Decompression marine natural gas hydrate mining method and submarine mining system

A mining method and hydrate technology, which are applied in the fields of production fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of complex natural gas hydrate storage conditions, difficult drilling and unevenness, etc., and reduce equipment investment. The effect of low cost, low manufacturing cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

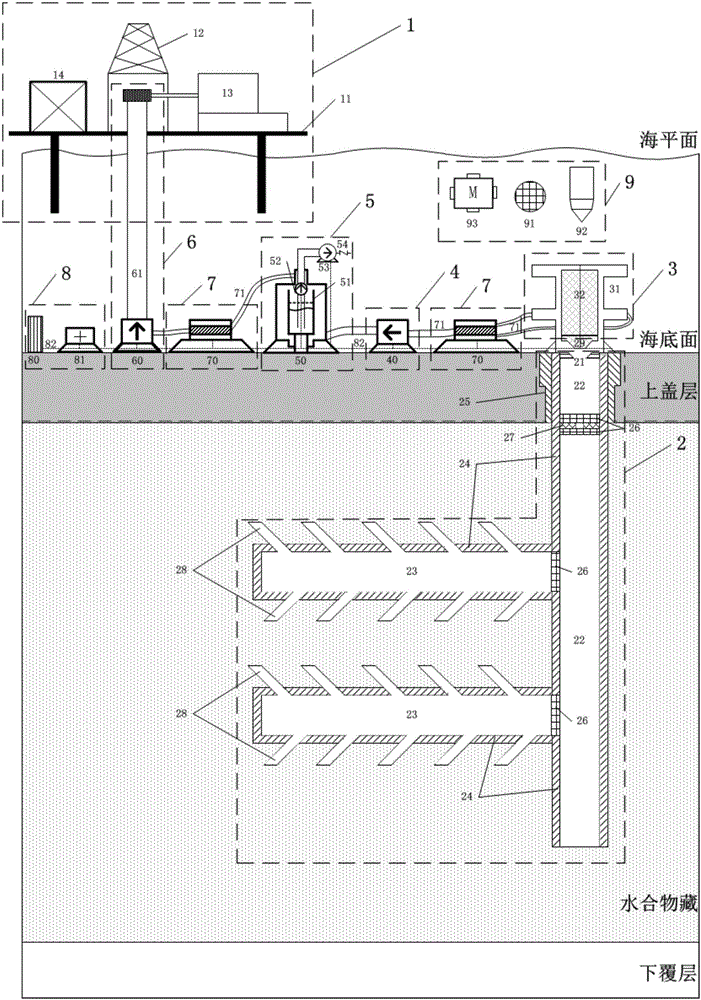

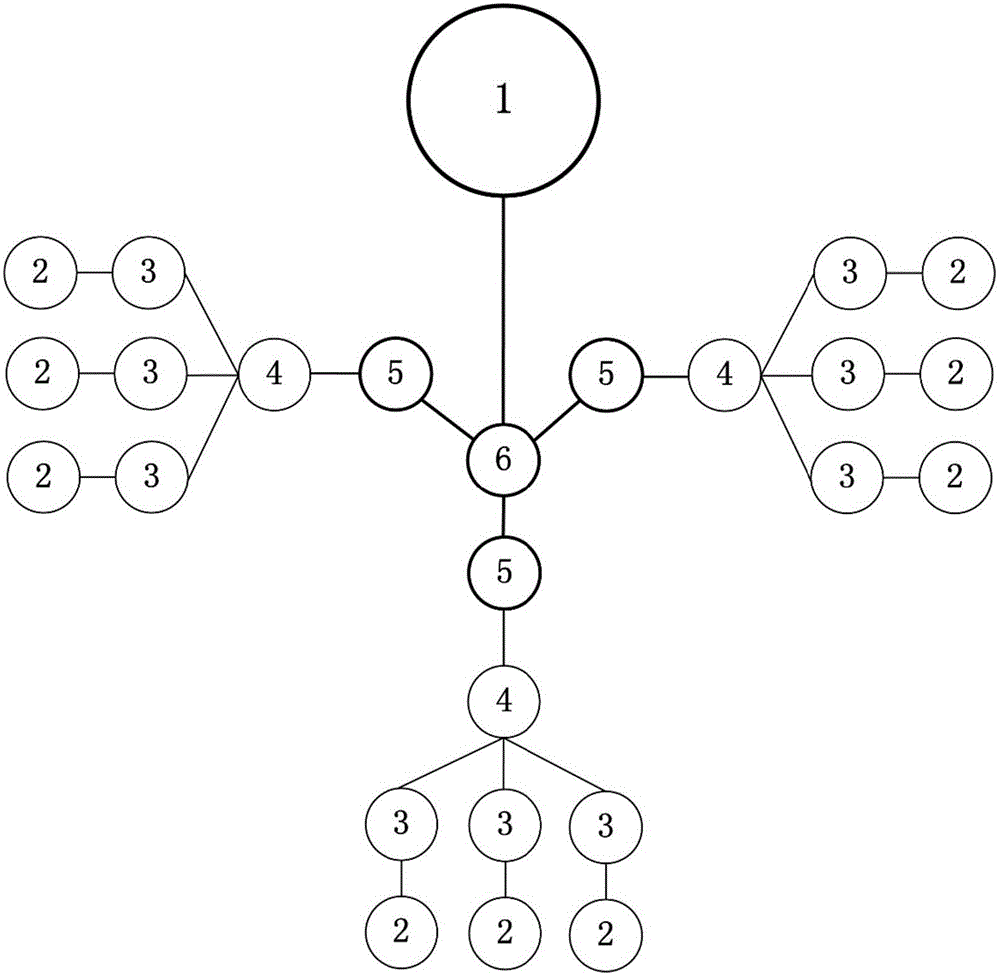

[0033] Such as figure 1 As shown, the mining system includes semi-submersible offshore platform 1, multi-cluster perforated production well 2, wellhead gas-water collection tree 3, gas-water mixed transportation system 4, seabed gas-water separation equipment 5, gas transmission system 6, pipelines System 7, power and communication system 8 and auxiliary equipment 9. The standardized mining process is as follows:

[0034] Detection: After the offshore platform 1 arrives at the predetermined sea area with various equipment, it first drops the auxiliary equipment 9, and the unmanned operation robot 93 starts the detection equipment 91 to conduct advanced and precise detection on the seabed surface to determine the depth, location and content of the hydrate reservoir distribution. Feedback to the terminal device 14 for decision making.

[0035] Comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com