Method for separating and recovering valuable metals in roasted product of lithium ion battery

A technology for lithium-ion batteries and roasted products, which is applied in the direction of improving process efficiency, etc., can solve the problems of low leaching rate of reduced roasted products, achieve the effects of improving leaching rate and recovery rate, facilitating industrialization, and increasing leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

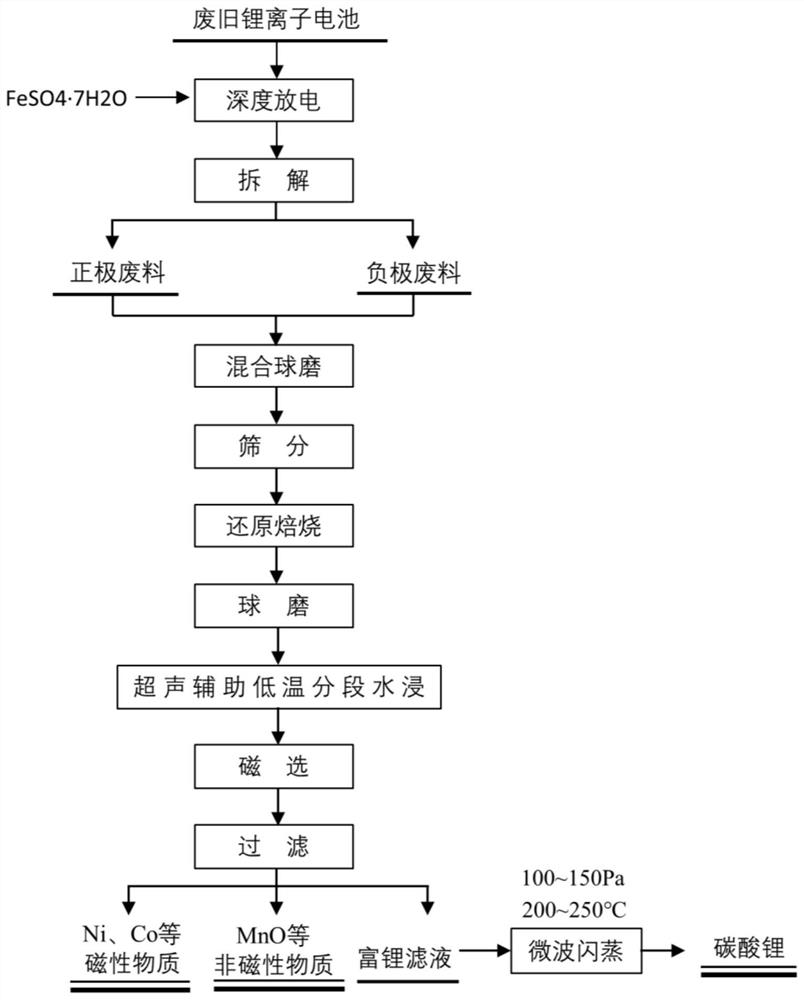

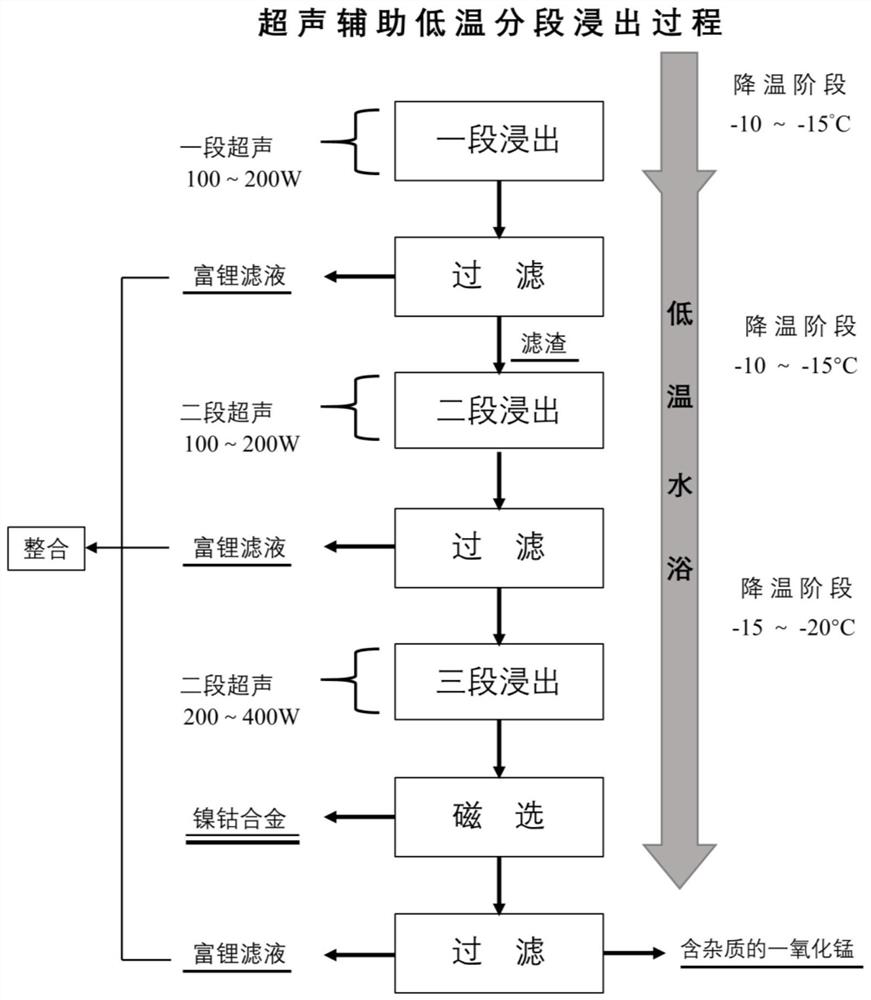

[0029] Embodiment 1: A method for separating and reclaiming valuable metals in the calcined product of lithium-ion batteries (see figure 2 ),Specific steps are as follows:

[0030] (1) Soak the waste lithium-ion battery (nickel-cobalt-lithium-manganese-oxide battery) in ferrous sulfate solution for 12 hours, and perform deep discharge. The concentration of ferrous sulfate is 1.5mol / L. Disassemble and strip the discharged lithium-ion battery to obtain positive electrode material (nickel cobalt lithium manganate material) and negative electrode material (graphite material);

[0031] (2) Nickel cobalt lithium manganate material and graphite material are mixed ball milled, dried, and sieved to obtain a mixed material; wherein the mass ratio of the positive electrode material to the negative electrode material is 3:1 when mixed, and the sieve aperture when sieved is 0.074 mm;

[0032] (3) The mixed material is heated to 600°C in an inert gas atmosphere and kept at a temperature ...

Embodiment 2

[0037] Embodiment 2: a method for separating and reclaiming valuable metals in the roasted product of lithium-ion batteries (see figure 2 ),Specific steps are as follows:

[0038](1) Soak the waste lithium-ion battery (lithium cobaltate battery) in the ferrous sulfate solution for 10 hours, and perform deep discharge. The concentration of ferrous sulfate is 2mol / L. Disassemble and peel off the discharged lithium-ion battery to obtain positive electrode material (lithium cobalt oxide material) and negative electrode material (graphite material);

[0039] (2) The lithium cobaltate material and the graphite material are mixed and ball milled, dried, and sieved to obtain a mixed material; wherein the mass ratio of the positive electrode material to the negative electrode material is 5:1 during mixing, and the sieve aperture during sieving is 0.046mm;

[0040] (3) The mixed material is heated to 750°C in an inert gas atmosphere and kept at a temperature of 40 minutes. After the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com