Patents

Literature

361results about How to "Improve gas production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

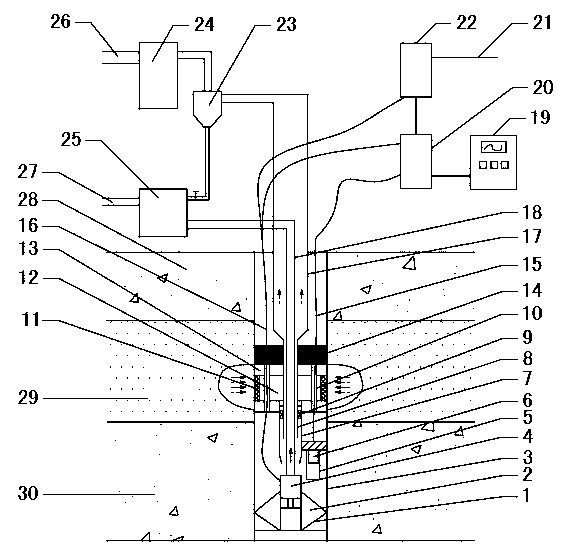

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

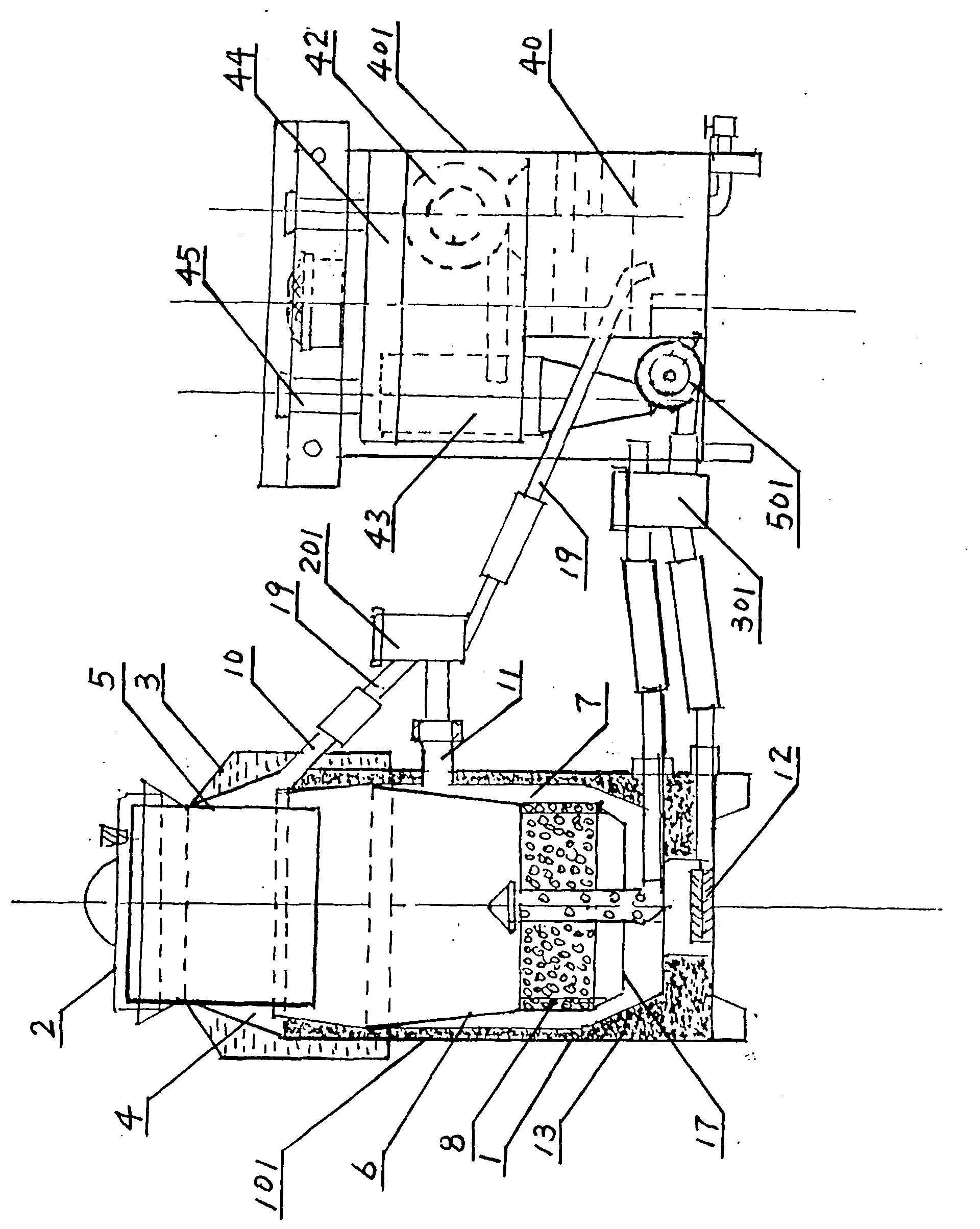

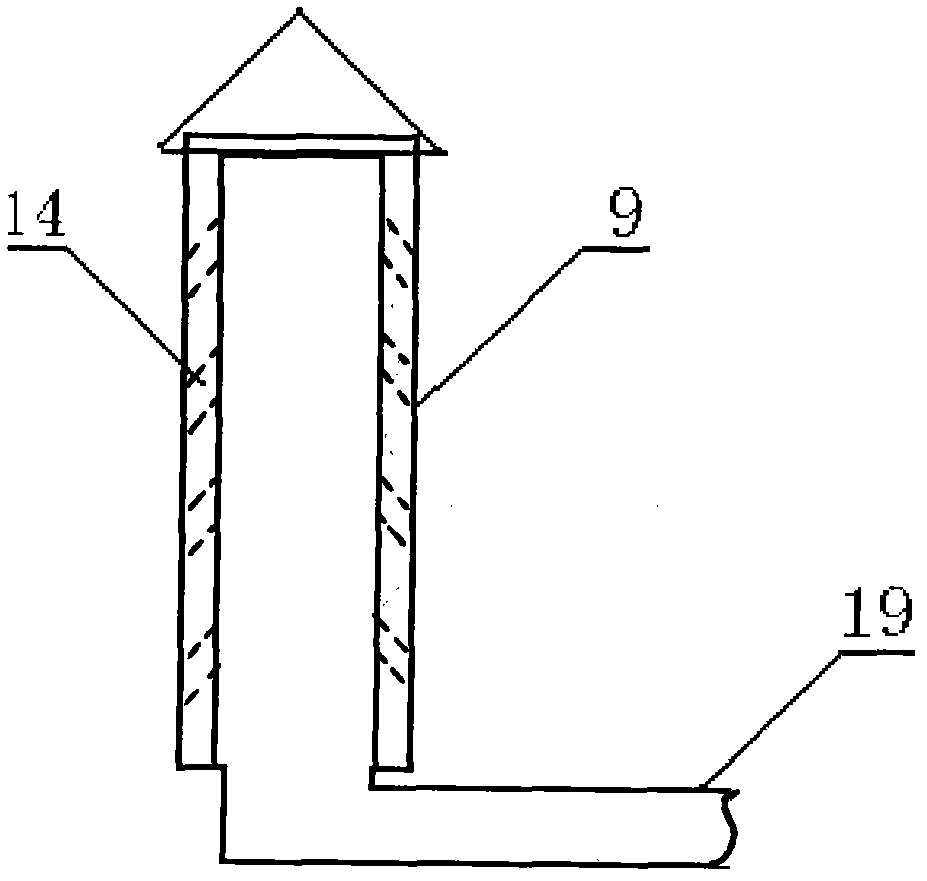

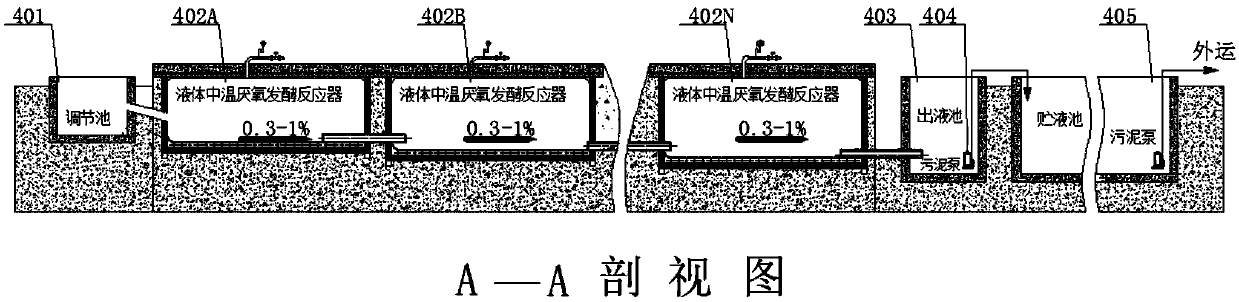

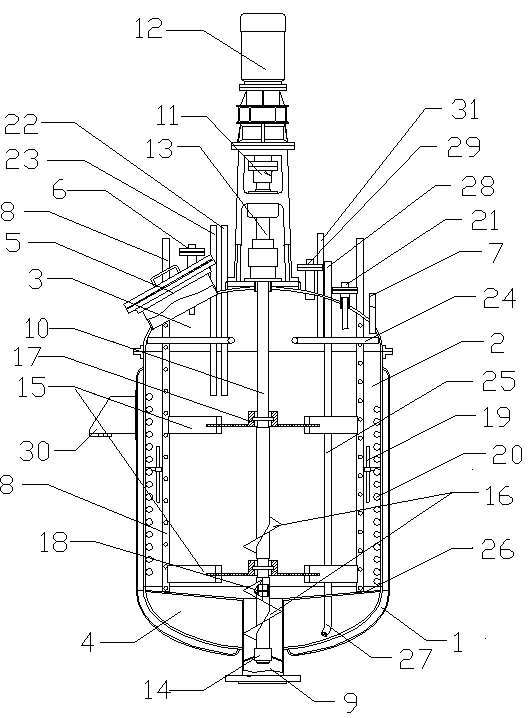

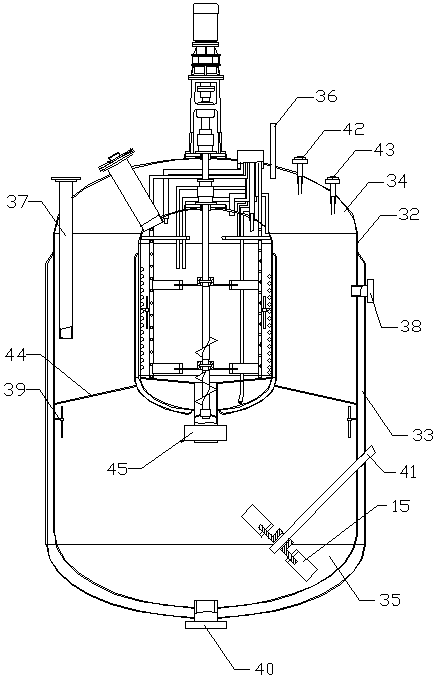

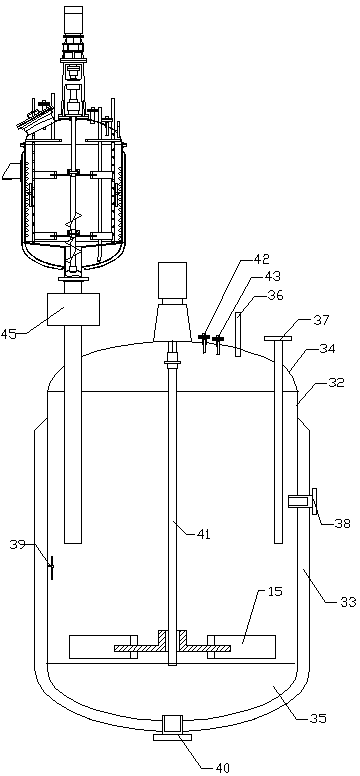

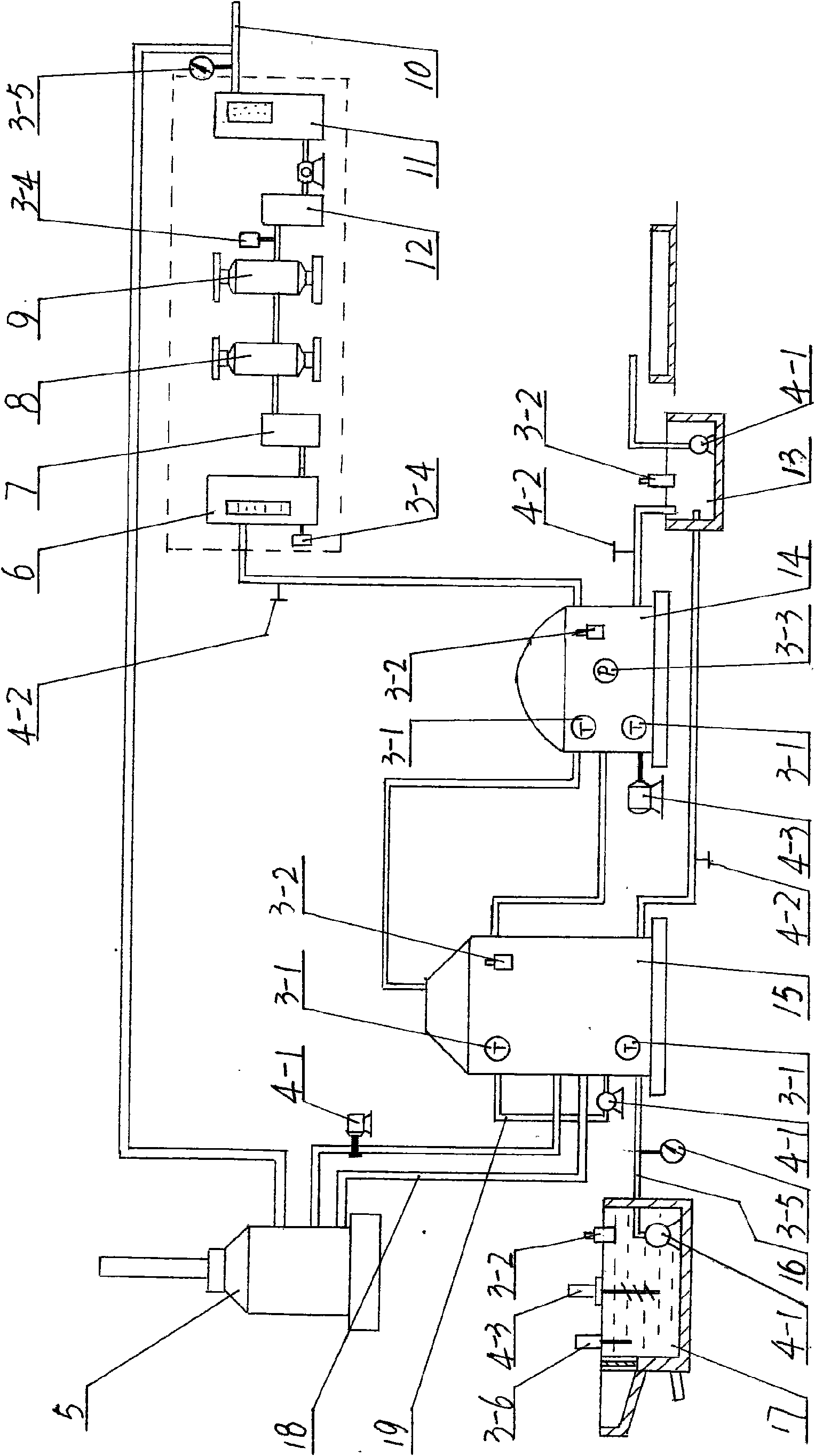

Secondary anaerobic fermentation and power generation system for large-middle scale biogas engineering

InactiveCN101597562AImprove processing efficiencyImprove gas production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiogas productionFermentation

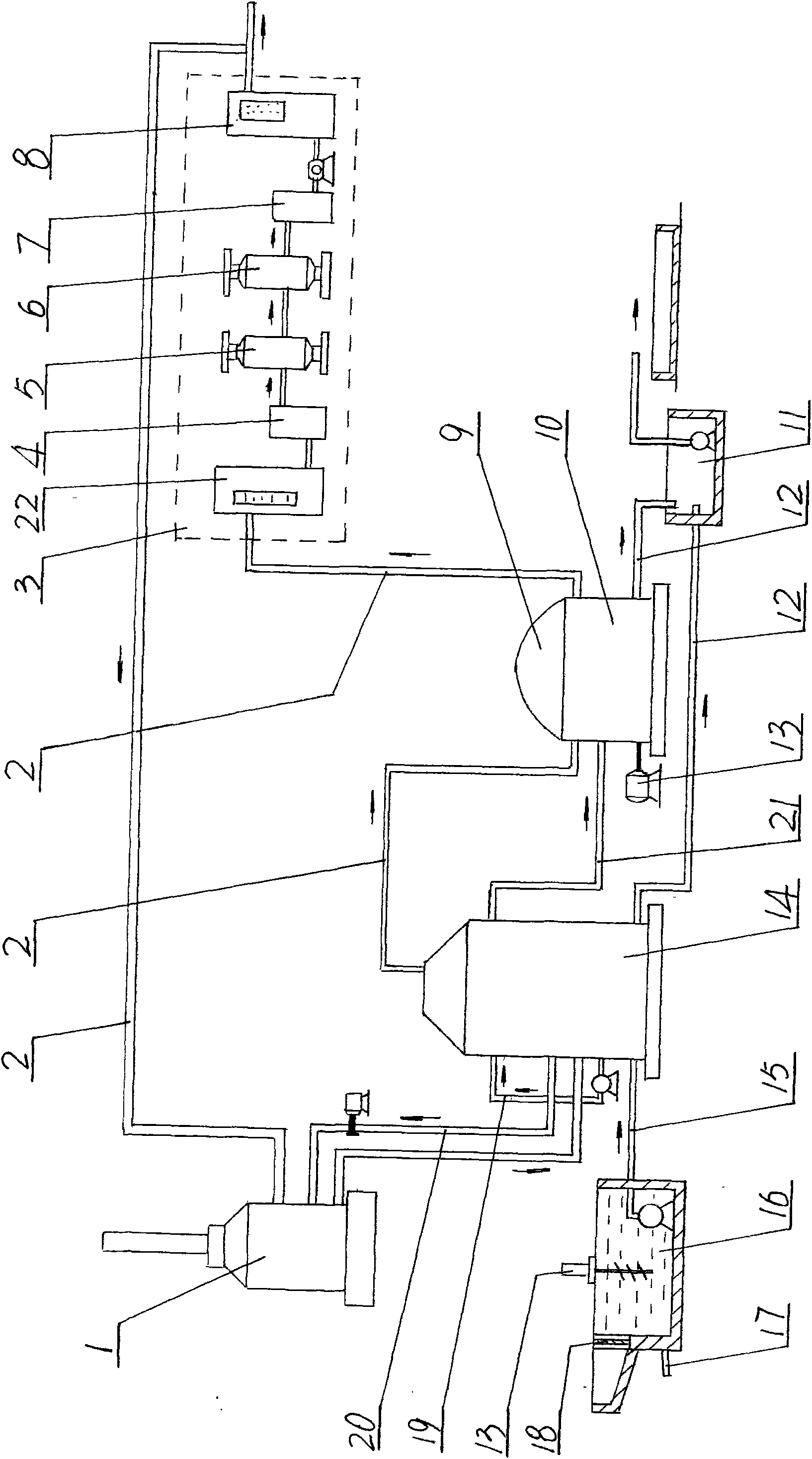

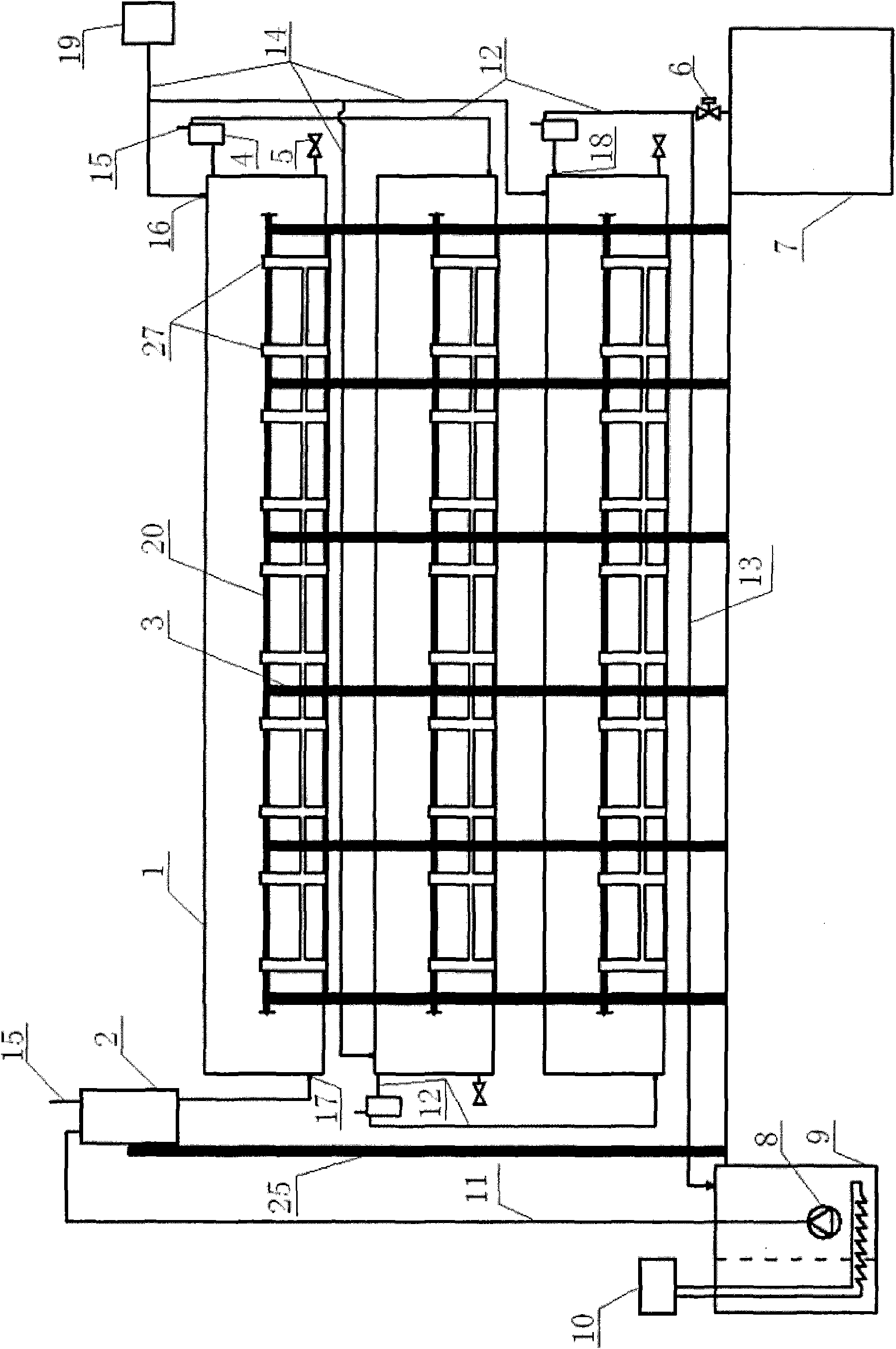

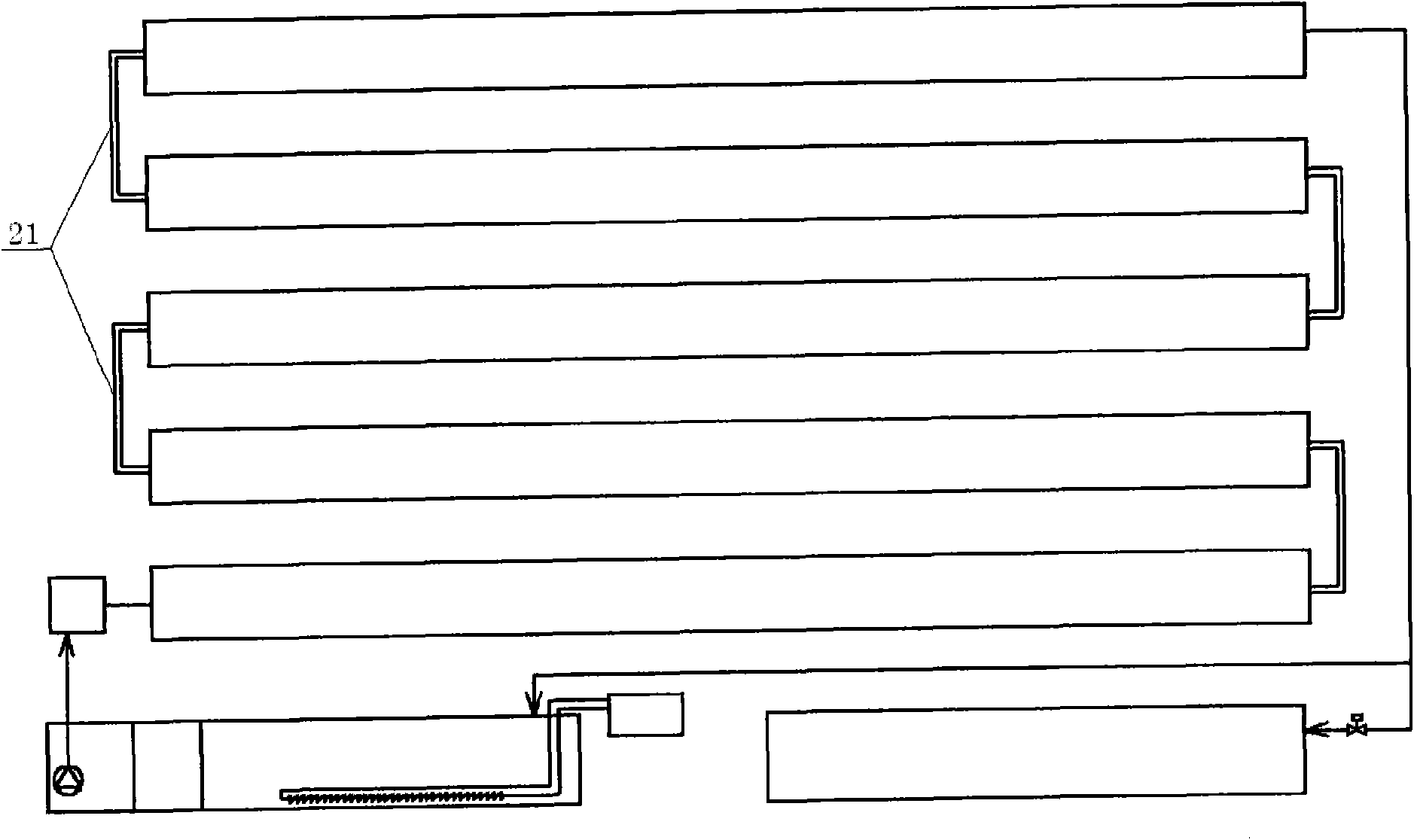

The invention discloses a secondary anaerobic fermentation and power generation system for large-middle scale biogas engineering, which belongs to a biogas production device. The invention aims to provide a biogas production system which can be used for centralized power generation. The system comprises a pretreatment tank, a primary fermentation tank, a secondary fermentation tank and a biogas residue tank; the pretreatment tank (16) is communicated with a USR reactor (14) through a feeding pipe (15), the USR reactor is communicated with the secondary fermentation tank (10) through an overflow pipe (21) and a gas conduit (2), and the USR reactor (14) and the secondary fermentation tank (10) are communicated with the biogas residue tank (11) through a residue discharge pipe (12) respectively; and the secondary fermentation tank supplies biogas for a generator through a biogas purification device (3). The system realizes the conversion of biogas fermentation from a small-scale production mode to a centralized high-efficiency large-scale mode, and has the advantages of low cost, high efficiency of wastewater treatment, high gas yield and the like; and the system can be matched with large-scale livestock and poultry farms for construction, thereby achieving the aims of saving energy sources, reducing the emission, and protecting the agricultural ecological balance.

Owner:GUIZHOU QIAN LIN ZHOU ENVIRONMENTAL PROTECTION ENERGY TECH +1

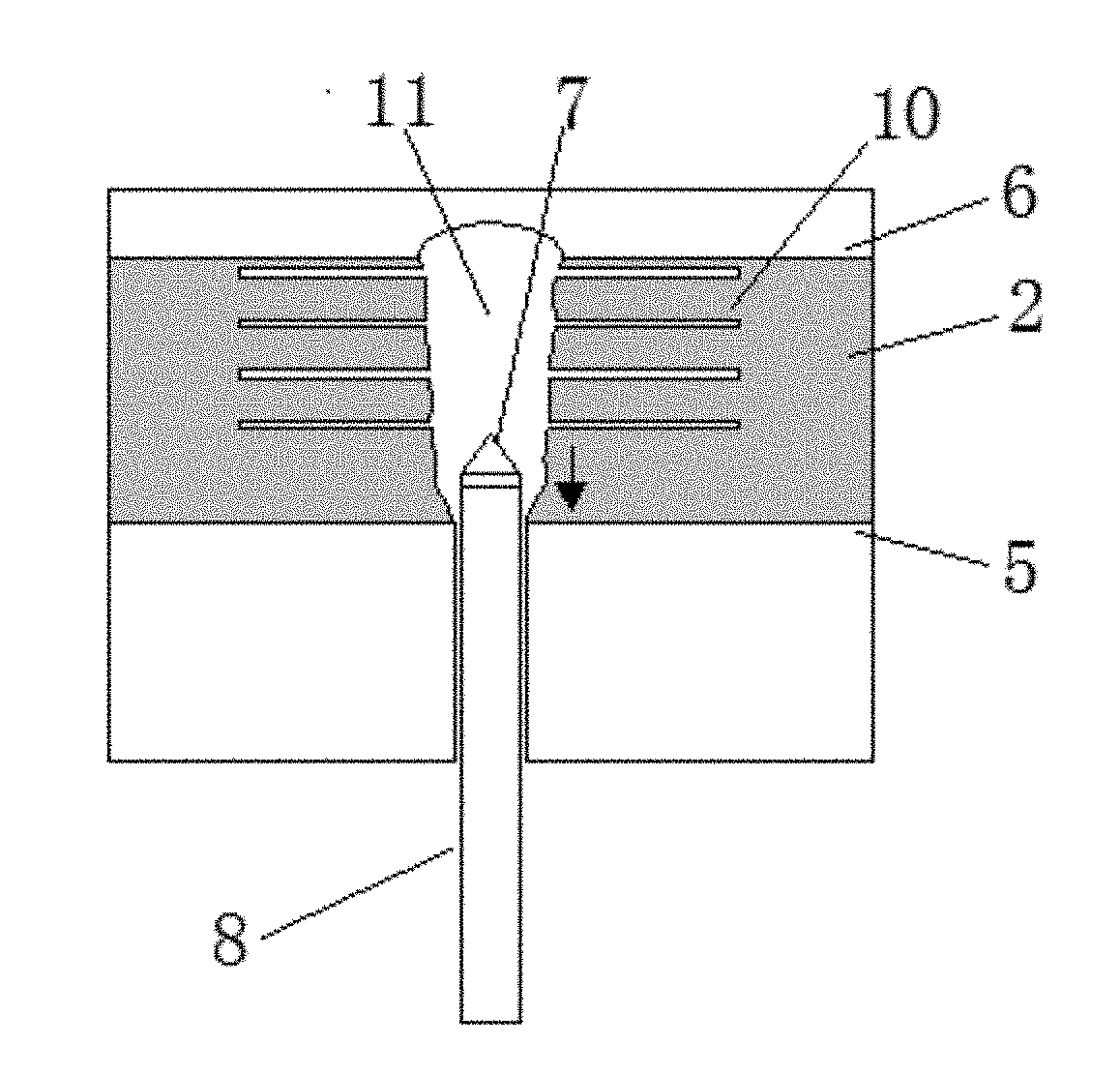

Decompression marine natural gas hydrate mining method and submarine mining system

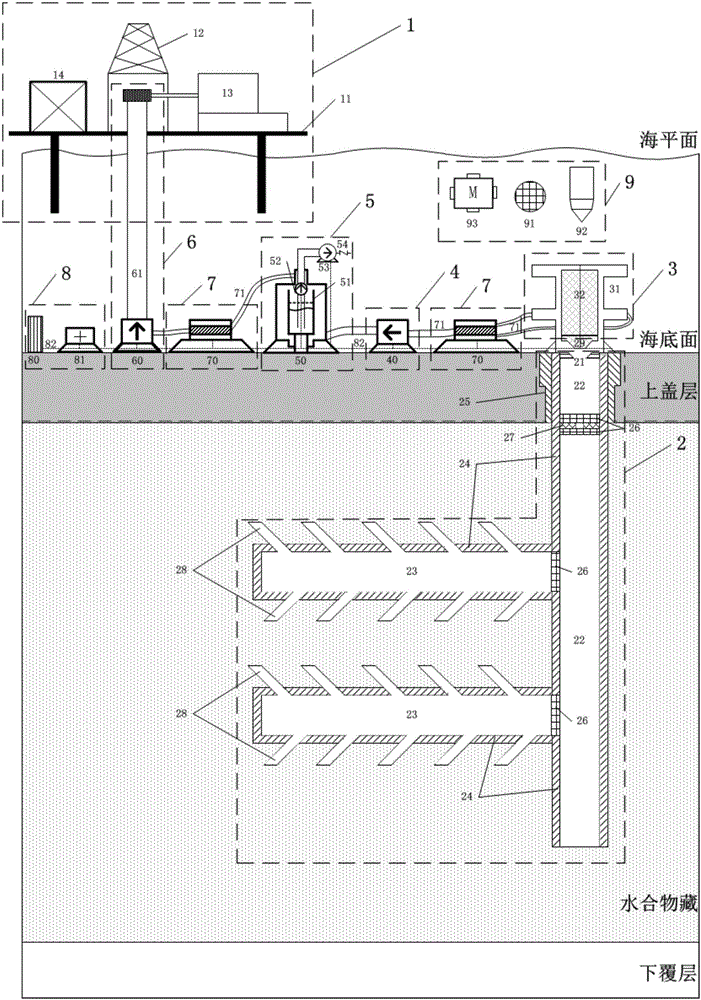

The invention relates to a decompression marine natural gas hydrate mining method and a submarine mining system. The submarine mining system comprises a semi-submersible offshore platform, a mining well with multiple shower holes, a wellhead gas and water acquisition tree, a gas and water mixed delivery system, a submarine gas and water separating device, a gas delivery system, a pipeline system, a power and communication system and an auxiliary device. The decompression marine natural gas hydrate mining method and the submarine mining system have the advantages that submarine natural gas hydrate reservoirs can be safely, efficiently and economically mined; the submarine mining system is complete, and various portions of the submarine mining system are high in modularization, low in manufacturing cost and short in manufacturing cycle and can be reused; most devices are positioned in submarine environments and are controlled via the offshore platform, only natural gas is delivered offshore, and accordingly the submarine mining system is low in extra energy consumption; owing to a technology for forming the multiple shower holes in the mining well, missed mining regions can be effectively reduced, and the gas yield can be effectively increased owing to multiple horizontal wells; the submarine mining system has functions of well blocking prevention, well blowout prevention, hydrate secondary generation and the like, and accordingly safety production can be guaranteed; various main devices can flexibly move and are used with one another, and accordingly movable regional production operation can be implemented.

Owner:DALIAN UNIV OF TECH

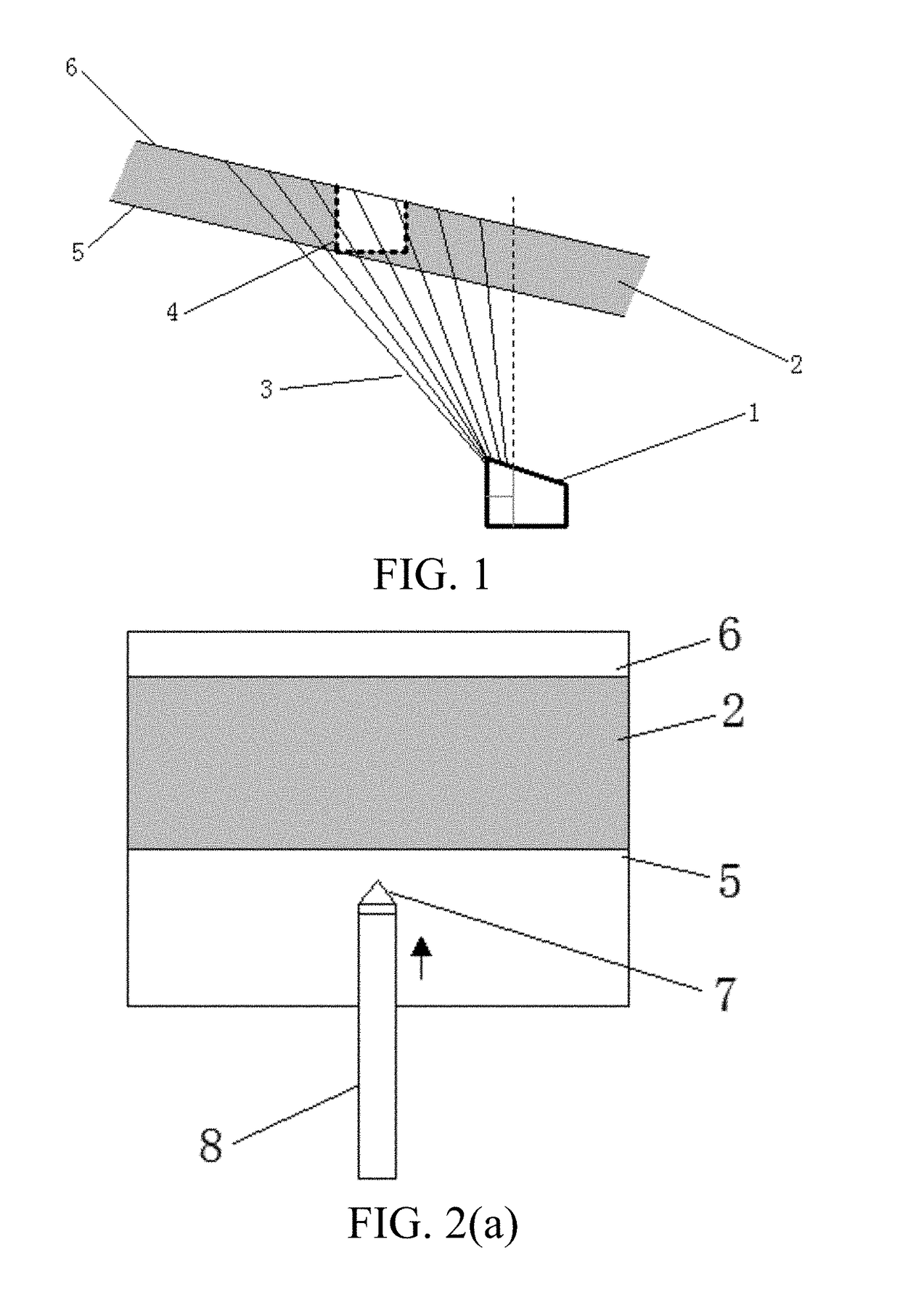

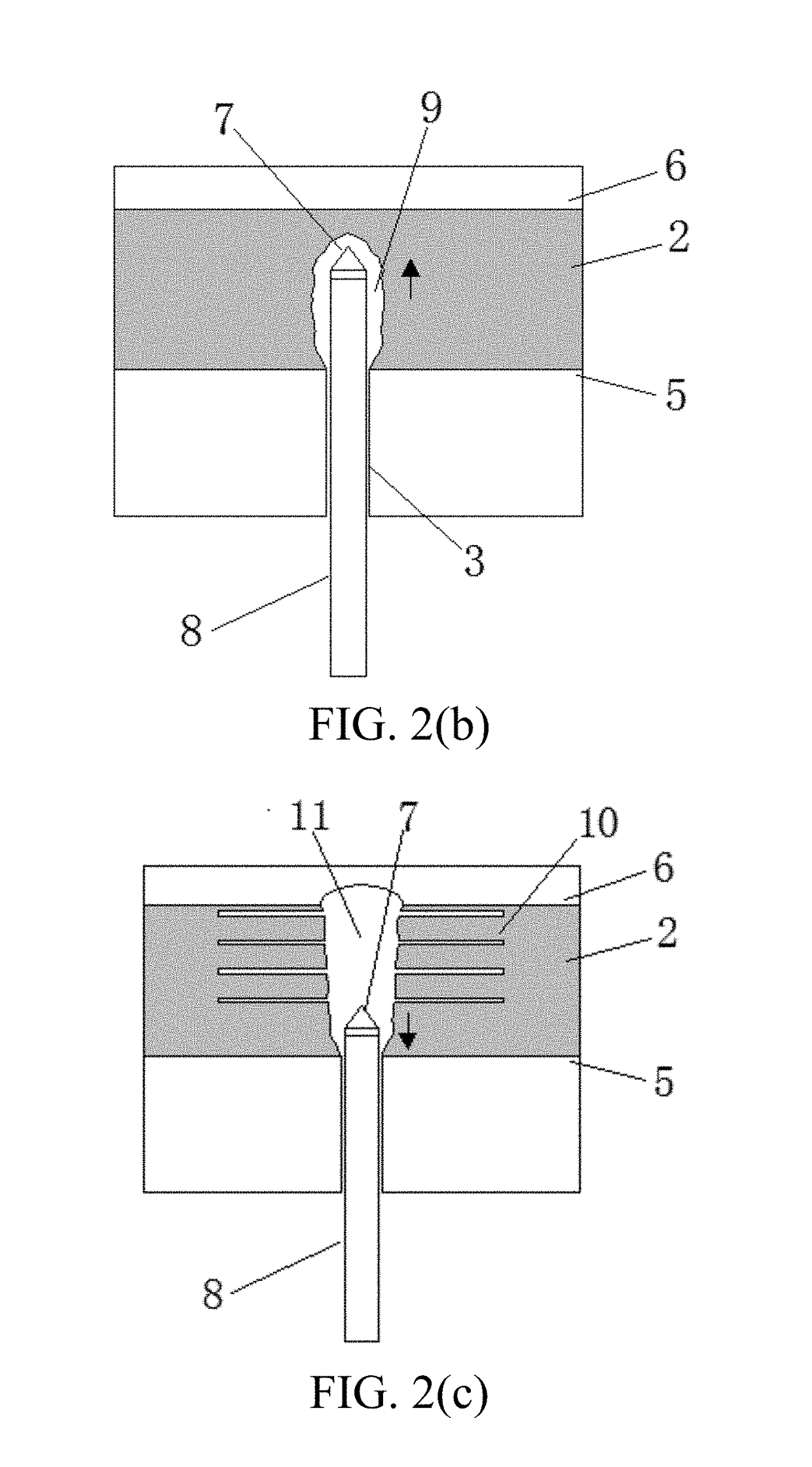

Method of performing combined drilling, flushing, and cutting operations on coal seam having high gas content and prone to bursts to relieve pressure and increase permeability

ActiveUS20170370156A1Simple processEfficient amplificationConstructionsLiquid/gas jet drillingWell drillingDesorption

The present invention relates to a “drilling-flushing-slotting” coupled pressure relief and permeability increasing method for a high gas outburst coal seam, which is more particularly suitable for the pressure relief and permeability increasing when gas of a roadway band of the high gas outburst coal seam is pre-extracted through crossing boreholes. On the basis of the crossing borehole pre-extraction measures for the coal seam gas, the hydraulic flushing and the hydraulic slotting are reasonably combined, and a “drilling-flushing-slotting” dedicated device is utilized to implement the coupled operation of “low pressure drilling-medium pressure flushing-high pressure slotting” in a borehole, so that the coal in the pre-extraction area is deformed and moved to form network cracks, passages are provided to the desorption flow of the gas, and the gas is easier to extract. The method can enlarge the single-hole pressure relief influence range, increase the gas permeability of the coal seam, improve the gas extraction efficiency, reduce the number of pre-extraction boreholes, shorten the pre-extraction time and have good applicability to the coal seams in different occurrence states. The present invention can reduce the number of the crossing boreholes by 32.5% and can reduce the length of each crossing borehole by 42.9%, is remarkable in coal roadway regional outburst eliminating effect, and obviously increases the tunneling speed.

Owner:CHINA UNIV OF MINING & TECH

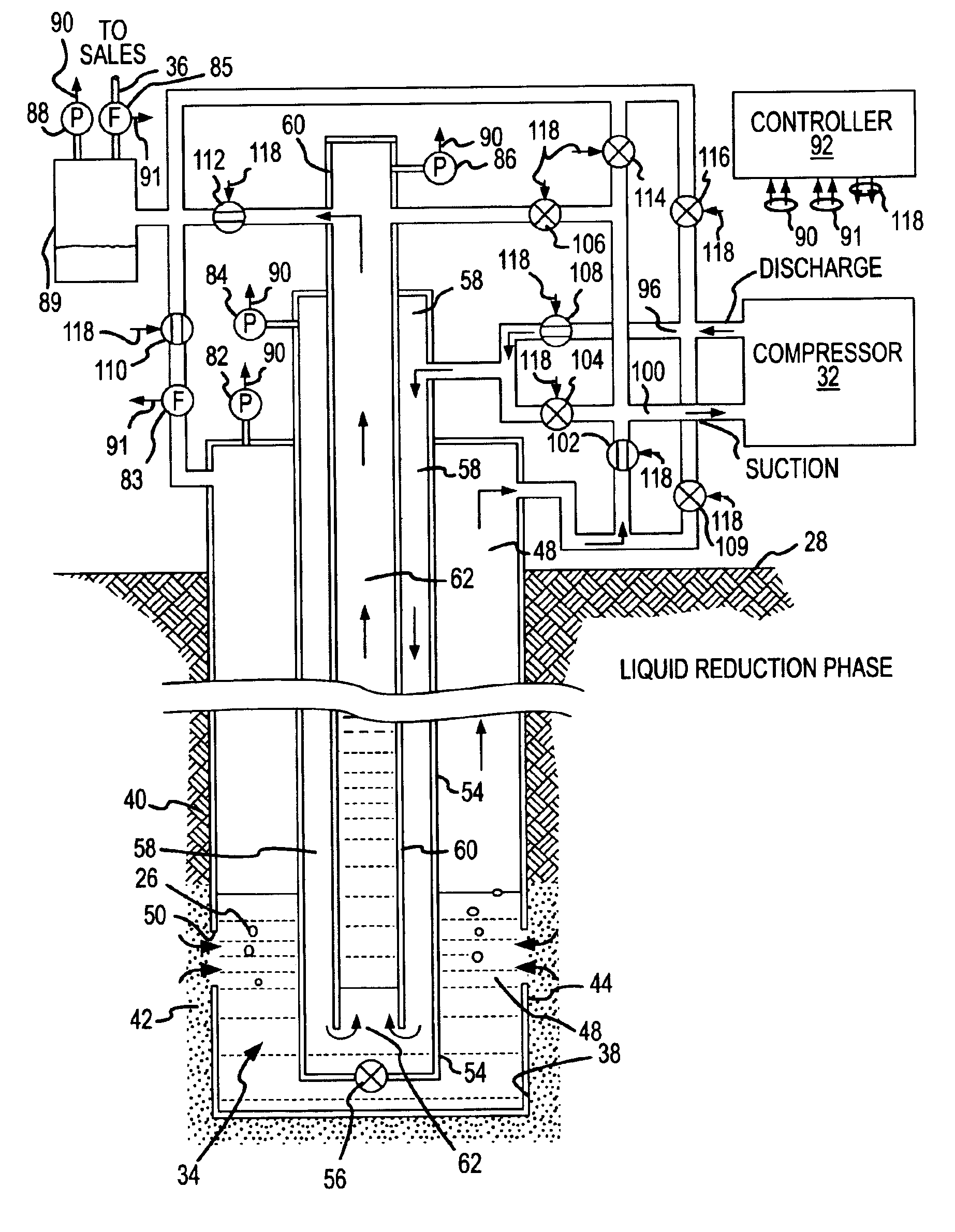

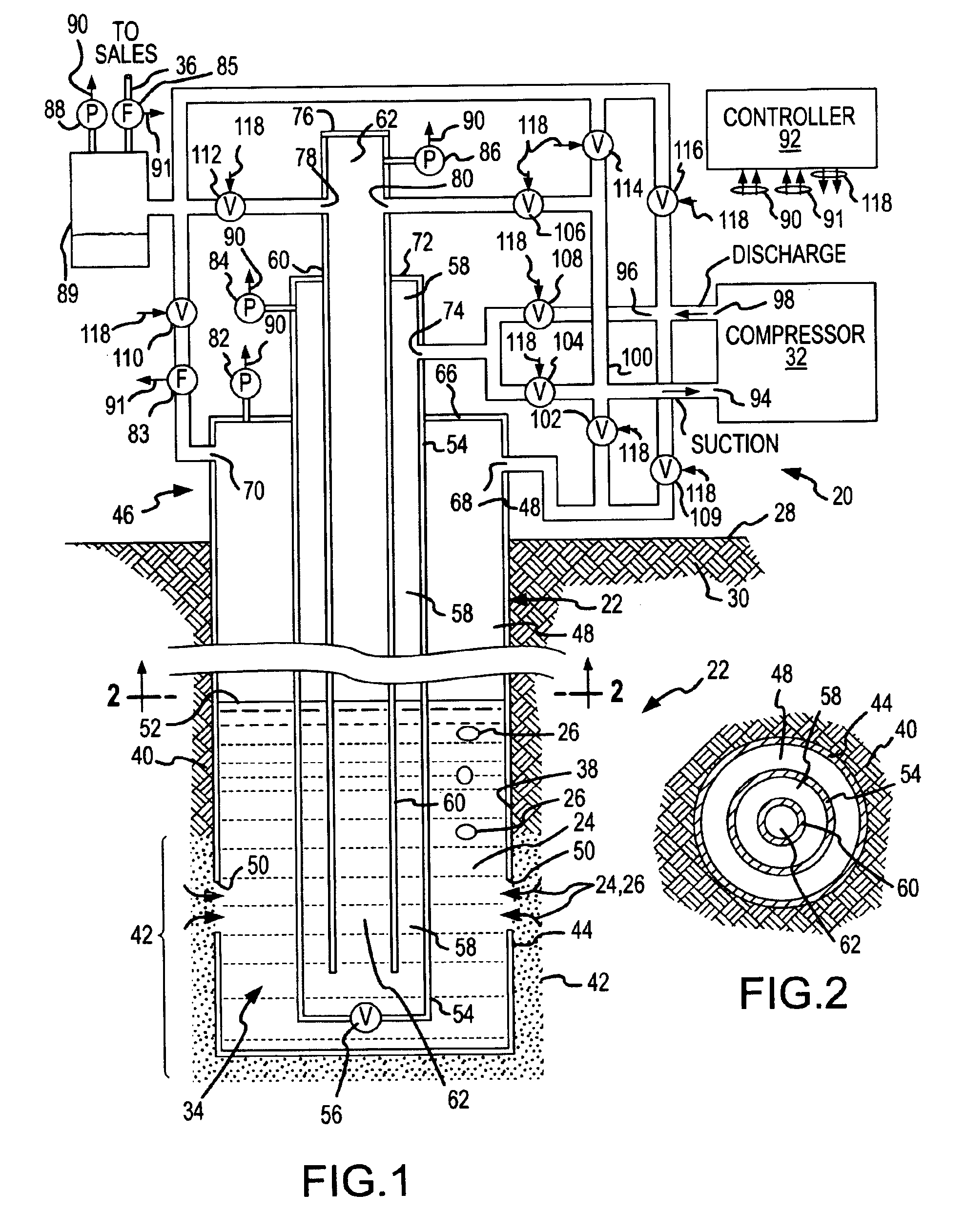

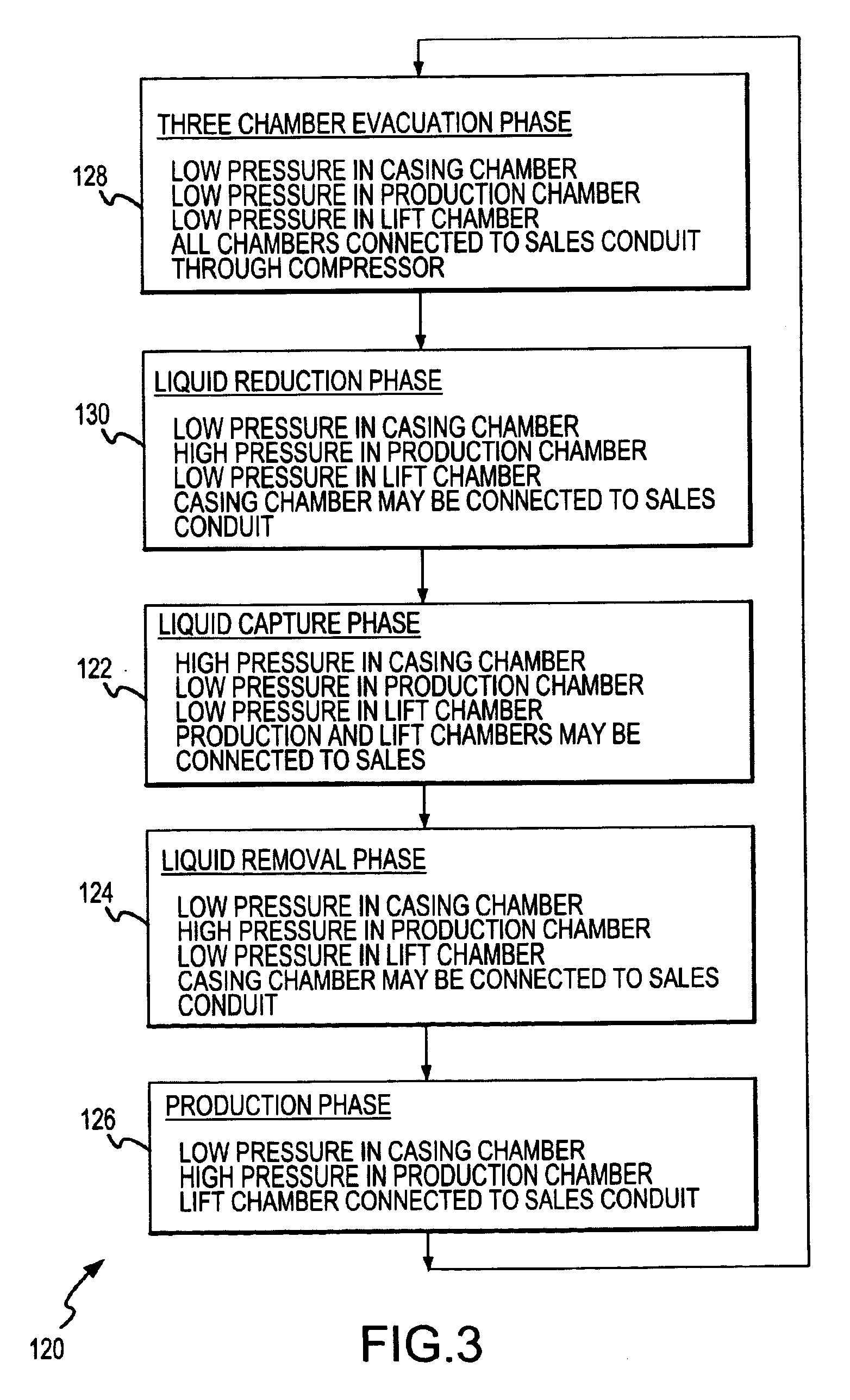

Gas recovery apparatus, method and cycle having a three chamber evacuation phase and two liquid extraction phases for improved natural gas production

InactiveUS7100695B2Reduce the amount requiredLess timeFluid removalSealing/packingProduction rateProduct gas

Natural gas produced from a well by executing a multiple-phase gas recovery cycle which includes a phase during which a relatively lower evacuation pressure is applied within three chambers in the well to assist in accumulating liquids at a well bottom, followed by a liquid reduction phase which clears the liquid from two of the chambers while leaving the liquid in the third chamber. The remaining liquid is thereafter lifted in subsequent liquid capture and liquid removal phases. The liquid reduction phase clears the fluid from the well more effectively with less interruption in the production of gas from the well while maintaining the full gas productivity of the well.

Owner:FORESTAR PETROLEUM

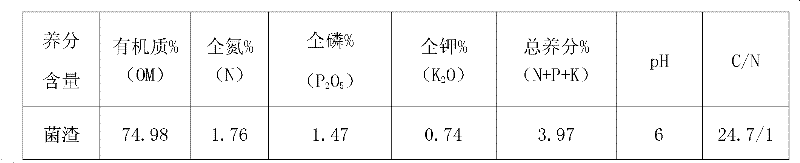

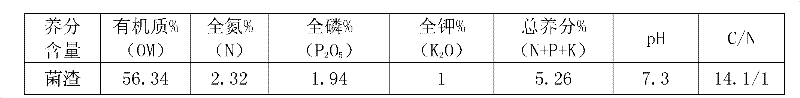

Method and device for recycling edible mushroom residues

ActiveCN102174586AImprove filtration efficiencyIncrease gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsRed mudNew energy

The invention relates to a method and device for recycling edible mushroom residues. The method mainly comprises the steps of placing waste mushroom residues and maize straws or excrements from a cattle farm into an anaerobic reactor for united fermentation to produce biogas, and covering a red-mud plastic head cover on the anaerobic reactor, wherein an inclined stirrer is arranged and is beneficial to feeding / discharging of mushroom residue raw materials and avoidance of crusting. The produced biogas is used for power generation and agriculture, biogas residues are used for manufacturing organic fertilizers, biogas slurry is prepared into foliar fertilizer for fruits or vegetables, and thus, new energy sources, namely the biogas and the organic fertilizers, are obtained while the mushroom residues are treated. The method and the device in the invention are mainly used in major edible mushroom producing areas, a solar-panel greenhouse and a solar heat supply device are assorted for the device, a composite microbial inoculum is assorted for the method, and the anaerobic reactor can be normally used all the year round.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

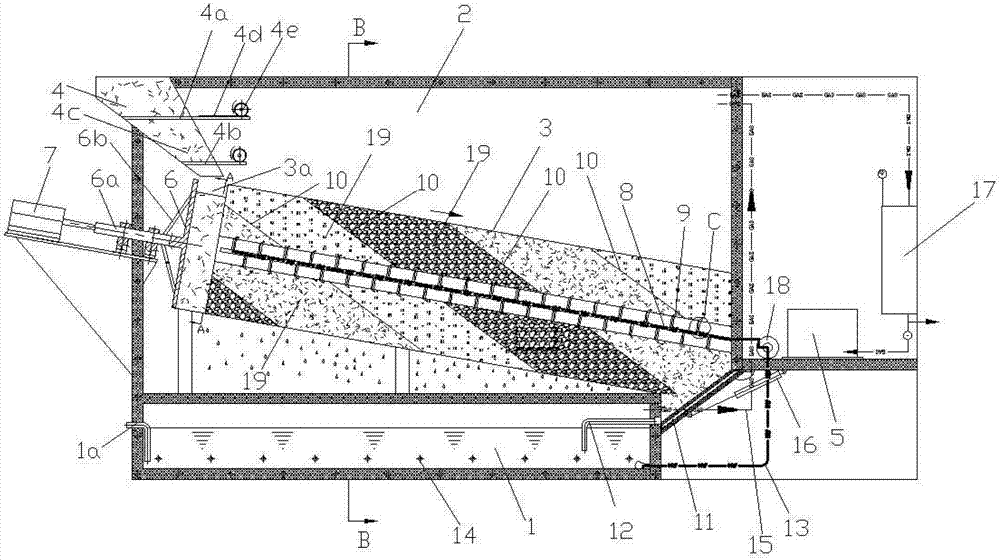

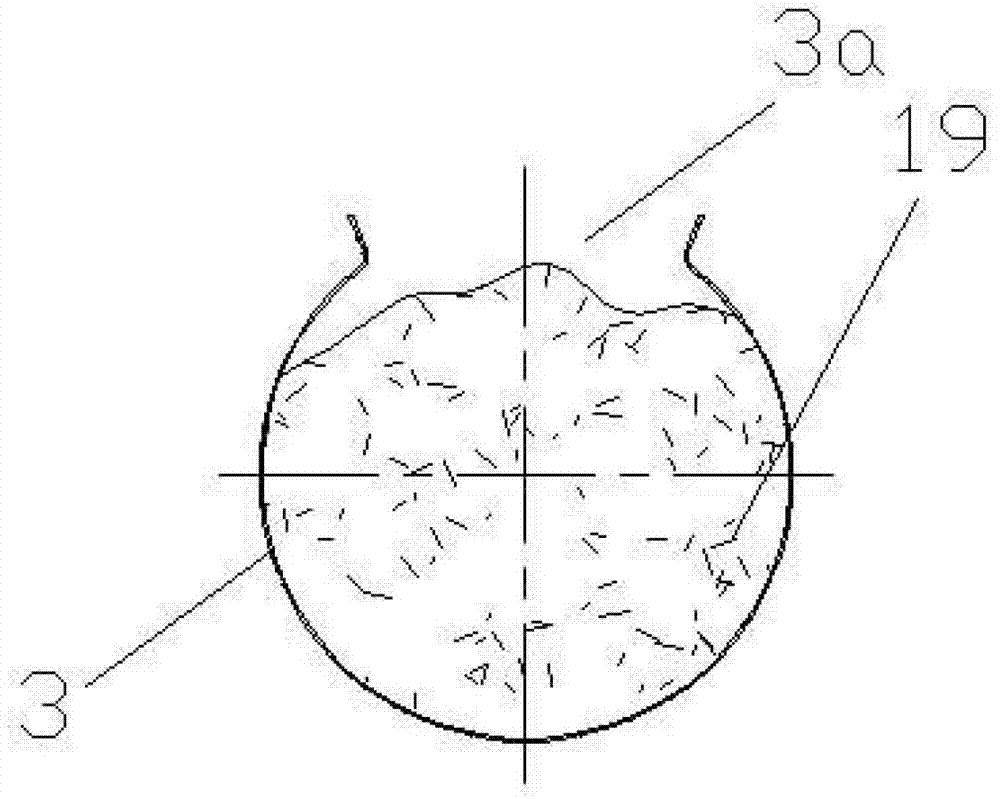

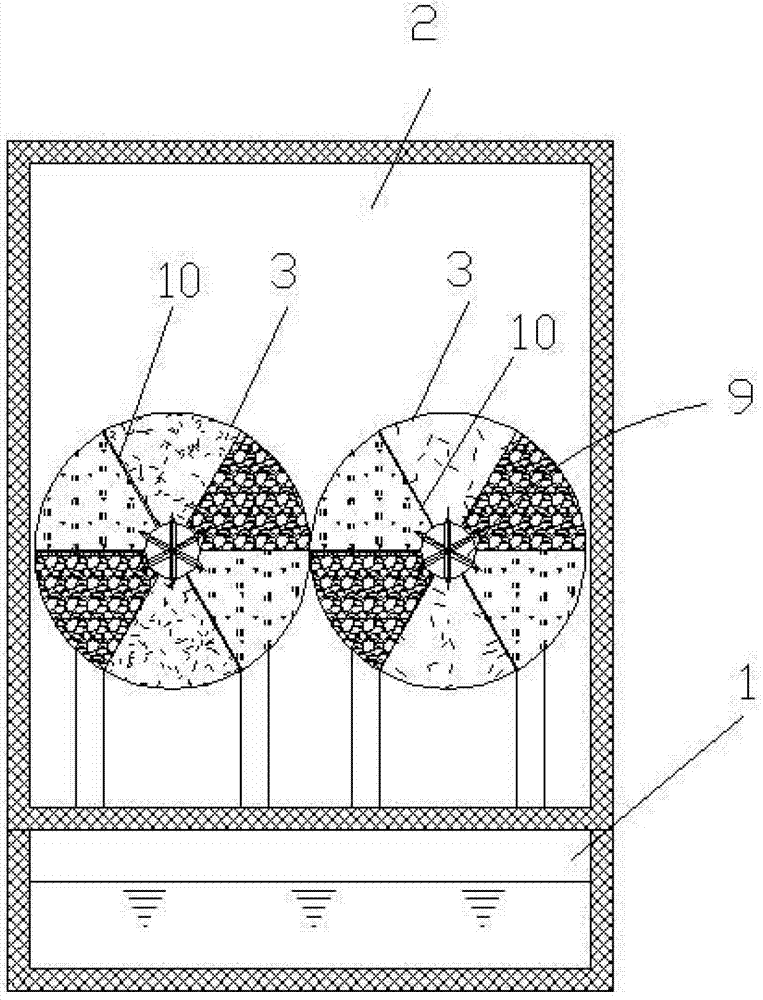

Spiral self-stirring dry fermenting device and method

ActiveCN102816690ARealize self-stirringReduced residence time required for anaerobic consumptionGas production bioreactorsWaste based fuelSlagSpray nozzle

The invention discloses a spiral self-stirring dry fermentation device and a method. Fermentation cylinders are obliquely arranged at the bottom in a gas storage tank which is installed on a top board of a leachate holding tank; an enclosed inner cylinder is arranged at the central part in each fermentation cylinder along an axial direction; a leachate jet pipe is mounted in the inner cylinder; nozzles are distributed on the leachate jet pipe and extend out from the inner cylinder; spiral separator plates are distributed in each fermentation cylinder along an axial direction, and initiating terminals of the spiral separator plates are located behind a feed inlet; a lower end of each fermentation cylinder is provided with a material outlet, a slag removal opening communicating with the material outlet of the fermentation cylinder is mounted on a base plate of the gas storage tank, and a slag removal door is arranged on the slag removal opening; the leachate holding tank is provided with a leachate return pipe communicating with the gas storage tank and a pipeline communicating with a leachate inlet of the leachate jet pipe; electric heating pipelines are distributed in the leachate holding tank; and a biogas conveying pipeline communicating with the upper part of the gas storage tank is arranged at the upper part of the leachate holding tank. The invention also provides the method of using the device for fermentation.

Owner:CHONGQING ACAD OF AGRI SCI +1

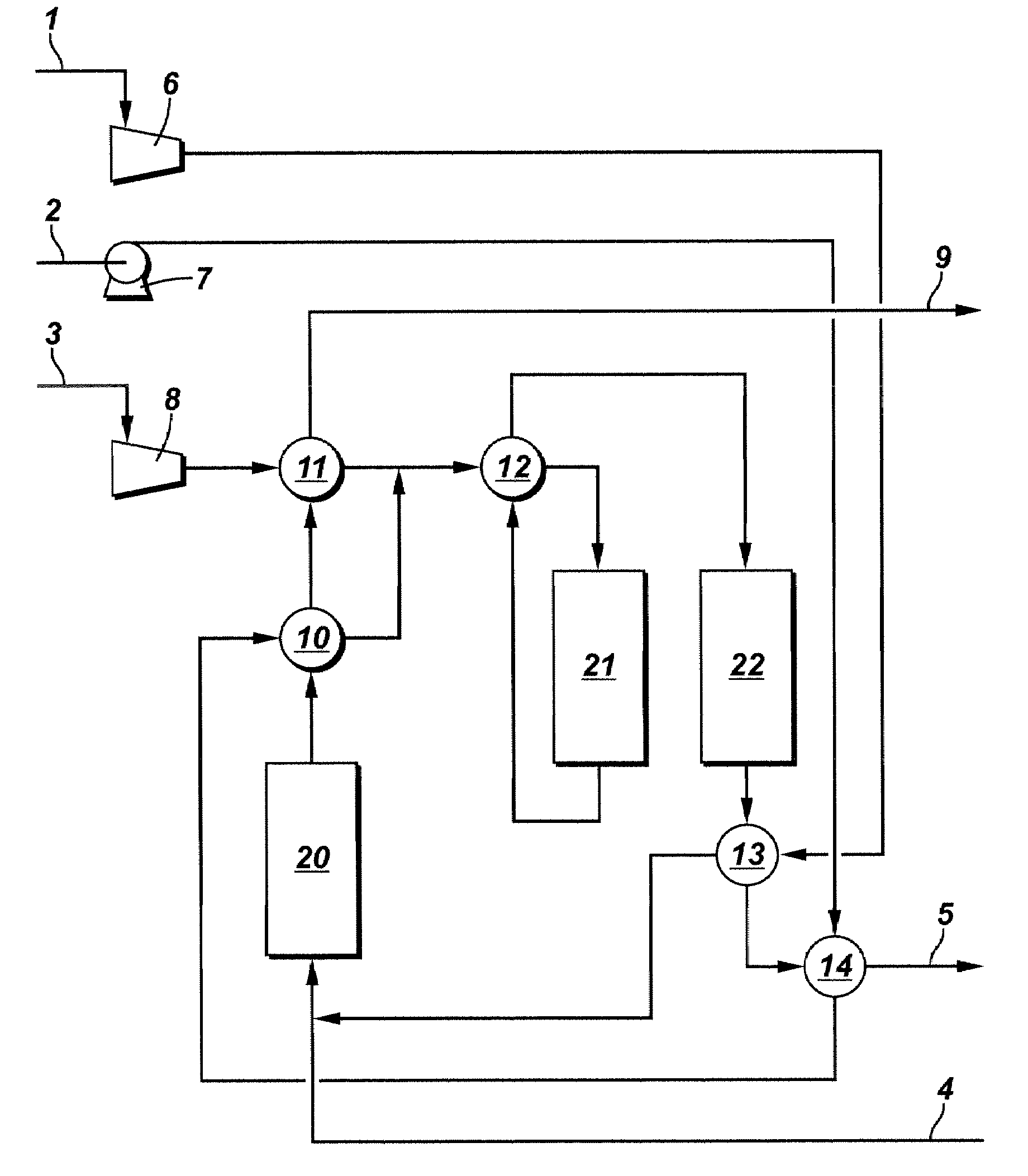

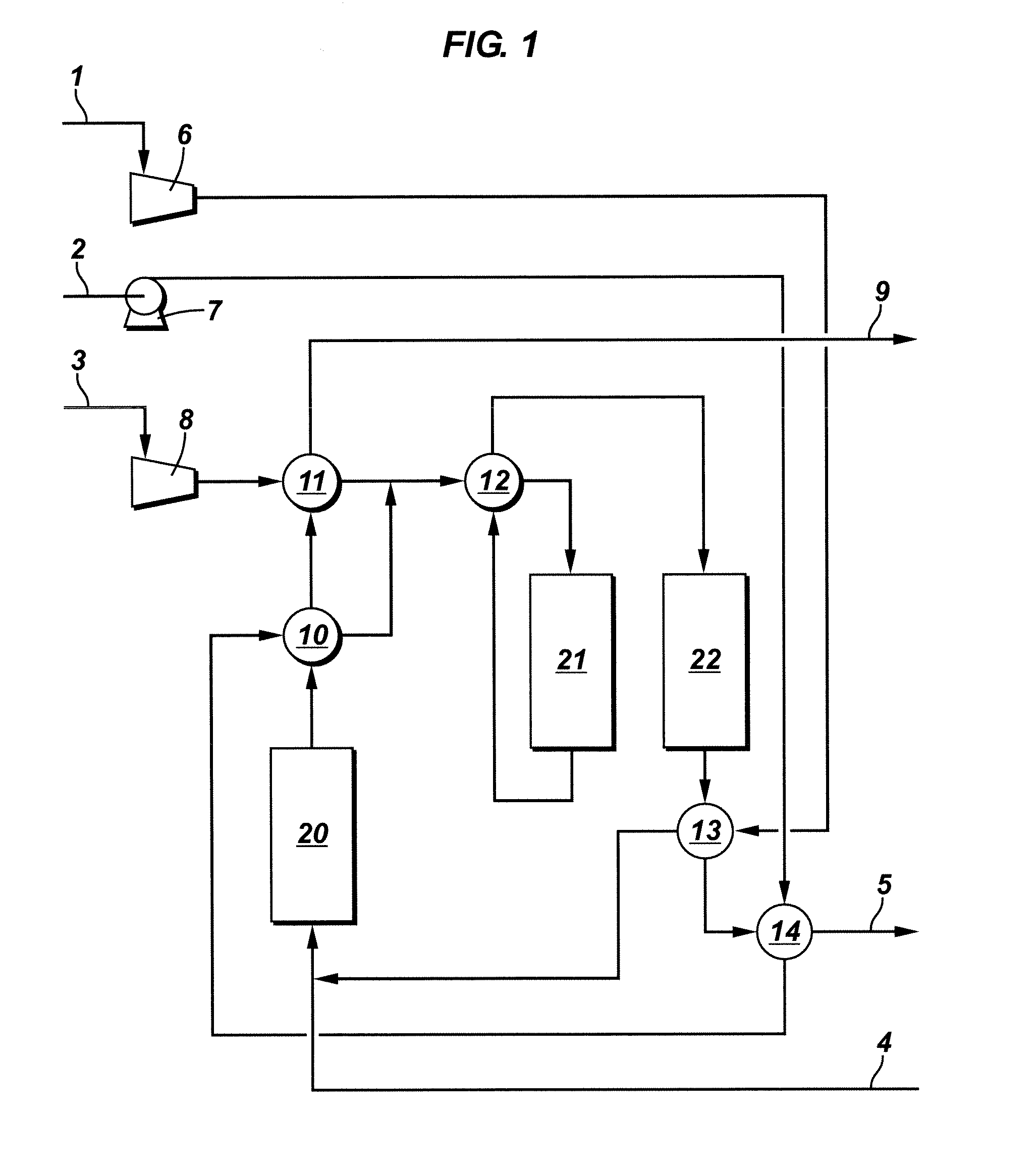

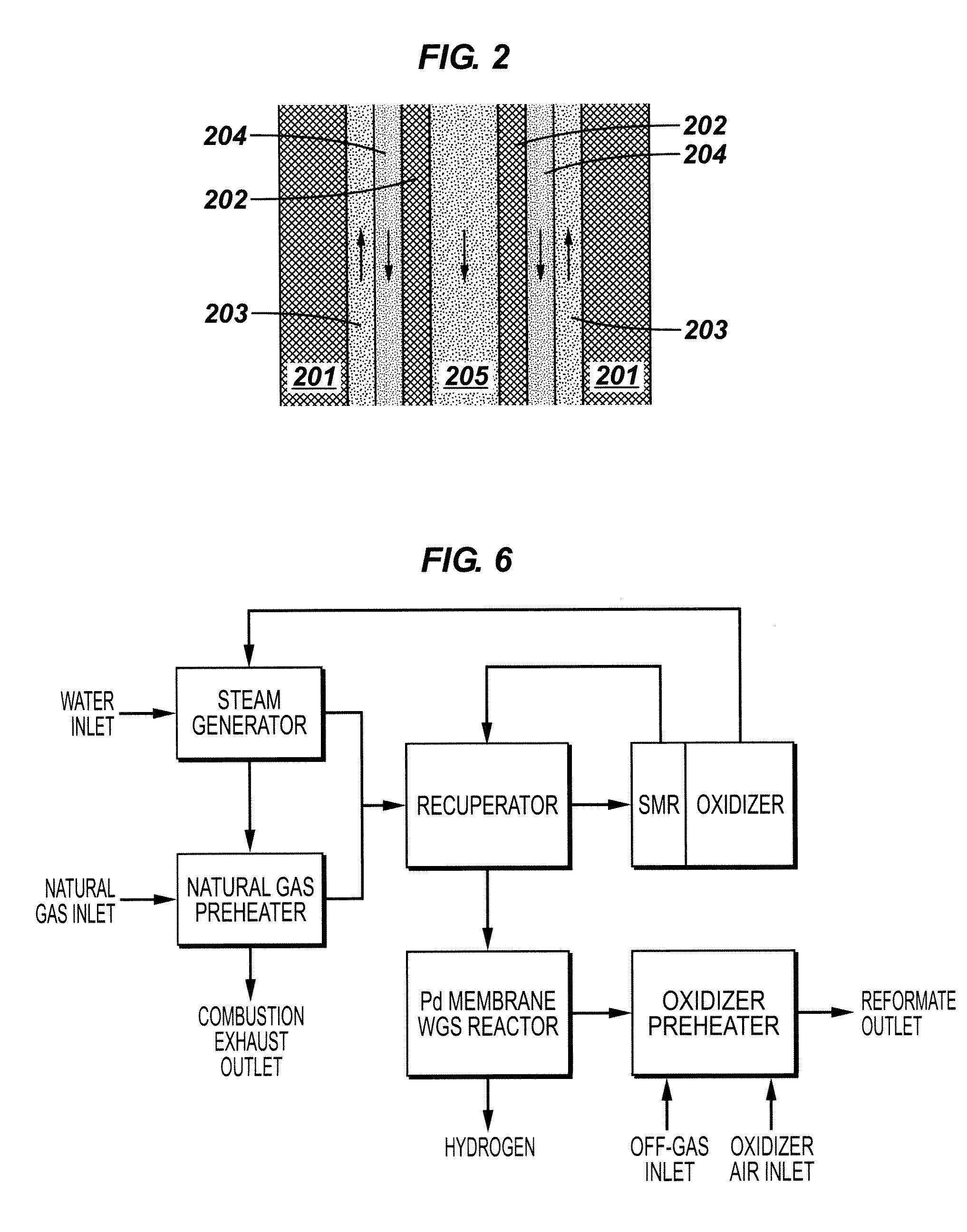

Process and apparatus for synthesis gas and hydrocarbon production

InactiveUS20090292030A1Reduce heat lossMaximize heat recoveryCatalytic gas-gas reactionHydrocarbon from carbon oxidesForming gasOperational costs

A process and apparatus for preparing a synthesis gas suitable for feeding to a suitable hydrocarbon production reactor, such as a Fischer Tropsch reactor is described. According to one aspect, the process and apparatus utilize heat exchangers that thermally integrate the reaction steps such that heat generated by exothermic reactions, e.g., combustion, are arranged closely to the heat sinks, e.g., cool methane, water and air, to minimize heat loss and maximize heat recovery. Effectively, this thermal integration eliminates excess piping throughout, reduces initial capital and operating costs, provides built-in passive temperature control, and improves synthesis gas production efficiencies.

Owner:TEXACO INC

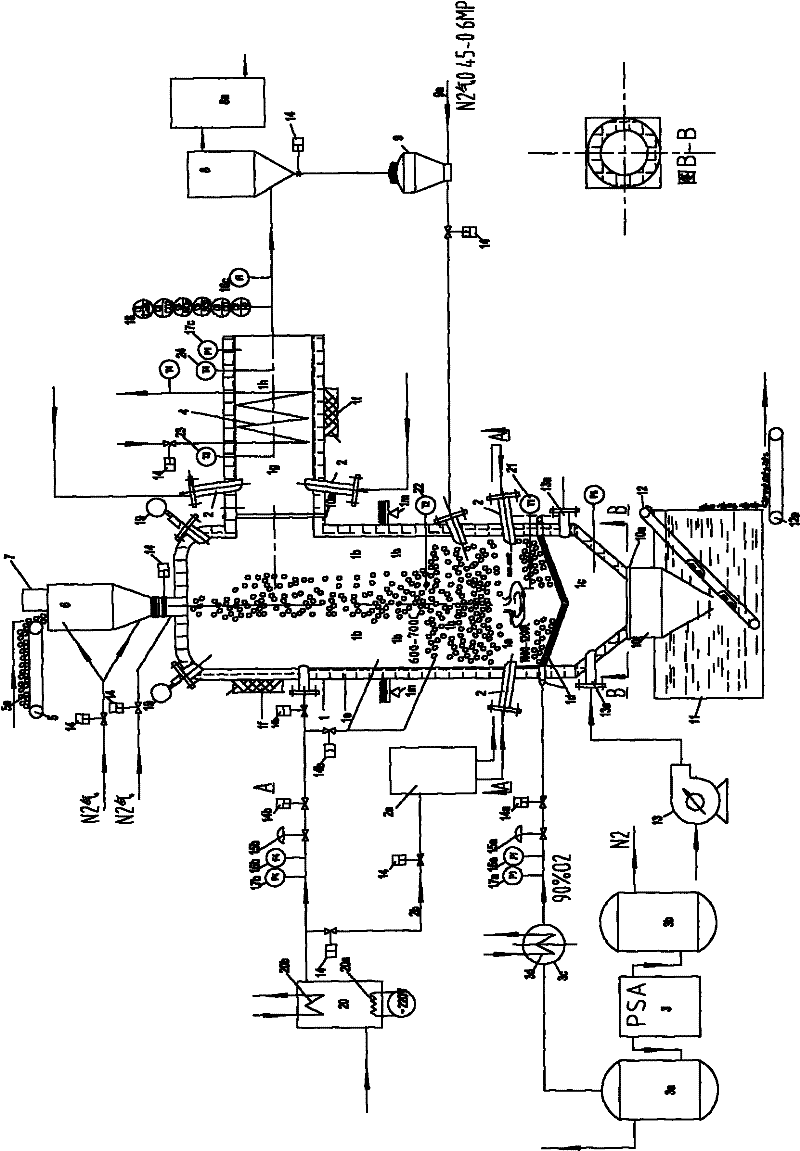

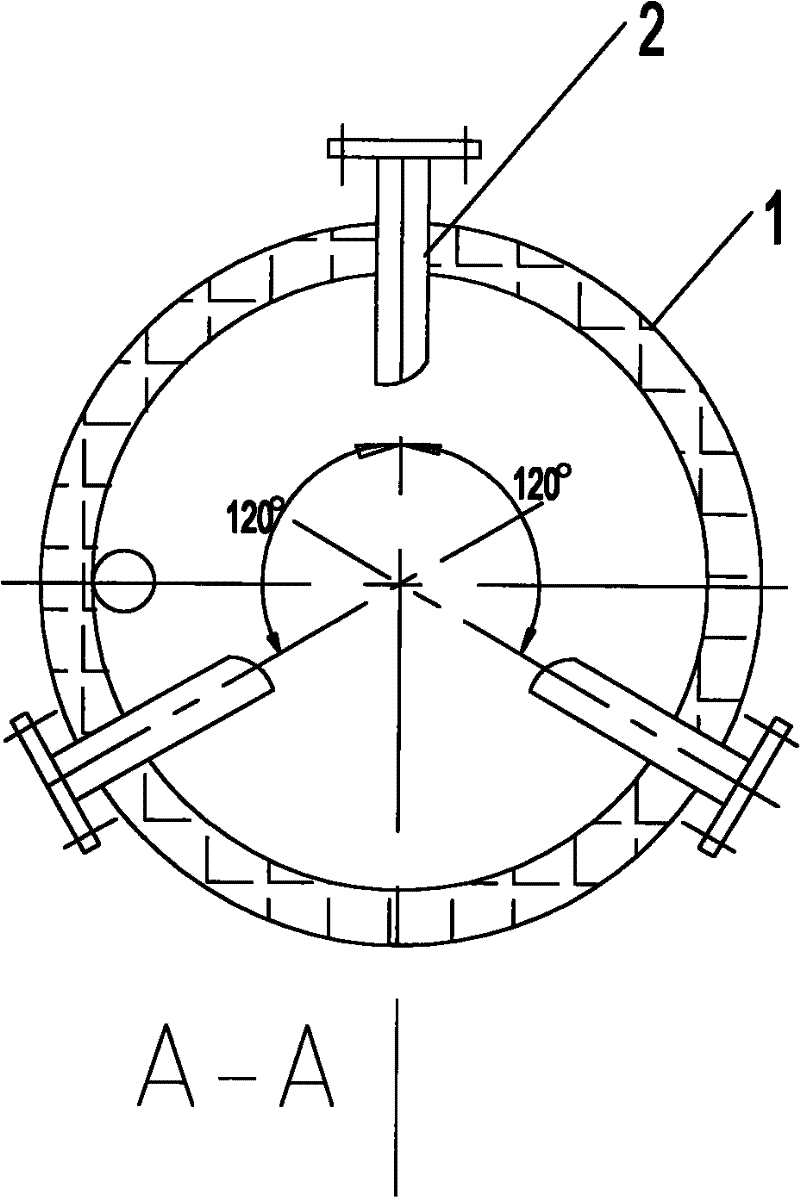

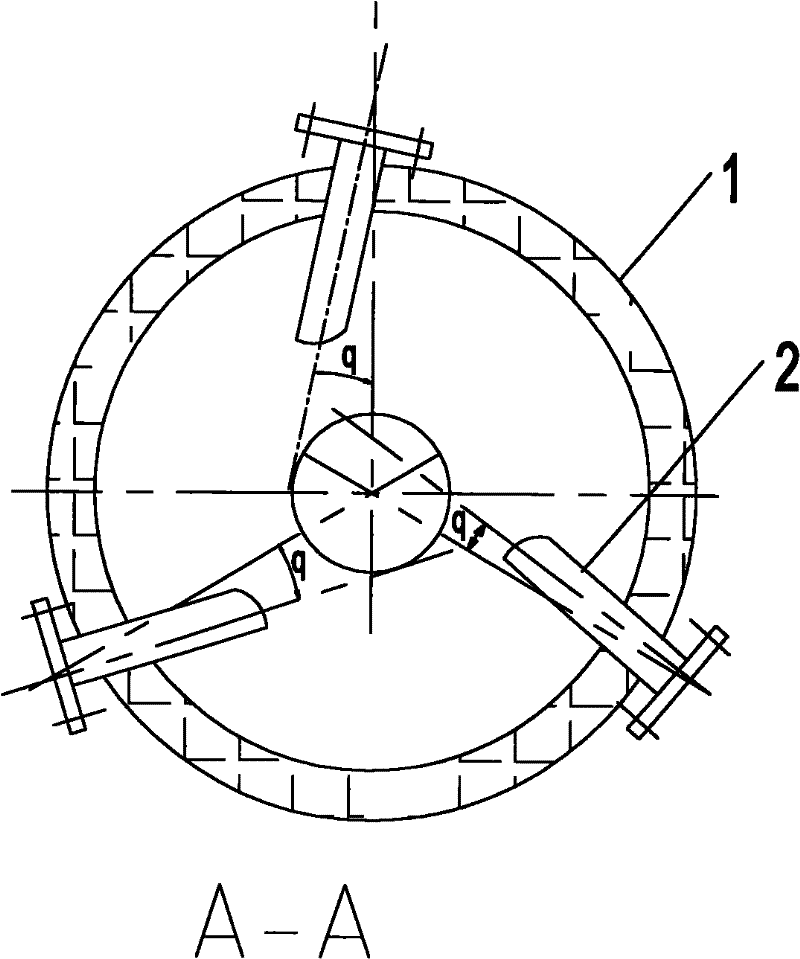

A device for producing combustible gas by plasma pyrolysis and oxygen-enriched combustion-supporting materials

ActiveCN102260537AControl furnace temperatureImprove gas production efficiencyGranular/pulverulent flues gasificationFurnace temperatureSlag

The invention relates to the technical field of combustible gas preparation by virtue of biomass pyrolysis and gasification and further relates to the clean energy field of combustible gas preparation by virtue of pyrolysis and gasification of waste polymer compounds. The device consists of a gasification furnace, a plasma generation device, an oxygen-enriched combustion-supporting device, a biomass transporting device, a cyclone separation conveying device, a steam generation device, an air blower and a slag processing device, wherein the plasma generation device, an oxygen-enriched combustion-supporting pyrolysis region, a steam-adding thermalization reaction region and a second cracking region are arranged in a gasifying hearth; and multiple operation and control means are set, thereby conveniently regulating and controlling the furnace temperatures of various functional regions in the furnace to the optimal temperatures for gasifying the biomass or polymer compounds. By using the device, the generation of tar and K and Na metal salt gases can be avoided, thus the device provided by the invention is a combustible gas preparing device capable of improving the gasifying efficiency and the product quality, reducing the energy consumption and prolonging the service life of equipment.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

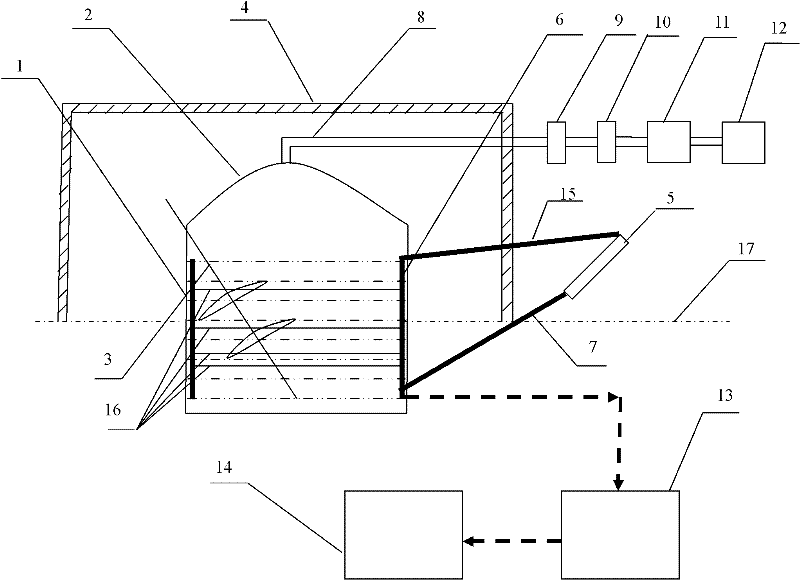

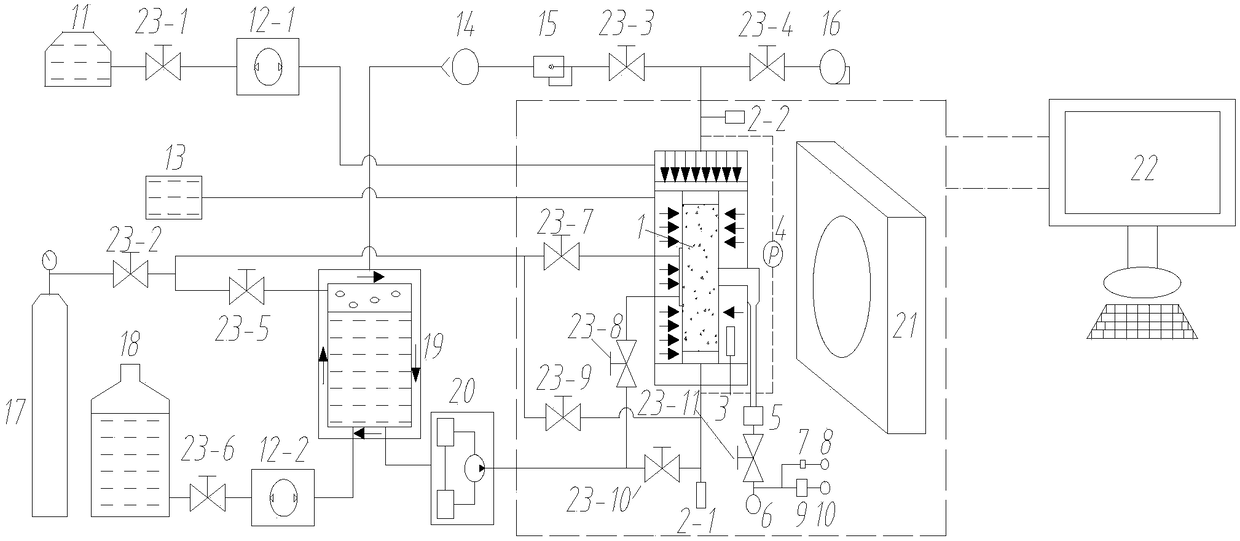

Hydrate sediment flow solid output measuring device combining X-CT technology and measuring method

ActiveCN109254137AImprove gas production efficiencyImprove the pressure reduction mining technology systemEarth material testingPermeability measurementsX-ray

The invention discloses a hydrate sediment flow solid output measuring device combining an X-CT technology and a measuring method. The measuring device comprises an X-ray penetration type reaction kettle, an X-CT scanning analysis system, a vacuum system, a temperature and pressure control system, a hydrate sample preparation system, a sand production monitoring system and a permeability measuringsystem, wherein through integrated application of a sand production-seepage system under the micro-scale multi-factor coupling effect, the coupling relationship of a reservoir structure and physicalspace-time evolution and flow solid output under the multi-factor collaborative action can be quantitatively described, different hydrate generation modes can be selected according to the experiment requirements, different hydrate occurrence states in natural sediments can be simulated and studied, and the device and the method can be used for researching the space-time evolution characteristics of a sediment pore structure under the hydrate convergence and divergence and effective stress conditions and an influence rule of the space-time evolution characteristics on sediment flow solid output, so that the theoretical bottleneck of the hydrate reservoir structure and a physical evolution and flow solid output mechanism in a hydrate production process is broken through, and the device and the method have important engineering significance to deeply understand a depressurizing production law of the South China Sea, practically improve the biogas production efficiency and perfect a depressurizing production technology system.

Owner:QINGDAO INST OF MARINE GEOLOGY

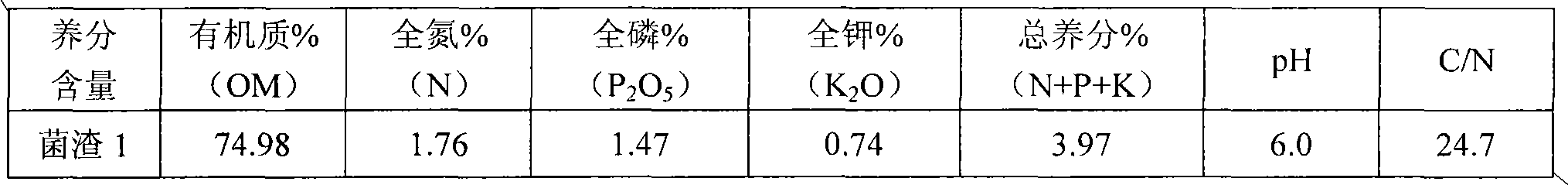

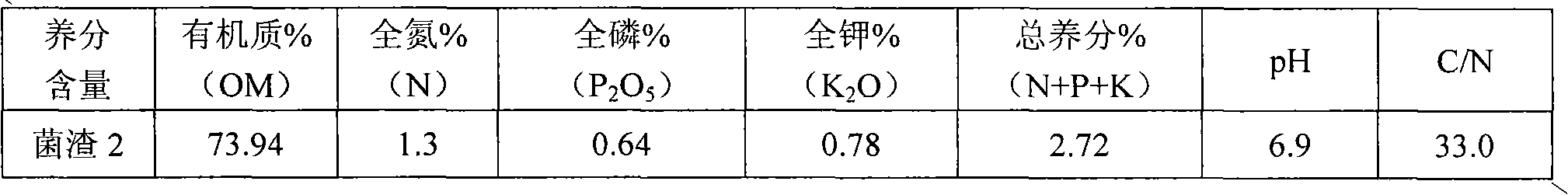

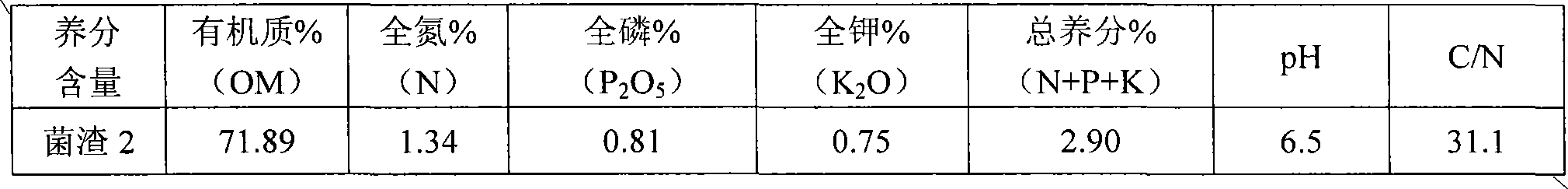

Method for producing marsh gas by utilizing corn cob fungi slag as raw material through anaerobic fermentation

InactiveCN102153261AIncrease profitSolve the problem of random discarding and polluting the environmentBio-organic fraction processingWaste based fuelBiotechnologySlag

The invention discloses a method for producing marsh gas by utilizing corn cob fungi slag as a raw material through anaerobic fermentation. The method comprises the following steps: mixing the fungi slag wasted after corn cob is used as a main raw material to cultivate edible fungus with pig manure or cow dung, adding a methane reagent, and carrying out pile fermentation; and putting fermentationraw materials in a household methane-generating pit or an anaerobic reactor, wherein the addition amount of the raw materials is 80-130 kg per cubic meter of pit volume. In the invention, generation of methane via anerobic fermentation is achieved by carrying out reasonable proportioning, pretreatment, pile outside the pit, fermentation starting and the like on the fermentation raw materials, thereby effectively solving the problem that the pollution is caused by discarding the fungi slag at random and simultaneously turning waste into wealth. After the method is utilized, the gas can be normally generated by the fungi slag in the household, and the method is simple with no need of special equipment and can be applied and disseminated in edible fungus cultivating households.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

Methane-producing composite microbial inoculum and preparation method thereof

InactiveCN101705199AReasonable designBreed fastBacteriaMicroorganism based processesBiogas productionLiquid methane

The invention relates to a methane-producing composite microbial inoculum and a preparation method thereof, which can solve the long-standing difficult problems that the existing biogas digester is lack of high-efficient methane-producing bacteria, thereby resulting in long initial start-up time of biogas production and poor stability of the biogas production. Methanosarcina acetoacidophilum DSM-N0.2834, methanobacterium formicicum DSM-No.1535, methanobrevibacter arboriphilicus DSM-No.1125, methanolobus tindarius DSM-No.2278 and methanothrix concilii DSM-No.6752 collected in German collection of microorganisms and cell cultures are adopted and inoculated in a liquid methane bacterial culture medium under the anaerobic condition, the independent enlarged culture is carried out grade by grade respectively, and bacterial liquid after the cultured methane bacteria is mixed together according to the volume ratio, thereby preparing a liquid methane-producing composite microbial inoculum; and the liquid methane-producing composite microbial inoculum can also be prepared into a solid methane-producing composite microbial inoculum. The method has reasonable design and adopts the high-efficient strains with the optimal combination and the rapid propagation technology, and the developed high-efficient methane-producing composite microbial inoculum can significantly accelerate the start-up time of the biogas production when in new construction of the biogas digester and large material change, and improve the efficiency and the stability of the biogas production of the biogas digester.

Owner:北京合百意可再生能源技术有限公司 +1

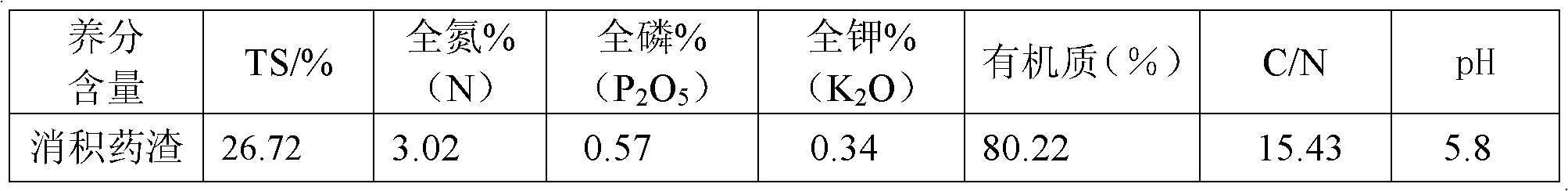

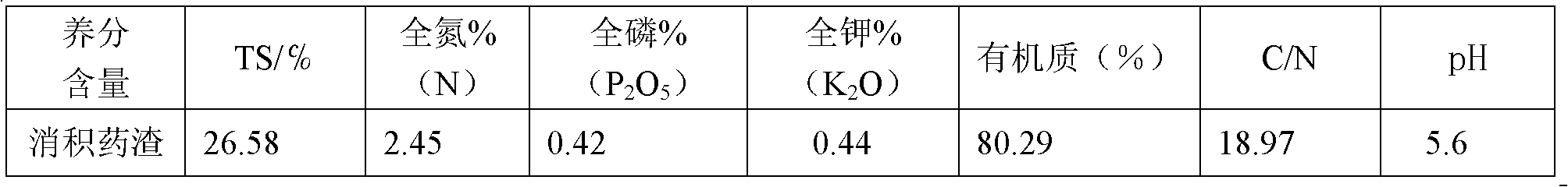

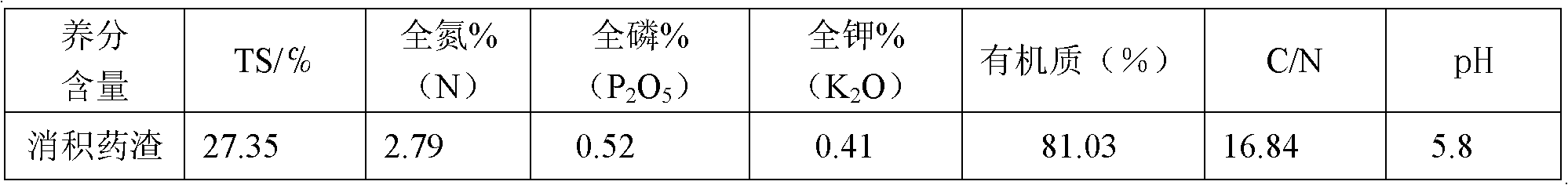

Method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials

ActiveCN102382859AEasy to operateSuitable for useWaste based fuelFermentationProduction effectMedicine

The invention relates to a method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials. Medicine dregs produced in a pharmaceutical factory of traditional Chinese medicine are used as fermentation raw materials, are united with waste water of the pharmaceutical factory for anaerobic fermentation, and are properly proportioned with biogas slurry and water for composting pretreatment, a proper amount of NaOH is added after the mixture enters a pool, the TS (total solid) concentration of the fermentation raw materials is 7-9%, 10-15% of biogas slurry is added as an inoculum so as to realize quick start, and the biogas production efficiency is high. Partial biogas slurry flows back after normal operation so as to ensure the concentration of microorganisms in an anaerobic tank. The traditional Chinese medicine dregs are taken as main raw materials for fermentation to produce the biogas, cow dung and other fermentation raw materials do not need to be added, the operation is simple, the gas production effect is good, the utilization ratio of the raw materials is high, the problem of environment pollution caused by the medicinedregs and the waste water can be solved, and simultaneously biogas energy sources can be recycled.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

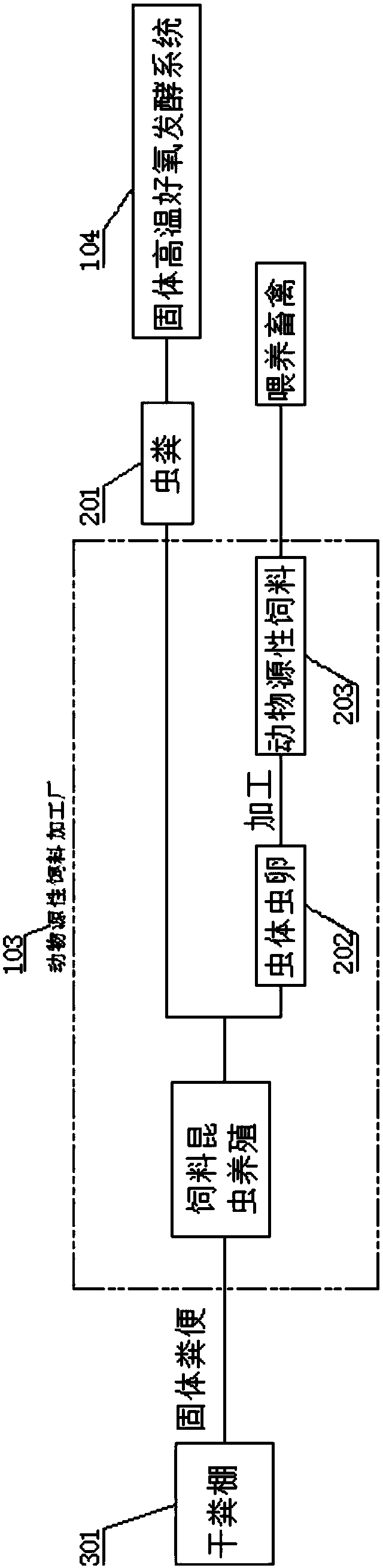

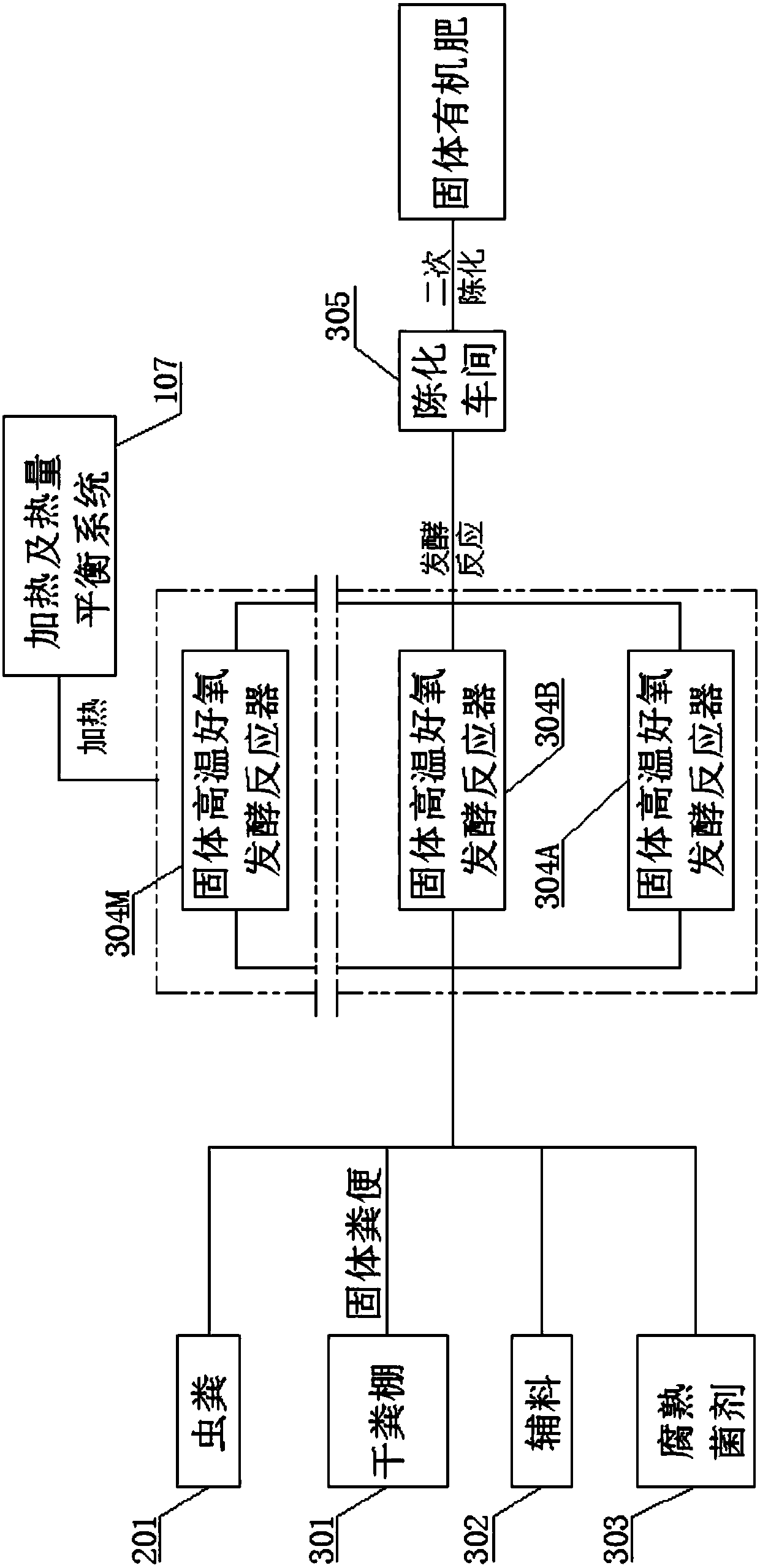

Ecological treatment system and method for pollution of livestock and poultry farm based on combination of planting and breeding

ActiveCN107759254AReduce distractionsHighly consistent qualityBio-organic fraction processingFabaceae cultivationPig farmsFeces

Owner:汪深

Method for producing methane through anaerobic fermentation of waste of vegetables and fruits

ActiveCN101914574AGood effectImprove gas production efficiencyWaste based fuelFermentationMicroorganismAnaerobic reactor

The invention relates to a method for producing methane through the anaerobic fermentation of waste of vegetables and fruits serving as raw materials, which comprises the following steps of: soaking the waste of the vegetables and fruits in fermented liquid for preprocessing, wherein the addition of the fermented liquid is helpful for the initial degradation of the waste of the vegetables and fruits and can regulate the carbon nitrogen ratio of the raw materials; and regulating the pH value of a mixture to between 7.0 and 8.5, putting the preprocessed raw materials into an anaerobic reactor or a methane tank for anaerobic fermentation, adding methane microbial inoculum, producing methane after 3 to 5 days, and fermenting for 60 to 90 days. Through the method, the problem that the raw materials in the methane tanks of non-cultivation farmers are insufficient and the problem that the waste of the vegetables and fruits is wasted and contaminative are solved effectively. By adopting the method, the methane can be produced normally in the methane tanks for the farmers by utilizing the waste of the vegetables and fruits, and the methane producing rate is more than or equal to that of methane tanks taking waste of livestock and poultry as raw materials.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Crop straw co-fermentation device

InactiveCN103436435APromote decompositionShorten the fermentation cycleBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseBiogas production

The invention discloses a crop straw co-fermentation device. The crop straw co-fermentation device comprises a pre-treatment reaction tank and an anaerobic fermentation tank, wherein materials in the pre-treatment reaction tank enter the anaerobic fermentation tank by virtue of a discharge pipe of the pre-treatment reaction tank. The pre-treatment reaction tank can carry out aerobic, micro aerobic or anaerobic pre-treatment on crop straw, so that degradation of lignocellulose can be promoted; meanwhile, the materials in the pre-treatment reaction tank and biological metabolism heat can be transferred to the anaerobic fermentation tank by virtue of a packing auger formed by combining a spiral stirrer with the discharge pipe of the pre-treatment reaction tank, so that high-efficiency conversion of straw anaerobic fermentation is realized; besides, leachate and biogas slurry can be recycled and are used for spraying, so that environmental pollution is reduced. The crop straw co-fermentation device can greatly improve biogas production potential of biological straw, increase biogas production efficiency of anaerobic fermentation, shorten a fermentation period and reduce energy consumption of the anaerobic fermentation and is simple in structure and easy to realize.

Owner:HENAN AGRICULTURAL UNIVERSITY

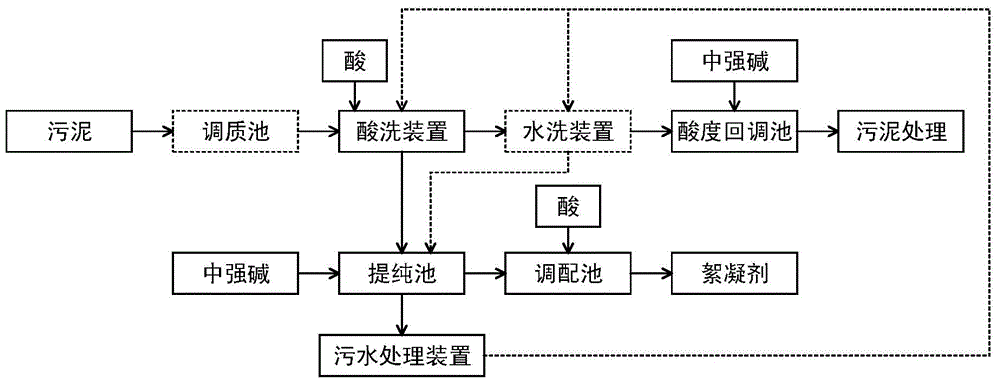

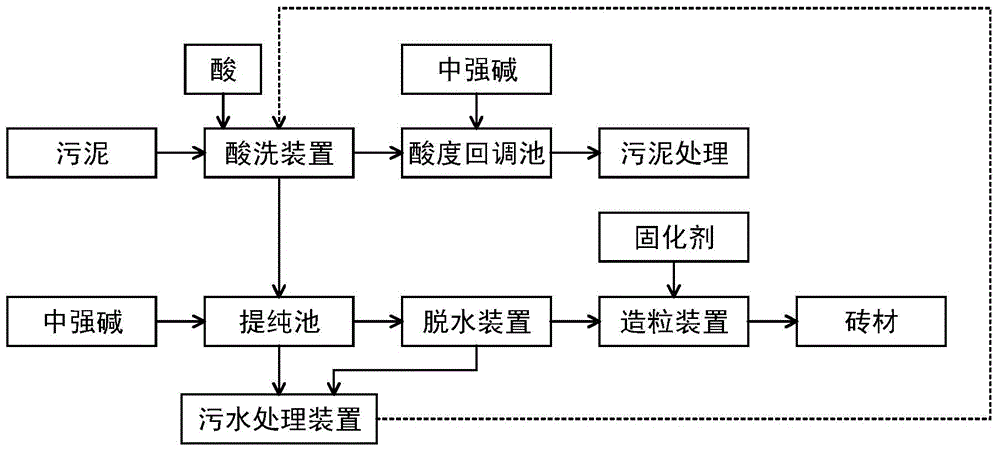

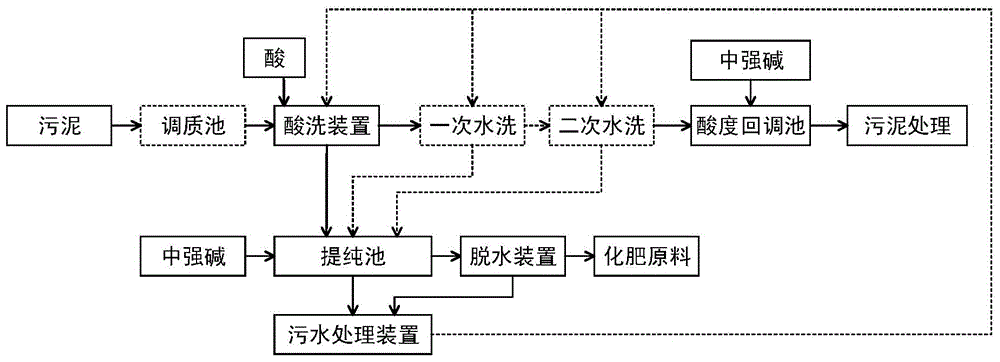

Sludge pretreatment technology with desalting effect

ActiveCN105110587AImprove the efficiency of subsequent processing and disposalReduce the amount requiredSludge treatmentInorganic saltsSludge

The invention provides a sludge pretreatment technology with a desalting effect. The sludge pretreatment technology with the desalting effect comprises the following steps of (1) placing sludge in an acid pickling device, feeding acid to perform acid pickling, and separating after stirring reaction to obtain desalted sludge and acid pickling liquid which contains inorganic salt and has pH value smaller than 2; (2) feeding the acid pickling liquid obtained in the step (1) in a purification pond, adding moderately strong alkali to regulate the pH value to 4-8 so as to obtain purified liquid and precipitates, and feeding the purified liquid to a sewage treatment device; (3) feeding the precipitates obtained in the step (2) in a regulating pond and adding inorganic acid to obtain flocculating agents; and (4) feeding the desalted sludge obtained in the step (1) in an acidity returning pond, adding moderately strong alkali until the pH value is greater than 6, and feeding obtained reactant to the sewage treatment device. The sludge pretreatment technology is used prior to a conventional sludge treatment technology. After the sludge is treated by the technology, inorganic salts in the sludge are reduced by 50-90%, and the extracted inorganic salts can be prepared into flocculating agents, fertilizer raw materials or building materials. Follow-up sludge treatment efficiency is improved, and treatment facility scale and operating cost are reduced.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

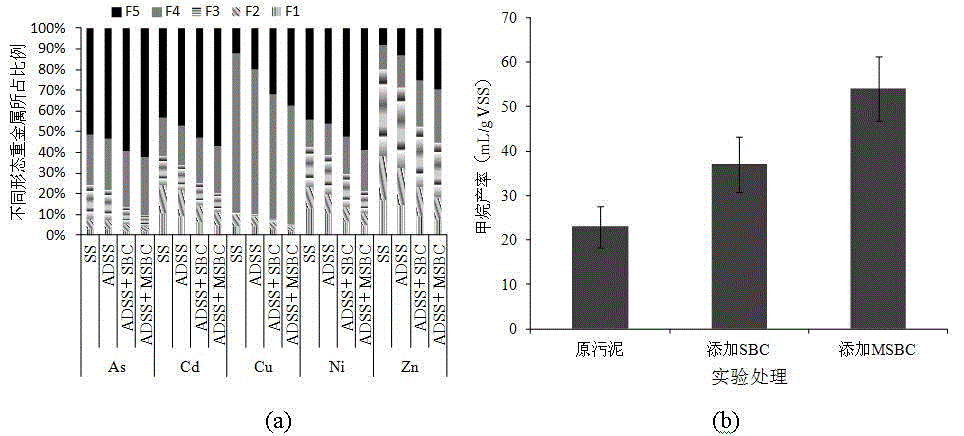

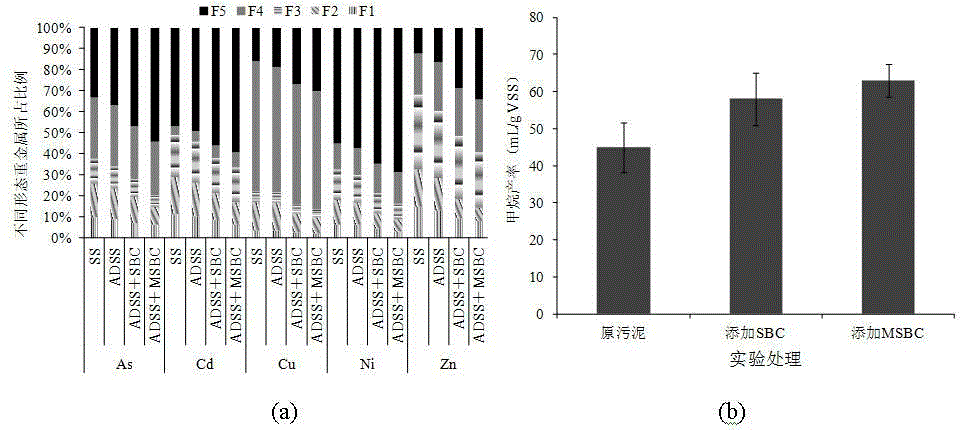

Method for enhancing heavy metal stabilization process in sludge anaerobic digestion process

InactiveCN104961313AGrain structure is stableBig gapSludge treatment by pyrolysisByproduct vaporizationWater contentChemistry

The invention relates to a method for enhancing heavy metal stabilization process in the urban sludge anaerobic digestion process. Municipal sludge serves as raw materials, a special vacuum reacting furnace is adopted, sludge biochar is prepared high-temperature pyrolysis under the anoxic condition, SBC is modified through glass fiber wetting, and finally the sludge biochar of a stable structure, with high voidage and resistant to acid and alkali impact is obtained; in the sludge anaerobic digestion acid production stage, the sludge is added to a reactor according to a proper proportion, free state heavy metal in the reactor can be absorbed and captured obviously, and finally the stabilizing process of the sludge heavy metal is accelerated and enhanced. The method basically cannot generate adverse influences on a sludge anaerobic digestion reaction system, the generated biogas residue is obviously lowered in the water content, and the dewaterability is obviously improved. The method can be used for remaining sludge anaerobic digestion engineering of sewage treatment plants in cities and towns, the heavy metal stabilization process in the anaerobic digestion process is effectively enhanced, the sludge stabilization process is accelerated, and the method has great significance for lowering the risk of heavy metal environmental pollution and improving the soil health quality in the utilization process of sludge lands generated after anaerobic digestion is conducted.

Owner:TONGJI UNIV

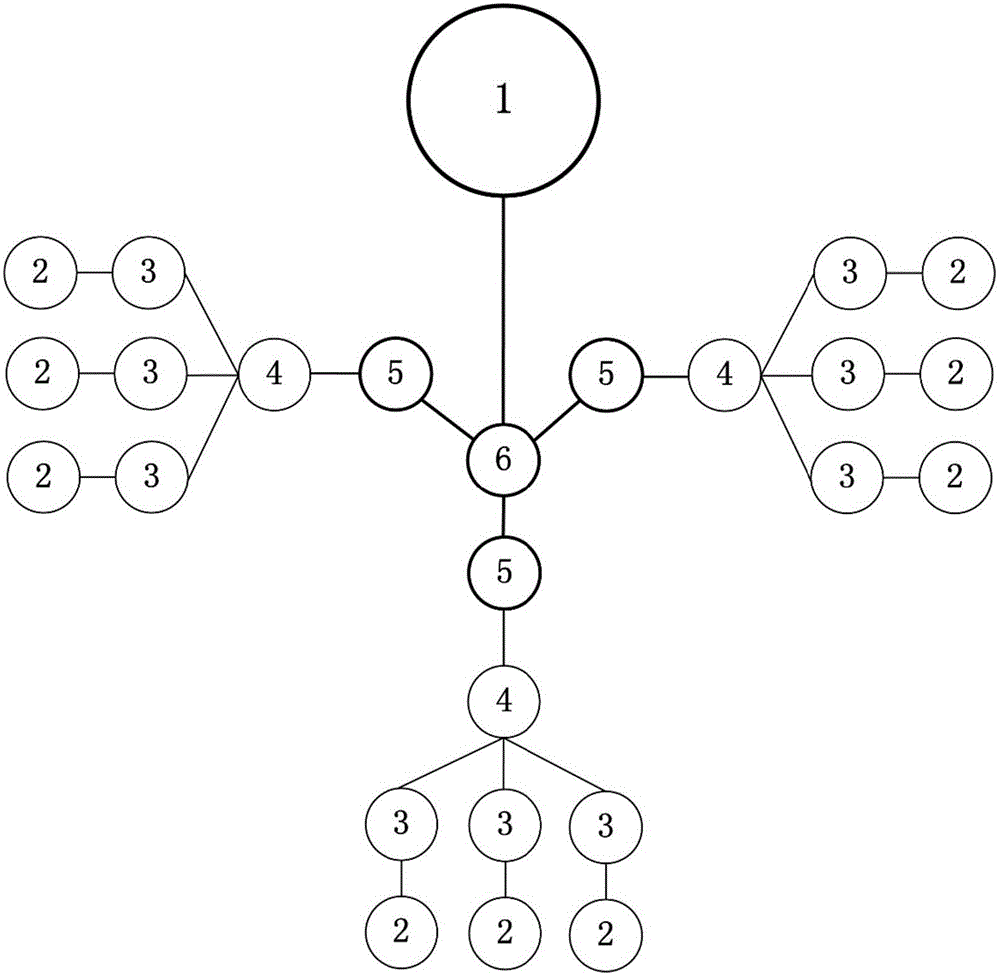

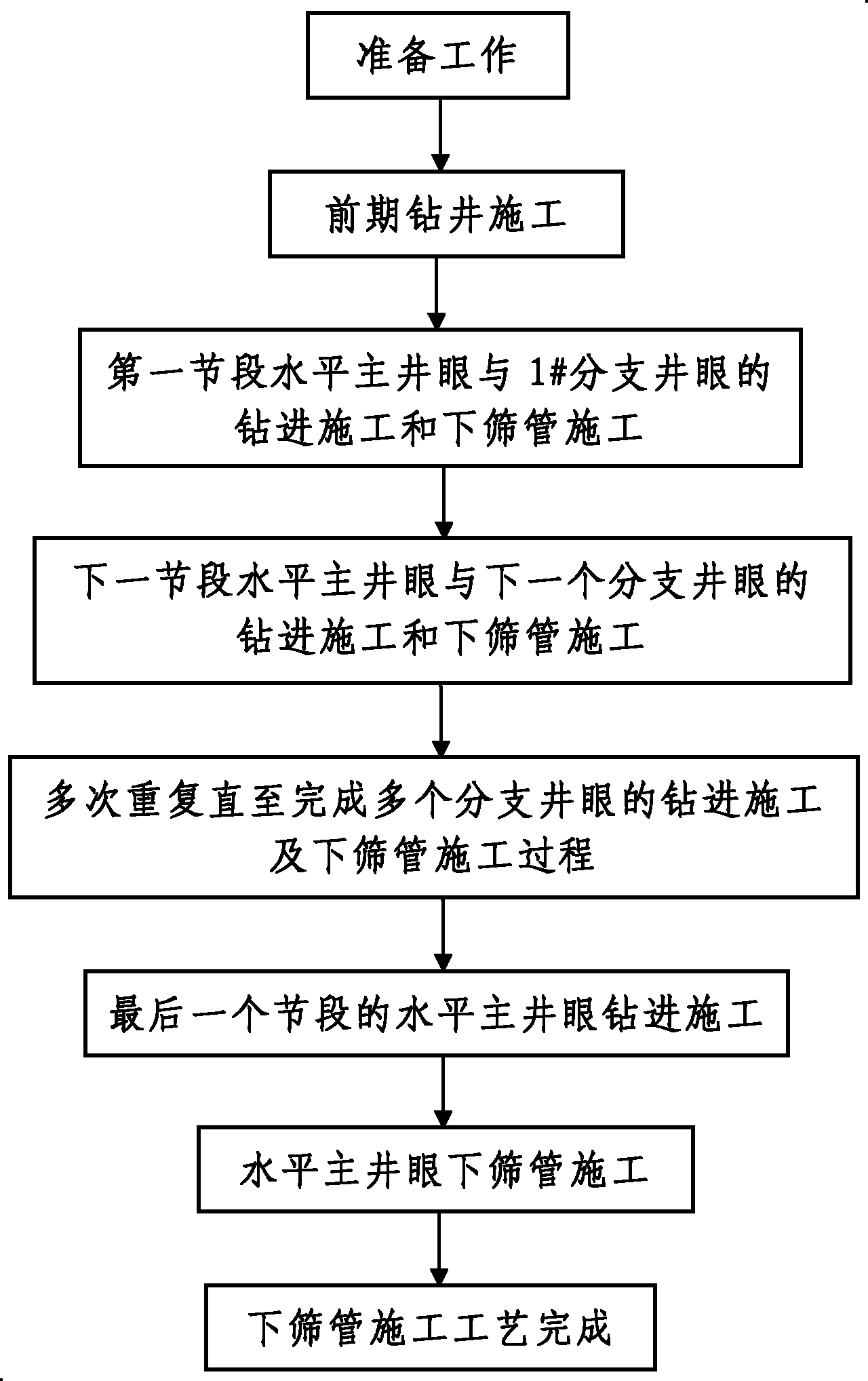

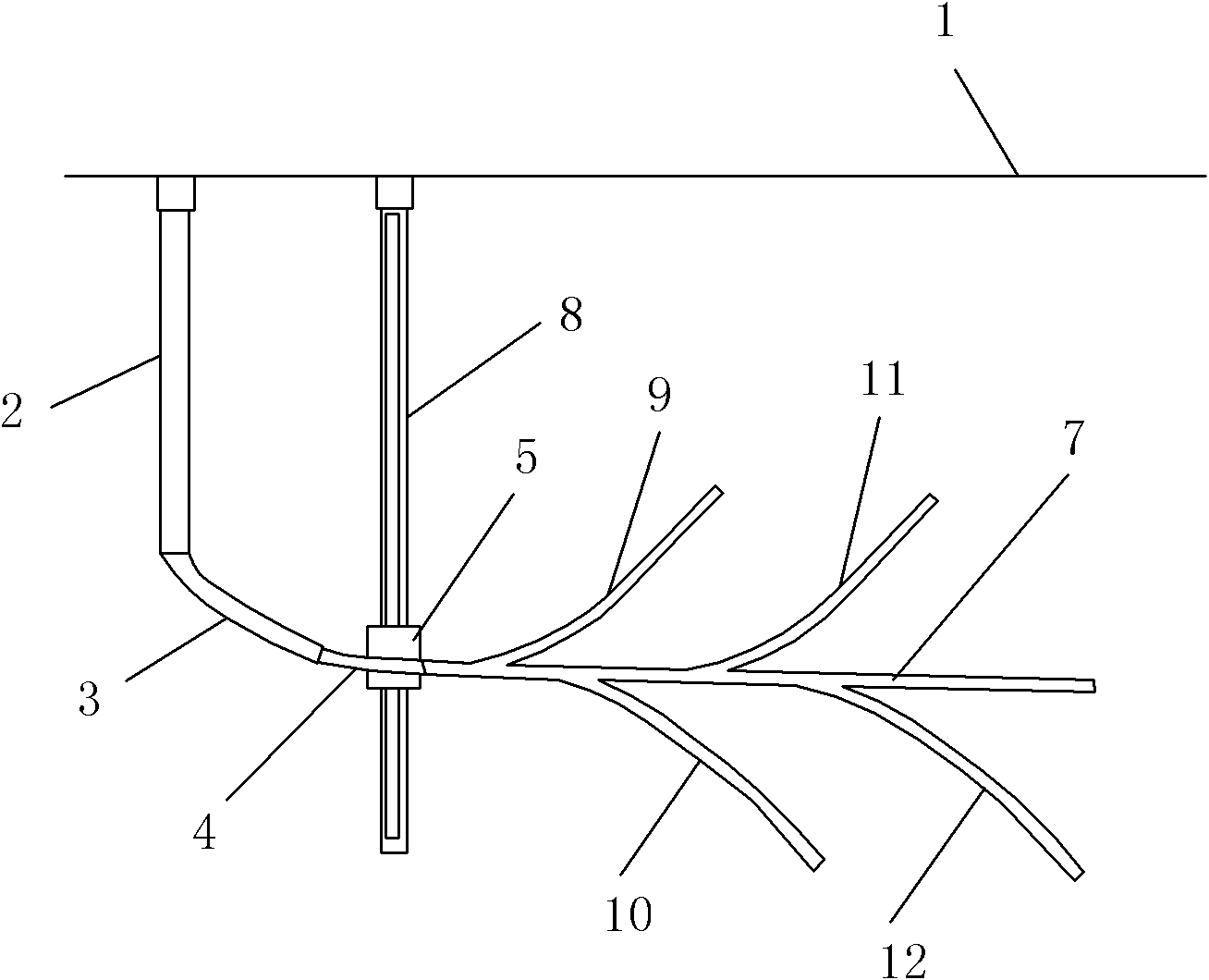

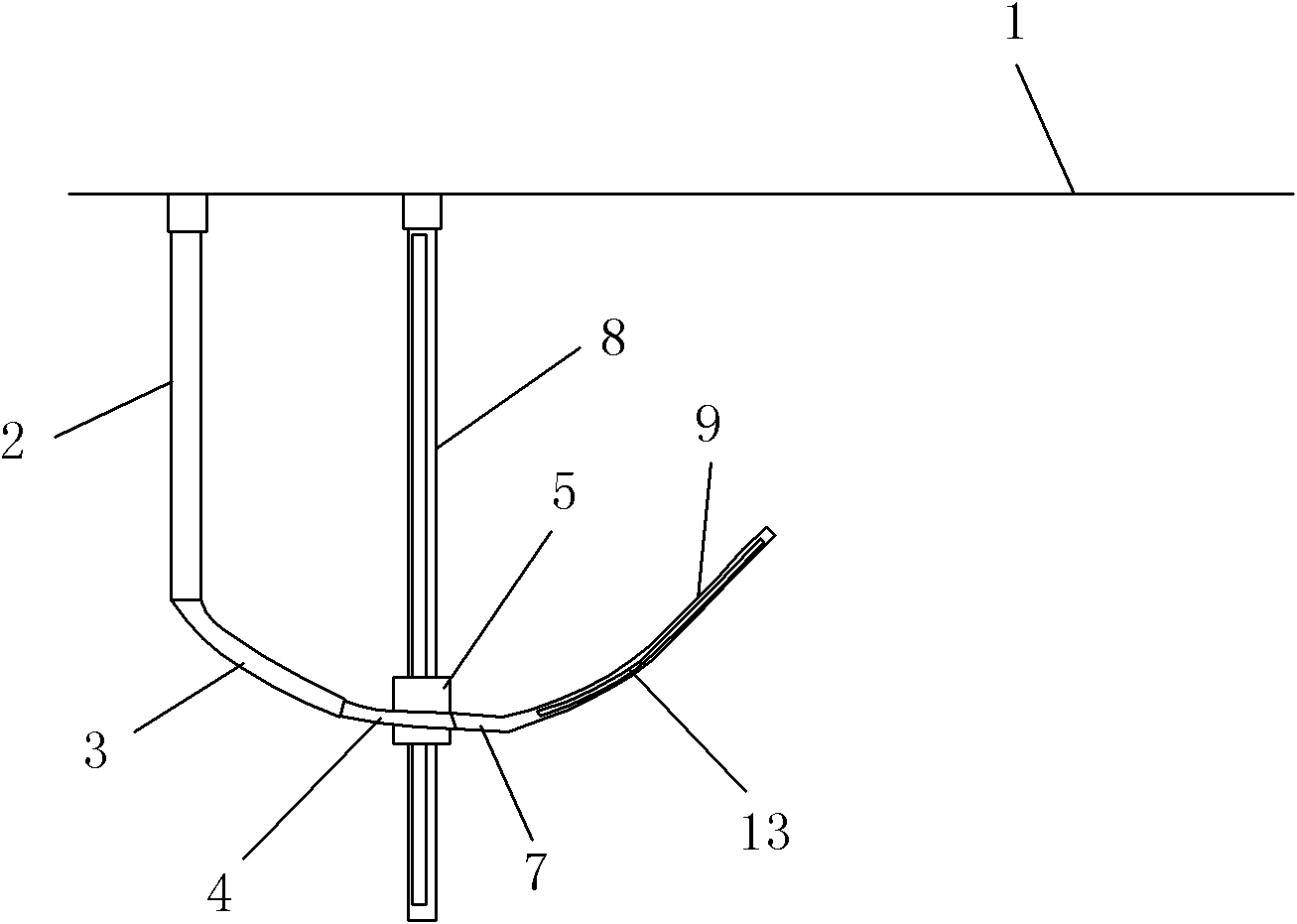

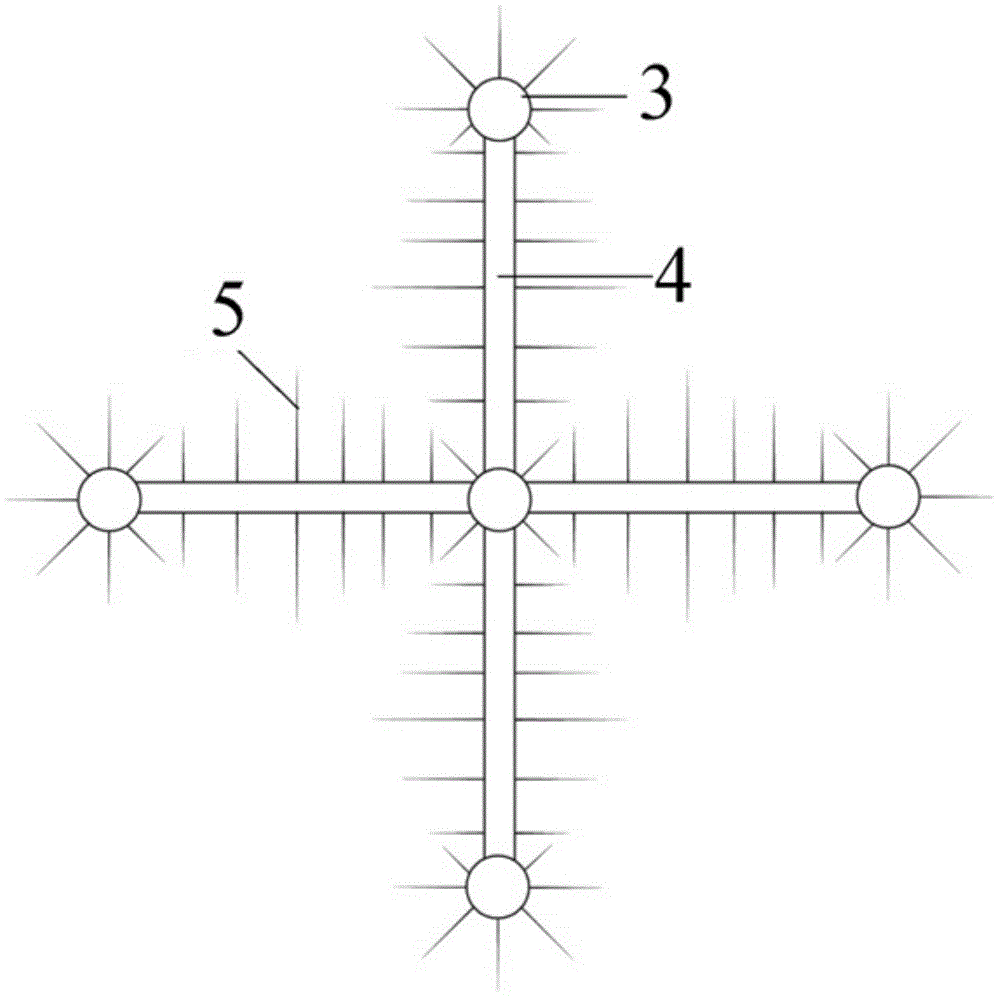

Construction process of multi-branch underground screen pipe

InactiveCN101975048AImprove efficiencyEasy to operateFluid removalInvestment costBuilding construction

The invention discloses a construction process of a multi-branch underground screen pipe, which comprises the following steps of: 1, preparing; 2, drilling in advance; and 3, drilling and laying the screen pipe: drilling a first section of horizontal main shaft hole and a first section of branch well hole and laying the screen pipe, drilling the next section of horizontal main shaft hole and the next section of branch well hole and laying the screen pipe, repeating the operation until completing the drilling of a plurality of branch well holes and the laying the screen pipe, the drilling of the last section of horizontal main well hole and the laying of the screen pipe of the horizontal main well holes. The invention has the advantages of reasonable design, high construction efficiency, low investment input and good use effect, is convenient for operation, can effectively increase the yield of a multi-branch horizontal well, and effectively solves the defects of high investment cost, larger construction risk, complex construction step and difficult realization of the steps, low yield of the multi-branch horizontal well subjected to the construction, and the like in the traditional construction process of the multi-branch horizontal well.

Owner:SHAANXI LONGMEN TIANDI COAL BED GAS TECH ENG

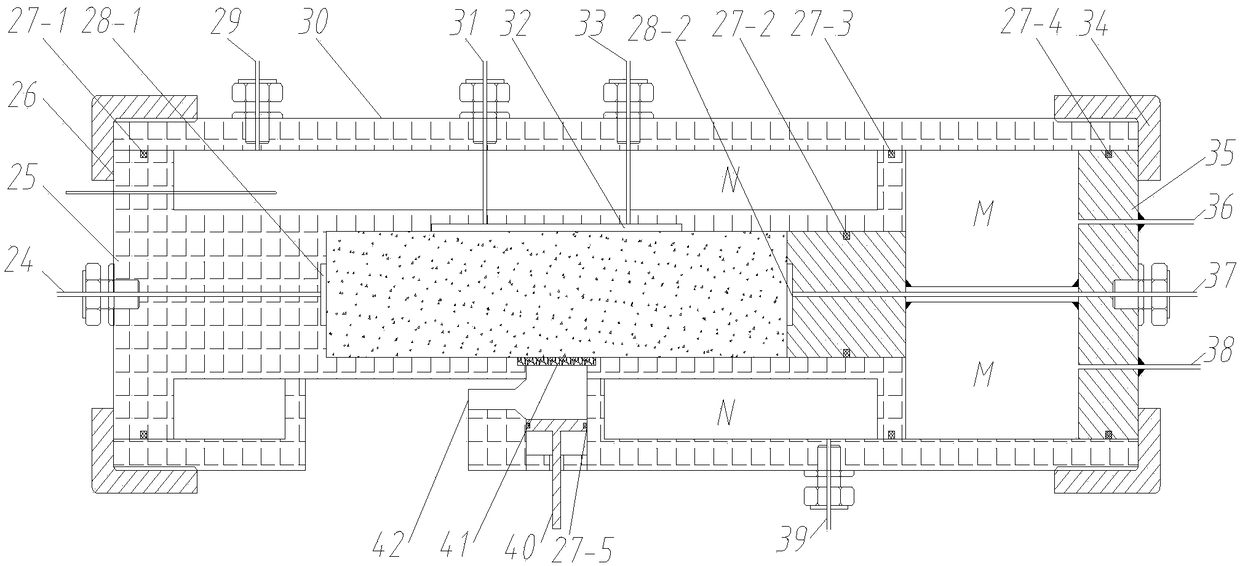

Biogas reaction device

InactiveCN101613658AAchieving Scale ProcessingReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsNew energySewage

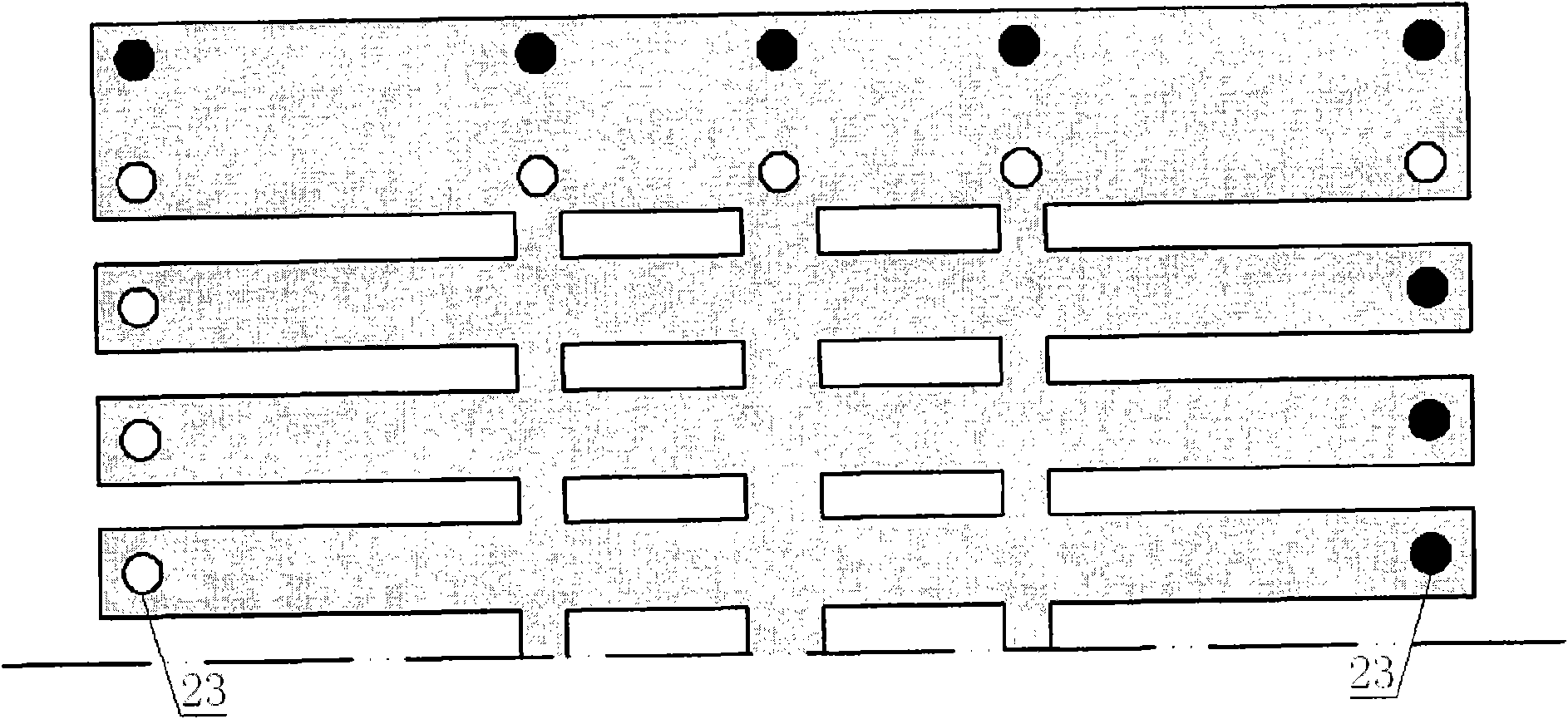

The invention relates to a biogas reaction device, which mainly comprises reaction bed monomers (1), an equalizer (2), an upright post (3), a current limiter (4), a charging pump (8), a support (20), a connector (21), a support bed (27) and a heating pool (9). The reaction bed has three layers, the reaction bed monomers (1) on each layer are combined through series connection, and the charging pump (8) is used for charging material and circulating material liquid. The core equipment of the reaction bed monomers (1) is made of a soft material, so the product is foldable, convenient to transport and suitable for factory production. The invention relates to the field of new energy and environmental protection and provides a bionic biogas reaction device which can be widely used for processing organic materials such as organic sewage, household garbage, human and animal excreta and crop straws.

Owner:吴兆流

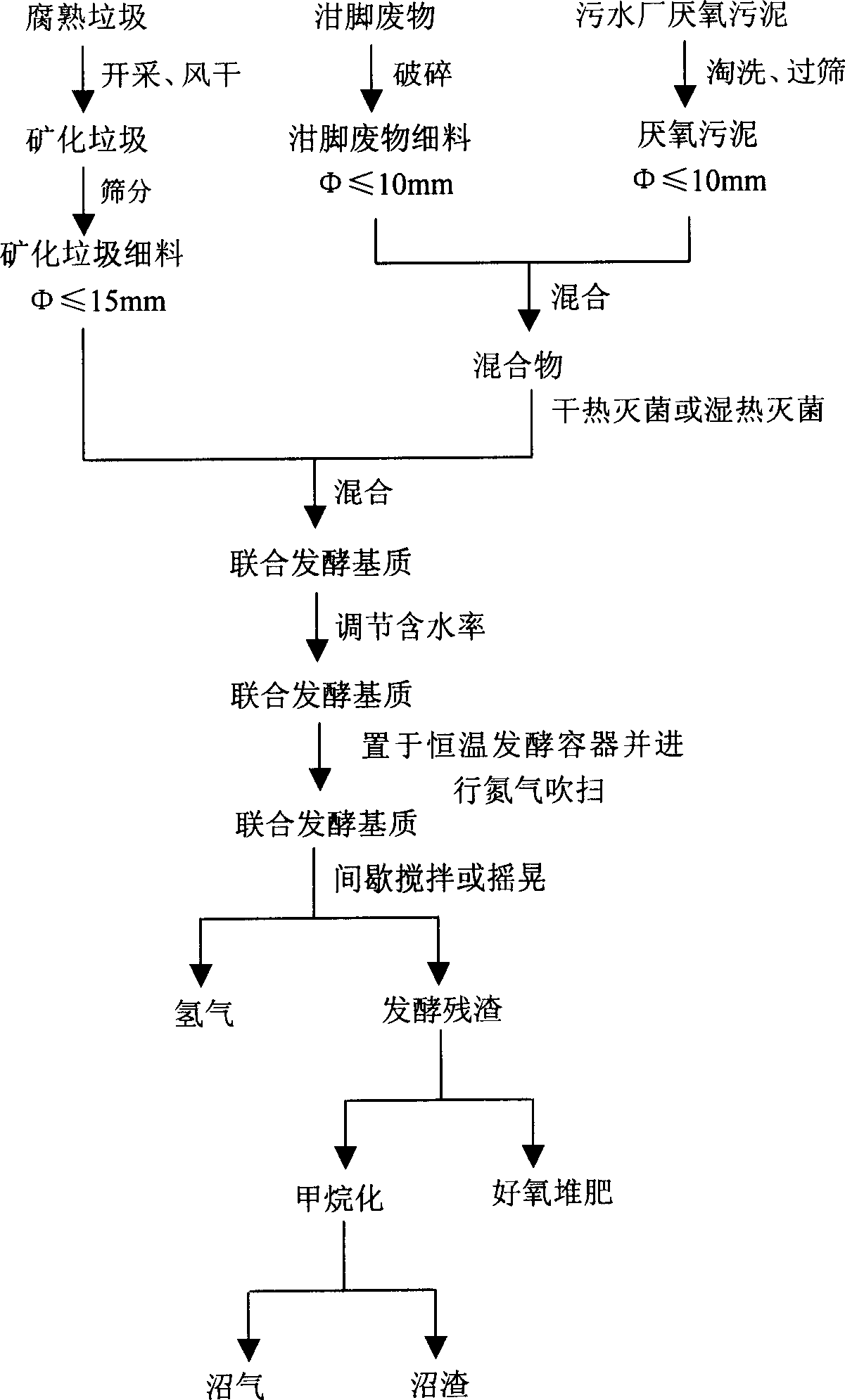

Production of hydrogen for combining mineralize refuse, swill waste and sludge

InactiveCN1896248AIncrease switching capacityAlkalinity improvementBio-organic fraction processingClimate change adaptationHydrogenLitter

Production of hydrogen from mineral refuse with swill waste and sludge is carried out by sieving mineral refuse underground for 1-20years to grain size 1-10mm, washing by water, mixing by proportion of 1:1-10:1 and with 1-10mm sieve sludge, dry-heat sterilizing or wet-heat sterilizing at 100-200degree for 0.5-2hrs, pre-treating for 0.5-2hrs to obtain combined fermented substrate, laying aside in closed thermostatic fermenting container, fermenting to produce hydrogen at 25-55degree, pre-treating and utilizing. It is cheap, simple, has more hydrogen output and no secondary pollution. It can be used as fuel or generation raw materials.

Owner:TONGJI UNIV

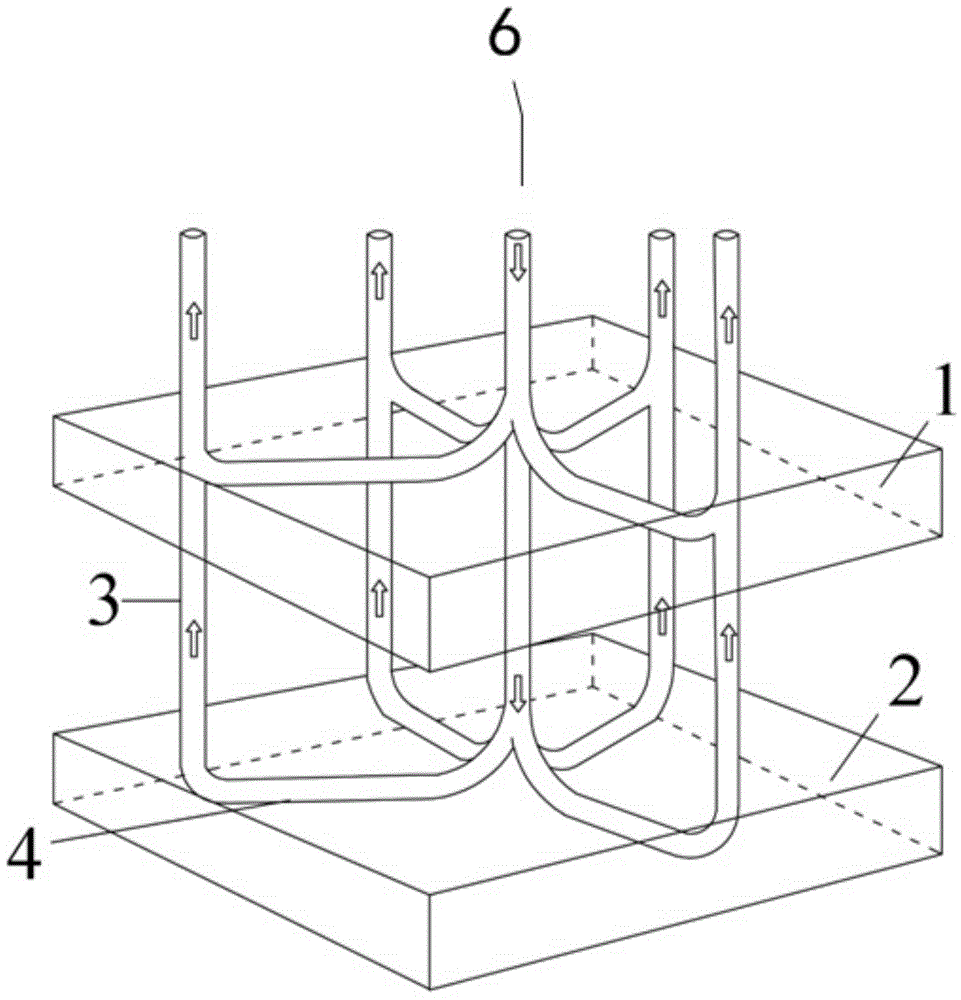

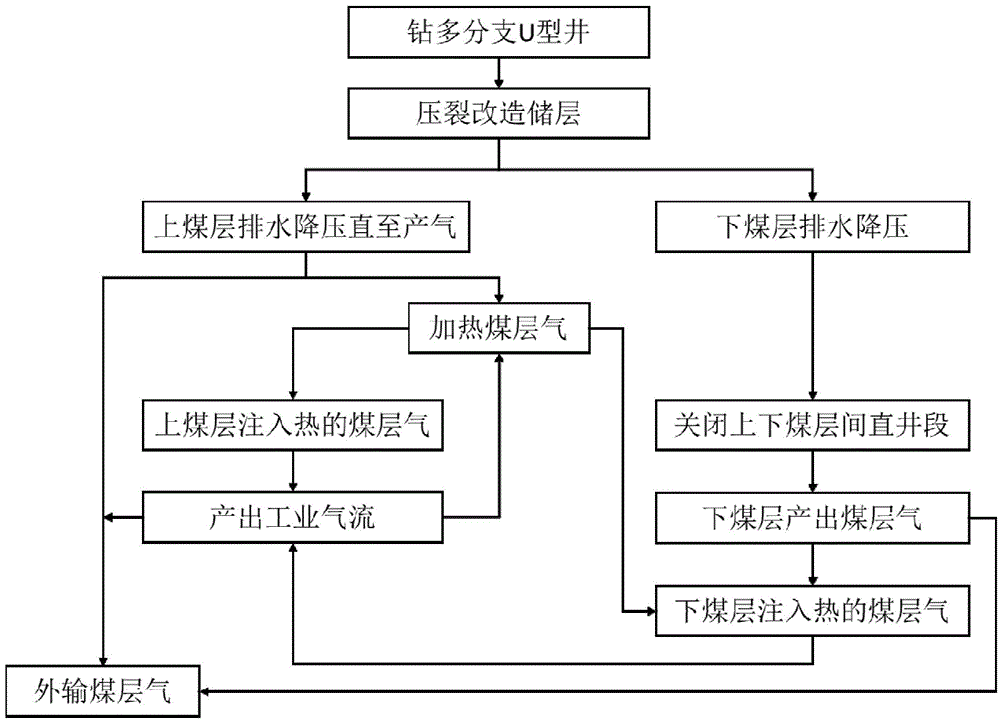

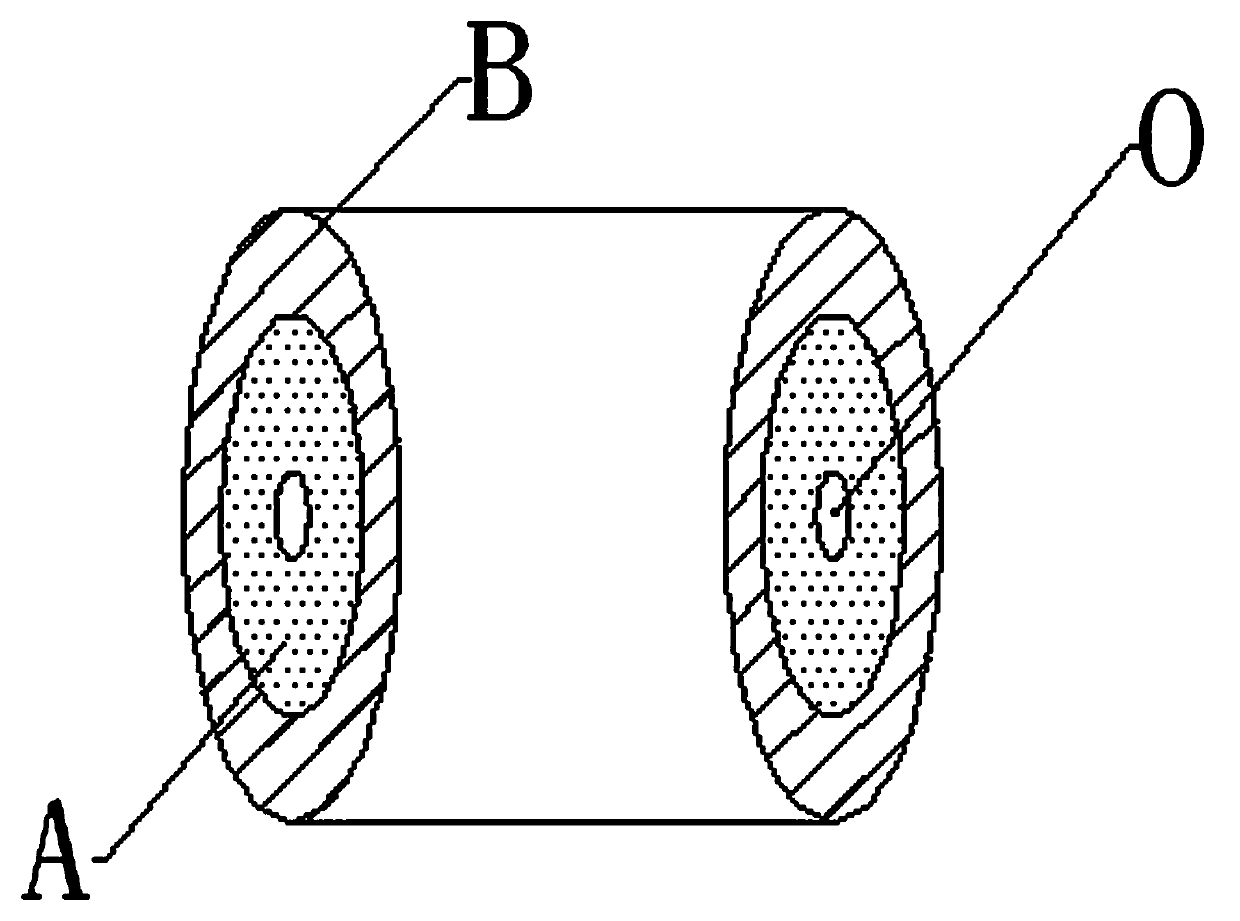

Coal bed methane recovery method

InactiveCN104790915AEnhanced overall recoveryImprove desorption environmentFluid removalRecovery methodProcess engineering

The invention discloses a coal bed methane recovery method. A multi-branch U-shaped well is used in cooperation with a coal bed methane heating injection shaft for recovering coal bed methane. By the adoption of the coal bed methane recovery method, the recovery efficiency can be improved, cost is reduced, safety and high efficiency are achieved, and operation is easy.

Owner:SOUTHWEST PETROLEUM UNIV +1

Preparation method for microbial organic soil bactericidal and insecticidal warming conditioning agent

InactiveCN105347926AImprove compactionAdjust the aggregate structureBioloigcal waste fertilisersOrganic fertiliser preparationDiseaseGround temperature

The invention relates to a preparation method for a microbial organic soil bactericidal and insecticidal warming conditioning agent. Fermentation raw materials are domestic fungus cultivation residue substances, the fermentation raw materials are crushed and added with water, and thus the water content mass percent of the fermentation raw materials is 25-35%; decomposing inoculants are added at a mass ratio of1:1000, the mixture is mixed uniformly, the fermentation raw materials mixed with strains are added with tourmaline powder with a mass percent of 5%, rare earth negative ion powder with a mass percent of 2%, composite biological insecticides accounting for 1% of the finished product total mass and composite biological bactericides accounting for 1% of the finished product total mass, the mixture is mixed uniformly, then loose packing or granulation is carried out, drying is carried out and the water content is 10%; packaging is carried out, and a microbial organic soil bactericidal and insecticidal warming conditioning agent is prepared. The produced conditioning agent is advantageous in that the organic matter content is high, the ground temperature is raised, absorption of phosphor and potassium for crops can be raised, the conditioning agent has functions of preventing soil borne diseases, releasing phosphorus and potassium, fixing nitrogen and killing nematodes and green environmental protection is achieved.

Owner:SUIHUA KAIHUA AGRI TECH CO LTD

Pretreatment fungicide for xylose residue or furfural residue, preparation method and application thereof

InactiveCN102154108AFast startup timeEasy to degradeFungiMicroorganism based processesDry weightBiogas production

The invention relates to a pretreatment fungicide for xylose residue or furfural residue, a preparation method and an application thereof, belonging to the technical field of agricultural microbiology. The invention relates to a microbial composite fungicide specially used for promoting the xylose residue or the furfural residue to degrade and improving the production efficiency of methane. The invention firstly adopts liquid fermentation technology to purely breed and ferment all components of the microbial fungicide, and then the components are compounded. The preparation method of the pretreatment fungicide comprises: 0.20-0.40 parts by weight of trichoderma viride liquid, 0.10-0.15 parts by weight of phanerochaete chrysosporium liquid, 0.05-0.10 parts by weight of aspergillus niger liquid, 0.08-0.16 parts by weight of aspergillus oryzae liquid and 0.05-0.10 parts by weight of trametes versicolor liquid, and the dry weight of fermentation hyphae is more than 20g / L. The composite fungicide can be used for improving the composite fungicide speed of the xylose residue or the furfural residue as well as the methane production efficiency; the methane production efficiency is improved by 30-60%; the fermentation time is shortened; the start period is shortened by 3-10 days; and the invention is also good in the effects on the aspects of pretreatment of smashed straws, and methane production.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Gas generating agent and preparing method thereof

ActiveCN103625413AImprove gas production efficiencyExtended service lifePedestrian/occupant safety arrangementPressure gas generationCombustionProduct gas

The invention provides a gas generating agent and a preparing method of the gas generating agent. The gas generating agent is of an A / B core shell structure. A core A comprises a first combustible agent and a first oxidizing agent, and a shell B comprises a second combustible agent and a second oxidizing agent. The combustion speed of the second combustible agent is lower than that of the first combustible agent, and the gas generating agent not only is adjustable in combustion speed and suitable for gas generators of various gas bags, but also is high in gas generation efficiency, long in service life and little in residue. Meanwhile, a coating structure can enable the gas generator to be longer in acting time and also has a very good moisture proof effect, so that service life of the gas generating agent is greatly prolonged, and using performance is very good. The gas generating agent is simple in technology, easy to prepare, free of harm and pollution and easy to produce in a large-scale mode.

Owner:BYD CO LTD

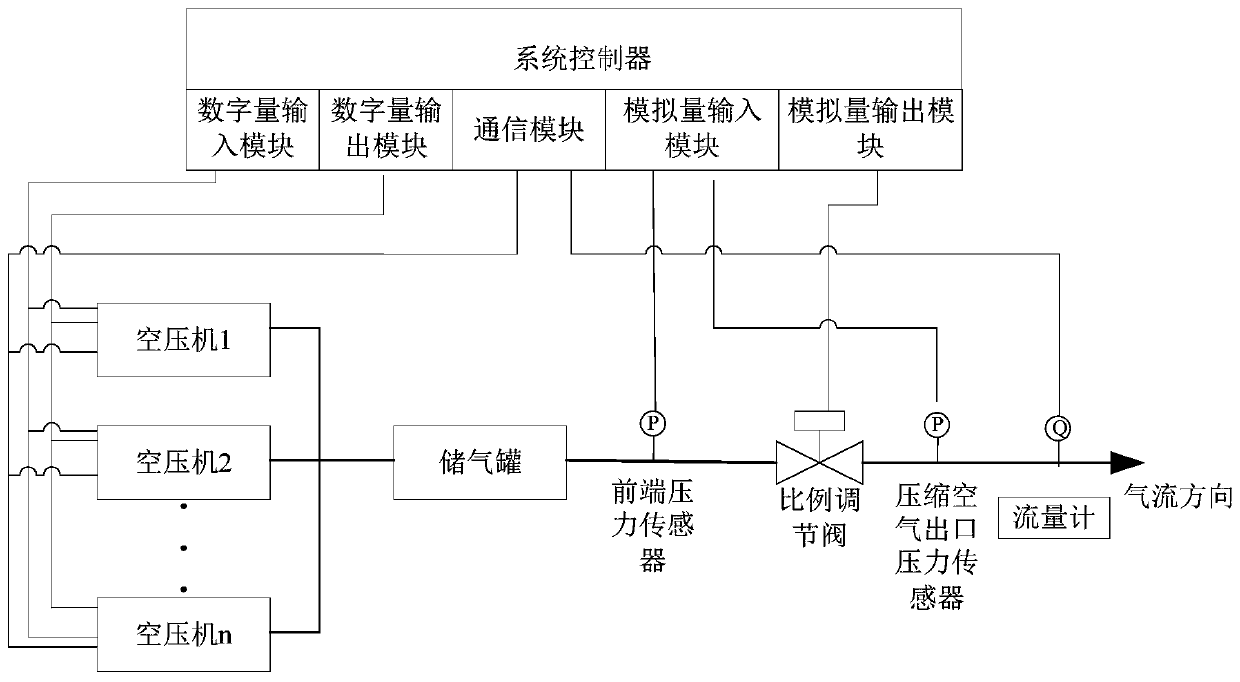

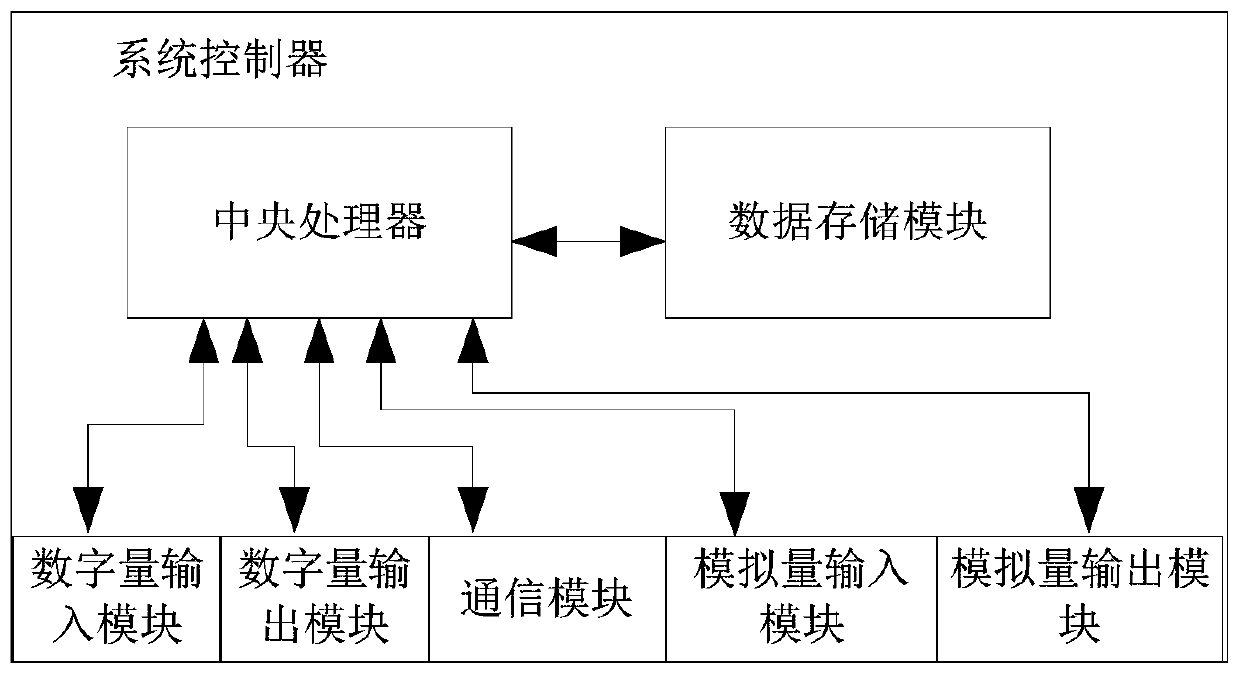

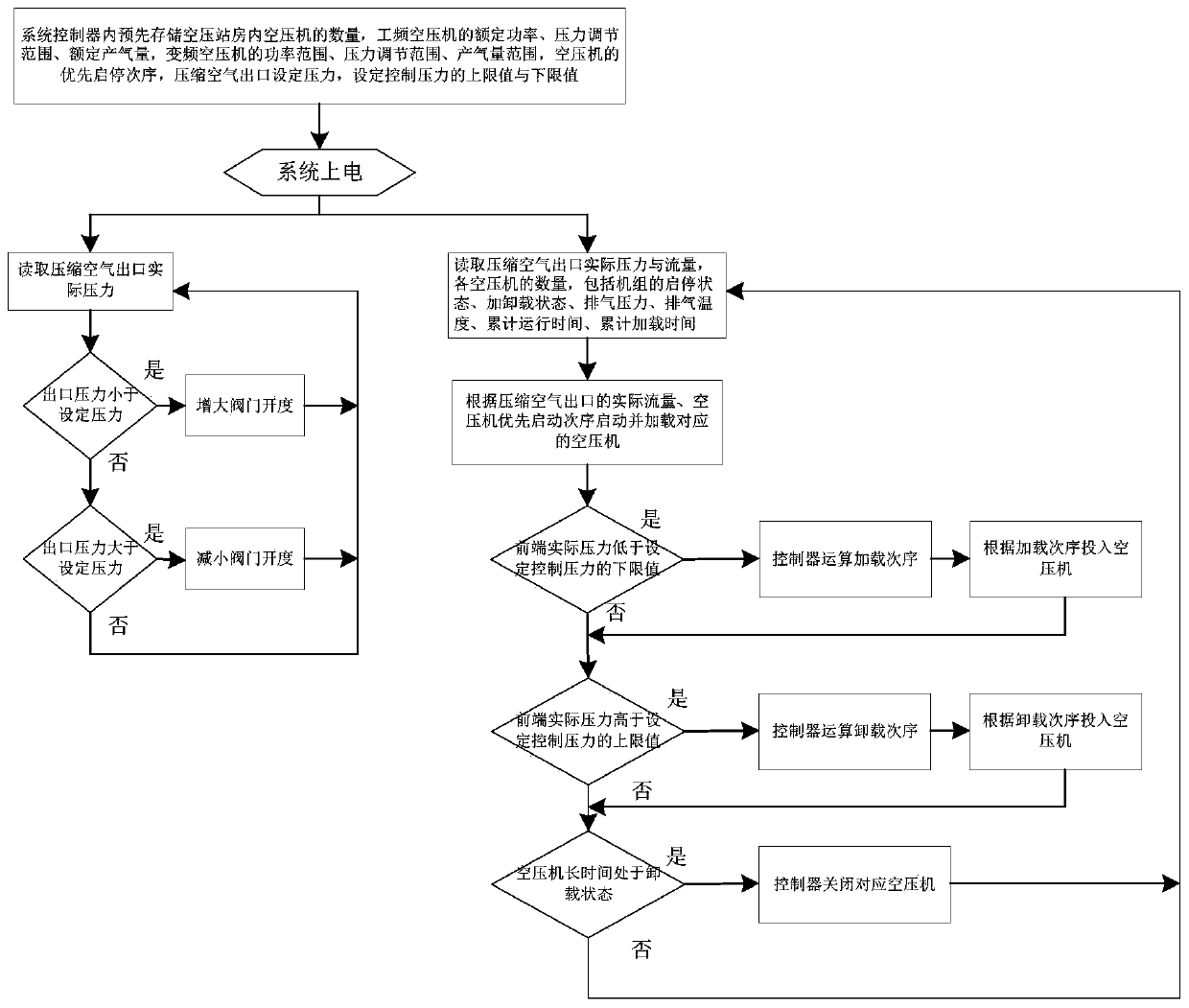

Compressed air control system and compressed air control method based on gas demand

ActiveCN109854492AImprove gas production efficiencyReduce consumptionPump controlPositive-displacement liquid enginesProportioning valveFlux control

The invention discloses a compressed air control system and a compressed air control method based on an air demand. The compressed air control system comprises one or more air compressors, a system controller, a front end pressure sensor, a compressed air outlet pressure sensor, a flowmeter and a proportioning valve. The air compressors are provided with external communication interfaces or external digital quantity input-output interfaces for feedback and control of data communication or dry contact state of the controller. From the aspect of demand of an air terminal, the air supply pressureof a compressed air general pipe is controlled dynamically through the proportioning valve as the lowest guarantee pressure needed by the air terminal, and the operating quantity of the air compressors is controlled according to the actual flow of the compressed air, so that air consumption and generation of the compressed air system are balanced dynamically, and therefore, the operating efficiency of the compressed air system is improved and the energy waste is reduced.

Owner:埃尔利德(广东)智能科技有限公司

Marsh gas engineering inoculum and preparation method thereof

ActiveCN104805125AIncrease productionHigh yieldBacteriaGas production bioreactorsMicroorganismMixed culture

The invention discloses a marsh gas engineering inoculum and a preparation method thereof, and aims to solve the problems of low anaerobic fermentation speed, long fermentation period and poor marsh gas engineering gas productivity and engineering running efficiency in the conventional marsh gas engineering. Organic waste sludge or biogas slurry is taken as a raw material, and a special marsh gas engineering inoculum is prepared through mixed culture and a fixed anaerobic fermentation microbial flora according to an anaerobic fermentation principle and a microbial ecology principle. Compared with the prior art in which an inoculum is prepared by culturing single strains respectively and mixing proportionally, the preparation method has the advantages that the inoculum is prepared through mixed culture of sludge or biogas slurry is stable in micro-ecology; moreover, the marsh gas engineering fermentation period can be remarkably shortened, the marsh gas yield is increased, and the marsh gas engineering economical benefit is increased.

Owner:马力通

Gas generating powder used for gas generator of automobile safety airbag and preparation method thereof

InactiveCN1544271ASimplified Filtration SystemImprove gas production efficiencyPedestrian/occupant safety arrangementAdhesiveFilter system

The invention discloses an aerogenic drug used in gas generator of automobile safety gas cell and its preparing method, composed of negative oxygen combustible agent, oxidant, slagging agent, and adhesive; it adopts a wet-mixing extrusion molding technique for preparing and the drug has very weak toxicity; suitable for large-scale low-cost production, and has a little dust in producing course, high safety; and has high gas generating efficiency, 1.7 times about as high as that of sodium azide aerogenic drug; etc. It simplifies the filter system of the gas generator and creates important conditions for the development of miniaturizing and lightening the gas generator. It can meet the requirements, is a non-azide aerogenic drug and can replace the sodium azide aerogenic drug and is used in the current popular multiple gas generators of automobile safety gas cells.

Owner:西安北方庆华电器(集团)有限责任公司

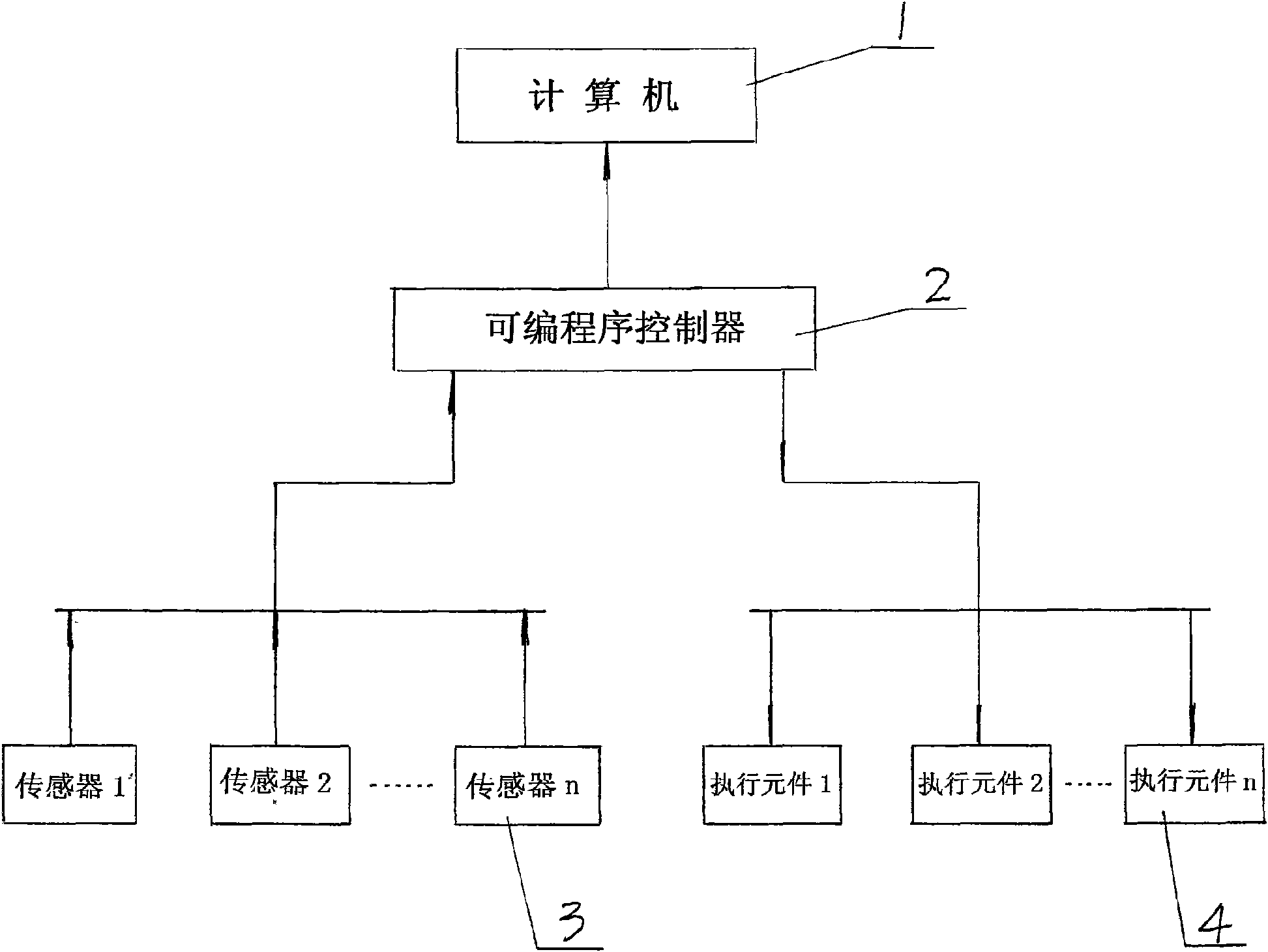

Methane fermentation intelligent management system

InactiveCN101613662AImprove processing efficiencyImprove gas production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsProcess equipmentGeneration rate

The invention discloses a methane fermentation intelligent management system, belonging to a methane generating automation device and aiming at providing the system which can automatically manage intensification large-scale methane generation. The system comprises a computer, a field data acquisition device and a sensor; a sensor (3) arranged on all major devices of a fermentation system is connected with the field data acquisition device (2) by a communication cable; the field data acquisition device is connected with the computer (1) by the communication cable. The system not only realizes the conversion of the methane fermentation from the miniaturization production mode to the large-scale concentration efficient mode, but also intuitively displays all major processing equipment and all technological parameters by a configuration device through the sensor in a pattern or digital mode, conveniently realizes the monitoring of the whole production system, increases the working efficiency, has the advantages of low cost, high waste water processing efficiency, high gas generation rate and the like, and is the ideal management system matched with large-scale poultry and livestock farms.

Owner:GUIYANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com