Low-cost solar heat-absorbing ceramic material and preparation method thereof

A technology for solar energy absorption and ceramic materials, which is applied in the field of low-cost solar energy absorption ceramic materials and their preparation, can solve the problems of thermal stress damage, low durability, poor air flow stability, etc. Solve the effect of poor thermal shock resistance, poor high temperature oxidation resistance and good high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

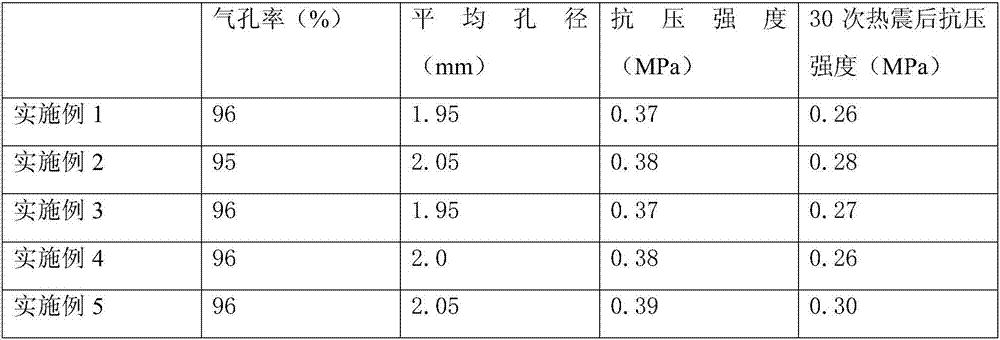

Examples

Embodiment 1

[0022] A low-cost solar heat-absorbing ceramic material, including the following components: 15kg of silicon nitride, 15kg of boron nitride, 5kg of titanium silicide, 5kg of nickel carbide, 5kg of chromium oxide, 5kg of aluminum oxide, 2kg of sodium silicate, 2kg of boron oxide, Manganese monoxide 2kg.

[0023] Wherein, each component is a powder with an average particle diameter of 1 nm.

[0024] The above-mentioned method for preparing a low-cost solar heat-absorbing ceramic material uses silicon nitride and boron nitride as substrates, and titanium silicide, nickel carbide, chromium oxide, aluminum oxide, sodium silicate, boron oxide, and manganese monoxide as substrates. Additives are used to synthesize a high-temperature-resistant binding phase, and polyurethane foam is used as a precursor to prepare ceramic materials by impregnating organic foam. Specific steps are as follows:

[0025] (1) Weigh each component of formula quantity, take dehydrated alcohol as dispersant,...

Embodiment 2

[0030] A low-cost solar heat-absorbing ceramic material, including the following components: 40kg of silicon nitride, 40kg of boron nitride, 15kg of titanium silicide, 15kg of nickel carbide, 12kg of chromium oxide, 12kg of aluminum oxide, 7kg of sodium silicate, 5kg of boron oxide, Manganese monoxide 3kg.

[0031] Wherein, each component is a powder with an average particle diameter of 100 nm.

[0032] The above-mentioned method for preparing a low-cost solar heat-absorbing ceramic material uses silicon nitride and boron nitride as substrates, and titanium silicide, nickel carbide, chromium oxide, aluminum oxide, sodium silicate, boron oxide, and manganese monoxide as substrates. Additives are used to synthesize a high-temperature-resistant binding phase, and polyurethane foam is used as a precursor to prepare ceramic materials by impregnating organic foam. Specific steps are as follows:

[0033] (1) Weigh each component of formula quantity, take dehydrated alcohol as dispe...

Embodiment 3

[0038] A low-cost solar heat-absorbing ceramic material, including the following components: 18kg silicon nitride, 20kg boron nitride, 8kg titanium silicide, 8kg nickel carbide, 7kg chromium oxide, 6kg aluminum oxide, 3kg sodium silicate, 3kg boron oxide, Manganese monoxide 2kg.

[0039] Wherein, each component is a powder with an average particle diameter of 1 nm.

[0040] The above-mentioned method for preparing a low-cost solar heat-absorbing ceramic material uses silicon nitride and boron nitride as substrates, and titanium silicide, nickel carbide, chromium oxide, aluminum oxide, sodium silicate, boron oxide, and manganese monoxide as substrates. Additives are used to synthesize a high-temperature-resistant binding phase, and polyurethane foam is used as a precursor to prepare ceramic materials by impregnating organic foam. Specific steps are as follows:

[0041] (1) Weigh each component of formula quantity, take dehydrated alcohol as dispersant, ZrO 2 The ball is a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com