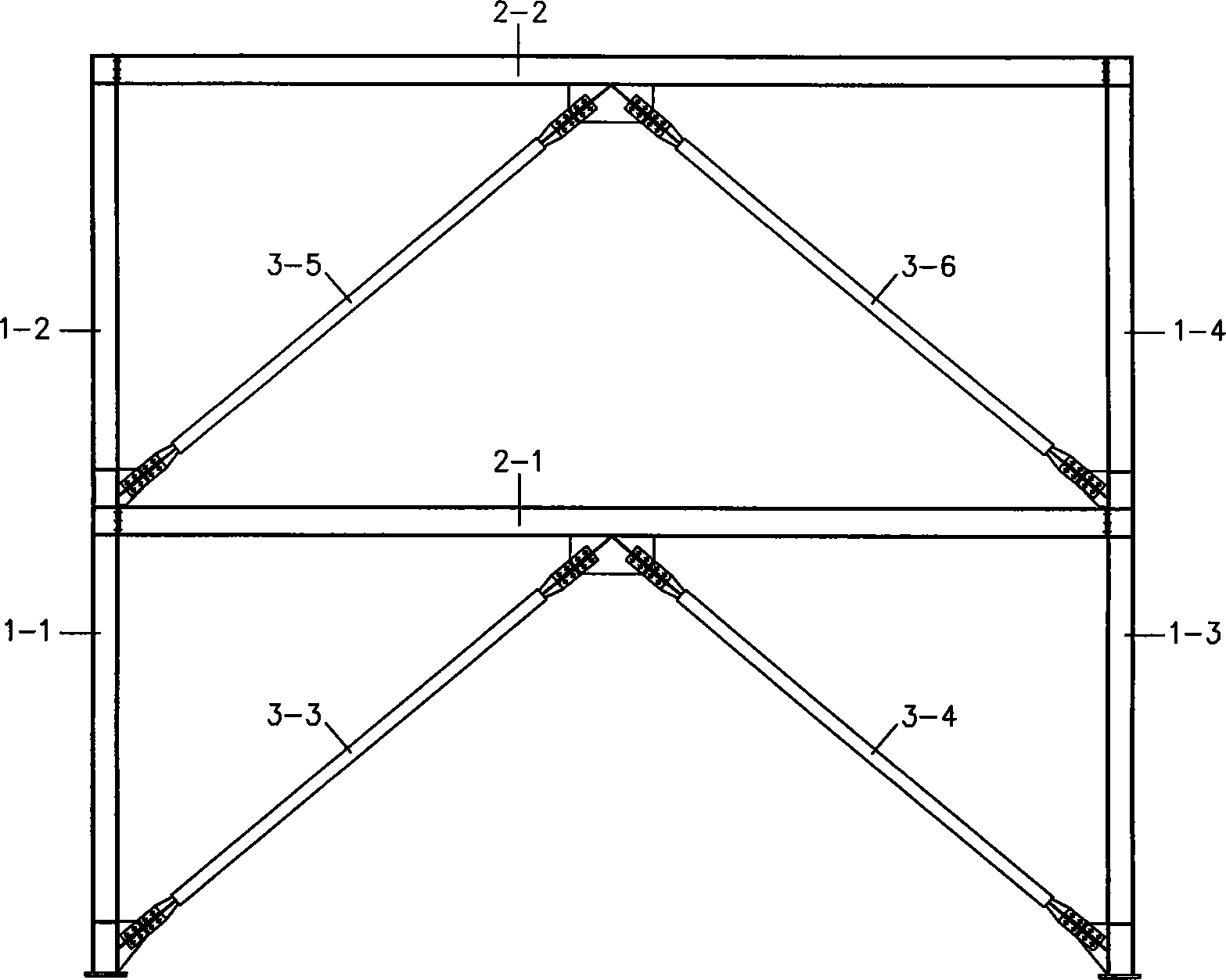

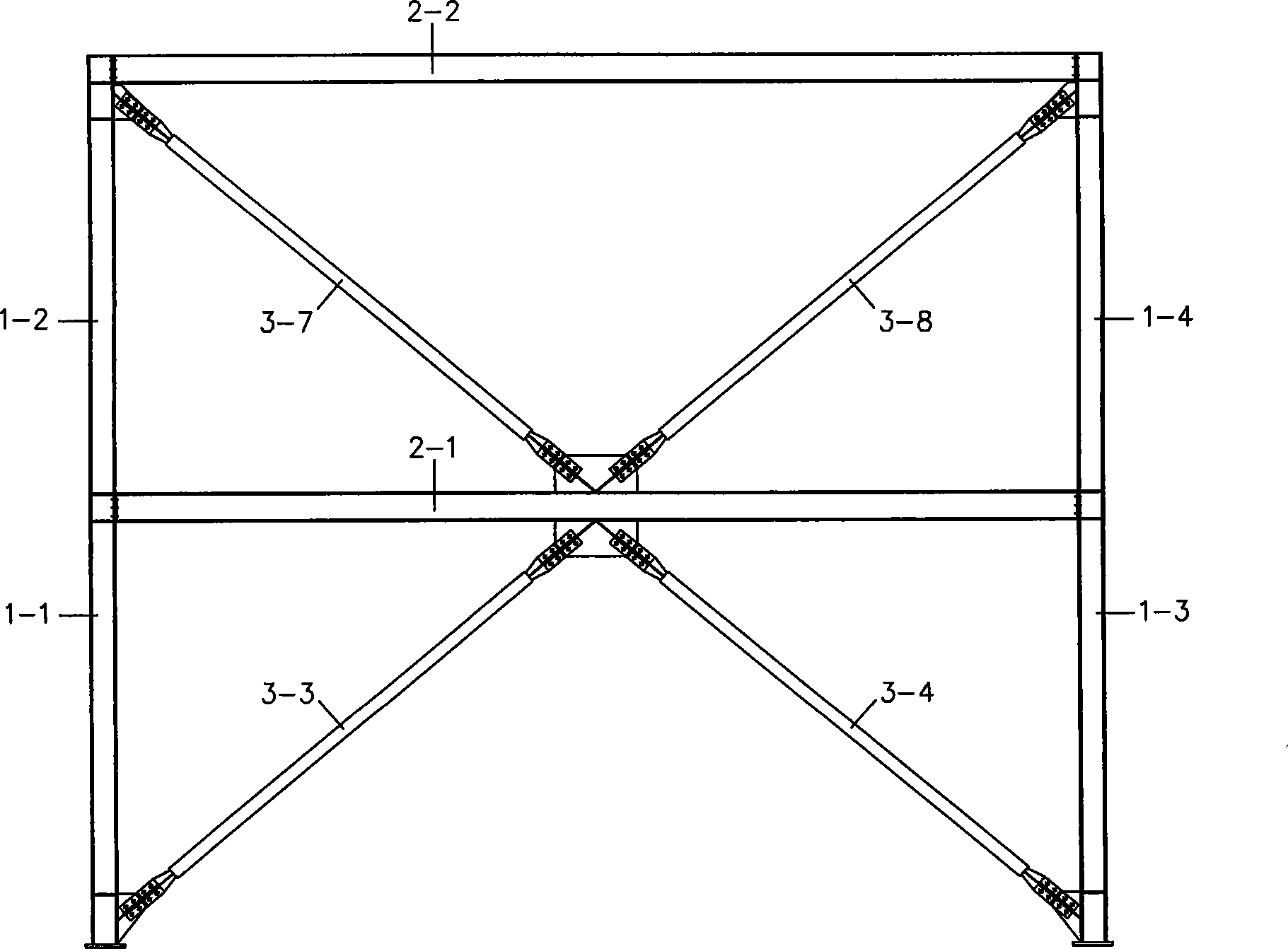

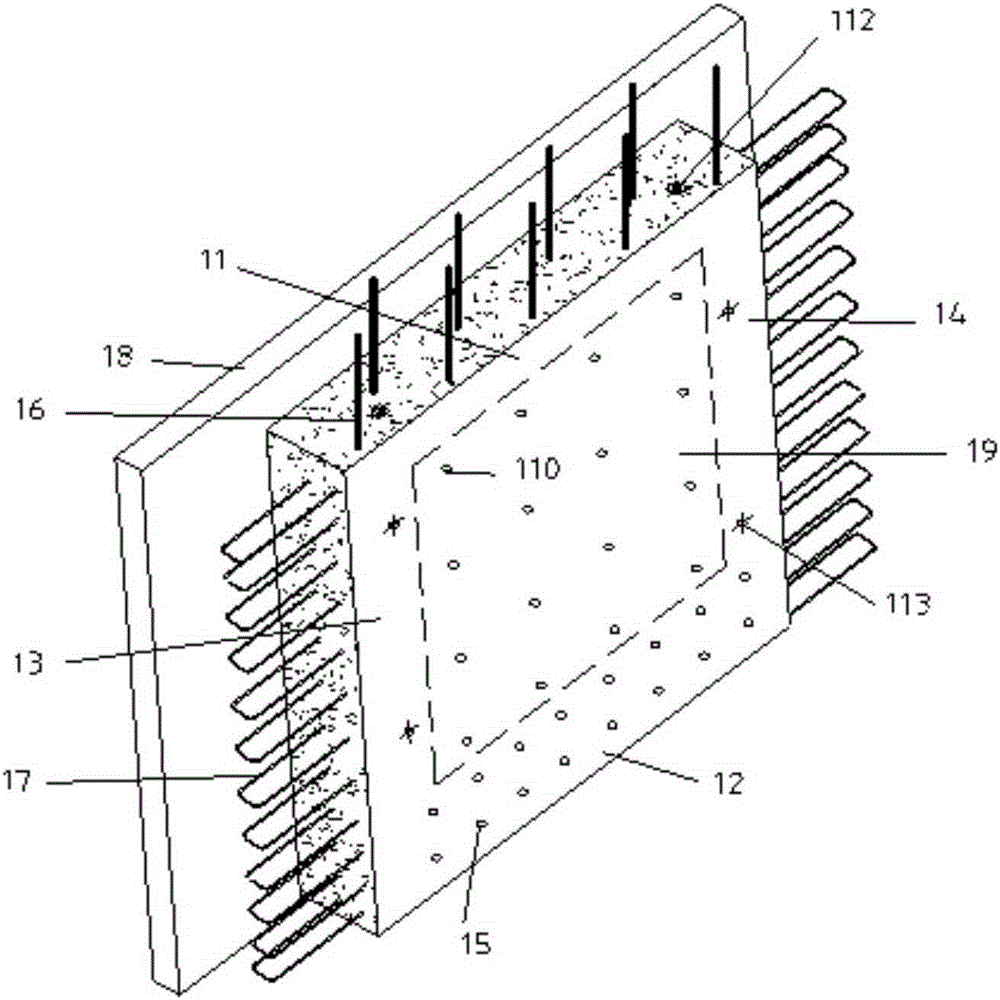

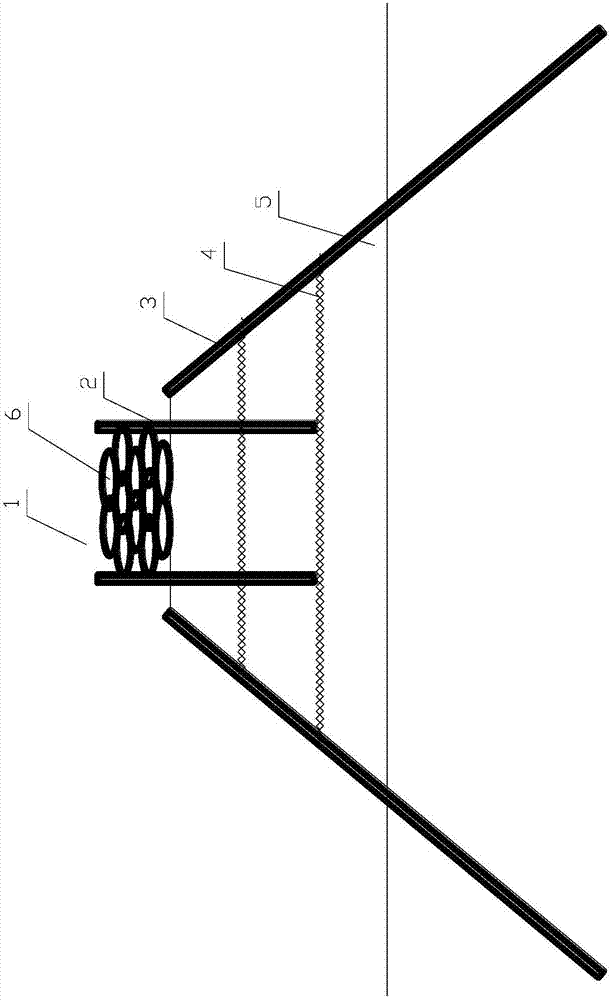

Semi-rigid connection-flection restriction support steel skeleton construction

InactiveCN101245611AGuaranteed not to collapseImprove energy consumptionShock proofingBuckling-restrained braceSteel frame

The invention belongs to the technical field of multistoried and high-rise buildings, particularly relates to a semi-rigid connection-bending and constraining support steel frame structure and is composed of a frame column, a frame beam and a bending and constraining support; the frame beam is connected with the frame column by adopting the semi-rigid connection mode and the bending and constraining support is arranged into a center support mode; based on the superiority of the steel structure, the invention can realize the optimum design, save the used steel quantity, reduce the workload of site welding, raise the construction speed, guarantee the quality of connection and is beneficial to structure arrangement; when used in earthquake areas, the restoration after earthquake is convenient and the earthquake damage can be reduced; when the structure is used in the multistoried and high-rise building, the prospect of application is wide.

Owner:TONGJI UNIV

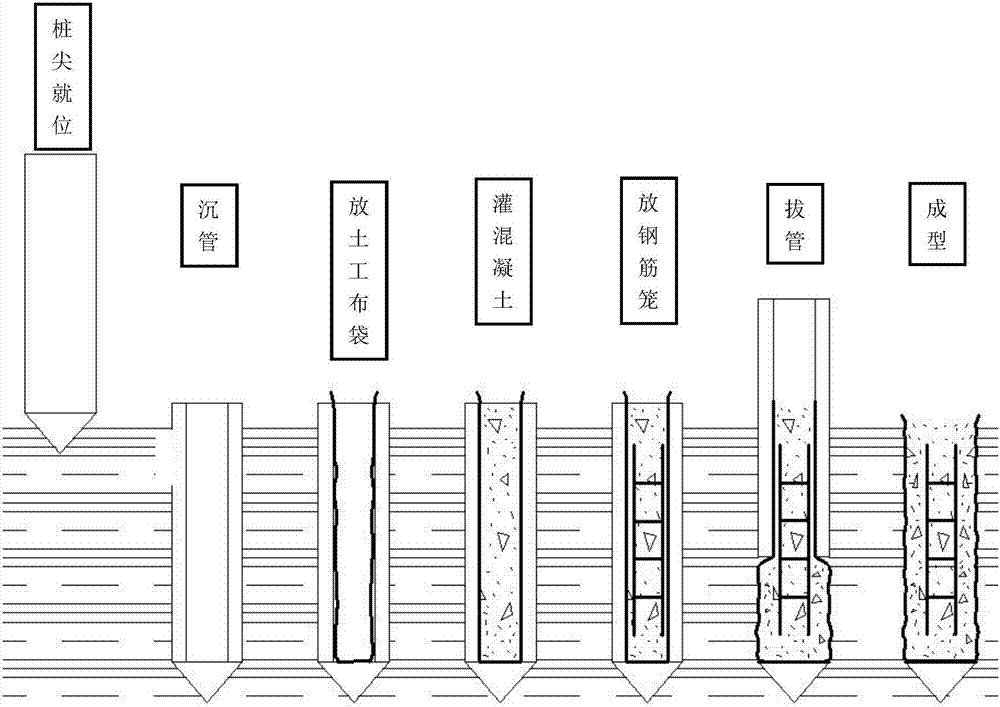

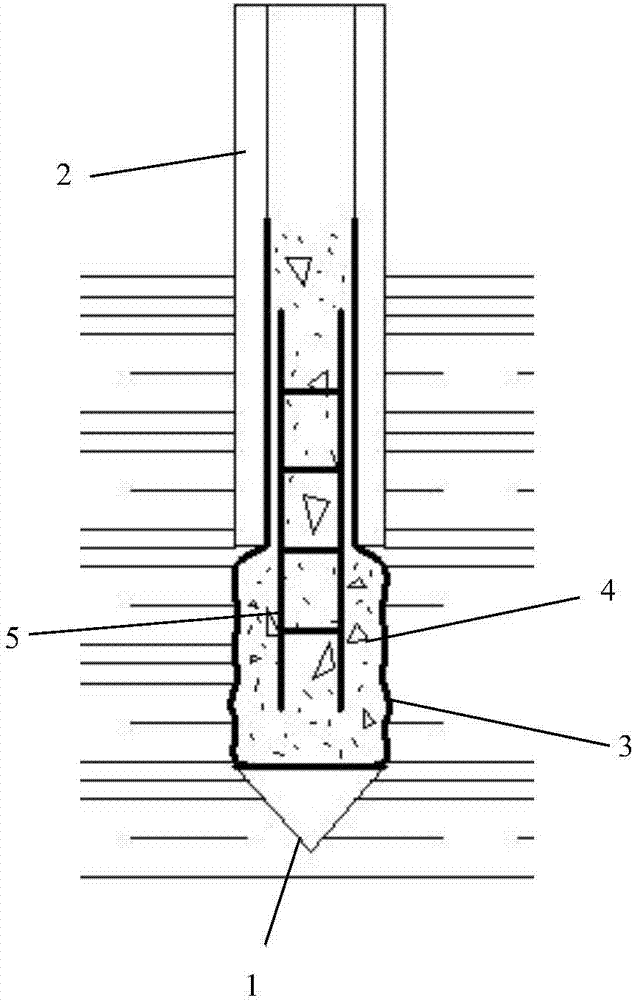

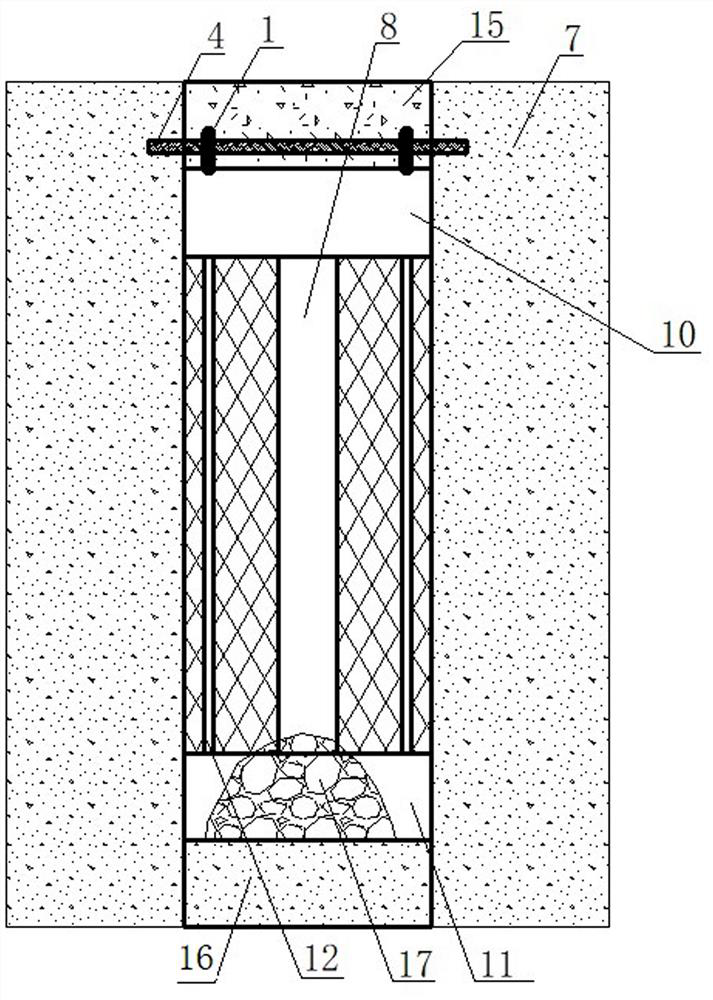

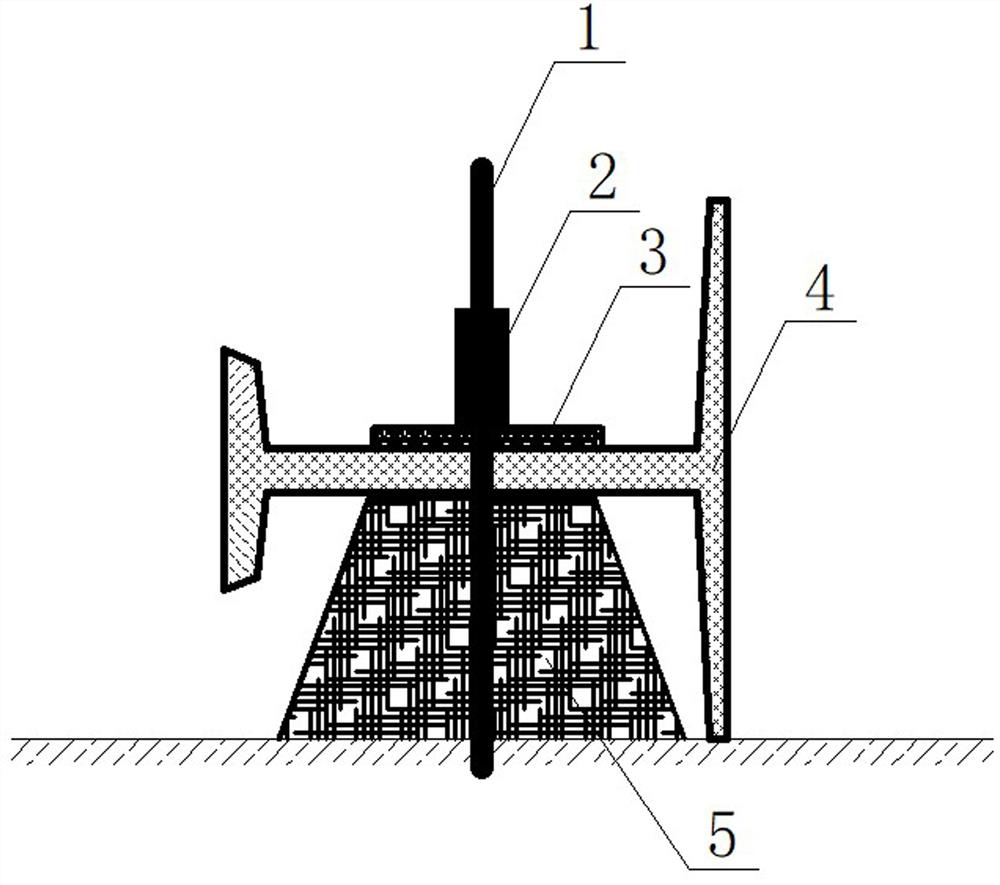

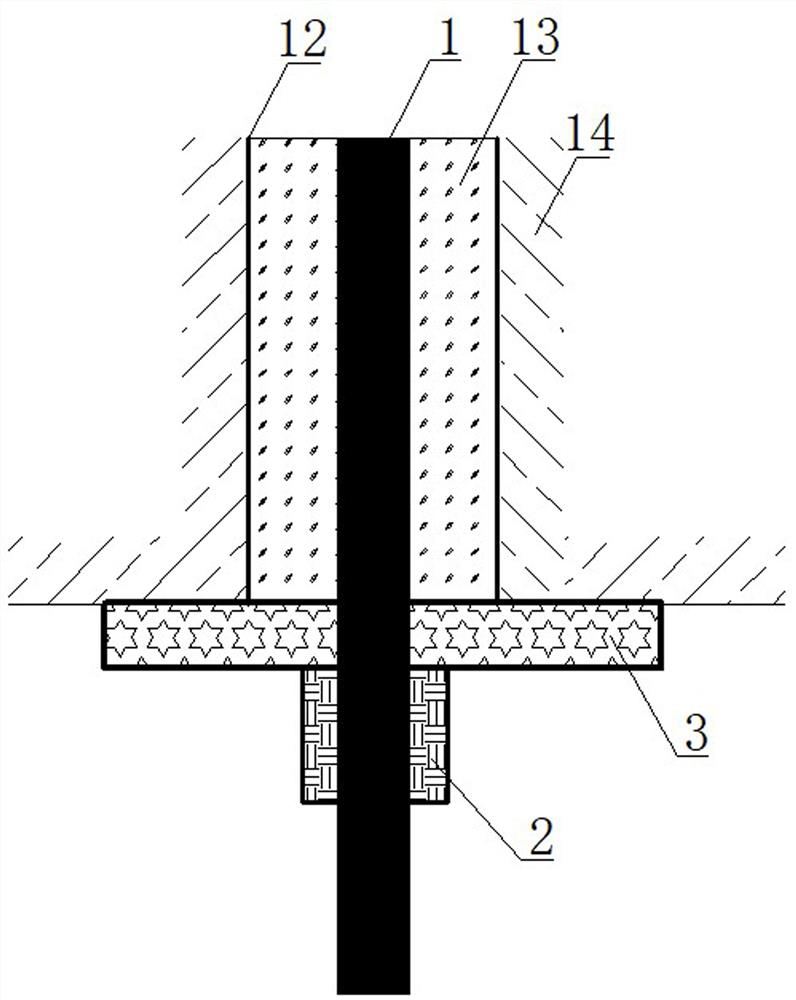

Tube-sinking cast-in-situ pile and construction technology thereof

The invention belongs to the technical field of foundation reinforcement, and discloses a tube-immersed cast-in-situ pile and its construction technology. The tube-immersed cast-in-place pile involves a pile tip, a pile pipe, a geotextile bag, a pile body and a reinforcement cage. The technological process is as follows: 1) 2) Immerse the pipe; 3) Put it into a geotextile bag; 4) Pouring concrete; 5) Hanging the reinforcement cage; 6) Pulling out the pipe; 7) Forming. The invention avoids common problems such as necking piles, broken piles, stilted piles and pile tip water inflow in the traditional sinking tube pouring pile process, and ensures the formation of the pouring piles, thereby effectively increasing the bearing capacity of the piles.

Owner:ANHUI UNIV OF SCI & TECH

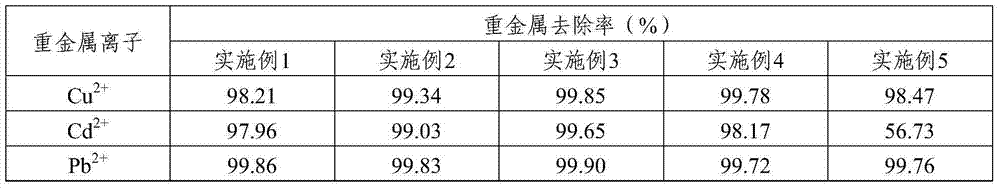

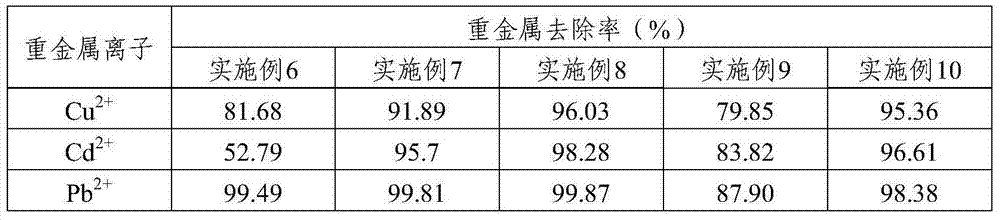

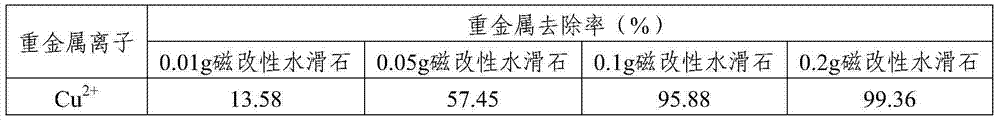

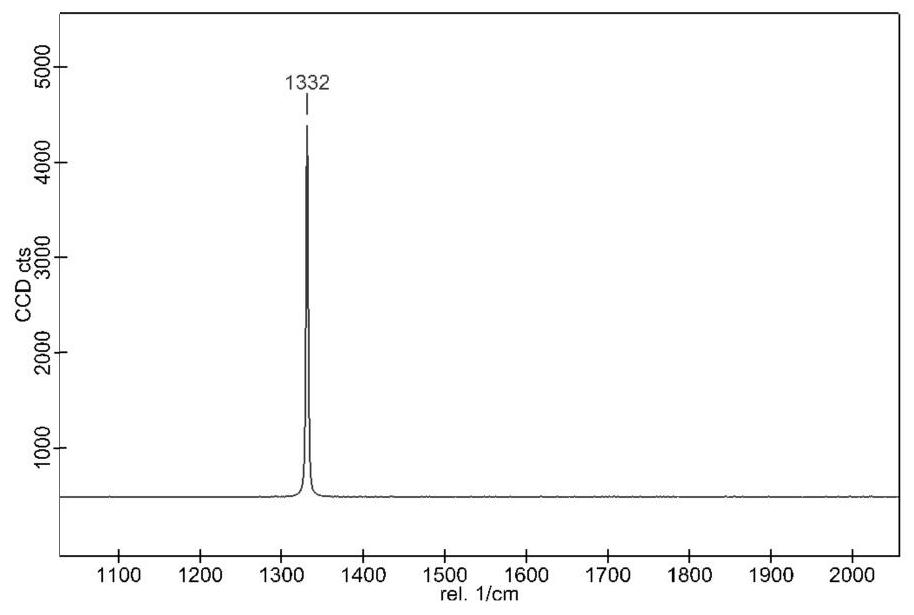

Magnetically modified hydrotalcite as well as preparation method and application thereof

InactiveCN104707563AControl the calcination temperatureGuaranteed not to collapseOther chemical processesAlkali metal oxides/hydroxidesSorbentHydrotalcite

The invention relates to magnetically modified hydrotalcite as well as a preparation method and an application thereof. A raw material of the magnetically modified hydrotalcite comprises the following components: hydrotalcite, Fe<2+>, Fe<3+> and ammonia water. The preparation method for the magnetically modified hydrotalcite is simple and easy to operate; as an excellent adsorbent, the magnetically modified hydrotalcite has a remarkable removal effect on heavy metal ions in wastewater.

Owner:HUNAN AGRICULTURAL UNIV

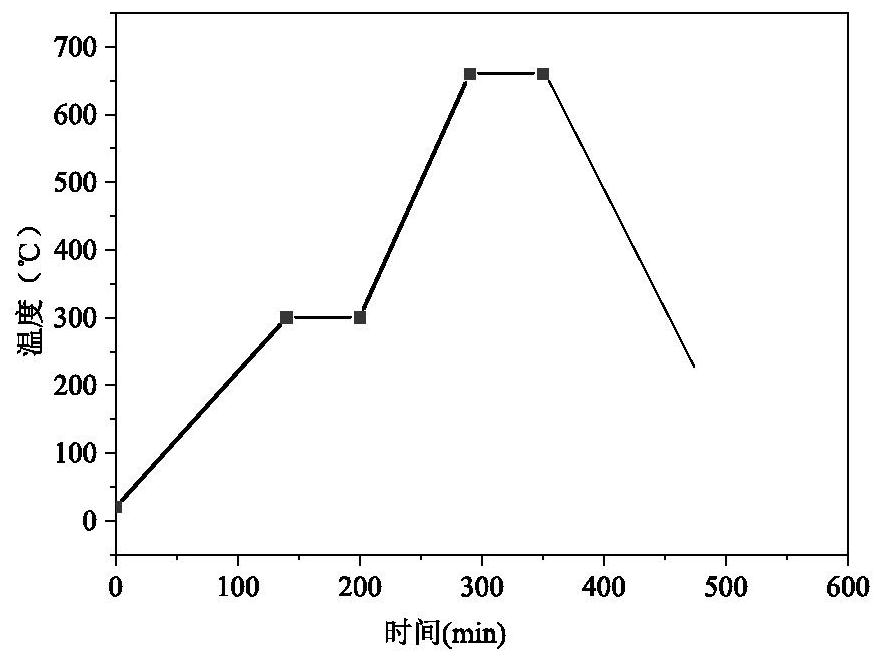

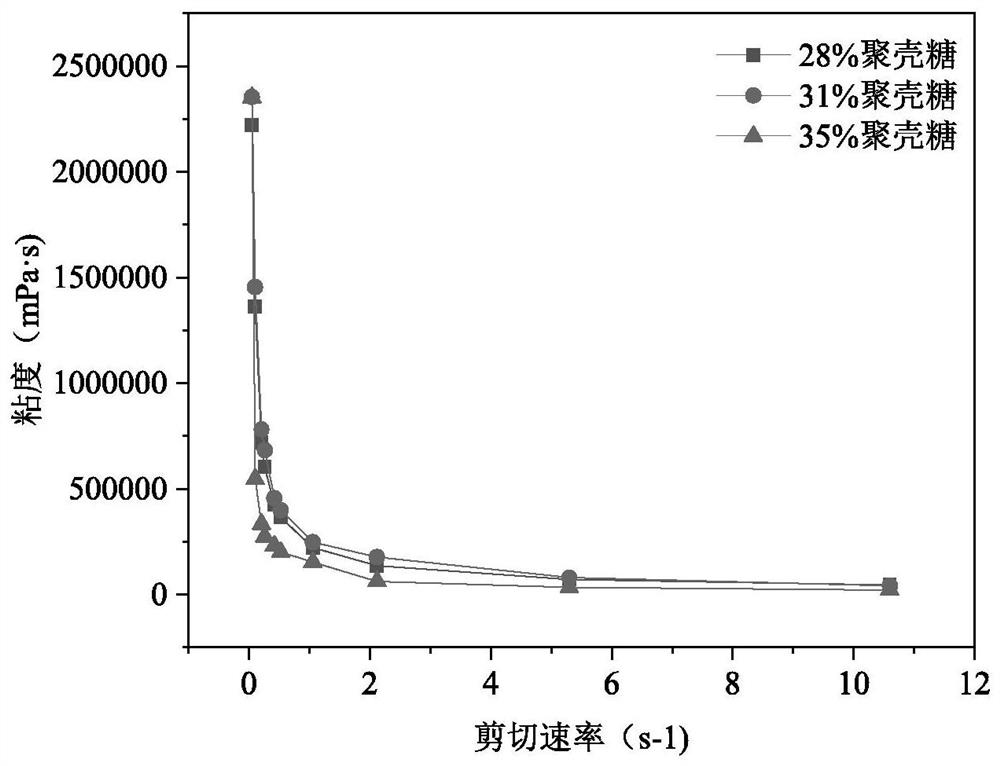

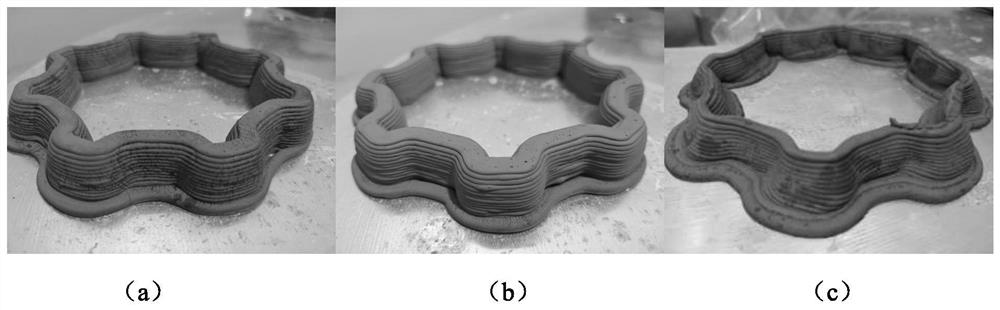

Slurry direct writing forming method of diamond tool

ActiveCN112723902APromote self-sharpeningUniform stomataAdditive manufacturing apparatusAbrasion apparatusPolymethyl methacrylateNanoceramic

The invention discloses a slurry direct writing forming method of a diamond tool, which comprises the following steps: (1) fully mixing nano ceramic powder, PMMA (polymethyl methacrylate) and diamond microparticles to obtain mixed powder; (2) fully dispersing xanthan gum in deionized water to obtain a xanthan gum solution; (3) uniformly mixing the mixed powder prepared in the step (1) with the xanthan gum solution obtained in the step (2) to obtain slurry; (4) adding the slurry prepared in the step (3) into a needle cylinder of slurry direct writing forming equipment, and printing into a designed shape in a layer-by-layer overlapping manner to obtain a green body; and (5) drying the green body prepared in the step (4) to constant weight, and then sintering to obtain the diamond tool. The diamond tool with a complex structure can be manufactured at a time through slurry direct writing forming, and the diamond tool has high consistency, proper mechanical property, controllable porosity and high shape precision.

Owner:HUAQIAO UNIVERSITY

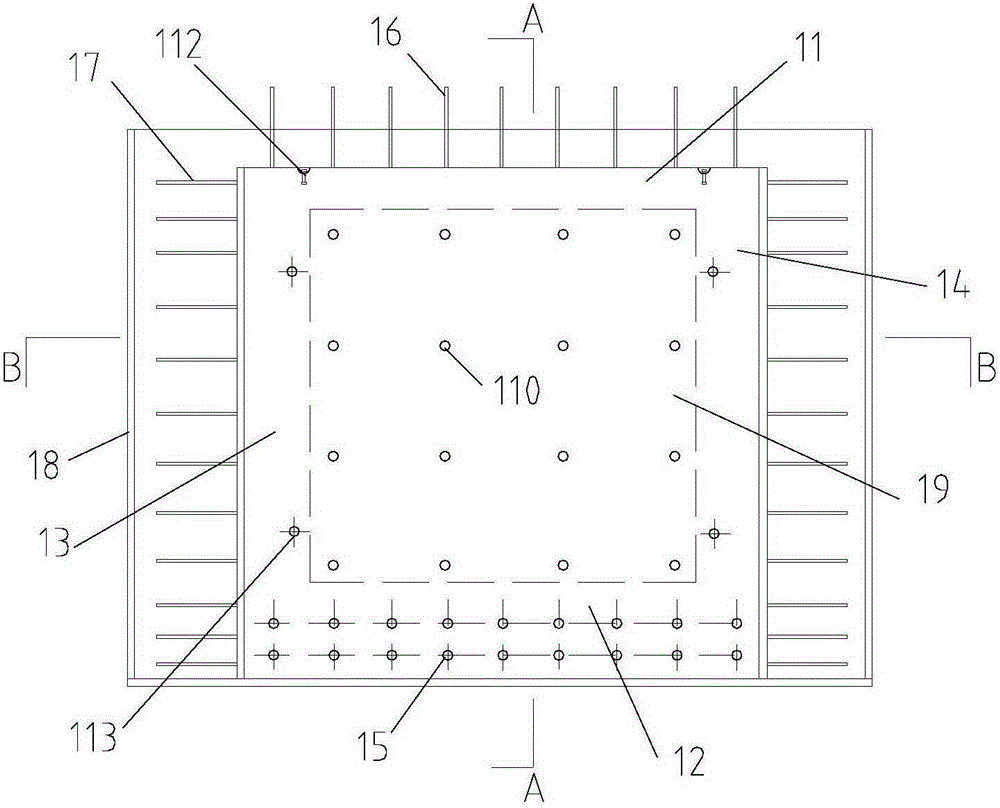

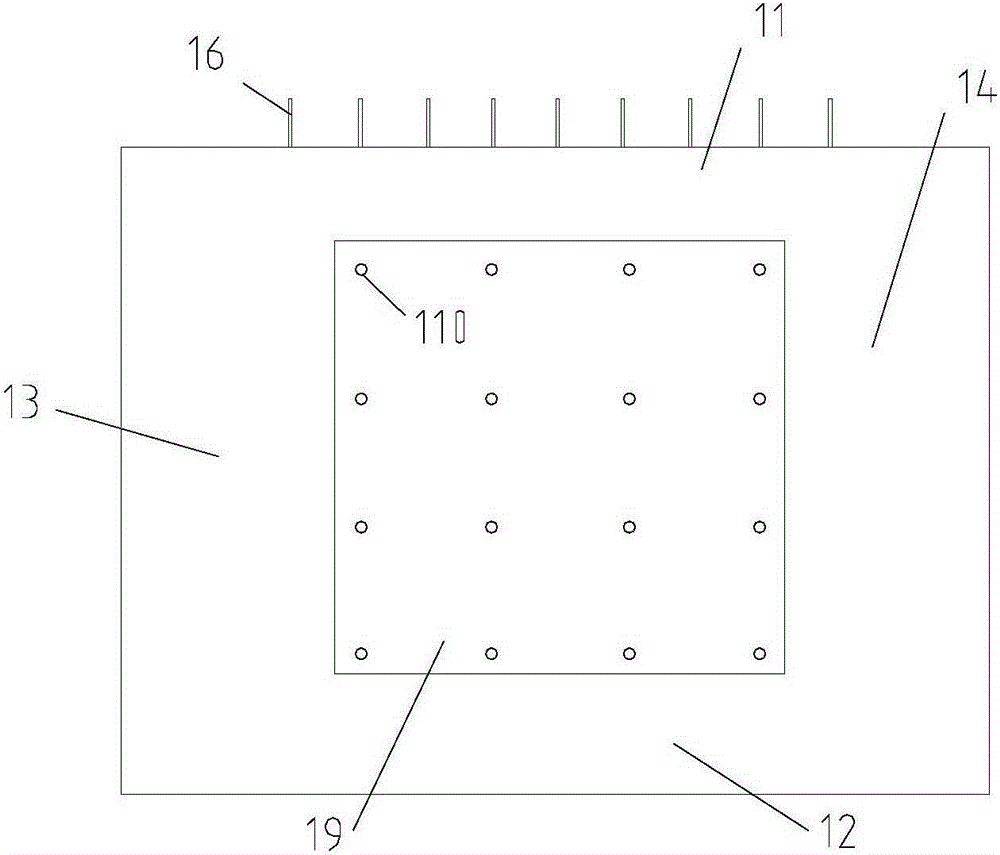

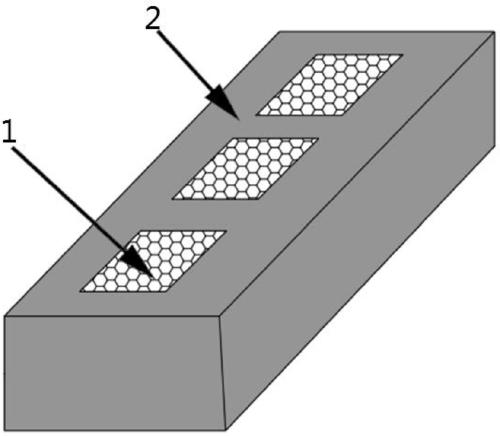

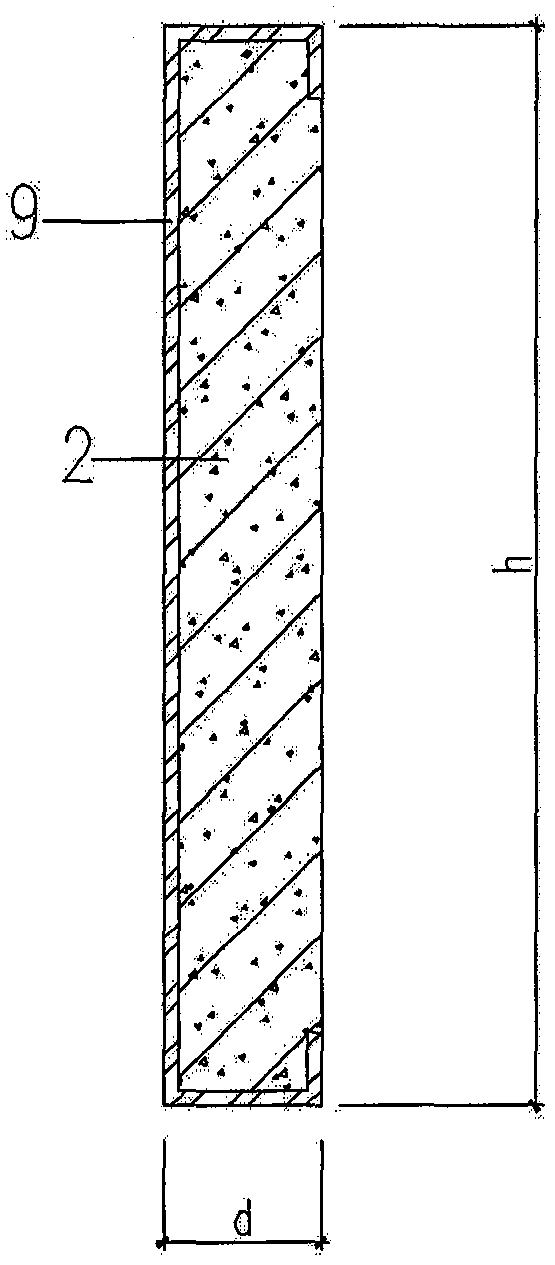

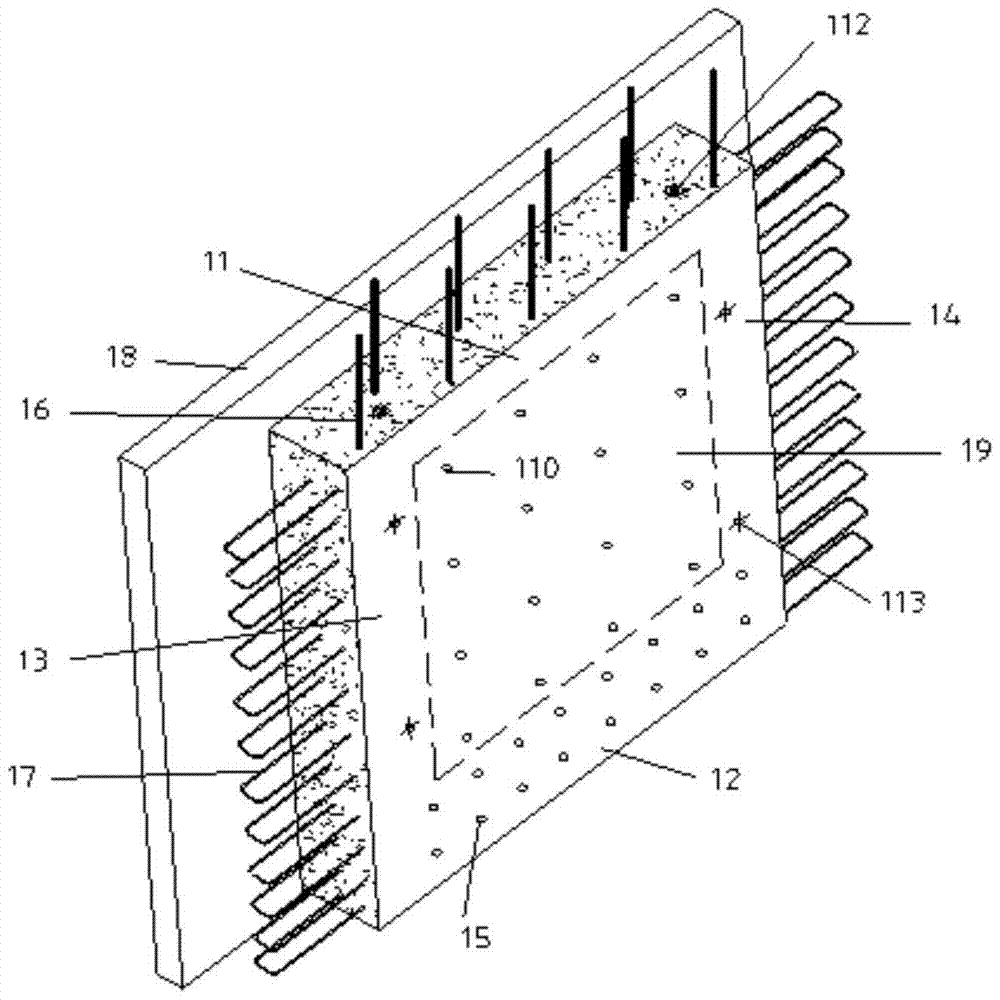

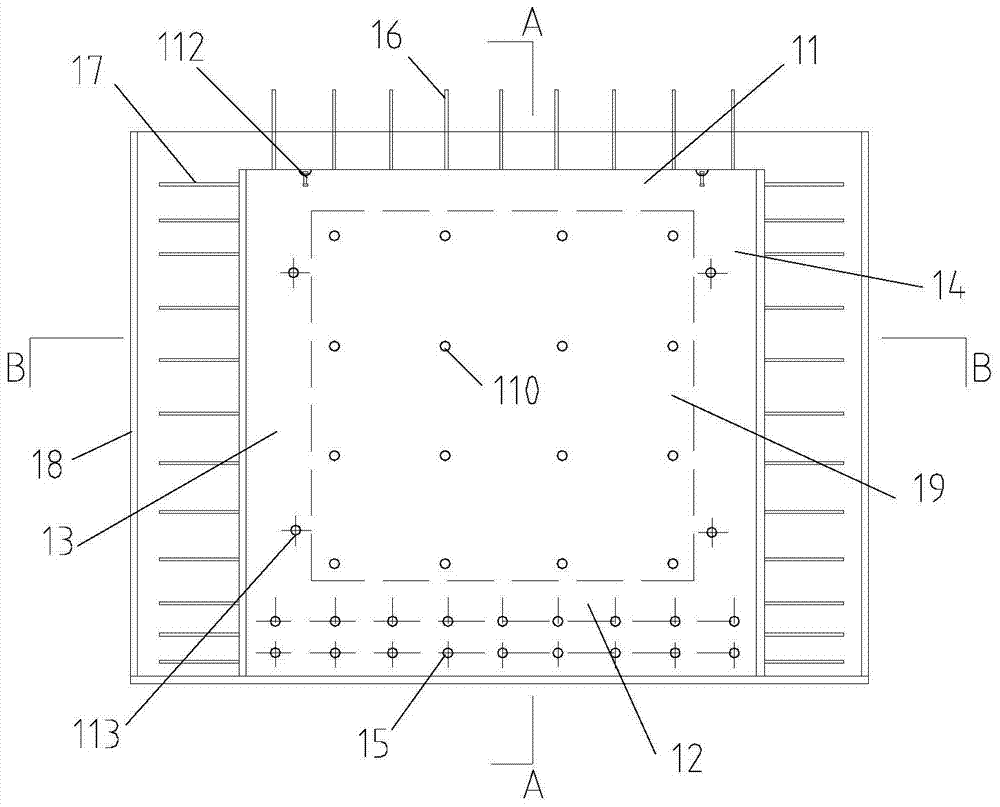

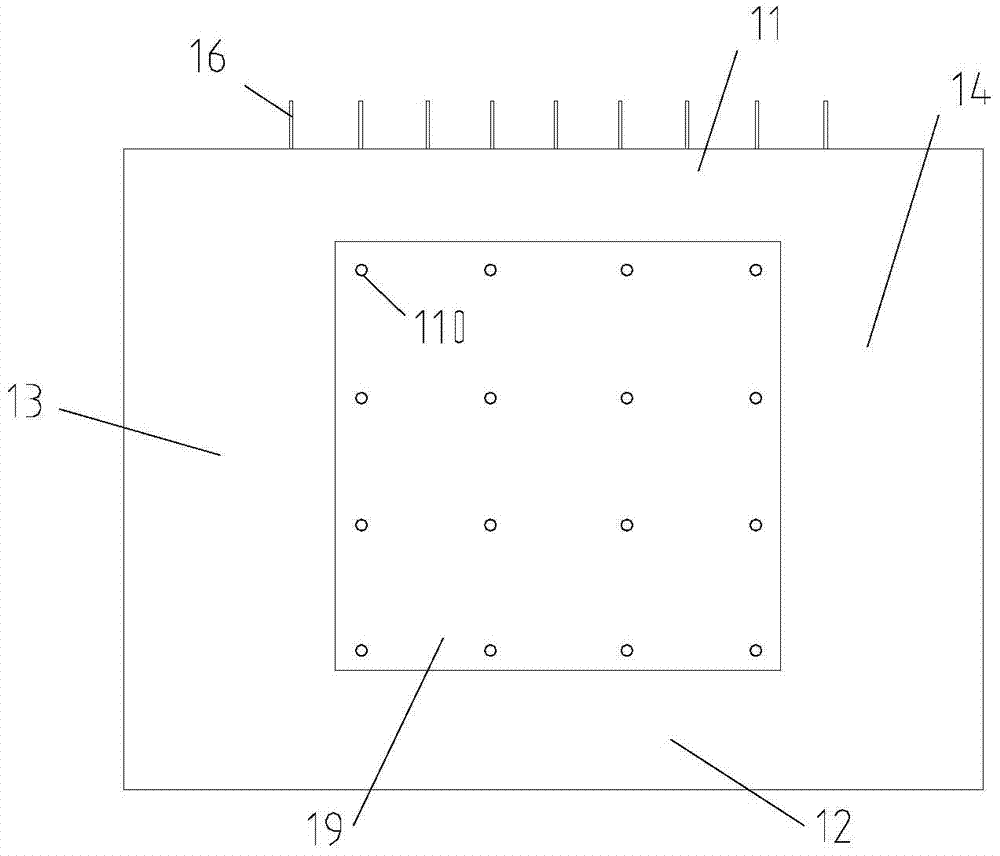

Prefabricated concrete component, shear wall module with same and making method of prefabricated concrete component

ActiveCN105220793AQuality improvementImprove efficiencyConstruction materialWallsRebarPrecast concrete

The invention relates to a prefabricated concrete component, a shear wall module with the same and a making method of the shear wall module. The prefabricated concrete component comprises a first shear wall plate, rebars are arranged in the first shear wall plate, four sides of the first shear wall plate are integrally formed with an upper edge concealed frame beam, a lower edge concealed frame beam, a left edge concealed frame column and a right edge concealed frame column, a reinforced concrete plate protruding out of the first shear wall plate is arranged on the back of each of the upper edge concealed frame beam, the lower edge concealed frame beam, the left edge concealed frame column and the right edge concealed frame column, a grouting sleeve is embedded in the lower edge concealed frame beam, vertical rebars extending out of the upper edge concealed frame beam are embedded in the upper edge concealed frame beam, each of the left edge concealed frame column and the right edge concealed frame column is provided with a U-shaped closed rebar extending out of the same. The prefabricated concrete component serves as a part of the shear wall module, and the shear wall module can be made by only mounting a concealed support and firmly connecting with another shear wall plate. A concealed support truss is arranged between two shear wall plates, so that good anti-seismic performance is realized.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Lost foam casting method

InactiveCN104874737AGuaranteed not to collapseAvoid damageFoundry mouldsFoundry coresVacuum extractionLiquid metal

The invention discloses a lost foam casting method which specifically includes the following steps: step 1: making a lost foam pattern; step 2: drying the prepared lost foam pattern; step 3: carrying out pattern repairing and model forming on the dried lost foam pattern to form a cluster model; step 4: coating the cluster model formed in the step 3; step 5: drying the cluster model coated in step 4; step 6: casting the cluster model obtained in step 5 to form an initial casting; step 7: polishing and painting the initial casting to form a final casting. According to the lost foam casting method provided by the invention, when the displacement between the liquid metal and the EPS cluster model is completed, a plastic film on the surface of a sand box is removed, and vacuum extraction is continued, so that the sand box does not collapse; the process is equivalent to crash handling for the casting, so that the residual stress in the casting is eliminated, and the mechanical properties of the casting are increased.

Owner:HANZHONG YANHANG PRECISION MACHINERY MFG

Foundation trench support technology for secondary branch pipe network project construction

InactiveCN111395363AGuarantee the stability of foundation grooveEnsure safetyFurnace typesExcavationsArchitectural engineeringStructural engineering

The invention discloses a foundation trench support technology for secondary branch pipe network project construction. The technology comprises the steps of (1) steel plate pile production; (2) secondary branch pipe network construction preparation; (3) surveying and setting-out; (4) road surface breakage and removal; (5) steel plate pile striking; (6) foundation trench excavation; (7) secondary branch pipe construction; (8) foundation trench backfilling; and (9) steel plate pile pull-out. In the whole construction process, according to the principles of high efficiency, economy and environmental friendliness, the construction period is greatly shortened, engineering efficiency is improved, the stability of a foundation trench in secondary branch pipe network engineering is guaranteed, andthe safety of constructors and equipment is ensured.

Owner:SINOHYDRO HARBOR CO LTD

Stope point column supporting, reinforcing and recovering method

PendingCN113622916ADoes not affect integrityHigh strengthUnderground miningBlastingStructural engineeringOperation safety

The invention discloses a stope point column supporting, reinforcing and recovering method. The method comprises the following steps that channels are constructed at the upper part and the lower part of a point column, the point column is supported and reinforced by adopting a long anchor cable, and the point column is maintained by adopting a flexible net; after stoping of a stope is finished, a charging channel is constructed under the protection of a filling body of the upper channel of the point column, an ore removal channel is constructed on the lower channel of the point column, a pilot shaft is constructed inside the point column, the pilot shaft serves as a free face, and charging blasting is conducted in a drill hole of the long anchor cable, so that the point column is recovered. According to the stope point column supporting, reinforcing and recovering method, the problems that the integrity of the point column is prone to damage, the operation safety is difficult to guarantee, the efficiency is low, the recovery difficulty is high and the recovery dilution rate is high in the conventional point column protection and recovery process are solved.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

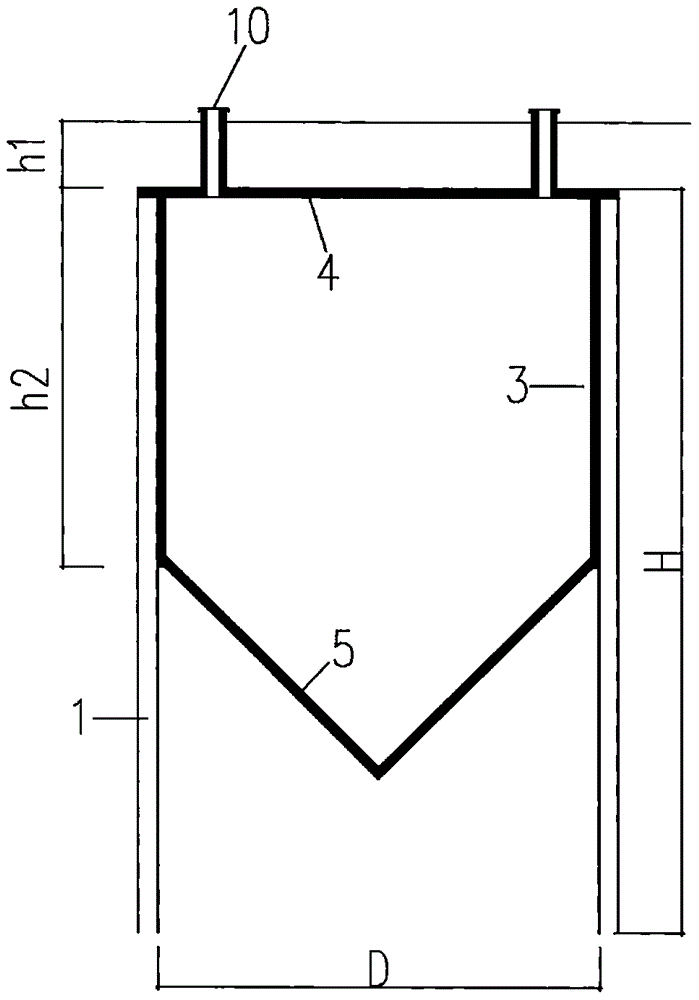

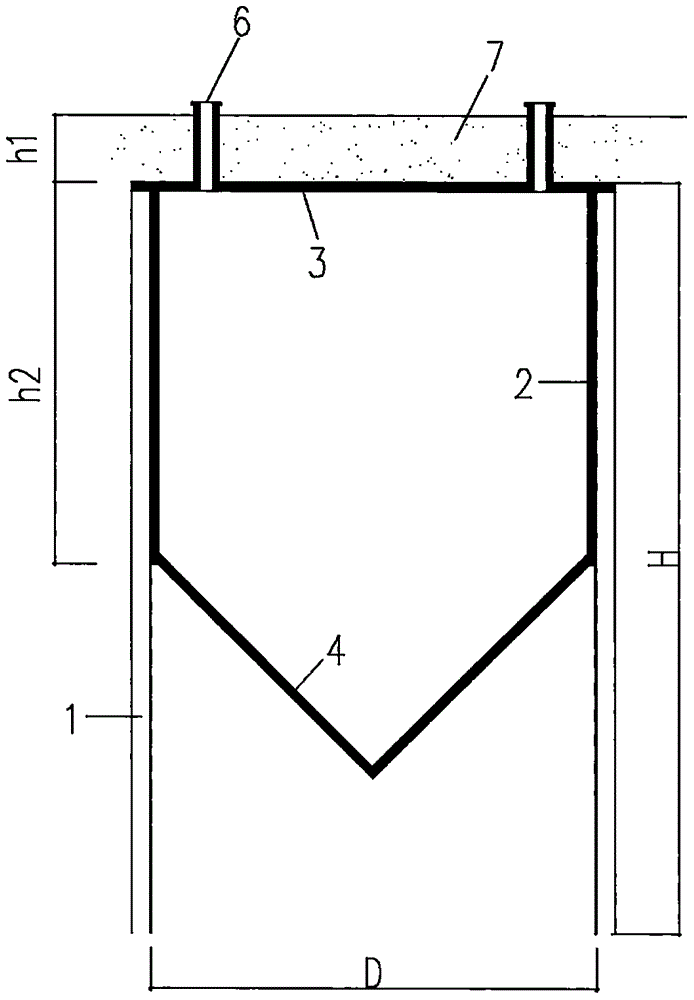

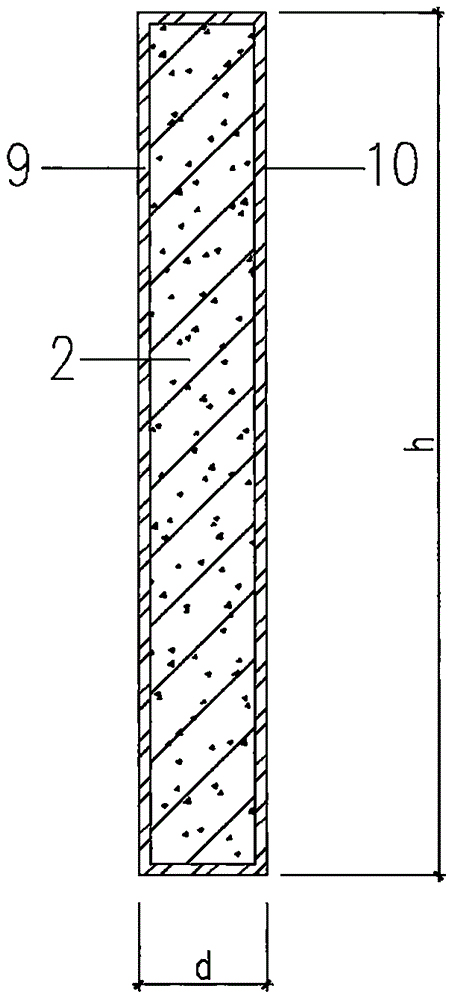

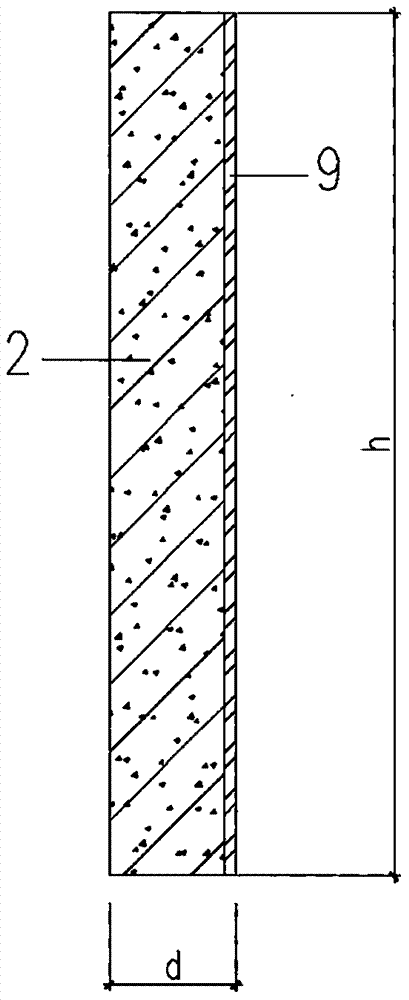

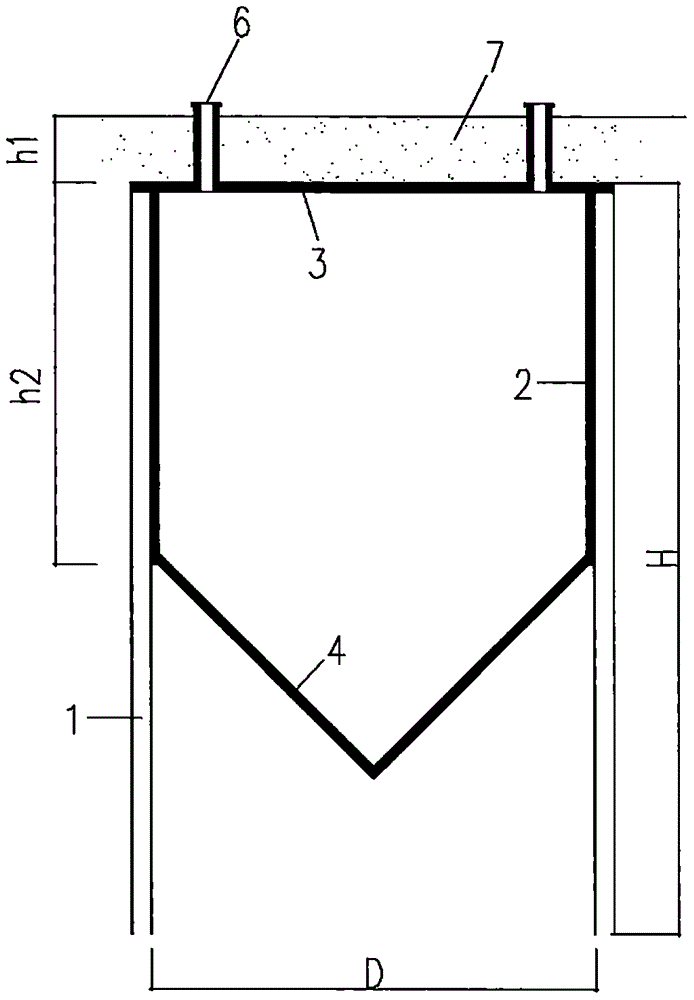

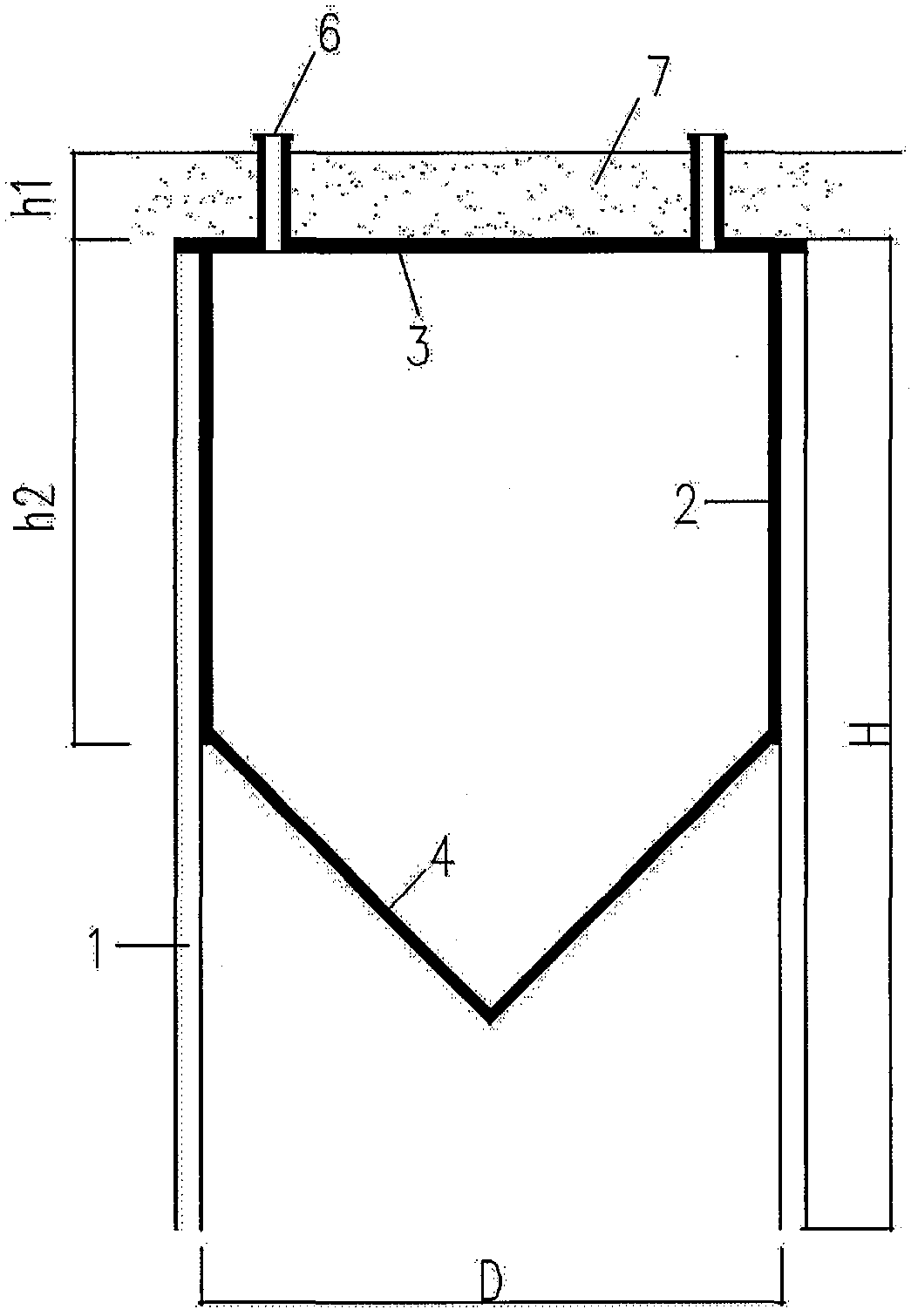

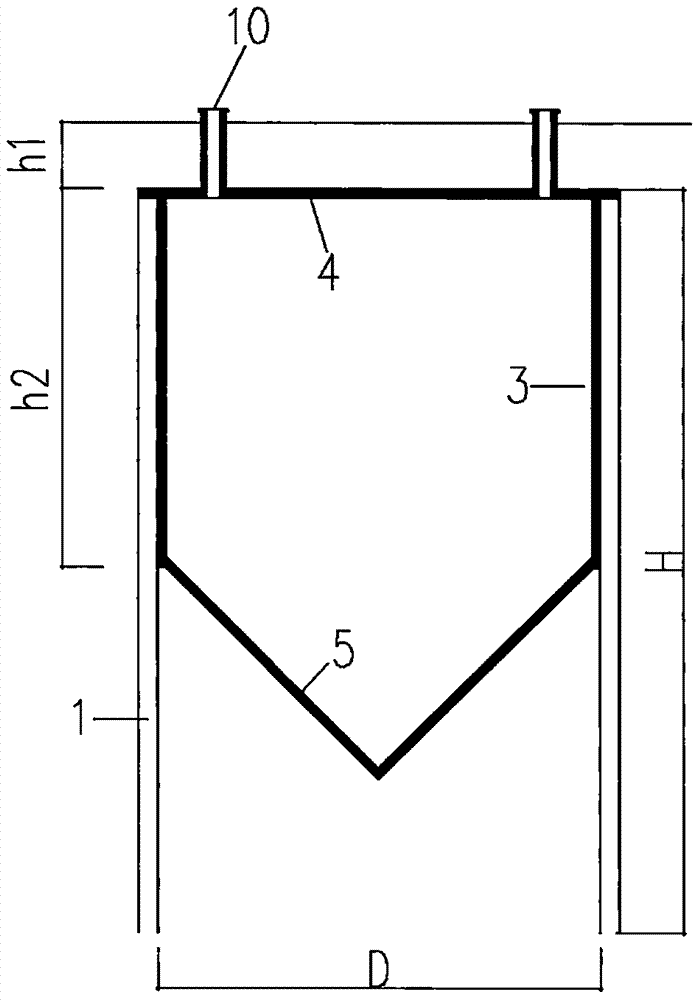

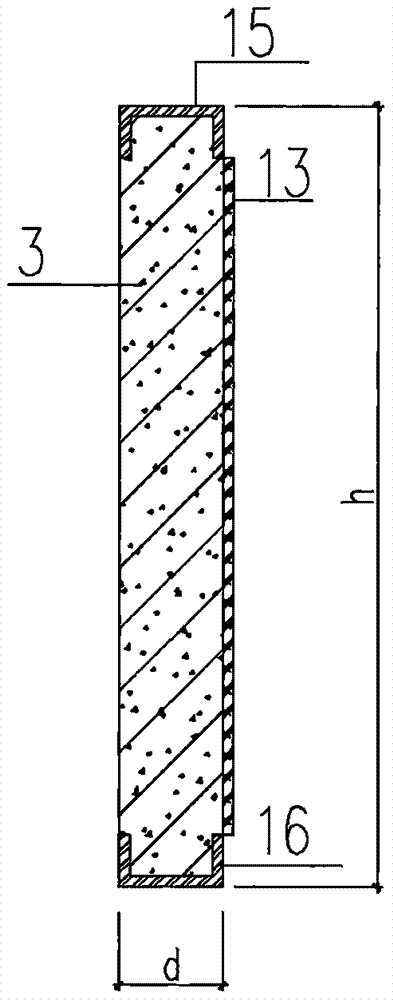

Plastic-wrapped prefabrication assembly type rectangular underground granary

ActiveCN106013909AGuaranteed not to collapseReasonable forceClimate change adaptationExcavationsEngineeringPrefabrication

A prefabrication assembly type underground granary comprises a granary bottom, multiple prefabricated granary wall plates, a granary top and multifunctional pillars, wherein each granary wall plate is of an integral structure formed by combining a plastic plate on the outer side and a concrete slab on the inner side, each granary wall plate is provided with connection devices on the periphery, and the granary wall plates can be connected with adjacent granary wallboards and the multifunctional pillars by means of the connection devices; the multifunctional pillars are wrapped by plastic plates, can be used for positioning the granary wall plates, and are main stress components for bearing soil pressure and grain side pressure and resisting buoyance, and the depth of each multifunctional pillar and each enhancing pillar anchored into soil is greater than the depth of the granary bottom; the underground granary is characterized in that each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on an uppermost layer is provided with a first-layer granary wall plate, the inner side of each second section is provided with a second-layer granary wall plate; by using an arrangement mode similar to that above, arranging is performed until a bottommost-layer granary wall plate is arranged, thus forming an assembly type underground granary structure.

Owner:郑州地天粮油仓厂科技有限公司

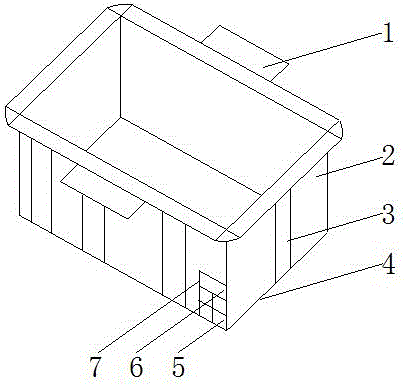

Food logistics box with constant-temperature sterilization function

InactiveCN106144239AEnsure safetyPrevent infiltrationShock-sensitive articlesRigid containersLogistics managementEngineering

The invention discloses a food logistics box with a constant-temperature sterilization function. The food logistics box comprises a steel box wall, ultraviolet germicidal lamps, a flip-open cover, a bracket and a sealing layer. The steel box wall is fixedly connected with a bottom plate. Reinforcing ribs are arranged on the steel box wall. A control panel is mounted on the steel box wall. A rain-proof plate and a connecting plate are mounted on the flip-open cover. The bracket is fixedly connected with the steel box wall. The sealing layer is hermetically connected with the steel box wall by the aid of silica gel. A temperature regulator is mounted on the sealing layer. A temperature detector is mounted between the ultraviolet germicidal lamps. The ultraviolet germicidal lamps and the temperature detector are mounted on the sealing layer. Positioning grooves and a non-slip mat are arranged on the bottom plate. The non-slip mat is arranged between the positioning grooves. The ultraviolet germicidal lamps can ensure that no bacteria exist in a product box, and moreover, the temperature detector and the temperature regulator are mounted, so that automatic temperature regulation can be realized, and the constant temperature is held.

Owner:尚华军

Hydrotalcite in-situ growth composite membrane, and preparation method and application thereof

InactiveCN112928322AHigh selectivityLow costRegenerative fuel cellsElectrical batteryPhysical chemistry

The invention discloses a hydrotalcite in-situ growth composite membrane, and a preparation method and application thereof, and belongs to the field of alkaline and neutral group secondary batteries. The hydrotalcite in-situ growth composite membrane comprises an ion conduction membrane substrate and a hydrotalcite layer grown on the ion conduction membrane in situ. By effectively controlling hydrotalcite synthesis conditions and interface interaction, the distribution uniformity of the synthesized hydrotalcite layer can be effectively controlled, and accurate size screening and high-efficiency ionic conductivity of the porous ionic conduction membrane are realized. In addition, the in-situ growth hydrotalcite film has super-strong alkali-resistant stability and mechanical properties, so that the alkaline zinc-based flow battery with high performance and long service life is realized, and a good application prospect is shown.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Man-made bamboo raft cofferdam and construction method thereof

PendingCN107190761AGuaranteed not to collapseSufficient filling capacityFoundation engineeringEngineeringUpper floor

The invention belongs to the field of man-made bamboo raft cofferdams, and particularly relates to a man-made bamboo raft cofferdam and a construction method thereof. The man-made bamboo raft cofferdam is divided into an upper bamboo raft cofferdam layer and a lower bamboo raft cofferdam layer. The lower bamboo raft cofferdam layer comprises two rows of lower-layer bamboo rafts, and the lower-layer bamboo rafts comprise lower-layer bamboo and iron wires used for tightly twisting the lower-layer bamboo. The length of the portion, located in soil, of the lower-layer bamboo is not smaller than that of the portion, exposed out of the soil, of the lower-layer bamboo. The lower bamboo raft cofferdam layer is constructed between the two rows of the lower-layer bamboo rafts. The upper bamboo raft cofferdam layer comprises two rows of upper-layer bamboo rafts. Upper-layer bamboo of the upper-layer bamboo rafts is vertically driven into the lower bamboo raft cofferdam layer. According to the man-made bamboo raft cofferdam and the construction method thereof, the cofferdam can be reinforced with the bamboo rafts, the strength requirement and the height requirement of the cofferdam can be met, the effect that the cofferdam does not collapse is guaranteed, and meanwhile the sufficient blow-fill capacity can be ensured.

Owner:CCCC TDC ENVIRONMENTAL ENG +1

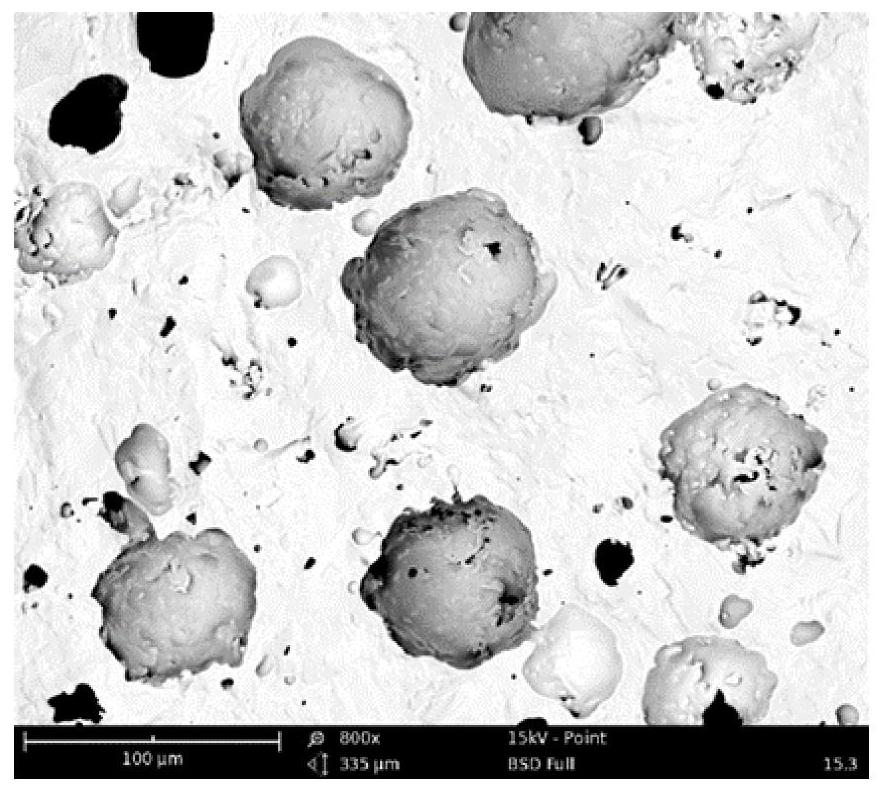

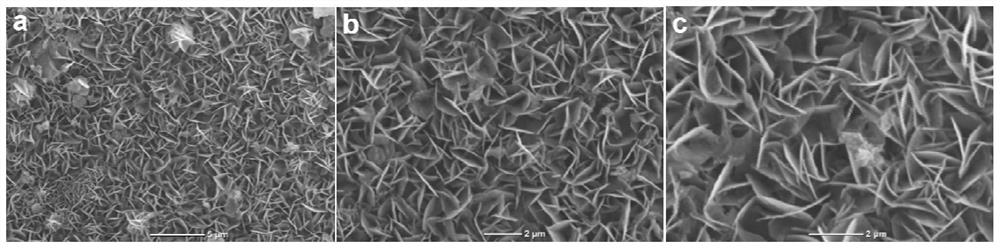

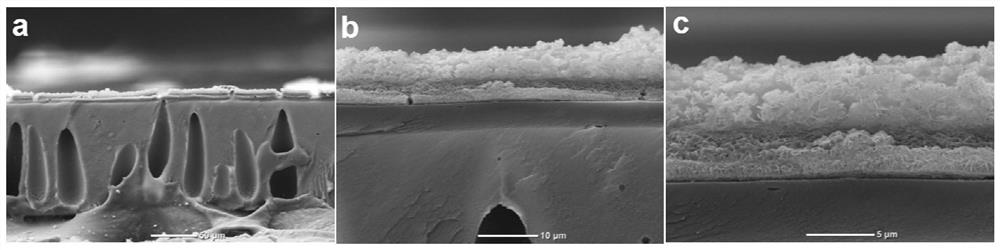

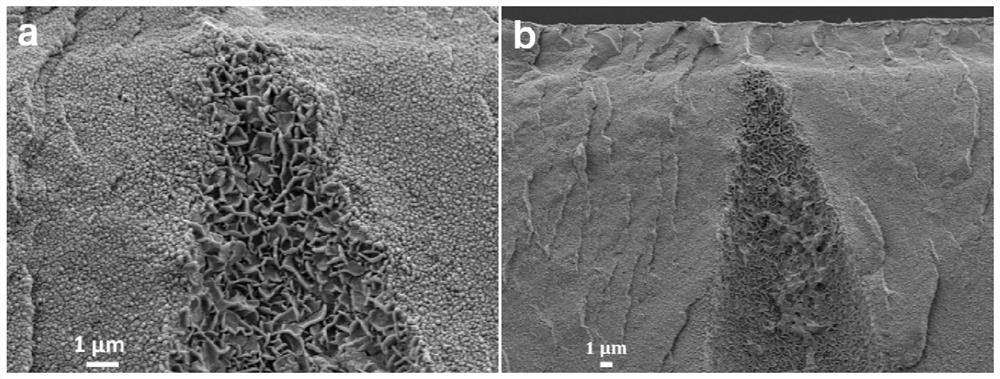

Preparation method of porous reticulated ceramic enhanced steel-based compound brake block

The invention discloses a preparation method of a porous reticulated ceramic enhanced steel-based compound brake block. The method includes the steps: mixing TiB2 powder and additives, and adding mixture into deionized water to sufficiently stir the mixture to prepare ceramic slurry suspension liquid; soaking organic foam bodies into ceramic slurry, drying soaked organic foam bodies, and sinteringthe dried organic foam bodies at high temperature to obtain porous reticulated TiB2 prefabricated bodies; casing the prepared porous reticulated TiB2 prefabricated bodies with metal solution by the aid of a cast-penetration process, and performing cooling and de-molding to obtain the porous reticulated ceramic enhanced steel-based compound brake block. The prepared compound brake block is high infriction coefficient and low in heat expansion coefficient, inter stress of the brake block is uniform, strength and toughness are enhanced, and the service life of the brake block is prolonged.

Owner:XI AN JIAOTONG UNIV +1

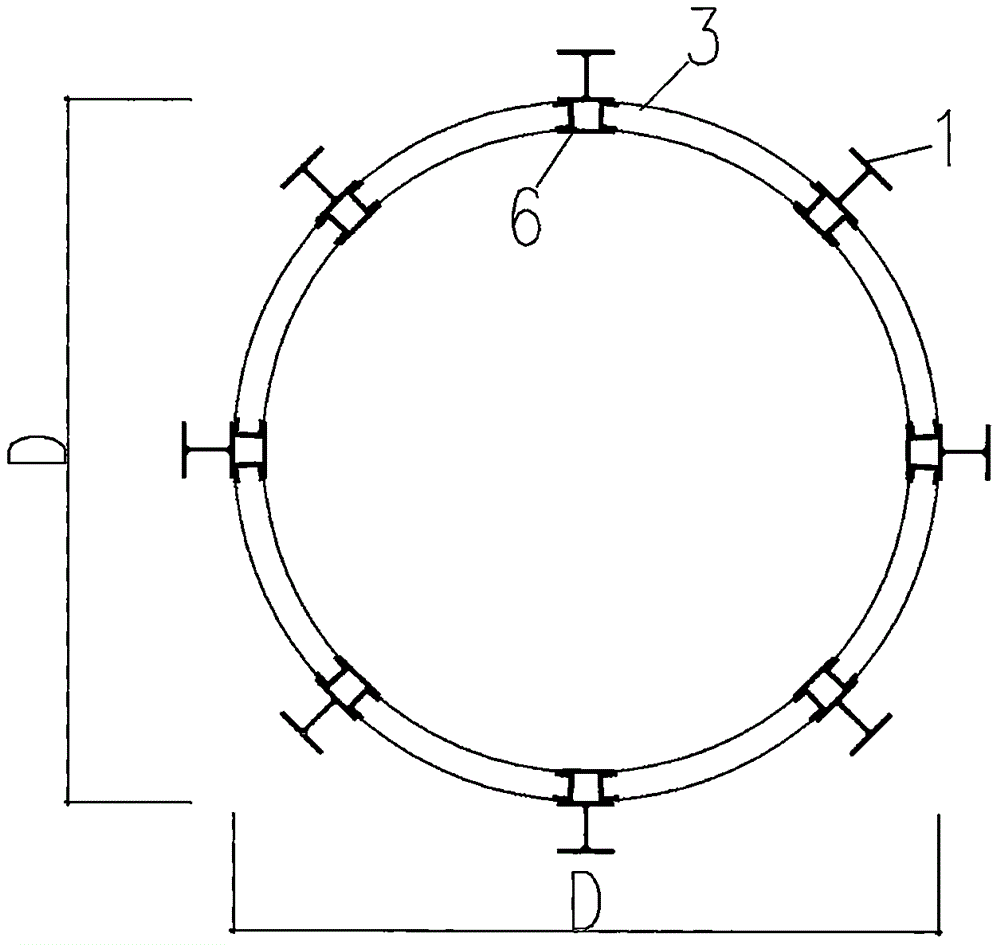

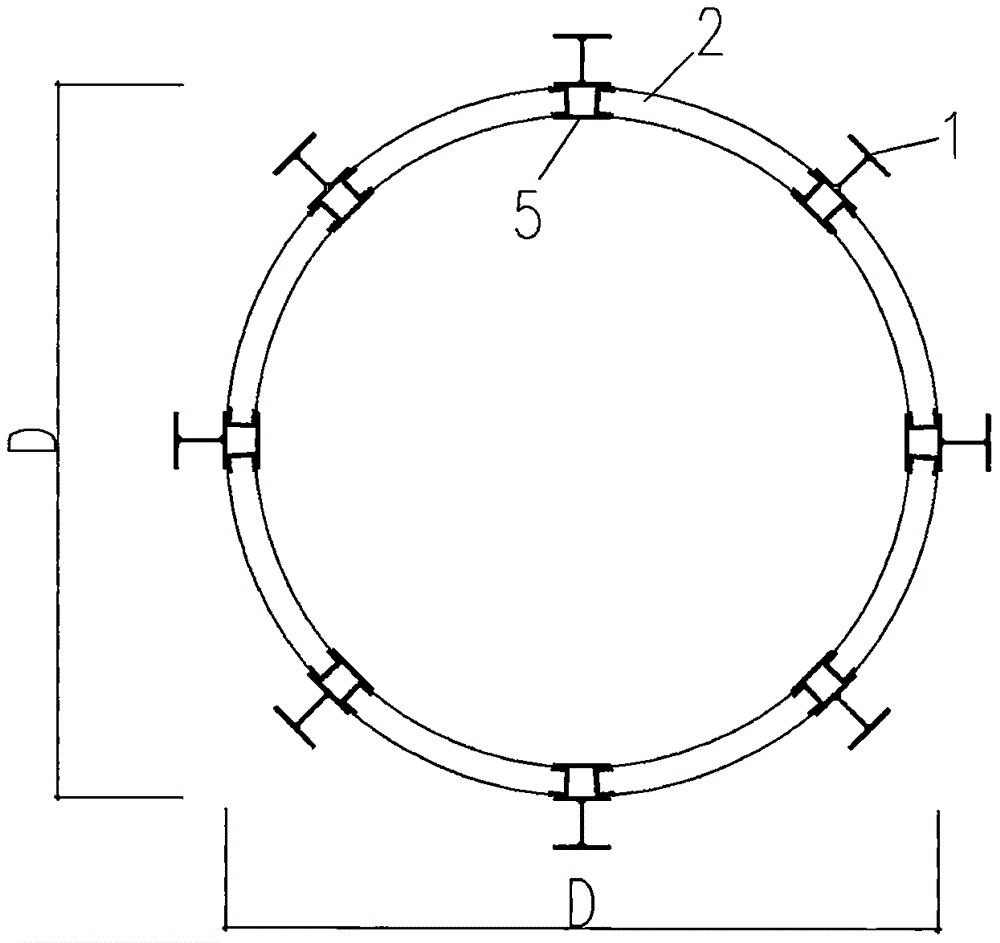

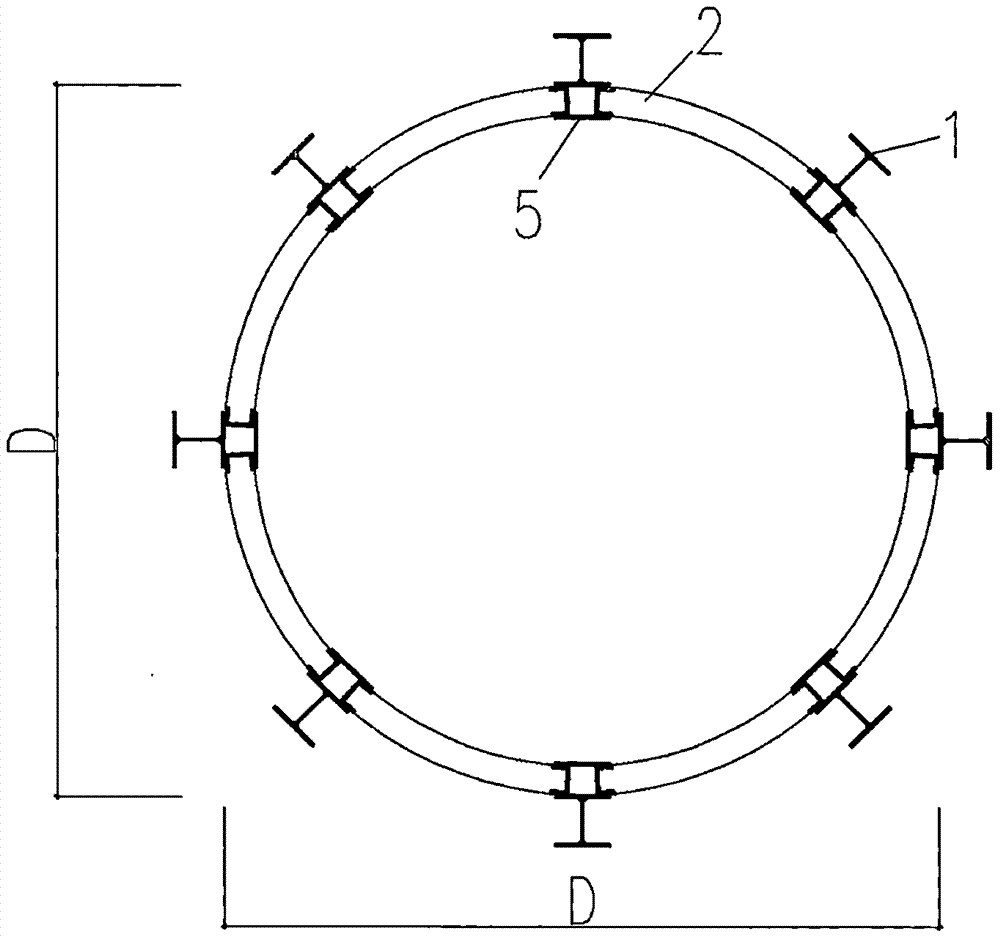

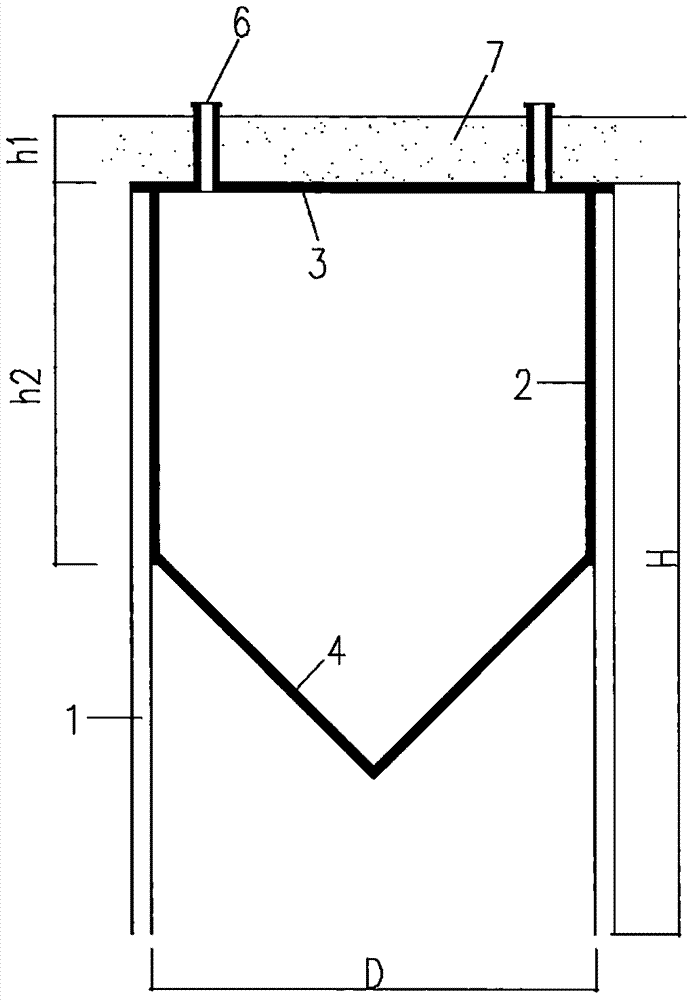

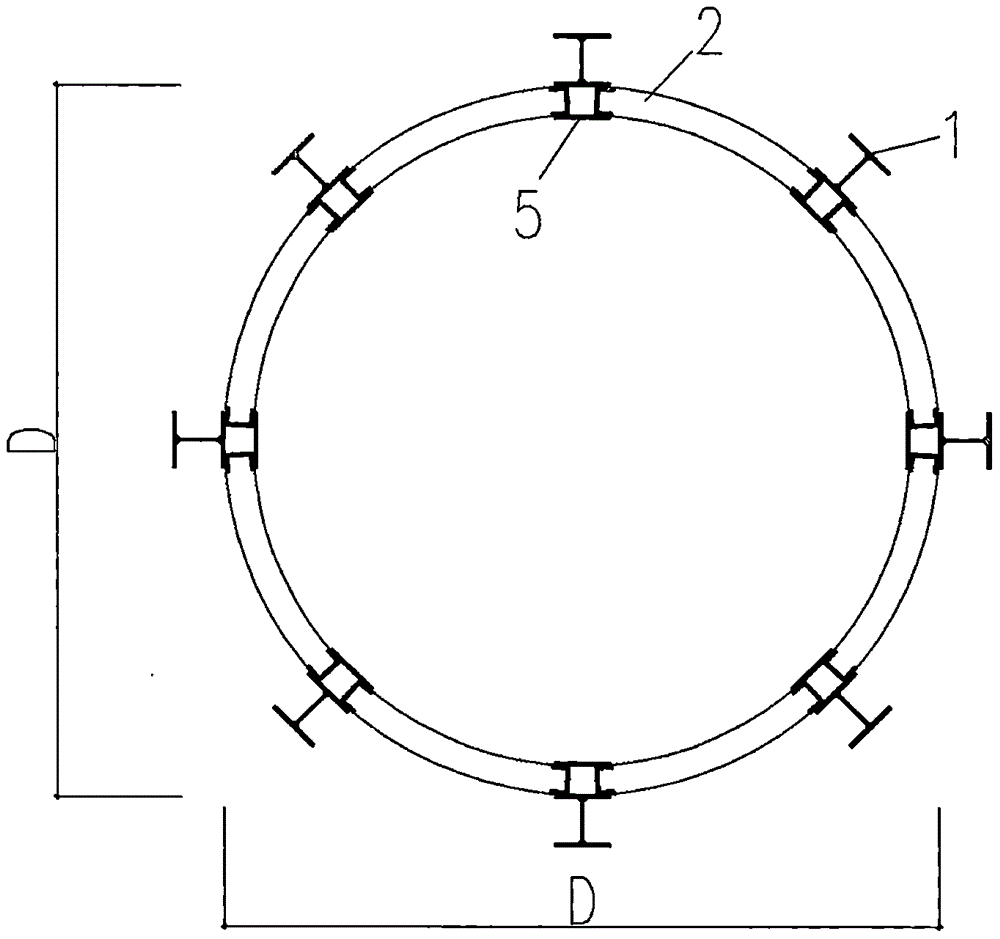

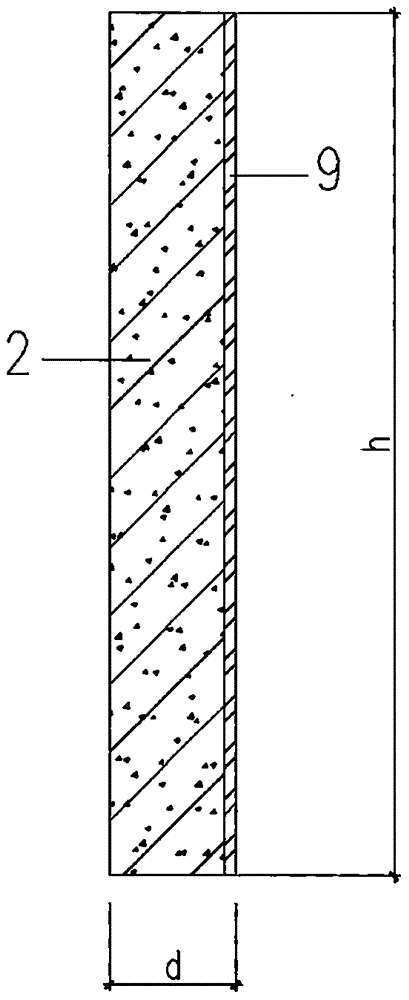

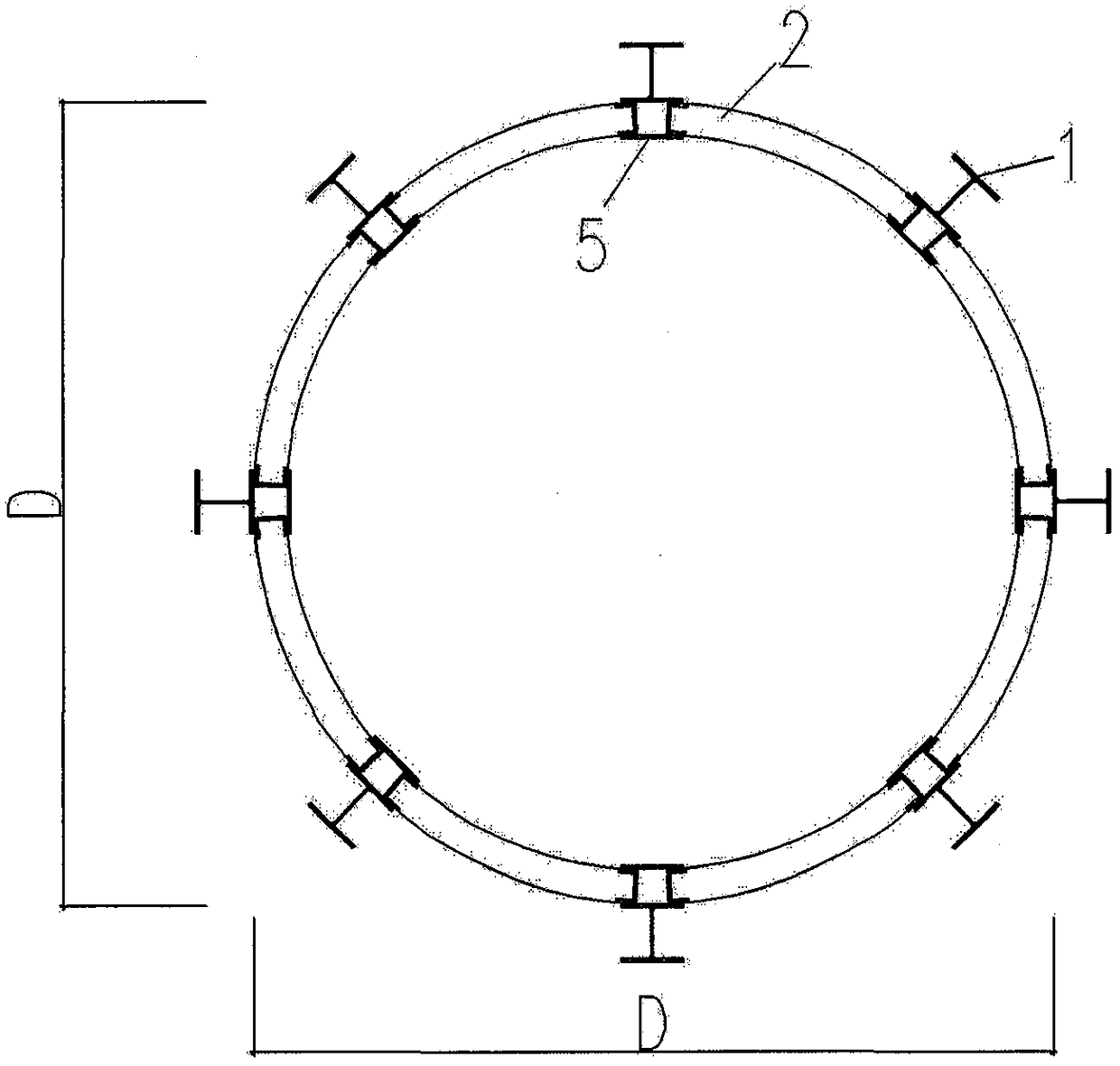

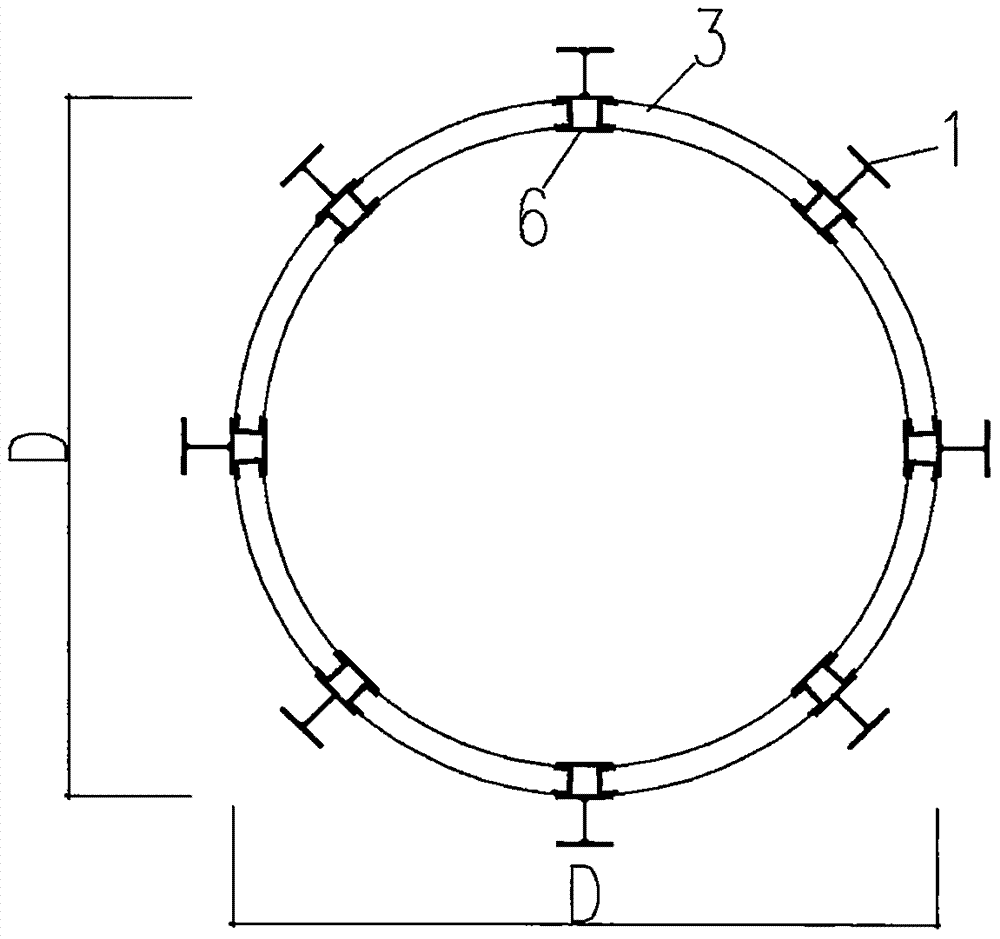

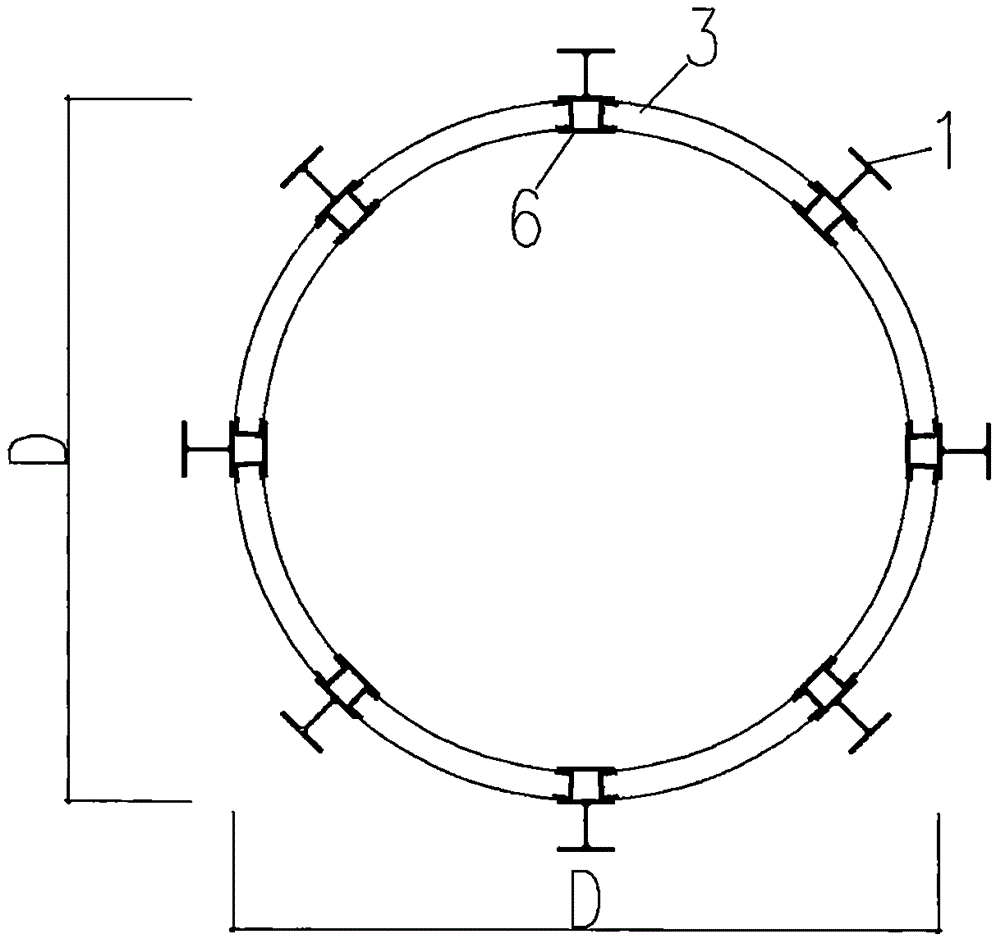

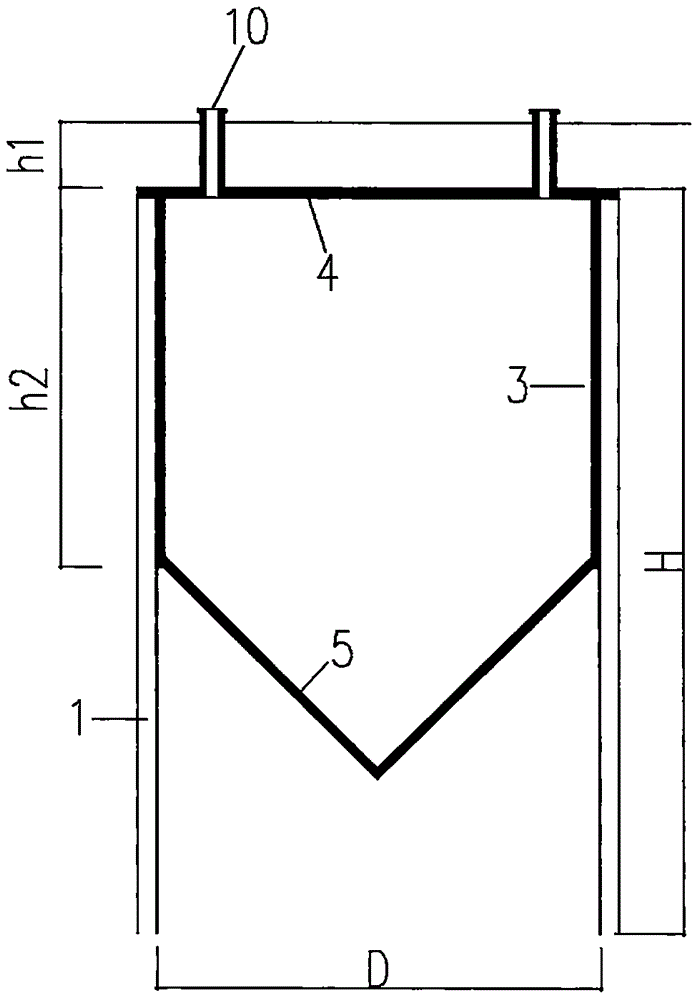

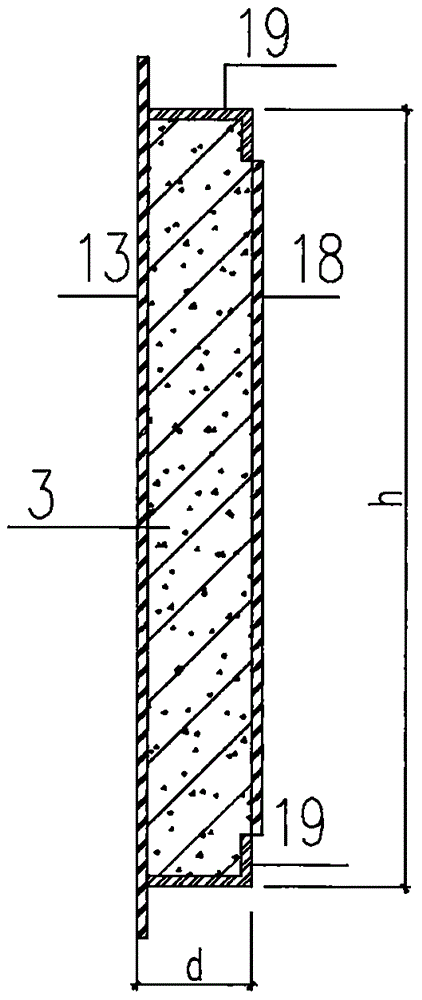

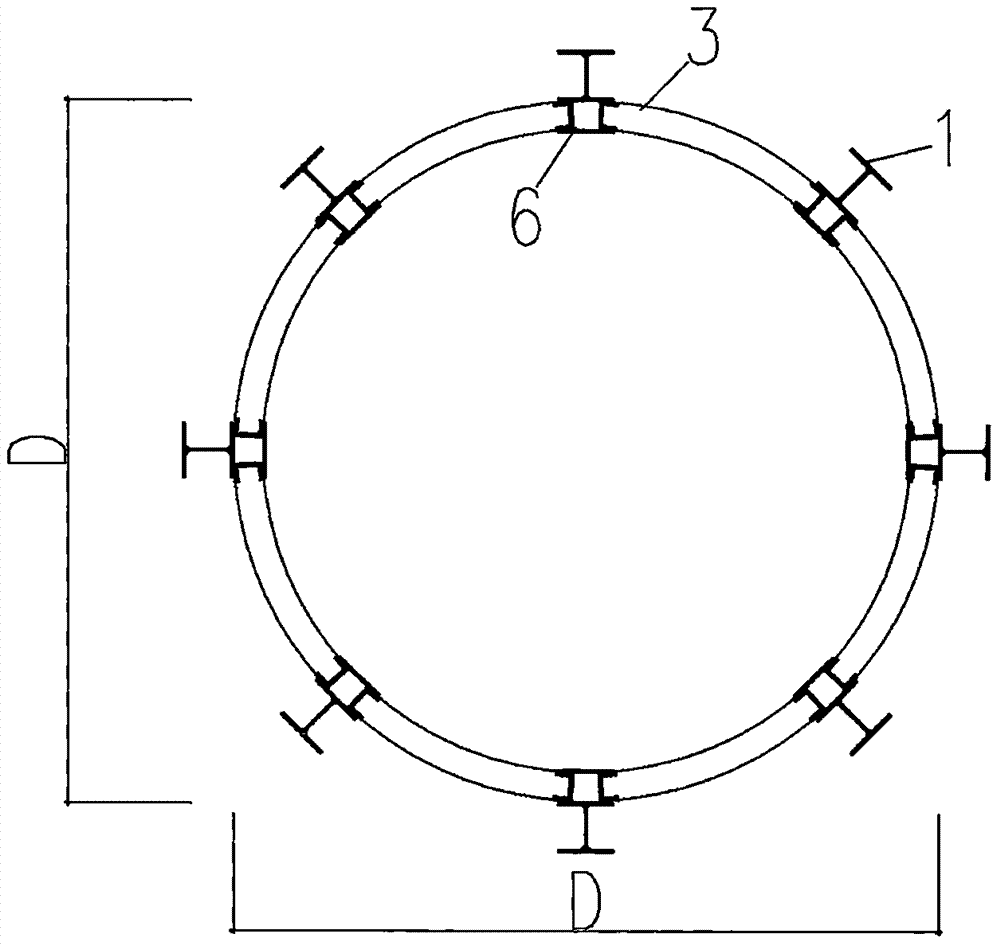

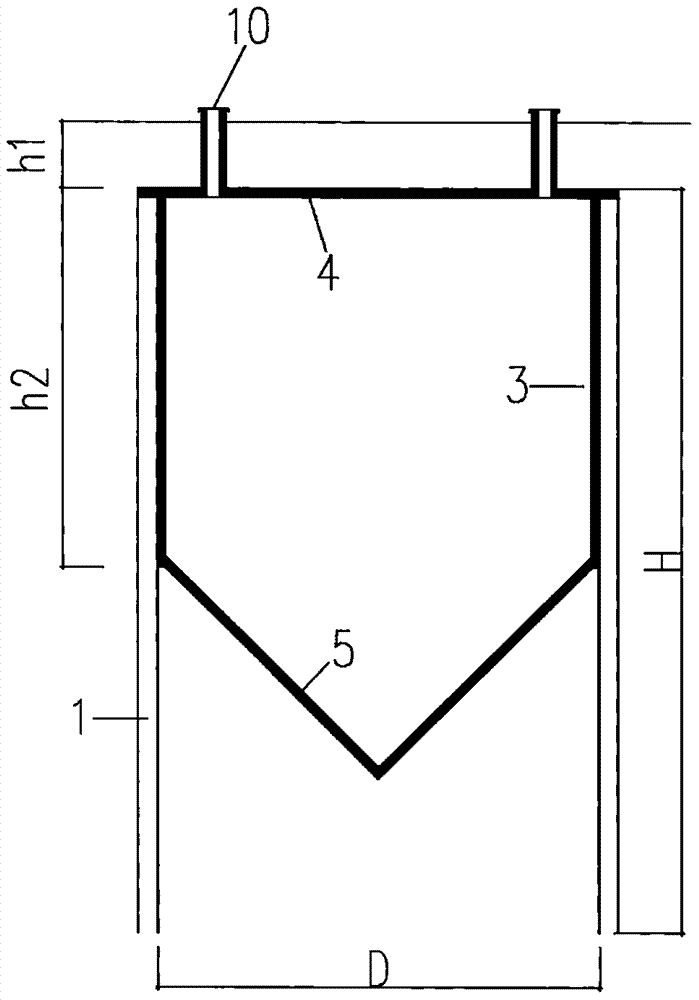

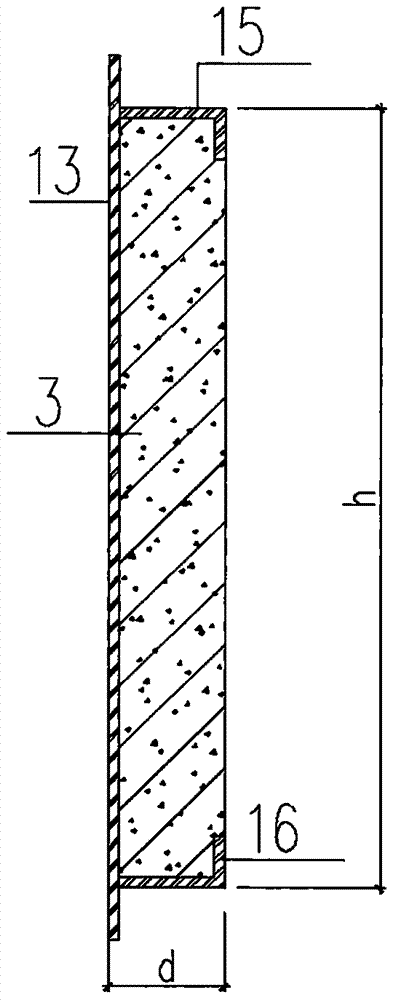

Circular precast assembly type underground granary with inside and outside both covered with steel plates

ActiveCN106193744AReduce construction costsReduce construction difficultyClimate change adaptationBulk storage containerSteel platesWall plate

Provided is a precast assembly type underground granary. The surface of the underground granary is a circle. The underground granary comprises a granary bottom, a plurality of precast granary wall plates, a granary roof and multifunctional posts. The granary wall plates are arc-shaped precast plate blocks; the periphery of each granary wall plate is provided with a connecting device; and each granary wall plate can be connected with the adjacent granary wall plate and the corresponding multifunctional post through the corresponding connecting device. A granary wall is positioned by the multifunctional posts; the depth of the multifunctional posts anchored in to soil is greater than the depth of the granary bottom; and the multifunctional posts are the main bearing components bearing the pressure of soil and grain and resisting buoyancy. The multifunctional posts are characterized in that each multifunctional post is divided into multiple sections from top to bottom, the first layer of the granary wall plates are arranged on the inner side of the first section of the uppermost layer, the second layer of the granary wall plates are arranged on the inner side of the second section, and a circular assembly type underground granary structure is formed by means of similar arrangement modes until the bottom layer of the granary wall plates are arranged. Each precast granary wall plate is an integral structure formed by covering the inside and the outside of concrete with steel plates, the steel plates and the concrete between the steel plates are connected through holdfasts, and the left end and the right end are covered with the steel plates.

Owner:郑州地天粮油仓厂科技有限公司

A circular prefabricated underground granary with inner cladding steel plate

ActiveCN106013915BGuaranteed not to collapseReasonable forceArtificial islandsClimate change adaptationSheet steelWall plate

The invention discloses a prefabricated assembly-type underground granary. The flat shape of the underground granary is round. The prefabricated assembly-type underground granary comprises a granary bottom, a plurality of prefabricated granary wall plates, a granary top and multifunctional columns, wherein the granary wall plates are arc-shaped prefabricated plate blocks; connecting devices are arranged on the peripheries of the granary wall plates; the granary wall plates can be connected with the adjacent granary wall plates and the multifunctional columns through the connecting devices; the multifunctional columns can be used for locating a granary wall; the depths that the multifunctional columns are anchored into earth are deepr than the depth of the granary bottom; the multifunctional columns are main stress components for bearing the pressure of the earth and the pressure of grains and resisting buoyant force. The prefabricated assembly-type underground granary is characterized in that the multifunctional columns are divided into several sections from tops to bottoms; the inner sides of first sections of the uppermost layer are provided with a first layer of the granary wall plates; the inner sides of the second sections are provided with a second layer of the granary wall plates; the granary wall plates are arranged until the bottommost layer of the granary wall plates by using a similar arrangement way, so as to form a round assembly-type underground granary structure; the prefabricated granary wall plates are of integral structures combined by inner-side steel plates and outer-side concrete slabs; the inner-side steel plates are connected with the outer-side concrete slabs by adopting ground anchors; further, and the left end part and the right end part are both clad with U-shaped steel plates.

Owner:郑州地天粮油仓厂科技有限公司

A preparation method of porous network ceramic reinforced steel-based composite brake block

The invention discloses a preparation method of a porous reticulated ceramic enhanced steel-based compound brake block. The method includes the steps: mixing TiB2 powder and additives, and adding mixture into deionized water to sufficiently stir the mixture to prepare ceramic slurry suspension liquid; soaking organic foam bodies into ceramic slurry, drying soaked organic foam bodies, and sinteringthe dried organic foam bodies at high temperature to obtain porous reticulated TiB2 prefabricated bodies; casing the prepared porous reticulated TiB2 prefabricated bodies with metal solution by the aid of a cast-penetration process, and performing cooling and de-molding to obtain the porous reticulated ceramic enhanced steel-based compound brake block. The prepared compound brake block is high infriction coefficient and low in heat expansion coefficient, inter stress of the brake block is uniform, strength and toughness are enhanced, and the service life of the brake block is prolonged.

Owner:XI AN JIAOTONG UNIV +1

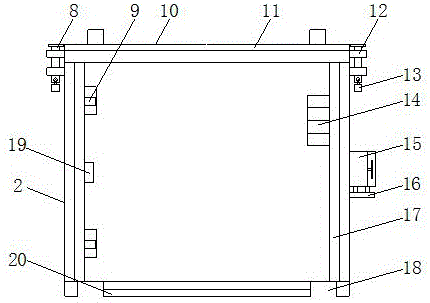

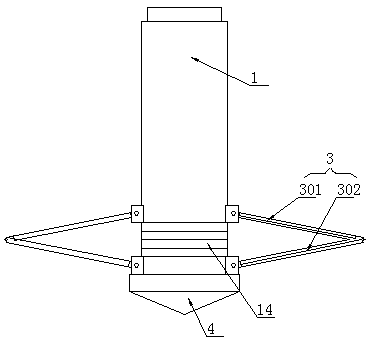

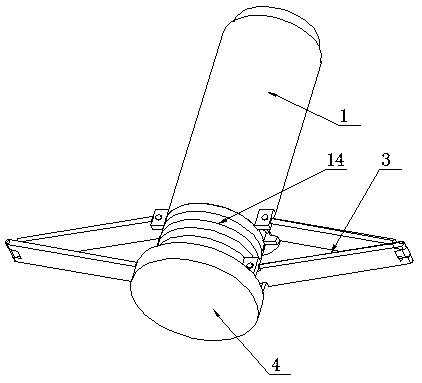

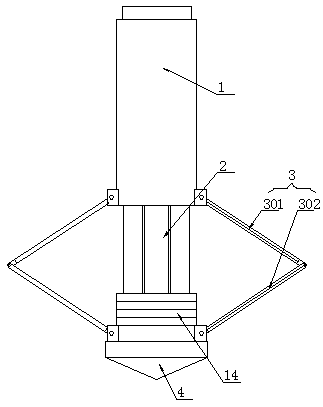

Underwater soil body expansion stirring device and underwater bottom expansion pile construction method

PendingCN110863484AGuaranteed not to collapseUnderwater drillingBulkheads/pilesGeotechnical engineeringDrill bit

Owner:HENAN POLYTECHNIC UNIV

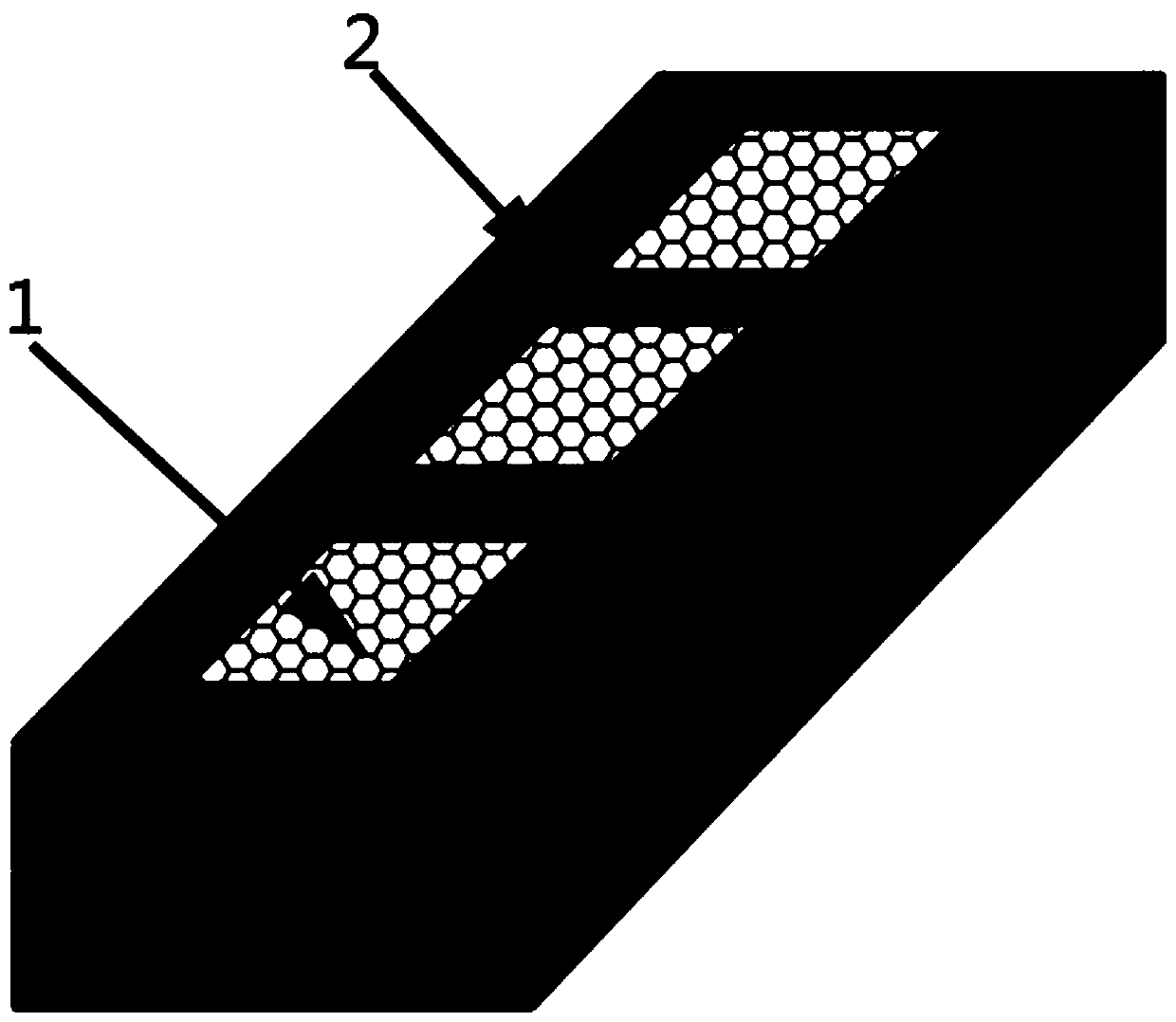

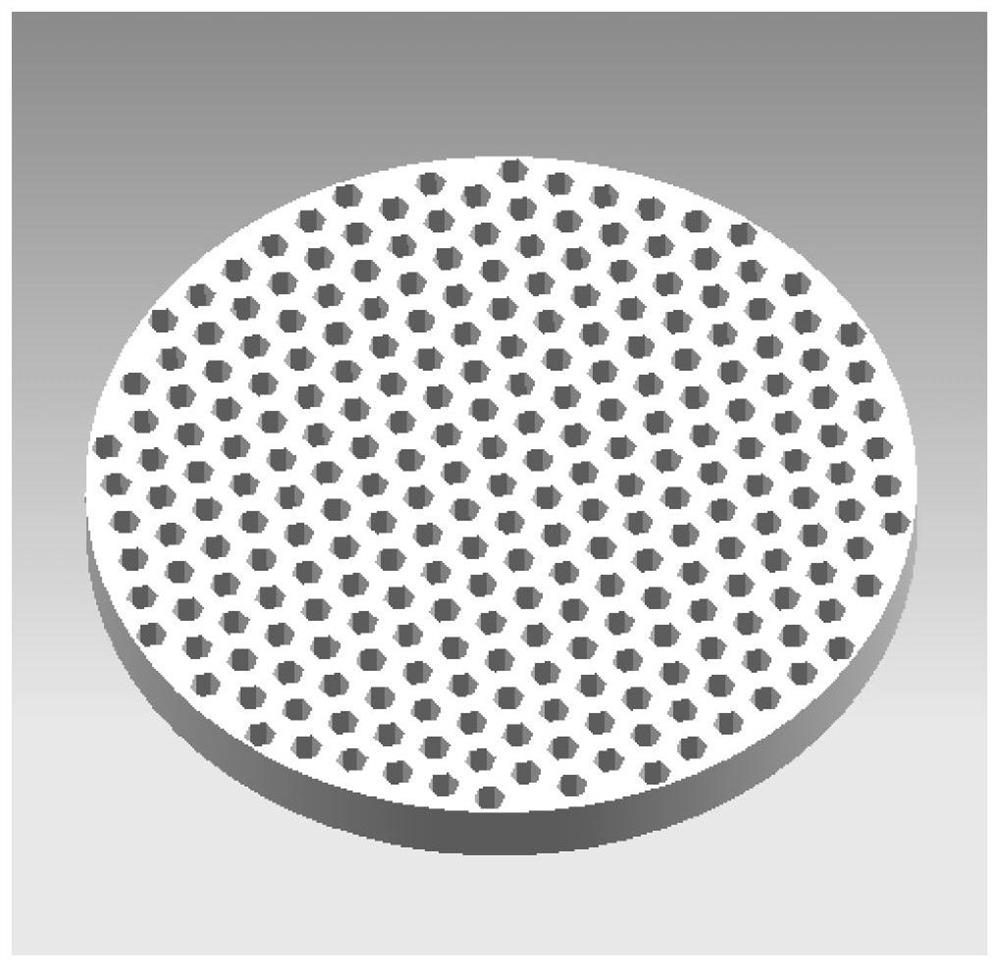

A kind of slurry direct writing molding method of honeycomb diamond tool

ActiveCN112692956BIncrease chip removal spaceEfficient exclusionAdditive manufacturing apparatusCeramic shaping apparatusDirect writingSlurry

The invention discloses a slurry direct writing method for a honeycomb diamond tool. The honeycomb diamond tool is a cylinder with a diameter of 80-150mm and a height of 50-120mm, and its upper and lower top surfaces are provided with several hexagonal honeycombs The side length of the hexagonal honeycomb through holes is 2-3mm, and the total area occupied by the hexagonal honeycomb through holes is 30-40% of the total area of the top surface of the cylinder. The invention can prepare complex honeycomb structures that are difficult to form by traditional methods, and can adjust the printing size of honeycomb holes according to grinding requirements. These porous honeycomb structures can improve the space for chip storage and chip removal, effectively remove chips generated by grinding, and accelerate heat dissipation. , Good self-sharpening, avoid thermal damage caused by clogging.

Owner:HUAQIAO UNIVERSITY

Round prefabricated assembly-type underground granary internally clad with steel plates

ActiveCN106013915AReduce construction difficultyIncrease stiffnessArtificial islandsClimate change adaptationSteel platesSheet steel

The invention discloses a prefabricated assembly-type underground granary. The flat shape of the underground granary is round. The prefabricated assembly-type underground granary comprises a granary bottom, a plurality of prefabricated granary wall plates, a granary top and multifunctional columns, wherein the granary wall plates are arc-shaped prefabricated plate blocks; connecting devices are arranged on the peripheries of the granary wall plates; the granary wall plates can be connected with the adjacent granary wall plates and the multifunctional columns through the connecting devices; the multifunctional columns can be used for locating a granary wall; the depths that the multifunctional columns are anchored into earth are deepr than the depth of the granary bottom; the multifunctional columns are main stress components for bearing the pressure of the earth and the pressure of grains and resisting buoyant force. The prefabricated assembly-type underground granary is characterized in that the multifunctional columns are divided into several sections from tops to bottoms; the inner sides of first sections of the uppermost layer are provided with a first layer of the granary wall plates; the inner sides of the second sections are provided with a second layer of the granary wall plates; the granary wall plates are arranged until the bottommost layer of the granary wall plates by using a similar arrangement way, so as to form a round assembly-type underground granary structure; the prefabricated granary wall plates are of integral structures combined by inner-side steel plates and outer-side concrete slabs; the inner-side steel plates are connected with the outer-side concrete slabs by adopting ground anchors; further, and the left end part and the right end part are both clad with U-shaped steel plates.

Owner:刘丽华 +1

Preparation method for meatball

The invention discloses a preparation method for a meatball. The preparation method comprises the following steps: selecting raw materials, finishing, cutting and stirring, seasoning, stirring, preparing the meatball, packaging and storing. According to the invention, meat is shredded when meat stuffing is prepared, and then the shredded meat is ground into meat grains, so that uniform grease of meat stuffing is guaranteed and taste is guaranteed; few mushrooms are added into the meat stuffing, so that freshness of meat stuffing is promoted and greasy feel of meat stuffing is reduced; due to the addition of sweet potato flour, the greasy feel of meat stuffing is reduced, and meanwhile, the coagulating property of meat stuffing is promoted and the end product of meatball is prevented from collapsing; boiled water is adopted for preparing the meatball, so that the greasy and unhealthy problems of the traditional fried meatball can be avoided, and meanwhile, the freshness of the meatballcan be guaranteed; the meatball is free from preservative and additive and is healthy and nutritive.

Owner:江苏华伯食品产业发展有限公司

A prefabricated circular underground granary with outsourcing steel plate

ActiveCN106193746BGuaranteed not to collapseReasonable forceClimate change adaptationBulk storage containerIn planeWall plate

A steel plate-clad prefabricated circular underground granary that is circular in plane shape and comprises a bottom, a plurality of prefabricated wall plates, a roof and a multifunctional column; the wall plates are arc prefabricated plates, connectors are arranged around each arc prefabricated plate, and one wall plate can be connected with the adjacent wall plate and the multifunctional column through the corresponding connectors; the multifunctional column can position a granary wall, depth of the multifunctional column anchored in soil is greater than bottom depth of the granary, and the multifunctional column is a main bearing member for bearing soil pressure, cereal pressure and resistive floating force; the granary is characterized in that the multifunctional column includes multiple segments from top to bottom, the uppermost first segment is provided with a first wall plate layer on the inner side, the second segment is provided with a second wall plate layer on the inner side, and the similar arrangement is carried out until the lowest wall plate layer to form the prefabricated circular underground granary; the prefabricated wall plates are of integrated structure formed by combining an outer steel plate and an inner concrete plate, the outer steel plate and the inner concrete plate are connected through anchors, and both the left and right ends of each prefabricated wall plate are clad with U-shaped steel plates.

Owner:郑州地天粮油仓厂科技有限公司

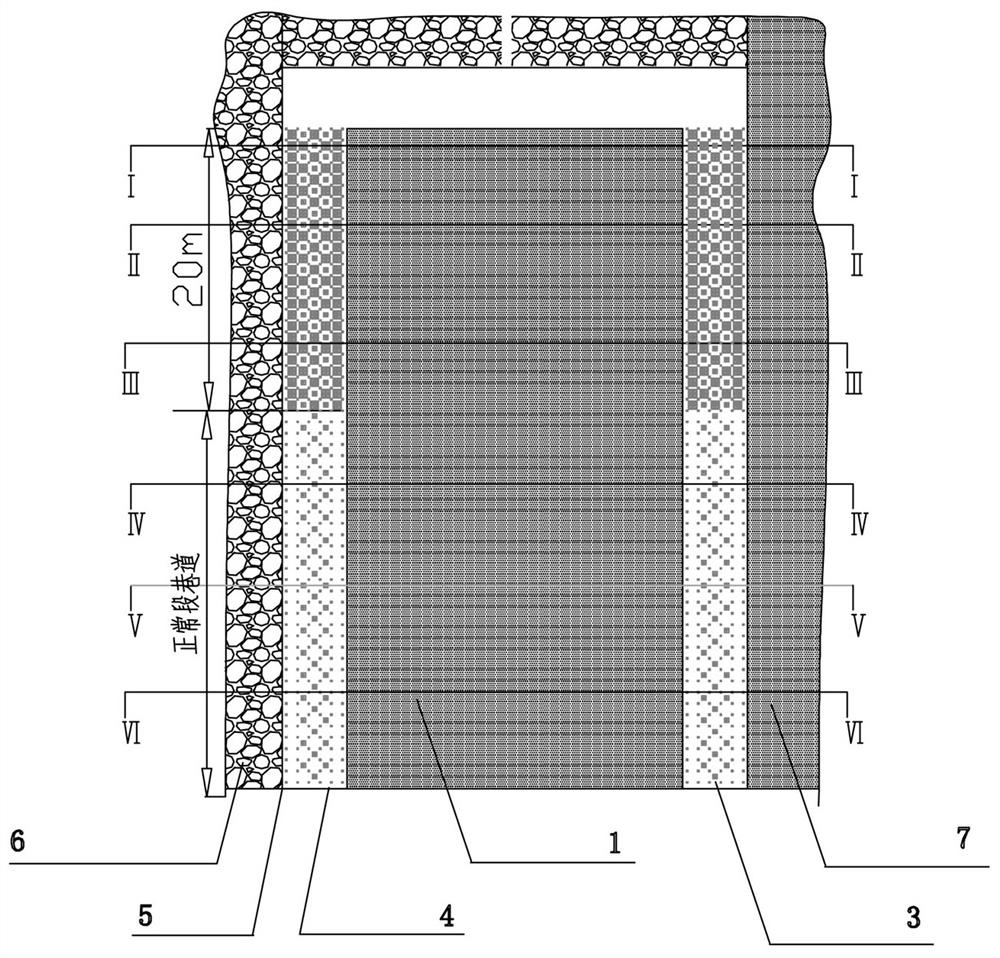

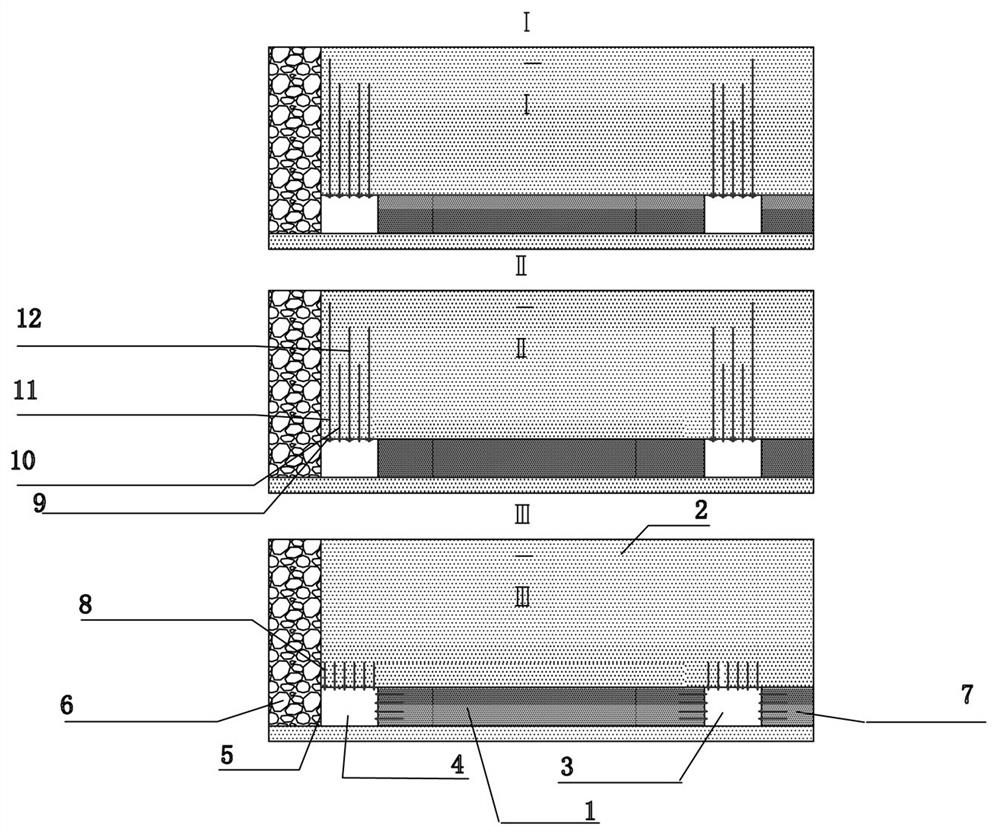

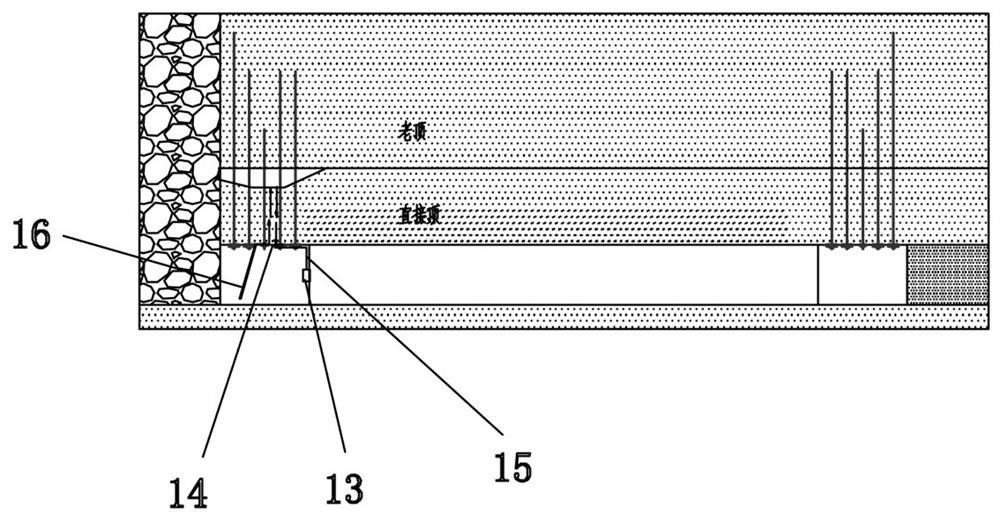

Gob-side entry retaining dynamic pressure area active supporting method and roof separation nondestructive monitoring device

PendingCN114704304AGuaranteed not to collapseReduce labor intensityAnalysing solids using sonic/ultrasonic/infrasonic wavesUnderground chambersArchitectural engineeringActive support

The invention discloses a gob-side entry retaining dynamic pressure area reinforced active support method and a roof separation lossless monitoring device for monitoring the support effect, which are characterized in that super-large-diameter anchor cables are added in advance on an advanced support section 20m away from a gob-side entry retaining in front of a working surface to be matched with the positions of anchor cables in the original support, so that an active superposition support structure is formed; the gob-side entry retaining method not only can ensure that the roadway roof of the forepoling area is not collapsed and the operation area is safe, but also can save the labor intensity of workers in the forepoling area, improve the roadway utilization space and ensure the efficient and safe stoping of the intelligent stoping working face. According to the nondestructive monitoring device and method for the roadway roof separation, the nondestructive monitoring method is adopted, a stress wave monitoring receiver is tightly attached to roof rock, an impact rod impacts a roof, stress waves are generated on the roof, and the distance of the roof separation is calculated according to the time difference of the stress waves received twice and the wave velocity of the stress waves. The device can be repeatedly used, and drilling on the top plate is not needed.

Owner:HENAN POLYTECHNIC UNIV +1

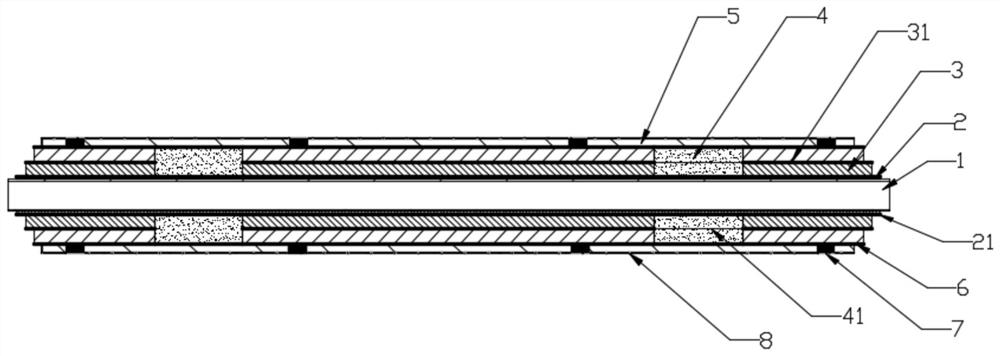

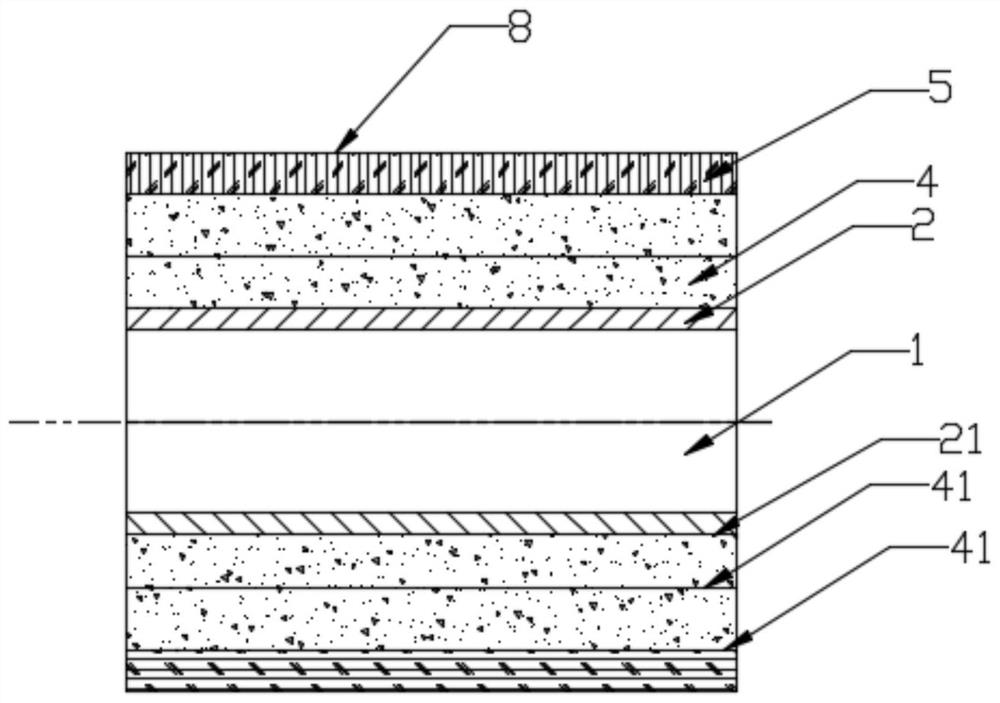

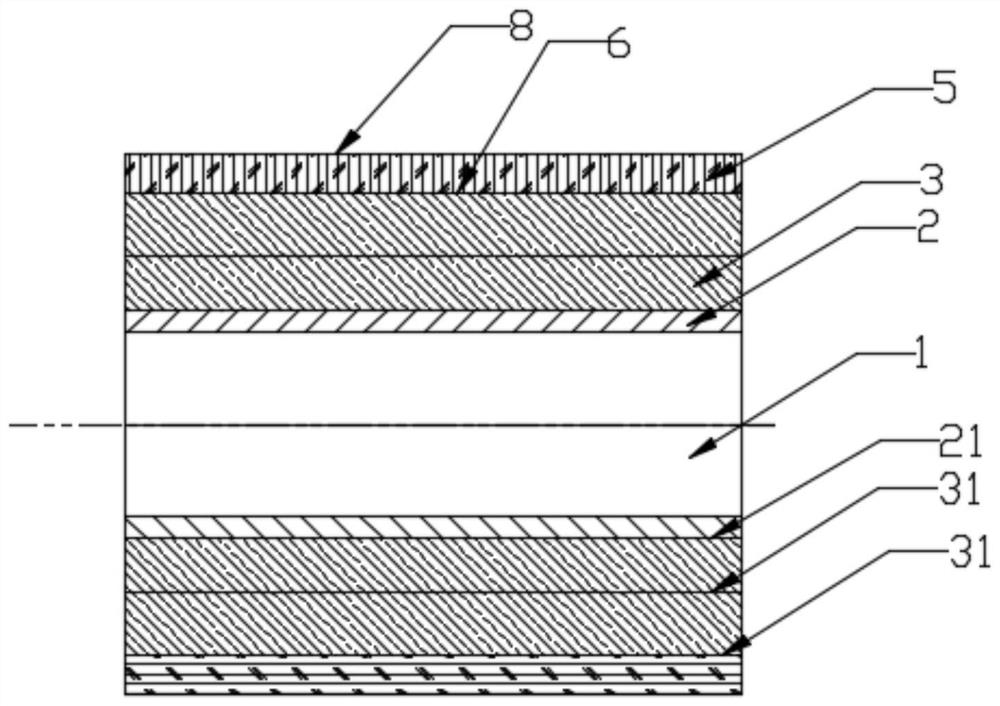

Intermittent prefabricated overhead heat insulation pipe and manufacturing method thereof

PendingCN112303347AReduce lossImprove support strengthLamination ancillary operationsThermal insulationThermodynamicsInsulation layer

The invention discloses an intermittent prefabricated overhead heat insulation pipe and a manufacturing method thereof, and relates to the technical field of long-distance steam conveying. The heat insulation pipe comprises a core pipe, an inner lining layer, an outer protection pipe, a plurality of hard heat insulation sections and a plurality of soft heat insulation sections, wherein the hard heat insulation sections and the soft heat insulation sections are arranged between the inner lining layer and the outer protection pipe, wrap the outer side of the inner lining layer and are arranged in a staggered mode in the length direction of the core pipe; the hard heat insulation sections and the soft heat insulation sections are in staggered lap joint through a heat insulation material; andan organic heat insulation layer is arranged on the inner side of the outer protection pipe and used for tightly wrapping the hard heat insulation sections and the soft heat insulation sections in theouter protection pipe together. By implementing the technical scheme provided by the embodiment of the invention, the manufactured heat insulation pipe can achieve the effects of bearing the operation load of a heat supply network and considering the heat insulation function, has excellent heat insulation performance, is low in heat conductivity coefficient and light in weight, beneficial to remarkably reducing the energy loss of a heat supply pipe network, and applied to the field of prefabricated overhead steam conveying so as to achieve the effects of safety, stability, high efficiency andenergy conservation of the whole pipe network.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

A plastic prefabricated underground granary

ActiveCN106013912BGuaranteed not to collapseReasonable forceClimate change adaptationExcavationsEngineeringWall plate

The invention discloses a prefabricated assembly-type underground granary, which comprises a granary bottom, a plurality of prefabricated granary wall plates, a granary top and multifunctional columns, wherein the granary wall plates are of integral structures combined by inner-side plastic plates and outer-side concrete slabs; connecting devices are arranged on the peripheries of the granary wall plates; the granary wall plates can be connected with the adjacent granary wall plates and the multifunctional columns through the connecting devices; the multifunctional columns can be used for locating the granary wall plates; the depths that the multifunctional columns are anchored into earth are deeper than the depth of the granary bottom; the multifunctional columns are main stress components for bearing the pressure of the earth and the lateral pressure of grains and resisting buoyant force. The prefabricated assembly-type underground granary is characterized in that the multifunctional columns are divided into several sections from tops to bottoms; the inner sides of first sections of the uppermost layer are provided with a first layer of the granary wall plates; the inner sides of the second sections are provided with a second layer of the granary wall plates; the granary wall plates are arranged until the bottommost layer of the granary wall plates by using a similar arrangement way, so as to form an assembly-type underground granary structure.

Owner:郑州地天粮油仓厂科技有限公司

A kind of anti-slip sound-absorbing composite floor and its production method

ActiveCN111993735BImprove the noise reduction effectAchieve anti-skid functionLamination ancillary operationsSynthetic resin layered productsNoise reductionUv treatment

The invention discloses a preparation method of an anti-slip and sound-absorbing composite floor, which belongs to the field of floor manufacturing, and comprises step 1: drawing reinforcing material; step 2: bonding; step 3: preparing a wear-resistant layer on the top surface of the bonded product; step 4: Cold paste the sound-absorbing layer on the bottom surface of the laminated product; Step 5: Coat the anti-slip layer; Step 6: Perform UV treatment on the surface of the wear-resistant layer; Step 7: Die-cut. The invention also discloses an anti-slip and sound-absorbing composite floor, which comprises a wear-resistant layer, a printing layer, a middle material layer, a strengthening material layer, a bottom material layer, a sound-absorbing layer and an anti-slip material layer sequentially from top to bottom. The invention provides an anti-skid and sound-damping composite floor and a manufacturing method thereof, which have the technical effects of good anti-skid effect, small expansion, good straightness, sound and noise reduction, and easy assembly and disassembly.

Owner:浙江海利得地板有限公司

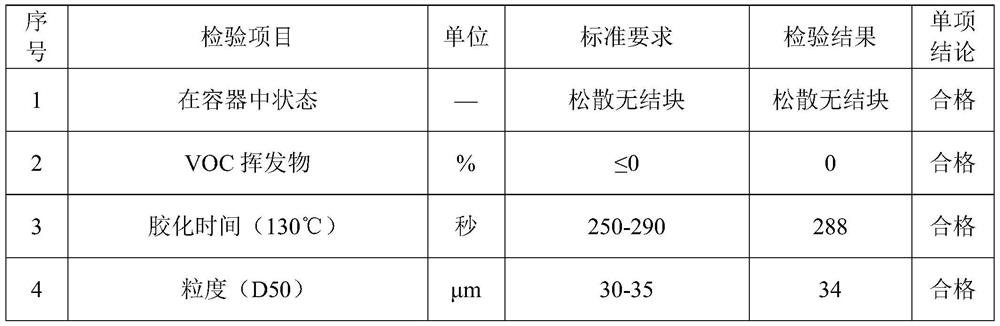

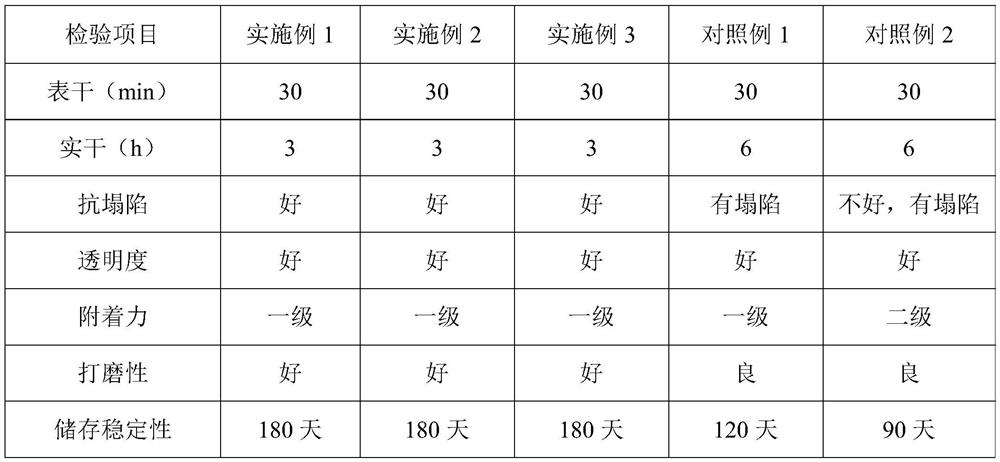

Anti-collapse high-filling water-based woodware transparent primer and preparation method thereof

PendingCN114015337AGuaranteed closed mirror effectEnsure transparencyPolyurea/polyurethane coatingsPriming paintsPolymer scienceAcrylic resin

The invention discloses an anti-collapse high-filling water-based woodware transparent primer. The transparent primer is prepared from a component A, a component B and water. The component A is prepared from the following raw materials in parts by weight: 65 to 80 parts of water-based hydroxy acrylic resin, 0.2 to 0.8 part of a wetting agent, 0.2 to 1 part of a dispersing agent, 0.2 to 0.6 part of a defoaming agent, 0.4 to 1 part of transparent powder, 1 to 2 parts of polishing powder, 6 to 10 parts of a coalescing agent, 0.1 to 0.2 part of a flatting agent, 3 to 5 parts of anti-settling slurry, 3 to 5 parts of water and 0.2 to 0.6 part of a thickening agent; the component B is a curing agent; the weight ratio of the component A to the component B to the water is 100: 20: (10-20). the formula primer provided by the invention not only can ensure the mirror surface sealing effect of a paint film after spraying, but also can ensure the transparency and non-collapse of the paint film, has the characteristics of good transparency, collapse resistance, good filling property, easiness in polishing and the like, and is suitable for the coating requirements of different furniture and wooden products, especially high-grade mirror surface sealing effect.

Owner:赣州市博品家具有限公司

Inner and outer plastic wrapping prefabricated underground barn

ActiveCN105971354AGuaranteed not to collapseReasonable forceClimate change adaptationExcavationsEngineeringMechanical engineering

The invention provides an inner and outer plastic wrapping prefabricated underground barn. The inner and outer plastic wrapping prefabricated underground barn comprises a barn bottom, multiple prefabricated barn wallboards, a barn top and multifunctional columns. The barn wallboards are of overall structures formed by inner plastic plates, outer plastic plates and concrete plates between the inner plastic plates and the outer plastic plates, connecting devices are arranged on the peripheries of the barn wallboards, and the barn wallboards can be connected with the adjacent barn wallboards and the multifunctional columns through the connecting devices. The multifunctional columns are wrapped by plastic plates, the barn wallboards can be positioned, the depth of the portions, anchored into soil, of the multifunctional columns is larger than the depth of the barn bottom, and the multifunctional columns are main force bearing components for bearing soil pressure and grain side pressure and resisting buoyancy. The barn is characterized in that the multifunctional columns are divided into multiple segments from top to bottom, a first barn wallboard layer is arranged on the inner side of the first section of the uppermost layer, a second barn wallboard layer is arranged on the inner side of the second section till the lowest barn wallboard layer by means of the similar arrangement mode, and then the assembled underground barn structure is formed.

Owner:郑州地天粮油仓厂科技有限公司

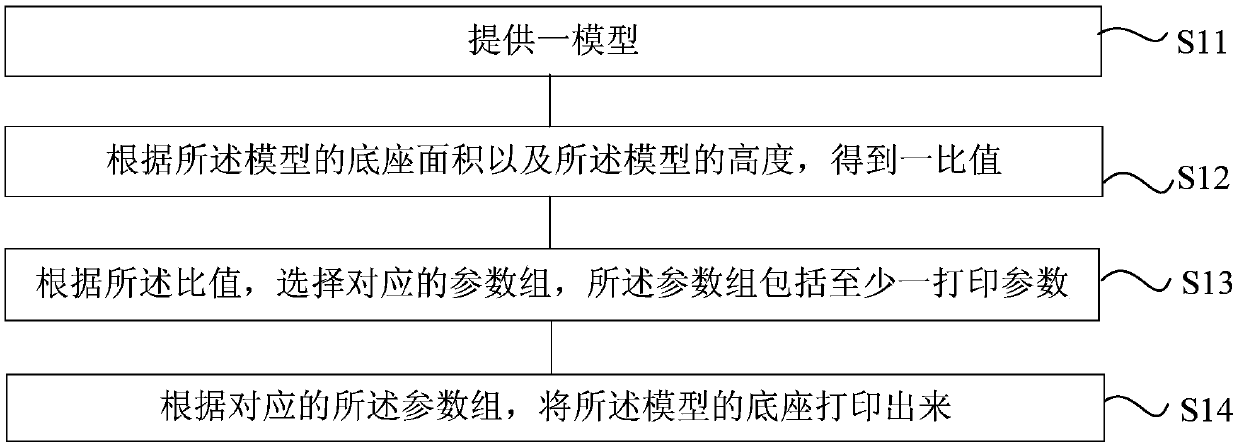

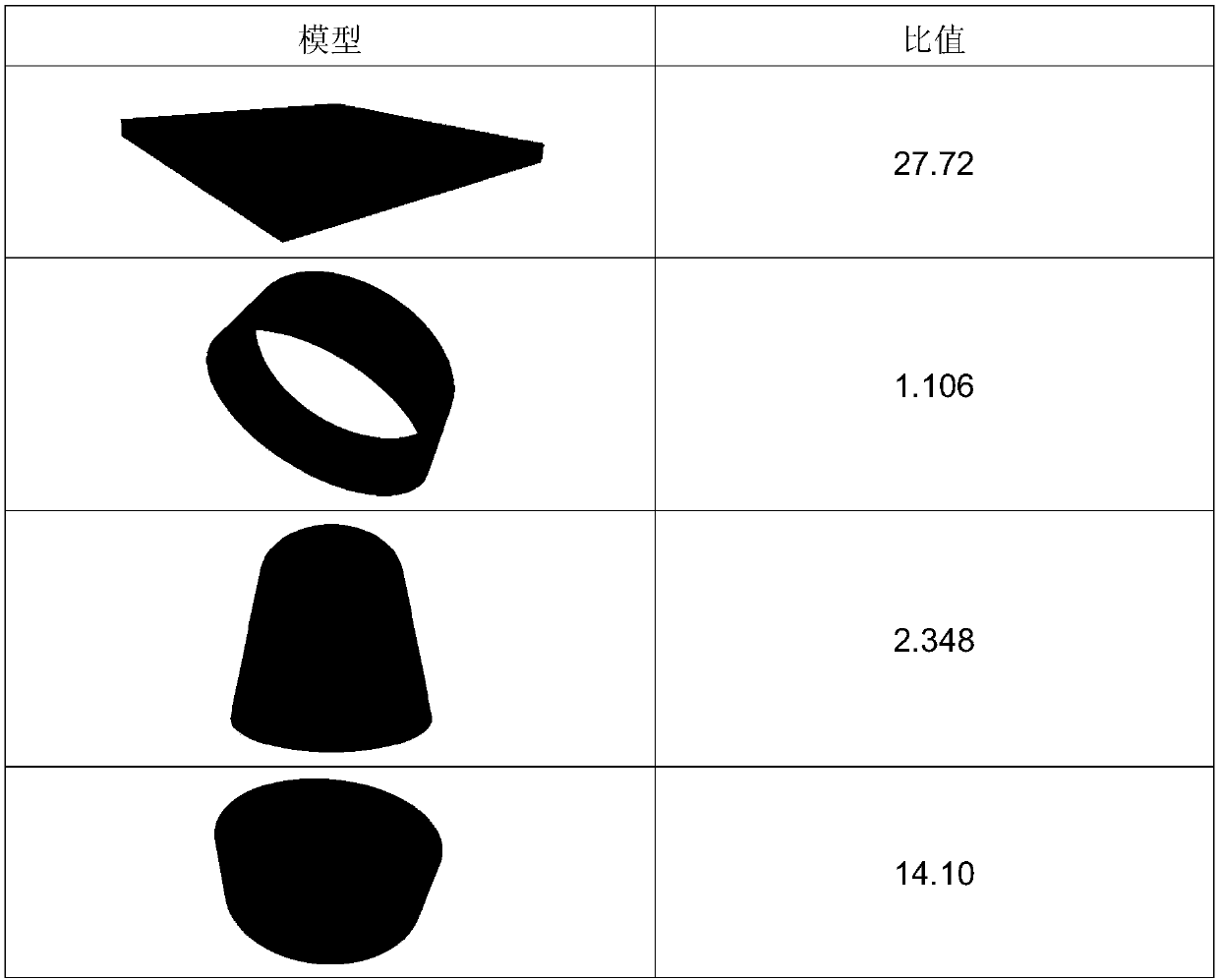

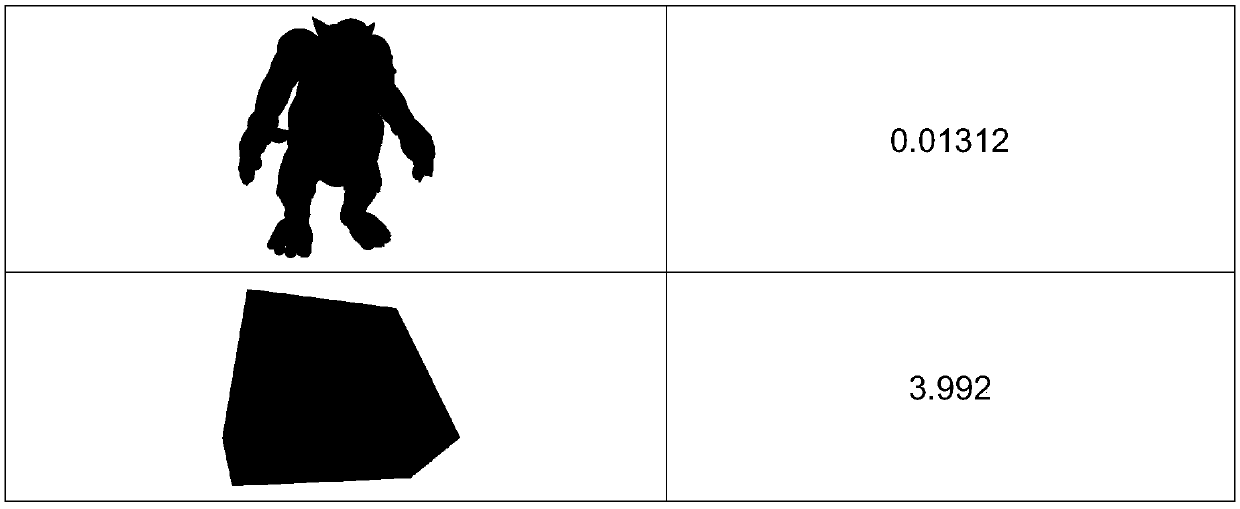

3D printing method and 3D printing system

InactiveCN106696277BGuaranteed not to collapseSuitable adhesionManufacturing platforms/substrates3D object support structuresEngineeringWorkbench

The invention discloses a 3D printing method and system. The method includes the steps that according to the base area of a model and the height of the model, a specific value is obtained; based on the specific value, a corresponding parameter set is selected; and a base of the model is printed out according to the corresponding parameter set. As for printing of various models, the proper degree of adhesion of goods and a workbench can be guaranteed, the effect that objects are not collapsed in the printing process can be ensured, and meanwhile the objects can be taken down from the workbench easily.

Owner:INVENTECSHANGHAI TECH +2

Prefabricated concrete element and shear wall module with same and manufacturing method thereof

ActiveCN105220793BGuaranteed not to collapseImprove bearing capacityConstruction materialWallsEarthquake resistanceArchitectural engineering

The invention relates to a prefabricated concrete component, a shear wall module with the component and a manufacturing method thereof. The prefabricated concrete components include: the first shear wall panel, and steel bars are arranged inside the first shear wall panel; The concealed frame columns on the right edge are integrally formed; the concealed frame beams on the upper edge, the concealed frame beams on the lower edge, the concealed frame columns on the left edge and the concealed frame columns on the right edge all have reinforced concrete slabs protruding from the first shear wall panel A grouting sleeve is pre-embedded in the hidden frame beam at the lower edge, a vertical steel bar protruding out of the hidden frame beam at the upper edge is pre-embedded, and a U-shaped closure protruding out of the hidden frame column at the left and right edges is provided. rebar. Prefabricated concrete components are used as a part of the shear wall module, and the manufacture of the shear wall module only needs to install hidden supports and connect firmly with another shear wall panel. There is a hidden support truss between the two shear wall panels, which has good seismic performance.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

A kind of outsourcing plastic prefabricated underground granary

ActiveCN106013909BGuaranteed not to collapseReasonable forceClimate change adaptationExcavationsEngineeringMechanical engineering

A prefabrication assembly type underground granary comprises a granary bottom, multiple prefabricated granary wall plates, a granary top and multifunctional pillars, wherein each granary wall plate is of an integral structure formed by combining a plastic plate on the outer side and a concrete slab on the inner side, each granary wall plate is provided with connection devices on the periphery, and the granary wall plates can be connected with adjacent granary wallboards and the multifunctional pillars by means of the connection devices; the multifunctional pillars are wrapped by plastic plates, can be used for positioning the granary wall plates, and are main stress components for bearing soil pressure and grain side pressure and resisting buoyance, and the depth of each multifunctional pillar and each enhancing pillar anchored into soil is greater than the depth of the granary bottom; the underground granary is characterized in that each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on an uppermost layer is provided with a first-layer granary wall plate, the inner side of each second section is provided with a second-layer granary wall plate; by using an arrangement mode similar to that above, arranging is performed until a bottommost-layer granary wall plate is arranged, thus forming an assembly type underground granary structure.

Owner:郑州地天粮油仓厂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com