Construction process of multi-branch underground screen pipe

A construction process and technology of lateral wells, which are applied in the directions of wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of difficulty in realization, low production of multi-lateral horizontal wells, and increased production of multi-lateral horizontal wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

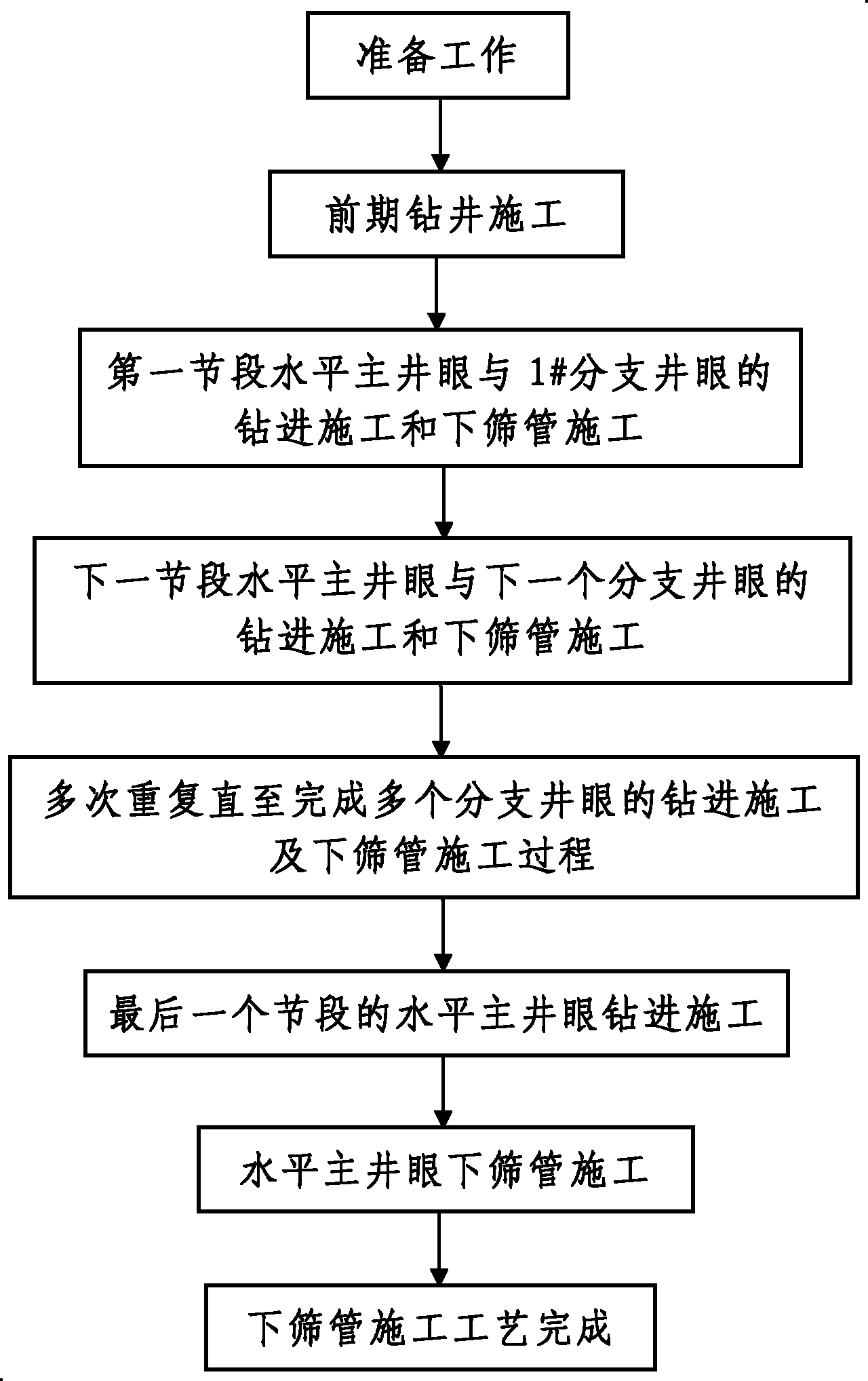

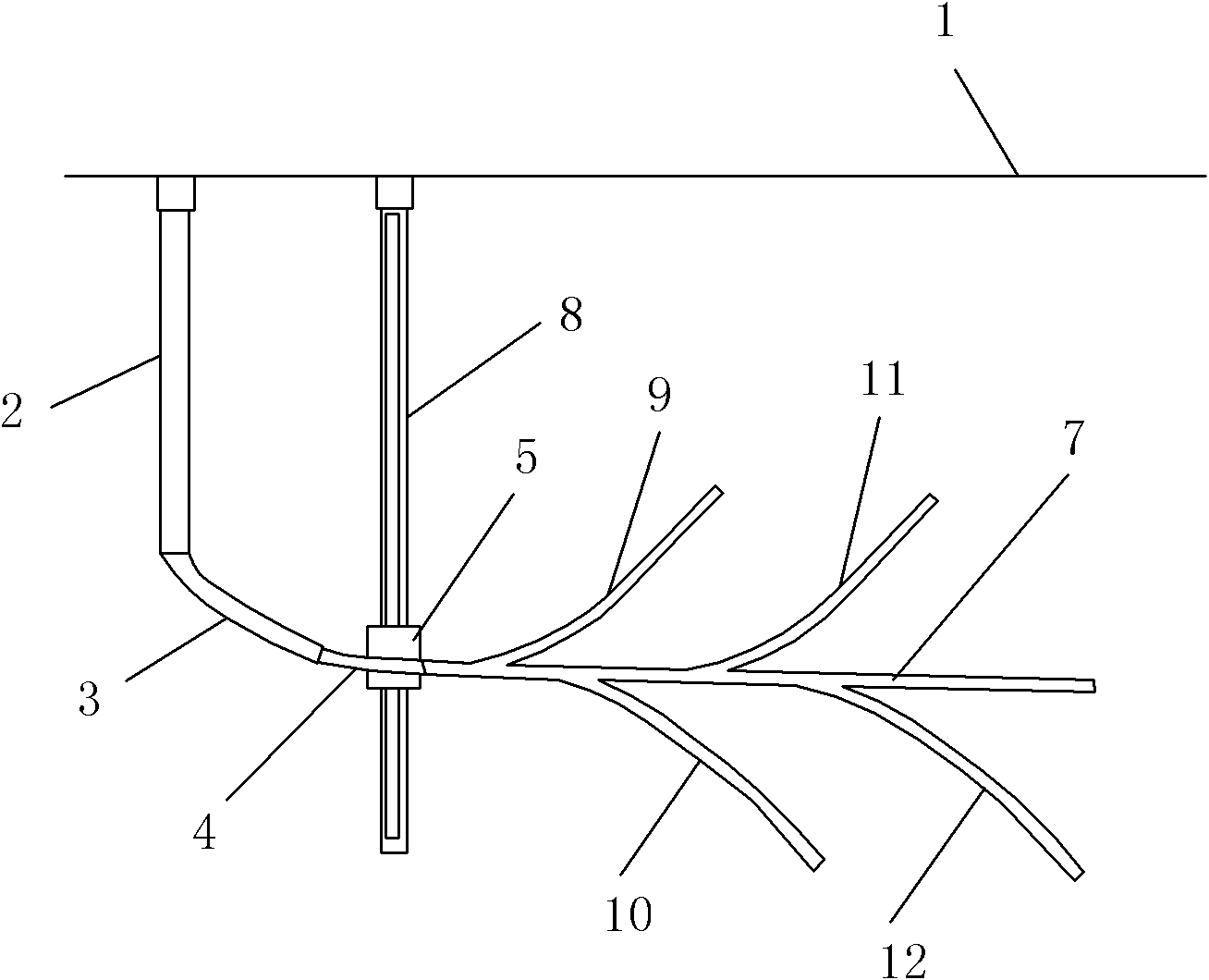

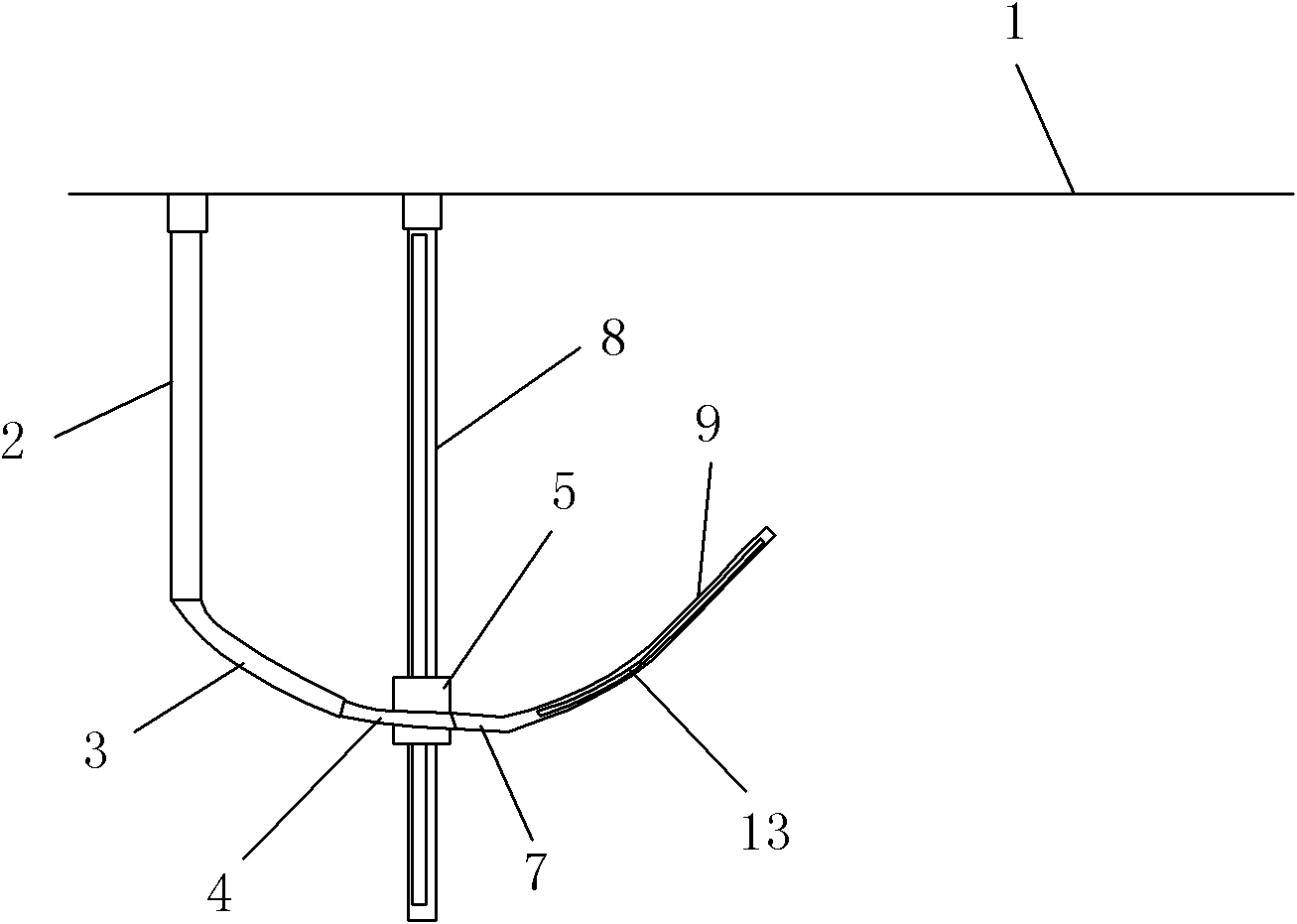

[0074] like figure 2 As shown, the multi-branch horizontal well constructed in the present invention comprises a starting section 2, a whipping section 3 connected with the starting section 2, and a horizontal branch section connected with the whipping section 3 through a connecting section 4, the horizontal The branch section includes a horizontal main wellbore 7 connected to the connecting section 4 and a plurality of branch wellbores distributed on the horizontal main wellbore 7 at intervals from front to back. A branch point where the branch wellbores meet. like figure 1 The construction process of the multi-branch horizontal downhole screen includes the following steps:

[0075] Step 1. Preparatory work: Number the multiple branch wellbores sequentially from front to back, the numbers of the multiple branches are 1#, 2#, 3#...n#, n is the branch The number of boreholes, the number of branch points is n.

[0076]In this embodiment, the number of branch wellbores is 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com