Patents

Literature

102 results about "Barium hydroxide octahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium Hydroxide Octahydrate is a highly water insoluble crystalline Barium source for uses compatible with higher (basic) pH environments. Hydroxide, the OH- anion composed of an oxygen atom bonded to a hydrogen atom, is commonly present in nature and is one of the most widely studied molecules in physical chemistry.

Phase-change energy-storage material

InactiveCN103666381AImprove cycle stabilityRaise the ratioHeat-exchange elementsFiberSodium phosphates

The invention relates to a phase-change energy-storage material which comprises the following components in percentage by mass: 75%-99% of an energy storage main body material, 0.1%-10% of a thickening agent, 0.2%-15% of a nucleating agent and 0.01%-8% of a reinforcing material, wherein the energy storage main body material comprises crystal water and salt; the thickening agent comprises one or more of an inorganic thickening agent, fibers, polyacrylates, polyurethanes and a natural polymer thickening agent; the nucleating agent comprises one or more of sodium pyrophosphate, sodium phosphate decahydrate, calcium sulfate dihydrate, potassium sulfate, potassium borate, barium hydroxide octahydrate, sodium phosphate dibasic dodecahydrate and sodium sulfate; the reinforcing material comprises one or more of metal and metal oxide powder, carbon materials, nanoparticles and foam materials. By selecting proper materials and ratio, the supercooling degree and the phase separation phenomenon are reduced and good circulating stability is achieved; especially the reinforcing material is added into a system to form a heat-conducting network so as to improve the heat conductivity of the material by more than two times.

Owner:PIONEER ENERGY JIANGSU

Solar water heater phase change heat storage material and its preparing method

InactiveCN1821340AHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSolar waterZinc Acetate Dihydrate

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

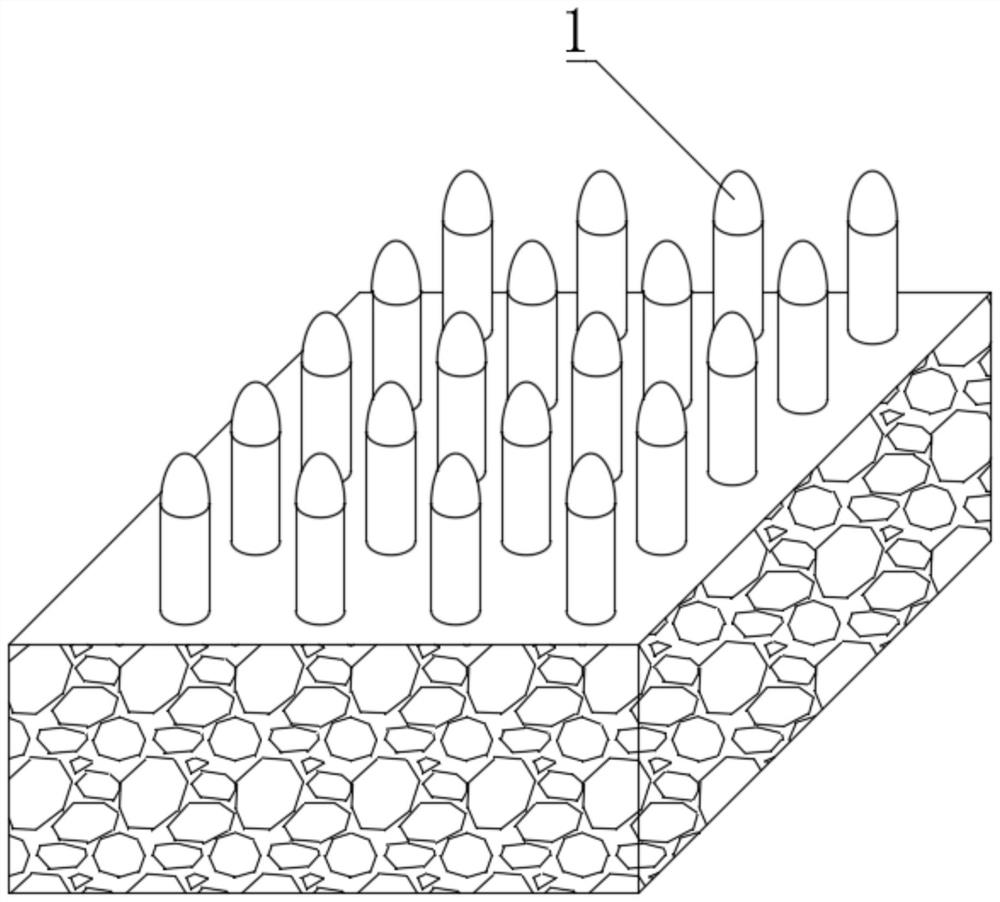

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

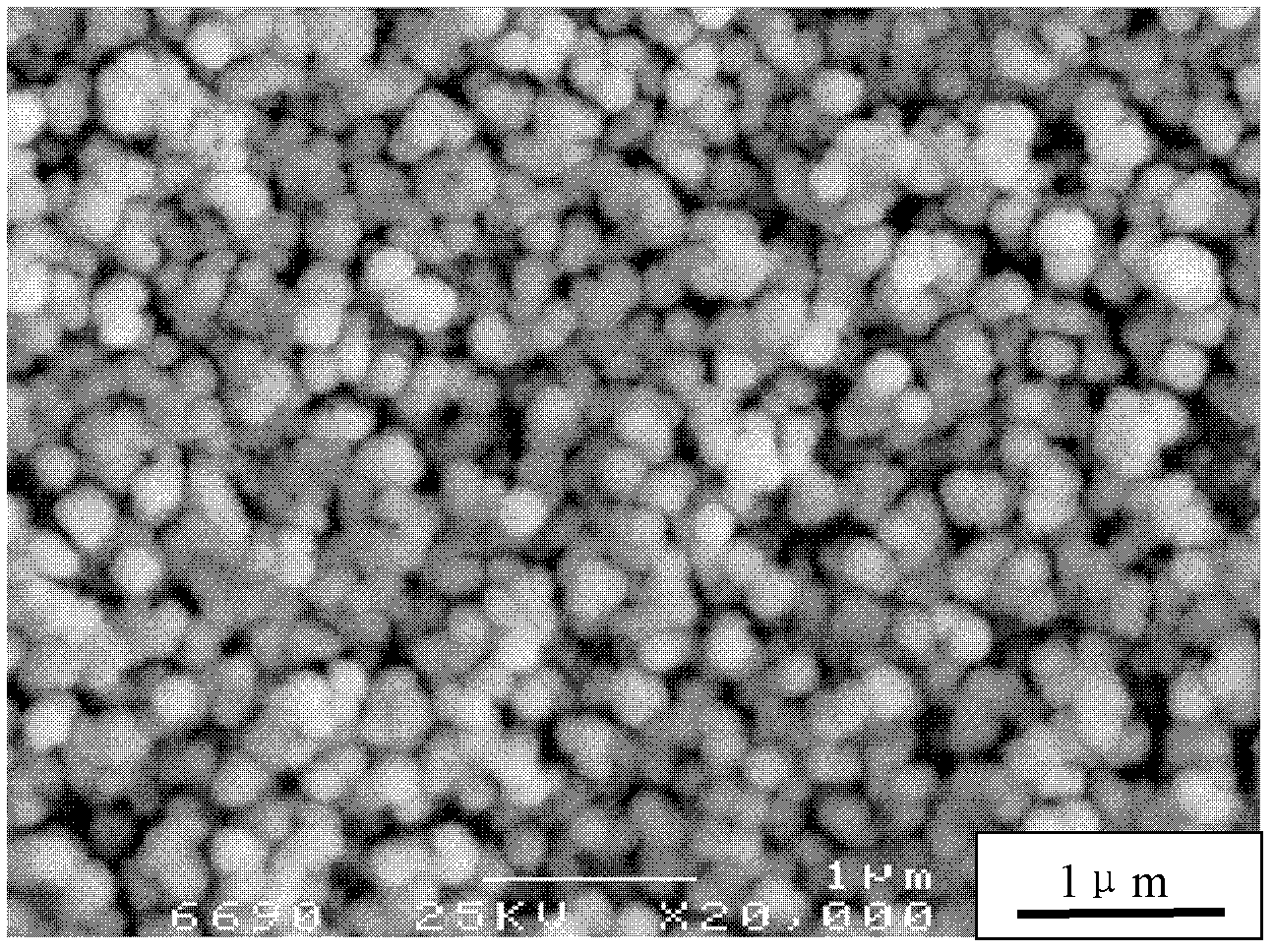

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

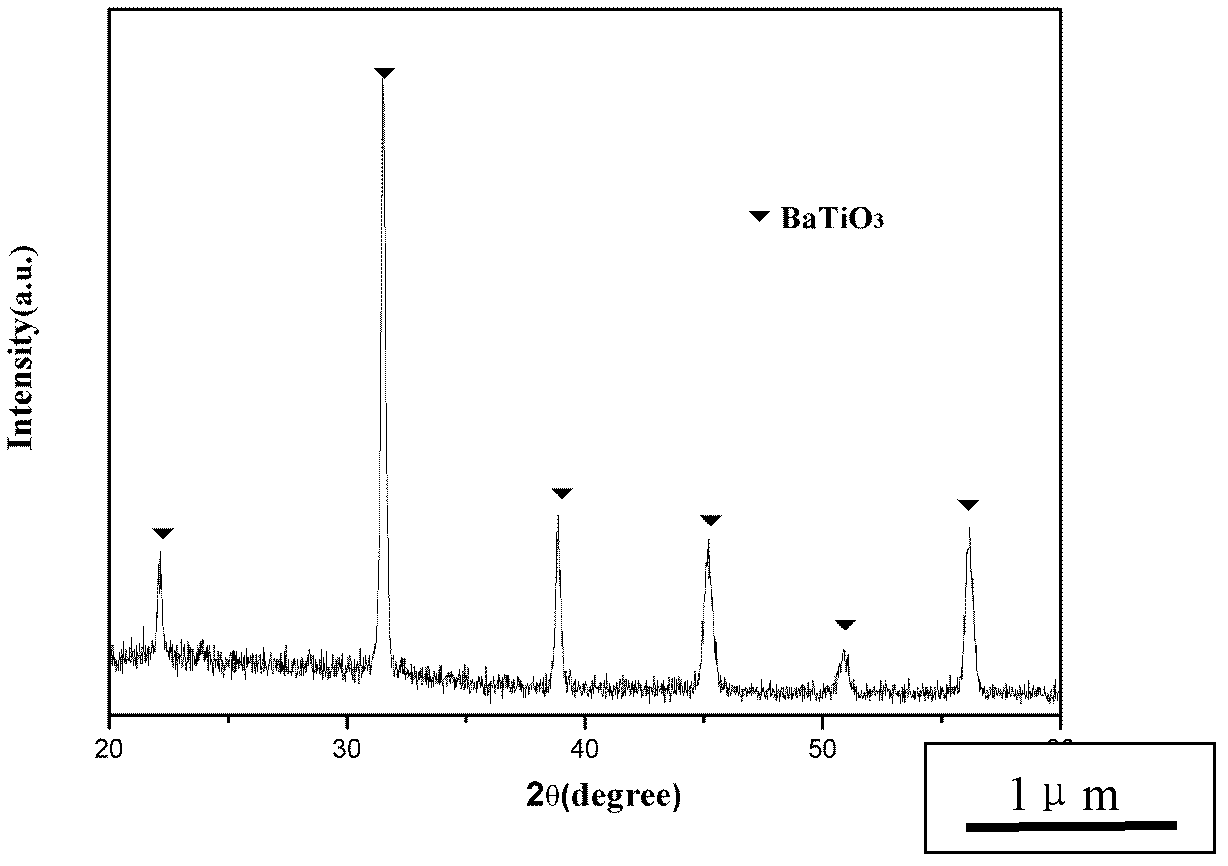

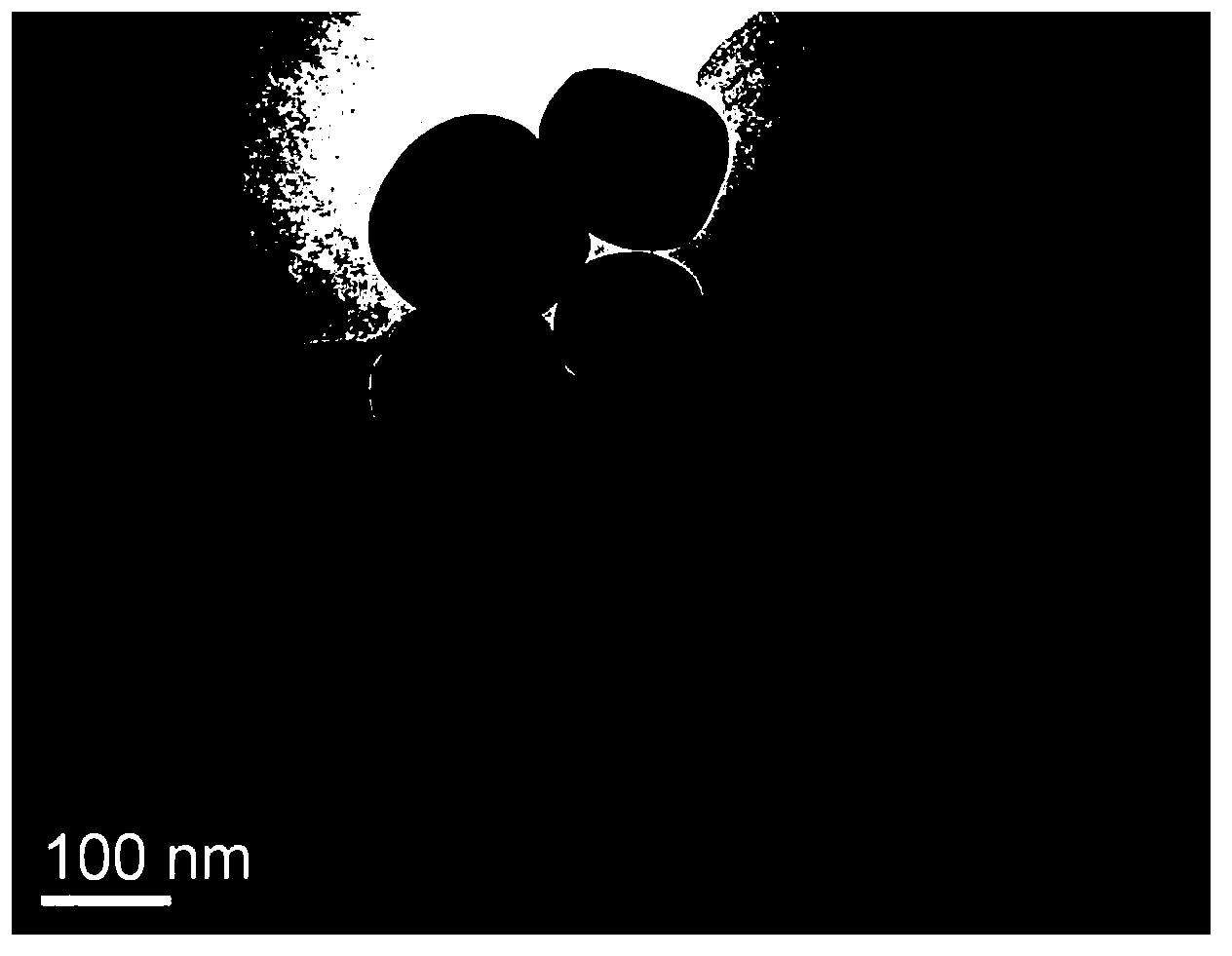

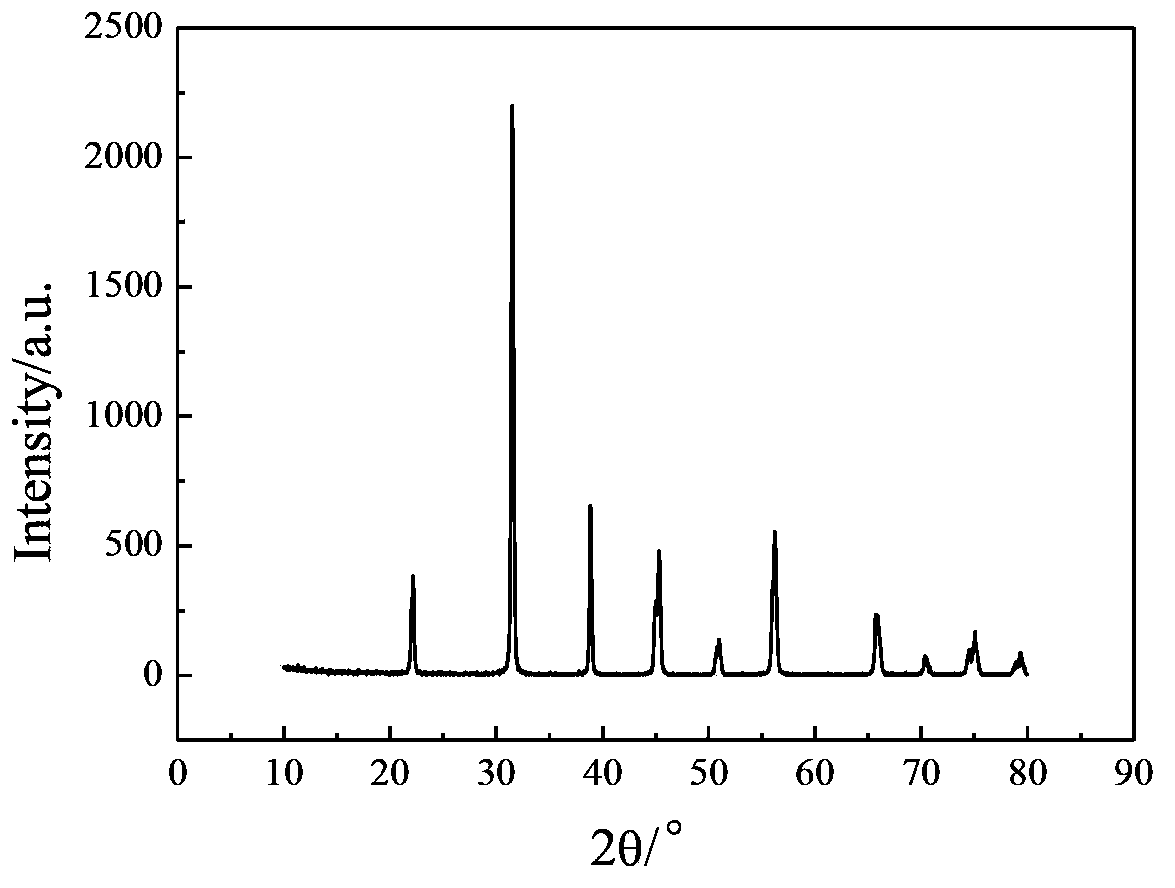

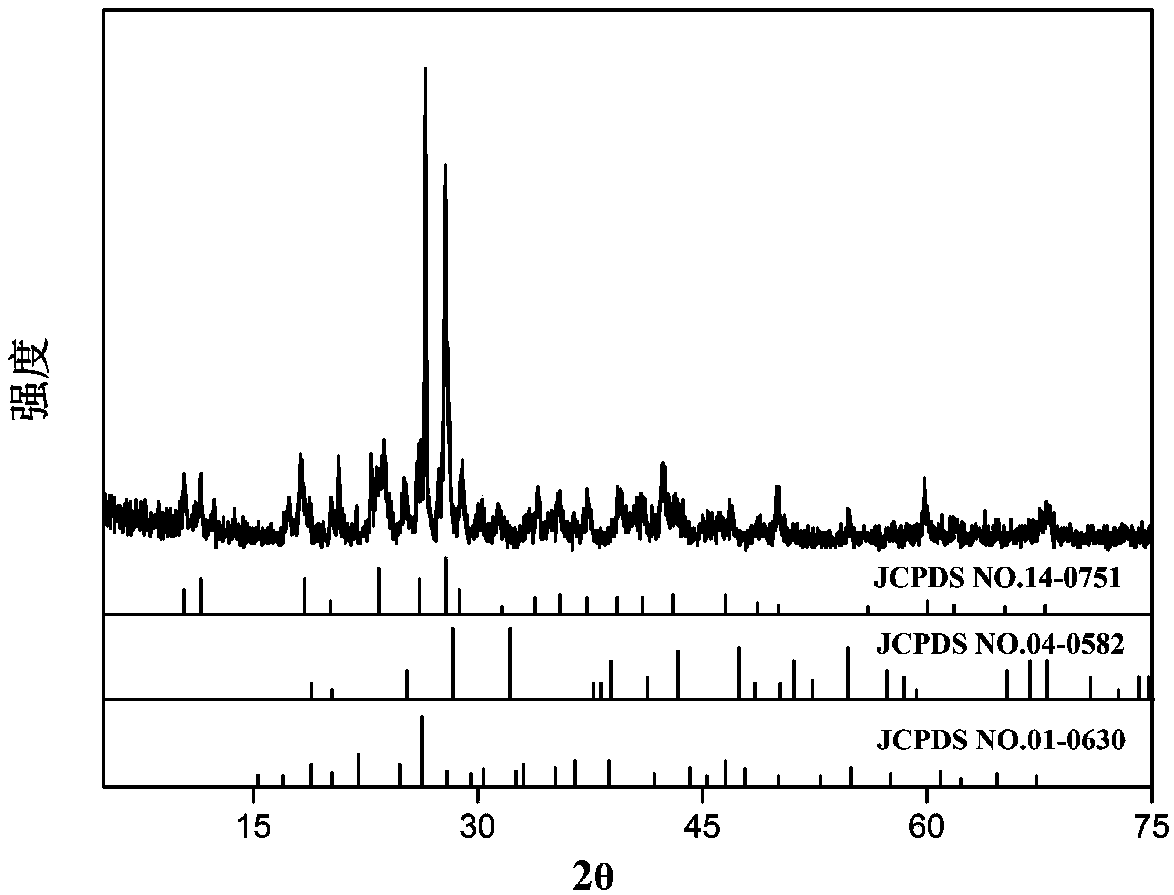

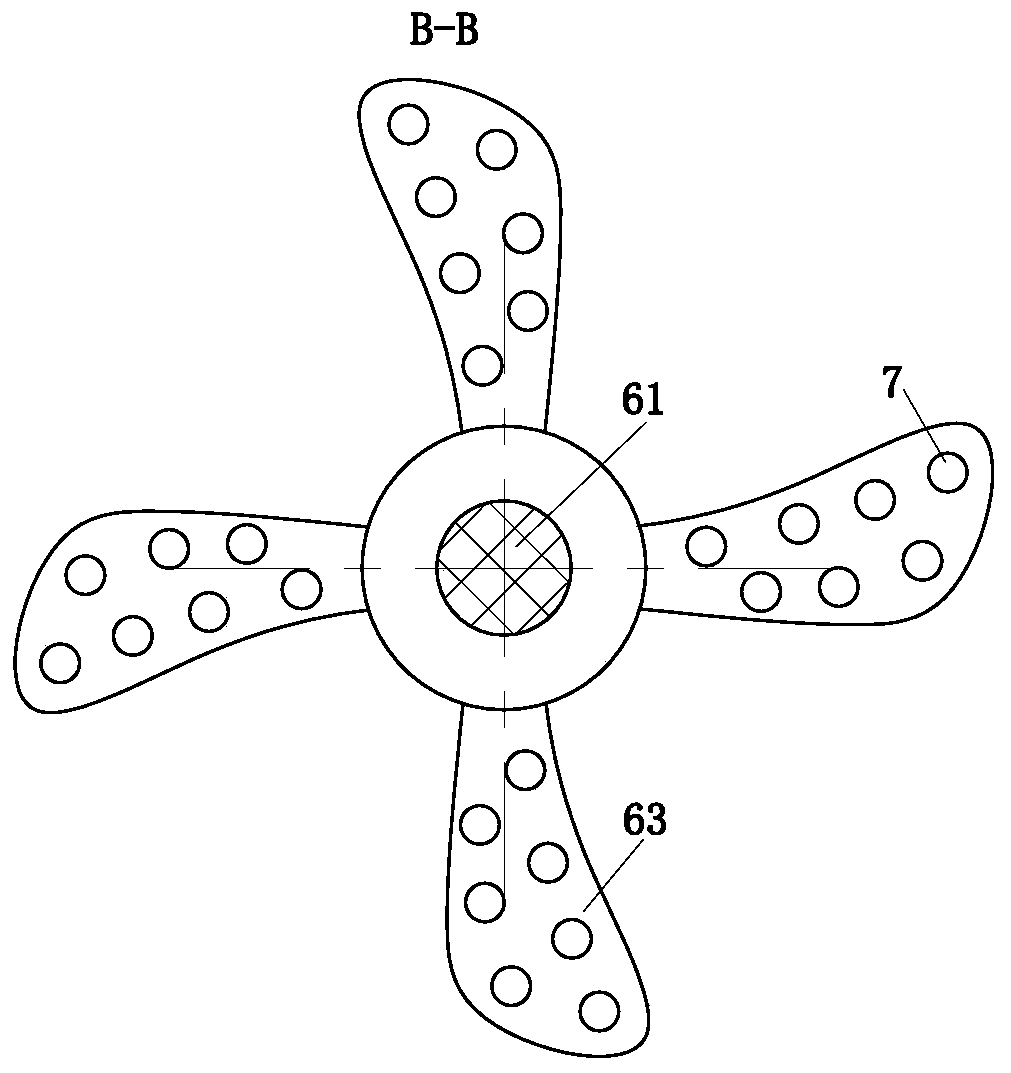

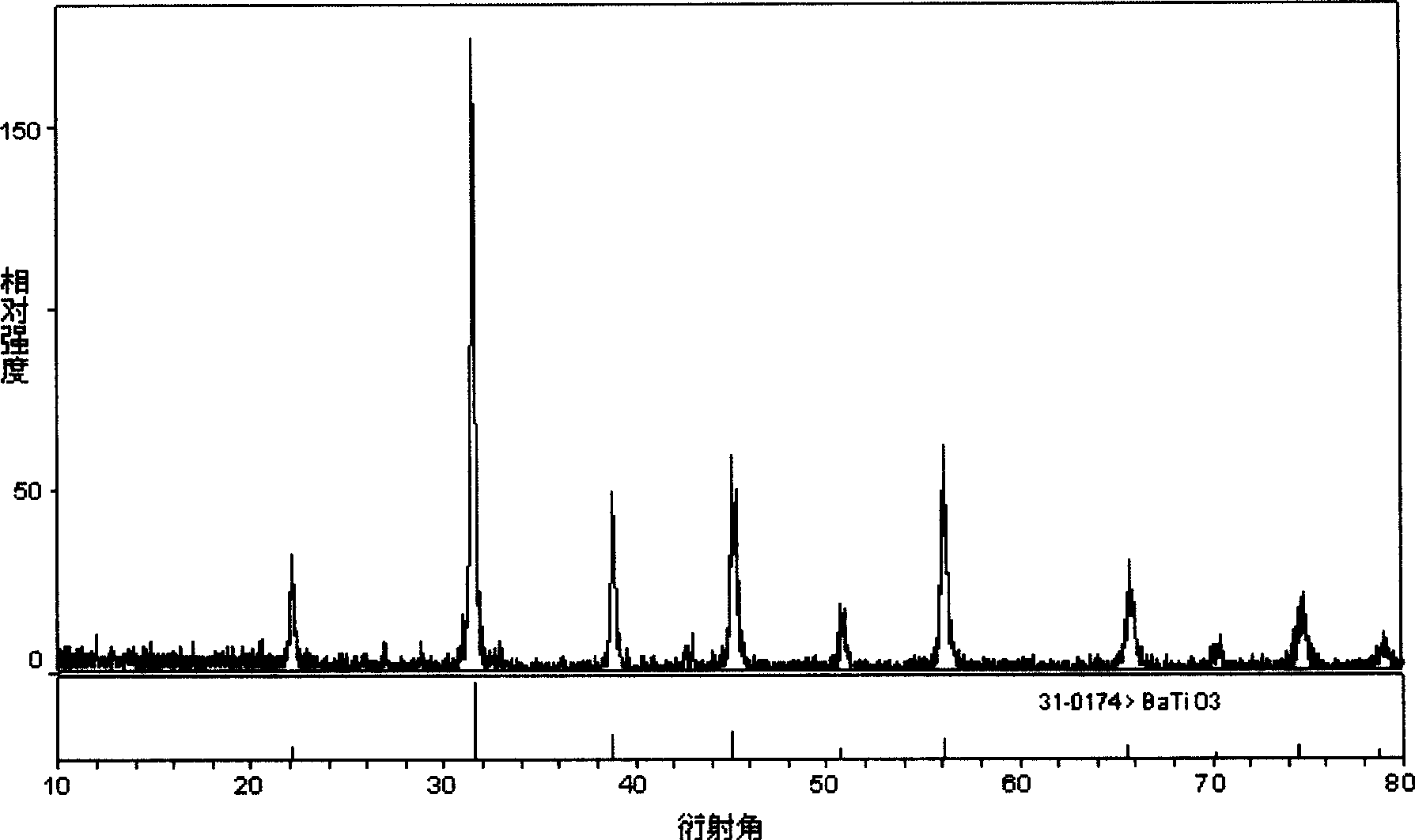

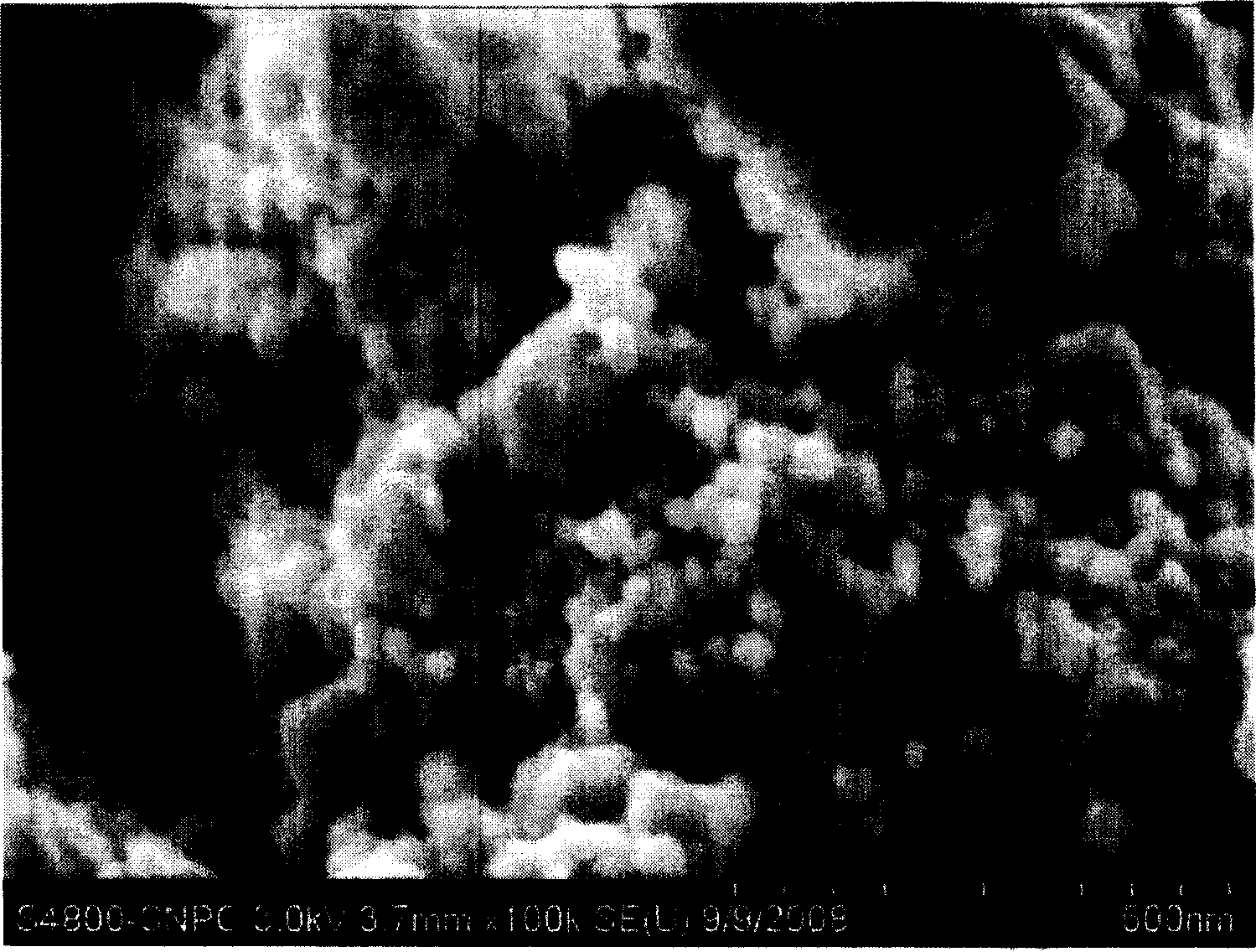

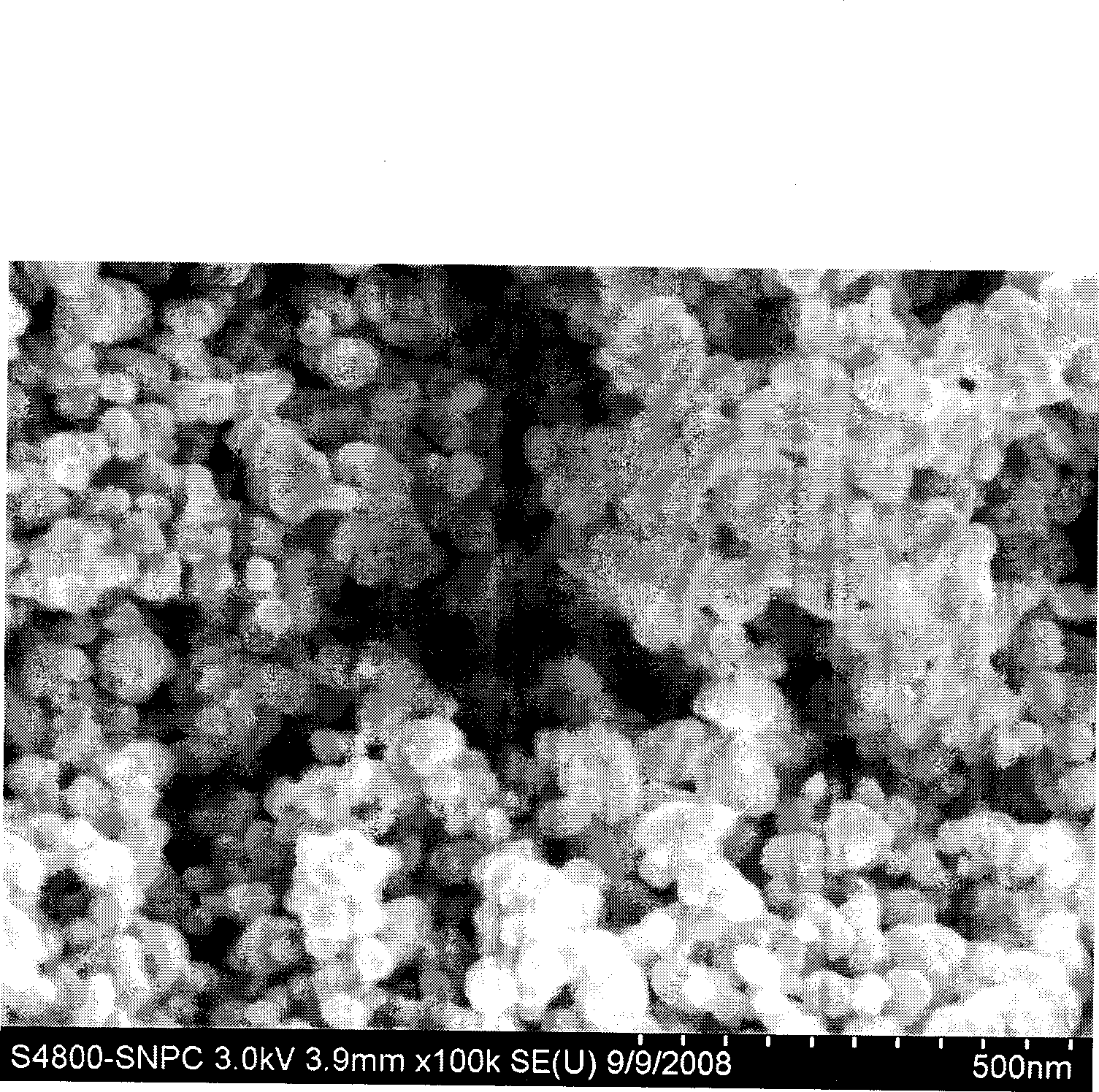

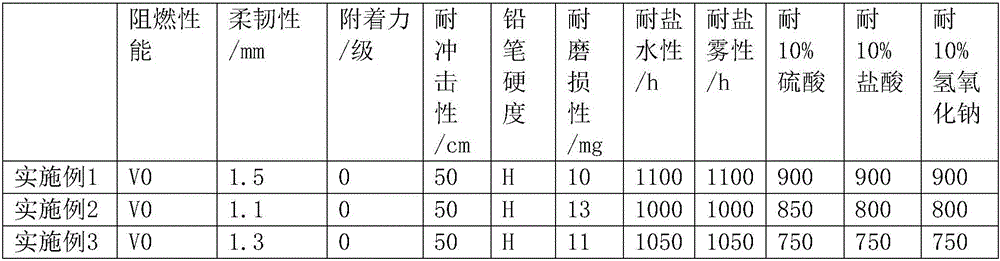

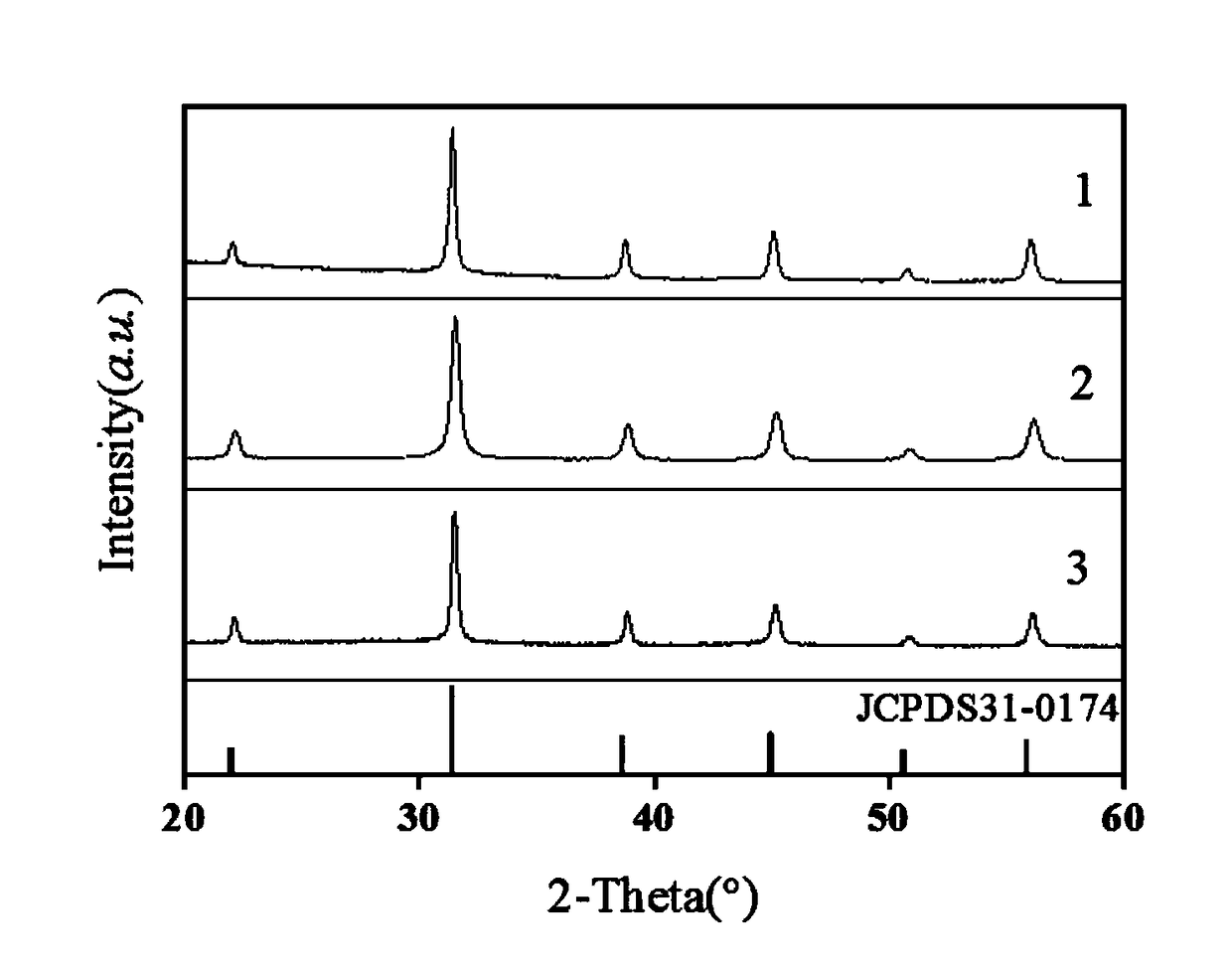

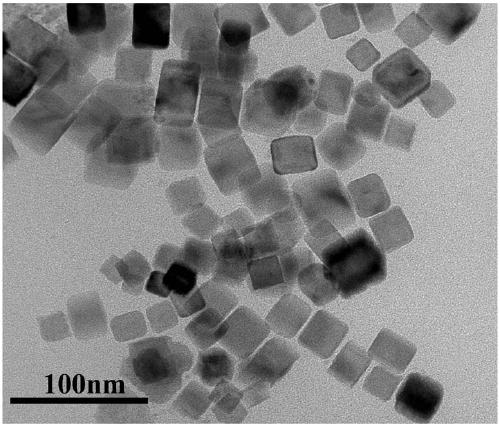

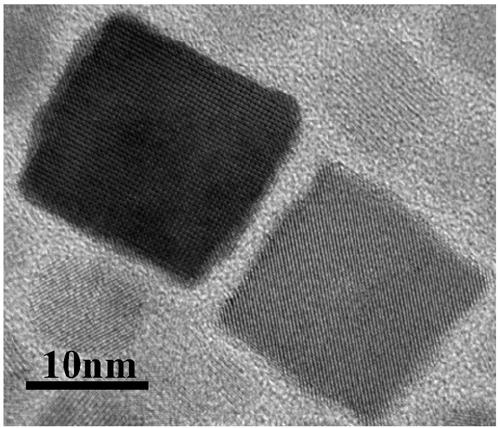

Preparation method for monodisperse barium titanate nanopowder

InactiveCN102502798AAvoid generatingHigh purityNanotechnologyTitanium compoundsHydration reactionBarium titanate

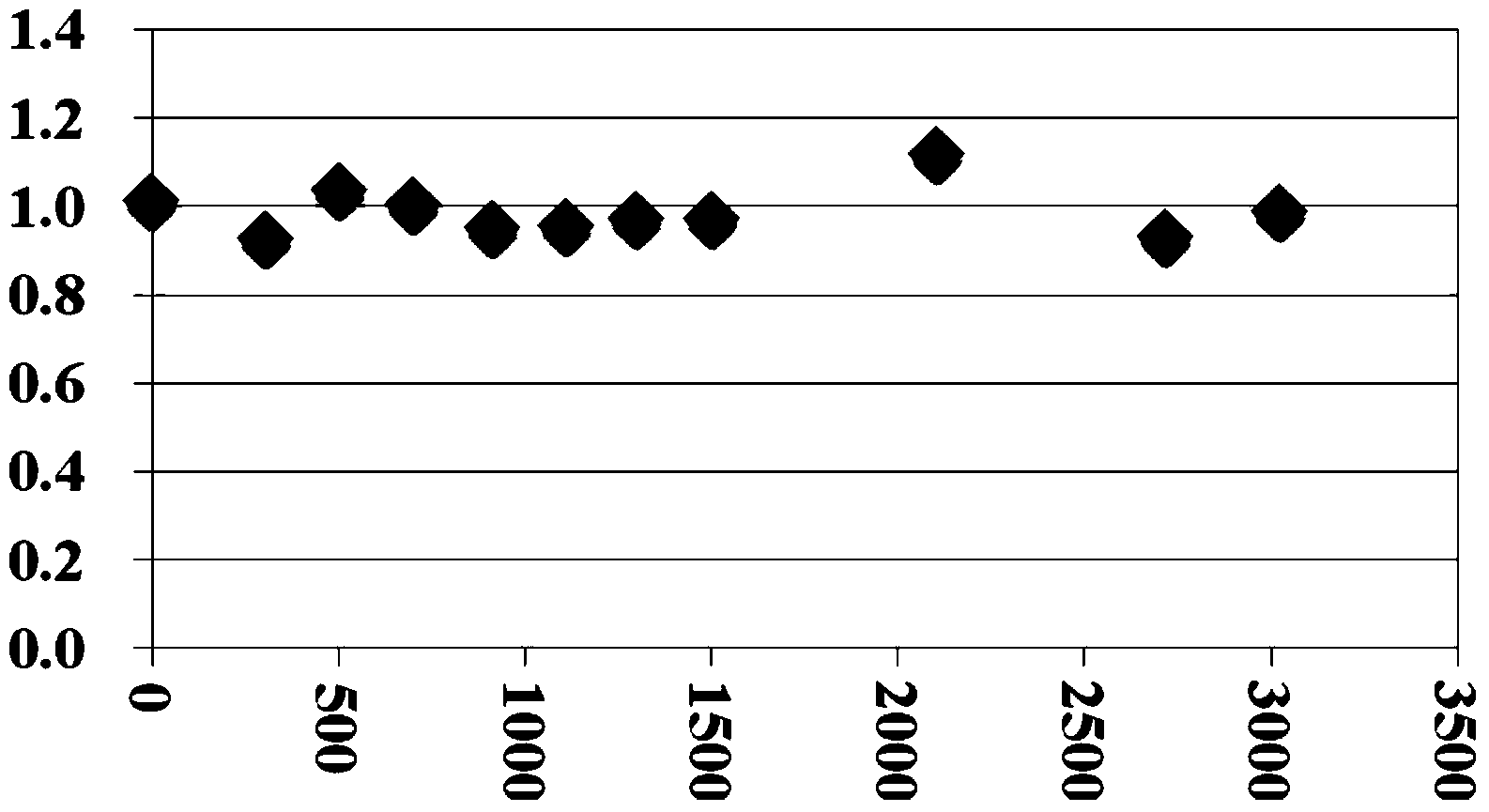

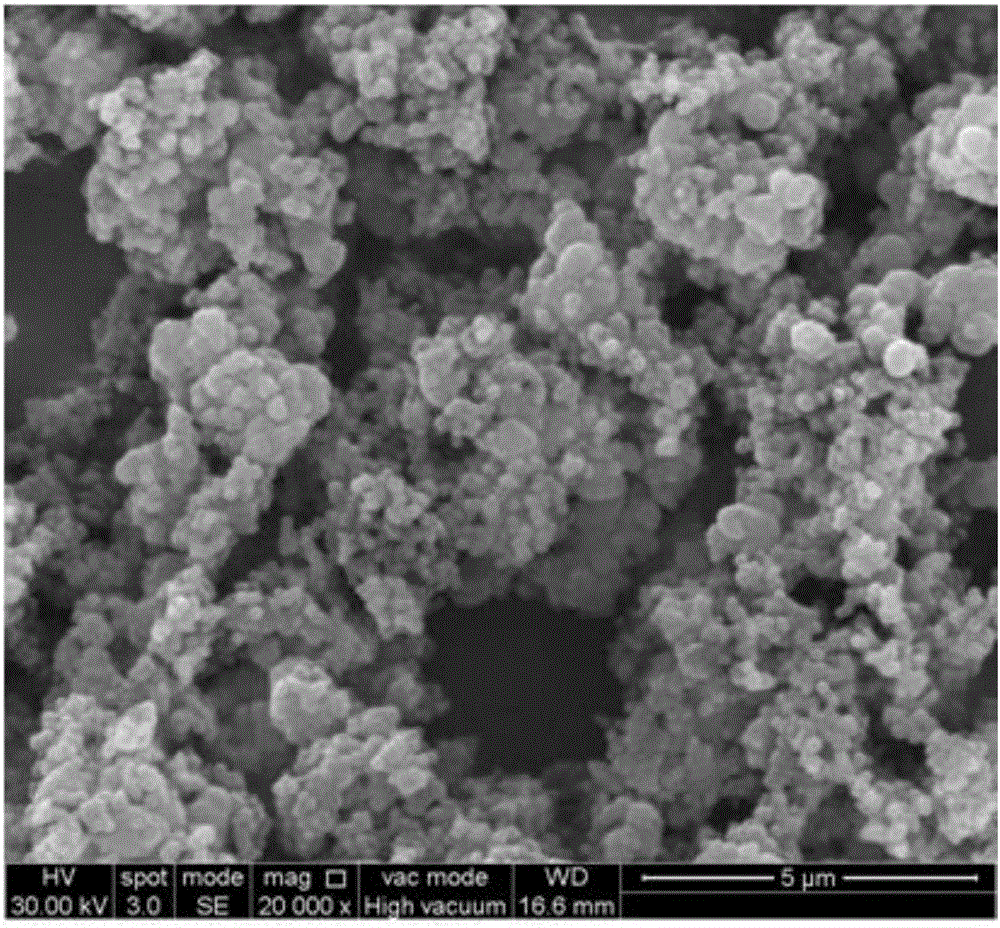

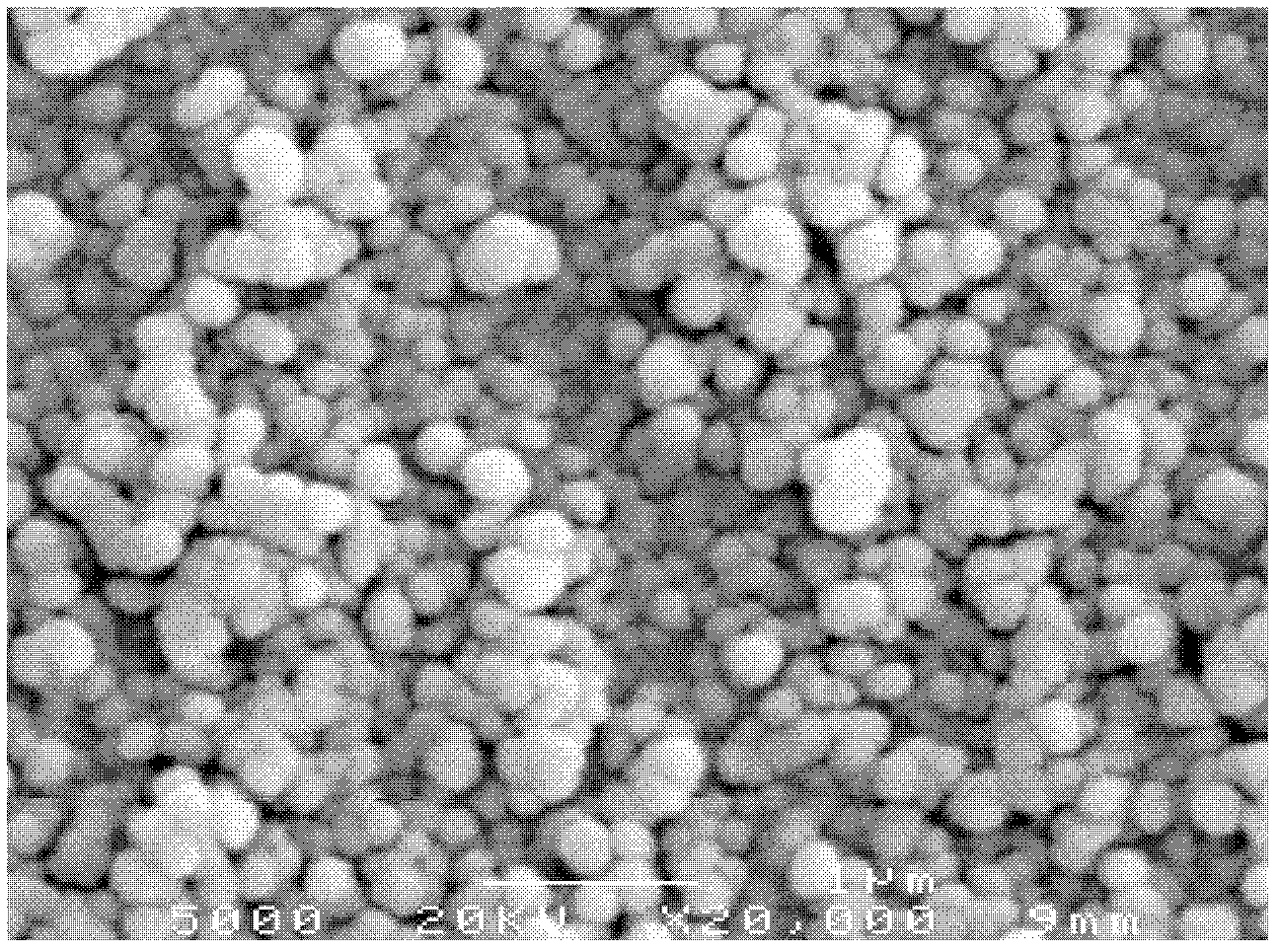

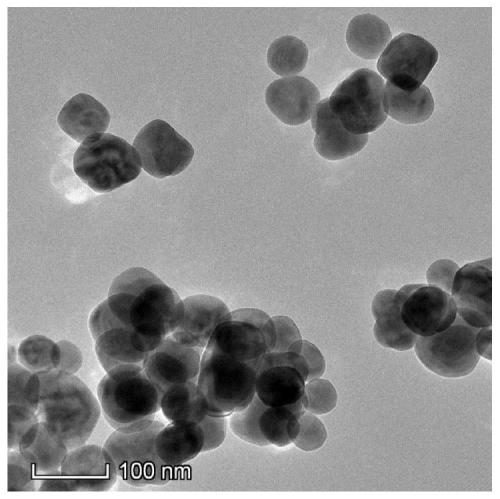

The invention discloses a preparation method for monodisperse barium titanate nanopowder combining with sol-gel method and hydrothermal method, comprising the following steps of: preparing original solution and dripping solution from absolute ethyl alcohol, tetrabutyl titanate, nitric acid and deionized water; mixing the dripping solution with the original solution to obtain TiO2 sol; pouring the TiO2 sol in the liner of a polytetrafluoroethylene high-pressure reactor, adding barium octahydrate precursor solution of different concentrations and then stirring; placing the liner in the step 3 in a stainless steel high-pressure reactor, sealing and then placing in a high-temperature oven to perform hydrothermal reaction; finishing the reaction and cooling, then opening the reactor, filtering and washing the reactants to be neutral by using the deionized water and the absolute ethyl alcohol, and then drying the reactants in the oven , so as to obtain the monodisperse barium titanate nanopowder. The preparation method for monodisperse barium titanate nanopowder disclosed by the invention combines with the advantages of sol-gel method and hydrothermal method for preparing powder, so that the synthesised barium titanate nanoparticles have the advantages of being high in purity, controllable in particle size, complete in crystal particle development etc; and the preparation method for monodisperse barium titanate nanopowder is simple in equipment, practicable in operation and convenient for industrialized batch production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anti-crack and self-repairing concrete and preparation method thereof

The invention discloses anti-crack and self-repairing concrete and a preparation method thereof. The anti-crack and self-repairing concrete is prepared from the following components in parts by weight: 200-300 parts of cement, 100-180 parts of fly ash, 500-700 parts of crushed stone, 80-140 parts of water, 40-60 parts of hemihydrate gypsum, 50-100 parts of silicon powder, 20-40 parts of polypropylene fiber, 10-15 parts of a silane coupling agent, 60-80 parts of calcium oxide, 5-10 parts of a water reducing agent, 30-50 parts of ammonium chloride and 10-20 parts of barium hydroxide octahydrate;and the preparation method comprises the steps that concrete slurry is mixed, specifically, the cement, the fly ash, the crushed stone, the hemihydrate gypsum and the silica powder are mixed and stirred for 30-40 min, the water reducing agent and the water are added and stirred for 5-10 min, then the ammonium chloride and the barium hydroxide octahydrate are added and stirred for 40-60 min, thenthe polypropylene fiber and the silane coupling agent are added to be stirred for 20-30 min, and then the concrete slurry is obtained; and the calcium oxide is sealed and loaded into a fiberglass pipe, and then the fiberglass pipe loaded with the calcium oxide is mixed in the concrete slurry to obtain the anti-crack and self-repairing concrete. The anti-crack and self-repairing concrete and the preparation method thereof have the advantages that the prepared concrete is resistant to cracking, self-repairing of cracks is realized, and strength after repairing is high.

Owner:北京天地建设砼制品有限公司

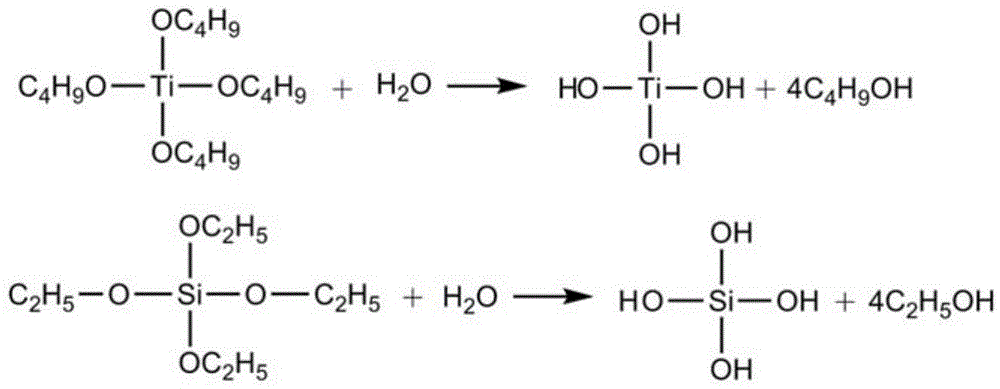

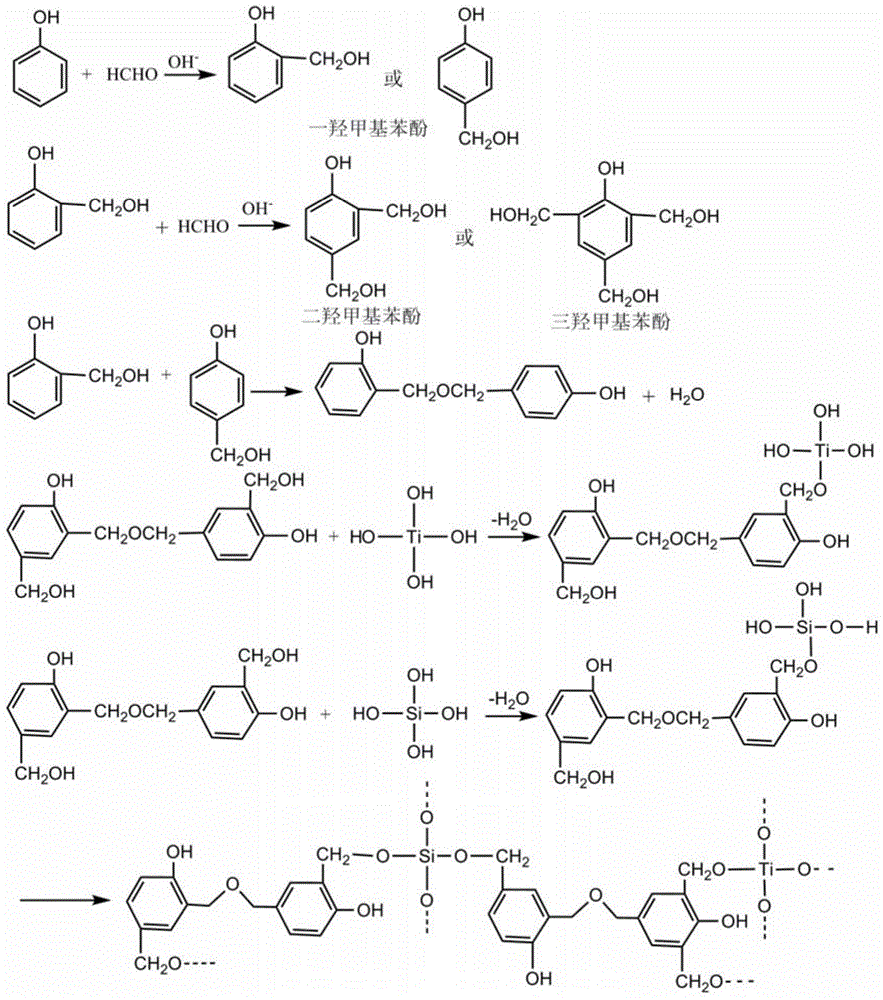

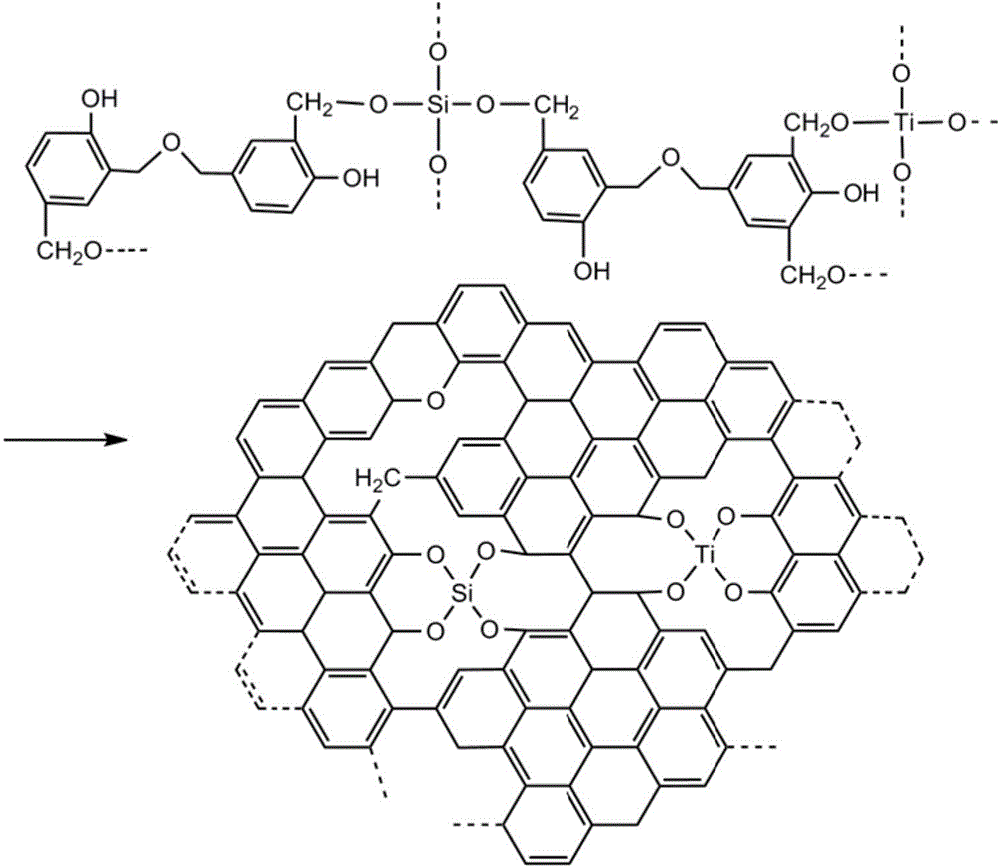

SiO2-TiO2 inorganic hybrid thermosetting thermosetting phenolic resin and preparation method thereof

The invention relates to a SiO2-TiO2 inorganic hybrid thermosetting thermosetting phenolic resin and a preparation method thereof. The phenolic resin comprises the following mass part: 100-200 parts of phenol, 85-175 parts of formaldehyde solution, 0.2-8 parts of ethyl orthosilicate and 0.2-8 parts of tetrabutyl titanate. The method comprises the following steps: taking phenol, a formaldehyde solution, ethyl orthosilicate and tetrabutyl titanate as a reactant, and adding 0.3-2 parts of barium hydroxide octahydrate and 0.5-2.5 parts of phosphoric acid solution to adjust pH value of the reactant. The problem of dispersibility of physically-doped silica and titanium dioxide in phenolic resin can be solved, the phenolic resin material with better and more uniform dispersibility can be obtained, Si-O bond and Ti-O bond with high bond energy can be formed after phenolic resin is solidified, residual carbon rate of phenolic resin can be effectively increased, and anti-ablation performance and mechanical property of the composite materials can be improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Solar water heater phase change heat storage material and its preparing method

InactiveCN100334179CHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSodium acetrizoateSolar water

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

Method for extracting ammonium thiocyanate from coking desulfurization waste liquid

InactiveCN102126732ASimple processEasy to operateThiocyanic acidWater/sewage treatmentActivated carbonLiquid waste

The invention discloses a method for extracting ammonium thiocyanate from coking desulfurization waste liquid. The method comprises: adding 3-5% of activated carbon to the coking desulfurization waste liquid, heating the mixture to 70-90 DEG C, stirring the mixture for 1-3 hours and filtering the mixture; adding sulfuric acid to the filtrate in a closed container to ensure the pH value of the filtrate to be 3.5-4.5, heating the mixture to 60-80 DEG C and stirring the mixture for 1-3 hours, leading out the escaping SO2 with a conduit and absorbing the escaping SO2 with dilute ammonia water; filtering the reaction liquid, adding barium hydroxide octahydrate with mass being equal to the mass of ammonium sulfate in the filtrate, heating the mixture to 60-80 DEG C in a closed container, stirring the mixture for 1-3 hours, leading out the escaping ammonia with a conduit and absorbing the escaping ammonia with water; and carrying out filtering after completing reaction, and heating, evaporating and crystallizing the filtrate to obtain the ammonium thiocyanate product with purity being more than 97%.

Owner:陈琳

Graphene aerogel compound enhanced medium-low-temperature phase change heat storage material and preparation method thereof

The invention relates to a graphene aerogel compound enhanced medium-low-temperature phase change heat storage material and a preparation method thereof. The heat storage material is prepared from aerogel blocks, barium hydroxide monohydrate and barium hydroxide octahydrate. The mass ratio of barium hydroxide octahydrate to barium hydroxide monohydrate is (70-90):1, and the mass ratio of a eutectic mixture of barium hydroxide monohydrate and barium hydroxide octahydrate to the aerogel blocks is (50-100):1. Compared with the prior art, the graphene aerogel compound enhanced medium-low-temperature phase change heat storage material has the advantages of being environmentally friendly, resistant to high temperature and high in heat conducting efficiency, the problems of supercooling and phase separation of an inorganic phase change heat storage material can be relieved, the heat storage amount of the heat storage material is large, the selected graphene aerogel can improve the heat conducting efficiency of barium hydroxide hydrate, and the problem of phase change supercooling is relieved.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing ceramic powder used for barium titanate-based low temperature co-fired plate

The invention relates to a method for preparing ceramic powder used for a barium titanate-based low temperature co-fired plate, mainly overcomes the problem that a sintering temperature of barium titanate powder is too high in the prior art and an application of the barium titanate powder in a low temperature co-fired ceramic material is limited, and belongs to the technical field of functional ceramics. According to the method, the barium titanate powder is prepared via a solvothermal method by using barium hydroxide octahydrate, barium chloride or barium nitrate as barium source and tetrabutyl titanate or isopropyl titanate as titanium source, and adding ethanol or isopropanol as an auxiliary agent; and the ceramic powder used for the barium titanate-based low temperature co-fired plate is prepared by using 85-98% by mass of BaTiO3 as a matrix and adding 2-15% by mass of a sintering promoter B2O3-SiO2 or Bi2O3 and through the steps of ball milling, drying and grinding. The method is characterized in that the barium titanate powder prepared by a low temperature solvothermal method has fine and uniform grain size and large surface activity; by adding a small amount of the sintering promoter, the late-stage sintering temperature of the ceramic is effectively reduced; and high-performance barium titanate-based low temperature co-fired plate can be prepared.

Owner:LIAONING SILICATE RES INST

Preparation method of barium hydroxide

InactiveCN1962451ASimple methodClean manufacturingCalcium/strontium/barium oxides/hydroxidesBarium sulphideSlag

The invention discloses a preparing method of barium hydroxide, which comprises the following steps: (1) reducing barite into barium sulphide through coal; (2) immersing barium sulphide through washing water to obtain mother liquid of barium sulphide; adjusting the temperature of mother liquid of barium sulphide to 30-70 Deg C and density at 50-150g / L; washing filter slag through water; immersing barium sulphide through washing water; (3) oxidizing barium sulphide to produce barium hydroxide, sulfur and manganese monoxide through manganese dioxide; filtering to obtain barium hydroxide mother liquid; obtaining the filter slag with sulfur and manganese monoxide; (4) condensing barium hydroxide; crystallizing; centrifuging; separating to obtain barium hydroxide octahydrate; (5) separating filter slag in the step (3); recycling sulfur; oxidizing manganese monoxide into manganese dioxide through air to circulate in the step (3).

Owner:李守德

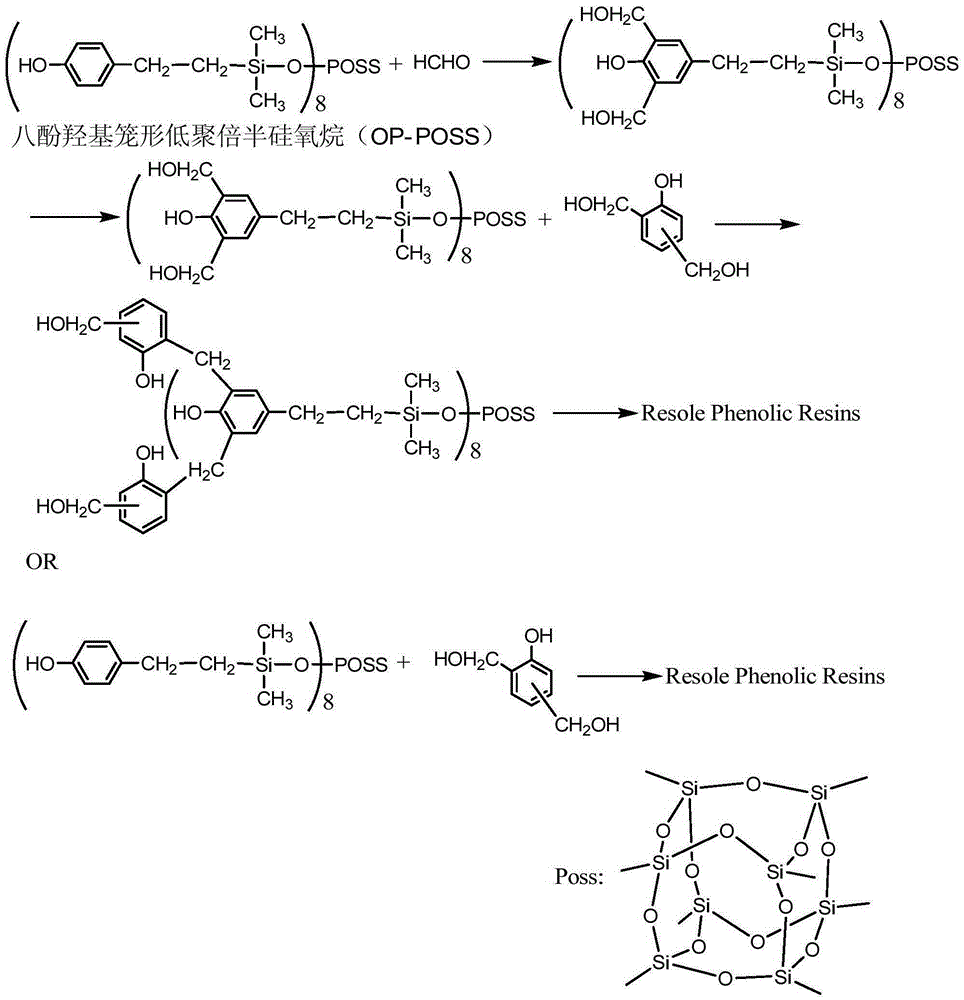

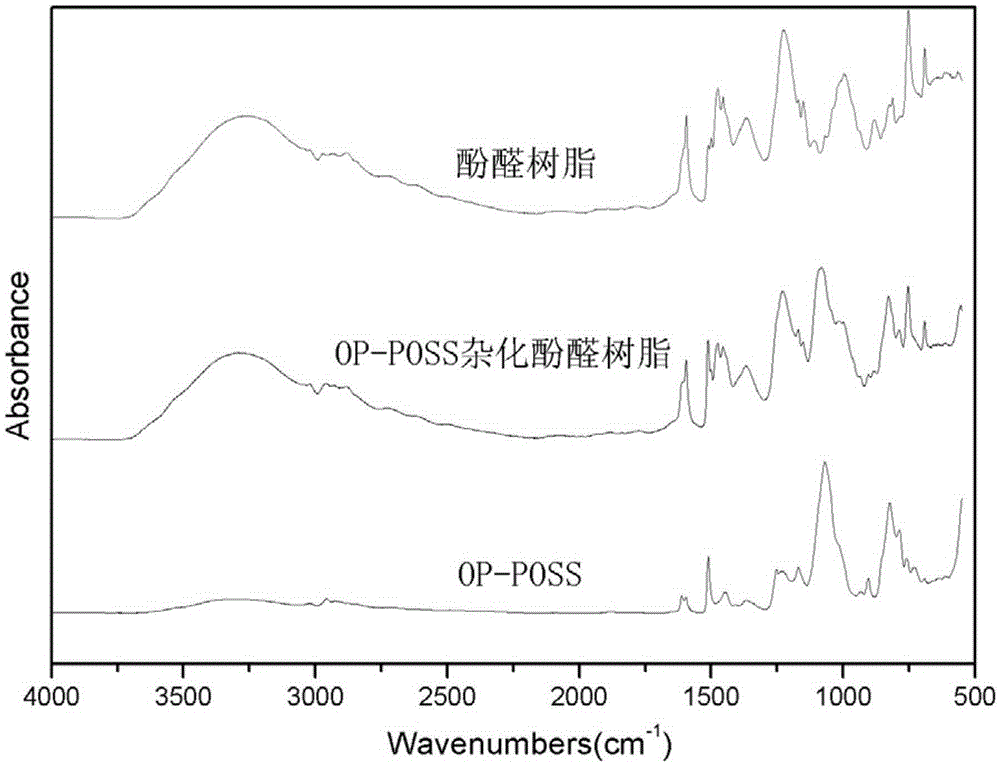

Cage-shaped oligomerization silsesquioxane hybridized phenolic resin with eight phenolic hydroxyl groups and preparation method thereof

The invention relates to cage-shaped oligomerization silsesquioxane hybridized phenolic resin with eight phenolic hydroxyl groups and a preparation method thereof. The phenolic resin is prepared by taking, by mass, 100-200 parts of phenol, 85-175 parts of formaldehyde solutions and 1-50 parts of cage-shaped oligomerization silsesquioxane as the reactants and taking, by mass, 0.2-3 parts of barium hydroxide octahydrate and 0.3-3.5 parts of phosphoric acid solutions as conditioning agents to adjust the PH value of the reactants. By means of the cage-shaped oligomerization silsesquioxane hybridized phenolic resin with the eight phenolic hydroxyl groups and the preparation method thereof, the dispersity problem of physical doped POSS in the phenolic resin is solved, the phenolic resin material which is better in dispersity and evener is obtained, and the oxidation resistance, the thermal property and the mechanical property are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

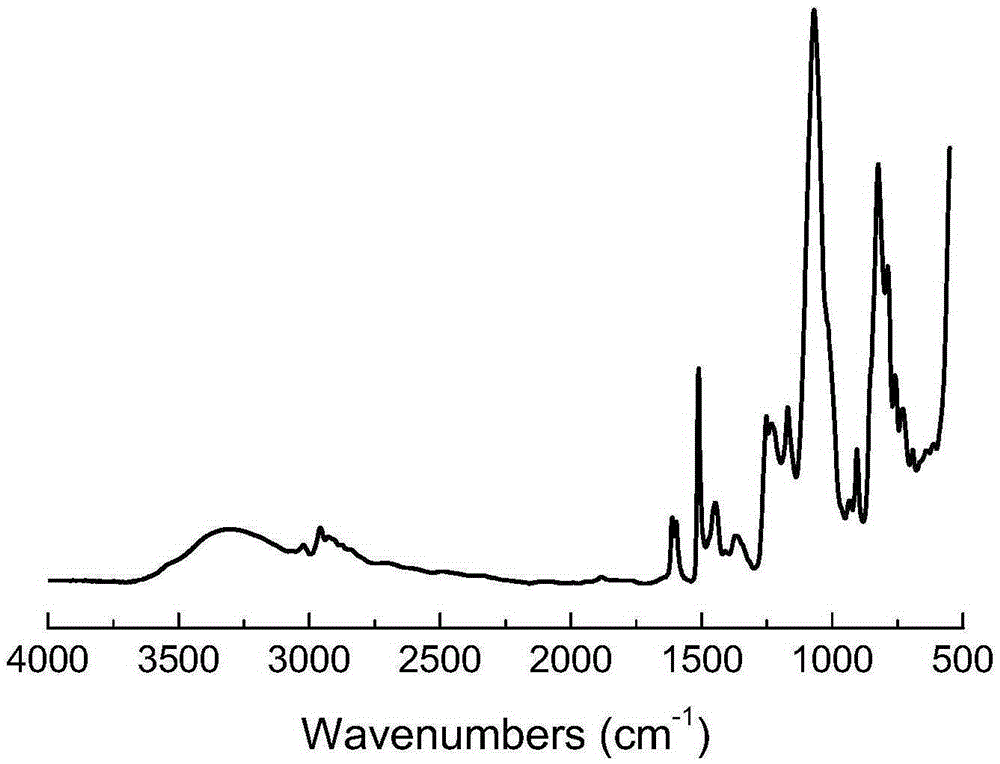

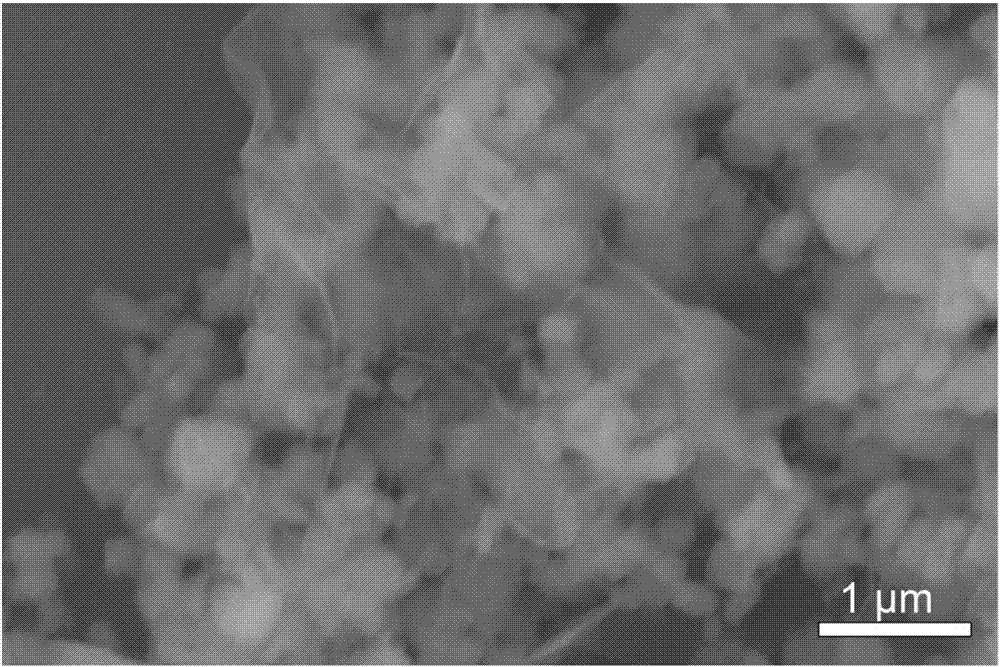

Nano barium hydroxide/graphene nano composite material and preparation method

ActiveCN107324365AImprove reinforcement strengthEasy to makeGrapheneCalcium/strontium/barium oxides/hydroxidesGraphene nanocompositesAlcohol

Owner:NORTHWESTERN POLYTECHNICAL UNIV

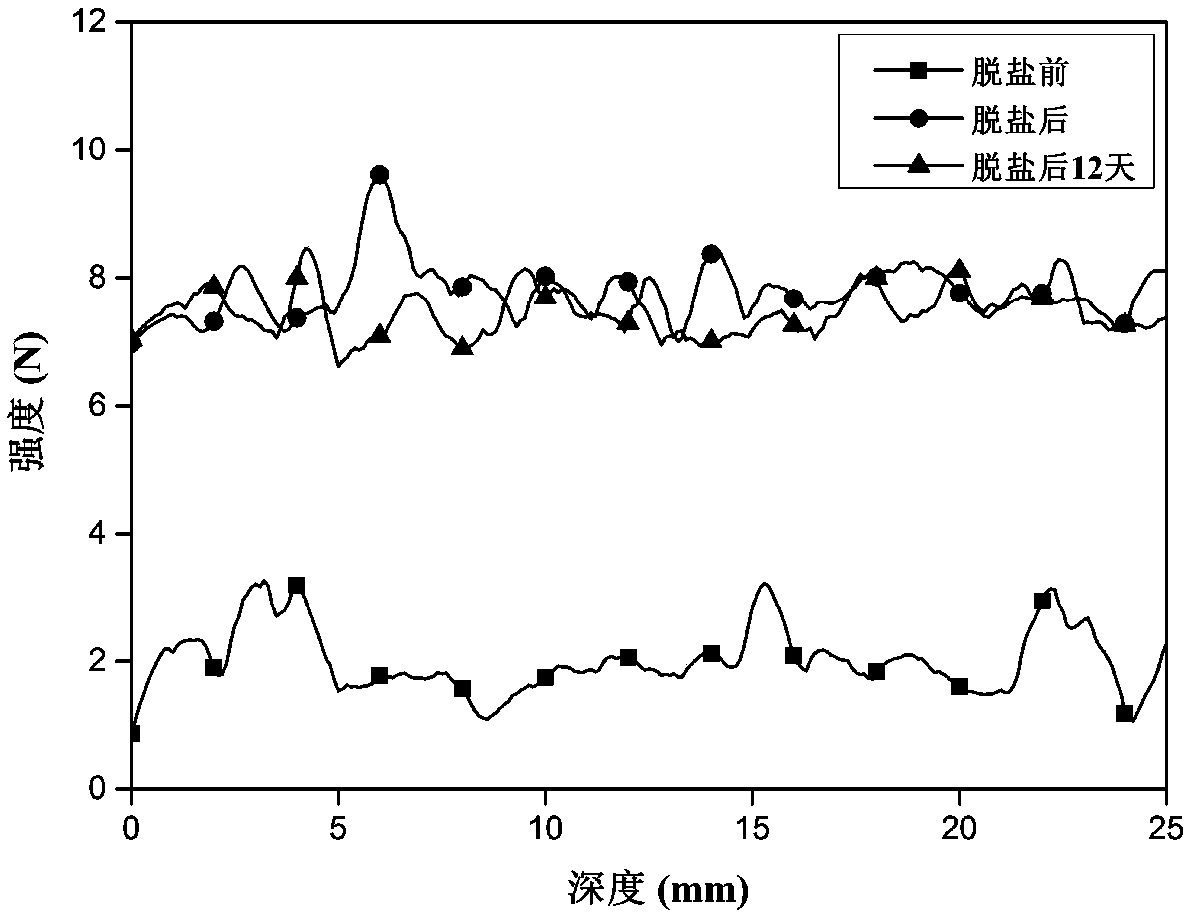

Method for removing sulphate from outdoor crisp brick cultural relic

The invention discloses a method for removing sulphate from an outdoor crisp brick cultural relic. The method is as follows: spraying a salt-damaged crisp part of a brick body with a solution A evenly, then evenly spraying the salt-damaged crisp part of the brick body with a deionized water and solution B mixed liquid with the volume ratio of deionized water to solution B of 1: 6 to 9, and repeating spraying with the solution A and the deionized water and solution B mixed liquid for 3 to 8 times, wherein the solution A is an ethanol solution containing 5 to 15 g / L of phosphoric acid and 10 to25 g / L of dihydrate oxalic acid, and the solution B is a methanol containing 8 to 25 g / L of barium hydroxide octahydrate. According to the method, the outdoor crisp brick cultural relic is desalted for transformation of most destructive Na2SO4 in the brick relic into BaSO4 to deposit in the brick, chlorine salt and sulfate that are not involved in the transformation can be separated from the brickbody in the manner of moving of salts along with water; while desalination, reinforcement function is achieved, the ''fragile'' status of salt-damaged crisp powder of the brick body may not be aggravated, the mechanical strength is significantly increased, the salt penetration increases after the desalination, and the salt retention time in the brick can be reduced.

Owner:SHAANXI NORMAL UNIV

Preparation method of organic modified barium titanate nano particle and preparation method of quantum dot optical film

ActiveCN111363385AShape is easy to controlParticle size adjustableNanoopticsLuminescent compositionsHydration reactionBarium titanate

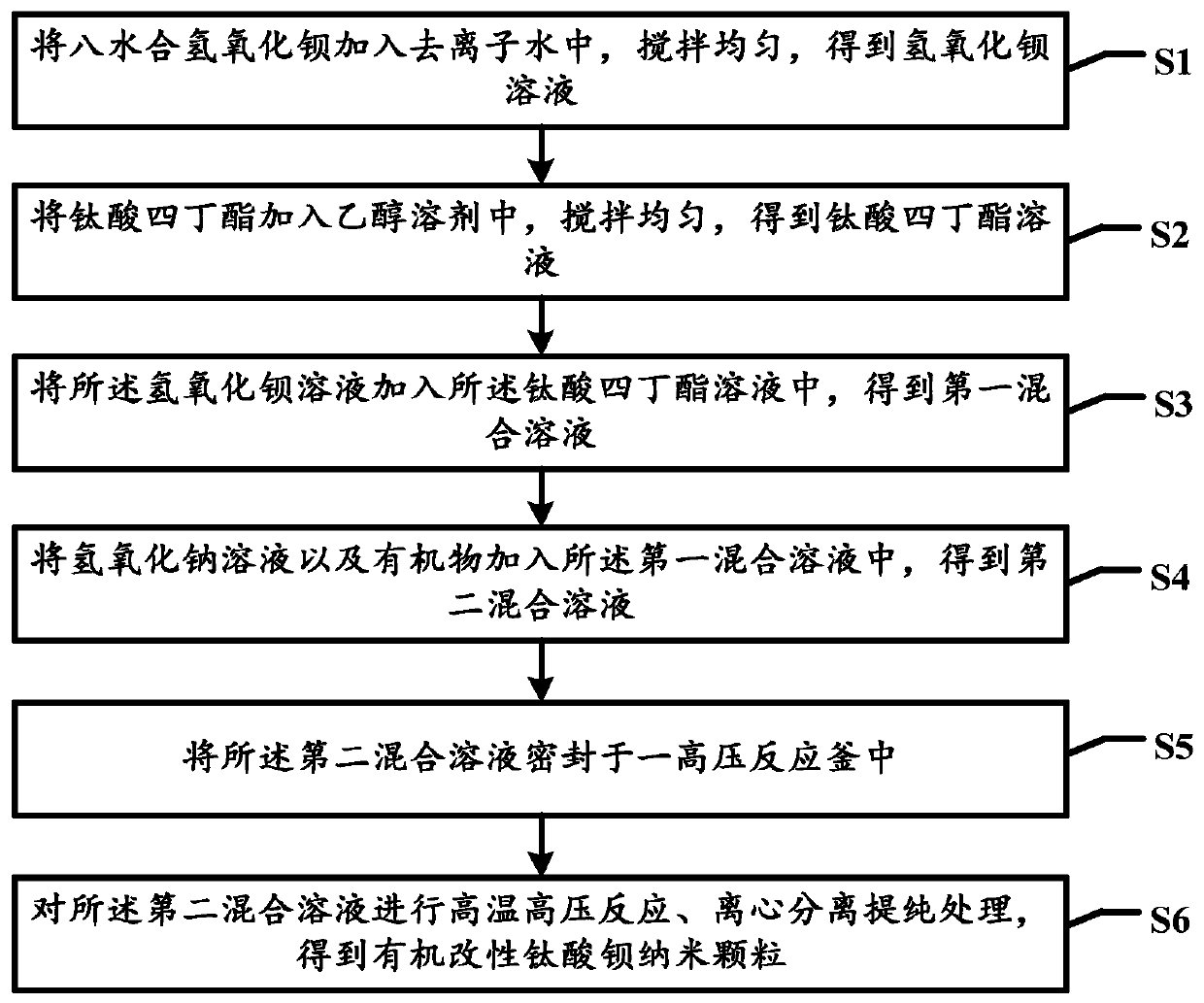

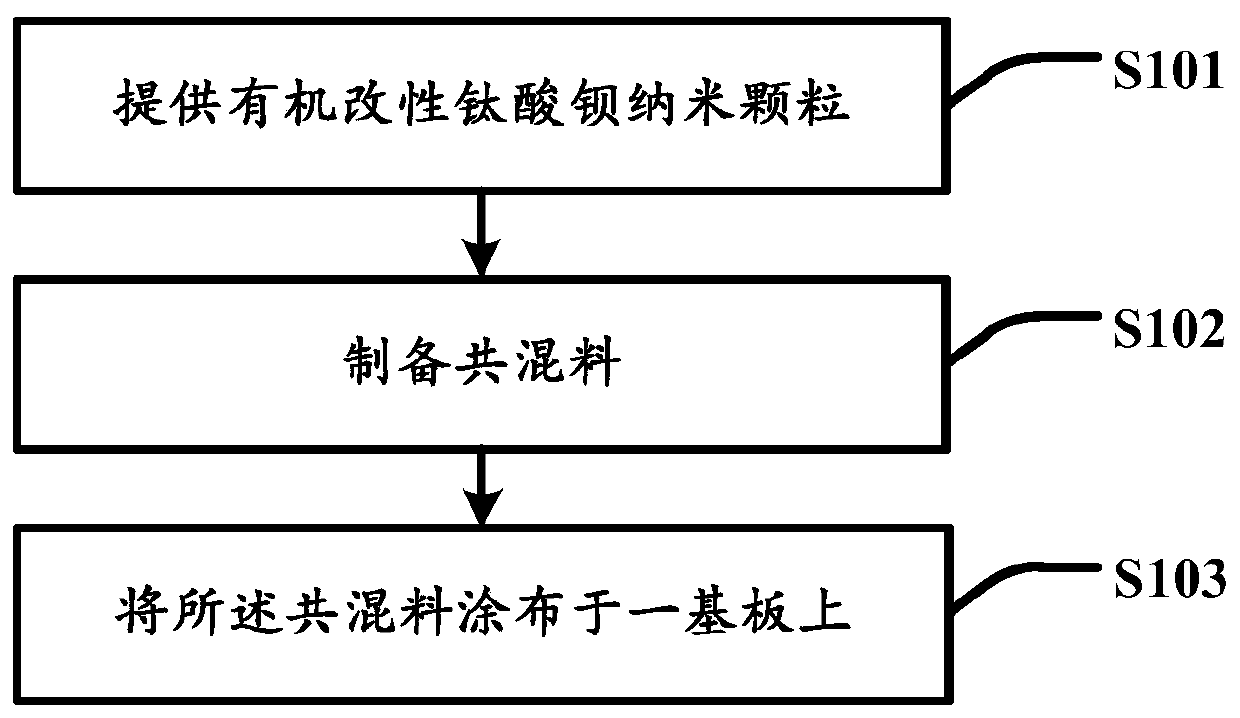

The invention provides a preparation method of an organic modified barium titanate nano particle and a preparation method of a quantum dot optical film. The preparation method of the organic modifiedbarium titanate nano particle comprises the following steps: adding barium hydroxide octahydrate into deionized water uniformly stirring to obtain a barium hydroxide solution; adding tetrabutyl titanate into an ethanol solvent, uniformly stirring to obtain a tetrabutyl titanate solution; adding the barium hydroxide solution into the tetrabutyl titanate solution to obtain a first mixed solution; adding a sodium hydroxide solution and an organic matter into the first mixed solution to obtain a second mixed solution, wherein the organic matter contains a carbon hydrogen bond and a carbon oxygen bond; sealing the second mixed solution in a high-pressure reaction kettle; carrying out high-temperature and high-pressure reactions on the second mixed solution, and carrying out centrifugal separation and purification to obtain the organic modified barium titanate nano particle.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for recovering lithium hydroxide from waste filtrate generated in preparation of LiFePO4 material by liquid-phase method

InactiveCN101830484AIncrease profitAvoid wastingAlkali metal oxides/hydroxidesCalcium hydroxidePotassium hydroxide

The invention relates to a method for recovering lithium hydroxide from waste filtrate generated in the preparation of LiFePO4 material by a liquid-phase method, belonging to the technical field of LiFePO4 material preparation. The method comprises the steps of: adding potassium hydroxide or sodium hydroxide to recovered waste filtrate in the process of preparing LiFePO4 material by the liquid-phase method; heating for concentration and filtering; concentrating filtrate by heating, and then filtering; washing and drying precipitate to obtain a crude hydrated lithium hydroxide product; dissolving the crude product in deionized water, adding 8-hydrate barium hydroxide, stirring and filtering; concentrating filtrate by heating, and then filtering; washing and drying precipitate to obtain a lithium hydroxide product. The invention not only recovers most lithium hydroxide remained in a reacted solution to be used as a part of lithium source for preparing the LiFePO4 material, but also recovers and obtains other byproducts, thereby effectively improving the utilization rates of lithium hydroxide and other resources and decreasing the cost for preparing the LiFePO4 material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Hydrated salt/modified expanded graphite shaped phase-change heat storage material for medium and low temperatures, and preparation method thereof

ActiveCN112574718AImprove adsorption capacityHigh energy storage densityChemical industryHeat-exchange elementsBarium hydroxide octahydrateGraphite

The invention provides a hydrated salt / modified expanded graphite shaped phase change heat storage material for medium and low temperatures, and a preparation method thereof. The phase change heat storage material is composed of barium hydroxide octahydrate, modified expanded graphite and a binder, wherein the mass ratio of the modified barium hydroxide octahydrate to the modified expanded graphite is (80-90%):(10-20%), and the mass of the binder is 1-3% of the total mass of the modified barium hydroxide octahydrate and the modified expanded graphite. The preparation method of the material comprises the following steps: mixing modified barium hydroxide octahydrate and modified expanded graphite in proportion, putting the mixture into a beaker, putting the beaker into a vacuum drying oven for vacuum melting adsorption, and then doping the binder for tabletting molding. According to the invention, the material selection is reasonable, the preparation process is advanced, the efficient medium-low temperature heat storage material can be produced from the nanoscale, the application of the heat storage composite material greatly improves the comprehensive properties including heat storage, heat release efficiency and the like, and the heat storage composite material can be used for industries such as heating, industrial waste heat utilization, electronic device heat dissipation andthe like.

Owner:HUANGGANG NORMAL UNIV

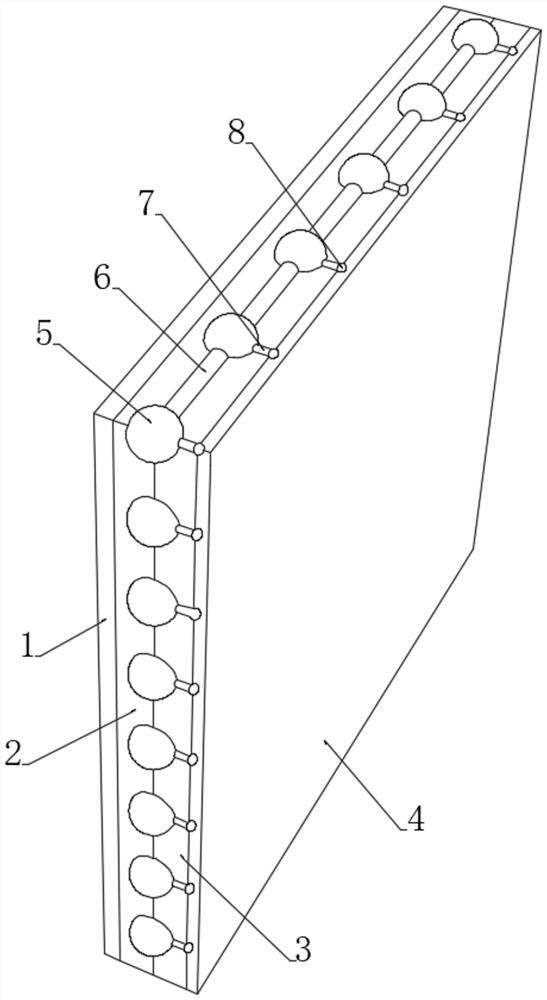

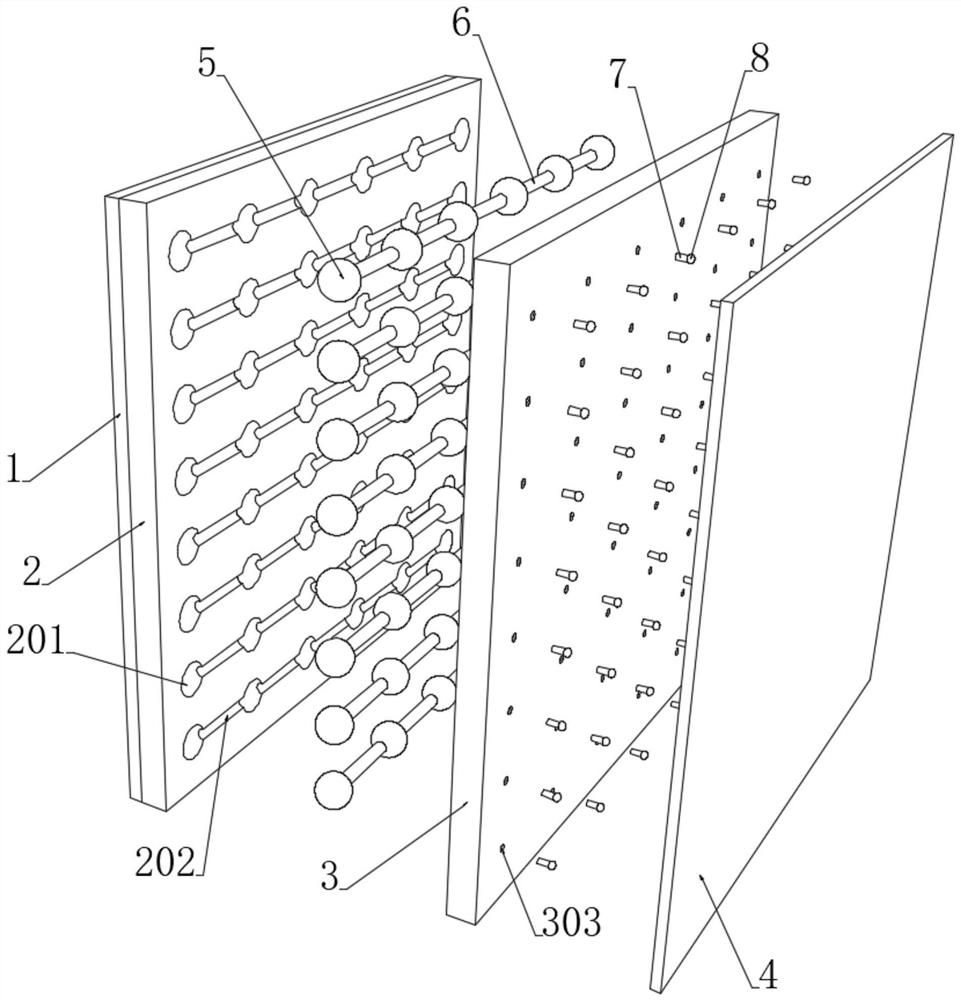

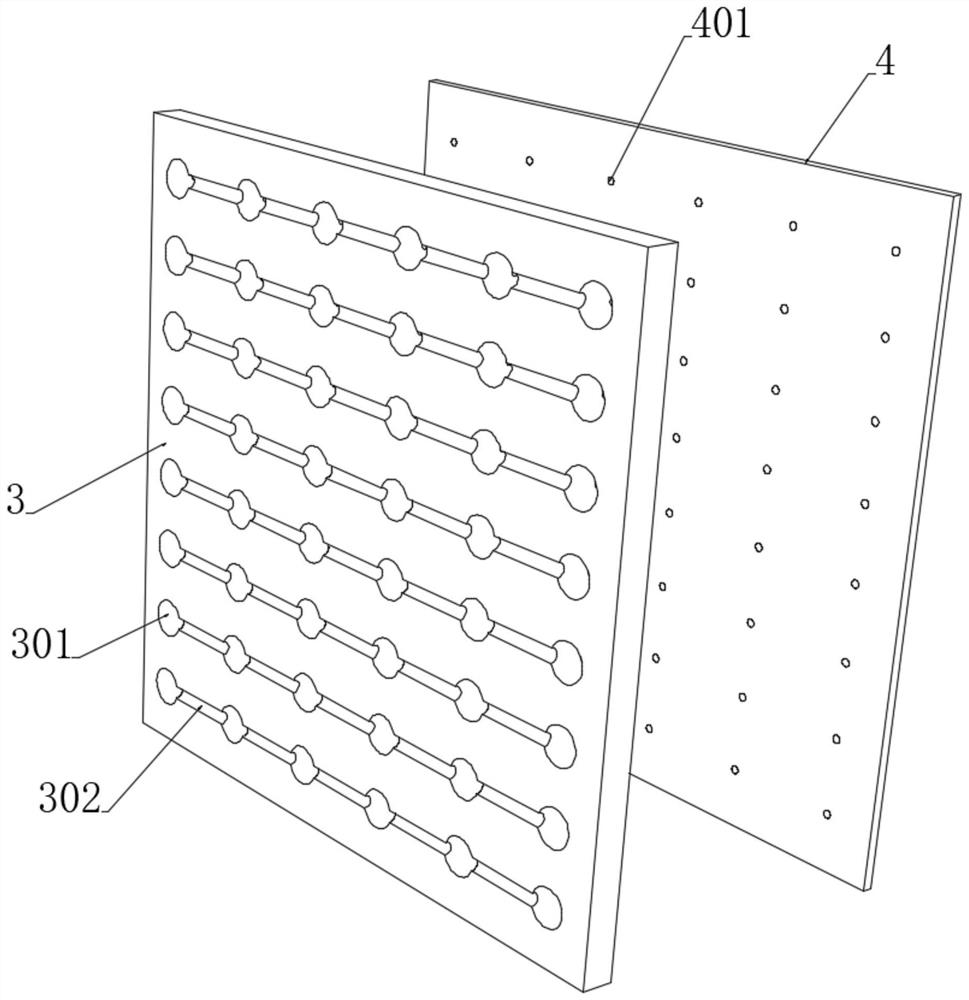

Heat-resistant and fireproof building fire-fighting floor slab

ActiveCN112982702AAids in fire resistanceImprove flame retardant performanceFire proofingInsulation layerFloor slab

Owner:XIAMEN ELECTRIC POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +2

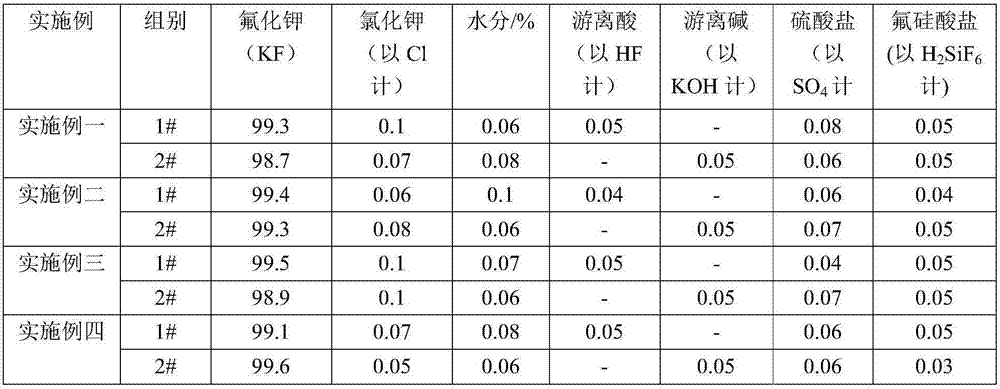

Preparation method of potassium fluoride

InactiveCN107973321ALow costReduce processing costsAlkali metal fluoridesPotassium fluoridePotassium

The invention relates to a preparation method of potassium fluoride. The method comprises: adding fluorosilicic acid and potassium fluosilicate into a reaction kettle, after starting to stir, continuously adding potassium hydroxide solution, and regulating a pH (power of hydrogen) value of mixed solution in the reaction kettle into a first preset pH value; after completing the reaction, carrying out solid-liquid separation, adding a first supernatant obtained by solid-liquid separation into a refining kettle, then adding sulfuric acid solution into the refining kettle and carrying out stirring; after continuously adding barium hydroxide octahydrate into the refining kettle and carrying out stirring, transferring liquid obtained by solid-liquid separation into a transfer groove, adding potassium carbonate to carry out stirring, and after completing the reaction, transferring second supernatant into a concentration kettle; after regulating a pH value of mother solution of the potassium fluoride in the concentration kettle by utilizing hydrofluoric acid, carrying out spray-drying on the mother solution of the potassium fluoride to obtain anhydrous potassium fluoride. According to thepreparation method of the potassium fluoride, which is disclosed by the invention, raw material cost and machining cost can be reduced; the preparation method of the potassium fluoride is beneficial to large-scale production application.

Owner:JIANGXI QUCHENG CHEM

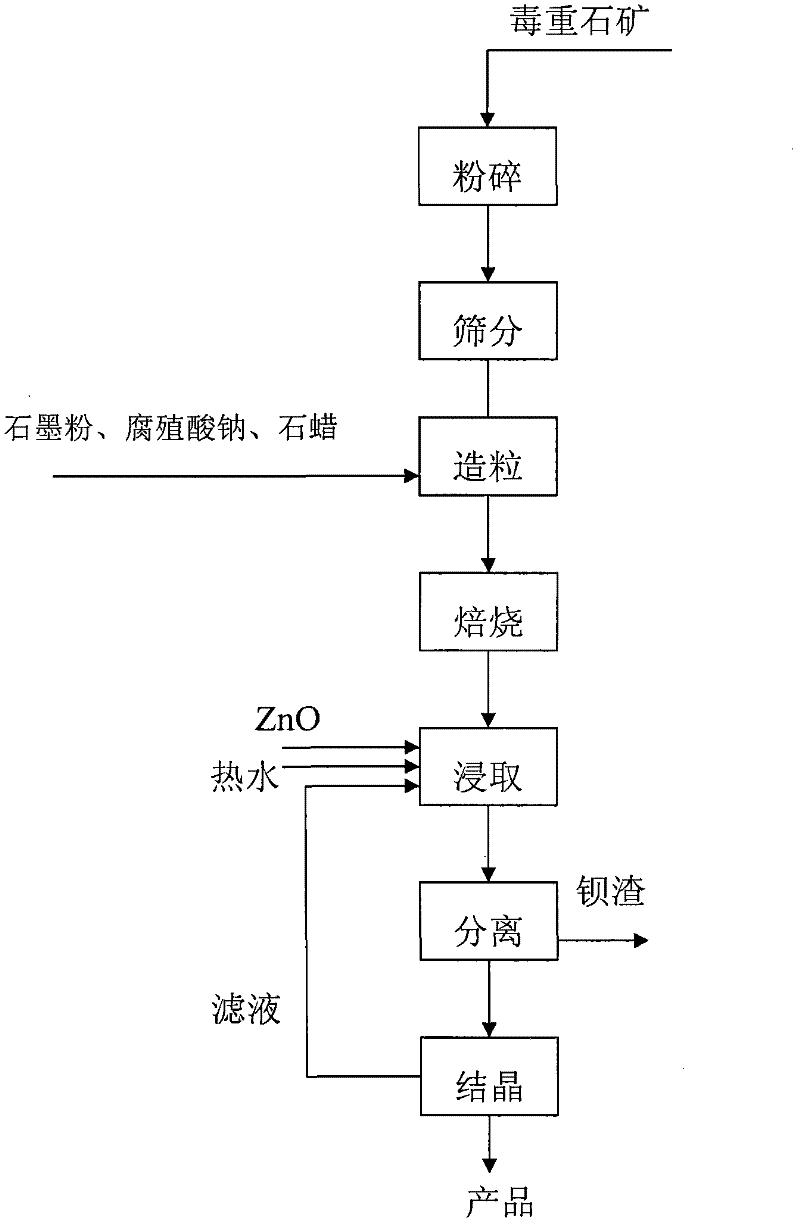

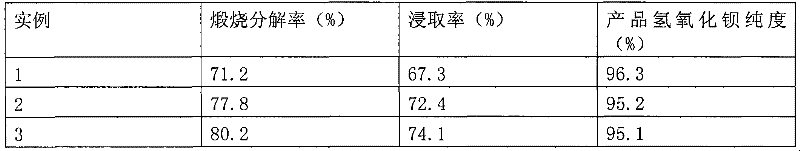

Method utilizing witherite to prepare barium hydroxide octahydrate

InactiveCN102583480AImprove decomposition efficiencyComposition is stable and controllableCalcium/strontium/barium oxides/hydroxidesSlagImpurity

The invention relates to a method utilizing witherite to prepare barium hydroxide octahydrate and belongs to the technical field of fine chemical engineering. The method utilizes witherite to serve as a raw material, witherite slag is sieved after grinding, the grain size is controlled at 120 mesh>50-80%, 8-15% of graphite powder, 1-2% of sodium humate and 2-3% of paraffin are added into the witherite, and pelletizing is performed through a pelletizer. After the grains are dry and hard, the grains are placed in a corundum boat and roasted for 2-3h at 1,000-1,200 DEG C, and the roasted grains are cooled to 500-700 DEG C, placed in hot water at 85-95 DEG C and soaked for 1-2h according to the solid-to-liquid ratio 1:(6-10). After desulfurization, material liquid is concentrated and crystallized so that a barium hydroxide product is obtained, and filtrate returns to a leaching tank to be recycled. Compared with other methods, the method enables thermal decomposition efficiency of witherite to be high, enables water leaching rate to be high, enables the product to be subjected to little influence of impurities in an additive, enables discharged solid residue to be little, and has a certain advantages.

Owner:CHONGQING UNIV OF ARTS & SCI

Mechanical antiwear restoration lubricant

The invention discloses a mechanical antiwear restoration lubricant which comprises the following components in parts by weight: 1-9 parts of wax solvent, 14-25 parts of pickling agent, 1-3 parts of phosphating solution, 1-3 parts of passivation solution, 1-3 parts of vitrification agent, 4-8 parts of calcium hydroxide, 7-10 parts of barium hydroxide octahydrate, 7-16 parts of sodium hydroxide, 5-16 parts of potassium nitrate, 7-15 parts of sodium nitrate, 2-4 parts of sodium sulfite, 1-3 parts of dispersant, 1-3 parts of thickener, 4-6 parts of flame retardant, 4-8 parts of stearic acid, 7-14 parts of stearate, 4-15 parts of stearamide, 1-3 parts of silicon oil and 4-10 parts of oleamide. The invention has the advantages of favorable use effect under high-temperature high-speed working conditions, no toxic or side effect and low manufacturing cost, and can be widely used.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

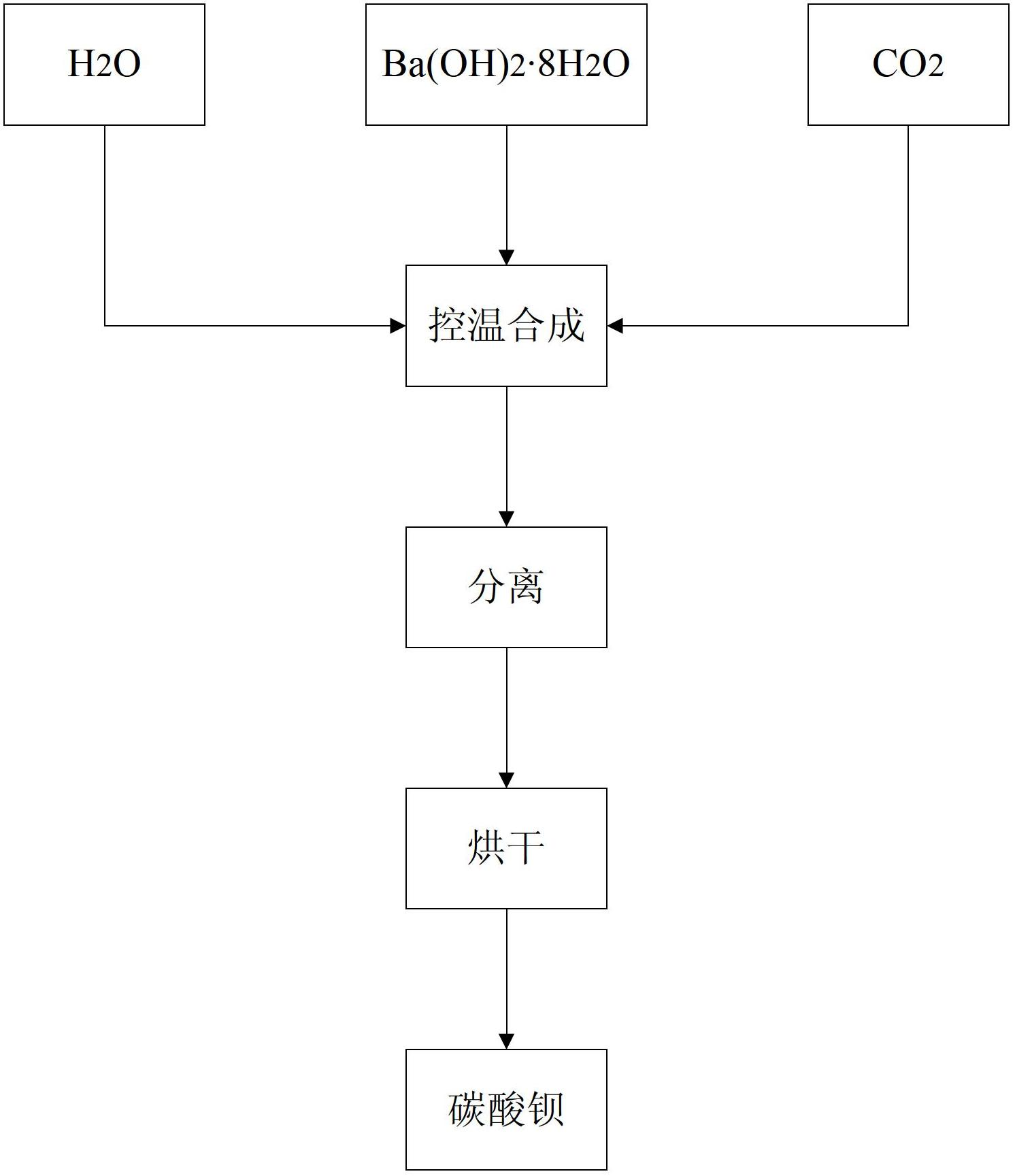

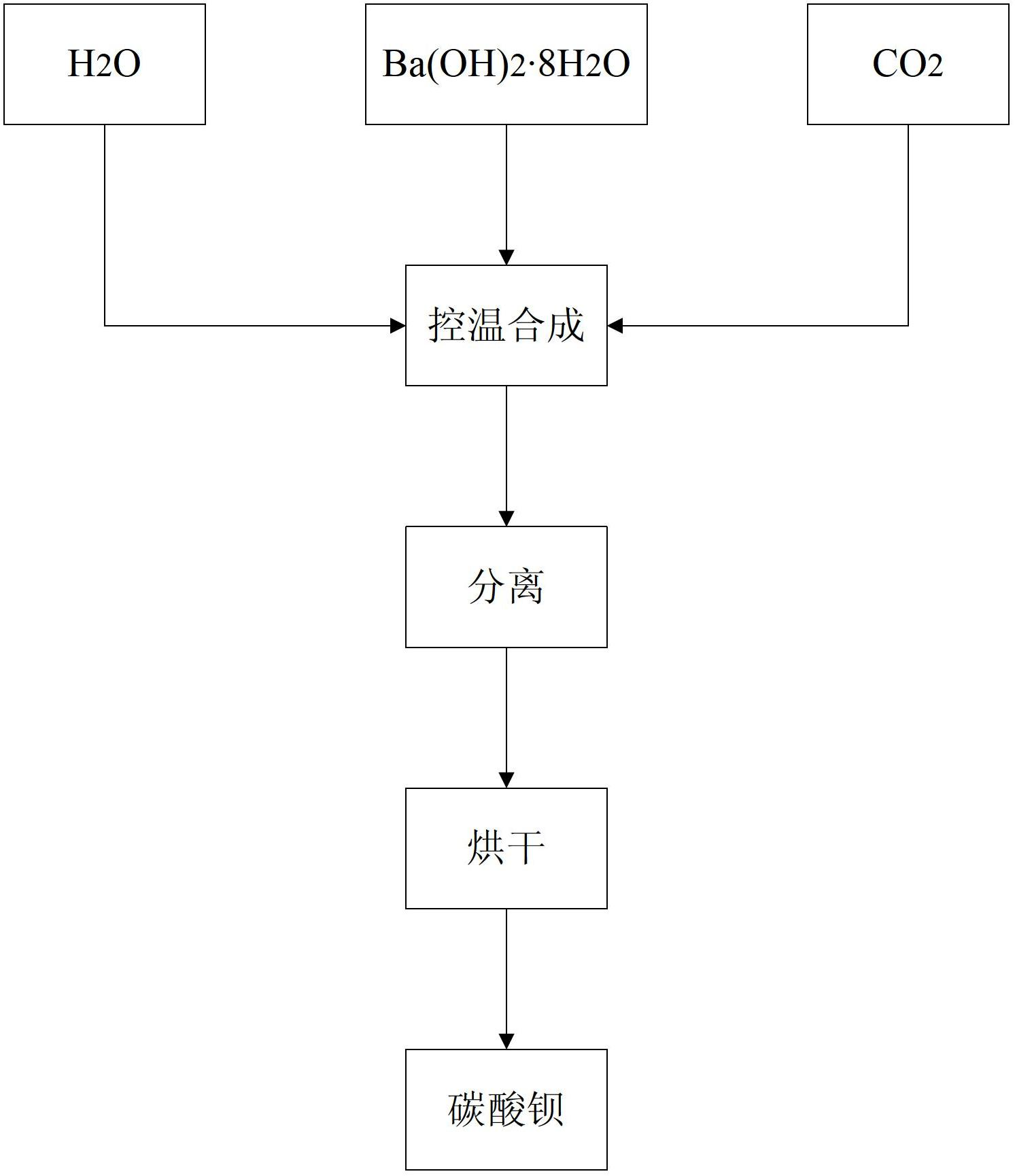

Preparation method of barium carbonate and product prepared by same

ActiveCN102674426ANo longer affects sintering temperatureImprove performanceBarium carbonatesThin material handlingHydration reactionIce water

The invention relates to a preparation method of barium carbonate and a barium carbonate product prepared by the same. The preparation method of the barium carbonate comprises the following steps: (1) adding barium hydroxide octahydrate crystals into an ice water bath, and mixing, wherein the temperature is controlled at 0-5 DEG C; (2) introducing carbon dioxide into the mixture obtained in the step (1) to react until the pH value of the reaction solution is 6.0-7.0; and (3) carrying out solid-liquid separation on the solid-liquid mixture obtained in the step (2), and drying the solid to obtain the large-specific-area high-purity barium carbonate product. The preparation method provided by the invention solves the problem of incompatible low strontium and large specific area in the existing preparation method, so that the barium carbonate product is no longer influenced by the sintering temperature, thereby enhancing the performance of the ceramic material.

Owner:SHENZHEN MODERN SKY TECH CO LTD

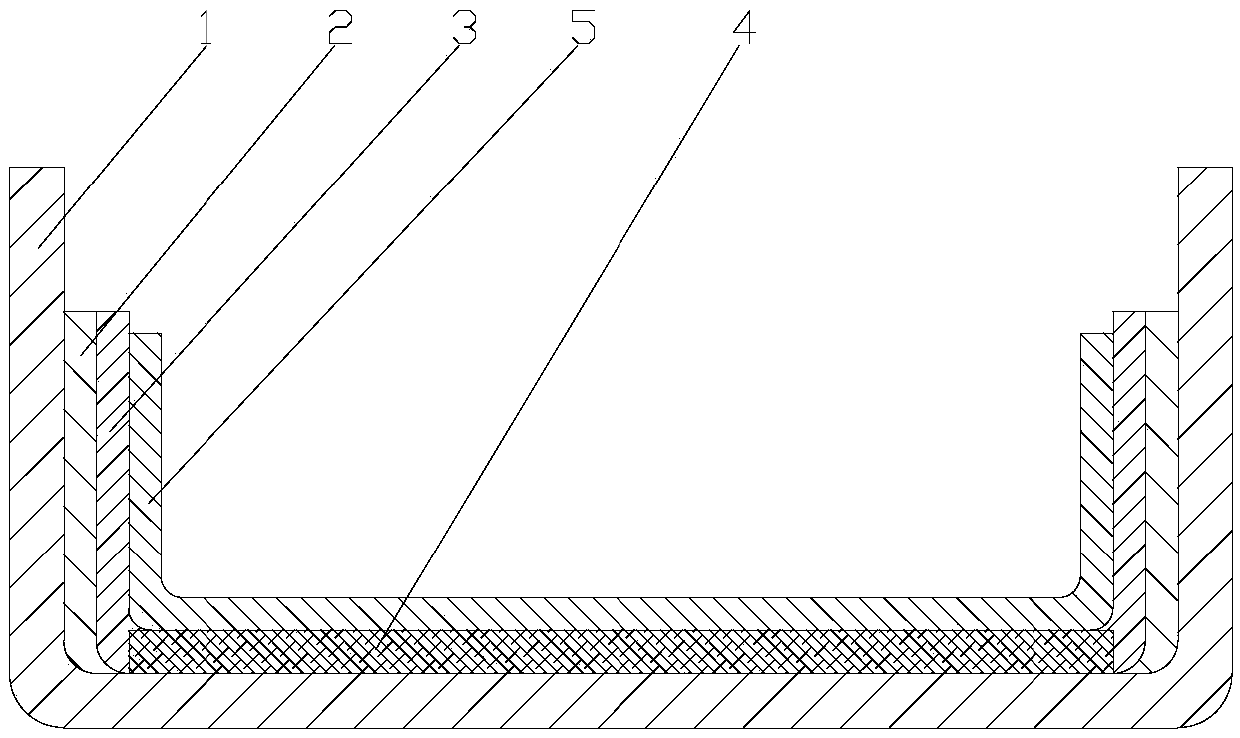

Polypropylene sheet

The invention belongs to the technical field of polypropylene plastics, and particularly relates to a polypropylene sheet. The polypropylene sheet comprises a sheet body; a rectangular cavity is formed in the sheet body, and the interior of the rectangular cavity is divided into a first cavity and a second cavity through a transverse plate made of polypropylene. A liquid storage chamber is formed in the top of the sheet body, a group of partition plates are attached to the interior of the liquid storage chamber, the adjacent partition plates are connected through compression springs, and mercury is filled between the ends, away from the compression springs, of the partition plates and the liquid storage chamber in a sealed mode. The polypropylene sheet is simple in modeling, and the pull rope can be separated from the piston plate on the basis that mercury is heated to expand, so that the barium hydroxide octahydrate crystals and the ammonium chloride crystals are subjected to mixed reaction to absorb heat, and the purpose of cooling the polypropylene sheet is achieved. When the temperature is high, the sheet body is protected, and therefore the polypropylene sheet holds the advantages of being high in impact resistance, tough in mechanical property and resistant to corrosion of various organic solvents and acid and alkali.

Owner:大庆海鼎新材料科技有限公司

Preparation of superfine cubic phase barium titanate powder

InactiveCN101372359AReduce manufacturing costEasy to operateTitanium compoundsAcetic acidBarium titanate

The invention discloses a method for preparing superfine cubic phase barium titanate powder, which comprises the following steps: sodium hydroxide or potassium hydroxide, industrial metatitanic acid, barium hydroxide octahydrate and water are mixed at the mol ratio of 10:1:0.5-2:55, stirred for 30min and then ultrasonically treated for 30-60min; the obtained mixture is transferred to a high pressure reaction kettle and reacts at the temperature of 90-200 DEG C for 4-15h; when the reaction is completed, the mixture is filtered or centrifugated to obtain a solid; the obtained solid is added with 1mol / L acetic acid until no bubble is generated, filtered, washed with deionized water until the pH value equals 7, and the solid is dried at the temperature of 60-80 DEG C and ground to obtain the superfine cubic phase barium titanate. The method has the advantages of simple operations, low requirement for equipment and low cost, and that the method is suitable for industrial production.

Owner:EAST CHINA NORMAL UNIVERSITY

Anti-flaming coating for plastic products

InactiveCN106189776AAdd lessIncreased and improved dispersionFireproof paintsAntifouling/underwater paintsAlkaneCyclohexanone

The invention relates to the technical field of preparation and application of novel high-molecular materials and especially relates to an anti-flaming coating for plastic products. The anti-flaming coating for plastic products mainly comprises the following components by weight part: 20-30 parts of waterborne polyurethane resin, 3-5 parts of anti-flaming compound, 8-15 parts of hydrophobic high-molecular compound, 2-5 parts of barium hydroxide octahydrate, 3-6 parts of petroleum ether, 1-2 parts of high temperature-resisting binder, 2-4 parts of carbonic ester coupling reagent, 1-3 parts of naphthenic hydrocarbon and alkane mixture, 1-2 parts of polyhydric alcohol, 1-2 parts of emulgator, 3-5 parts of fillers and 20-30 parts of water, wherein the anti-flaming compound is formed by the mixture of silicon compound, graphene oxide and polyamide; the silicon compound comprises silicon carbide and silicon sulfide; the mixture of cyclohexanone hyperoxide and polylactic ester is taken as the emulsifier. The anti-flaming coating provided by the invention is especially fit for surface decoration of the plastic products and has the advantages of chemical property stability, high anti-flaming property and low dosage of the anti-flaming compound.

Owner:DAYANG RIYUE LIQUOR IND CO LTD

Preparation method of monodisperse barium titanate cubic nanometer particles

InactiveCN109399700APromote crystallizationHigh crystallinityAlkaline earth titanatesNanotechnologyBarium titanateCrystallinity

The invention discloses a preparation method of monodisperse barium titanate cubic nanometer particles. According to the method, barium hydroxide octahydrate and 2-hydroxypropanoate are respectively used as a barium source and a titanium source; the materials are firstly dissolved into deionized water to form a mixed precursor solution; then, the pH value of the precursor solution is regulated bya 5M sodium hydroxide solution; furthermore, a proper amount of oleic acid and tert-butylamine are used as surfactants and additives; and the monodisperse BaTiO3 cubic nanometer particles are preparedunder the condition of 180 to 220 DEG C. The method has the advantages that the energy consumption is low; the operation is simple and convenient; the BaTiO3 nanometer particles prepared by the method are cubic phases with high purity and good crystallinity through XRD tests; the regular cubic appearance is realized; and the average crystal grain dimension is 20 to 40 nm, so that wide applicationprospects are realized in the fields of scientific research and electronic industry.

Owner:YUNNAN UNIV

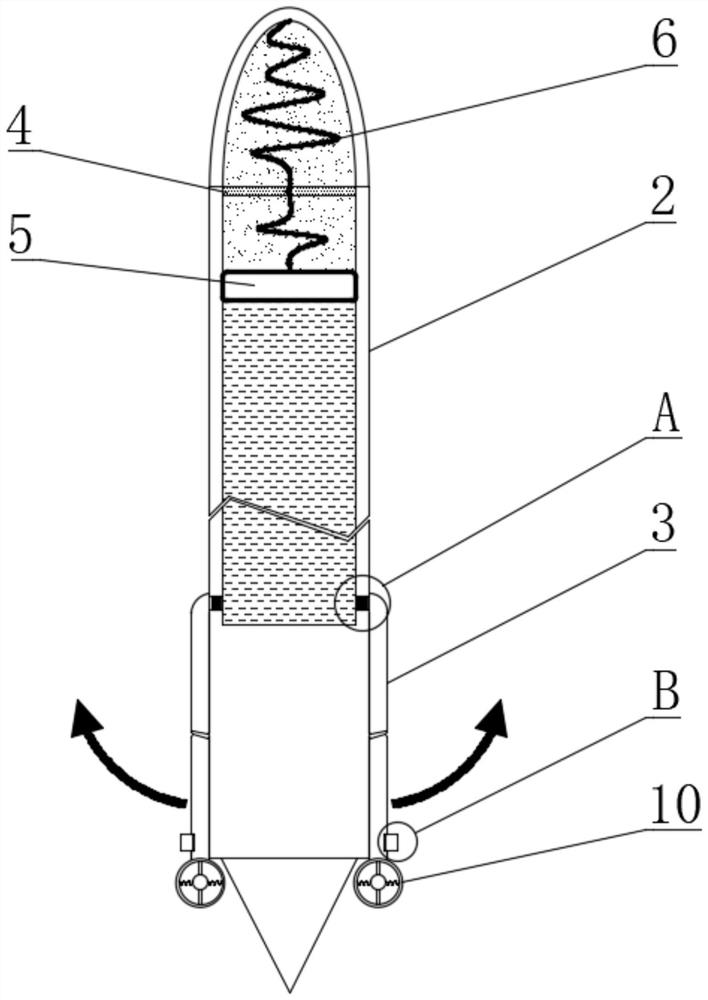

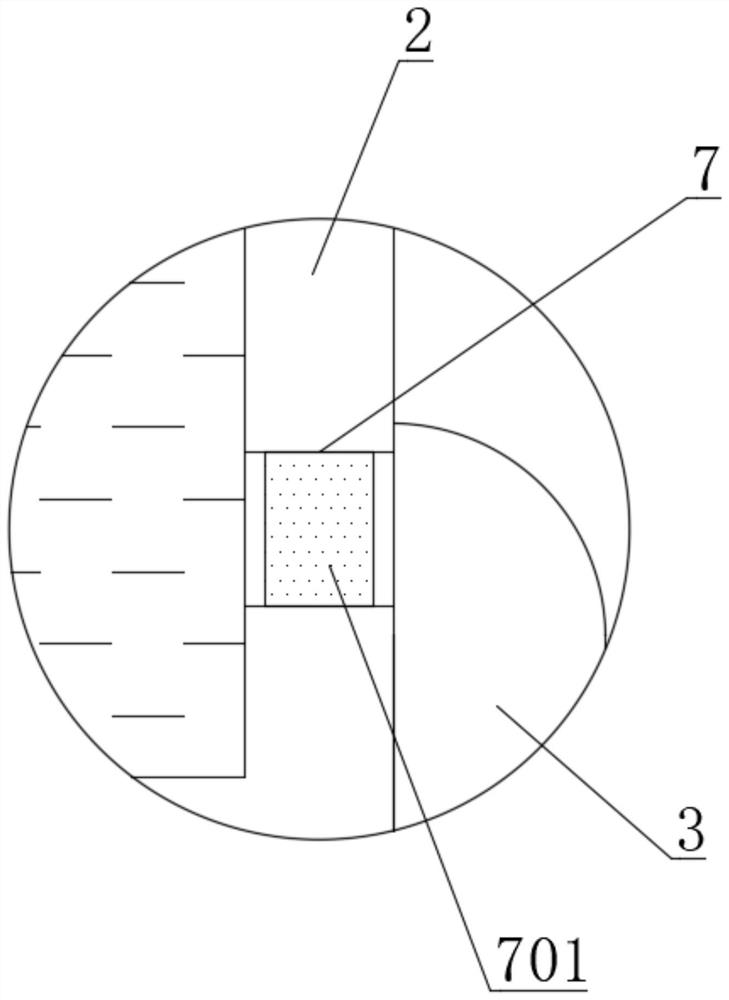

Cold diffusion remediation rod based on organic contaminated soil

InactiveCN112170473APromote mutual mixingFacilitated releaseDomestic cooling apparatusLighting and heating apparatusSoil scienceSoil remediation

The invention discloses a cold diffusion remediation rod based on organic contaminated soil, and belongs to the technical field of soil remediation. According to the scheme, an embedded remediation rod is inserted into the organic contaminated soil, the top end of a remediation storage barrel is pressed, barium hydroxide octahydrate and ammonium chloride powder in the remediation storage barrel are promoted to be mixed with each other, refrigeration can also be achieved while ammonia gas is generated, along with the gradual increase of the ammonia gas, a movable plug plate can be pushed to slide downwards, and the soil remediation agent is extruded into a lateral diffusion hose, so that on one hand, a sealing plug can be moved out of a second flow division guide hole, and the soil remediation agent in the lateral diffusion hose is promoted to be released from the second flow division guide hole, and on the other hand, by virtue of temperature reduction during refrigeration, a tractionmoving ball is driven to be magnetically shielded, so that the traction moving ball drives the lateral diffusion hoses to be separated from each other and spread, the release range of the soil remediation agent is widened, soil can be stirred and dispersed, and the absorption efficiency of the soil to the soil remediation agent is improved.

Owner:刘玉福

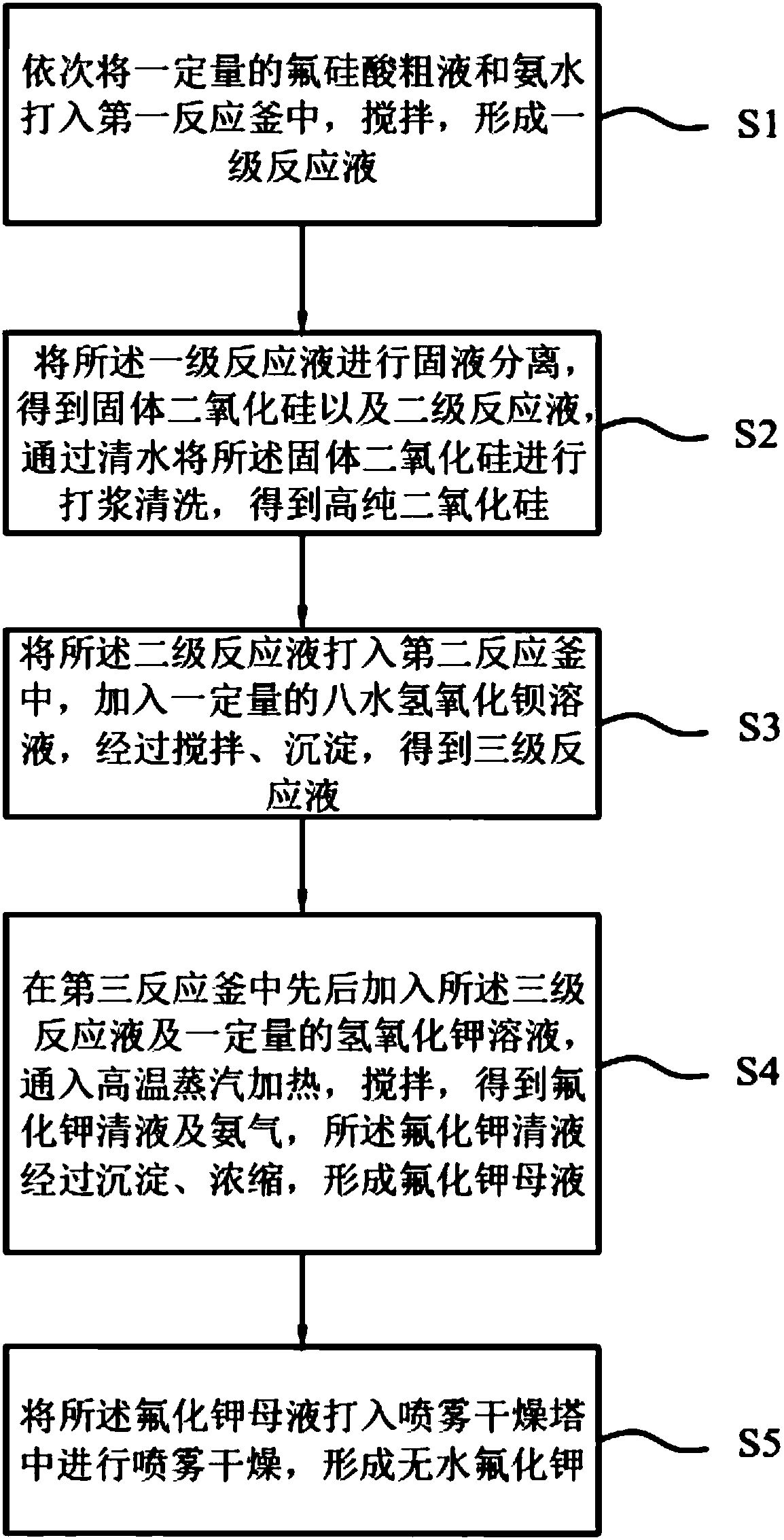

Preparation method of anhydrous potassium fluoride

InactiveCN108033465ALow costSolve the use problemSilicaCalcium/strontium/barium sulfatesPotassium fluoridePotassium hydroxide

The invention provides a preparation method of anhydrous potassium fluoride. The preparation method comprises the following steps: enabling a fluosilicic acid crude solution and ammonia water to reactto form a reaction solution, performing solid-liquid separation for a primary reaction solution to form solid silicon dioxide and a secondary reaction solution, enabling the secondary reaction solution to react with barium hydroxide octahydrate to form a tertiary reaction solution, enabling the tertiary reaction solution to react with potassium hydroxide, introducing high-temperature steam, heating, stirring, obtaining potassium fluoride clear solution and ammonia gas, concentrating the potassium fluoride clear solution to form potassium fluoride mother solution, introducing the potassium fluoride mother solution into a spray drying tower, spray drying the potassium fluoride mother solution to form anhydrous potassium fluoride, wherein the fluosilicic acid crude solution is a byproduct onan anhydrous hydrogen fluoride production line and comprises the ingredients such as fluosilicic acid, little sulfuric acid and little hydrofluoric acid. The fluosilicic acid crude solution is used for substituting anhydrous hydrofluoric acid, so that not only can the raw material cost be decreased, but also the comprehensive utilization of the fluosilicic acid crude solution can be realized; andmeanwhile, while the anhydrous potassium fluoride is produced, the silicon dioxide and barium sulfate can be co-produced, and the economic benefit can be improved.

Owner:JIANGXI QUCHENG CHEM

Mobile phone shell based on mobile phone film gap cold suction type ash removal

InactiveCN111818211APlay a role in breaking upImprove reaction efficiencyTelephone set constructionsCleaning processes and apparatusWater vaporEngineering

The invention discloses a mobile phone shell based on mobile phone film gap cold suction type ash removal. The invention belongs to the technical field of electronic products, according to the scheme,a movable rod is pulled outwards, the movable rod is promoted to bring part of ammonium chloride powder into the external wrapping frame to be mixed with barium hydroxide octahydrate powder; under the stirring effect of the movable rod, the ammonium chloride powder is promoted to react with the barium hydroxide octahydrate powder; a large amount of ammonia gas can be generated during refrigeration; refrigeration, the water vapor is promoted to liquefy on the inclined surface embedded into the incision sac to form small liquid drops; on the other hand, the generated ammonia gas is used, according to the method, the barium hydroxide octahydrate powder and the ammonium chloride powder can be scattered, so that the reaction efficiency of the ammonium chloride powder and the barium hydroxide octahydrate powder is improved, and meanwhile, the embedded cutting bag can be promoted to expand, so that an edge gap between the smart phone and the tempered film is filled by the embedded cutting bag, and dust on the surface of the smart phone and the tempered film is adsorbed.

Owner:顾鑫平

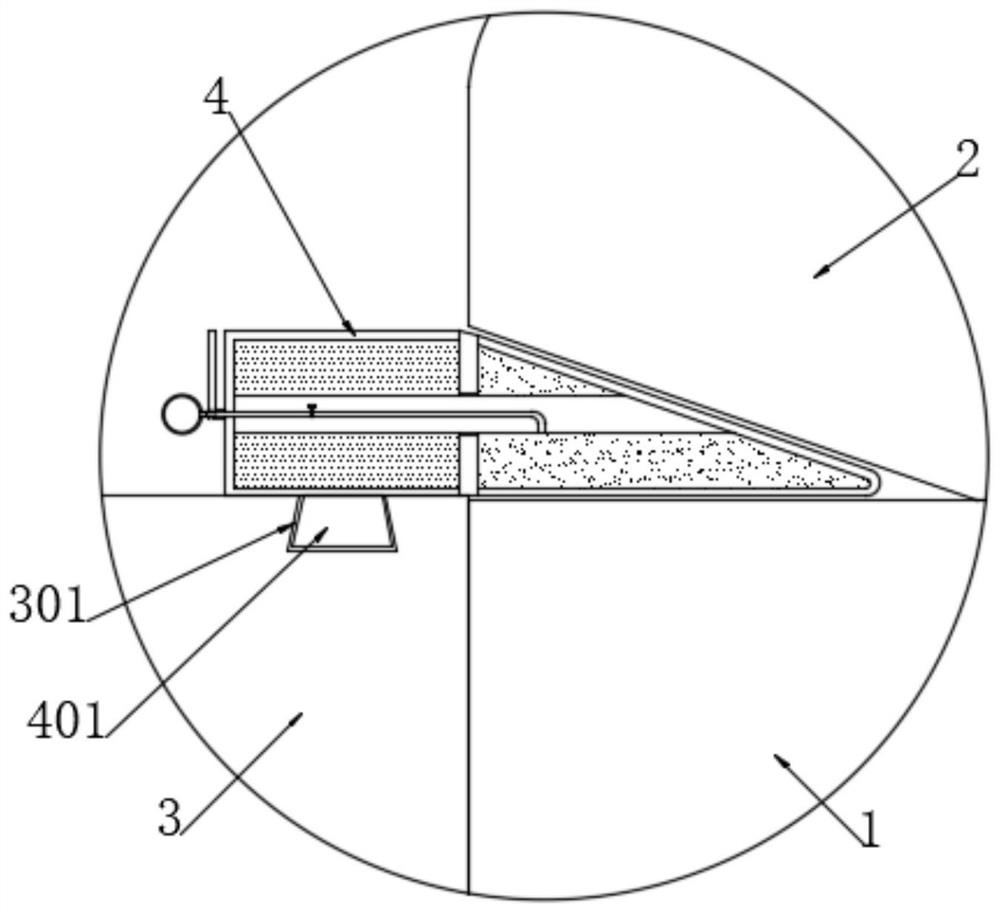

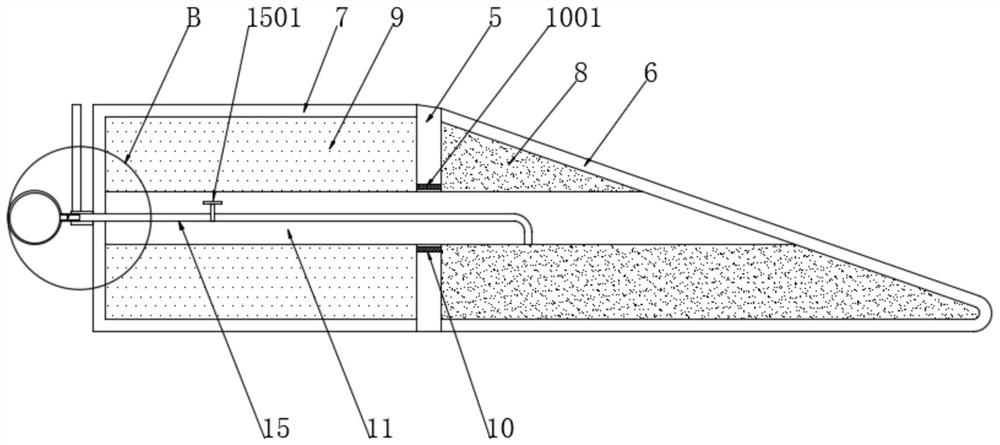

Crucible capable of increasing solar energy silicon ingot yield, and preparation method thereof

InactiveCN110055584ABarrier entryPromote nucleationPolycrystalline material growthSingle crystal growth detailsSlurry coatingBarium hydroxide

The invention discloses a crucible capable of increasing solar energy silicon ingot yield, and a preparation method thereof. The crucible capable of increasing solar energy silicon ingot yield comprises a quartz crucible main body, a high purity barium hydroxide octahydrate coating layer, a high purity fused quartz slurry coating layer, a high purity quartz wafer, and a demoulding silicon nitridecoating layer. The preparation method comprises following steps: 1, preparation of the high purity barium hydroxide octahydrate coating layer, 2, preparation of the high purity fused quartz slurry coating layer, 3, bottom quartz wafer pasting, and 4, preparation of the demoulding silicon nitride coating layer. The advantages are that: the high purity barium hydroxide octahydrate coating layer andthe high purity fused quartz slurry coating layer are arranged between the internal side wall of the quartz crucible main body and the demoulding silicon nitride coating layer, so that entering of impurities into liquid state silicon is prevented, and silicon ingot yield is increased; the bottom of the quartz crucible main body is provided with the high purity quartz wafer through bonding, so thatentering of impurities into liquid silicon is prevented, and silicon ingot yield is increased; in the demoulding silicon nitride coating layer, an adopted demoulding silicon nitride solution is highin beta crystal phase silicon nitride content, so that it is beneficial for silicon ingot nucleation.

Owner:内蒙古上航新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com