Slurry direct writing forming method of diamond tool

A diamond tool, direct writing molding technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of shape change, unfavorable product quality control, large dimensional shrinkage rate, etc., and achieve high consistency and controllable porosity. , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Silicon powder, sodium oxide, aluminum oxide, potassium oxide and diboron trioxide are mixed for 4h at a speed of 600r / min with a mixer in parts by weight shown in Table 1 below, to obtain nano-ceramic powder;

[0035] Table 1

[0036]

[0037]

[0038] (2) Fully disperse xanthan gum in deionized water (using a stirrer to stir for 90min at a speed of 800r / min), to obtain a xanthan gum solution with a concentration of 3wt%;

[0039] (3) Mix the nano-ceramic powder prepared in step (1) with the xanthan gum solution obtained in step (2) to obtain a slurry, and the volume ratio of the mixed powder to the xanthan gum solution is 70%: 30% ;

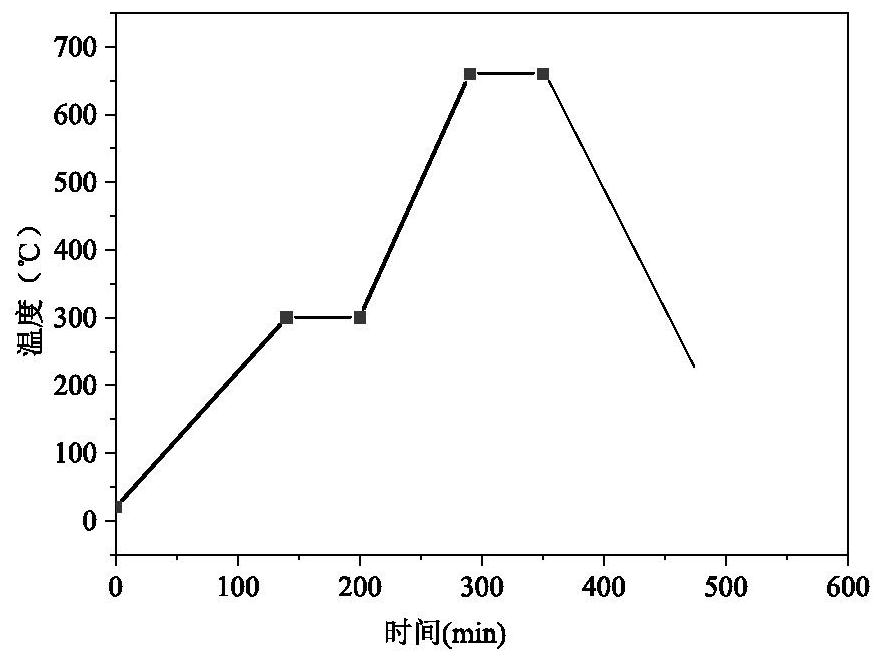

[0040] (4) Add the slurry prepared in step (3) into the syringe of the slurry direct-writing molding equipment, and print it into the designed shape by layer-by-layer stacking to obtain the green body; the printing process parameters are: needle printing speed 4mm / min, the nozzle radius is 1.5mm, the shear rate is 10.6 / s, the...

Embodiment 2

[0045] (1) Silicon powder, sodium oxide, aluminum oxide, potassium oxide and diboron trioxide are mixed for 4h at a speed of 600r / min with a mixer in parts by weight shown in Table 3 below, to obtain nano-ceramic powder;

[0046] table 3

[0047] serial number Silica fume sodium oxide Aluminum oxide potassium oxide Diboron trioxide 1 70 5 12 3 10 2 67 5 12 3 10 3 64 5 12 3 10 4 61 5 12 3 10

[0048] Step (2) to step (5) is the same as embodiment 1, and the performance of the diamond tool that the nano-ceramic powder of different formulations in table 3 makes is as shown in table 4 below:

[0049] Table 4

[0050] Numbering Dimensional change rate (%) Bending strength (MPa) Compressive strength (MPa) 1 0.16 56.2 50.2 2 0.28 54.3 49.3 3 0.37 52.8 47.1 4 0.45 50.7 45.9

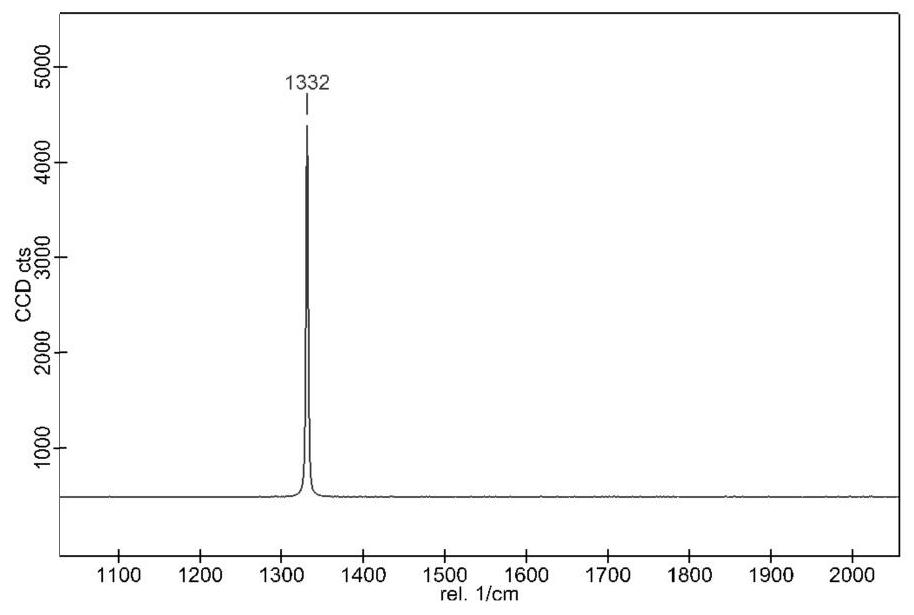

[0051] In conjunction with the data of Example 1, it is determined that the melting point of the nano-ce...

Embodiment 3

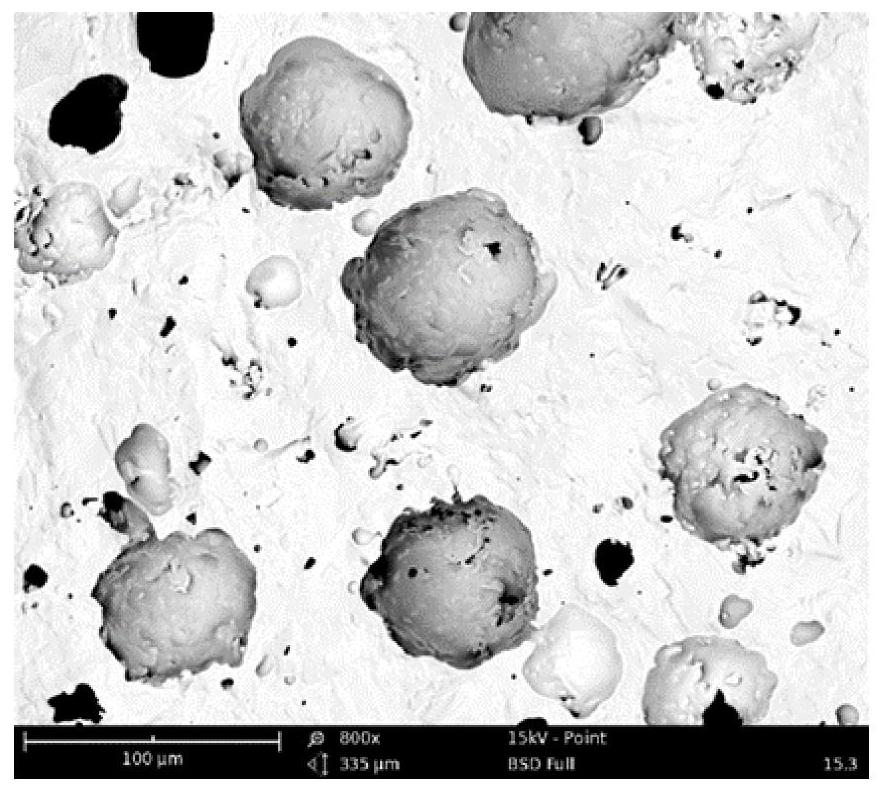

[0053] (1) The nano-ceramic powder, PMMA and W10 diamond microparticles determined in embodiment 2 are mixed with a mixer for 4h at a rotating speed of 600r / min in the ratio shown in Table 5 below, to obtain mixed powder;

[0054] table 5

[0055] serial number Nano ceramic powder (%) W10 Diamond (%) Porogen PMMA(%) 1 75 20 5 2 70 20 10 3 65 20 15 4 60 20 20

[0056] (2) Fully disperse xanthan gum in deionized water (using a stirrer to stir for 90min at a speed of 800r / min), to obtain a xanthan gum solution with a concentration of 3wt%;

[0057] (3) Mix the mixed powder prepared in step (1) with the xanthan gum solution obtained in step (2) to obtain a slurry, and the volume ratio of the mixed powder to the xanthan gum solution is 70%: 30%;

[0058] (4) Add the slurry prepared in step (3) into the syringe of the slurry direct-writing molding equipment, and print it into the designed shape by layer-by-layer stacking to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com