Hydrate sediment flow solid output measuring device combining X-CT technology and measuring method

An X-CT and measurement device technology, applied in the field of hydrate sediment flow solid output measurement device, can solve problems such as uneven distribution, inability to accurately evaluate flow solid output, and inability to reflect the response law

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

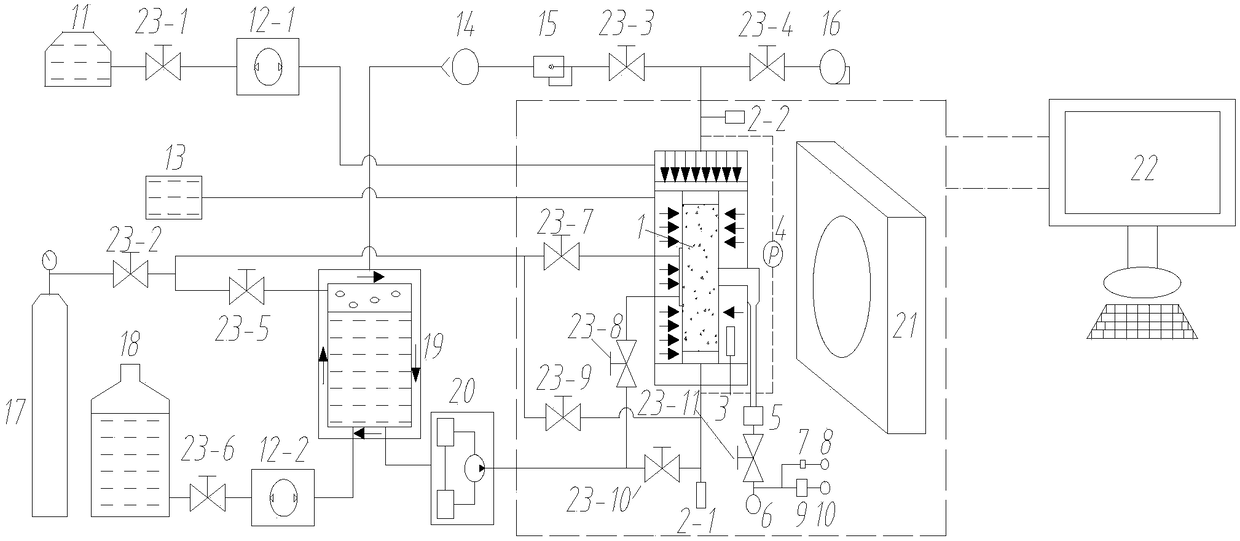

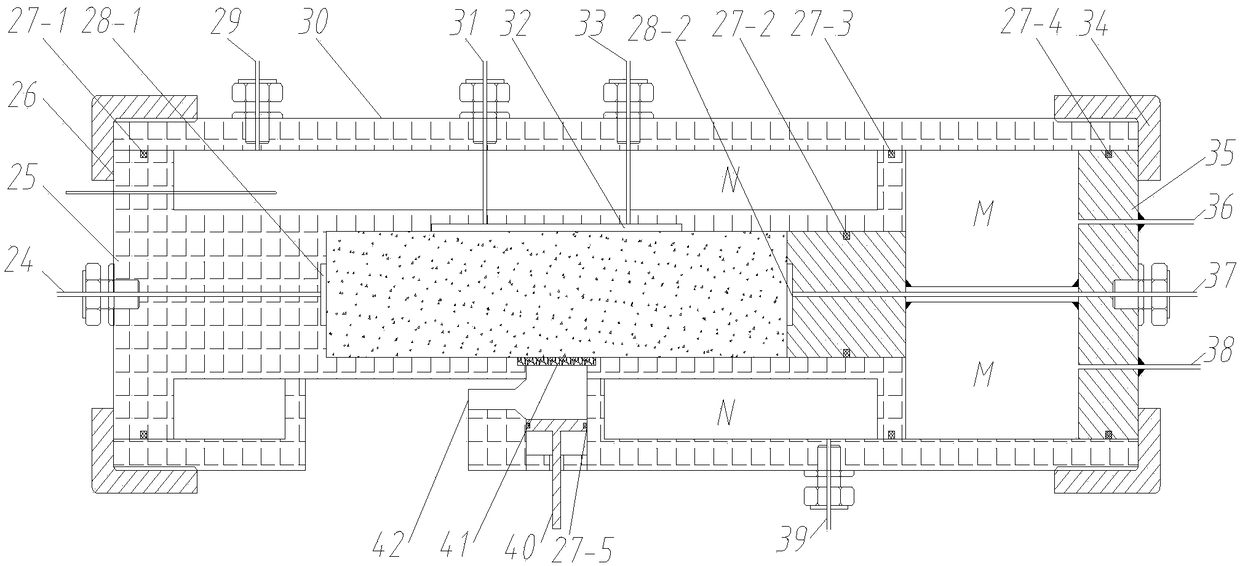

[0037] Embodiment 1, a hydrate sediment flow solid output measurement device combined with X-CT technology, including an X-ray penetrating reactor, an X-CT scanning analysis system connected to the X-ray penetrating reactor, and a vacuum pump system, temperature and pressure control system, hydrate sample preparation system, sand production monitoring system and permeability measurement system, and the X-CT scanning analysis system, temperature and pressure control system, sand production monitoring system and permeability measurement system are all connected with a computer 22 connected; the X-ray penetrating reactor is used for the synthesis and decomposition of hydrate; the X-CT scanning analysis system is used for real-time scanning of sediment microstructure, and the X-CT scanning analysis system consists of a micron-scale switchable X-ray source , a stage and a high-resolution flat panel detector, the highest resolution can reach 500nm, and its built-in rotatable three-di...

Embodiment 2

[0049] Embodiment 2, based on the measurement device described in embodiment 1, the present invention also proposes a measurement method based on the above-mentioned combined X-CT technology of the hydrate sediment flow solid output measurement device, comprising the following steps:

[0050] (1) Airtightness inspection of the device: Check whether the sealing ring and vulnerable parts of the device are intact, close the first valve 23-1, the fourth valve 23-4 and the sixth valve 23-6, open the high-pressure gas cylinder 17 and the 2. Valve 23-2, let 1MPa gas flow in, if the pressure of the device does not change significantly within 10 hours, it means that the device has good airtightness;

[0051] (2) Sample loading: according to the needs of the experiment, the sand control pipe 41 and the sintered plate 32 of the corresponding size are selected, respectively placed in the inner cavity 25 of the reaction kettle, and the prefabricated sediment sample 1 is filled in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com