Patents

Literature

99 results about "Manganese monoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

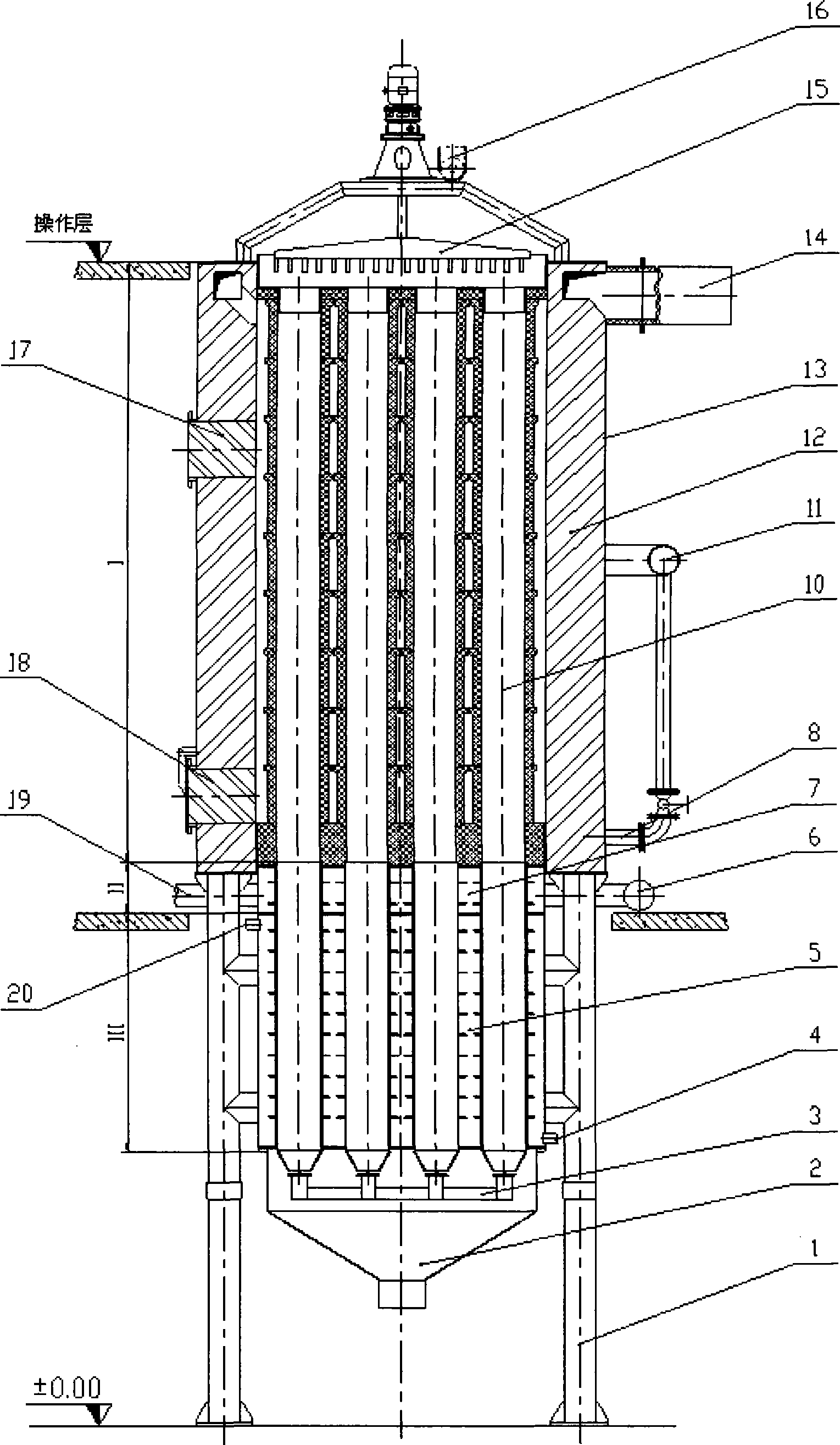

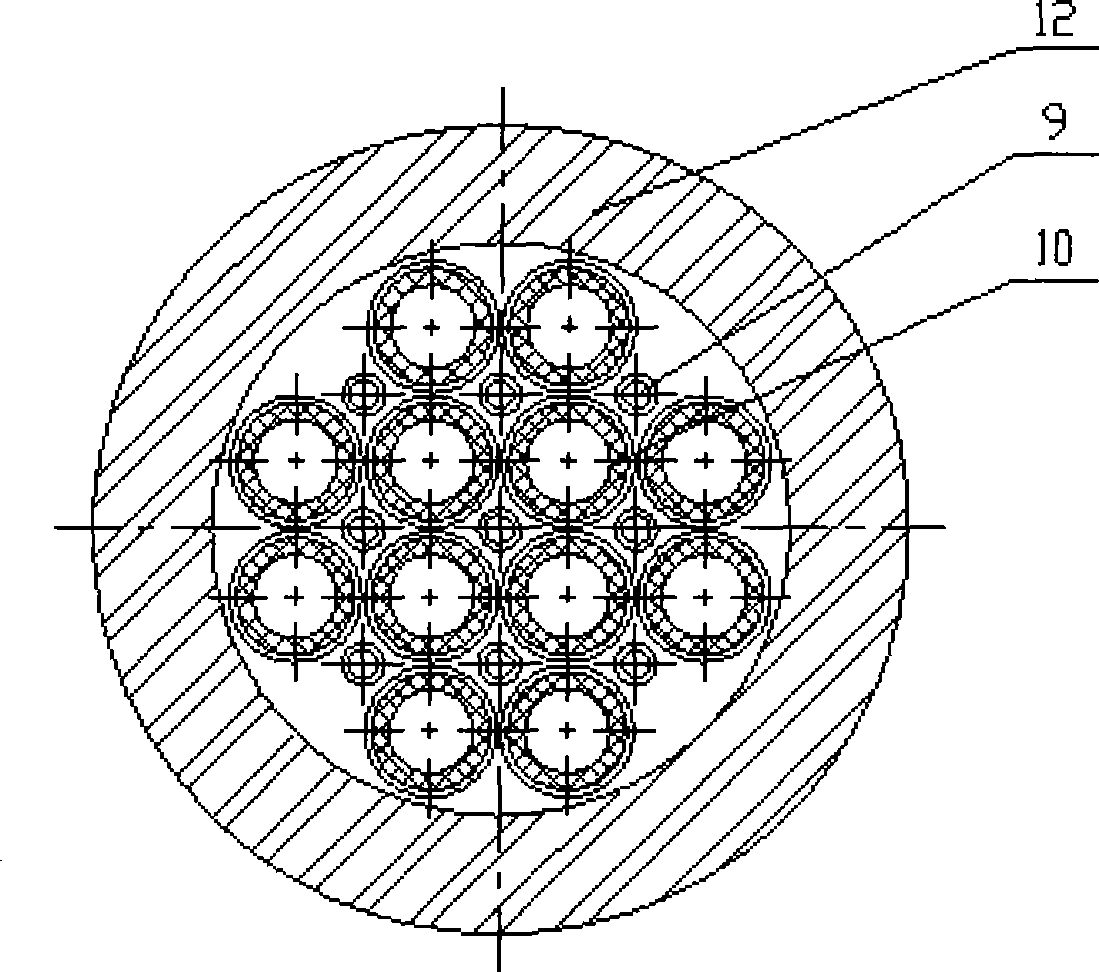

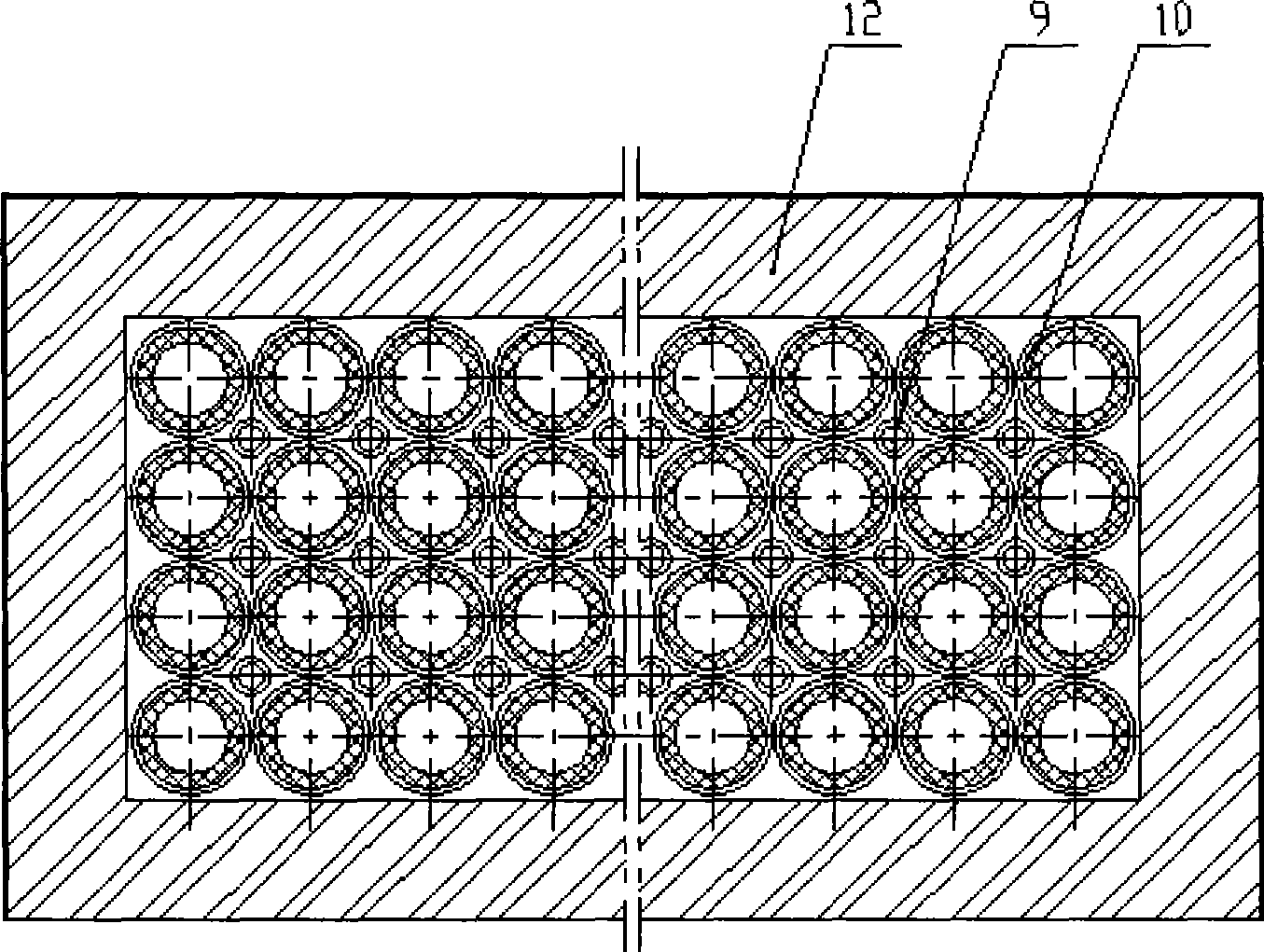

Manganese ore reduction calcination method and apparatus

The invention discloses a method and a device for reducing and roasting manganese dioxide into manganese monoxide in electrolytic manganese industry. The method comprises the following steps: dried manganese dioxide mineral powder is ground, well mixed with reducing powder and conveyed to a feeding bin on the top of a roasting furnace, and then enters hermetic roasting devices; a plurality of burners are arranged among the hermetic roasting devices; fuel is burnt so as to roast manganese dioxide ore; the manganese dioxide ore and the reducing powder are heated and roasted to 900 to 970 DEG C in the hermetic roasting devices with no oxygen supplement; under the circumstance of oxygen-free contact after reaction in the lower ends in the hermetic roasting devices, the temperature of roasted manganese ore is lowered, so as to recover heat and cool the manganese ore; and finally, the manganese ore is discharged out of a furnace by an automatic discharging device and then is subjected to a subsequent process. The method and the device can reduce and roast the high / low-grade manganese dioxide ore, have the advantages of low production cost, simple process and convenient operation, can control the reduction rate of manganese dioxide and other metals through the automatic discharging device, and improve the quality of final products.

Owner:朱军

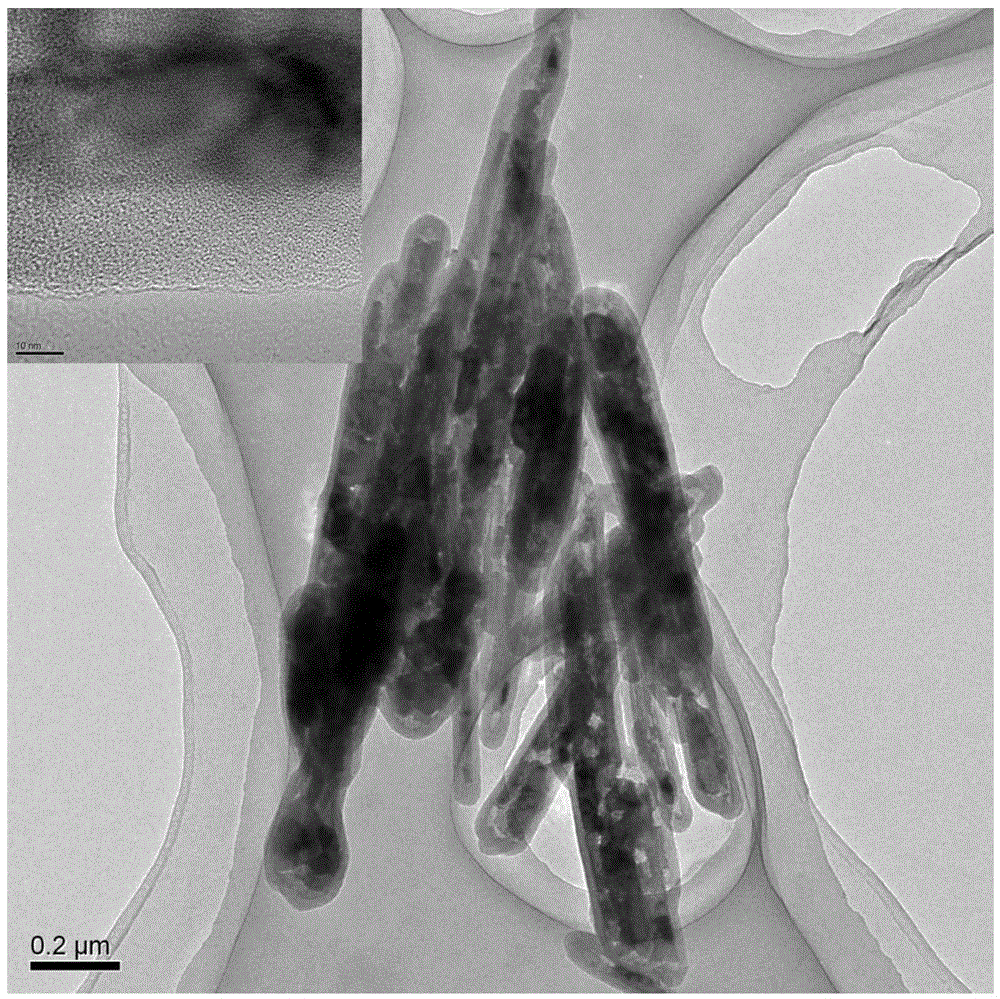

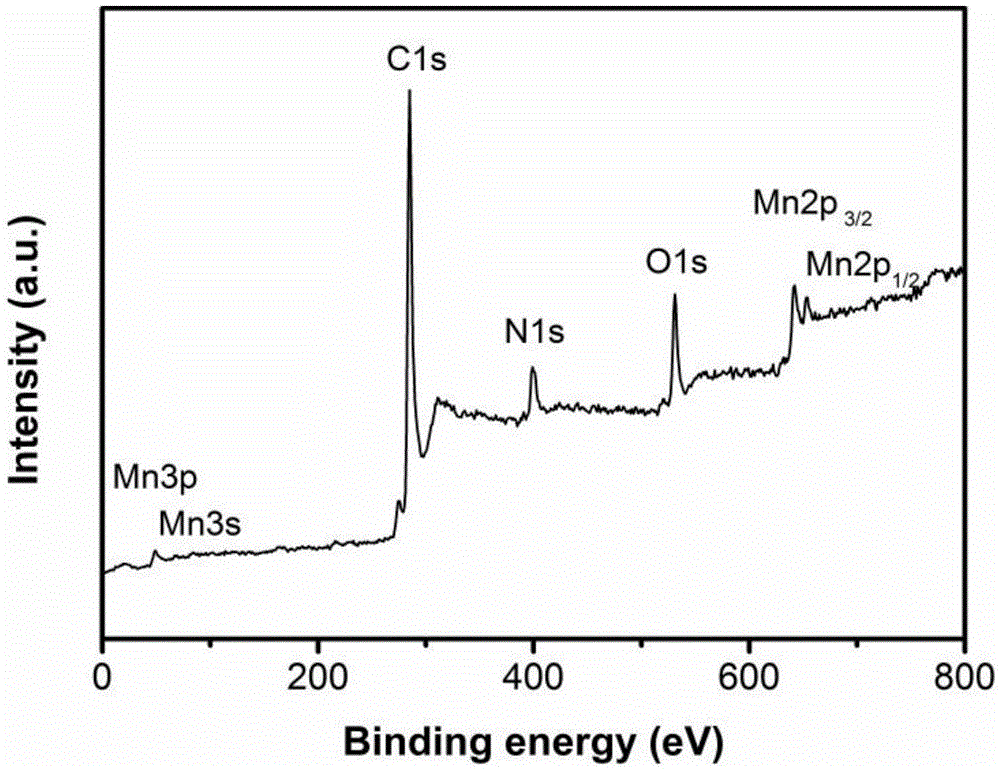

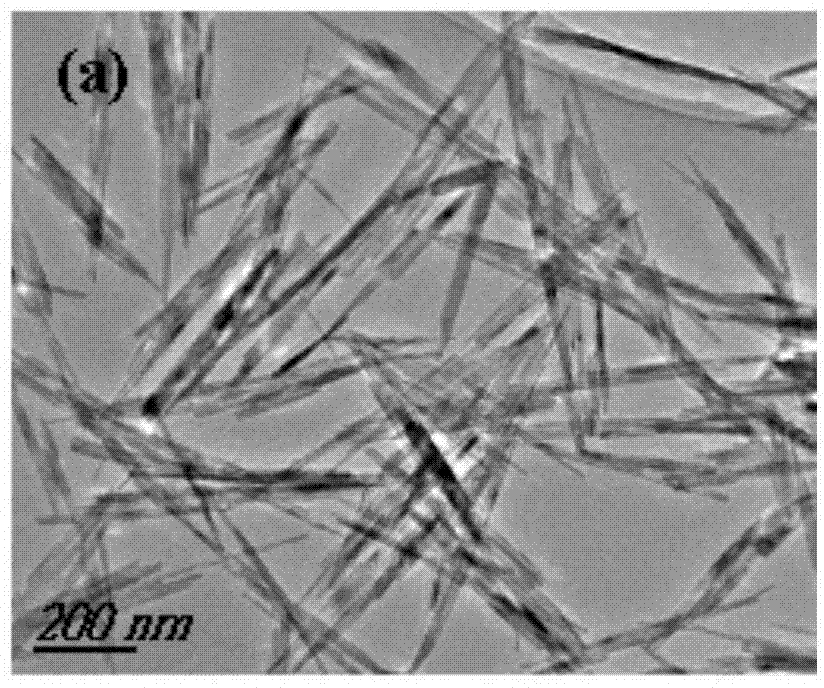

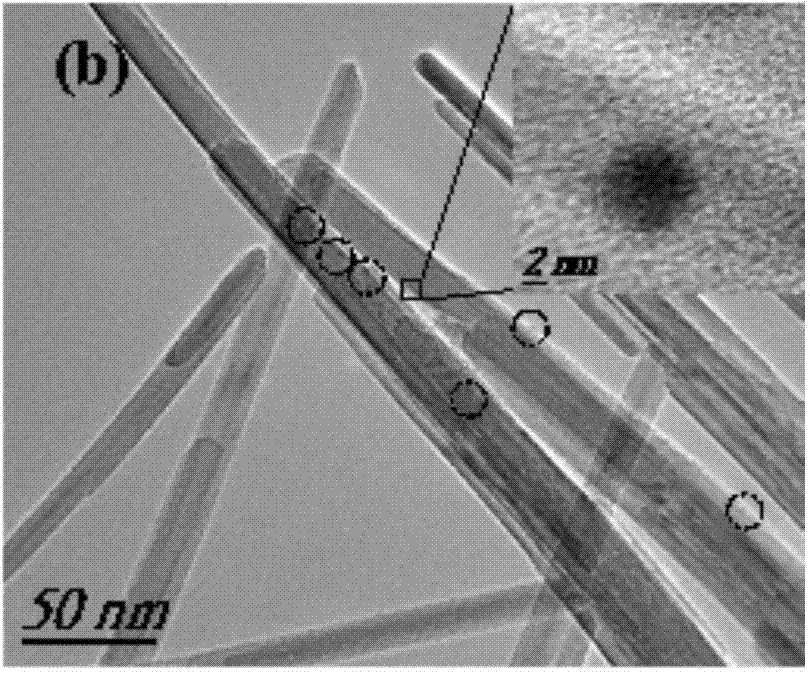

Nitrogen-doped carbon-coated manganese monoxide composite material with one-dimensional porous core-shell structure and preparation method of nitrogen-doped carbon-coated manganese monoxide composite material

InactiveCN105470481AImprove conductivityOvercoming the problem of rapid capacity fadingMaterial nanotechnologyCell electrodesCarbon layerIn situ polymerization

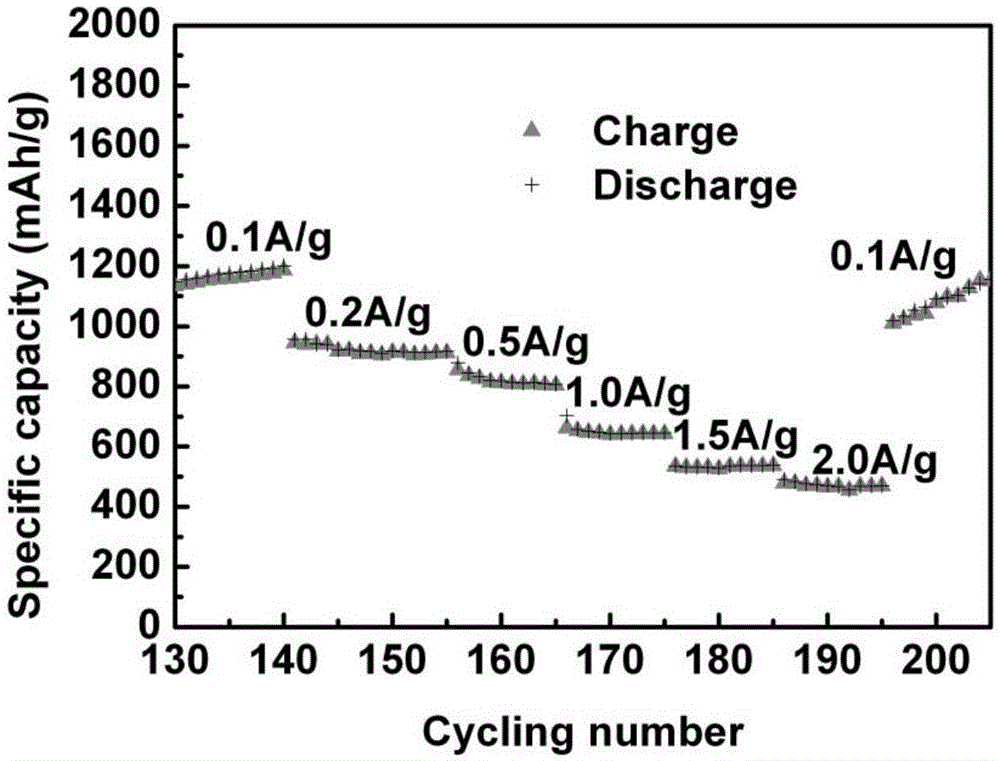

The invention relates to a nitrogen-doped carbon-coated manganese monoxide composite material with a one-dimensional porous core-shell structure and a preparation method of the nitrogen-doped carbon-coated manganese monoxide composite material. The composite material is doped with nitrogen, is in a one-dimensional porous carbon-coated manganese monoxide core-shell structure; manganese monoxide is in a nano rodlike structure; and an outer layer of a manganese monoxide nanorod is coated with an amorphous carbon layer. The nitrogen-doped carbon-coated manganese monoxide composite material is obtained by an in-situ polymer coating method accompanied by burning. The preparation method of the composite material is simple and novel, and high in adjustability; and meanwhile, nitrogen-doped carbon can store lithium ions. Due to the ingenious design, the specific capacity of the composite material exceeds the theoretical specific capacity of the manganese monoxide; furthermore, according to the composite material, the problems of low capacity and fast attenuation caused by poor conductivity and high volumetric strain of a pure manganese monoxide material are solved; and the composite material has excellent electrochemical properties, cycle lifetime and structural stability.

Owner:WUHAN UNIV OF TECH

Method for producing manganese sulfate by high-temperature crystallization process

InactiveCN101224908AReduce manufacturing costImprove product qualityManganese sulfatesManganese sulphateManganese(II) carbonate

The invention provides a method for producing high-purity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressure-filtered to obtain a manganese sulfate solution with the content of 160-200g / L, which is pumped to a manganese sulfate solution for carrying out crystallization and purification; the crystallization and purification includes crystallization, solid-liquid separation, dissolution, pressure filtration and other technologies; the pressure-filtered manganese sulfate solution can be crystallized and purified repeatedly as required. The invention can adopt a large amount of low-grade manganese ore with the manganese content of 10-20 percent as the raw material to produce the high-purity manganese sulfate solution and further deep process various high-purity manganese products, such as: electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade mangano-manganic oxide and manganese monoxide, chemical manganese dioxide, industrial grade manganese sulfate monohydrate, chemical grade manganese sulfate monohydrate, medicine grade manganese sulfate monohydrate, food grade manganese sulfate monohydrate, analytically pure manganese sulfate monohydrate and so on.

Owner:广西双德锰业有限公司

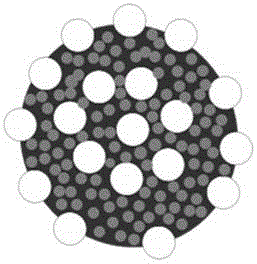

Carbon-coated porous manganese monoxide composite material and preparation method and application thereof

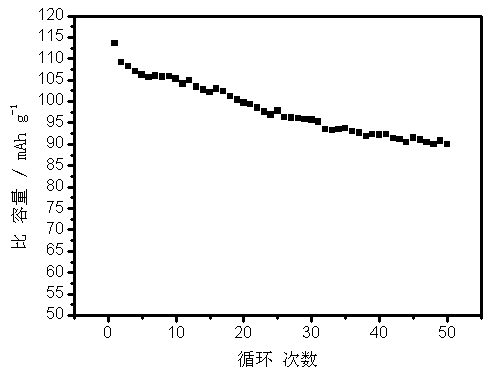

ActiveCN105633373AAvoid growing upImprove conductivityCell electrodesSecondary cellsCarbon layerMicroparticle

The invention discloses a carbon-coated porous manganese monoxide core-shell structure composite material and a preparation method and an application thereof. The preparation method comprises the following steps: firstly, with styrene as a carbon source and potassium peroxodisulfate as an initiator, carrying out soap-free emulsion polymerization to obtain a polystyrene microsphere template, and then carrying out surface modification on microspheres with concentrated sulfuric acid; with common manganese sulfate as a manganese source, preparing manganese carbonate particles embedded with a plurality of polystyrene microspheres by a liquid phase deposition method, and then adding a shell layer material to coat the particle surfaces with a carbon layer; and finally, carrying out high-temperature carbonization to obtain a novel carbon-coated porous manganese monoxide core-shell structure composite material. The composite material is spherical particles with uneven surfaces; and the spherical particles comprise manganese monoxide grains, multi-scale holes and the carbon layer. The special structure with the carbon layer and the multi-scale holes can play a role in buffering volume expansion of manganese monoxide in the repeated charging and discharging processes. The composite material disclosed by the invention has excellent cycling stability and rate capability as an anode material for a lithium-ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing manganese sulfate solution by two-ores method

InactiveCN101456595AReduce consumptionReduce manufacturing costManganese sulfatesElectrolysisFiltration

The invention discloses a method for preparing a manganese sulfate solution by using a two-ore method. The method for preparing the manganese sulfate comprises: crushing manganese ore to grains less than 2mm by using a crusher; grinding the manganese ore into 100 mesh slurry by using a wet grinder; grinding iron pyrite containing less than 32 percent of sulfur into 100 mesh slurry by using the same wet grinder; mixing the slurry of the manganese ore with the slurry of the iron pyrite; adding water and sulfuric acid into the mixture; and carrying out heating reaction, iron removal, heavy metal removal, neutralization and pressure filtration and obtaining the manganese sulfate solution. Due to the technical proposal, the method for preparing the manganese sulfate solution has the advantages of small sulfuric acid consumption, low production cost, high content of manganese of products, high recovery rate of manganese and so on compared with the prior art, wherein the content of manganese of the products is increased to 98 to 99 percent from original 60 to 65 percent, and the recovery rate of manganese is up to 85 percent. The products can be used for deep processing of various high-purity manganese products such as electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade manganese monoxide and chemical manganese dioxide.

Owner:杜祖德

Method for preparing manganic manganous oxide

The invention relates to a preparation method of mangano-manganic oxide, belonging to the technical field of inorganic non-metallic material, wherein the purified manganese ore extract, manganese sulfate solution, is used as raw material; carbonate (bicarbonate) is used as precipitating agent; the manganese ion in the manganese sulfate solution is precipitated into manganese carbonate sediment, which is then thermal oxidized and decomposed into a manganese admixture containing manganese dioxide, manganese monoxide and manganese carbonate with air or oxygen at a temperature of 120 DEG C to 800 DEG C, and then calcined into mangano-manganic oxide at a temperature of 800 DEG C to 1200 DEG C. The invention has the advantages that the dust cloud of manganese admixture is practically avoided during the process of preparation; the recovery rate of manganese is high; the obtained mangano-manganic oxide has dramatic activity and the cost is low.

Owner:李宏亮

Manganese oxide catalyst used for toluene liquid phase catalytic oxidation, its preparation method and application

InactiveCN1824383AHigh activityGood choiceOrganic compound preparationCarboxylic compound preparationBenzoic acidBenzaldehyde

The present invention relates to a manganic oxide catalyst for toluene liquid-phase catalytic oxidation to prepare benzoic acid and benzaldehyde, its preparation method and application. The described manganic oxide can be manganese dioxide, manganese sesquioxide, trimanganese tetraoxide and manganese monoxide and other mixed valence manganic oxide, and said catalyst can be prepared by means of thermolysis method, hydropyrolysis process or precipitation process. Said catalyst has higher activity, selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

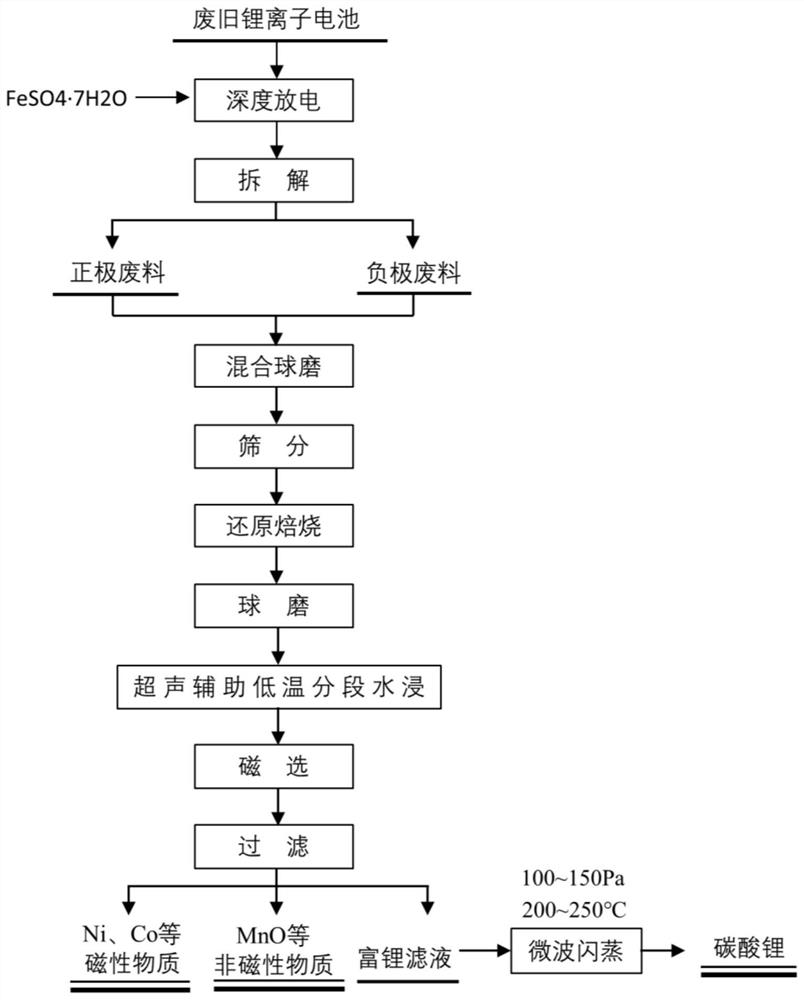

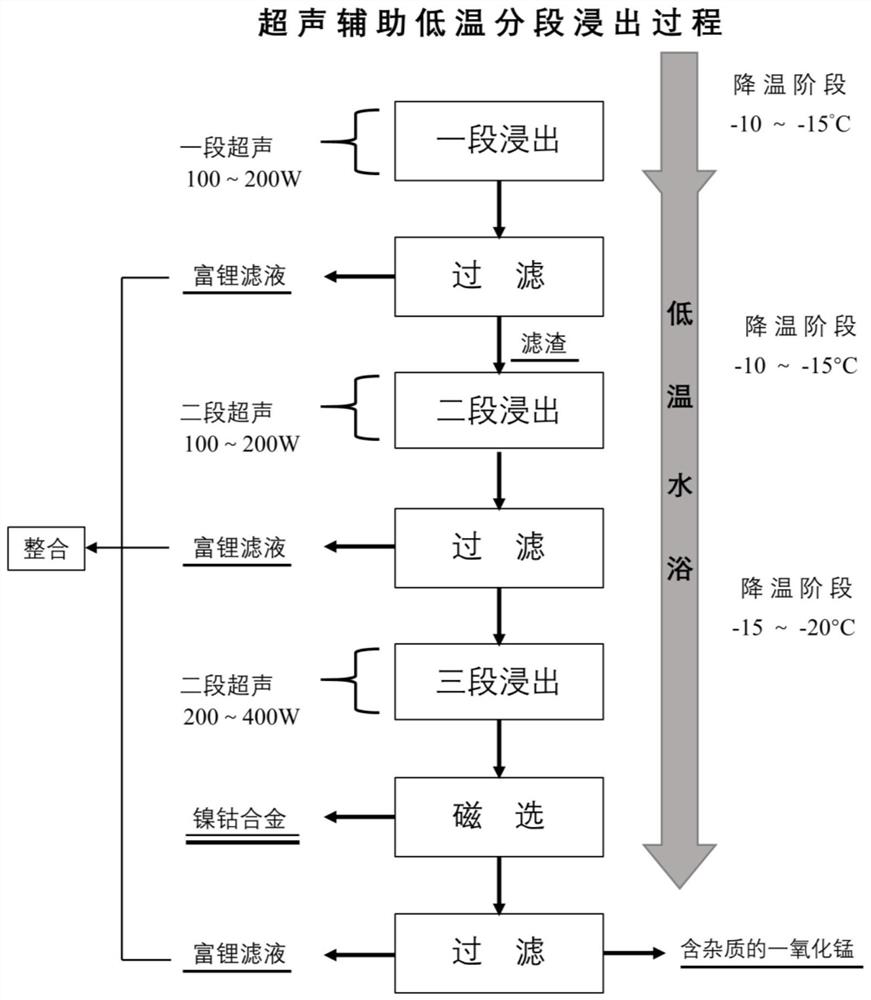

Method for separating and recovering valuable metals in roasted product of lithium ion battery

InactiveCN111945006AImprove leaching rateEfficient separationProcess efficiency improvementElectrical batteryManganese oxide

The invention relates to a method for separating and recovering valuable metals in a roasted product of a lithium ion battery. The method for separating and recovering the valuable metals in the roasted product of the lithium ion battery comprises the following steps of mixing and ball-milling a stripped positive electrode material and a stripped negative electrode material of the lithium battery;after an obtained ball-milled product is screened, carrying out reduction roasting on the screened product in an inert gas atmosphere; cooling the reduction roasting product to room temperature underan oxygen-free condition to obtain a roasted product; carrying out sectional ultrasonic-assisted low-temperature water leaching on the roasted product; carrying out magnetic separation and solid-liquid separation on a solution after the sectional leaching is finished to obtain magnetic substances (nickel, cobalt and the like), filtrate and filter residues (manganese monoxide and the like); and carrying out microwave flash evaporation treatment on the filtrate to obtain lithium carbonate crystals. According to the method for separating and recovering the valuable metals in the roasted productof the lithium ion battery, efficient separation of the valuable metals in the lithium ion battery is realized, the problem of low leaching rate of the reduction roasting products is solved by utilizing the mechanical effect and the cavitation effect of ultrasonic waves, and the leaching rate of lithium is greatly increased.

Owner:KUNMING UNIV OF SCI & TECH

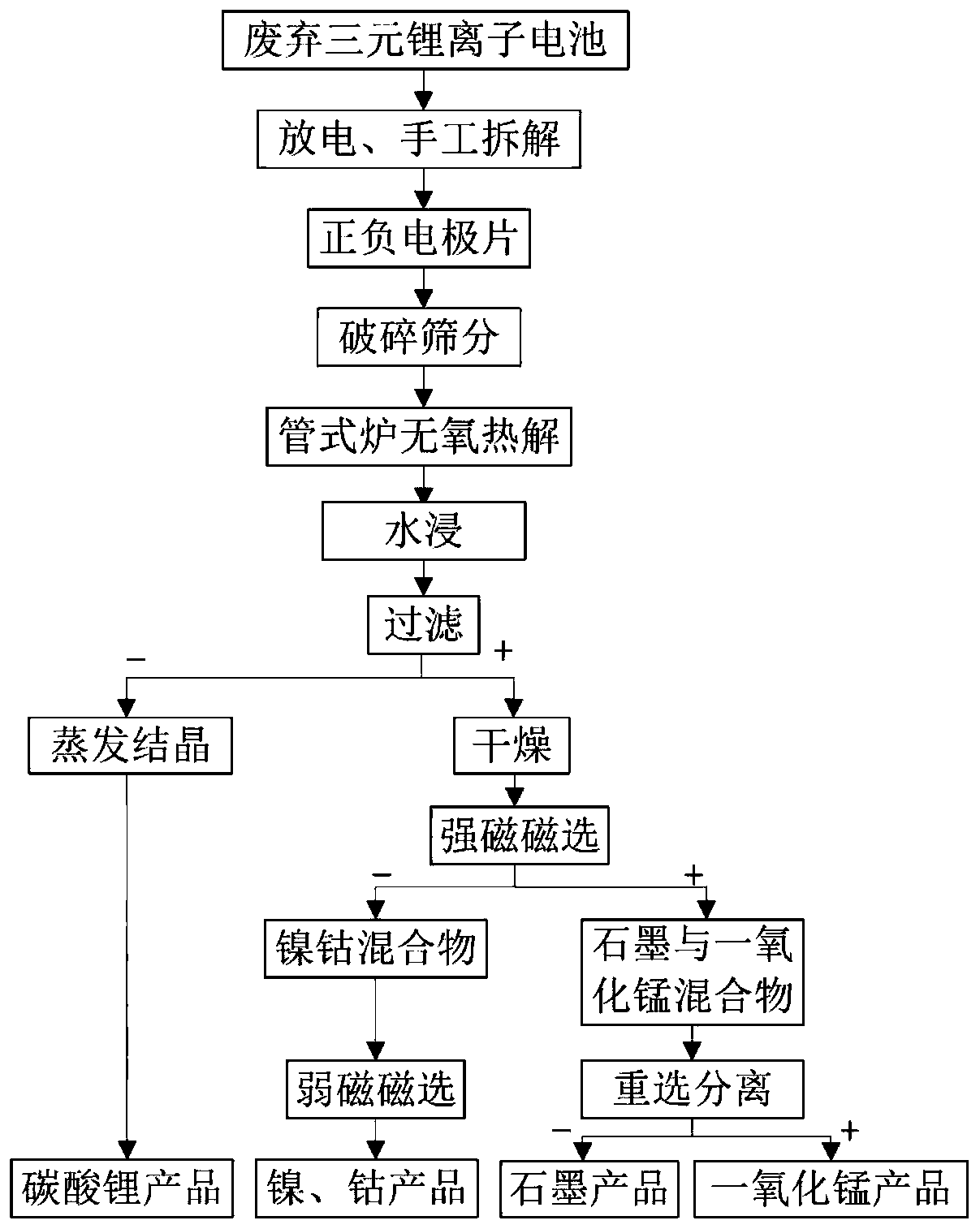

Method for recycling valuable components in waste ternary lithium ion battery through high-temperature in-situ heat treatment

ActiveCN111244566AReduce distractionsSimple recycling processWaste accumulators reclaimingBattery recyclingElectrolysisHydrometallurgy

The invention discloses a method for recycling valuable components in a waste ternary lithium ion battery through high-temperature in-situ heat treatment. The method comprises the steps of carrying out the in-situ thermal reduction on the nickel-cobalt-manganese high-valence elements in an electrode material by utilizing the organic substances, such as a positive and negative electrode material surface binder, carbon black, etc., reducing the nickel and cobalt to be in an elemental form, and reducing manganese to be low-valence oxide manganese monoxide; recycling the lithium element by adopting a water immersion method, and drying the residual materials, and then separating the ferromagnetic nickel-cobalt elementary substances, diamagnetic graphite and non-magnetic manganese monoxide through a magnetic separator with high magnetic flux; selecting a magnetic separator with low magnetic flux to separate and recover nickel and cobalt. Compared with a traditional ore pulp electrolysis process and other hydrometallurgy processes, a reducing agent does not need to be added, the interference of impurity elements in a recovery system is reduced, and finally the recovery rates of nickel, cobalt, manganese and negative electrode graphite are all larger than 98%. According to the process, the process of recycling the valuable components in the waste ternary lithium ion battery electrode material is simplified, the cost is reduced, and the method is a good choice for industrial application.

Owner:CHINA UNIV OF MINING & TECH

Nano-scale manganese monoxide-conductive carbon black composite material and synthetic method thereof

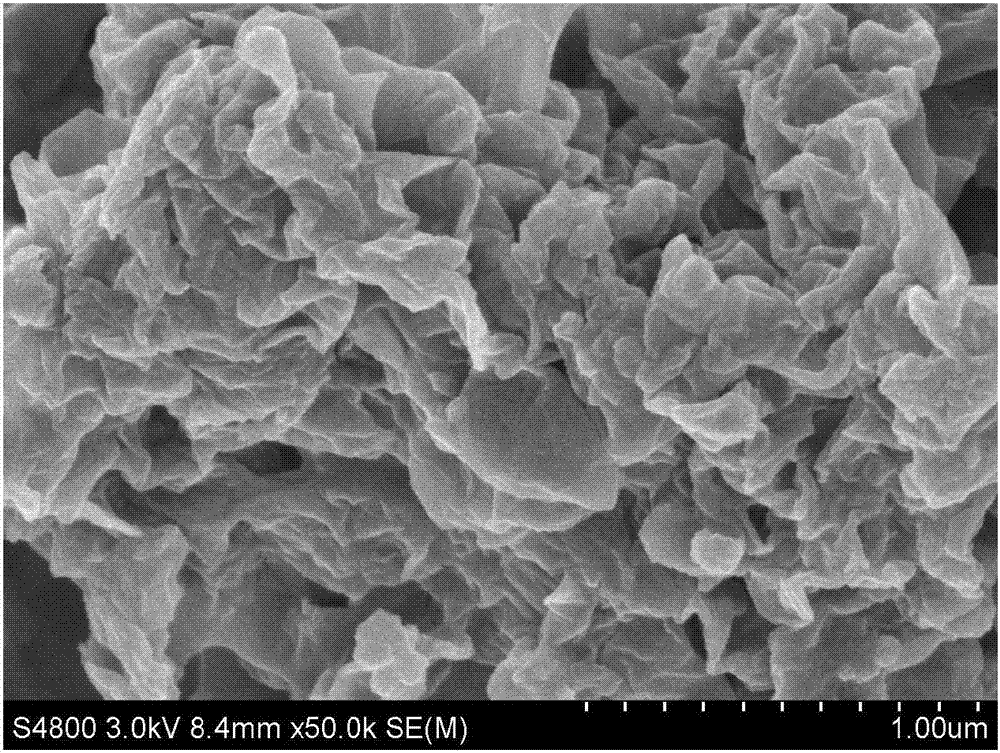

InactiveCN104638257ASimple technical processImprove electrochemical performanceMaterial nanotechnologyCell electrodesManganese oxideOxidation reduction

The invention provides a nano-scale manganese monoxide-conductive carbon black composite material and a synthetic method thereof. According to the synthetic method, a commercial low-cost conductive carbon black is used as a substrate to have oxidation-reduction reaction with potassium permanganate. The synthetic method comprises the following steps: generating nano-scale manganese oxide nano sheet-conductive carbon black composite particles at first, and then roasting in a reducing atmosphere or inert atmosphere to obtain a final nano-scale manganese monoxide-conductive carbon black composite material. The process is simple in operation, accords with environmental requirements, and is low in reaction equipment requirement, low in production cost and very suitable for industrial production. The prepared manganese monoxide-conductive carbon black composite material has excellent performance when being applied to a cathode of a lithium ion battery.

Owner:NANJING UNIV OF TECH

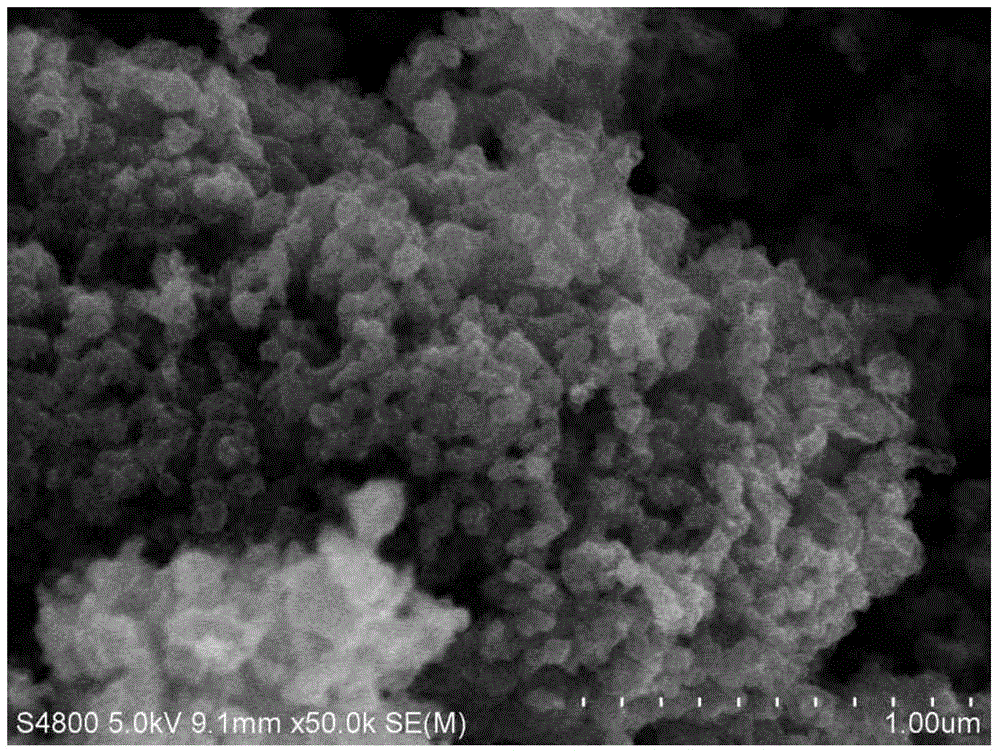

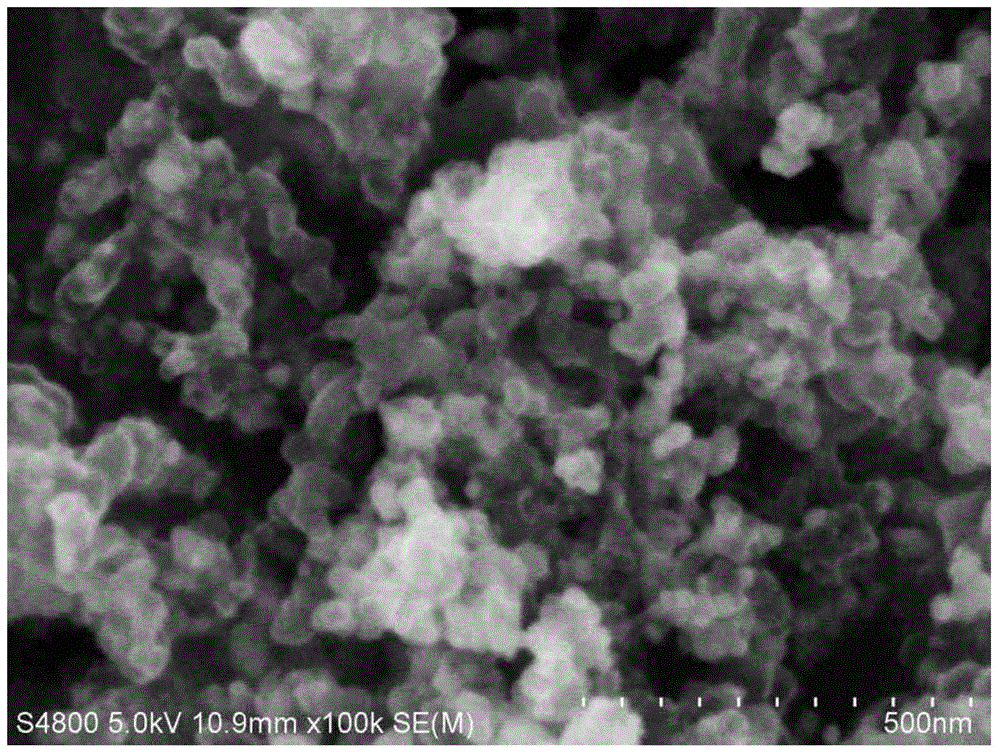

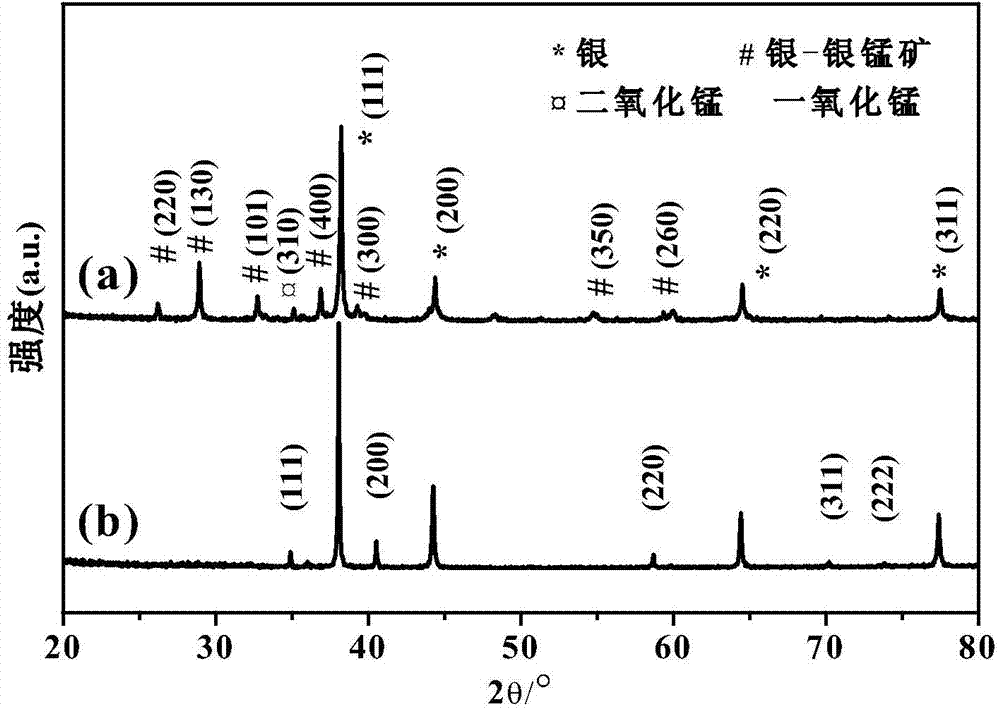

Controllable preparation method of Ag-manganese monoxide nanorods

ActiveCN103691438ACell electrodesMetal/metal-oxides/metal-hydroxide catalystsSimple Organic CompoundsPhysical chemistry

The invention relates to a controllable preparation method of Ag-manganese monoxide nanorods and especially relates to a method for controllable preparation of the Ag-manganese monoxide nanorods by an in-situ oxidation-reduction reaction technology. The method solves the problems of the prior art of pure one-dimensional manganese monoxide preparation and especially solves the problems of one-dimensional nanomaterial preparation adopting the simple and mild method, and the problems comprise manganese organic compound use, high-temperature reaction and multi-valence state coexistence in the reaction.

Owner:JIANGSU UNIV

Preparation method of ternary layered positive electrode material for sodium ion battery

ActiveCN108539141AImprove performanceSimple preparation processCell electrodesSecondary cellsSlurrySodium-ion battery

The invention provides a preparation method of ternary layered positive electrode material for a sodium ion battery. The preparation method comprises the following steps: mixing sodium carbonate, manganese monoxide, ferrous oxide and nickel oxide according to a given ratio, adding deionized water, preparing the mixture slurry with a solid content of 30 to 45 percent, ball milling, obtaining a uniformly-mixed raw material with small particles, obtaining a precursor in an atomizing manner, wherein the precursor consists of spherical particles formed by clustering small particles, calcining the spherical particles at high temperature, preserving the heat for a given time, cooling, and obtaining the needed NaMn1-x-yFexNiyO2(x is greater than 0 and less than 0.5, and y is greater than 0 and less than 0.5) positive electrode material. The ternary layered positive electrode material for the sodium ion battery synthesized in the invention has the spherical particle appearance characteristic and nano porous internal structure, so that the transport distance of the sodium ions between the interior of a material lattice and electrolyte can be reduced, and the electrochemical performance of the material can be improved.

Owner:浙江钠创新能源有限公司

Preparation method of barium hydroxide

InactiveCN1962451ASimple methodClean manufacturingCalcium/strontium/barium oxides/hydroxidesBarium sulphideSlag

The invention discloses a preparing method of barium hydroxide, which comprises the following steps: (1) reducing barite into barium sulphide through coal; (2) immersing barium sulphide through washing water to obtain mother liquid of barium sulphide; adjusting the temperature of mother liquid of barium sulphide to 30-70 Deg C and density at 50-150g / L; washing filter slag through water; immersing barium sulphide through washing water; (3) oxidizing barium sulphide to produce barium hydroxide, sulfur and manganese monoxide through manganese dioxide; filtering to obtain barium hydroxide mother liquid; obtaining the filter slag with sulfur and manganese monoxide; (4) condensing barium hydroxide; crystallizing; centrifuging; separating to obtain barium hydroxide octahydrate; (5) separating filter slag in the step (3); recycling sulfur; oxidizing manganese monoxide into manganese dioxide through air to circulate in the step (3).

Owner:李守德

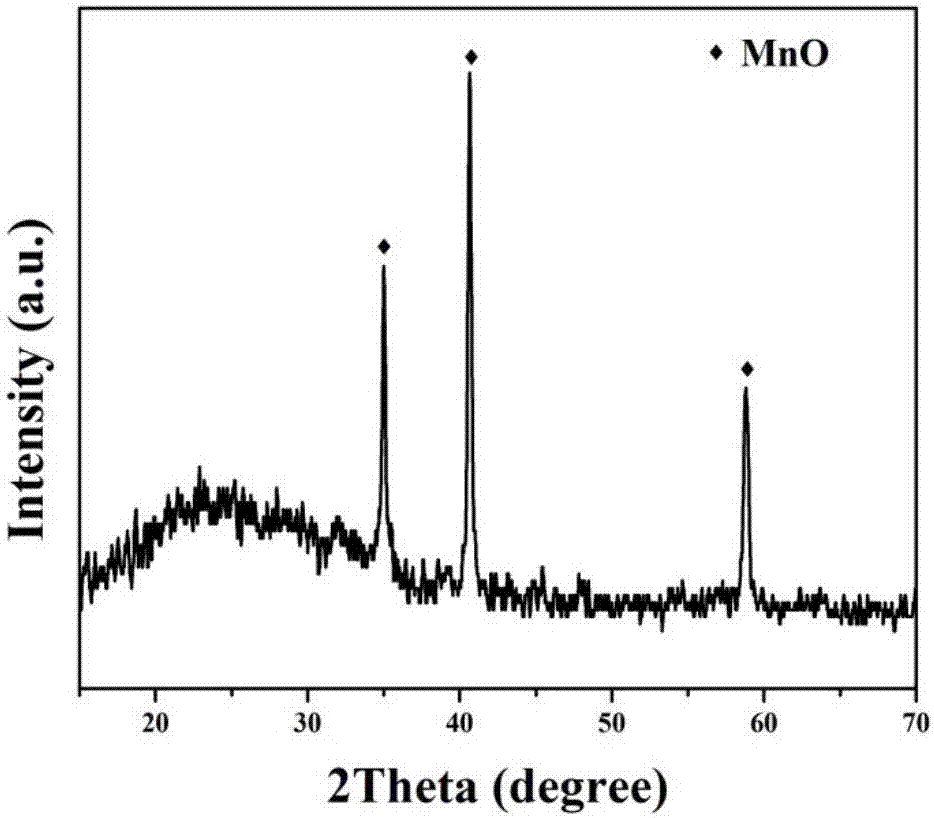

Preparation method of carbon-coated-manganese oxide/nitrogen-doped reduced graphene oxide anode material for lithium ion battery

ActiveCN107123794AImprove cycle stabilityEvenly dispersedCell electrodesSecondary cellsMANGANESE ACETATECarbon layer

The invention discloses a preparation method of a carbon-coated-manganese oxide / nitrogen-doped reduced graphene oxide anode material for a lithium ion battery. The preparation method comprises the following steps: using manganese acetate, graphene oxide and saccharose as main raw materials; firstly, obtaining a compound of manganese carbonate and reduced graphene oxide by adopting a microwave-hydrothermal method; secondly, obtaining a compound of carbon-coated manganese carbonate and the reduced graphene oxide by a traditional hydrothermal method; finally, carrying out heat treatment on the compound in an atmosphere furnace to obtain carbon-coated-manganese oxide particles, and loading the carbon-coated-manganese oxide particles on a reduced graphene oxide sheet; meanwhile, realizing nitrogen doping of graphene oxide, wherein the material can be used as a high-performance anode material of the lithium ion battery. According to the synthetic method, the graphene oxide is introduced into the first-time hydrothermal treatment process for improving poor electrical conductivity of MnO, and uniformly dispersing MnO particles on the surface of graphene; in the second-time hydrothermal treatment process, the surfaces of the MnO particles are coated with uniform carbon layers; a carbon shell is used as an elastic limiting body and can be used for preventing aggregation and pulverization of the MnO particles in the charge / discharge process; a buffer zone with volume expansion is provided for improving the cyclic stability of the material serving as the lithium ion battery to a great extent.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing manganese sulfate by using low grade manganese mud

The invention provides a method for preparing manganese sulfate from low-grade manganese slag, which comprises: the slurry of manganese ore and the slurry of iron pyrite are subjected to heating reaction, iron removal, heavy metal removal, neutralization and pressure filtration to form a manganese solution of which the concentration is 150 to 200g / L; and the manganese solution is pumped for crystallization and purification. The crystallization and purification comprises crystallization, solid-liquid separation, dissolution, pressure filtration and so on. The method uses rich low-grade manganese ore containing 10 to 20 percent of manganese as a raw material to produce a high-purity manganese sulfate solution which is used for deep processing of various high-purity manganese products such as electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade trimanganese tetroxide and manganese monoxide, chemical manganese dioxide, industrial manganese sulfate monohydrate, chemical manganese sulfate monohydrate, medical manganese sulfate monohydrate, food manganese sulfate monohydrate, and analytical pure manganese sulfate monohydrate.

Owner:杜祖德

Method for preparing trimanganese tetroxide

InactiveCN102849800AFast heatingShorten the heating cycleManganese oxides/hydroxidesManganese(II) carbonateManganous-manganic oxide

The invention discloses a method for preparing trimanganese tetroxide. Manganese carbonate is used as a raw material, added with a carbon source, placed in sealed microwave equipment, then heated to 650-750 DEG C with a heating rate of 8-20 DEG C / min, and sintered for 0.5-2 h; and the product is ground by a wet grinding after tapping, so as to obtain trimanganese tetroxide. According to the present invention, rapid and comprehensive heating of the microwave equipment and ''non-thermal effect'' enable carbon dioxide generated from decomposition of manganese carbonate to timely react with manganese oxide at a low temperature, so as to produce trimanganese tetroxide; and the method has the advantages of simple process, easy control process, low energy consumption, complete reaction process and stable specific surface area.

Owner:湖南隆泰环保能源科技有限公司

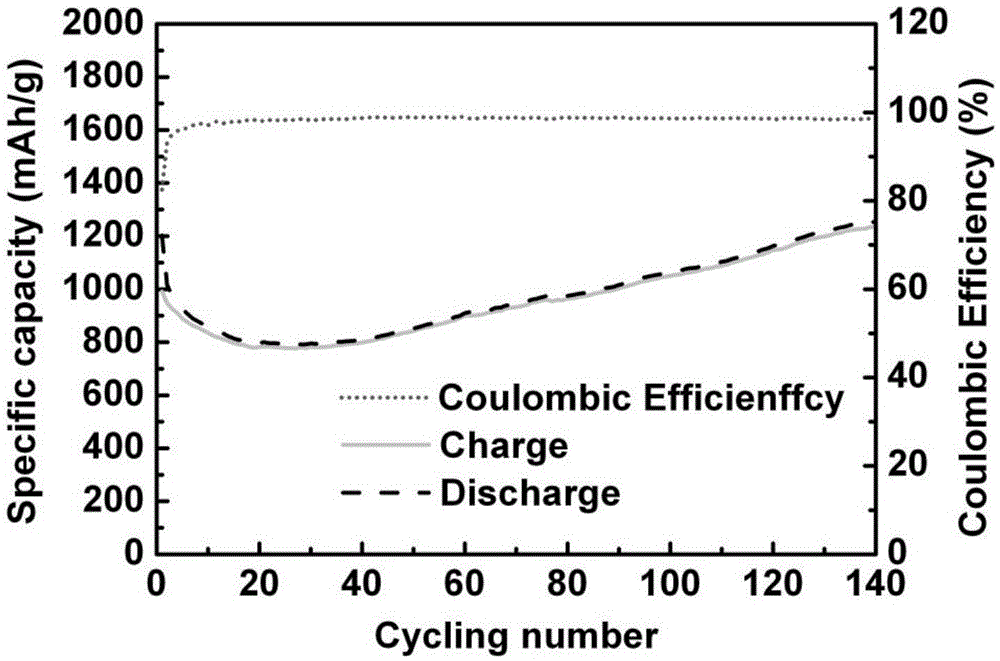

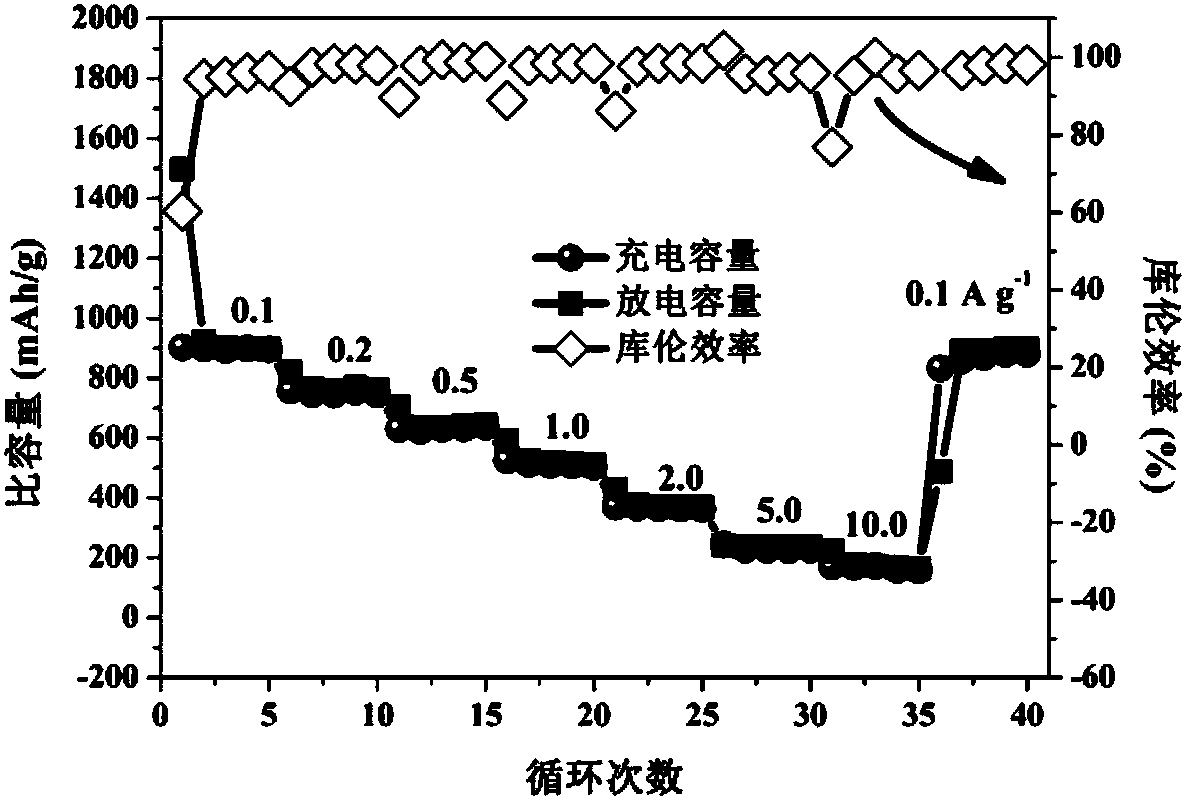

One-dimensional porous carbon coated manganese monoxide composite electrode material and preparation method thereof

InactiveCN107732171AHigh specific capacityImprove cycle performanceMaterial nanotechnologyCell electrodesComposite electrodePorous carbon

The present invention discloses a one-dimensional porous carbon coated manganese monoxide composite electrode material for lithium ion battery negative electrodes, and a preparation method thereof, wherein the porous carbon-coated manganese oxide particles in the composite material are integrally aggregated in the form of a one-dimensional rod shape, the particle size of the porous carbon coated manganese monoxide particles is 10-20 nm, and the one-dimensional porous carbon coated manganese monoxide composite electrode material is prepared by carrying out one-step thermal treatment on a metalorganic framework. According to the present invention, with the application of the composite material as the lithium ion battery negative electrode, the advantages of high initial coulombic efficiency, high specific capacity, excellent cycle performance, excellent rate performance, long cycle life and the like can be provided; and the preparation method is simple, has the low cost, and is suitablefor industrial large-scale production.

Owner:宿州学院

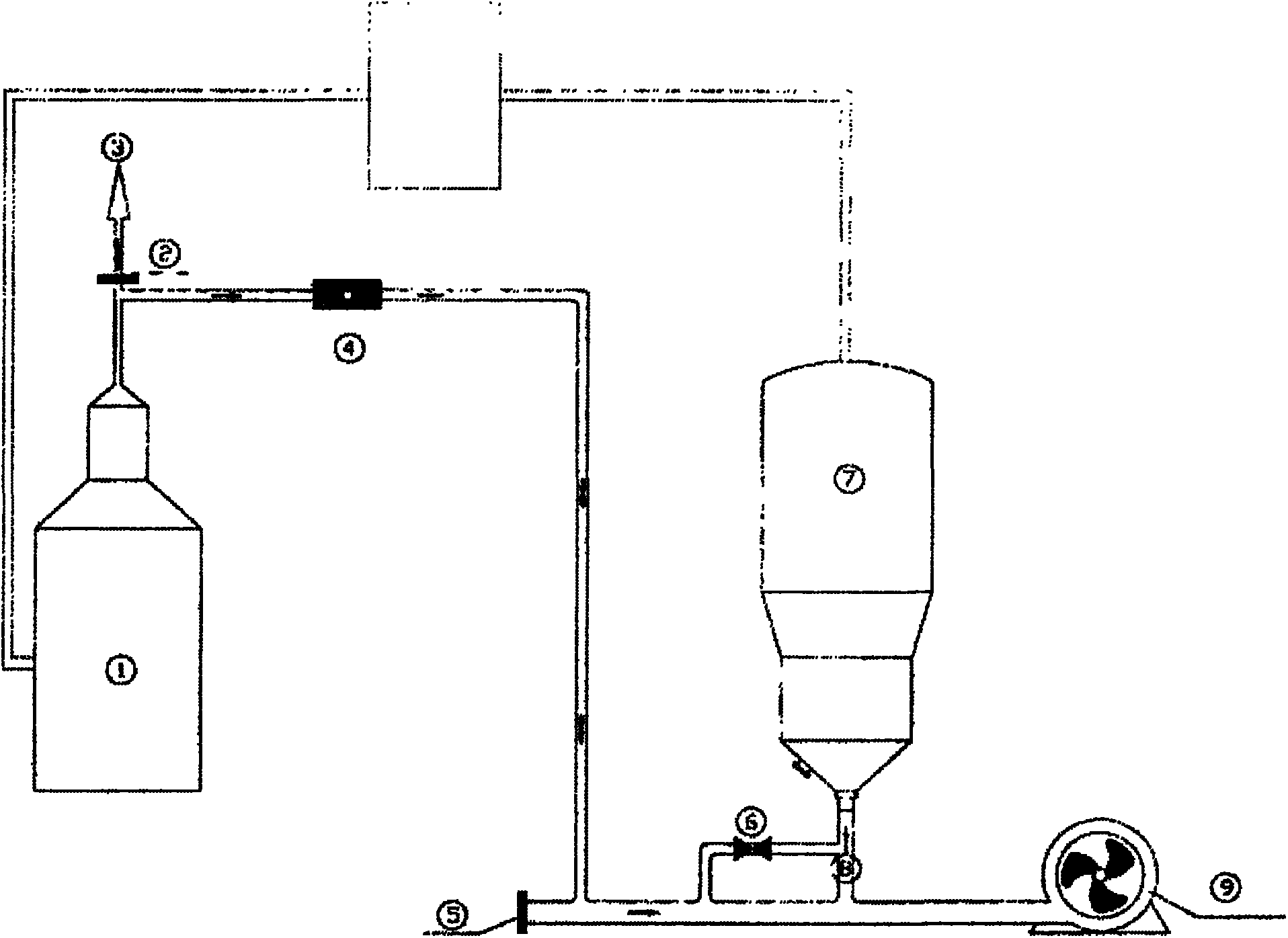

Recycling method of tail gas from pyrolusite reduction and sulfuric acid coproduction in fluidized bed furnace

InactiveCN102424365AGuaranteed normal boilingImprove the efficiency of the reduction reactionSulfur compoundsManganese sulfatesPyrolusiteFluidized bed

The invention provides a recycling method of tail gas from pyrolusite reduction in a fluidized bed furnace, belonging to the technical field of ore product processing. In order to improve the conversion of manganese peroxide to manganese monoxide in the fluidized bed furnace, the reduction reaction is necessarily carried out under a low-oxygen condition, and the mixed gas formed by air and tail gas of the fluidized bed furnace is blown from the lower segment of the fluidized bed furnace so as to guarantee that the oxygen content in the mixed gas is very low. The technique is simple and easy in operation, has high manganese peroxide conversion rate, recycles the tail gas, and reduces the environmental pollution.

Owner:HUNAN LUXI JINXU ZHIHUA CO LTD

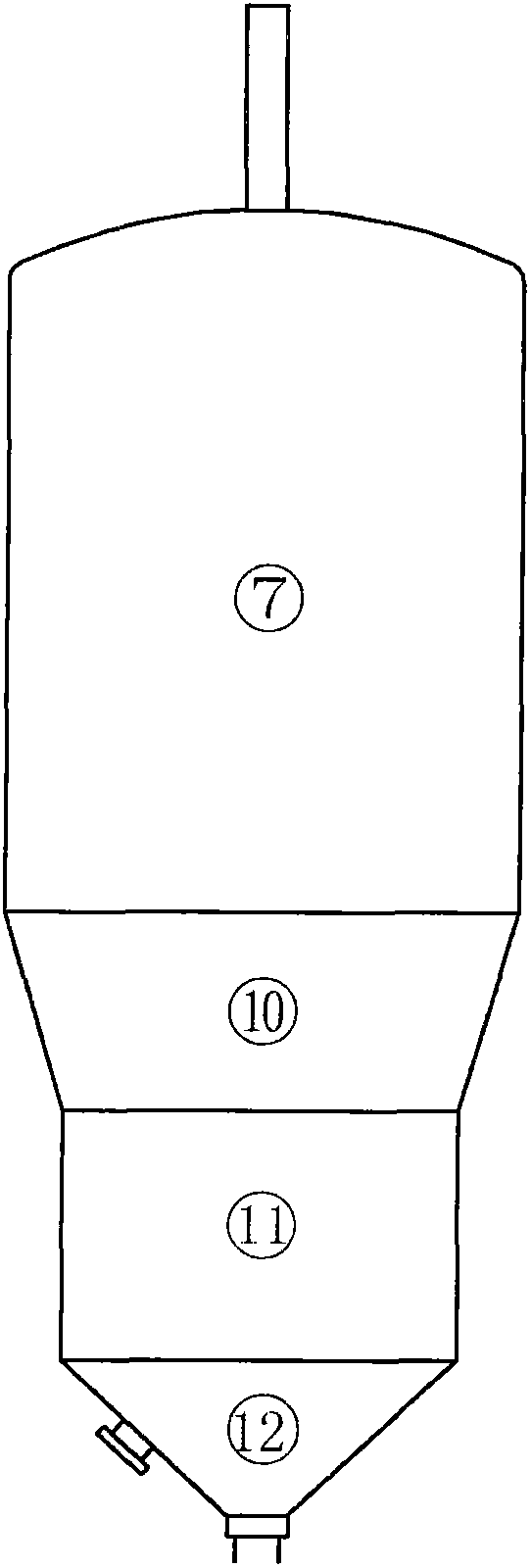

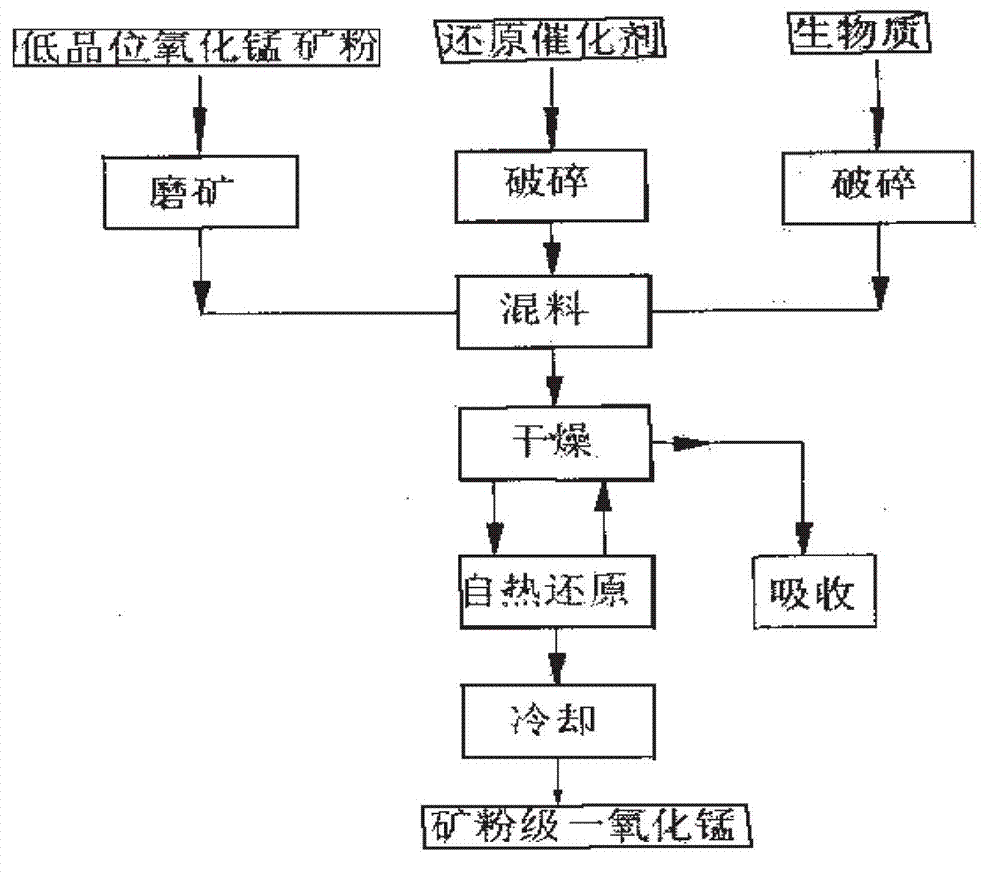

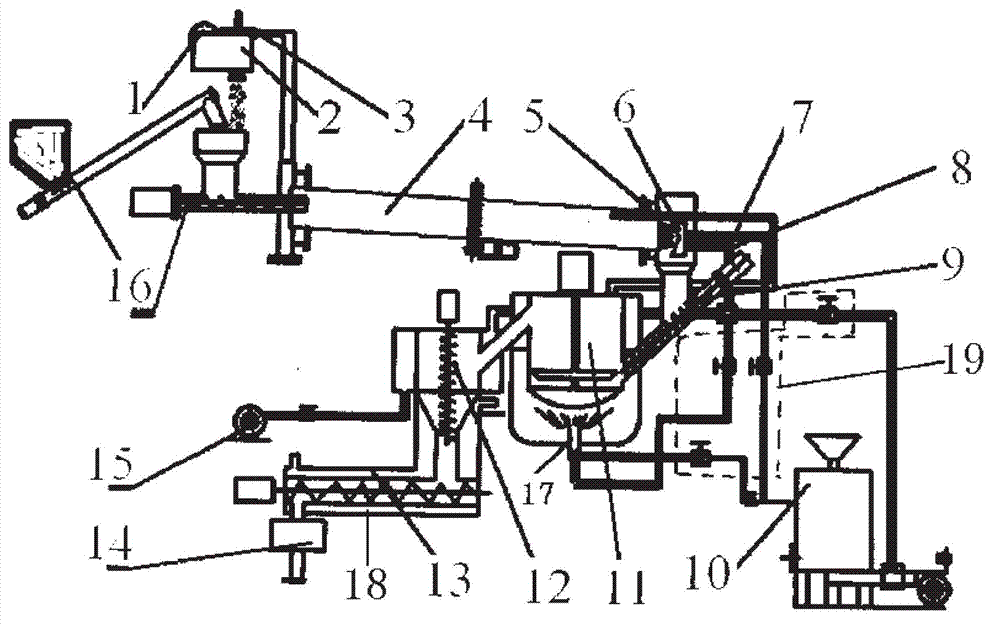

Device and process for producing manganese monoxide through reduction of low-grade manganese oxide ore by using biomass

InactiveCN102849801AReduced activityReduce consumptionManganese oxides/hydroxidesManganese oxideReducing agent

The invention discloses a device and a process for producing manganese monoxide through the reduction of low-grade manganese oxide ore by using biomass. The invention belongs to the technical field of ferrous metallurgy. According to the device, a biomass gas combustor is arranged on the rear of a rotary kiln. The rotary kiln is connected to a reaction furnace through a reaction furnace thruster. The reaction furnace is connected with a stewing tank. The stewing tank is connected with a spiral cooler. The process comprises the steps that: the mineral, a reduction catalyst, and biomass are respectively crushed and are mixed; the mineral, the reduction catalyst, and the biomass are dried in the rotary kiln; through biomass gas combustion, the reduction reaction between the biomass and the mineral is ignited; the raw material is delivered into the reaction furnace; a self-heating reduction reaction is carried out, wherein the reduction upon the mineral is further accelerated with the reaction heat in the reaction furnace; The material is delivered into the stewing tank, such that the reaction can be carried out more sufficiently; the material is cooled to normal temperature, such that mineral-powder-grade manganese monoxide is obtained. Traditionally, coal is adopted as a reducing agent in manganese oxide reduction, the reduction temperature is high, energy consumption is high, and production cost is high. With the device and the process provided by the invention, the defects are overcome.

Owner:TSINGHUA UNIV

Method for producing high-purity manganese monoxide

InactiveCN101659446ALow impurity contentNo pollution in the processManganese oxides/hydroxidesElectrolysisWater vapor

The invention discloses a method for producing high-purity manganese monoxide, which comprises the following steps: crushing an electrolytic manganese metal which is used as a raw material into a certain fineness, heating the electrolytic manganese metal powder to between 400 and 1,000 DEG C, introducing water vapor and inert gas or water vapor and carbon dioxide into the powder, thermally treating the mixture for 2 to 8 hours, and cooling the mixture to room temperature to obtain the high-purity manganese monoxide. The method has the advantages of sufficient, cheap and pure raw material, simple preparation process, low production cost, no environment pollution and high product purity.

Owner:HUNAN JOYFLY NEW MATERIAL

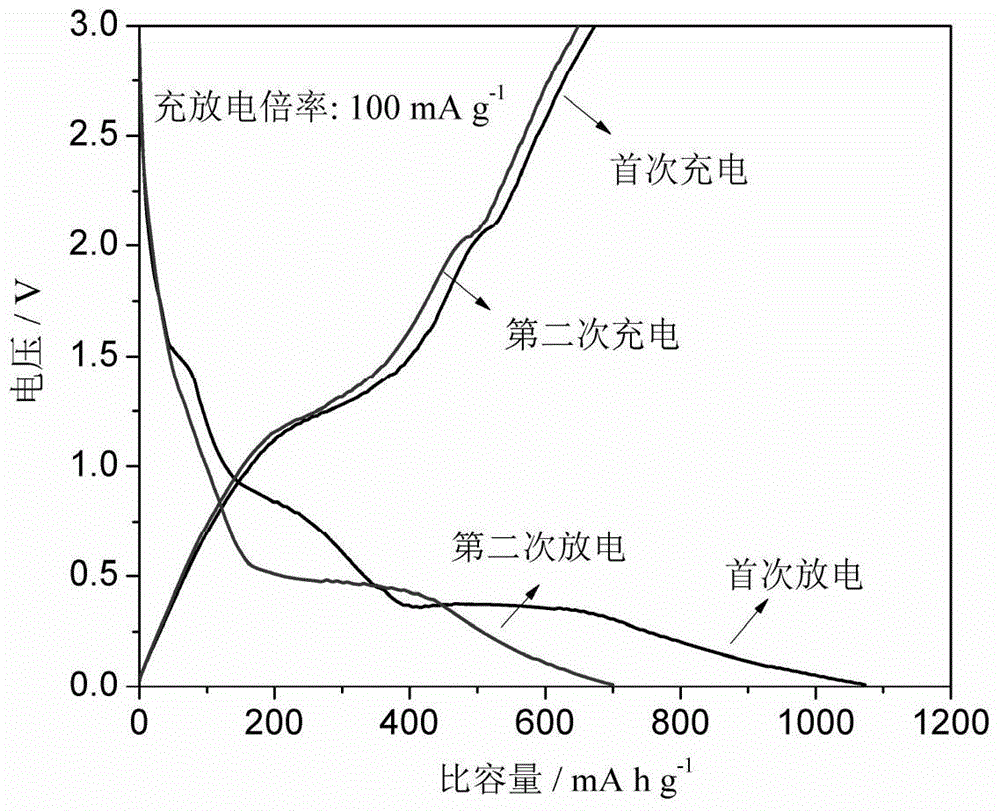

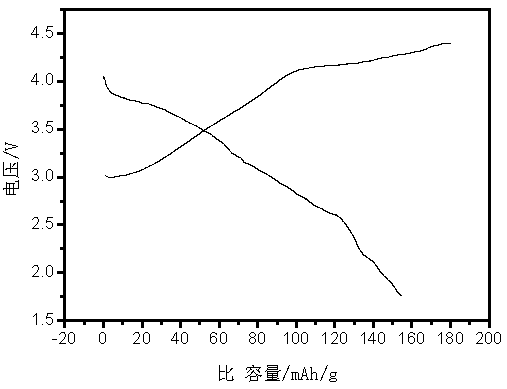

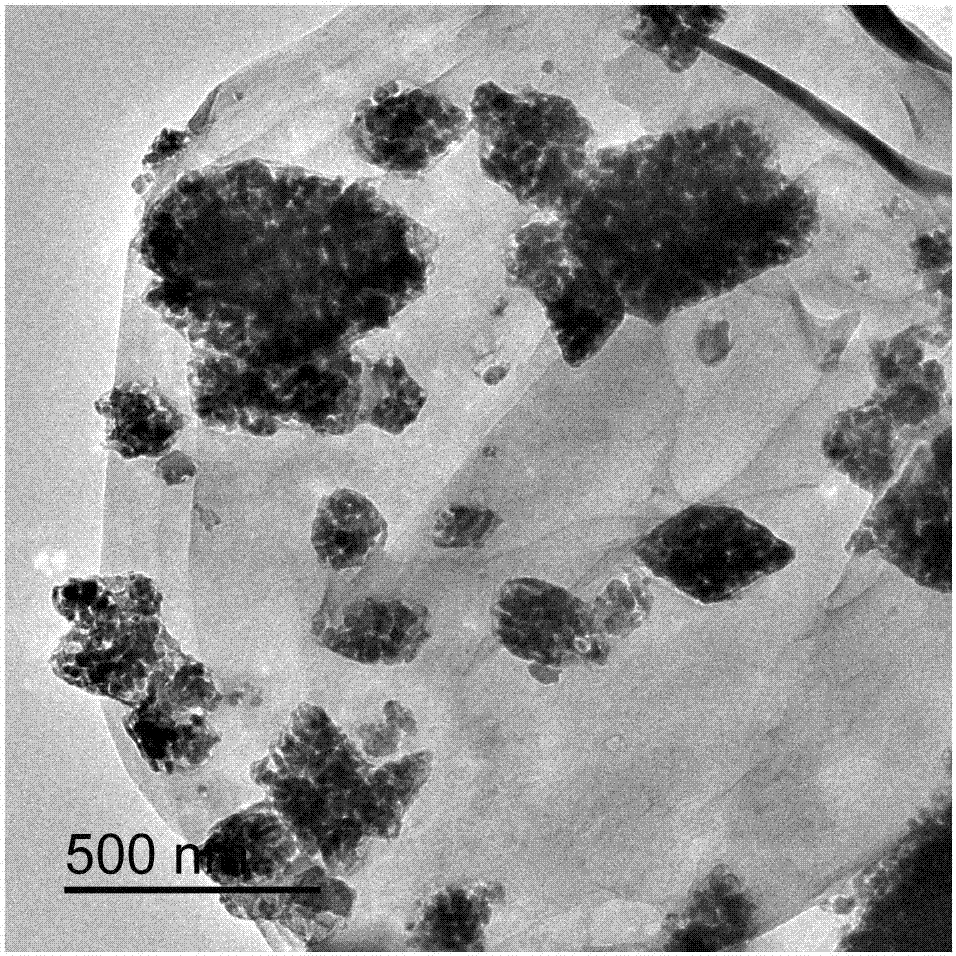

Manganese monoxide/graphene composite material used as negative electrode of lithium ion battery and preparation method of composite material

ActiveCN107658453AUniform shape and sizeImprove discharge capacityCell electrodesSecondary cellsSodium-ion batteryLithium electrode

The invention discloses a manganese monoxide / graphene composite material used as a negative electrode of a lithium ion battery and a preparation method of the composite material. The composite material is prepared by the steps of (1) dissolving a manganese source and a soft template into polyalcohol to obtain a mixed solution; (2) performing a backflow reaction, cooling, centrifuging, washing, anddrying to obtain manganese alcohol salt; (3) performing calcining and cooling to obtain a manganese monoxide precursor; (4) putting the precursor into a graphene oxide water solution, and performingstirring, freezing and drying to obtain blank powder; and (5) performing a reaction between hydrazine hydrate steam and the black powder, and then carrying out cooling, filtering, washing and drying.The composite material provided by the invention adopts a hollow structure; the granule surface is coated with graphene; the initial discharge capacity per gram can be as high as 1,065.1mAh / g at 0.01-3.00V and 70mA / g; the initial efficiency can reach 77.4%; the discharge specific capacity still can be 360mAh / g at 3,500mAh / g after 160 cycles; and the method is simple, low in cost and suitable for industrial production.

Owner:CENT SOUTH UNIV

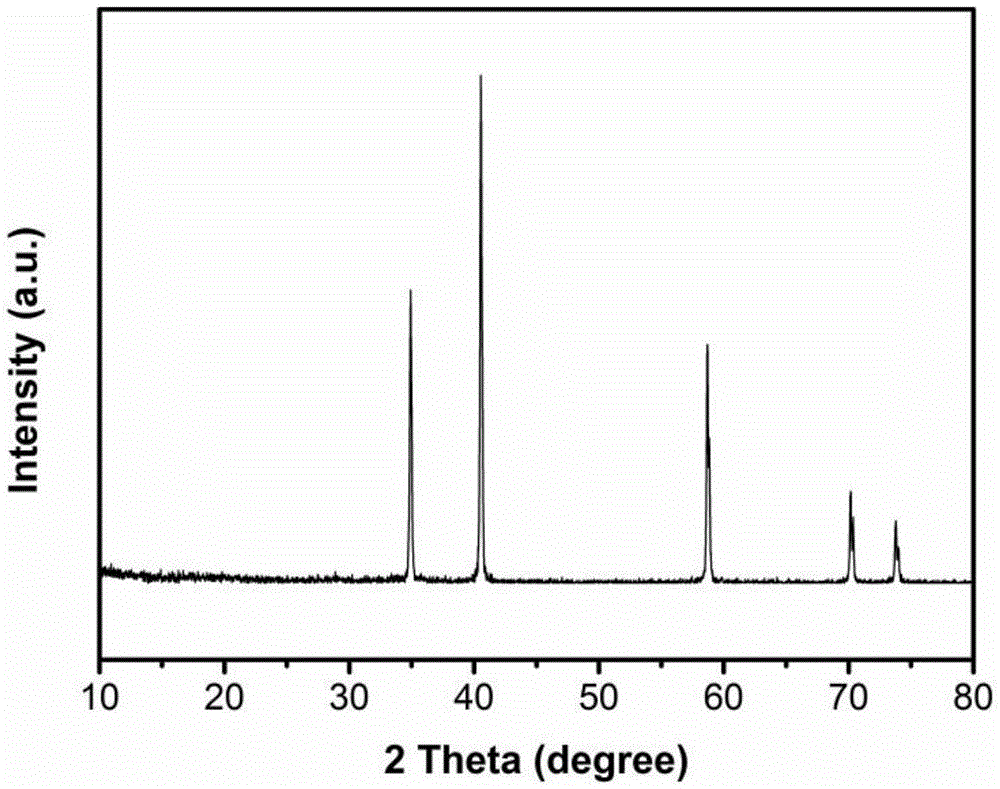

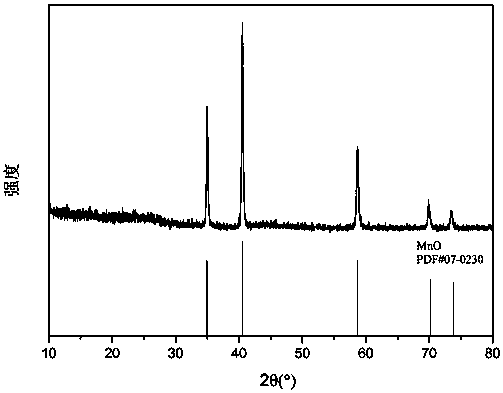

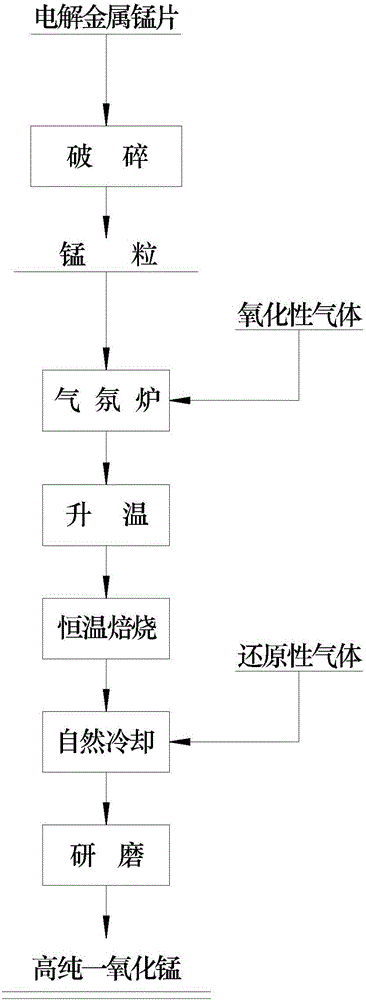

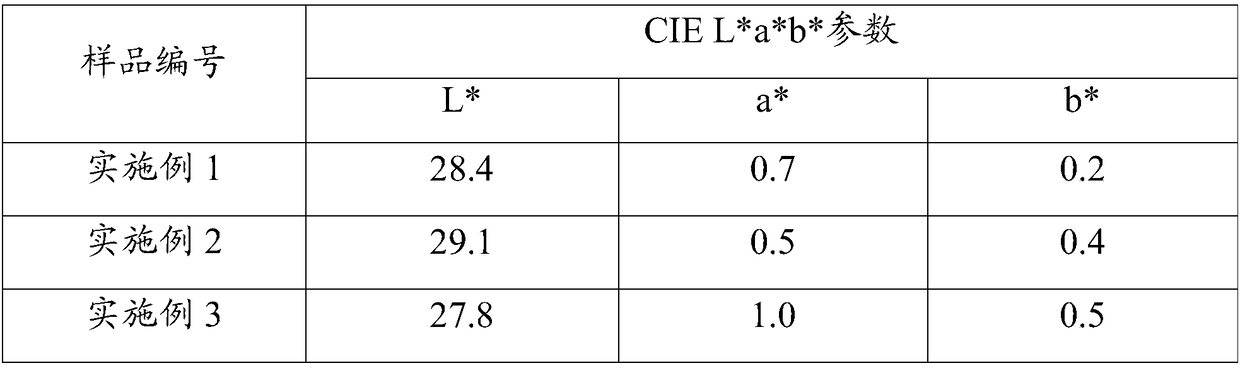

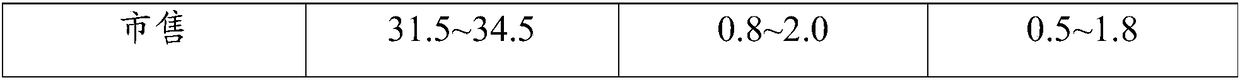

Preparation method of high-purity manganese monoxide

InactiveCN106654248ALow costWide range of choicesCell electrodesSecondary cellsElectrolysisManganese

The invention relates to a preparation method of high-purity manganese monoxide. The preparation method comprises the following steps: smashing electrolytic manganese metal into pieces to obtain manganese particles; putting the manganese particles into an atmosphere furnace; introducing oxidizing gas into the atmosphere furnace, and expelling air in the furnace; warming the atmosphere furnace; when the temperature of the atmosphere furnace reaches 700 to 750 DEG C, proceeding into a constant-temperature calcining stage, and keeping constant-temperature calcination for a period of time; after the constant-temperature calcination is ended, introducing reducing gas, and carrying out natural cooling on material in the furnace; after the temperature of the material in the furnace is reduced, taking the material out of the furnace; and grinding the obtained material to obtain the high-purity manganese monoxide. The preparation method is simple in preparation technology, easy to operate, low in raw material cost and sufficient in raw materials; and the technology is low in production cost, and is easy to realize industrial scale production. The manganese monoxide prepared in the invention is high in purity, and the chemical composition and physical performance of the manganese monoxide can meet the requirement for chemical composition and physical performance of lithium ion battery material lithium manganate.

Owner:CENT SOUTH UNIV

Black ceramic pigment and preparation method thereof

ActiveCN109456617ALow firing temperatureOptimizing crystal form compositionPigmenting treatmentAir atmosphereNickel Monoxide

The invention provides a preparation method for a black ceramic pigment. The preparation method comprises the following steps: 1) uniformly mixing electric furnace smelting stainless steel fly ash containing an iron element with chromic oxide, nickel monoxide and manganese monoxide according to a molar ratio of Fe to Cr to Ni to Mn being equal to1:(0.8-1.3):(0.5-1.1):(0.7-1.2), so as to obtain a mixture material; and 2) placing the mixture material in a microwave field, microwave-heating in an air atmosphere, while a temperature of the mixture material rises to 1050-1200 DEG C, preserving heatfor 10-20 min, taking out the roasted material from the microwave field, and cooling to room temperature, so as to prepare the black ceramic pigment. The method uses the industrial solid waste electric furnace smelting stainless steel fly ash as a raw material, so that while transition metal elements richly contained in the fly ash are greatly used, the effect on the environment by emission thereof is eliminated, and defects that sintering time is long, a needed temperature is high and energy consumption is high caused by of preparing the black ceramic pigment by using an industrial solid waste currently. The prepared black ceramic pigment has the characteristics of high blackness, pure color generation and good coloring property.

Owner:WUHAN UNIV OF SCI & TECH

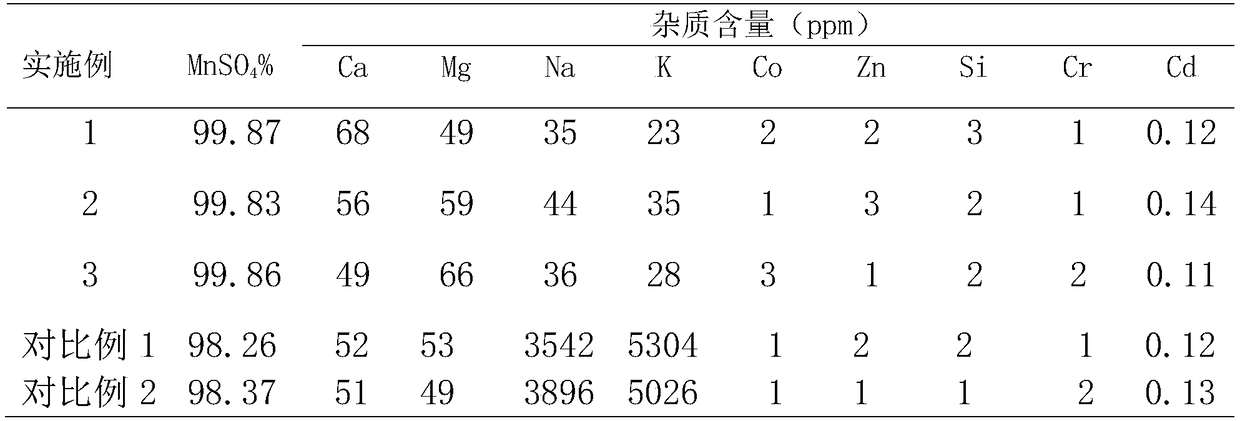

Method for preparing cell level manganese sulfate by reducing manganese ores at medium and low temperature

ActiveCN109231278ARaw materials are easy to getReduce the temperatureManganese sulfatesSulfateMixed materials

The invention discloses a method for preparing cell level manganese sulfate by reducing manganese ores at medium and low temperature. The method specifically comprises the following steps that (1) manganese oxide ores and biomass fuel are smashed and levigated respectively, and then mixed uniformly at the weight proportion of 1000 : (100 to 200), so that a mixed material is obtained; (2) the mixedmaterial is calcinated for 50-90 minutes at the medium and low temperature of 550-600 DEG C, and then naturally cooled to be 50 DEG C or below under a sealing condition, so that a manganese monoxideproduct is obtained; (3) water and a compound rinsing agent are added into the manganese monoxide product at the proportion of 1000g : (1.0 to 1.5 L) : (10 to 15g), and stirred, and solid-liquid separation is conducted, so that a manganese monoxide wet product is obtained; and (4) water and sulphuric acid are added into the manganese monoxide wet product at the proportion of 1000g : (2.5-3.0L) : (360 to 375mL) to be subjected to a leaching reaction, the pH value of the mixture is regulated to 5-6, the mixture is heated, sulfide and fluoride are added in the mixture and stirred at the weight proportion of 1000 : (5 to 15) : (2 to 5), stirring is conducted, and solid-liquid separation is conducted to obtain high-purity manganese sulfate liquid, and then the high-purity manganese sulfate liquid is concentrated and dried to obtain the cell level manganese sulfate product.

Owner:广西锰华新能源科技发展有限公司

Method for preparing iron ore concentrate and manganese chemical products by carrying out dual reduction on refractory ferro-manganese symbiotic lean ore

InactiveCN102417972ARealize gas ground state reductionAvoid disproportionation reactionsProcess efficiency improvementMagnetic separationCelluloseChemical products

The invention belongs to a refractory symbiotic ore biochemical and chemical metallurgical technology, in particular relates to a method for carrying out comprehensive treatment on the refractory symbiotic ore with ferric content and manganese content of being less than 20wt%. The method provided by the invention comprises the following technological steps of: with cellulose-containing plant waste as a reducing agent and limestone as an active agent, respectively smashing the reducing agent, the active agent and the ferro-manganese symbiotic lean ore with the ferric content and the manganese content of being less than 20wt%, burdening and uniformly mixing according to calculated quantity of complete reaction, heating and carrying out reduction reaction to obtain magnetic Fe3O4, Fe0 and acid soluble MnO, carrying out magnetic separation to obtain iron ore concentrate with the ferric content of being more than 60wt% and manganese enriched tailings, and leaching the manganese enriched tailings with sulfuric acid or hydrochloric acid, purifying, concentrating and crystallizing to directly prepare manganese sulfate, or tetrahydrate manganese chloride or anhydrous manganese chloride product; and transforming to prepare manganese chemical products such as manganese carbonate, manganese dioxide and manganese monoxide. The method provided by the invention has the advantages of simple and feasible process, low cost and high recovery rate, and the problem of resource utilization of refractory ferro-manganese symbiotic lean ore can be better solved.

Owner:云南德宁生物化工研究有限公司 +2

Purple red colorant for low-temperature colored glass and preparation method and using method thereof

The invention belongs to the field of colored glass, and particularly relates to a purple red colorant for low-temperature colored glass and a preparation method and a using method thereof. The purplered colorant comprises the following raw materials in parts by mass: 30-50 parts of quartz powder, 10-30 parts of borax, 10-25 parts of sodium carbonate and 10-30 parts of a coloring additive, wherein the coloring additive is one or a mixture of several of manganese monoxide, manganese dioxide, manganese trioxide and potassium permanganate. The purple red colorant is prepared by mixing the materials, melting at high temperature, performing water quenching, drying, and crushing. Through use of a large amount of silicon oxide, the borax and the sodium carbonate with low melting points in a colorant base material, the diffusion rate of a colorant in 1200 DEG C glass liquid is greatly increased, so that a uniform colored glass stock solution is formed; in a preparation technology of the colorant, composite powder is directly added into a high-temperature frit furnace for melting, and the reaction temperature is instantly raised from room temperature to 1350-1500 DEG C, so that decomposition, volatilization and composition segregation of the materials in a slow heating process are prevented, and a colorant product with a high stoichiometric ratio and high high-temperature diffusion rate is obtained.

Owner:JIANGSU BAIFU TECH CO LTD

Modified additive for recycling copper and iron in depleted slag of electric copper smelting furnace and application thereof

ActiveCN106929684ARecoveries remain unchanged or slightly improvedHigh recovery rateProcess efficiency improvementManganese oxideMolten slag

The invention relates to a modified additive for recycling copper and iron in depleted slag of an electric copper smelting furnace and an application thereof. The modified additive comprises, by mass, 40-50% of quick lime, 10-15% of manganese monoxide, 10-15% of pyrite, 5-15% of copper pyrite and 10-20% of iron oxides. According to the application of the modified additive for recycling copper and iron in depleted slag of the electric copper smelting furnace, the amount of the added modified additive is 8-20% of the mass of the copper slag. By means of the modified additive, mineral phase reconstruction of iron and copper target minerals is realized by making full use of high-temperature latent heat of depleted slag of the electric copper smelting furnace. The modified additive has the functions of fayalite modification, induced crystallization of initial crystal seeds and stabilization of copper matte minerals. Copper concentrates for copper smelting and magnetite concentrates for iron smelting can be produced by using modified slag through a floatation-magnetic separation process. Accordingly, efficient separation and recycling of iron and copper in depleted slag of the electric copper smelting furnace are realized, resources are saved, and energy consumption is reduced.

Owner:CENT SOUTH UNIV

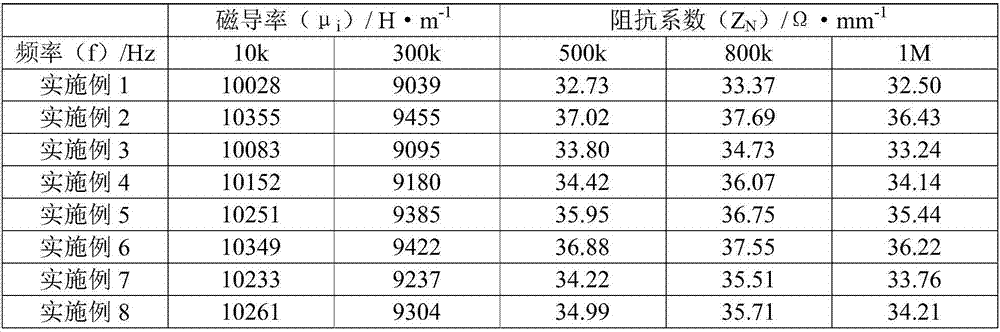

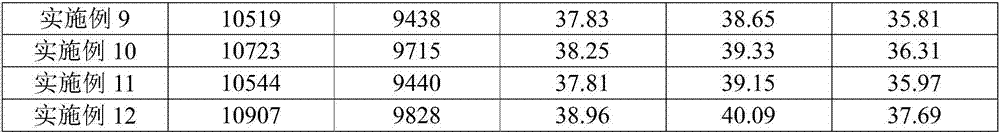

Manganese-zinc ferrite with high BS, High ZN and excellent ultra-wide-band characteristic and preparation method thereof

ActiveCN107311638AHigh curie temperatureHigh saturation flux densityInorganic material magnetismSesquioxideManganese

The invention belongs to the technical field of magnetic materials and preparation thereof. The invention discloses a manganese-zinc ferrite with high BS, high ZN and excellent ultra-wide-band characteristic and a preparation method thereof. The manganese-zinc ferrite comprises a main material and an auxiliary material, wherein the main material is prepared from iron sesquioxide, zinc oxide and manganese monoxide; the auxiliary material is prepared from calcium oxide, bismuth oxide, molybdenum oxide, niobium pentoxide and cobalt sesquioxide; the preparation method comprises the steps of preparing materials, mixing the main material and the auxiliary material, pre-burning the main material, adding the auxiliary material, performing secondary ball milling, performing granulation molding and sintering. The prepared manganese-zinc ferrite has the characteristics of high Curie temperature, high saturation flux density, high impedance performance and excellent ultra-wide-band characteristic, the permeability at 300kHz is 9,000 or more, the permeability within 300kHz does not attenuate basically, an excellent wide-band characteristic is achieved, and the advantages of the material are further improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

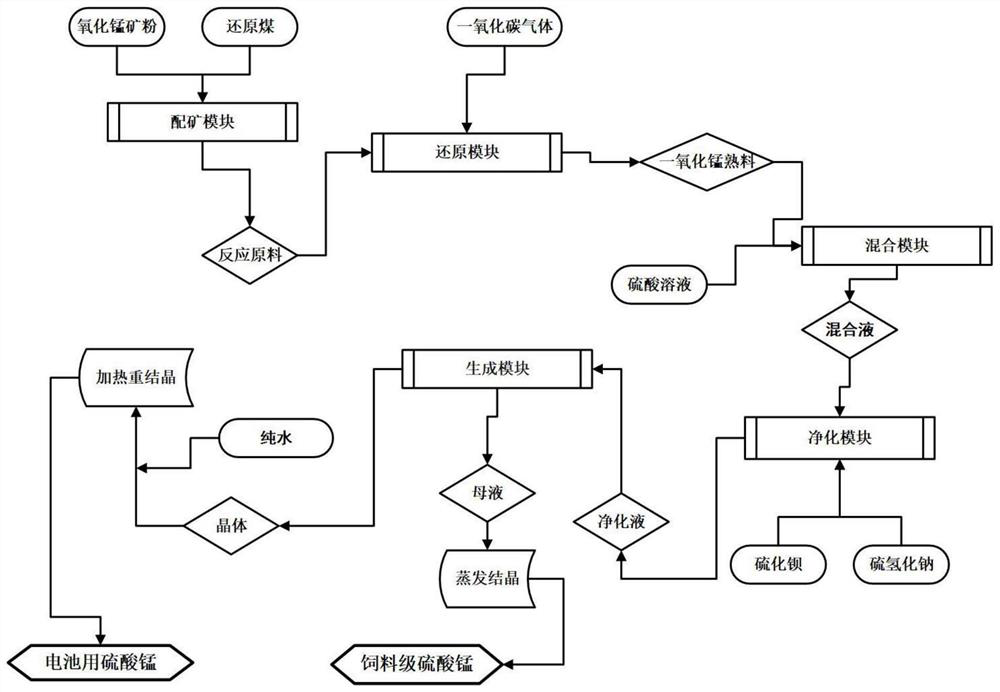

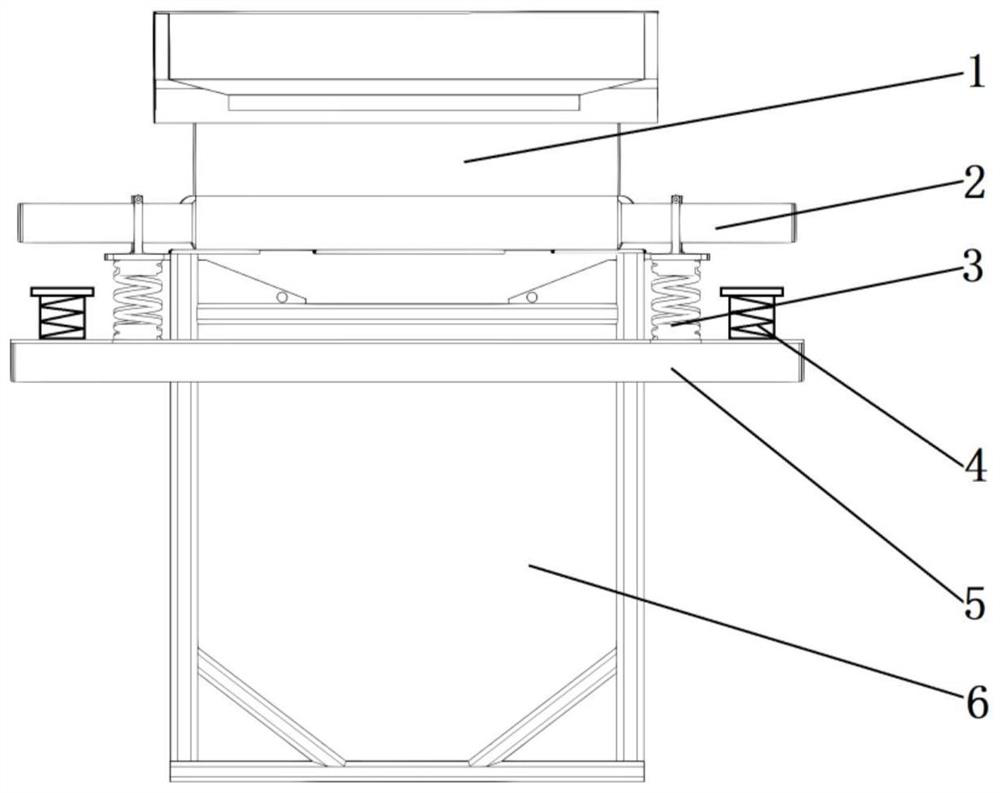

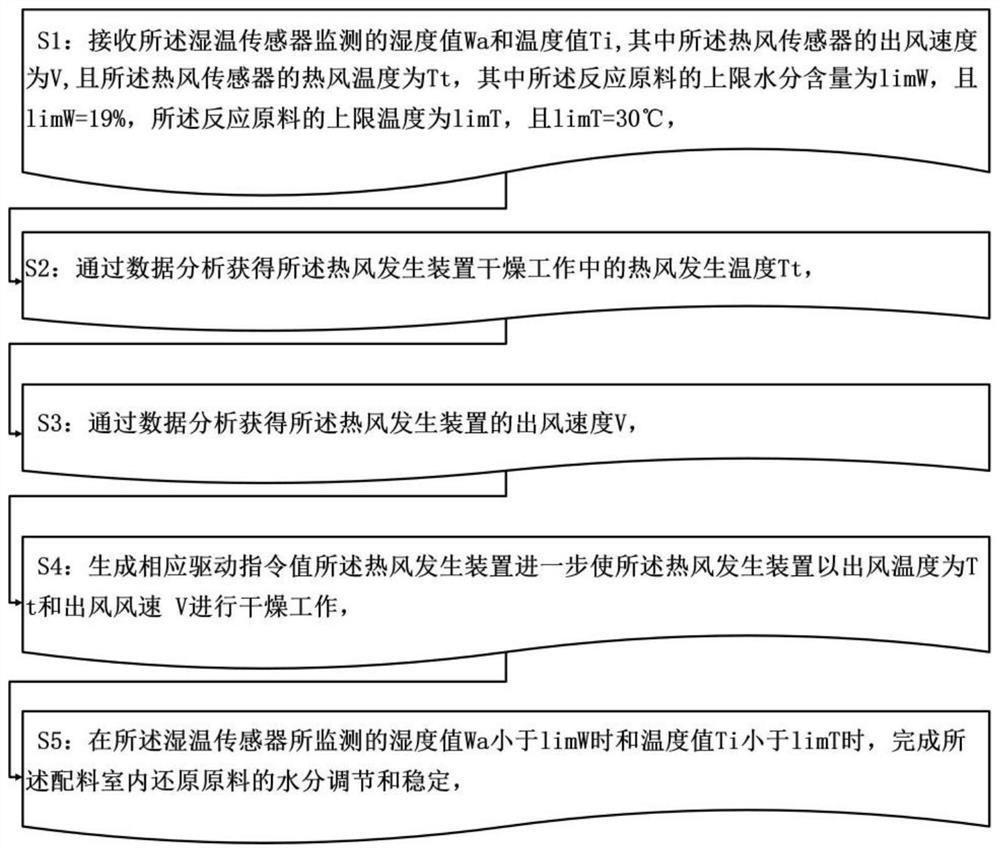

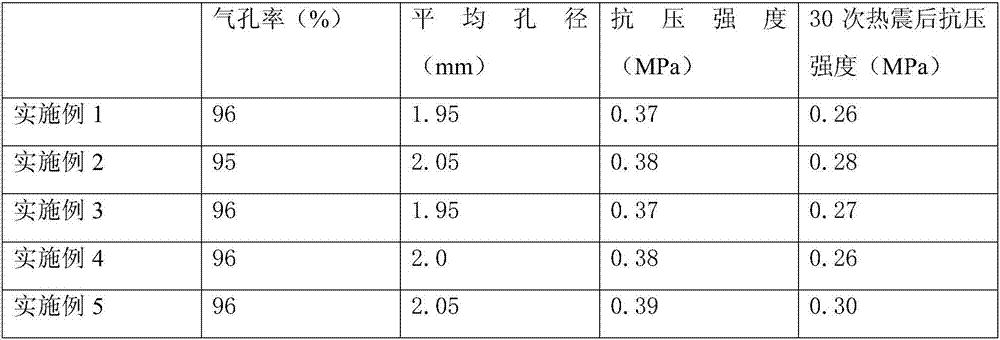

Manganese sulfate production system based on manganese oxide ore

ActiveCN113387391AIncrease productivityImprove filtration rateManganese sulfatesSodium hydrosulfideManganese oxide

The invention provides a manganese sulfate production system based on manganese oxide ore. The manganese sulfate production system comprises an ore blending module which is used for automatically feeding manganese oxide ore powder and reducing coal respectively and effectively and uniformly mixing to obtain a reaction raw material; a reduction module which is used for introducing carbon monoxide gas into the reaction raw materials under temperature safety monitoring to carry out reduction curing until divalent manganese in the reaction raw materials is reduced into monovalent manganese so as to obtain manganese monoxide clinker, a mixing module which is used for adding a sulfuric acid solution into the manganese monoxide clinker to carry out a mixing reaction so as to further obtain a mixed solution, and a purification module which is used for adding barium sulfide and sodium hydrosulfide into the mixed solution and carrying out cyclic repeated stirring and filtering to obtain a corresponding purified solution. According to the invention, the production efficiency of manganese sulfate is further effectively improved by assisting the process steps in the manganese sulfate production system based on an intelligent detection technology.

Owner:广西埃索凯新材料科技有限公司

Low-cost solar heat-absorbing ceramic material and preparation method thereof

ActiveCN107010962AGood high temperature oxidation resistanceImprove thermal shock resistanceCeramicwareBoron nitrideThermal shock

The invention discloses a low-cost solar heat-absorbing ceramic material. The low-cost solar heat-absorbing ceramic material contains the following components in parts by weight: 15-40 parts of silicon nitride, 15-40 parts of boron nitride, 5-15 parts of titanium silicide, 5-15 parts of nickel carbide, 5-12 parts of chromium oxide, 5-12 parts of aluminum oxide, 2-7 parts of sodium silicate, 2-5 parts of boron oxide and 2-3 parts of manganese monoxide. The heat-absorbing ceramic material with good high-temperature oxidation resistance and thermal shock resistance, a three-dimensional network structure, a high specific surface area and high thermal conductivity is prepared by virtue of an organic foam dipping process and is particularly suitable for tower type solar thermal power generation heat-absorbing bodies.

Owner:泾县凡泽科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com