Biogas generation system and production technology

A technology for generating system and biogas, which is applied in the fields of gas production bioreactor, biological sludge treatment, waste fuel, etc., can solve the problems of low mixing degree of raw material and biogas slurry, poor mixing uniformity of raw material, low working efficiency, etc. The effect of improving equipment utilization, improving gas production efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

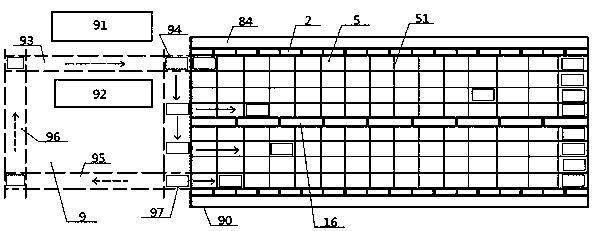

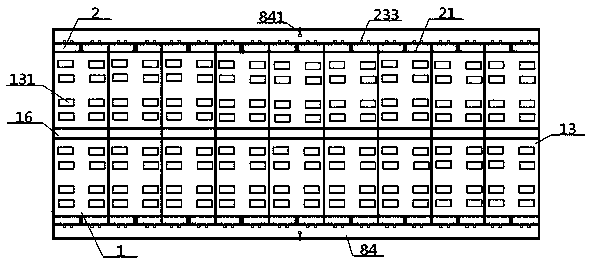

[0061] see Figure 1 to Figure 13 , a biogas generation system, including a raw material workshop 9 and a fermentation workshop 90, the raw material workshop 9 includes a manure stacking area 91 and a straw stacking area 92, and the fermentation workshop 90 includes a stacking board 5, a biogas tank 1 and an outer cover 98, An outer cover 98 is covered above the stockpiling plate 5, and a biogas digester 1 is arranged below the stockpiling plate 5, and both sides of the biogas digester 1 communicate with a feed channel 2; the raw material workshop 9 includes end-to-end loading Track 93, steering track 94, horizontal return track 95, vertical return track 96, the loading track 93 is sandwiched between the manure stacking area 91 and the straw stacking area 92, and the lateral direction of the horizontal return track 95 and the stacking The boards 5 communicate with each other, and a plurality of parking spaces 51 are arranged on the top surface of the stacking board 5; the feed...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

[0066]A dodge door 3 is arranged in the described feed inlet 22, and the top of this dodge door 3 contacts with the top edge of feed inlet 22, and the bottom end of dodge door 3 is hinged with the bottom edge of feed inlet 22, and movable The side portion of door 3 is oppositely arranged with outer road wall 23, and the top of outer road wall 23 is connected with the inner end of transverse platform 24, and the top surface of transverse platform 24 is in contact with the bottom of pressing side pusher 4, and presses down. One end near the feed channel 2 on the side pusher 4 is provided with an inner push rod 43 and an outer push rod 44. It is set directly opposite, and the fermentation chamber 14 communicates with the feed channel 2 through the movable door 3 . The push-down side pusher 4 includes a base 41 and a binder block 42 connected thereon, an inner push rod 43, an outer push rod 44, an inner cylind...

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

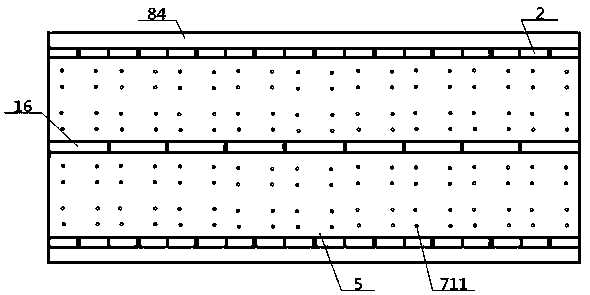

[0069] The biogas generation system also includes a vibrating screen 7, the vibrating screen 7 includes a vibrating vertical shaft 71 and a vibrating grid plate 72, and the vibrating grid plate 72 is provided with a plurality of grid plate through holes 721; No. assembly vertical side 73, No. 1 supporting horizontal side 731, No. 2 assembling vertical side 732, No. 2 supporting horizontal side 733, No. 1 assembling vertical side 73, No. 2 assembling vertical side 732 facing each other, No. 1 supporting horizontal side 731 1. The No. 2 supporting horizontal edge 733 is set oppositely, and the No. 1 assembling vertical edge 73 and the No. 2 assembling vertical edge 732 are respectively embedded with an I-shaped beam 74 on the front and rear ends of the respective inner walls. The upper beam in the I-shaped beam 74 The plate 741 and the lower beam plate 742 are exposed in the air vent 131, and the four lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com