Biogas reaction device

A reaction device and biomass gas technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve problems such as waste of resources, short service life of biogas digesters, pollution of water sources and the environment, etc. , to achieve the effect of cleaning slag and maintaining safety, reducing its own energy consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

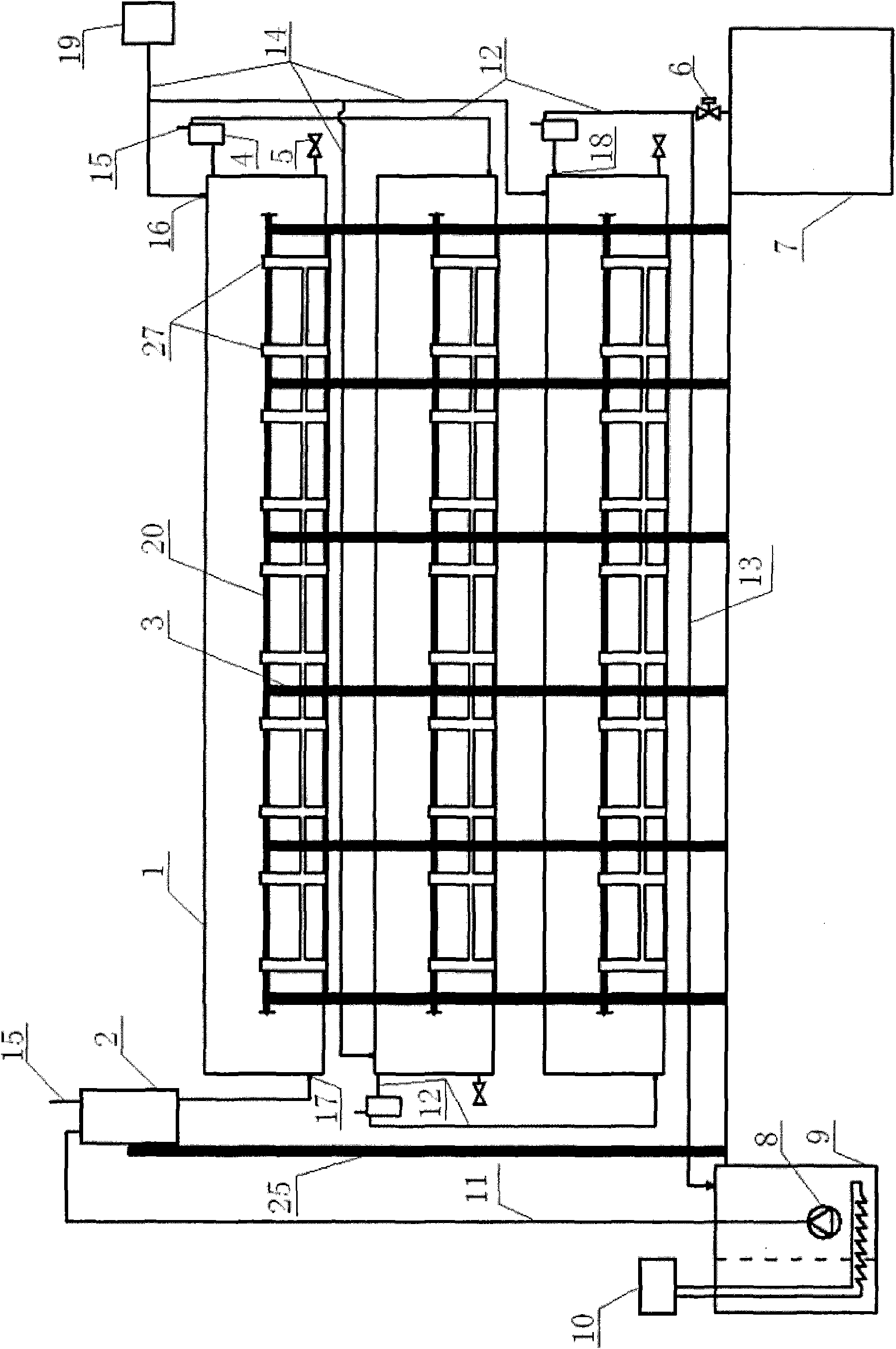

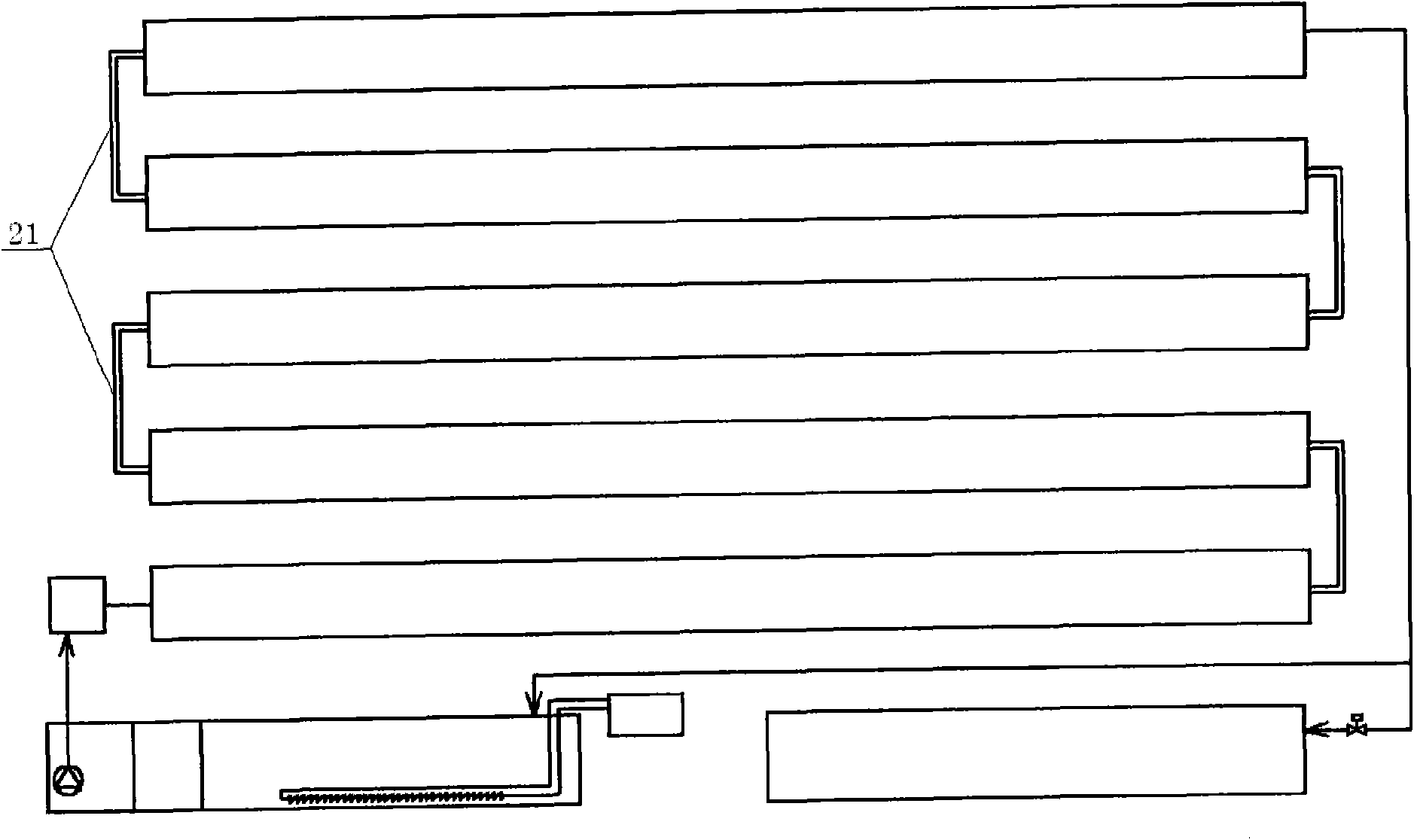

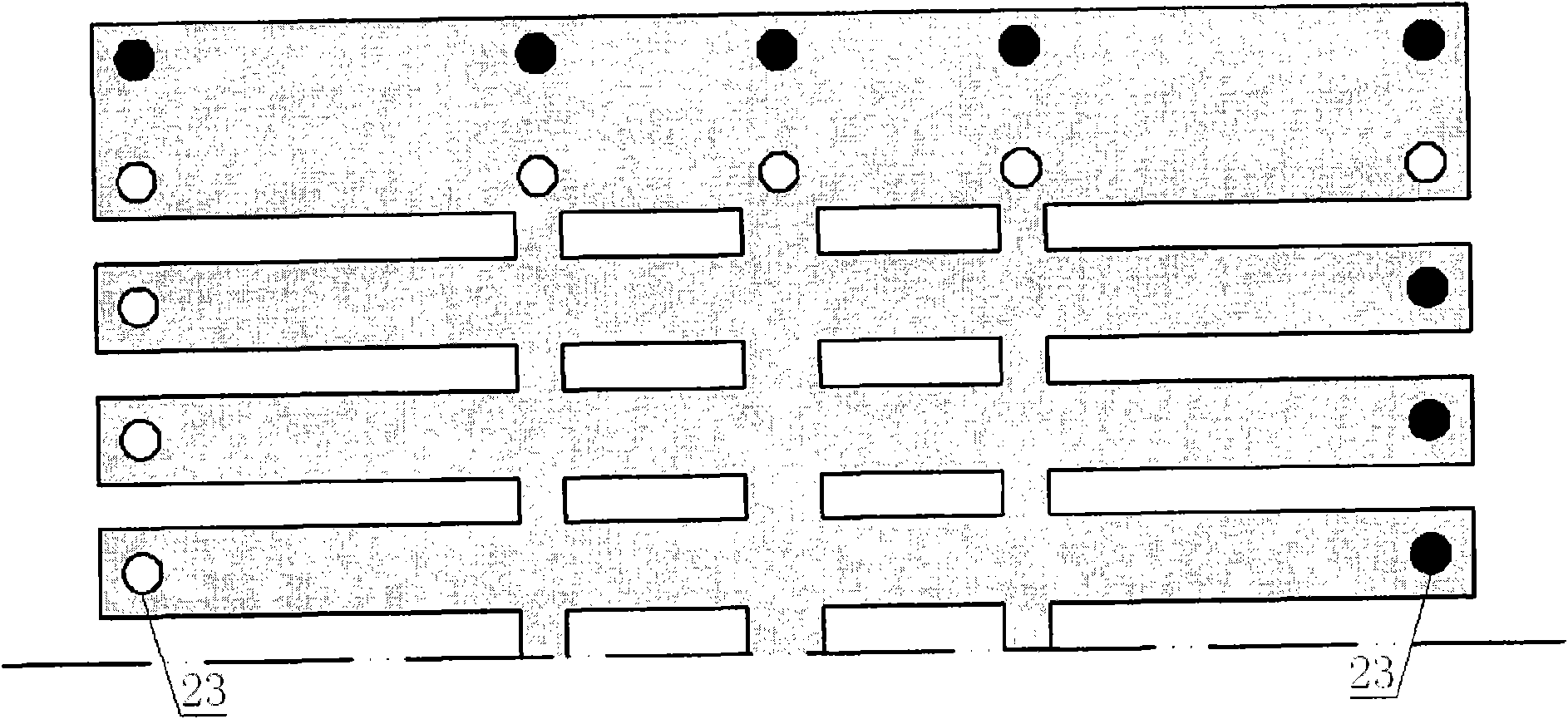

[0041] Example of the present invention is realized like this:

[0042] The reaction bed monomer (1) and the support bed (27) of the present invention are formed by heat-sealing with a market-bought plastic cloth (such as EVA coated cloth, PVC coated cloth, red mud plastic cloth, etc.) , and the reaction bed monomer (1) is provided with a feed inlet (17), a feed outlet (18) and an air outlet (16), the support bed (27) is a grid structure, and a connecting button (23) is provided around the periphery. The flow limiter (4) and the connector (21) are made by hot-melt welding of plastic pipes (such as PVC pipes, PE pipes, PPR pipes and other pipes). Column (3), support (20) and pull bar (22) are made of steel pipe blanking, drilling, and galvanizing bought in the market, and column (3), pull bar (22), support (20) are all equipped with screw holes (26). These products are custom-made installations.

[0043] Heating system (10), feed pump (8), slag discharge valve (5) and electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com