Preparation method of organic modified barium titanate nano particle and preparation method of quantum dot optical film

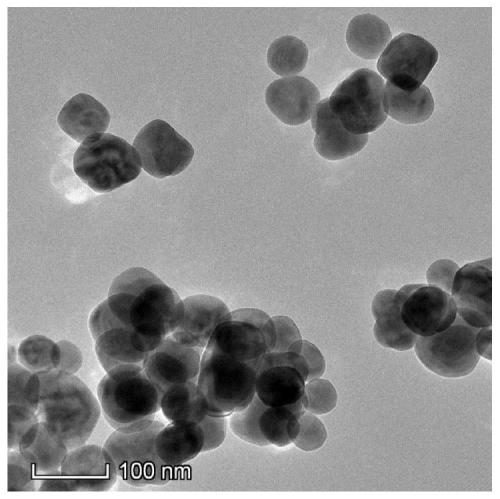

A nanoparticle and barium titanate technology, which is applied in nano optics, nanotechnology, nanotechnology, etc., can solve the problems that affect the uniformity of quantum dot optical film, easy aggregation, precipitation, etc., and achieve good scattering ability and high refraction rate, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

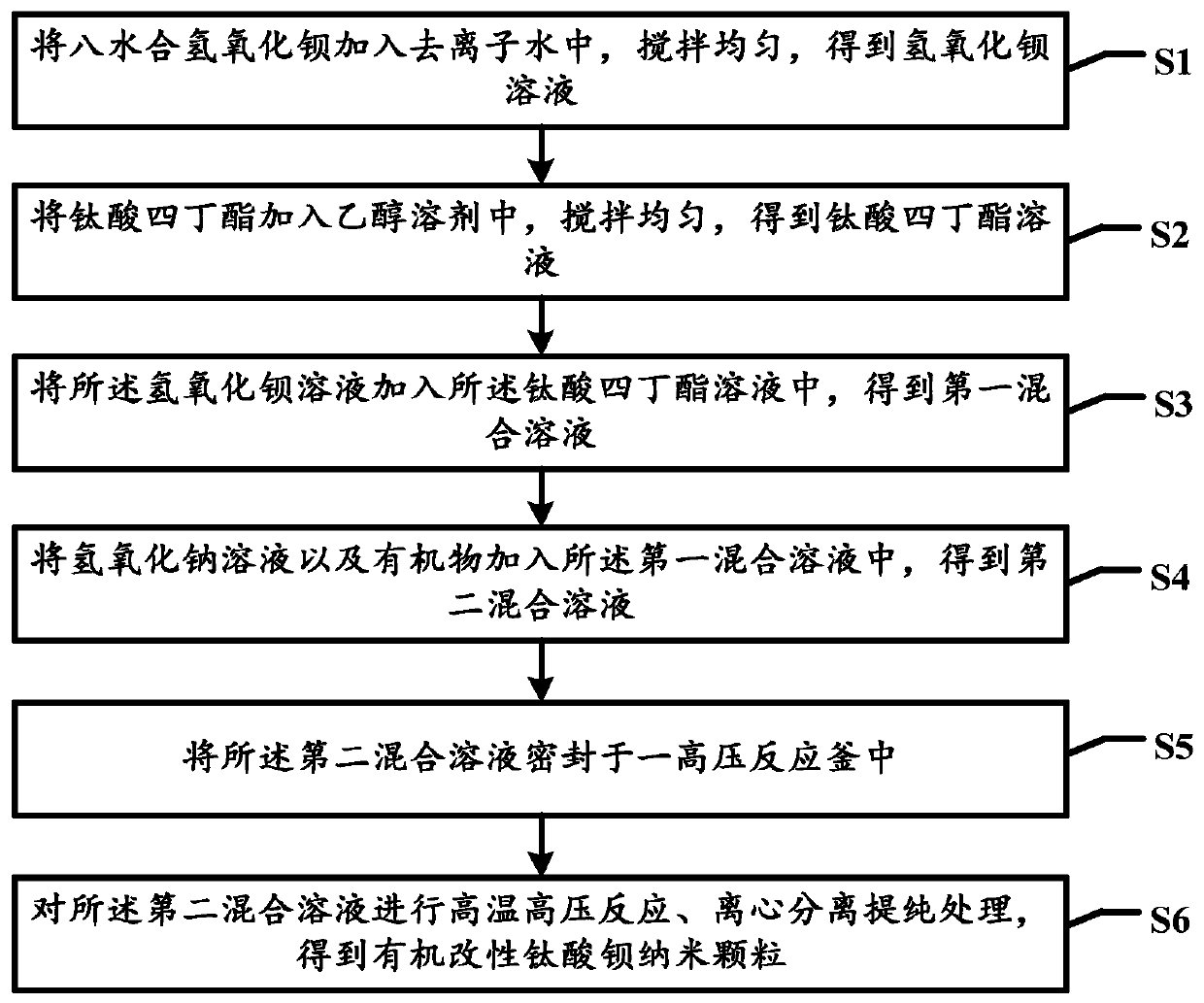

[0030] like figure 1 As shown, the present application provides a method for preparing organically modified barium titanate nanoparticles, including the following steps S1)-S6).

[0031] S1) adding barium hydroxide octahydrate into deionized water and stirring evenly to obtain a barium hydroxide solution.

[0032] S2) adding tetrabutyl titanate into ethanol solvent, stirring evenly to obtain tetrabutyl titanate solution.

[0033] S3) adding the barium hydroxide solution into the tetrabutyl titanate solution to obtain a first mixed solution, the molar ratio of titanium ions to barium ions is 1:1.

[0034] S4) Adding sodium hydroxide solution and organic matter into the first mixed solution to obtain a second mixed solution, the organic matter contains carbon-hydrogen bonds and carbon-oxygen bonds. In this embodiment, the carbon-oxygen bond of the organic matter may be a carbon-oxygen single bond or a carbon-oxygen double bond. The organic matter is acrylic acid series, COOH-...

Embodiment 1

[0044] This embodiment provides a method for preparing organically modified barium titanate nanoparticles, including the following steps S11)-S18). Wherein, the organic matter is acrylic acid series, and the acrylic acid series includes any one of methacrylic acid and sodium polymethacrylate. This embodiment takes methacrylic acid as an example to describe in detail.

[0045] S11) Add 200.0 mg of barium hydroxide octahydrate into 15 mL of deionized water, and stir evenly to obtain a barium hydroxide solution. Specifically, the barium hydroxide octahydrate is added into ionized water at a temperature of 50-100° C., and stirred evenly to obtain a barium hydroxide solution.

[0046] S12) Add 215.8 mg of tetrabutyl titanate into 15 mL of ethanol solvent, and stir evenly to obtain a tetrabutyl titanate solution. In this embodiment, adding the ethanol solvent in order to prevent the tetrabutyl titanate from being directly hydrolyzed in the air requires operation in a glove box with...

Embodiment 2

[0058] This example provides a method for preparing organically modified barium titanate nanoparticles and a method for preparing a quantum dot optical film, including most of the technical solutions in Example 1. The difference is that the organic compound is replaced by acrylic acid series with COOH -(CH 2 )n-COOH series, the COOH-(CH 2 ) n-COOH series of malonic acid, succinic acid, glutaric acid, azelaic acid, pimelic acid, this embodiment will use glutaric acid as an example to describe in detail.

[0059] Specifically, in the second mixed solution preparation step of the method for preparing organically modified barium titanate nanoparticles, 1 mol / L sodium hydroxide solution and 100 mg glutaric acid were added to the first mixed solution to obtain the second mixed solution. Two mixed solutions. Wherein, the glutaric acid contains carbon-hydrogen bonds and carbon-oxygen bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com