Patents

Literature

52results about How to "Promote mutual mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly industrial oil stain cleaning agent and preparing method thereof

ActiveCN106318692AGood oil washing effectReduce heavy metal contentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsManganeseCleansing Agents

An environment friendly industrial oil stain cleaning agent is prepared from, by weight, 3.5 parts of sodium carbonate, 7.6 parts of ethylene diamine tetraacetic acid, 3 parts of sodium citrate, 7.5 parts of sodium alcohol ether sulphate, 4 parts of amine oxide, 1.4 parts of polyquaternium, 2 parts of sodium dodecylbenzenesulfonate, 3.6 parts of isopropyl alcohol, 3.4 parts of polyethyleneglycol, 2.4 parts of corrosion inhibitor, 1.5 parts of foam suppersor and 60 parts of water. The cleaning agent of the invention has high oil removal efficiency, free of ions of such heavy metals as manganese and chromium, chloridion, phosphorus and other toxic and harmful components. It is biodegradable, has no pollution to the environment and will not produce toxic or harmful gas during utilization. It will not cause human injury or environmental pollution. The corrosion rate caused by the cleaning agent to devices is very low, thus prolong the service life of devices.

Owner:南京南炼宏泰技术开发有限公司

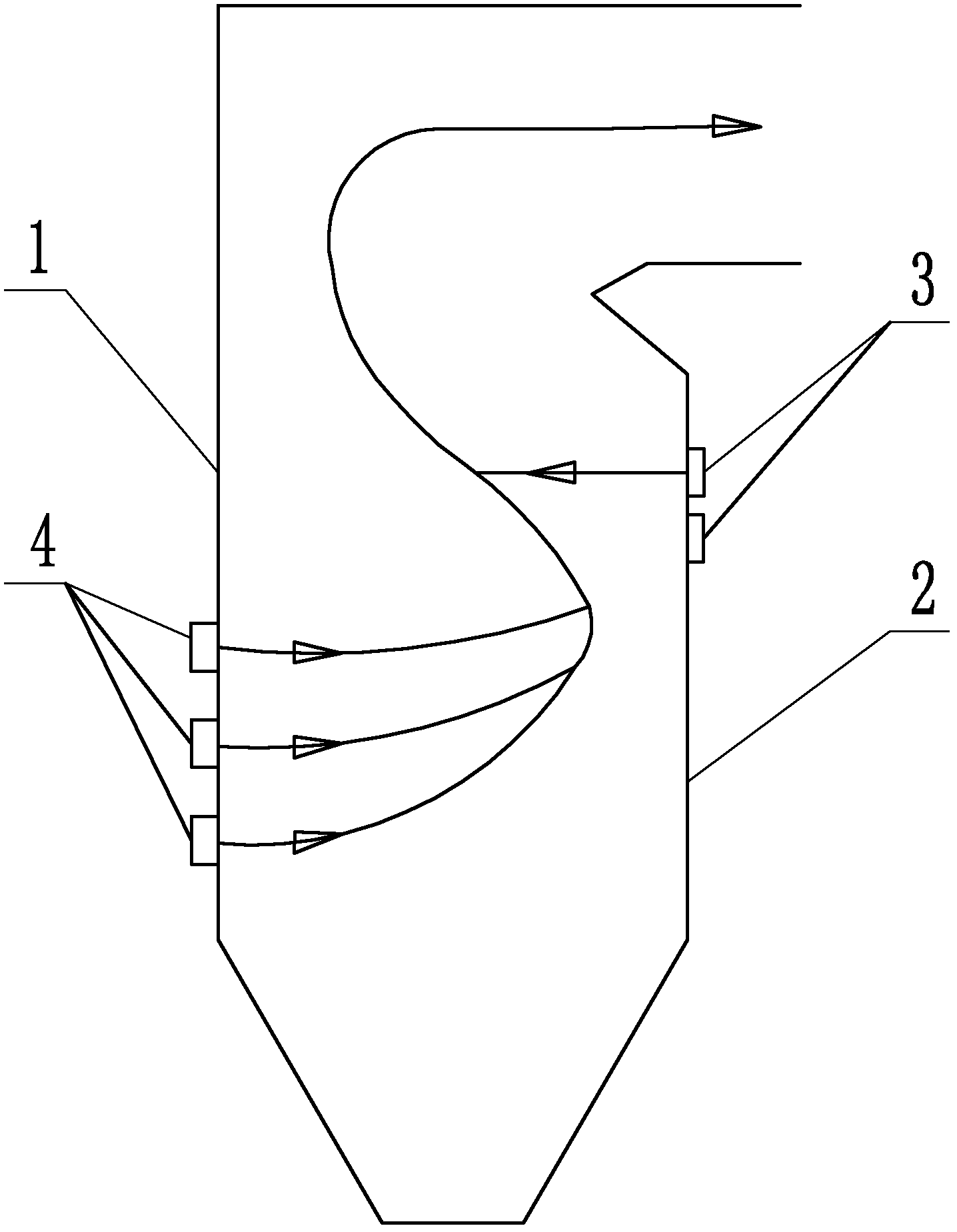

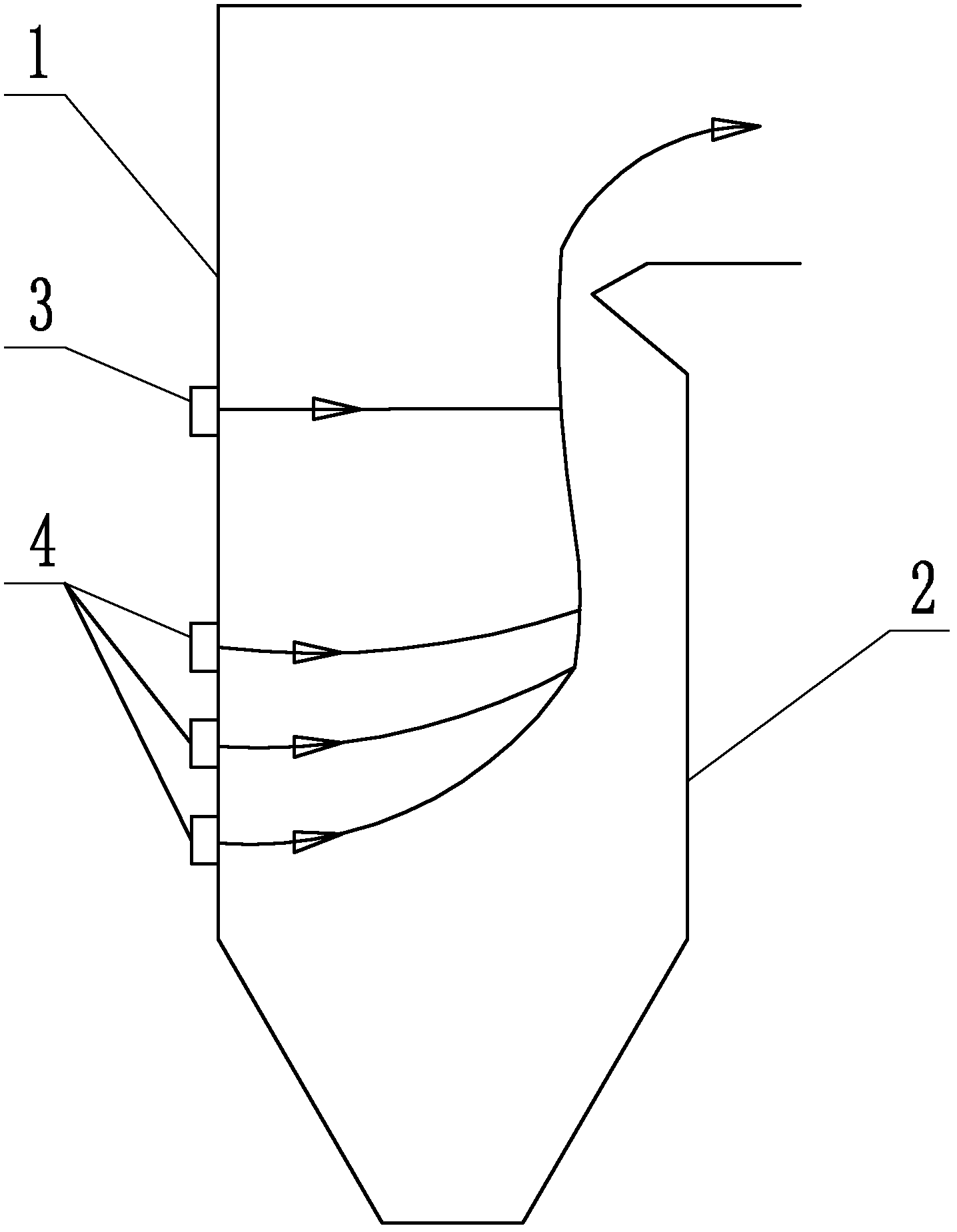

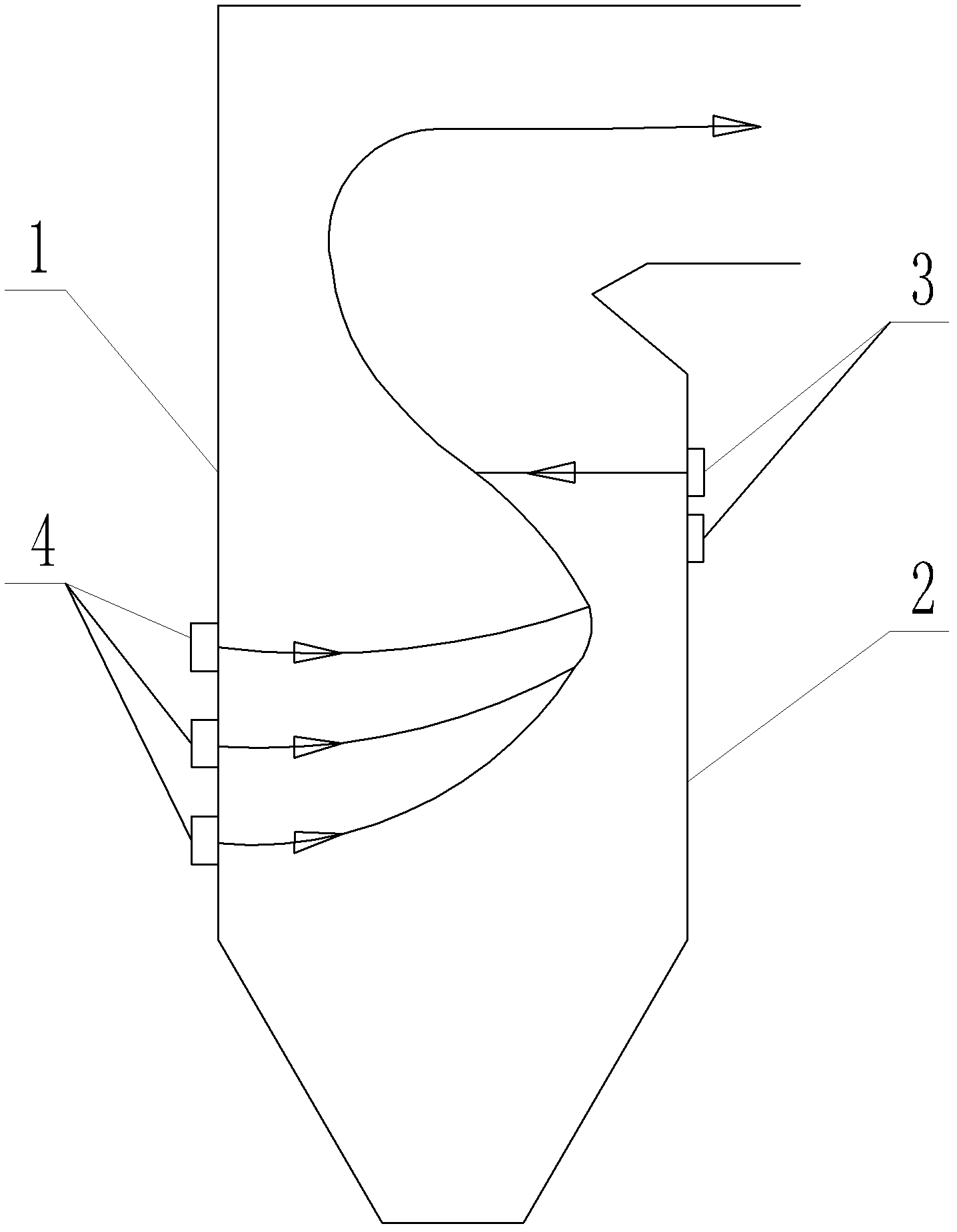

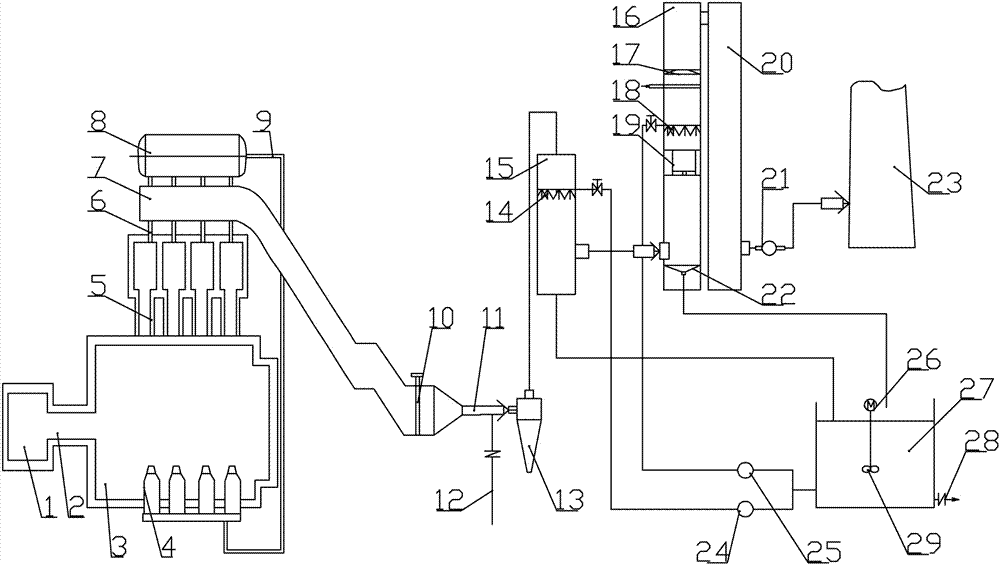

Cyclone burner and air burnout arrangement structure for boiler

InactiveCN102620285AReduce carbon content in fly ashImprove operational efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion

A cyclone burner and an air burnout arrangement structure for a boiler relate to cyclone burners and air burnout arrangement structures, and solve the problems of low boiler combustion efficiency and intensification of rear wall slagging and high temperature corrosion of an existing air burnout arrangement structure with the cyclone burner arranged on a front wall. An air burnout spout is arranged on the rear wall of the boiler and positioned laterally above the cyclone burner. The cyclone burner and the air burnout arrangement structure for the boiler are used for reducing unburned carbon in flue dust of the boiler and improve operating efficiency of the boiler.

Owner:HARBIN INST OF TECH

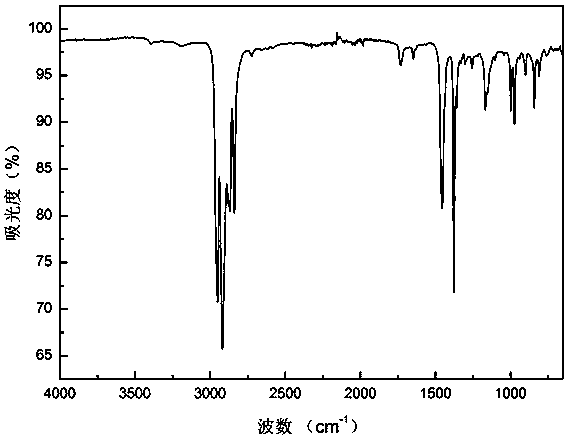

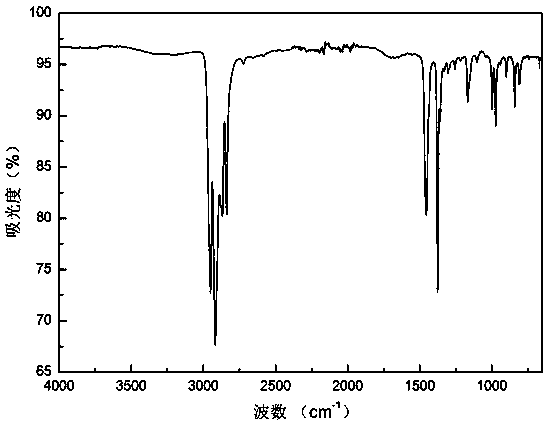

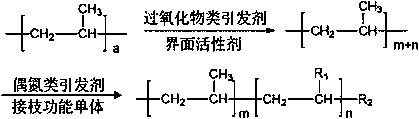

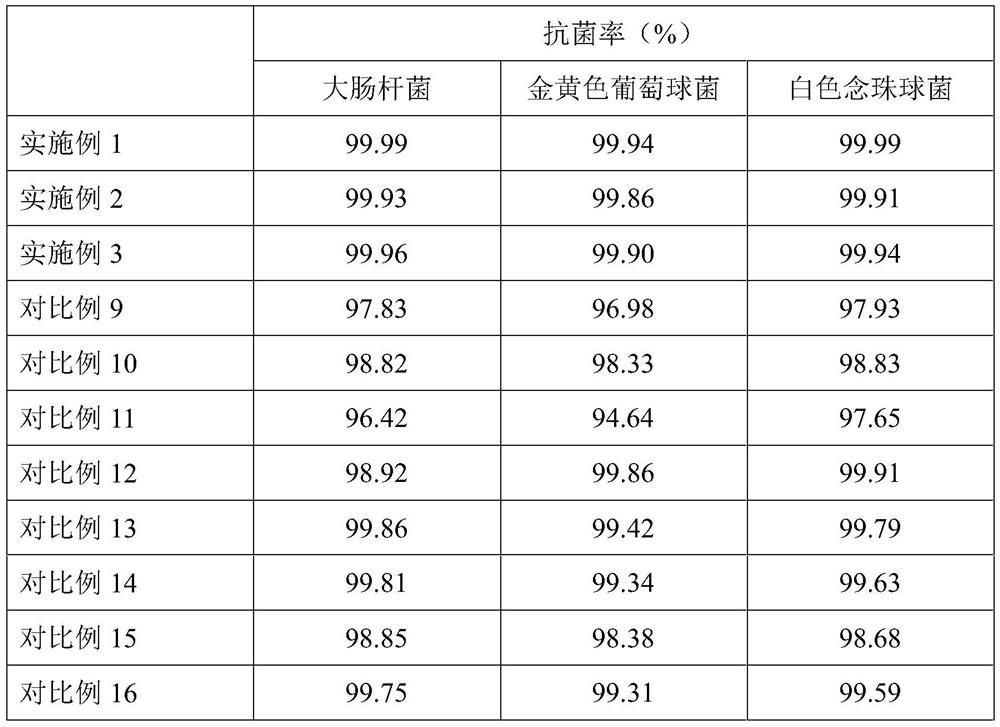

Polypropylene-based composite material and preparation method thereof

The invention discloses a polypropylene-based composite material and a preparation method thereof. The polypropylene-based composite material is prepared from the following materials by taking the weight part of polypropylene as 100 parts: 10 to 100 parts of polyamide, 2 to 30 parts of functionalized polypropylene compatilizer, 0.5 to 5 parts of lubricant, 0.5 to 5 parts of plasticizer and 0.01 to1 part of stabilizing agent. The novel functionalized polypropylene compatilizer is added so that mutual mixing of the polypropylene and the polyamide can be promoted very well and the compatibilization effect is remarkable; an original shape of polypropylene powder can be kept through synthesis of the functionalized polypropylene compatilizer and the step of reprocessing and molding a subsequentmaterial is reduced; when the polypropylene-based composite material is blended and extruded, the temperature of each heating section and the rotary speed of a screw rod are regulated and controlled,and the dispersion of the functionalized polypropylene compatilizer in the polypropylene and the polyamide can be promoted to the extremely great extent, so that the compatibilization effect of the functionalized polypropylene compatilizer is displayed very well; a preparation process is simple and convenient and is suitable for large-scale industrial production.

Owner:义乌斌泰工艺品有限公司

A refreshing bath gel formula with moisturizing and skin care functions

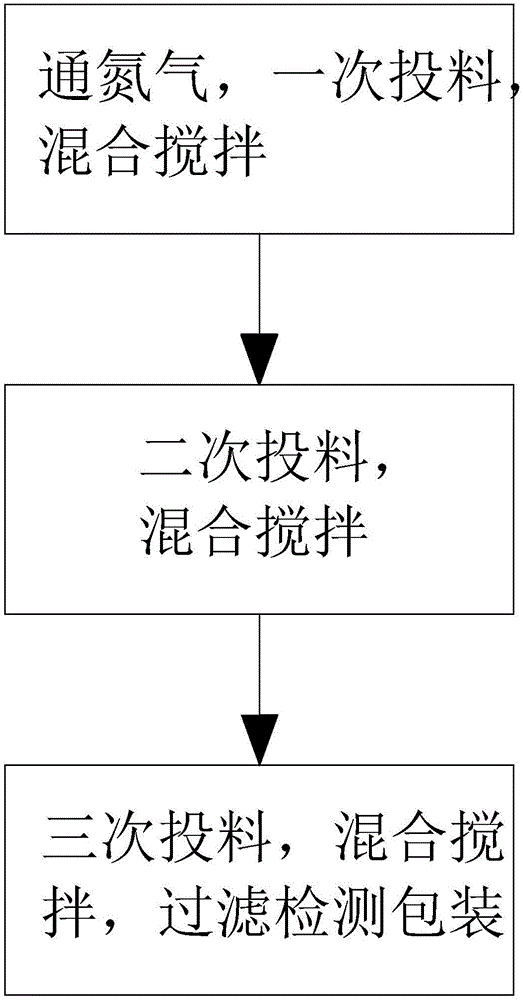

InactiveCN109223686APromote mutual mixingSmall particle sizeCosmetic preparationsToilet preparationsAdditive ingredientGrape seed

The invention discloses a refreshing bath gel formula with moisturizing and skin care functions, which comprises the following raw materials in parts by weight: green tea powder 10-14 part, aloe extract 10-14 part, mint leaf 10-14 part, grape seed 6-10 part, sweet orange extract 10-14 part, milk 2-6 part, pearl powder 3-7 part, bamboo charcoal powder 3-7 part, glycerin 8-12 part, natural beeswax 8-12 part, vitamin E 1-5 part, emulsifier 3-9 parts, moisturizer 3-7 part, diatomaceous earth 3-7 parts, flavor 1-5 part, deionized water 2-10 part. A method for preparing that beeswax comprises weighing green tea powder, mint leaf, grape seed, milk, pearl powder, bamboo charcoal powder, glycerol, natural beeswax, vitamin E, emulsifier, humectant, diatomaceous earth, essence and deionized water according to the weight ratio. The refreshing bath gel formula is reasonable in design and convenient in manufacture, can effectively advance the ingredients in the plant raw materials, is beneficial tothe bath gel prepared by natural plants, reduces the sensitive reaction of the skin, can effectively nourish the skin, and improves the use experience of the user.

Owner:陈晓霞

Pervious concrete and preparation method thereof

The invention provides pervious concrete and a preparation method thereof. The content of each component in raw materials is as follows: 21-34 parts of ore coarse aggregates, 23-27 parts of fine sand,17-24 parts of Portland cement, 16-23 parts of diatomite, 13-17 parts of a polymer cementing material, 2-4 parts of phosphorus slag fine powder, 1-3 parts of iron powder, 8-13 parts of phenolic fibers and 6-15 parts of polypropylene fibers. Through the preparation by using the preparation method, the adhesion degree of all the components in the raw materials can be enhanced; gaps are generated between the phenolic fibers and the polypropylene fibers, and facilitate water permeation; and the pervious concrete can be further promoted in the actual building industry.

Owner:山东鲁盛新能源有限公司

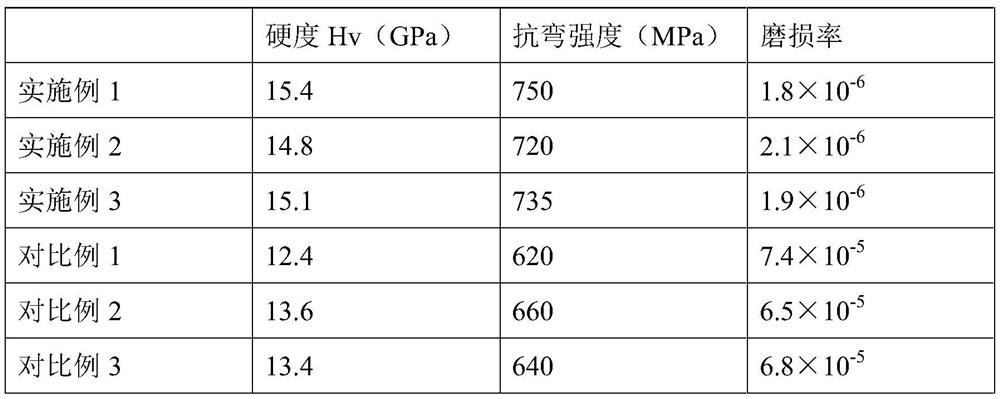

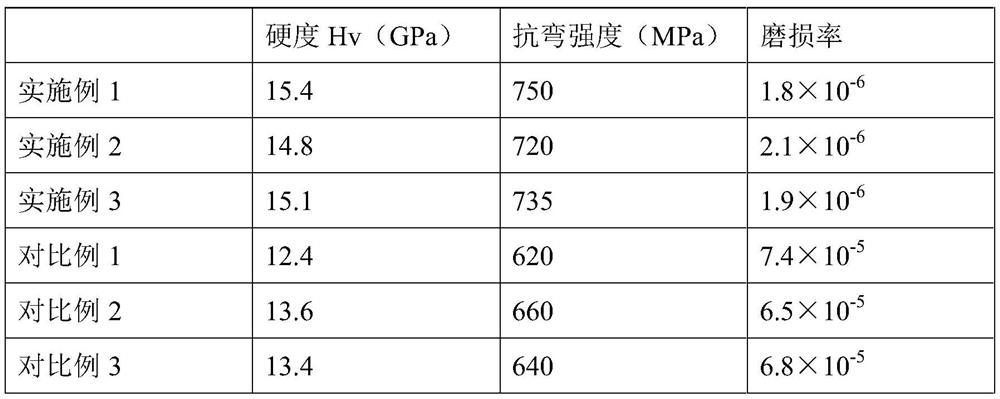

Antibacterial wear-resistant domestic ceramic and preparation method thereof

PendingCN114195388AIncreased strength and wear resistancePromotes non-abnormal swellingSodium triphosphateSodium lignosulfonate

The invention belongs to the technical field of domestic ceramics, and particularly relates to an antibacterial wear-resistant domestic ceramic and a preparation method thereof. The antibacterial wear-resistant domestic ceramic comprises a domestic ceramic green body and a glaze layer, wherein the glaze layer is prepared from the following raw materials in parts by weight: 35-45 parts of zircon sand; 15 to 20 parts of baddeleyite; 4-8 parts of magnesite; 2-6 parts of calcite; 1-3 parts of molybdenum powder; 2-4 parts of erbium oxide; 2-4 parts of neodymium oxide; 3-7 parts of zinc oxide; 3-7 parts of tungsten oxide; 2-4 parts of silver powder; 3-5 parts of sodium lignin sulfonate; 3-5 parts of sodium tripolyphosphate; and 25-35 parts of water. According to the antibacterial wear-resistant domestic ceramic disclosed by the invention, through mutual matching of the components and control of the preparation method, the obtained product has excellent wear resistance and antibacterial property.

Owner:苏长全

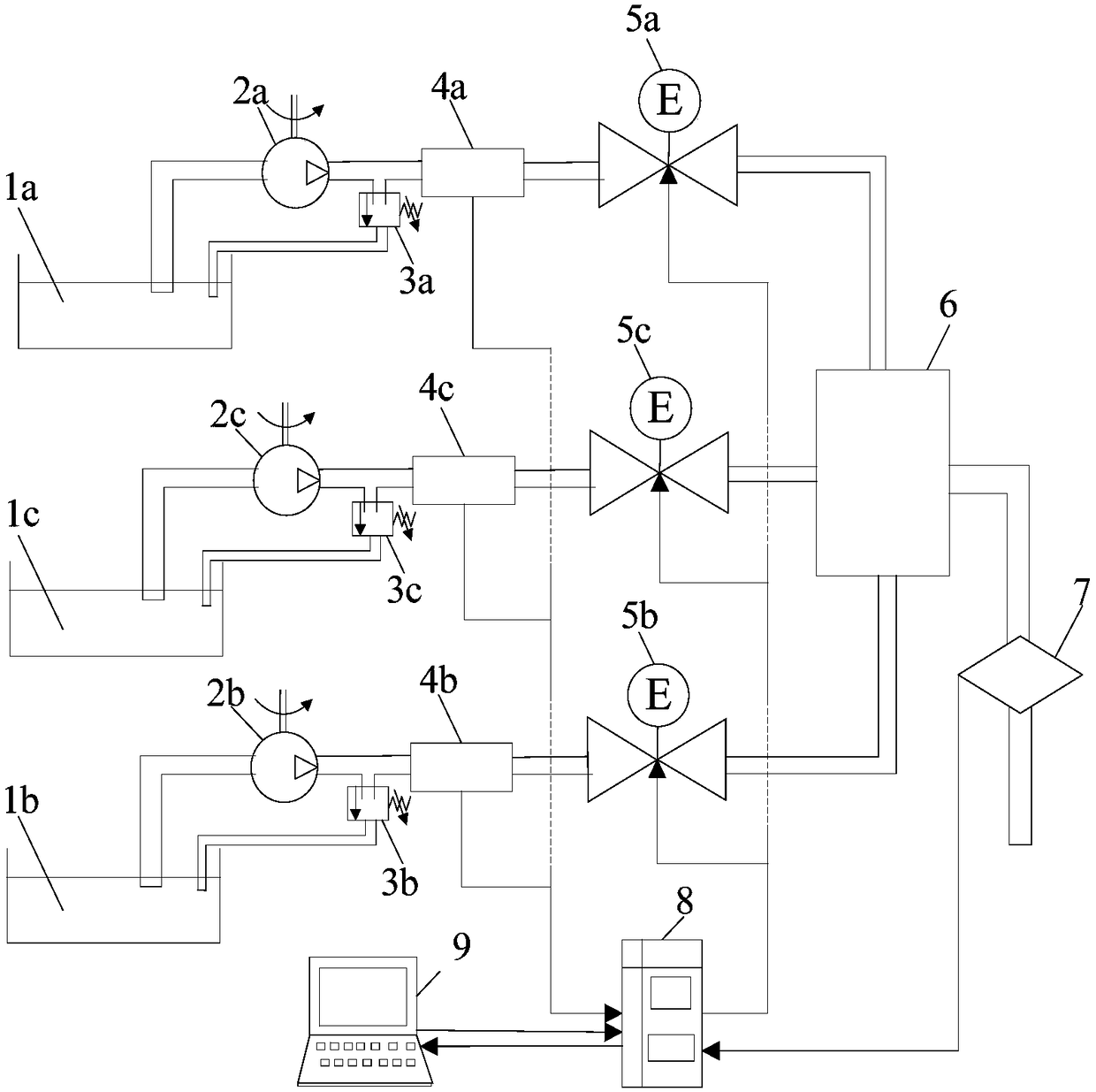

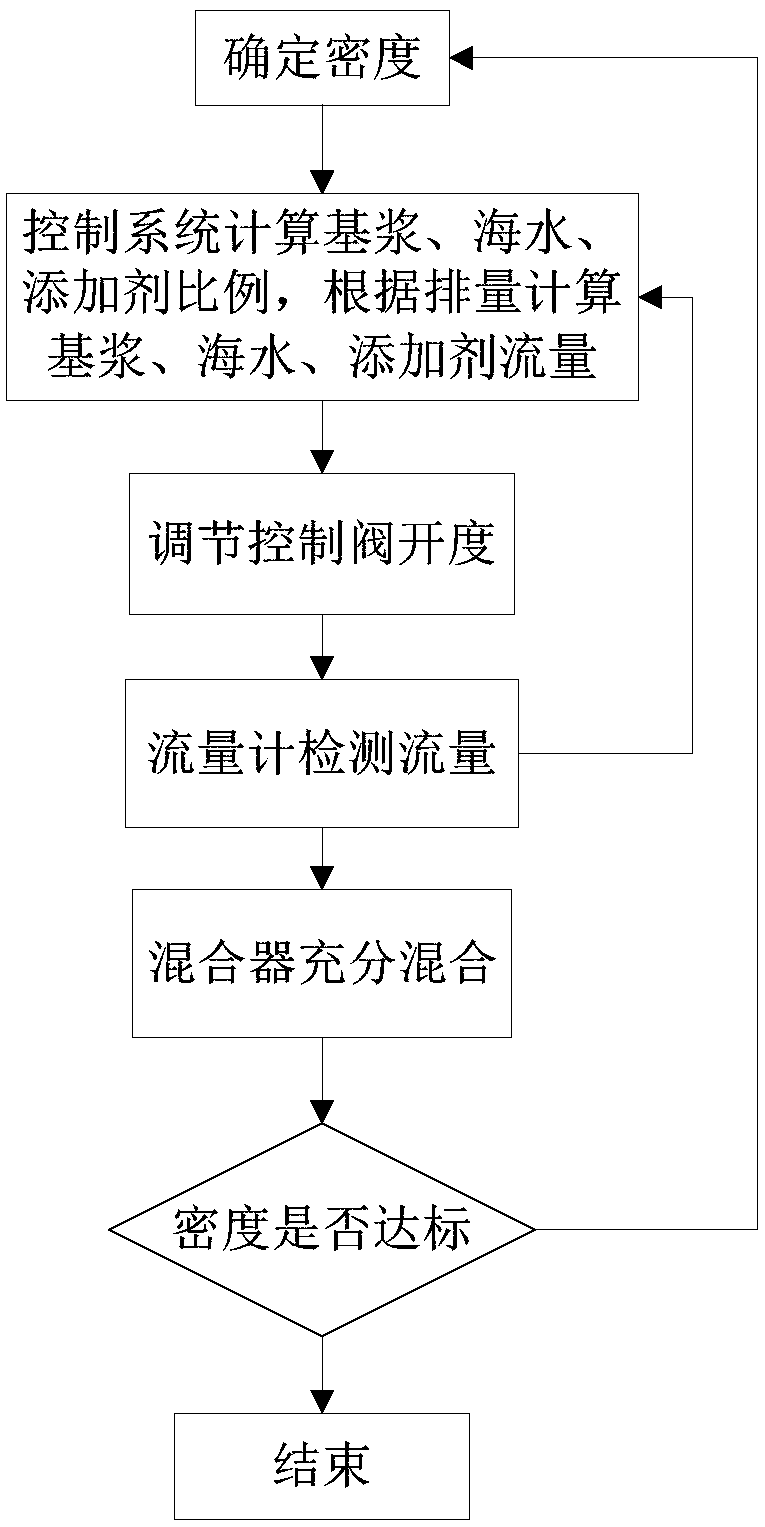

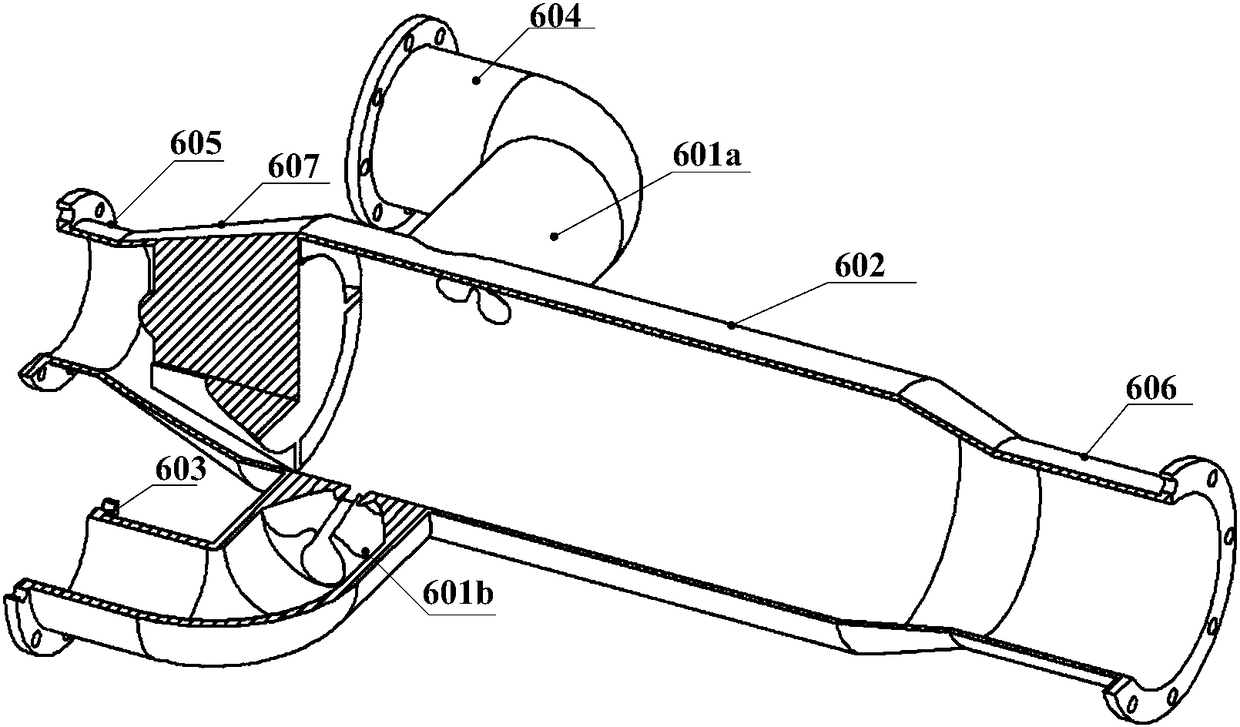

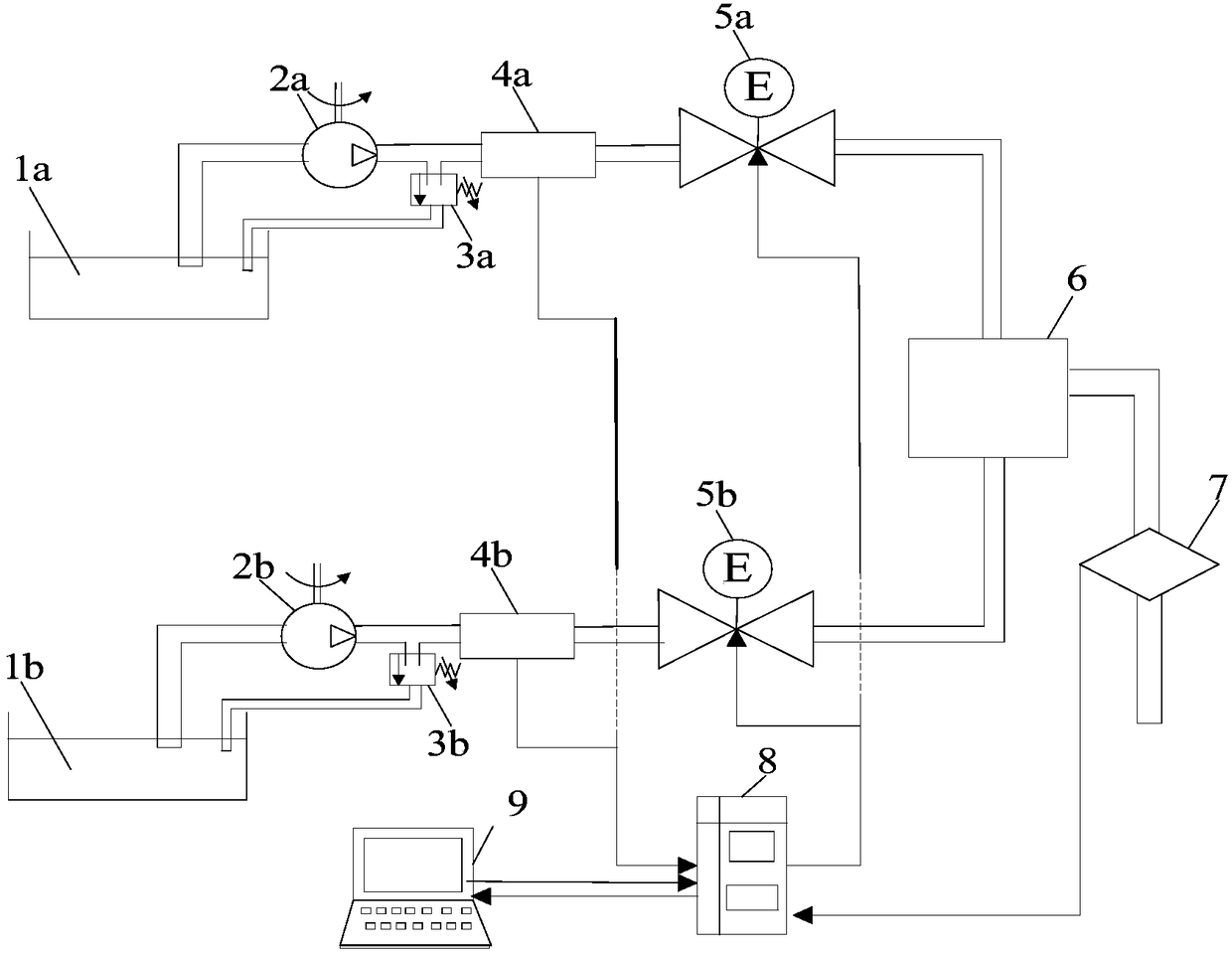

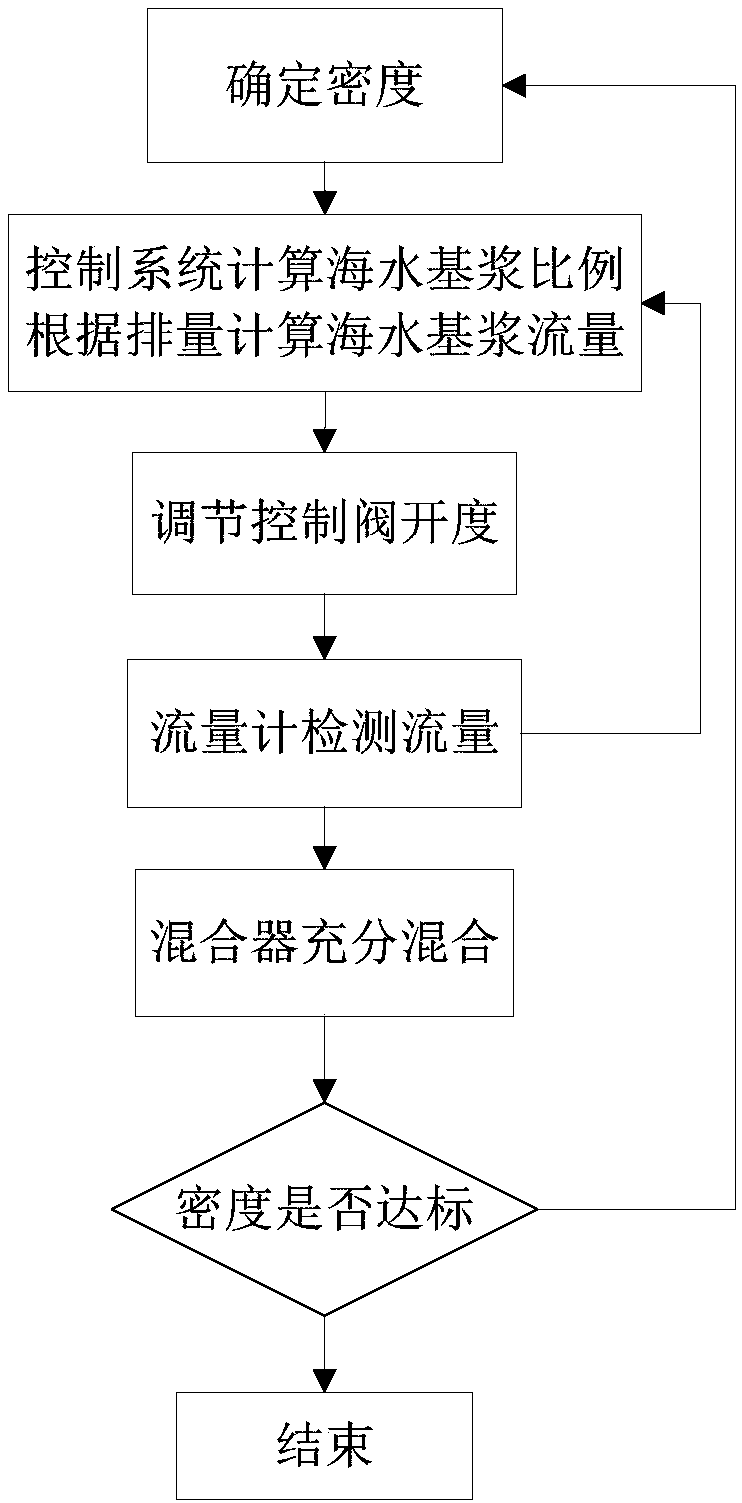

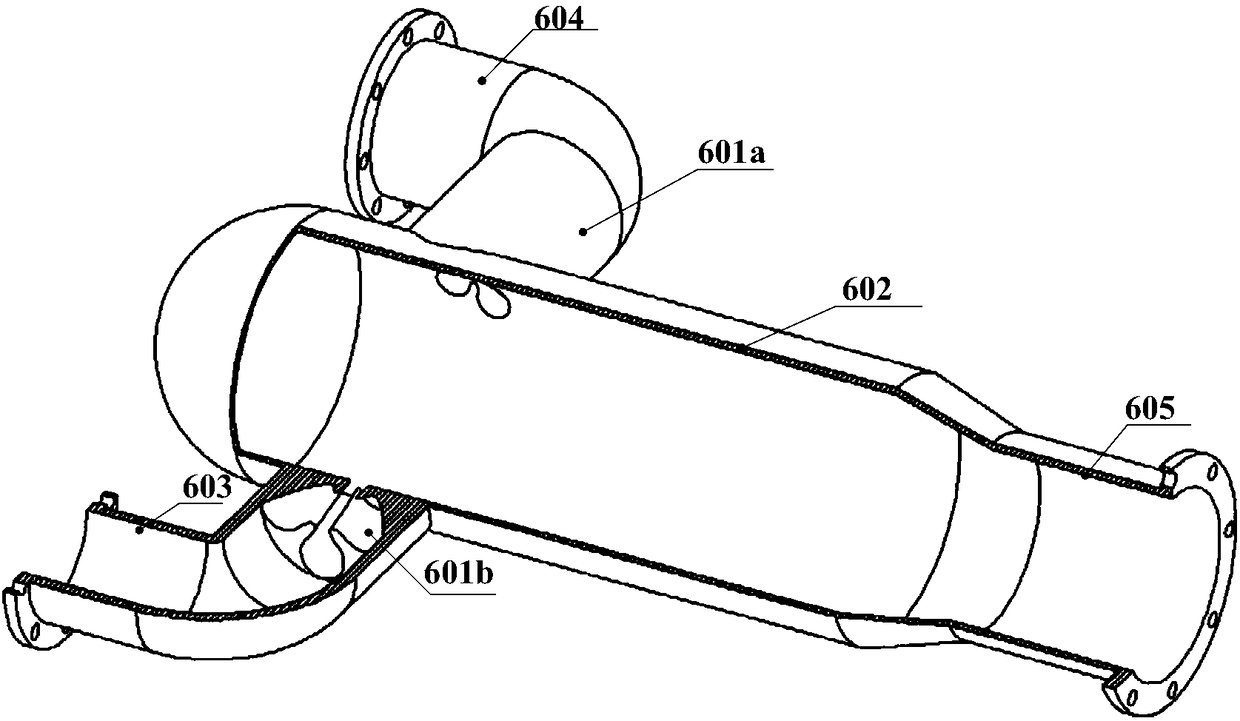

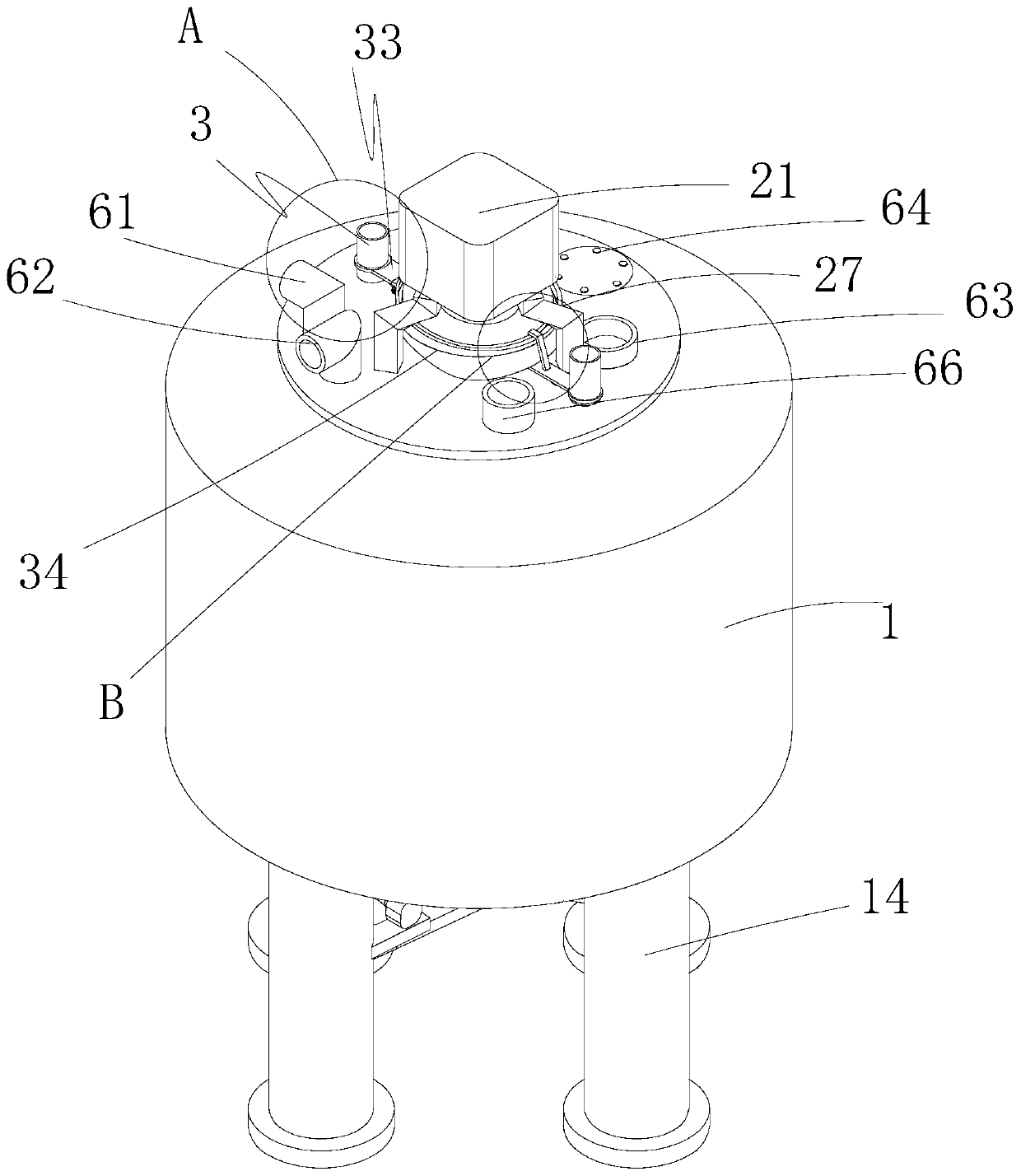

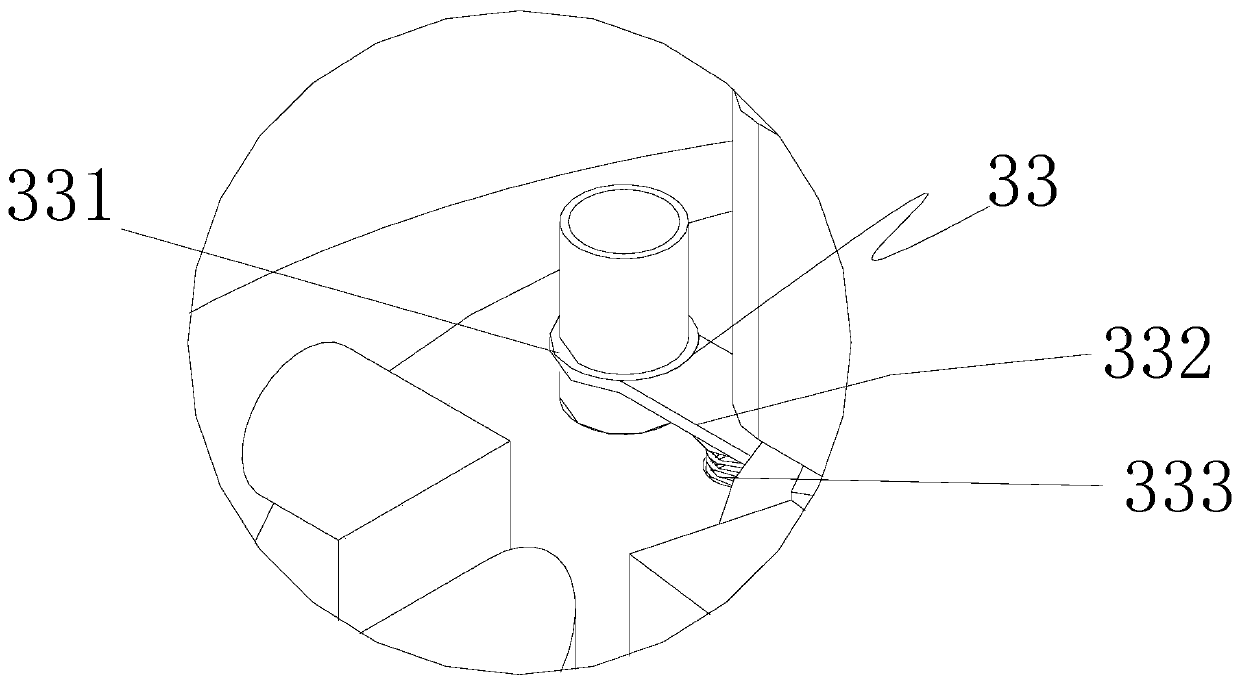

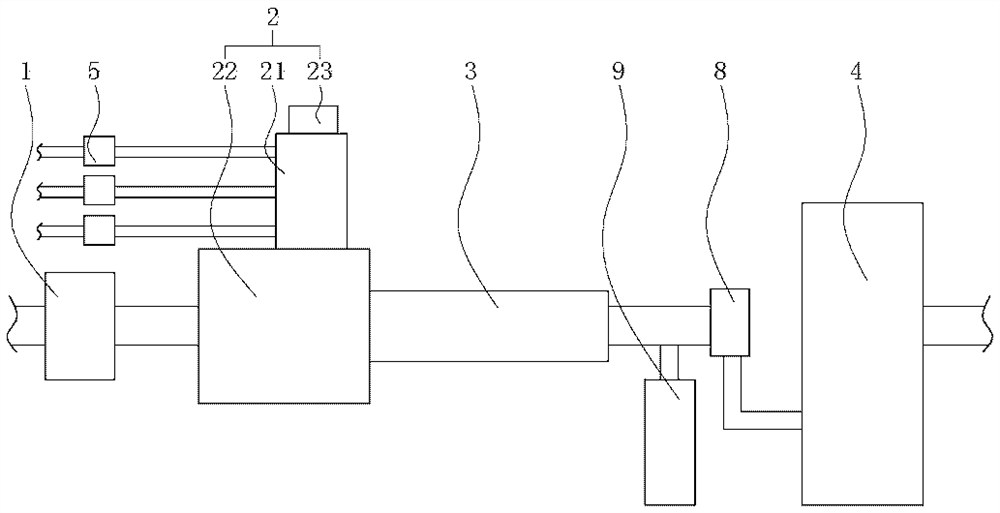

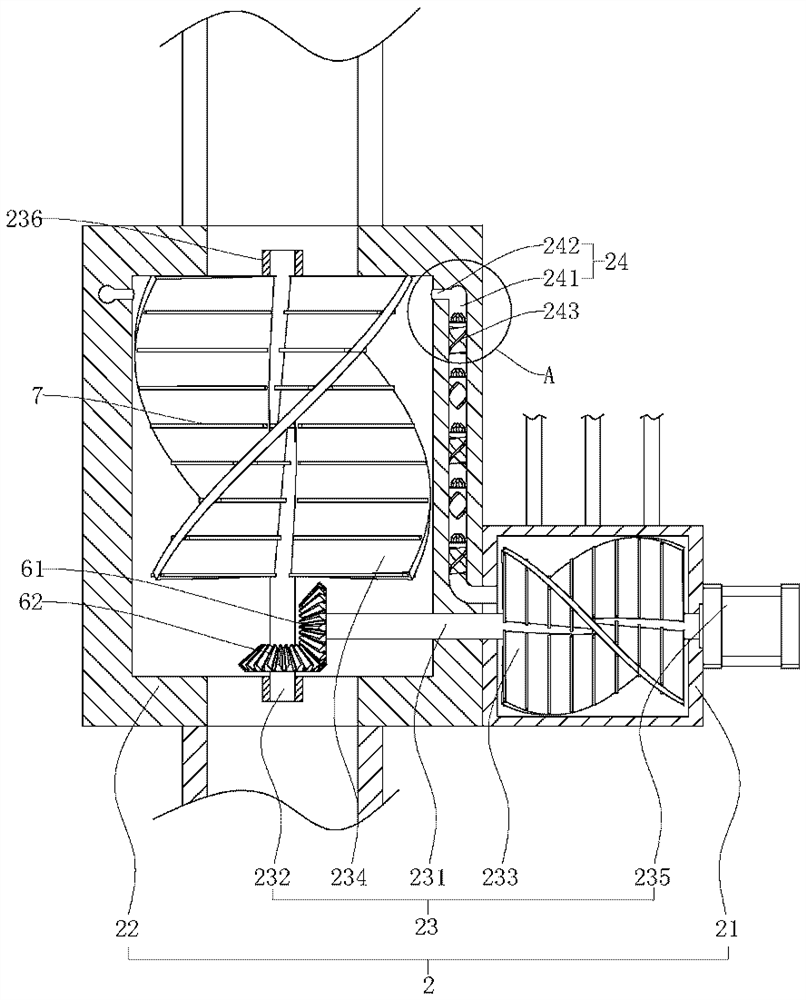

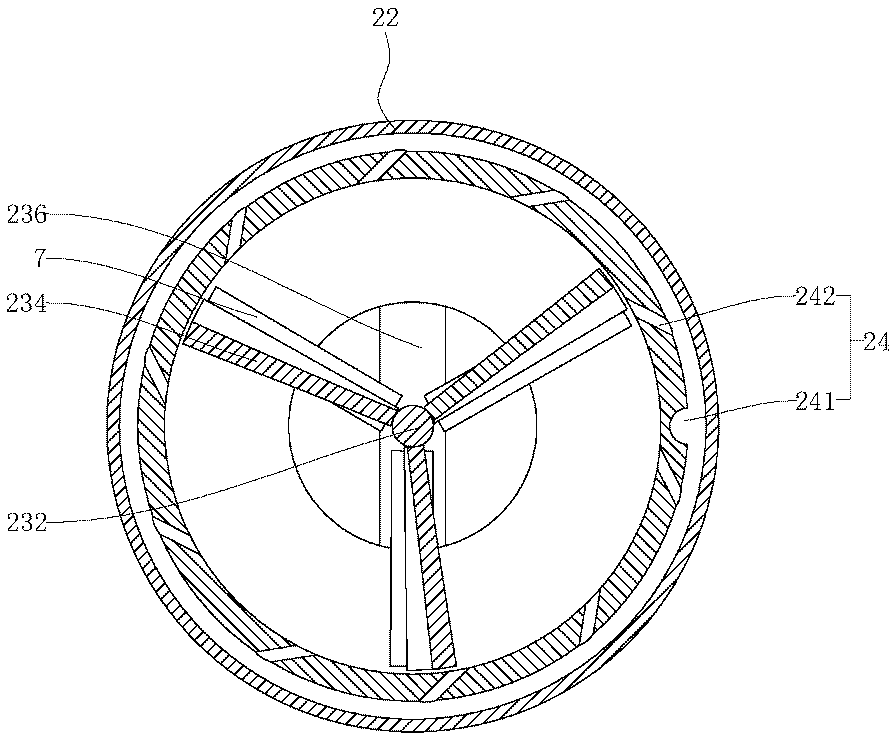

Self-feedback three-phase-system well drilling liquid mixing system and method for mixing well drilling liquid

The invention relates to a self-feedback three-phase-system well drilling liquid mixing system which comprises a mixing device, a seawater pool, a basic mud pool and an additive pool. The seawater pool is connected with the mixing device through a first pipeline, the basic mud pool is connected with the mixing device through a second pipeline, and the additive pool is connected with the mixing device through a third pipeline. The seawater pool contains seawater and is used for supplying seawater raw materials to the first pipeline, the basic mud pool contains basic mud and is used for supplying basic mud raw materials to the second pipeline, and the additive pool contains additives and is used for supplying additive raw materials to the third pipeline. The seawater, the basic mud and the additives enter the mixing device to be mixed and then enter a mud pool or a mud pump manifold through a density self-feedback module. By additionally arranging the density self-feedback module of theself-feedback well drilling liquid mixing system, the density of well drilling liquid can be more accurate, a flowmeter can further be corrected through comparison of the detected density and the setor designed density, and the system can achieve mixing of the raw materials of various proportions under the situation that the pump power is not controlled.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Wear-resistant domestic ceramic and preparation method thereof

ActiveCN112174697AImprove the toughness of the glaze layerImprove resistance performanceClaywaresCeramic glazeTitanium carbide

The invention discloses a wear-resistant domestic ceramic and a preparation method thereof. The wear-resistant domestic ceramic comprises a domestic ceramic body and a glaze layer, wherein the glaze layer is prepared from the following raw materials in parts by weight: 30-40 parts of zircon sand, 10-15 parts of baddeleyite, 5-10 parts of nepheline syenite, 3-6 parts of titanium carbide powder, 3-5parts of titanium dioxide, 4-6 parts of lutetium oxide, 2-4 parts of tungsten powder, 2-4 parts of polyvinyl alcohol with mass fraction being 5 wt%, 2-4 parts of glycerin, and 20-30 parts of water. According to the wear-resistant domestic ceramic disclosed by the invention, through synergistic cooperation of the components, the obtained wear-resistant domestic ceramic is flat and smooth in glazesurface and good in texture, and has excellent hardness, bending strength and wear resistance.

Owner:潮州市欧博瓷业有限公司

Self-feedback two-phase system drilling fluid mixing system and method of mixing drilling fluid

The invention relates to a self-feedback two-phase system drilling fluid mixing system. The self-feedback two-phase system drilling fluid mixing system comprises a mixer, a sea water pool and a base slurry pool; the sea water pool is connected to the mixer through a first pipeline, and the base slurry pool is connected to the mixer through a second pipeline. The sea water pool contains sea water and used for providing a sea water raw material for the first pipeline; the base slurry pool contains base slurry and used for providing a base slurry raw material for the second pipeline; the sea water and the base slurry enter a slurry pool or a slurry pump manifold through a density self-feedback module after being mixed in the mixer. Compared with the prior art, the self-feedback two-phase system drilling fluid mixing system is provided with the density self-feedback module which can not only make the density of mixed liquid more precise, but also calibrate a flowmeter by detecting the density and setting or designing density comparison, an overflow valve added between a pump and the flowmeter can make the system mix materials of various proportions in the state that the power of the pump is not controlled, and mixing is more efficient.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A wear-resistant daily-use ceramic and its preparation method

The invention discloses a wear-resistant ceramic for daily use and a preparation method thereof. The wear-resistant daily-use ceramics include a daily-use ceramic body and a glaze layer, and the glaze layer is made of the following raw materials in parts by weight: 30-40 parts of zircon sand, 10-15 parts of baddeleyite, and 5-10 parts of syenite, 3-6 parts of titanium carbide powder, 3-5 parts of titanium dioxide, 4-6 parts of lutetium oxide, 2-4 parts of tungsten powder, 2-4 parts of polyvinyl alcohol with a mass fraction of 5wt% 2-4 parts of glycerin, 20-30 parts of water. The wear-resistant daily-use ceramics of the present invention are obtained through synergistic cooperation of components, and the obtained wear-resistant daily-use ceramics have a smooth glazed surface, good texture, excellent hardness and bending strength, and excellent wear resistance.

Owner:潮州市欧博瓷业有限公司

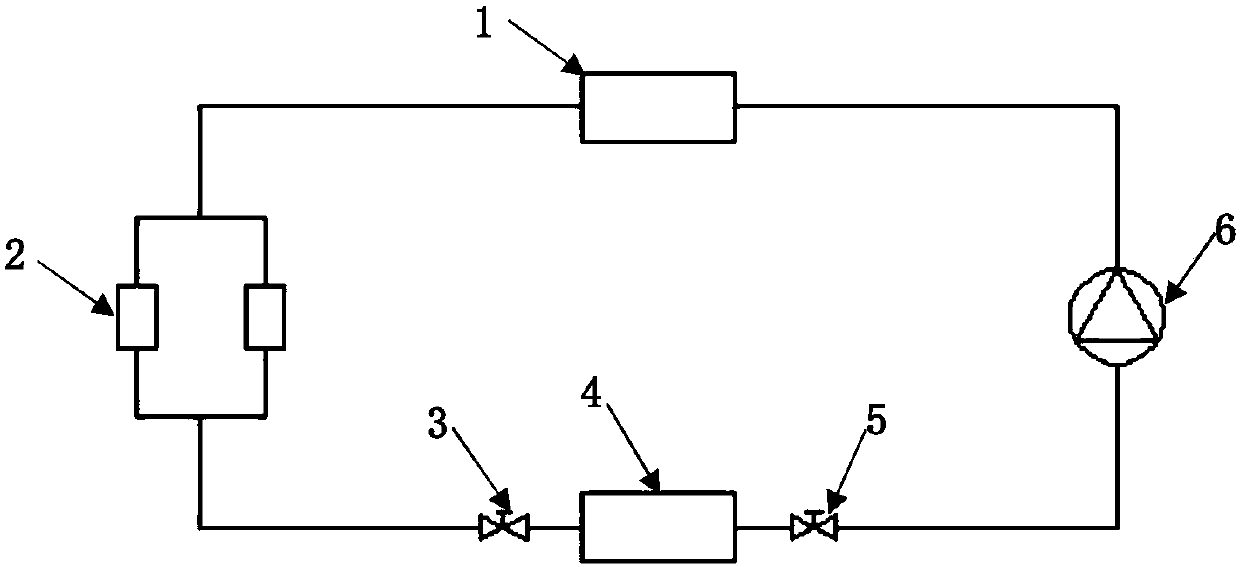

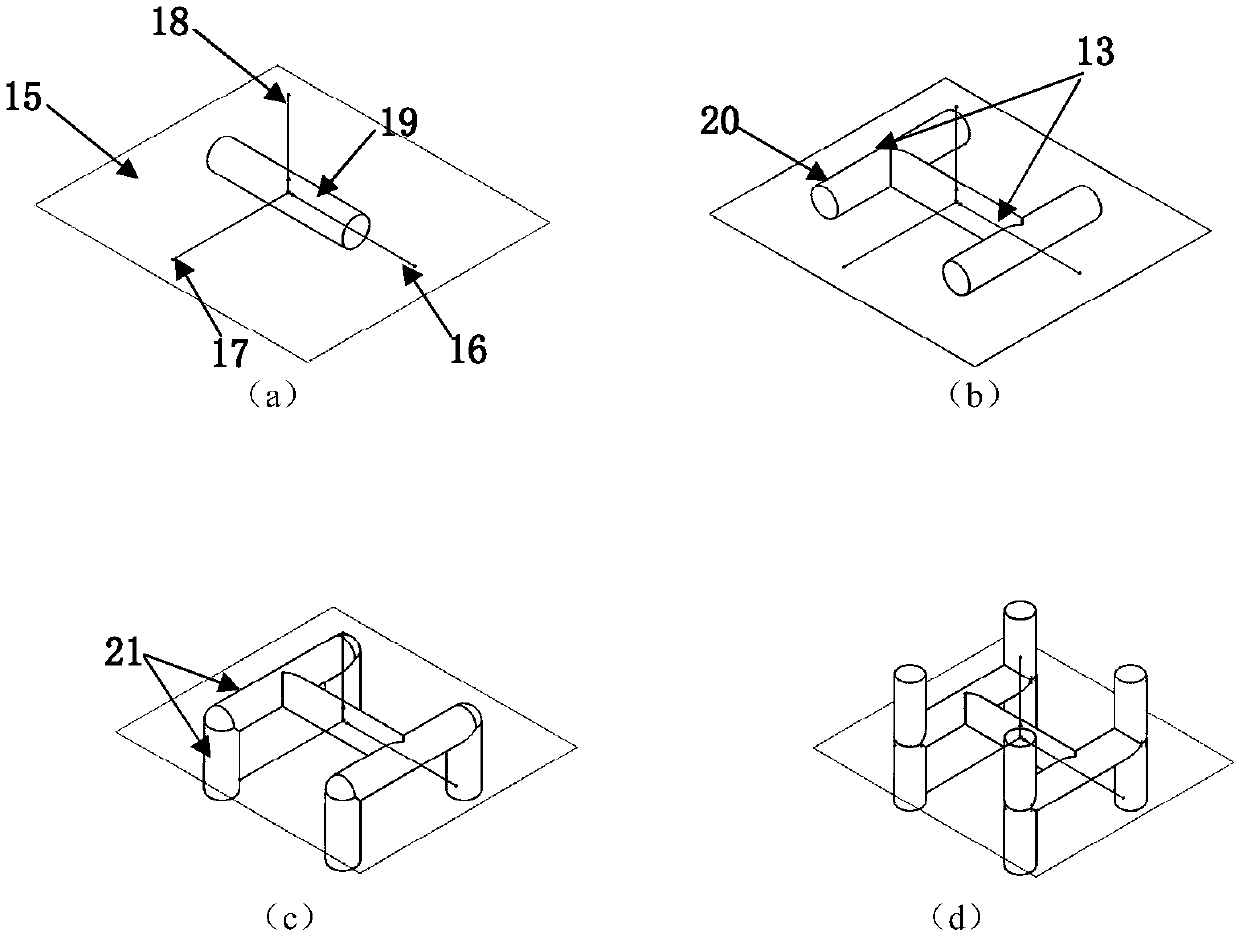

Phase change cold accumulation device

ActiveCN107560477AImprove heat transfer performancePrevent crystallizationHeat storage plantsLimited resourcesPower grid

The invention discloses a phase change cold accumulation device comprising a cold accumulation module and an outer circulation module. The outer circulation module comprises an air conditioning load,a water chilling unit, a water pump, a pressure stabilizing valve and a check valve. The cold accumulation module comprises a shell, a cold accumulation tank, a water inlet, a water outlet, water collection tanks, eutectic salt phase change materials and a three-dimensional network flow channel. The water inlet and the water outlet are formed in the shell. The cold accumulation tank is formed in the shell. The water collection tanks are formed in the two sides of the cold accumulation tank. The three-dimensional network flow channel is arranged in the cold accumulation tank. The spaces, exceptthe three-dimensional network flow channel, in the cold accumulation tank are filled with the eutectic salt phase change materials. Peak shifting and valley filling of electric power can be conducted, so that power grid safety is guaranteed, the efficiency of power generation equipment and power transmission and transformation equipment is improved, and limited resources are effectively utilized;and meanwhile, the operation cost of an air conditioning system is reduced, and intermittent work is well achieved.

Owner:SOUTHEAST UNIV

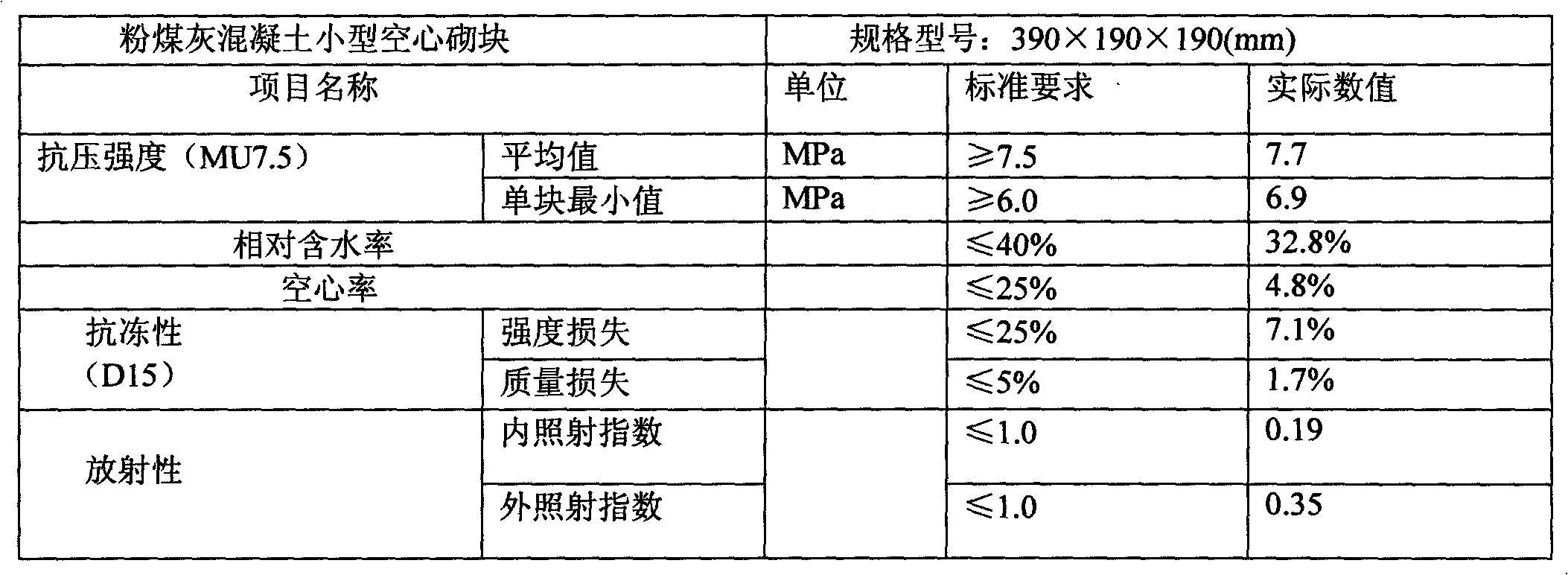

Fly ash concrete small hollow block and preparation method thereof

InactiveCN102432235AIncrease dosageHigh strengthSolid waste managementCeramic shaping apparatusThermal insulationFly ash brick

The invention relates to a fly ash concrete small hollow brick and a preparation method thereof, which are particularly suitable for a frame structure and high-rise building block filled wall, and belong to the field of building industry. Compared with the conventional preparation method for a fly ash block, the preparation method has the advantages that: the doping amount of fly ash is large, the common ash doping amount in China is 20 to 60 percent, and the ash doping amount in the preparation method is 80 percent; strength is high; the strength grade is more than or equal to MU7.5; wet-discharged fly ash is not required to be dried again, so that cost is saved; and any other additive except the fly ash is not required to be added, so that the current conditions that the doping amount of the solid waste fly ash in a building material block is small and the additive is needed are avoided. The fly ash concrete small hollow brick has the characteristics of high strength, energy conservation, thermal insulation, light weight, good sound insulation effect and waste recycling, is easy to widely use and popularize, and can be suitable for the frame structure and high-rise building block filled wall and the like, production cost is effectively reduced, and the construction cost of a building is reduced.

Owner:鹤壁福田舒布洛克建材有限公司

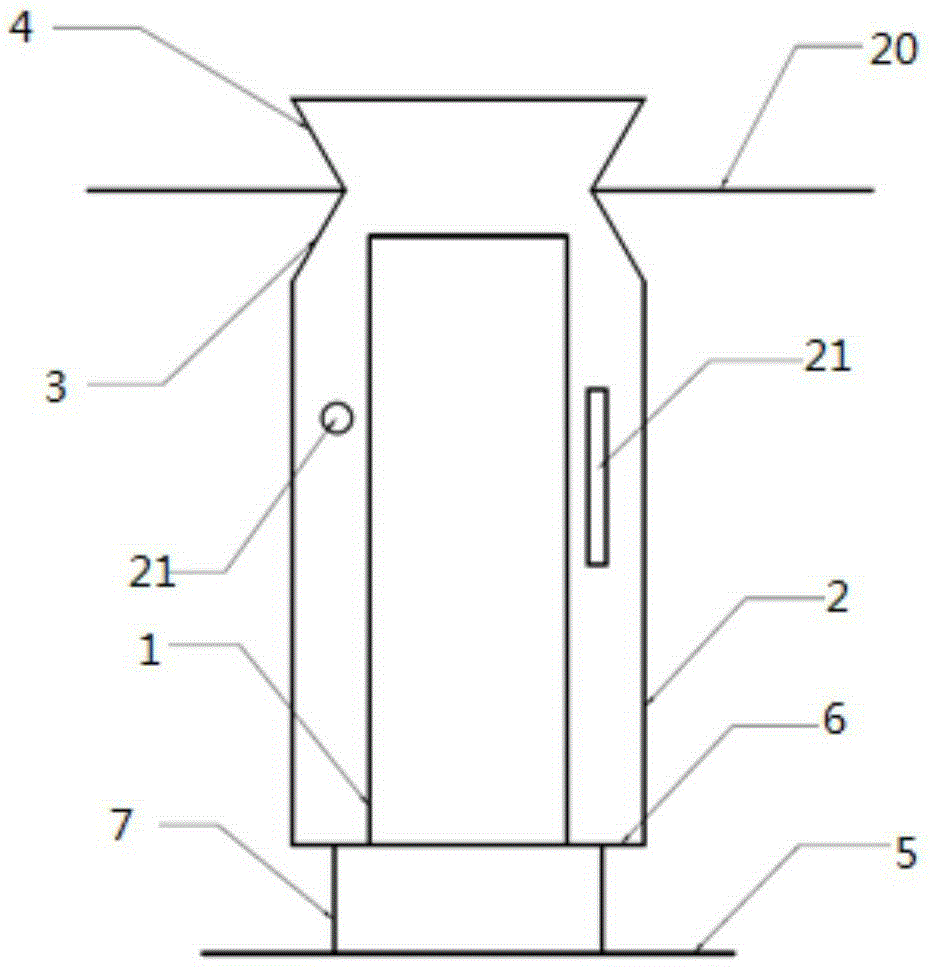

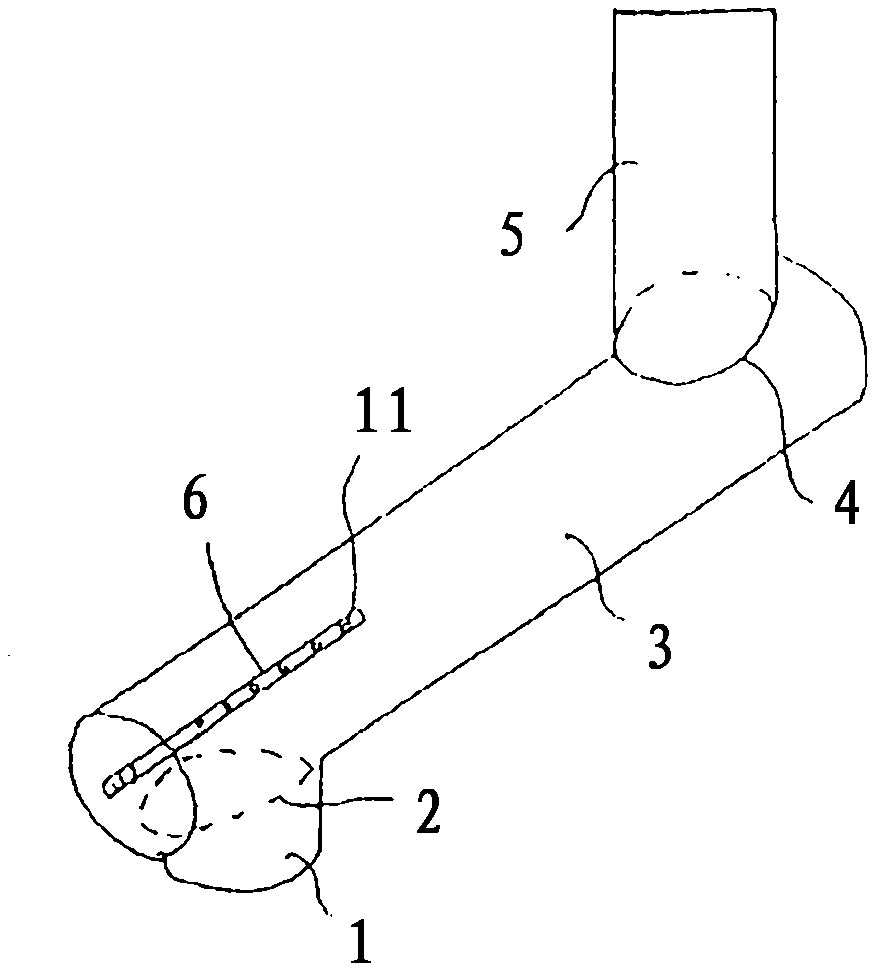

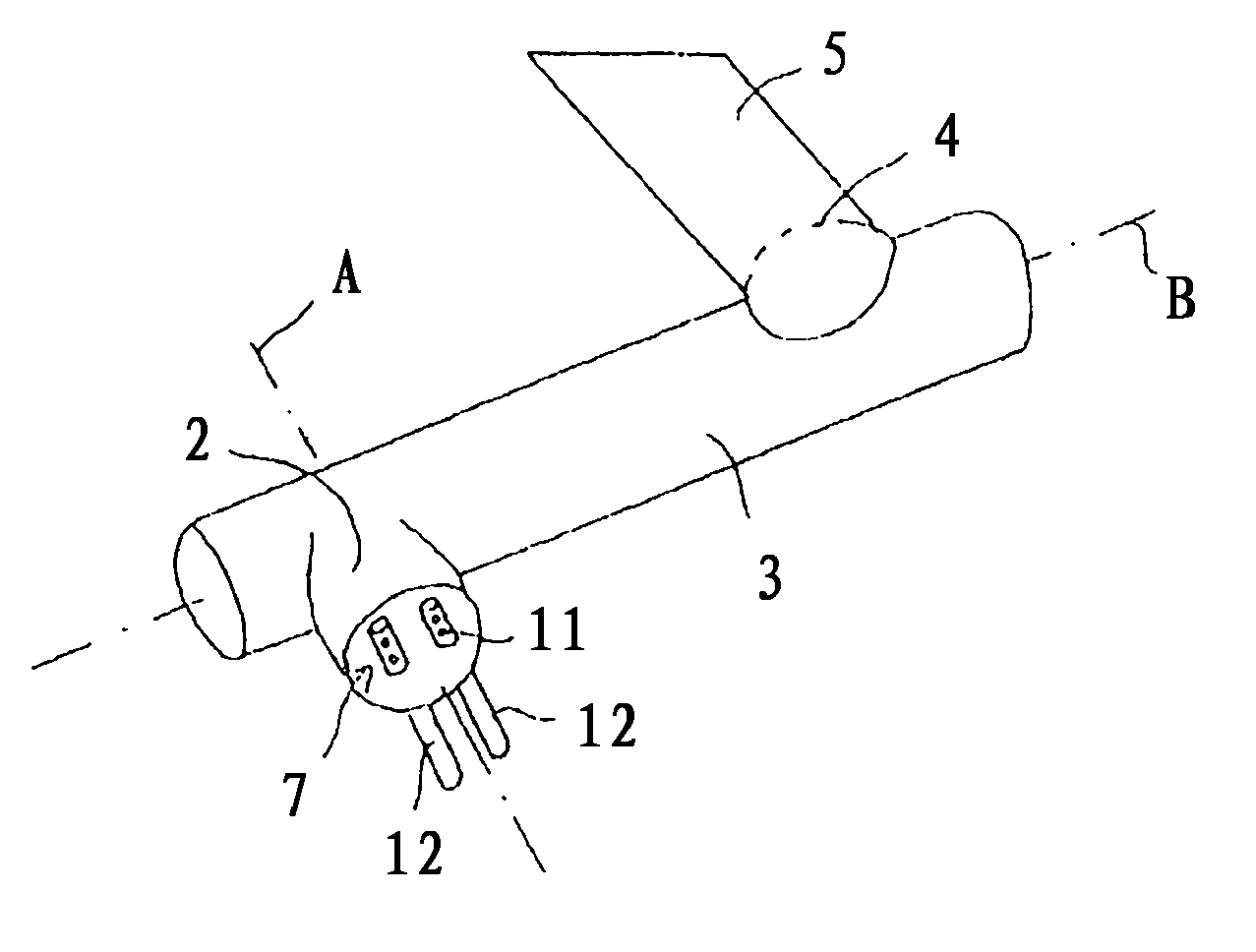

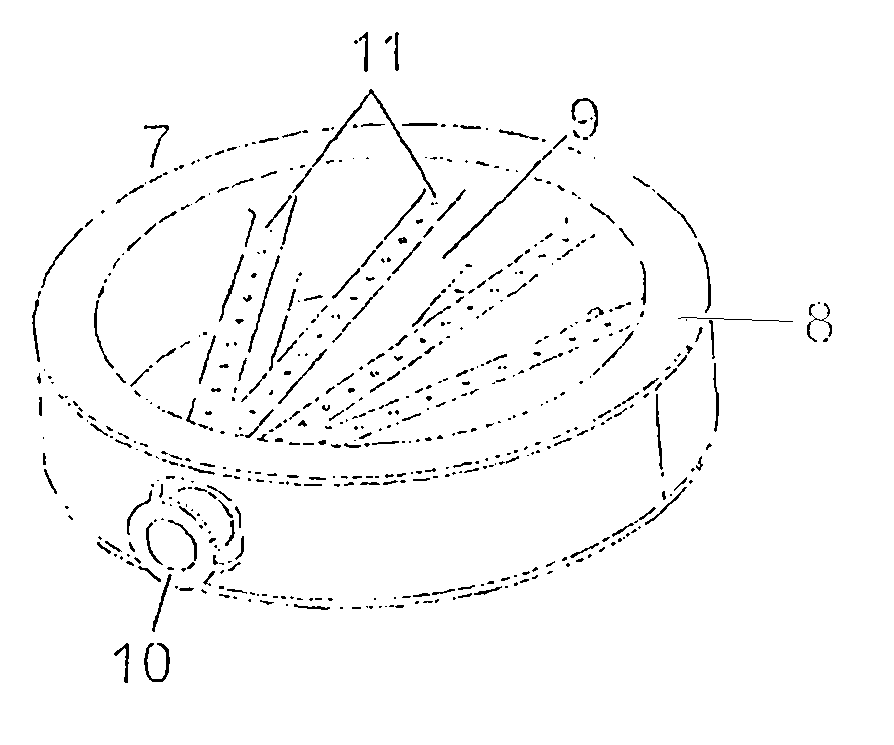

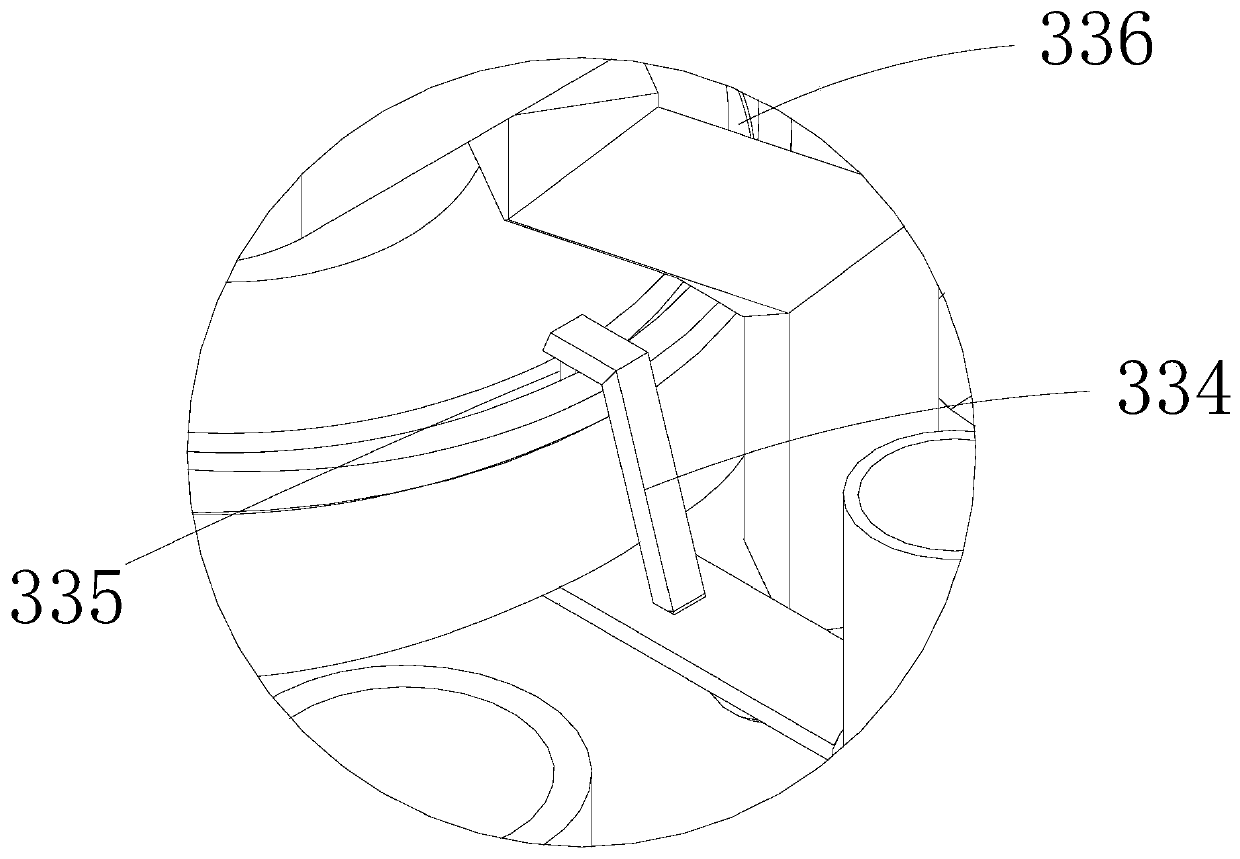

Upflow distributor and upflow reactor

The invention relates to the field of petrochemical engineering and discloses an upflow distributor and an upflow reactor. The upflow distributor comprises a main flow guiding tube (1), a gas flow guiding tube (2) and a mixing part (3), wherein gas stream can be transmitted by the gas flow guiding tube (2); and the upper end orifices of the main flow guiding tube (1) and the gas flow guiding tube (2) both communicate with the mixing part (3). The gas flow guiding tube is mainly used for transmitting gas fluid separated from mixed fluid while the main flow guiding tube is used for transmitting the rest fluid which is mainly liquid fluid, and the fluids flowing through the main flow guiding tube and the gas flow guiding tube are mixed at the mixing part. By adoption of the technical scheme, the fluids flowing through the main flow guiding tube and the gas flow guiding tube reach the mixing part, and the mixing part enables gas and liquid in the mixed fluid to be better mixed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of durable GX forming machine special wax rod and novel mould of production process

The invention discloses a production process of a durable GX forming machine special wax rod and a novel mould of the production process. The novel mould of the production process comprises a meltingfurnace, a driving motor, a base and an air blower. A feeding port is formed in the surface of the middle of the top end of the melting furnace, a clamping ring is fixedly connected on the inner wallof the supporting rod in a pasting mode, adsorption magnets are installed on the inner wall of the clamping ring, a fastening mechanism is installed between the clamping ring and the adsorption magnets, wax rod moulds are tightly adsorbed on the inner walls of the adsorption magnets, the air blower is installed on the right side wall of the melting furnace, an air outlet pipe is seamlessly installed on the lower part of the left wall of the melting furnace in a penetrating mode, and a water tank is installed at the output end of the air outlet pipe. According to the production process of the durable GX forming machine special wax rod and the novel mould of the production process, a dispersion plate is arranged of a circular-arc-shaped structure with endpoint facing downwards, after materials enter the feeding port, the materials smoothly enter and dissipate into all surfaces in the melting furnace in the drainage action of the dispersion plate, and thus the materials, after entering the melting furnace, are dispersed uniformly.

Owner:CHAOYANG LONG MARCH TIRE

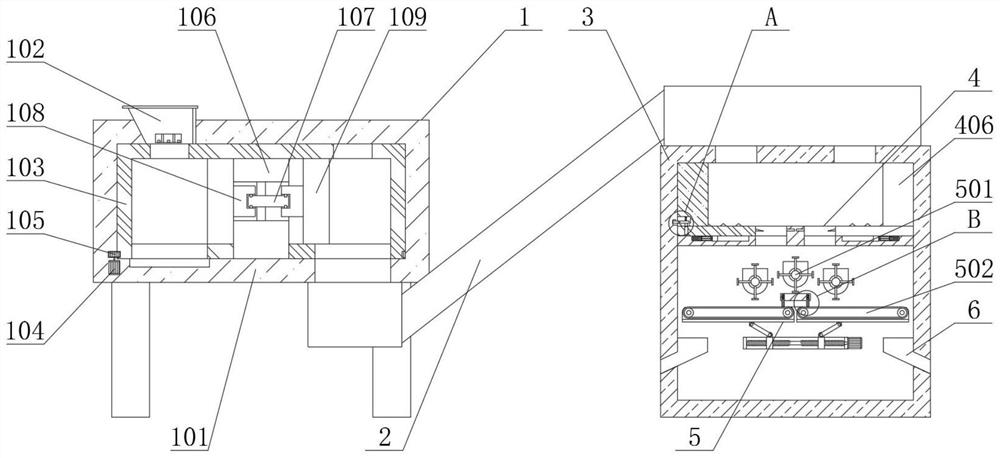

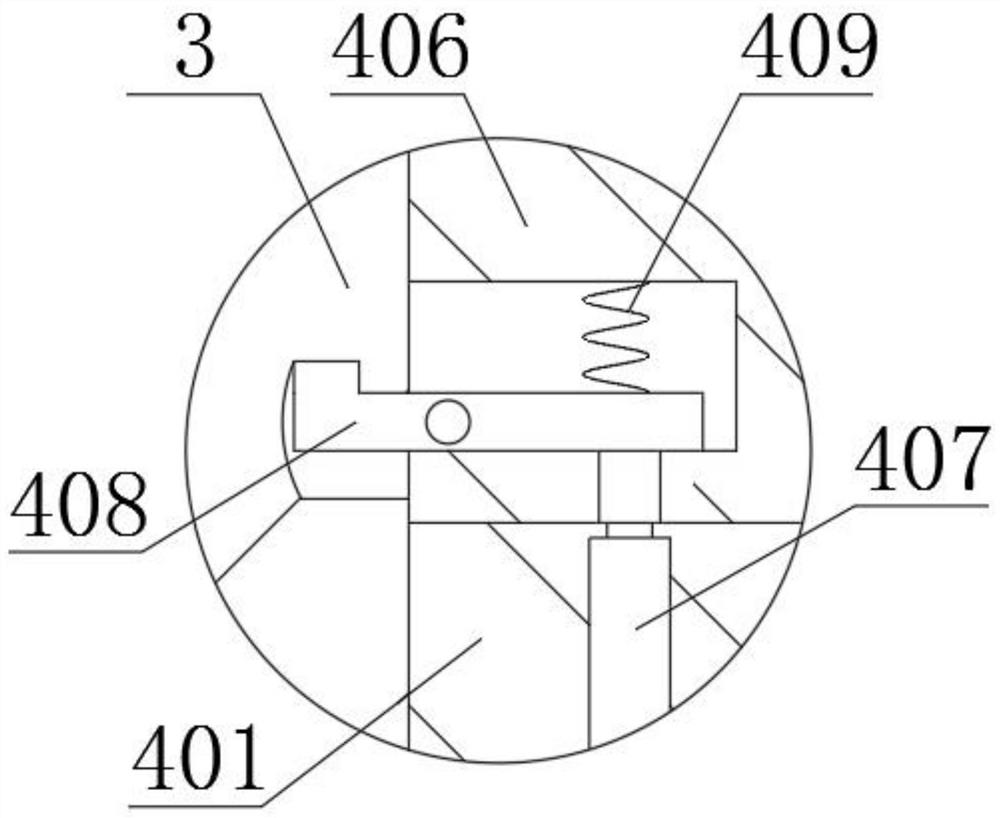

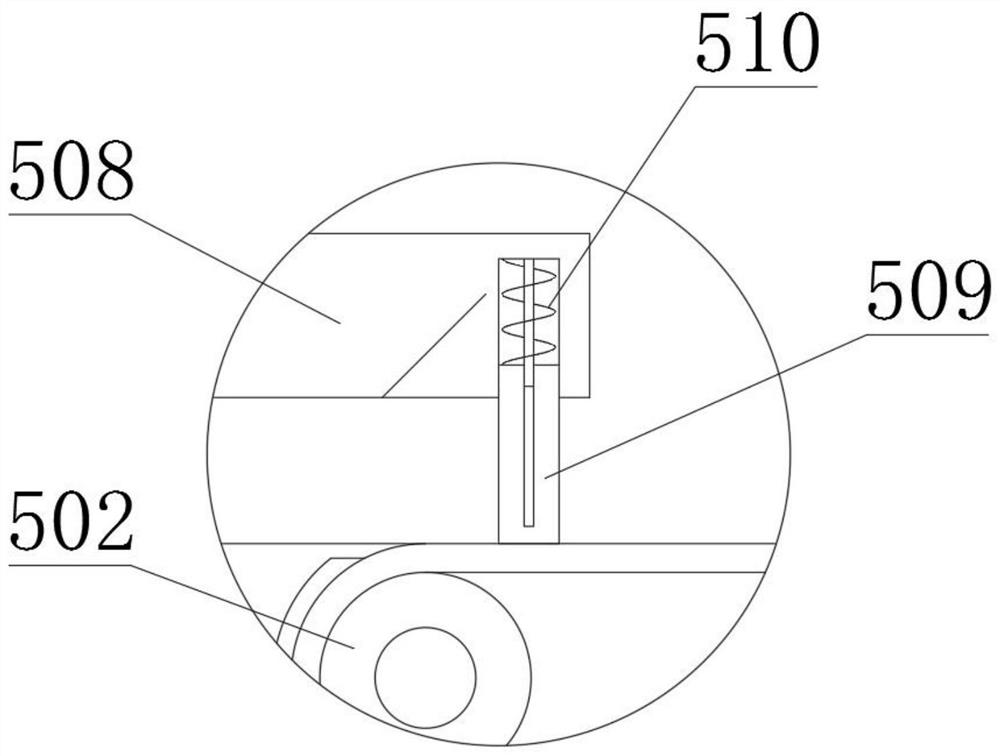

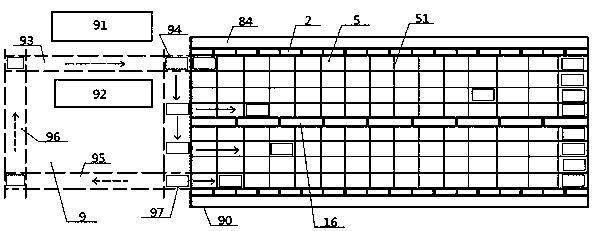

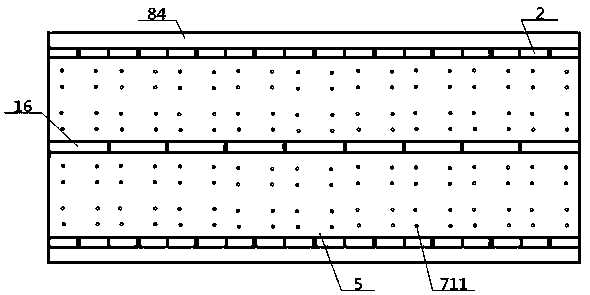

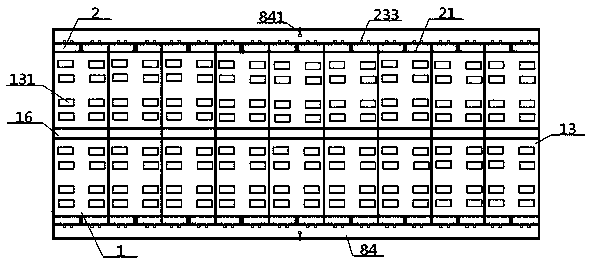

Quantitative rule-based automatic batching assembly line for prefabricated dishes and batching method

ActiveCN112957982AImprovement ingredientsAvoid residueTransportation and packagingMixer accessoriesGear wheelElectric machinery

The invention relates to the technical field of production of prefabricated dishes, in particular to a quantitative rule-based automatic batching assembly line for prefabricated dishes and a batching method. The assembly line comprises a quantitative classification device for the prefabricated dishes, a conveyor and a batching box, wherein the top end of the batching box communicates with the conveyor, the quantitative classification device for the prefabricated dishes is arranged at the left end of the conveyor and comprises a classification box, a hopper, a round material-pushing basin, a first motor, a transmission gear, a fixed cylinder, an eccentric wheel, a sliding seat and a push plate, the hopper is fixedly connected to the inner side of the top end of the classification box, the round material-pushing basin is rotatably connected to the inner side of the classification box, the push plate is slidably connected to the inner side of the round material-pushing basin, and a material cutting mechanism and a batching mechanism are arranged on the inner side of the batching box. According to the device, through the arrangement of the quantitative classification device for the prefabricated dishes and the round material-pushing basin, the prefabricated dishes can be quantitatively distributed and driven to the conveyor, and batching of the prefabricated dishes is facilitated.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method and apparatus for adjusting the concentration of acids or lyes

ActiveCN103025652AStrongly mixed with each otherUniform concentration distributionFlow mixersTransportation and packagingChemistrySulfuric acid

For adjusting the concentration of acids or lyes, in particular of sulfuric acid, the acid or lye is supplied through an inlet to a mixing chamber, is mixed therein with a medium for adjusting the concentration, and the concentration-adjusted acid or lye is discharged from the mixing chamber through an outlet. To achieve a uniform dilution of the acid or lye and small concentration deviations with low pressure loss, the medium for adjusting the concentration, in particular water, is charged to the acid or lye before the inlet to the mixing chamber and the acid stream or lye stream and the stream of the medium subsequently are deflected preferably by 90 DEG .

Owner:OUTOTEC OYJ

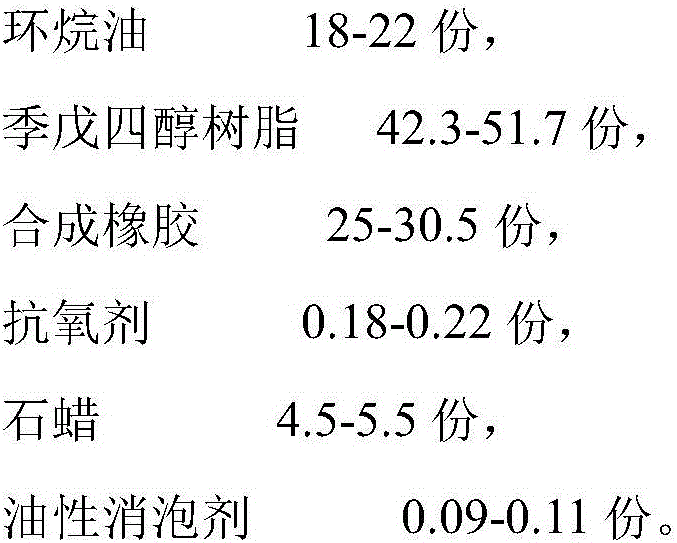

Hot melt adhesive for sanitary product and production process thereof

InactiveCN109777332AImprove flow performanceImprove liquidityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMaleic anhydrideIon

The invention discloses a hot melt adhesive for a sanitary product. The hot melt adhesive is prepared from the following components in parts by weight: 30-35 parts of naphthenic oil, 55-65 parts of modified hydrogenated petroleum resin, 15-20 parts of synthetic rubber, 0.3-0.6 part of an antioxidant, 5-8 parts of paraffin, 12-22 parts of negative ion powder and 0.02-0.3 part of an oily defoamer. The modified hydrogenated petroleum resin is modified C5 modified hydrogenated petroleum resin which is synthesized by carrying out a reaction of maleic anhydride and C5 hydrogenated petroleum resin under the action of a catalyst. By adding paraffin into the conventional structural adhesive, the structural adhesive has very a good flowing property when being lower than the temperature of the conventional structural adhesive and promotes mutual mixing of the components. Due to the adoption of the negative ion powder which has a sterilizing function, the hot melt adhesive applied to the disposalsanitary product is not only sanitary and clean, but also can reduce bacteria breeding.

Owner:QUZHOU STANLEY ADHESIVE IND CO LTD

Biogas generation system and production technology

ActiveCN109810880AImprove work efficiencySave operating spaceGas production bioreactorsWaste based fuelSlagBiogas

The invention relates to a biogas generation system. The biogas generation system comprises a raw material workshop and a fermenting workshop, wherein the raw material workshop comprises a loading rail, a steering rail, a transverse return rail and a vertical return rail which are connected in a head-to-tail way; the fermenting workshop comprises a material stacking plate, a biogas tank and an outer cover; the biogas tank comprises a left inclined bottom casing, a right inclined bottom casing, a top plate of the biogas tank and a fermenting cavity; the inner ends of the left inclined bottom casing and right inclined bottom casing are connected; the outer ends of the left inclined bottom casing and right inclined bottom casing are connected with the top plate of the biogas tank through a material inlet and an upper wall passage of the material inlet; the heights of the left inclined bottom casing and right inclined bottom casing are gradually increased from the inner ends to the outer ends; a biogas accommodation cavity is clamped between the top plate of the biogas tank and the material stacking plate; the fermenting cavity is communicated with the biogas accommodation cavity through a gas ventilating port; a slag intake passage is arranged at the middle parts of the top plate of biogas tank and the material stacking plate and just vertically faces the crossing part of the leftinclined bottom casing and right inclined bottom casing. By adopting the design, the biogas generation system has the advantages that the mixing degree of biogas slurries is high, the mixing uniformity between the raw materials is better, the working efficiency and biogas production efficiency are higher, the interference between the slag intake and biogas production is avoided, and the slag intake efficiency is higher.

Owner:方旭华

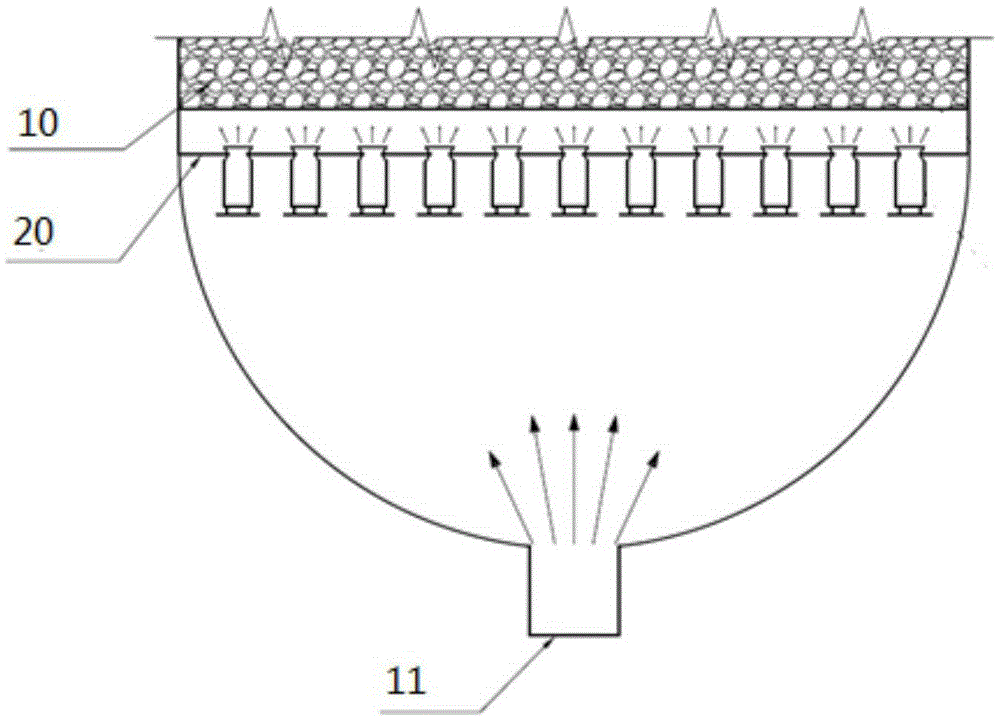

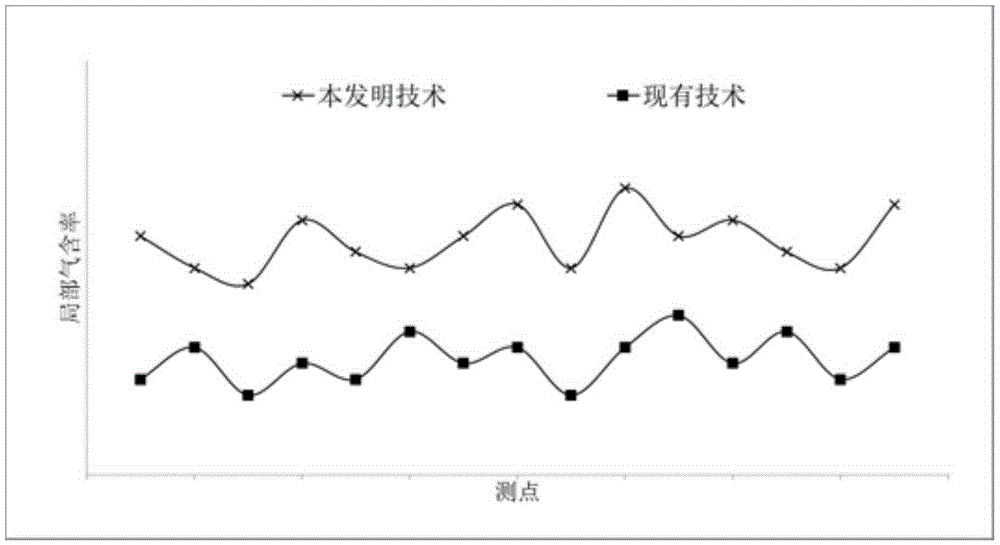

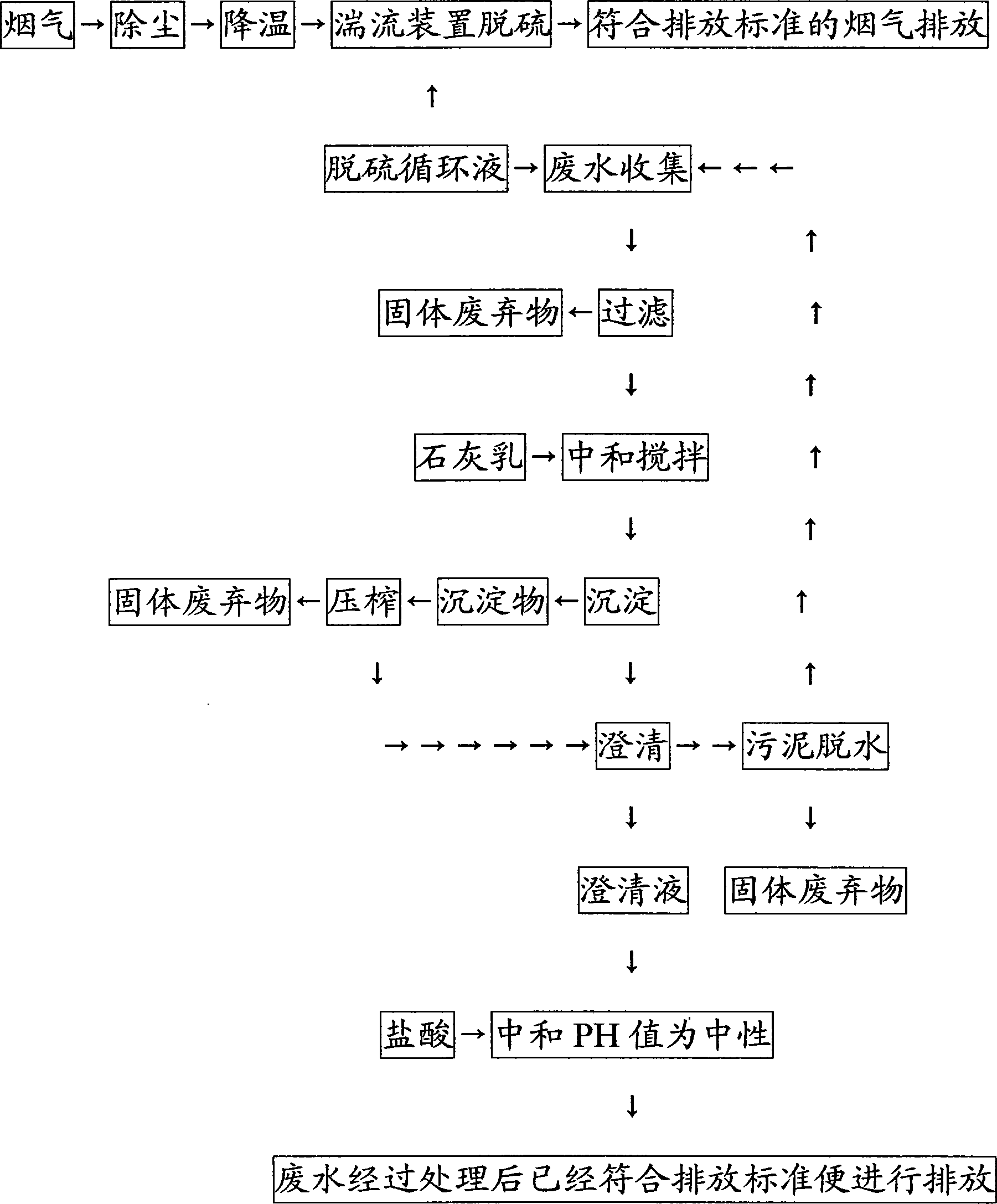

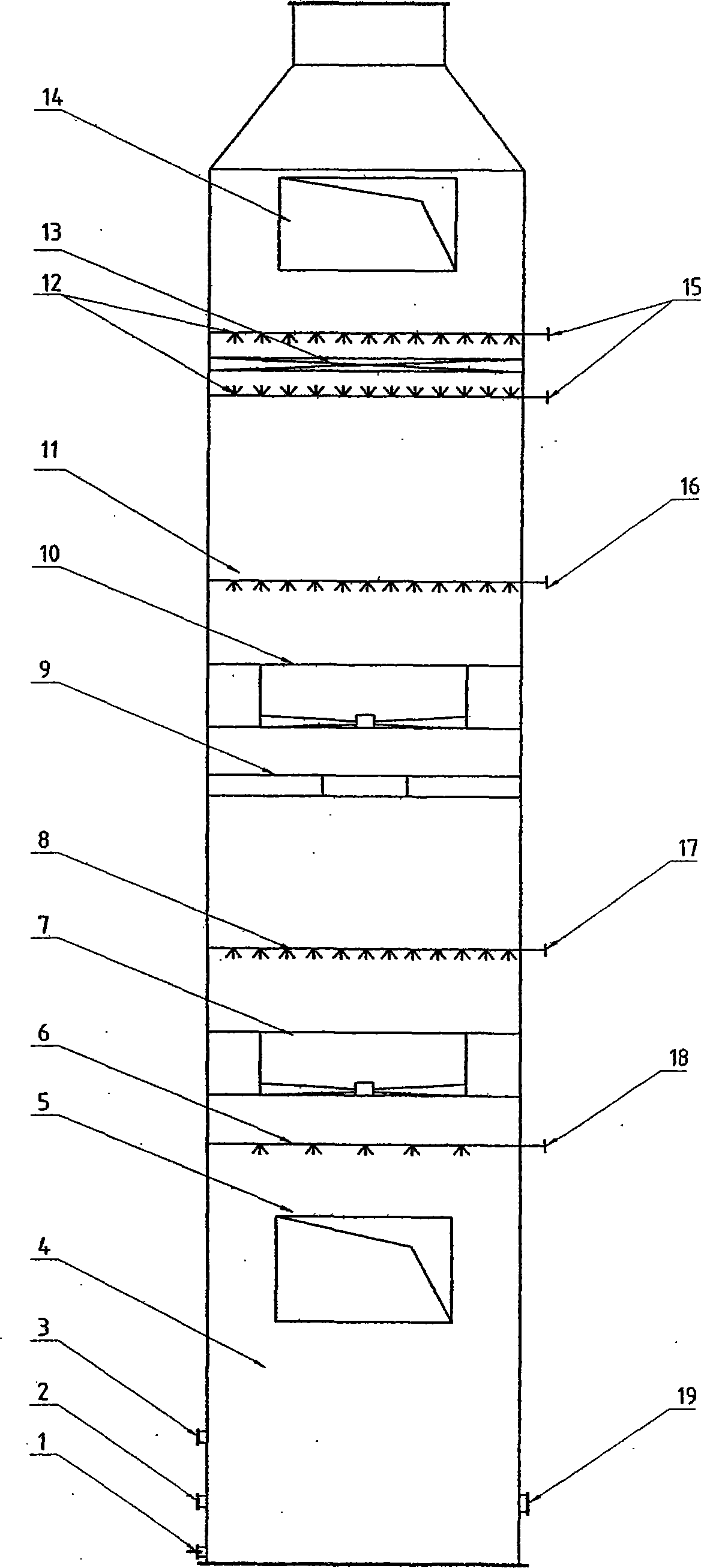

Process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment

InactiveCN104028097AAdvanced technology and scienceEasy to operateDispersed particle separationMultistage water/sewage treatmentFlue gasEngineering

The invention discloses a process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment and relates to the technical field of environmental protection. A body of a device is provided with a flue gas inlet and a flue gas outlet and is fixed with a blow-off pipe, a desulfurizing agent supplementing inlet, a water pipe and a desulfurizing agent outlet, the body between the flue gas inlet and the flue gas outlet is fixed with a desulfurizing agent inlet, a first-stage turbocharging turbulator, a first-stage desulfurizing agent inlet, a receiving tank, a second-stage turbocharging turbulator, a second-stage desulfurizing agent inlet, a first water inlet pipe, a demister and another water inlet pipe respectively from bottom to top, a liquid outlet pipe of the receiving tank penetrates out of the body, the desulfurizing agent inlet is fixed with a spray nozzle, the desulfurizing agent inlet is fixed with a first-stage spray nozzle, the second-stage desulfurizing agent inlet is fixed with a second-stage spray nozzle, and the water inlet pipes are fixed with water spray nozzles; and the wastewater treatment process comprises the steps of collecting wastewater, filtrating, neutralizing with lime milk, precipitating, clarifying, neutralizing with hydrochloric acid and then draining. The process technology is applied to flue gas desulfurization and wastewater treatment; and the device is ingenious, and the effect is good.

Owner:BEIJING ZHONGYE LONGSHENG ENVIRONMENTAL PROTECTION TECH

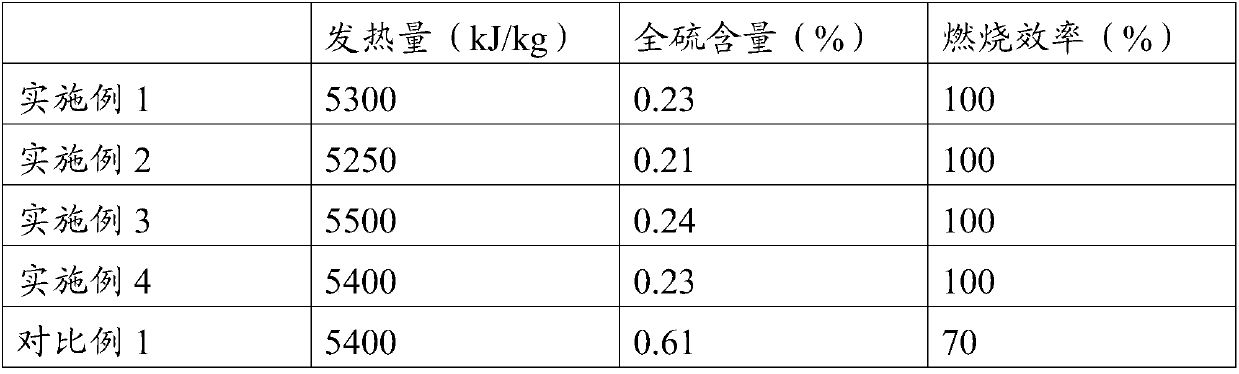

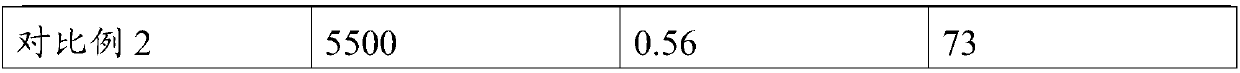

Biomass type carbon processing technology

The invention discloses a biomass type carbon, which includes biomass carbon powder, a combustion promoter, a proppant and an adhesive. The biomass type carbon can realize biomass carbon powder moulding, and then can achieve further development and utilization of biomass carbon, and has the characteristics of high calorific value, low volatile component, long combustion time and ultra-low emission. At the same time, the invention also discloses a biomass type carbon processing technology, the technology has simple process, can achieve industrial production, and is convenient for popularizationand utilization.

Owner:河北省隆盛生物质能源开发有限责任公司

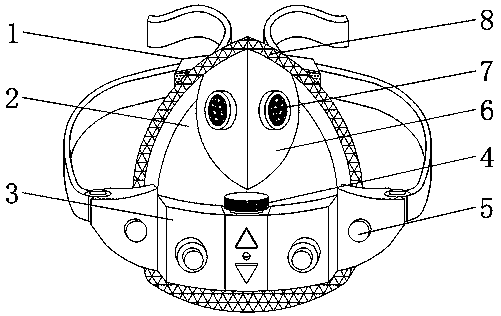

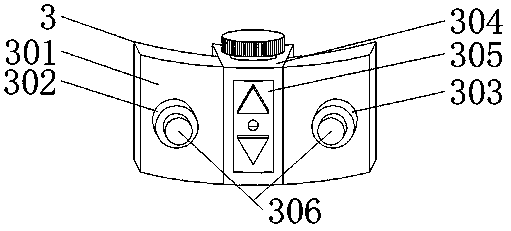

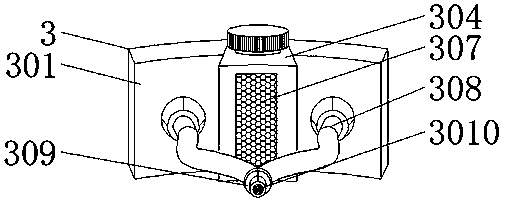

Mouth nursing device for emergency and severe diseases

InactiveCN110478578APromote mutual mixingPromote absorptionRespiratory masksMedical devicesHead sizeLap joint

The invention discloses a mouth nursing device for emergency and severe diseases. The mouth nursing device comprises a mouth nursing device body, a nursing mask body, a nursing device, an applicator and a binding device. The nursing mask body is fixedly connected to the middle of the mouth nursing device body. The nursing device is fixedly connected to the bottom of the front of the nursing mask body. The applicator is embedded in the middle of the top end of the nursing device. The binding device is in lap joint with two ends of the middle of the nursing mask body. The binding device is convenient for medical personnel to adjust; the use is adjusted according to the head size of a patient; the filtering cover achieves a certain nursing effect, and treatment efficiency is increased. The isolation performance of the device is embodied; a rubber cushion layer has a certain protection effect on a patient so as to show protection performance of the device; the nursing device helps improvethe mouth nursing problem which is ignored under common emergency and severe disease condition to a great extent, and the nursing performance of the device is embodied. The device has wide developmentprospects in the future.

Owner:SHANGQIU INST OF TECH

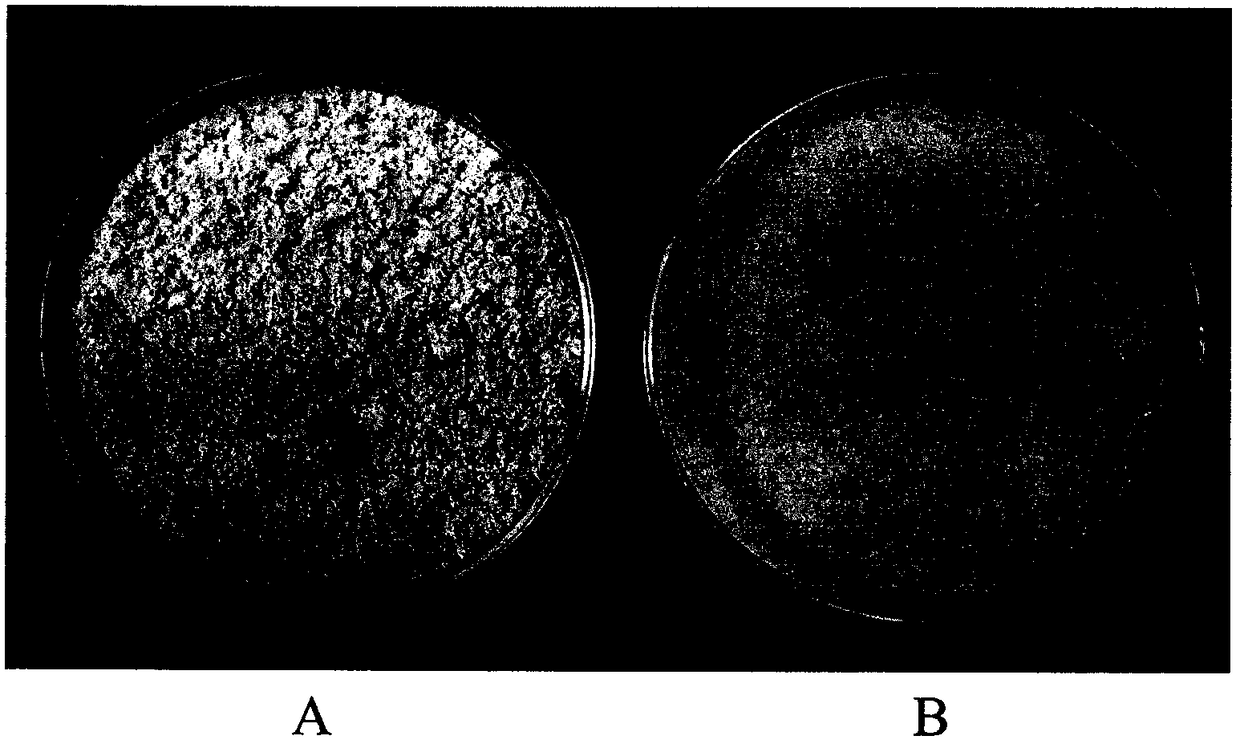

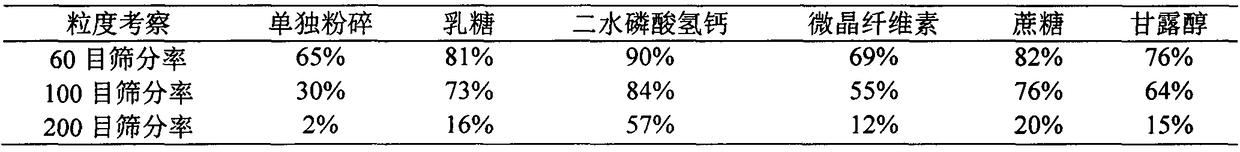

Thyroid tablets produced by direct whole-powder tabletting and preparation process thereof

ActiveCN109464411AHigh densityLow densityPowder deliveryInorganic non-active ingredientsHydrogen phosphateMedicine

The invention belongs to the technical field of pharmaceutical preparations, and relates to thyroid tablets produced by direct whole-powder tabletting and a preparation process of the thyroid tabletsproduced by the direct whole-powder tabletting, in particular to synergetic application of calcium hydrogen phosphate-assisted optimization of powder properties of thyroid raw materials and freeze-drying assisted grinding technology. More than 98% of the particle sizes of thyroid mixed ground materials prepared by the invention are smaller than 250 microns, and the thyroid mixed ground materials are difficultly reaggregated, and uniformly mixed with other auxiliary materials; RSD of the T3 and T4 contents in thyroid powder is not greater than 4%; the angle of repose of the mixed powder is smaller than 35 degrees, so that requirements of powder direct tabletting are met; the content uniformity (A+2.2S) of T3 and T4 in the thyroid tablets is not greater than 20, each tablet is disintegratedwithin 15min, and the disintegration time limit difference is small (RSD is not greater than 5%). The thyroid tablets produced by the direct whole-powder tabletting and the preparation process of thethyroid tablets produced by the direct whole-powder tabletting disclosed by the invention effectively solve the problems that the thyroid raw materials are not easily ground, and not uniformly mixed with the auxiliary materials and the like, optimize the grinding effect of the thyroid raw materials, improve the powder properties of the thyroid raw materials, and greatly enhance the content uniformity of T3 and T4 in the thyroid tablets.

Owner:CHINA PHARM UNIV

Glass kiln exhaust gas waste-heat utilization and exhaust gas desulfurization system

InactiveCN107303464AIncrease profitForced insulationGas treatmentDispersed particle separationMelting tankHazardous substance

The invention provides a glass kiln exhaust gas waste-heat utilization and exhaust gas desulfurization system which comprises a melting tank of a glass kiln, wherein the melting tank is connected with a working tank through a throat; an oil gun is arranged at the bottom of the melting tank; a heat storage chamber is arranged on the other side of the melting tank; the heat storage chamber is connected with a waste-heat boiler steam pot through a boiler exhausting pipe; the waste-heat boiler steam pot is heated and dried by the heat storage chamber through a vaporizing pipe and then is in parallel connection with the oil gun; a main flue is arranged at the top of the heat storage chamber; an exhaust gas gate is arranged on an outlet position of the main flue; an exhaust gas outlet is formed on the rear side of the exhaust gas gate; and an exhaust gas desulfurization system is arranged on the rear side of the exhaust gas outlet. The system can fully utilize the outward dispersing waste heat of the glass kiln, can additionally generate a large amount of steam for production and life, can save energy and can reduce environmental pollution. The exhaust gas desulfurization system is used for increasing the exhaust gas treating efficiency and reducing the damage of harmful matters to a human body.

Owner:宜昌晶品玻璃制品有限公司

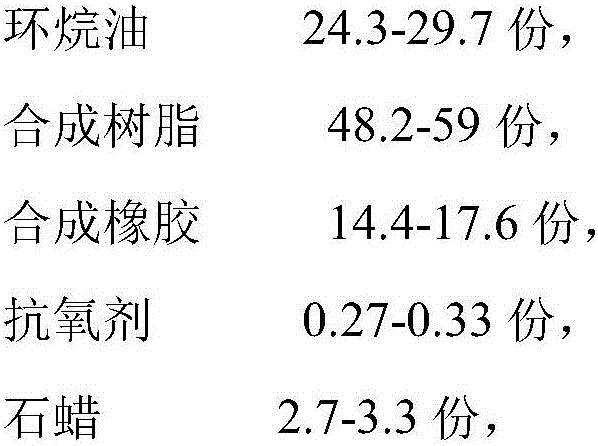

Structural adhesive used for compositing sanitary napkin PE membrane and non-woven fabrics and preparation method thereof

ActiveCN106520070AGood fluidityLow viscosityMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesChemistryWoven fabric

The invention discloses a structural adhesive used for compositing a sanitary napkin PE membrane and non-woven fabrics. The structural adhesive comprises the following components: 24.3-29.7 parts of naphthenic oil, 48.2-59 parts of synthetic resin, 14.4-17.6 parts of synthetic rubber, 0.27-0.33 parts of an anti-oxidant, 2.7-3.3 parts of paraffin, and 0.09-0.11 parts of an oiliness antifoaming agent. In a traditional structural adhesive, paraffin is added as an auxiliary agent, flowing speed of paraffin due to heat is fast, solidification is fast after cooling, usage temperature is reduced, carbon formation on equipment is reduced, and the production efficiency is increased.

Owner:天津登峰卫生用品材料有限公司

Efficient and continuous silicone adhesive coloring system

ActiveCN112221421ASmall color differenceImprove uniformityTransportation and packagingMixer accessoriesChemistryEngineering

The invention relates to the technical field of silicone adhesive production, particularly to an efficient and continuous silicone adhesive coloring system, which sequentially comprises a primary color adhesive metering cylinder used for metering and extracting a primary color adhesive, a dynamic mixer, a static mixer and a racking machine in the conveying direction of the primary color adhesive,wherein a plurality of color paste metering cylinders used for metering extracted color paste are arranged on the primary color adhesive metering cylinder side by side, the discharging port of each color paste metering cylinder and the discharging port of the primary color adhesive metering cylinder are both communicated with the feeding port of the dynamic mixer, the discharging port of the dynamic mixer is communicated with the feeding port of the static mixer, and the discharging port of the static mixer is communicated with the racking machine. According to the invention, the color difference of the silicone adhesive can be reduced, and the mixing uniformity of the primary color adhesive and the color paste is improved, so that the product quality of the silicone adhesive is improved.

Owner:FOSHAN PULIDA TECH

Formula of radiating fin material for computer mainboard

The invention relates to a formula of a radiating fin material for a computer mainboard. The formula comprises silver, aluminum, copper, gold, lead, epoxy resin, silicone grease, polyvinyl alcohol, polyester, polyacrylonitrile, phenolic resin, amino plastics, silicate, graphite powder, carbon fibers, aminopropyltriethoxysilane, methyl triethoxy silane, fatty alcohol polyoxyethylene ether, alkyl phenol polyoxyethylene ether, polyvinyl alcohol, hydrophobically modified polyacrylate, fatty amine, polyamide, dimethyl glutarate, dimethyl adipate, xanthan gum and aluminium-magnesium silicate in parts by weight. A radiating fin manufactured by the radiating fin material formula provided by the invention can greatly enhance the effects of heat absorption, storage and evacuation of the radiating fin, so as to avoid the burning phenomenon of a circuit board.

Owner:JISHOU UNIVERSITY

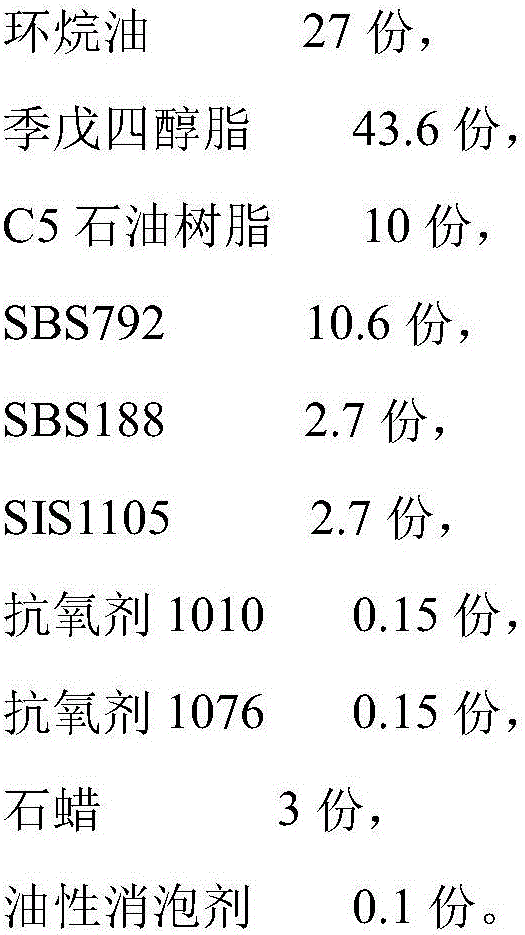

A seal line adhesive for a sanitary napkin single-sheet package film and a preparing method thereof

ActiveCN106497514AWon't tearEasy to peelNon-macromolecular adhesive additivesWax adhesivesParaffin waxPentaerythritol

A seal line adhesive for a sanitary napkin single-sheet package film is disclosed. The adhesive includes, by weight, 18-22 parts of naphthenic oil, 42.3-51.7 parts of pentaerythritol resin, 25-30.5 parts of synthetic rubber, 0.18-0.22 part of an antioxidant, 4.5-5.5 parts of paraffin and 0.09-0.11 part of an oil-based defoamer. Through adding the paraffin on the basis of traditional seal line adhesives, the production and using temperatures are reduced, and individual packages are protected from being burnt during a production process. Viscosity is reduced after the paraffin is added so that the individual packages cannot be tore during using.

Owner:天津登峰卫生用品材料有限公司

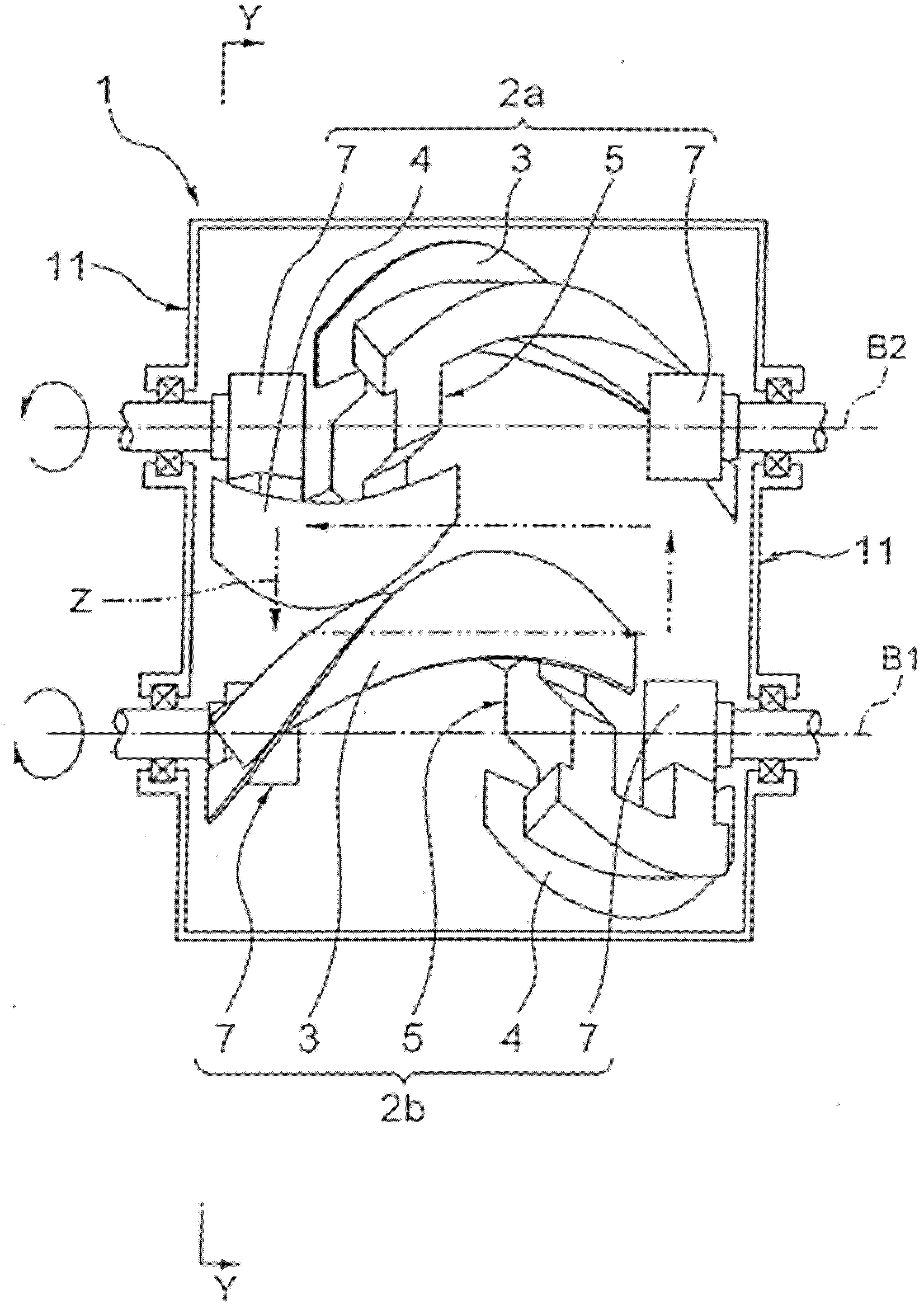

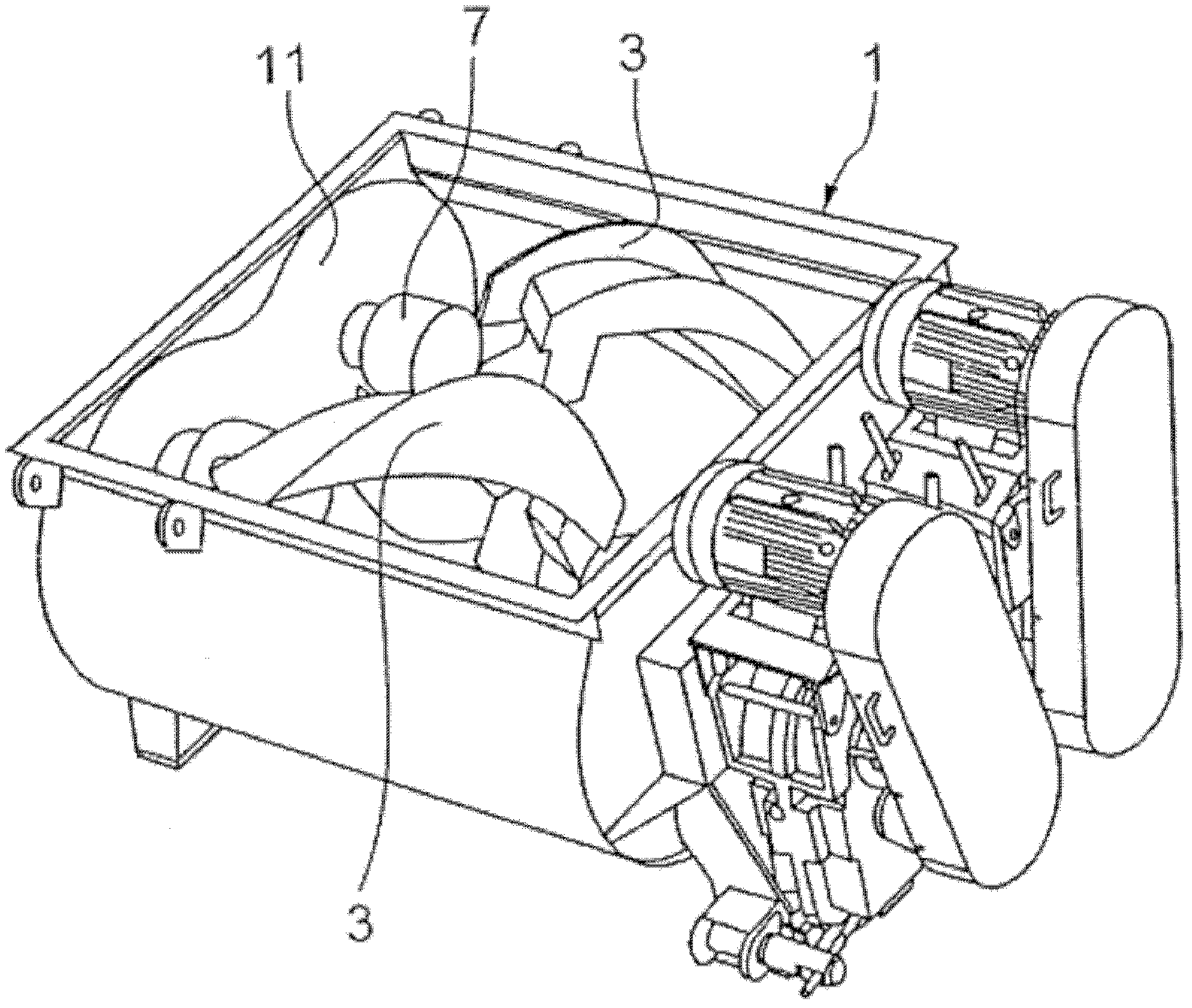

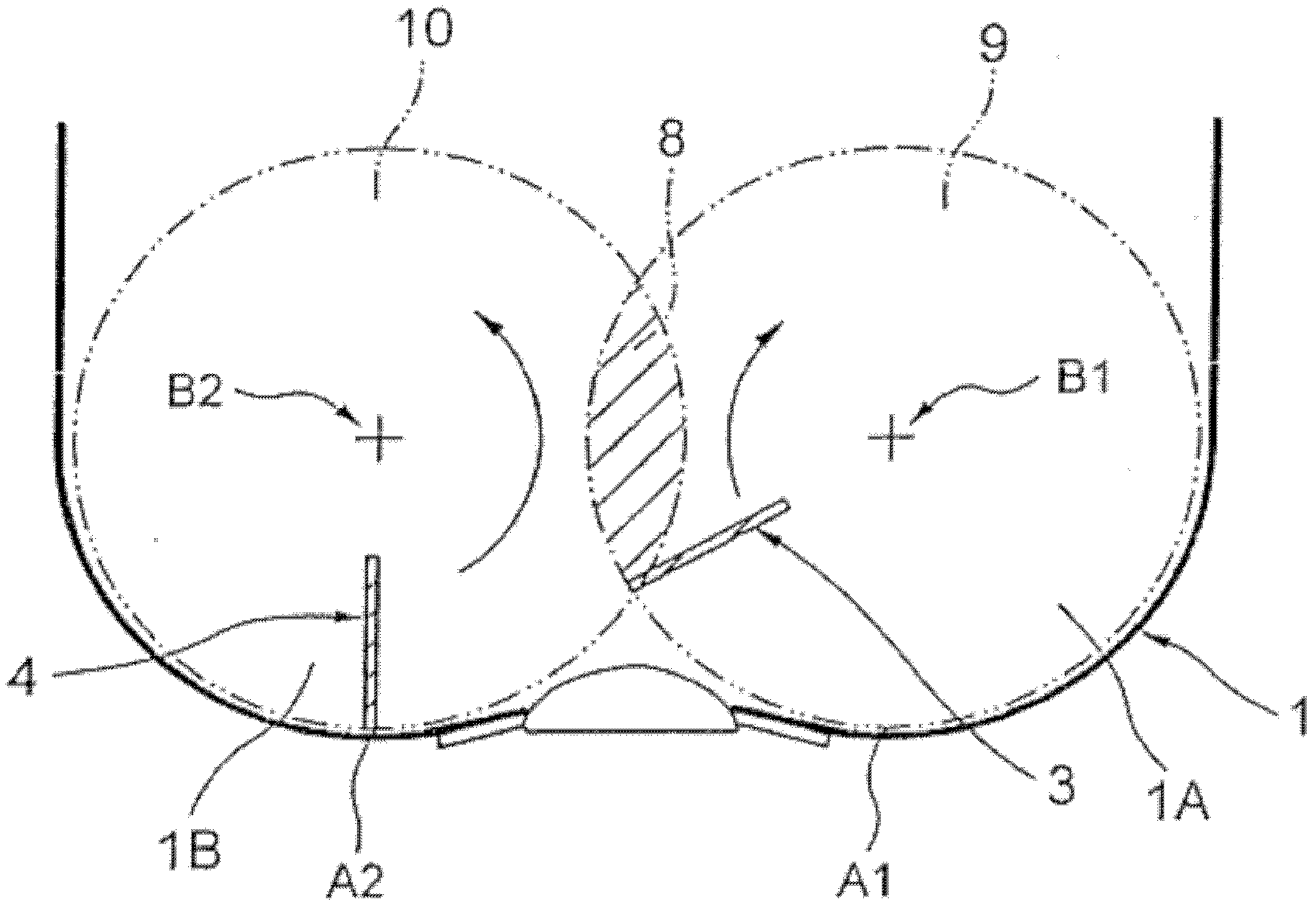

Double-shaft stirrer

InactiveCN102430355AStirring speed is fastImprove stirring efficiencyRotary stirring mixersPulp and paper industry

Owner:成都鑫三洋科技发展有限公司

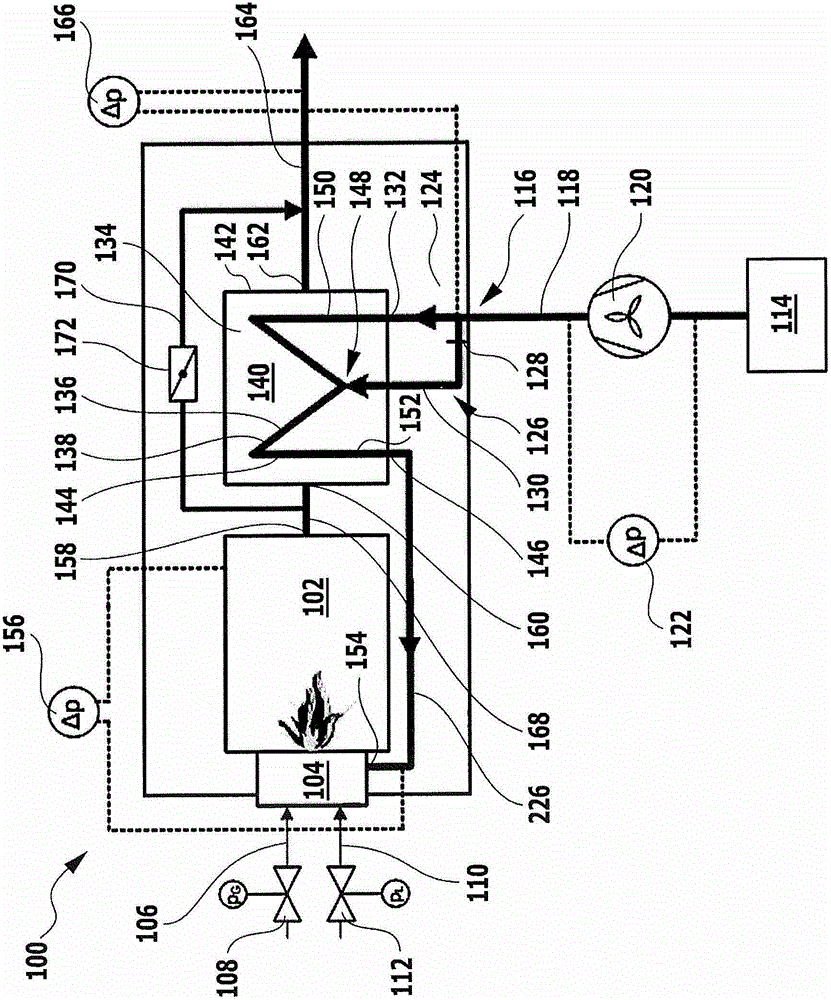

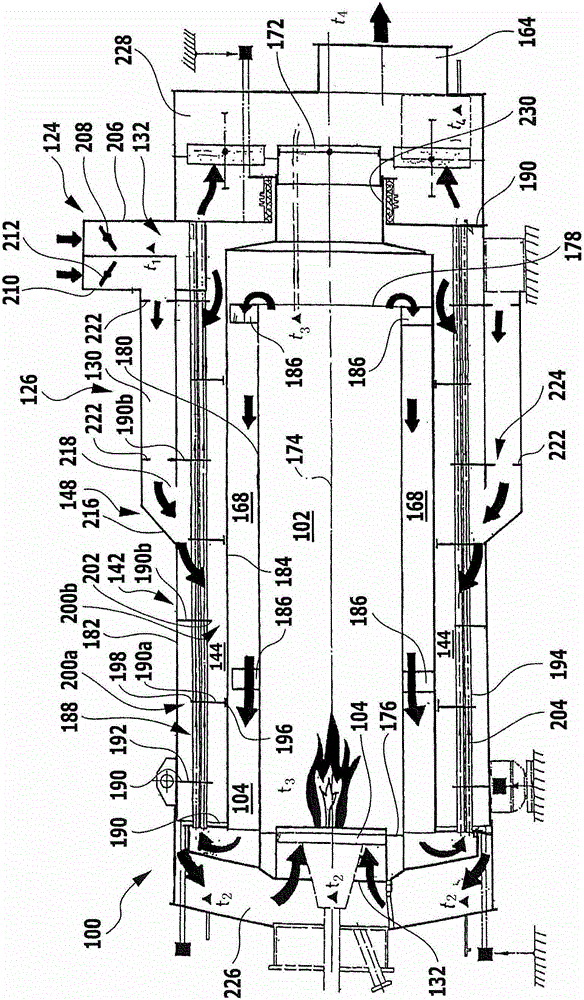

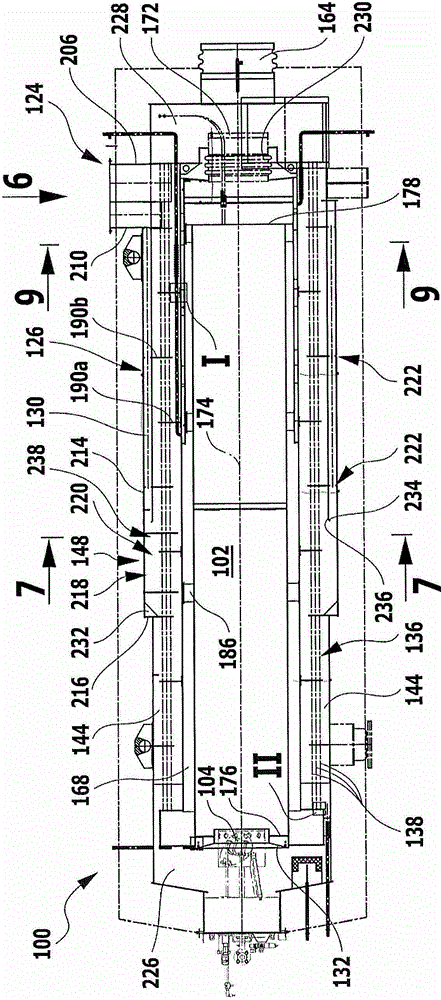

Thermal exhaust air treatment plant

ActiveCN102803853AEvenly mixedImprove distributionIncinerator apparatusCombustion chamberPlate heat exchanger

To provide a thermal exhaust air treatment plant, comprising a combustion chamber and a heat exchanger for transferring heat from a cleaned gas produced in the combustion chamber to an untreated gas to be supplied to the combustion chamber, wherein the heat exchanger comprises an inner heat exchanger chamber through which an inner fluid medium can flow and comprises an outer heat exchanger chamber through which an outer fluid medium can flow, which thermal exhaust air treatment plant permits regulation of the cleaned gas outlet temperature without a reduction in the cleaned gas quality, it is proposed that the thermal exhaust air treatment plant comprises a bypass device with a separating device by means of which a part of the outer fluid flow can be separated, as a bypass fluid flow, from an outer residual fluid flow, and with an admixing device by means of which the bypass fluid flow can be admixed to the residual fluid flow again after the residual fluid flow has passed through a section of the outer heat exchanger chamber.

Owner:杜尔涂装系统工程(上海)有限公司

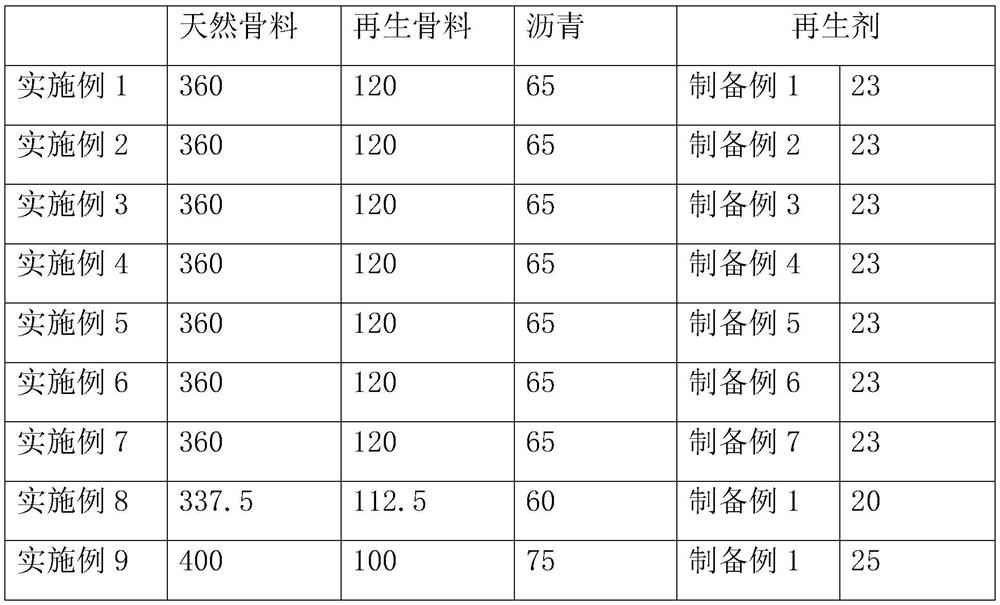

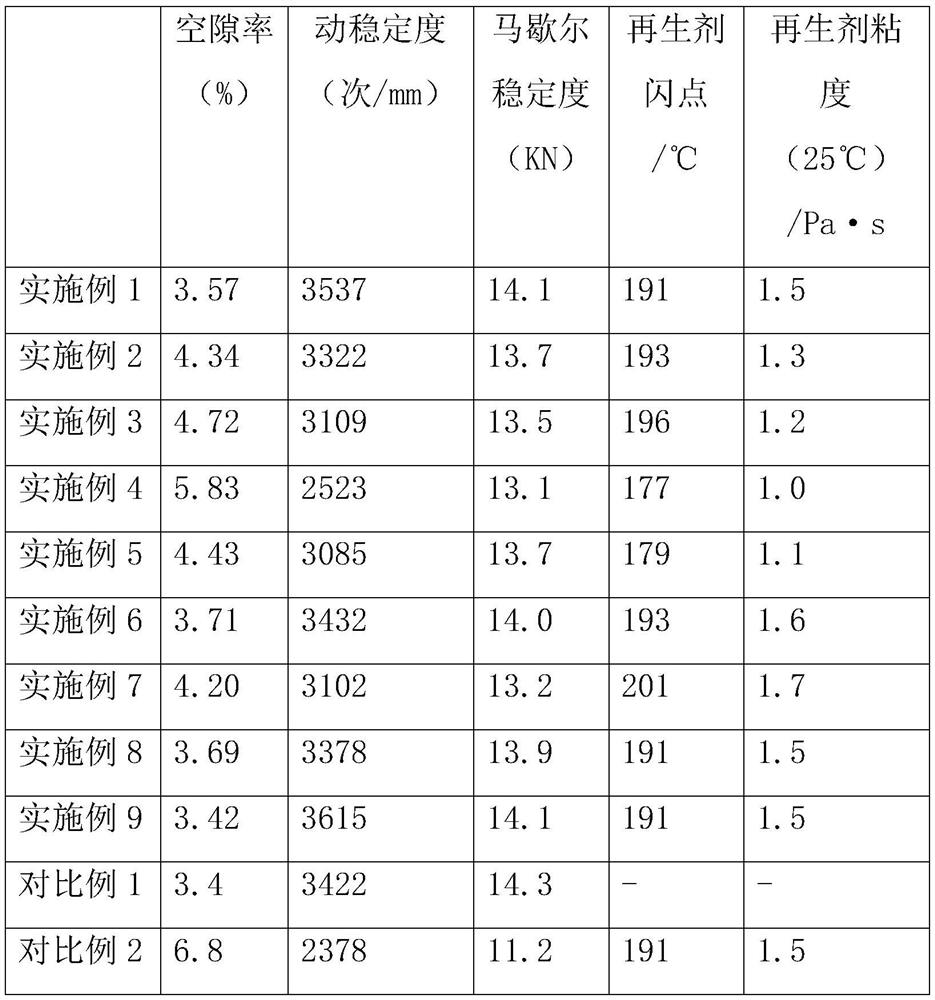

Recycled asphalt mixture and preparation method thereof

The invention relates to the field of asphalt mixture preparation, and particularly discloses a recycled asphalt mixture and a preparation method thereof. The recycled asphalt mixture comprises the following components in parts by weight: 450-500 parts of aggregate, 60-75 parts of asphalt and 20-25 parts of a recycling agent, wherein the aggregate comprises natural aggregate and recycled aggregate, and the weight ratio of the natural aggregate to the recycled aggregate is (3-4):1. The preparation method comprises the following steps: milling an asphalt pavement of a target pavement, and crushing into particles with the average particle size of 5 mm; mixing recycled aggregate and a recycling agent, and stirring for 1 minute at an ambient temperature of 160 DEG C; and adding natural aggregate and the asphalt in proportion, and stirring for 1 minute; The method has the effect of improving the utilization efficiency of the waste asphalt mixture.

Owner:北京岭北筑路材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com