Method for purifying slight pollution sewage through waste sulfuric acid picking liquid

A sulfuric acid pickling, micro-pollution technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high introduction cost and treatment cost, secondary aluminum salt treatment agent The problems of pollution and high cost of chemical agents can achieve the effect of low processing cost, short reaction time and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

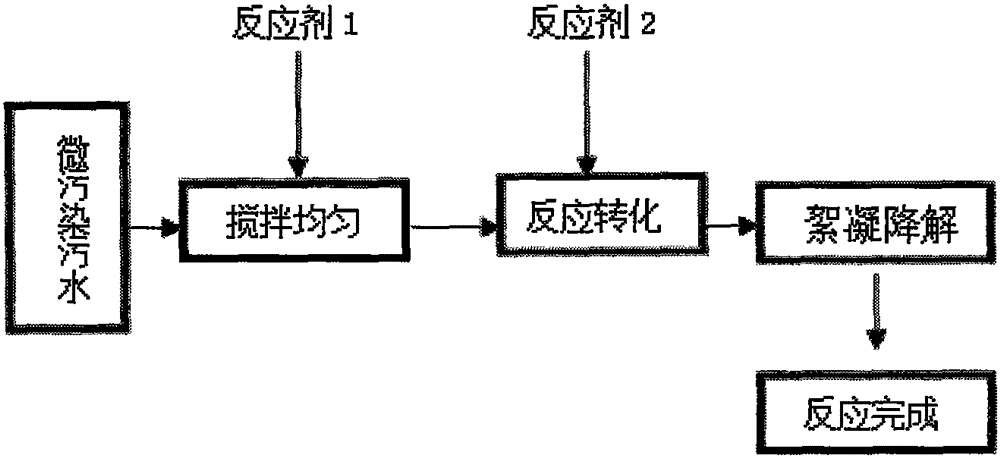

[0018] like figure 1 As shown, this embodiment includes slightly polluted sewage, reactant 1, uniform stirring, reactant 2, reaction conversion, flocculation degradation, and reaction completion.

[0019] During work, according to the weight of slightly polluted sewage (detecting its chroma is 20 degrees, suspended solids is 36mg / L, and other indicators are normal), add reactant 1 (detecting its composition to be sulfuric acid) in the sewage by spraying with a sprayer 4.5%, the total iron content is 10%) 5 parts, stir and dissolve with electric stirrer (rotating speed is 300 revs / min), evenly add reactant 2 (detection its composition is calcium oxide 50%, sodium hydroxide 50%) 1 part for reaction transformation, after stirring for 10 minutes, the measured pH value was 6.5, then evenly added reactant 2, the addition amount was 1 part and carried out reaction conversion, after stirring for 10 minutes, the measured pH value was 7.75, stop stirring After 2 hours of standing still...

Embodiment 2

[0021] like figure 1 As shown, this embodiment includes slightly polluted sewage, reactant 1, uniform stirring, reactant 2, reaction conversion, flocculation degradation, and reaction completion.

[0022] When working, according to the weight of micro-polluted sewage (detected its chroma is 56 degrees, suspended matter is 76mg / L, fluoride is 0.17mg / L and other indicators are normal), add the reactant in the sewage by spraying it with a sprayer 1 (the composition of which is detected as sulfuric acid 5.2%, and the total iron content is 11%) 10 parts, stir and dissolve with an electric stirrer (rotating speed is 300 rpm), slowly add reactant 2 after the dissolution is completed (the composition of which is detected as oxidation Calcium 66.7%, sodium hydroxide 33.3%) 4 parts are carried out reaction transformation, and after stirring for 10 minutes, the pH value measured is 8.1, stop stirring, after standing still for 2 hours, the sewage pollutants flocculate and settle to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com