Hydrotalcite in-situ growth composite membrane, and preparation method and application thereof

An in-situ growth and hydrotalcite technology, applied in electrochemical generators, regenerative fuel cells, fuel cells, etc., can solve the problems of reduced proton conductivity, battery performance attenuation, poor selectivity, etc., to improve selectivity, Effect of improving battery performance, excellent mechanical properties and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Using polyethersulfone PES / SPEEK resin as the base material, dissolve PES / SPEEK in DMAC solvent with a mass ratio of 4:1 to obtain a blend solution with a solid content of 35%, stir it evenly, and pour it on a clean and flat glass On the board, under the condition of 20% humidity, use a 200 μm scraper to scrape out a flat diaphragm, immerse it in water, wait for the solvent to dissolve, and remove the solvent to obtain a PES / SPEEK porous base membrane (porous ion-conducting membrane), soak in water for later use.

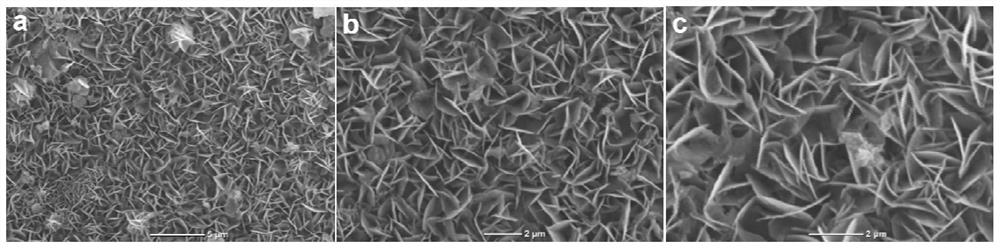

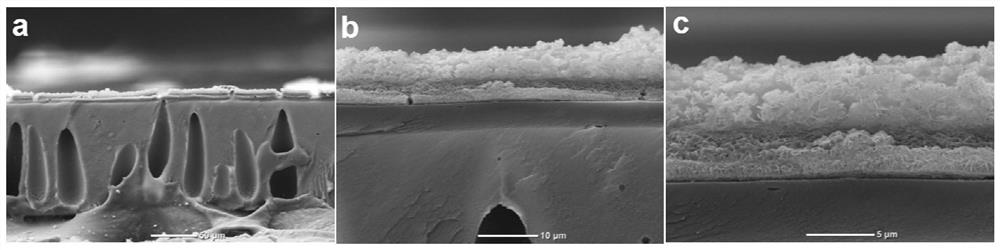

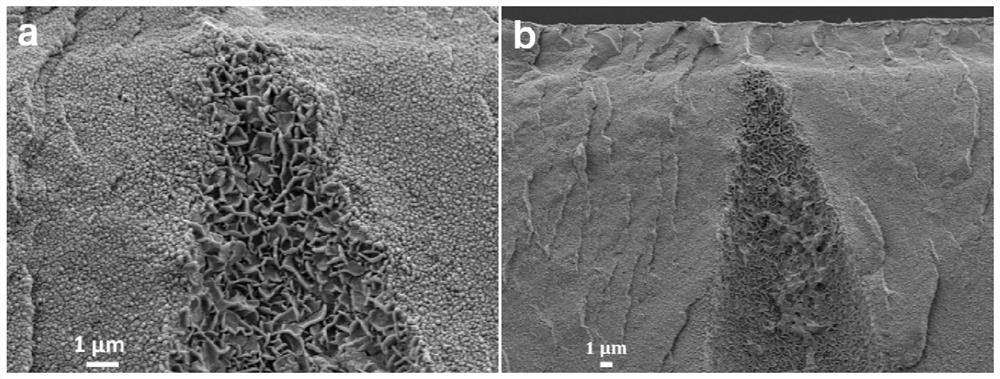

[0069] Soak the PES / SPEEK porous base membrane obtained above in 50mL of 0.6mol / L MgCl 2 and 0.3mol / LAlCl 3 12h in the mixed salt solution to ensure that the SO in the diaphragm 3- Fully interact with the metal ions in the salt solution, then configure 40mL alkali solution containing 0.45mol / L NaOH, add it into the above-mentioned salt solution containing the basement membrane under stirring, stir for 10 minutes, and then transfer to a Teflon-lined In a sta...

Embodiment 2

[0078] Using polyethersulfone PES / SPEEK resin as the base material, dissolve PES / SPEEK in DMAC solvent with a mass ratio of 2:1 to obtain a blended solution with a solid content of 35%, stir it evenly and let it stand, pour it on a clean and flat glass On the board, under the condition of 20% humidity, use a 200 μm spatula to scrape out a flat diaphragm, immerse in water, wait for the solvent to dissolve, remove the solvent to obtain a polyethersulfone porous ion-conducting membrane, and soak in water for later use. The growth conditions and subsequent drying process of the hydrotalcite film were the same as in Example 1, and finally a hydrotalcite in-situ growth composite film (referred to as LDHM-2) with a layer spacing of 0.76 nm and a porosity of 35% was obtained. The thickness of the hydrotalcite layer is 1.54 μm, the total thickness of the composite membrane is 114 μm, the pore diameter of the polyethersulfone porous ion-conducting membrane is 0.5-50 nm, and the porosity ...

Embodiment 3

[0085] Using polyethersulfone PES / SPEEK resin as the base material, dissolve PES / SPEEK in DMAC solvent with a mass ratio of 1:1 to obtain a blended solution with a solid content of 35%, stir it evenly and let it stand, pour it on a clean and flat glass On the board, under the condition of 20% humidity, use a 200 μm spatula to scrape out a flat diaphragm, immerse in water, wait for the solvent to dissolve, remove the solvent to obtain a polyethersulfone porous ion-conducting membrane, and soak in water for later use. The growth conditions and subsequent drying process of the hydrotalcite film were consistent with those in Example 1, and finally a hydrotalcite in-situ growth composite film (referred to as LDHM-3) with a hydrotalcite layer spacing of 0.76 nm and a porosity of 30% was obtained. The thickness of the hydrotalcite layer is 1.56 μm, the total thickness of the composite membrane is 116 μm, the pore diameter of the polyethersulfone porous ion-conducting membrane is 0.5-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com