Sludge pretreatment technology with desalting effect

A sludge treatment and pretreatment technology, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of reduced efficiency of anaerobic digestion and aerobic composting, sludge drying and incineration Reduce the risk of heavy metal pollution, facilitate subsequent treatment, and increase the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

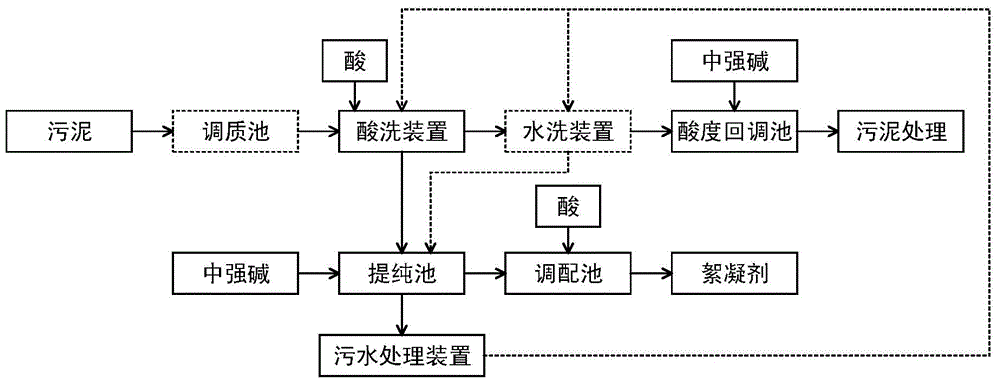

Embodiment 1

[0045] as attached figure 1As shown, the water content of the water supply plant sludge is 80-85%, randomly sampled, and after partial drying, the total content of iron salts and aluminum salts in the sludge is measured by a spectrophotometer as 65%, and the sludge is put into the sludge Mud conditioning tank, add water to condition and dilute to 90% water content, put the sludge into the pickling tank, then put 20% hydrochloric acid, fully stir and react for 70 minutes for pickling, after pickling, use gravity concentration method to concentrate , the concentration time is 30 minutes to obtain desalted sludge and pickling solution, the pH of the pickling solution is 6, randomly sample, and use a spectrophotometer to detect the total content of inorganic salts after partial drying is 5%, and the sludge enters the sludge treatment; the washing liquid is discharged into the purification pool, and then poured Put in sodium hydroxide, adjust the pH to 4, obtain the purified liquid...

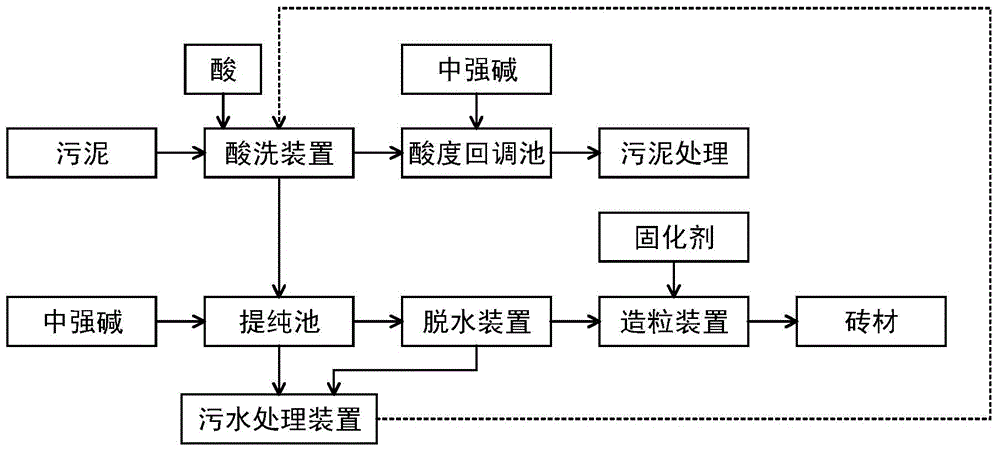

Embodiment 2

[0047] as attached figure 2 As shown, the municipal sludge of the sewage treatment plant has a moisture content of 85-99.8%. Random sampling is used to detect the organic matter content of 45% by gravimetric method, and the total content of inorganic salts is detected by spectrophotometer and other methods after partial drying. 36%, put the sludge into the pickling tank, then put in 35% sulfuric acid to pickle the sludge, stir and react for 30 minutes, make the pH6. Random sampling, part of the organic matter content was detected by gravimetric method to be 58%, and the total content of inorganic salt was detected by spectrophotometer and other methods after part of drying was 14%, and the inorganic salt was removed by 61%. After the acidity was adjusted, the sludge entered the sludge treatment; The pickling solution enters the purification tank, then puts calcium oxide into the purification tank, adjusts the pH to 7, and obtains the purified solution and the precipitate cont...

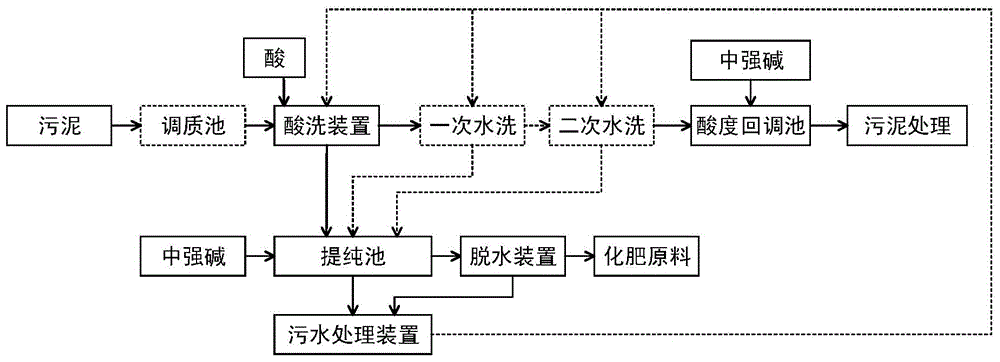

Embodiment 3

[0049] as attached image 3 As shown, take the dewatered sludge from the sewage plant, the water content of the sludge is 80-85%, random sampling, part of the organic matter content is 35% by gravimetric method, and the total content of inorganic salts is detected by spectrophotometer and other methods after part of the drying. 40%, put the sludge into the sludge conditioning tank, add water to condition and dilute to a water content of 95%, enter the pickling device, then put in 10% oxalic acid and 20% sulfuric acid, and fully stir the reaction for 120 minutes to make the pH 6.5, take random samples, partly use the gravimetric method to detect the organic matter content of 55%, and partly use spectrophotometer and other methods to detect after drying The total content of inorganic salts is 4%, and 90% of inorganic salts are removed, and the second washing sludge enters the sludge treatment; the washing liquid is discharged into the purification pool, and then magnesium oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com