Spiral self-stirring dry fermenting device and method

A dry fermentation device and self-stirring technology, applied in fermentation, biochemical equipment and methods, solid-phase fermentation bioreactors, etc., can solve problems such as incomplete consumption of organic matter, low volumetric gas production rate, and high energy consumption for stirring. Achieve the effects of simple structure, high gas production efficiency and reduced residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

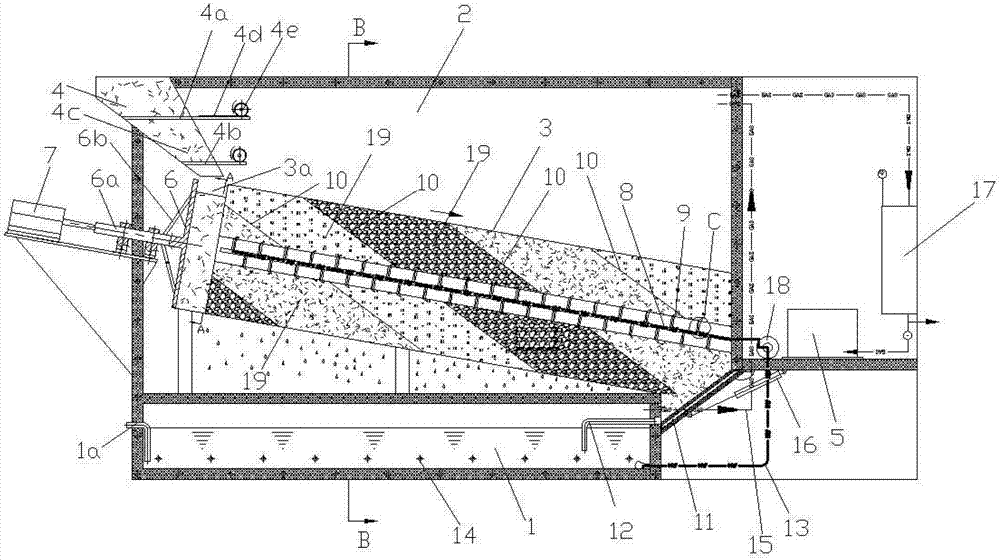

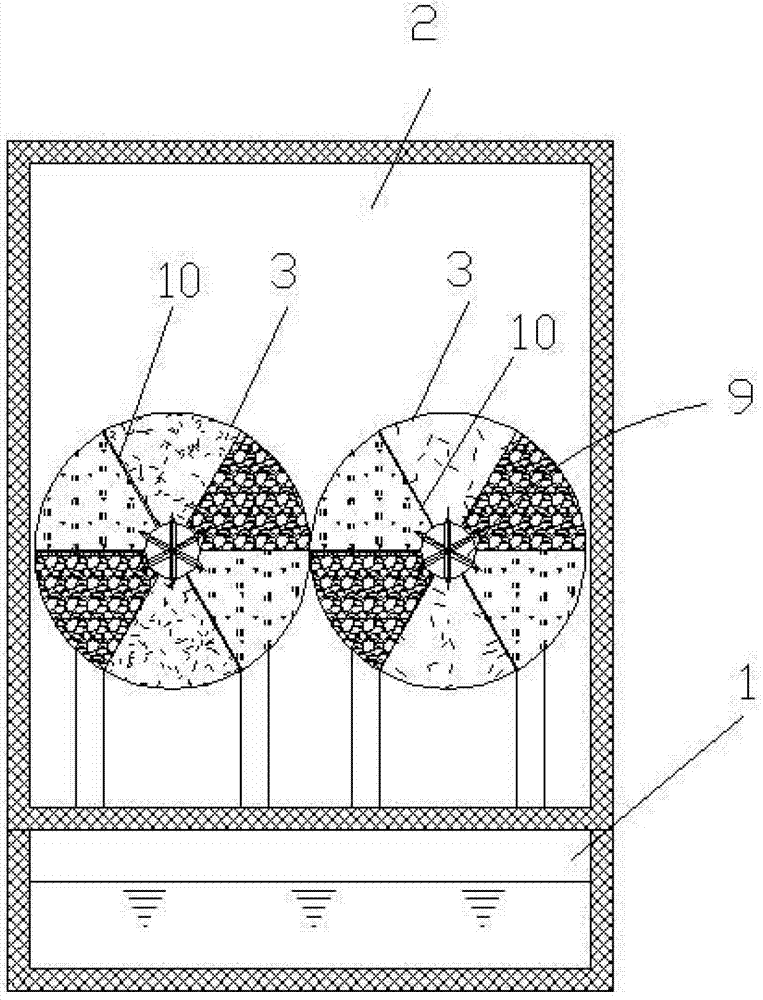

[0031] Example 1, such as Figure 1-5 As shown, a spiral self-stirring dry fermentation device of the present invention is mainly composed of a leachate collection tank 1, a gas storage tank 2, a fermentation cylinder 3, a material funnel 4, an oil-gas generator 5, a pushing plate 6, a pushing oil cylinder 7, Leachate injection pipe 8, nozzle 9, spiral partition 10, slag discharge door 11, leachate return pipe 12, pipeline 13, electric heating pipeline 14, biogas delivery pipeline 15, hydraulic support rod 16, biogas purification device 17, booster Pressure pump 18 etc. components are formed.

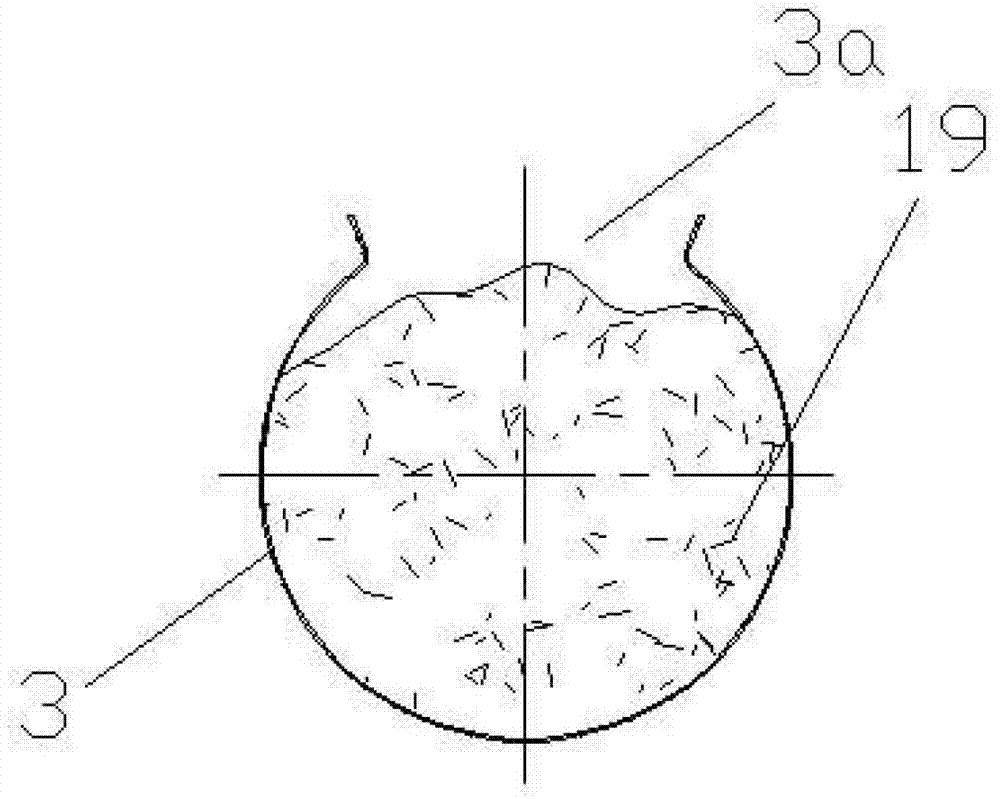

[0032] The two fermentation cylinders 3 are placed side by side obliquely at the bottom of the gas storage cabinet 2, one end of the fermentation cylinder 3 is supported on the bottom plate of the gas storage cabinet 2 through a support column, and the other end is directly in contact with the bottom plate of the gas storage cabinet 2 , the middle part of the fermenting cylinder 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com