Gas generating agent and preparing method thereof

A gas generating agent and solvent technology, which can be used in the production of compressed gas, attacking equipment, vehicle parts, etc., and can solve the problems of poor comprehensive performance of gas generating agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

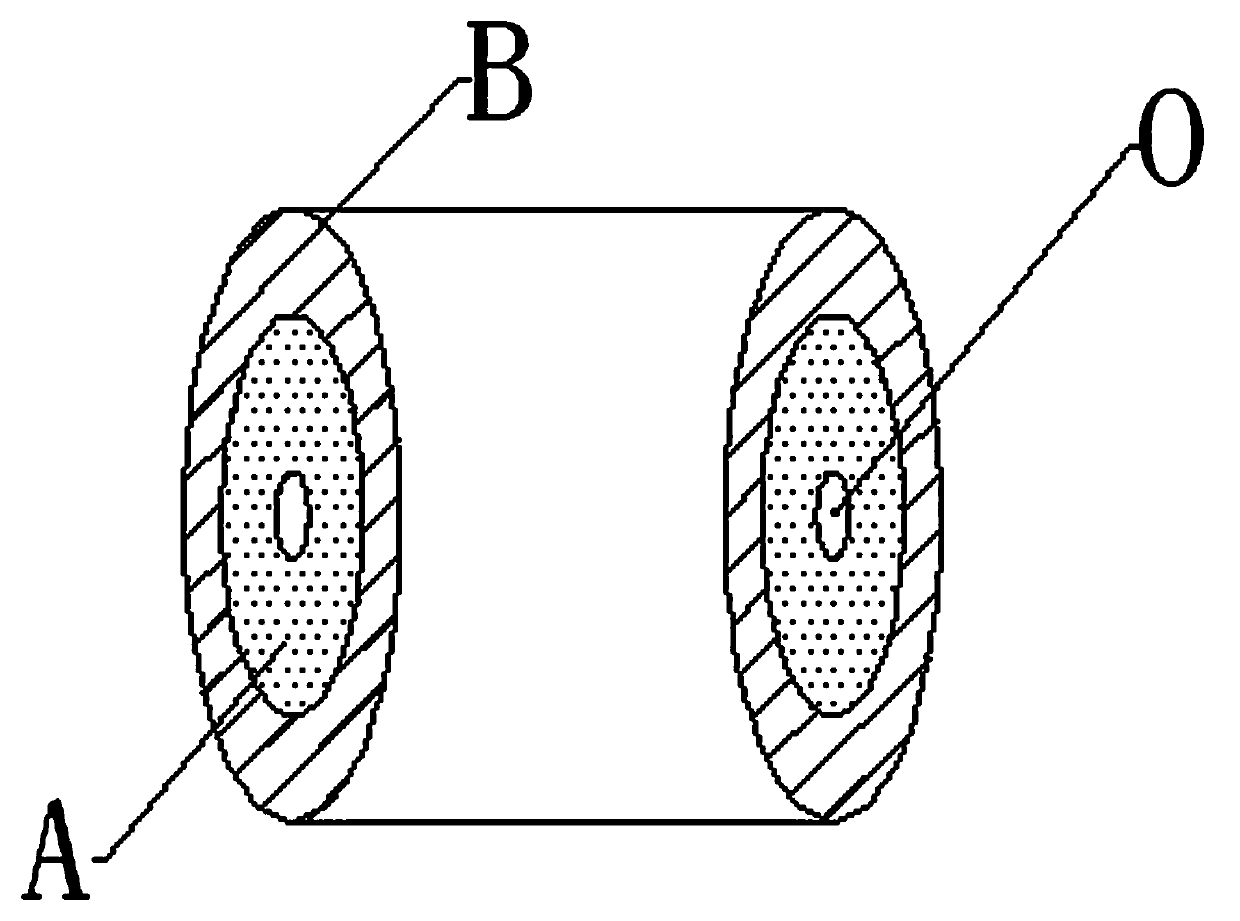

[0021] The present invention also provides a method for preparing the above-mentioned gas generating agent, which includes mixing the first flammable agent and the first oxidant with a solvent, and mixing the second flammable agent and the second oxidizer with a solvent; A gas generating agent with an A / B core-shell structure was obtained.

[0022]The first flammable agent and the first oxidant are mixed with solvent, the second flammable agent and the second oxidant are mixed with solvent. The temperature can be -10-90°C, preferably 20-70°C; the time for mixing is as long as the surface of the mixture is smooth, the structure is uniform and dense, and there is no hard material, for example, it can be 10-60 minutes, preferably 10-30 minutes Specifically, the first combustible agent and the first oxidizing agent, and the second combustible agent and the second oxidizing agent can be dry-mixed in a mixer for about 6 minutes, and a solvent is added to the mixer, mixed and prepare...

Embodiment 1

[0030] (1) Add 54wt% guanidine nitrate (molecular weight 122.08g / mol) with a particle size of 1-10μ, 34wt% basic copper nitrate with a particle size of 1-6μ, 5wt% potassium nitrate with a particle size of 1-6μ, and 3wt% perchloric acid with a particle size of 10-20μ Ammonium, 3wt% aluminum oxide with a particle size of 1-5μ was added to the vacuum kneader and mixed for 8 minutes, and then a solvent of about 27wt% alcohol acetone (volume ratio 4:1) of the total amount of the above substances was added to mix, and the vacuum pump was turned on. Discharge A1 at 11wt%;

[0031] Add 12wt% nitrocellulose (molecular weight 504.28g / mol), 78wt% strontium nitrate with a particle size of 1 to 6μ to a vacuum kneader for 8 minutes, and then add about 27wt% alcohol acetone (volume ratio 4:1 ) solvent, turn on the vacuum pump, and discharge B1 when the volatile content is 11wt%.

[0032] (2) Add materials A1 and B1 to the inner runner and outer runner of the dual-channel mold respectively. ...

Embodiment 2

[0034] The same mold method as in Example 1 was used to prepare a gas generating agent sample S2 with an A / B core-shell structure having a hollow inner core with a thickness of 0.8 mm in layer A and a thickness of 0.2 mm in layer B. The difference is preparation B1, 65 wt % nitrocellulose (molecular weight 504.28 g / mol), 35 wt % ammonium nitrate with a particle size of 1 to 10 μ was added to the vacuum kneader for 8 minutes, and then about 27 wt of the total amount of the above substances was added % alcohol acetone (volume ratio 4:1) was mixed, the vacuum pump was turned on, and B1 was discharged when the volatile matter content was 11wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com