Asphalt stirring device

An asphalt mixing and mixing tank technology, which is applied in the field of machinery, can solve the problems of long storage time of modified asphalt, escape of toxic gas, easy precipitation and separation, etc., and achieves the effect of simple structure, not easy to escape, and preventing asphalt precipitation and separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

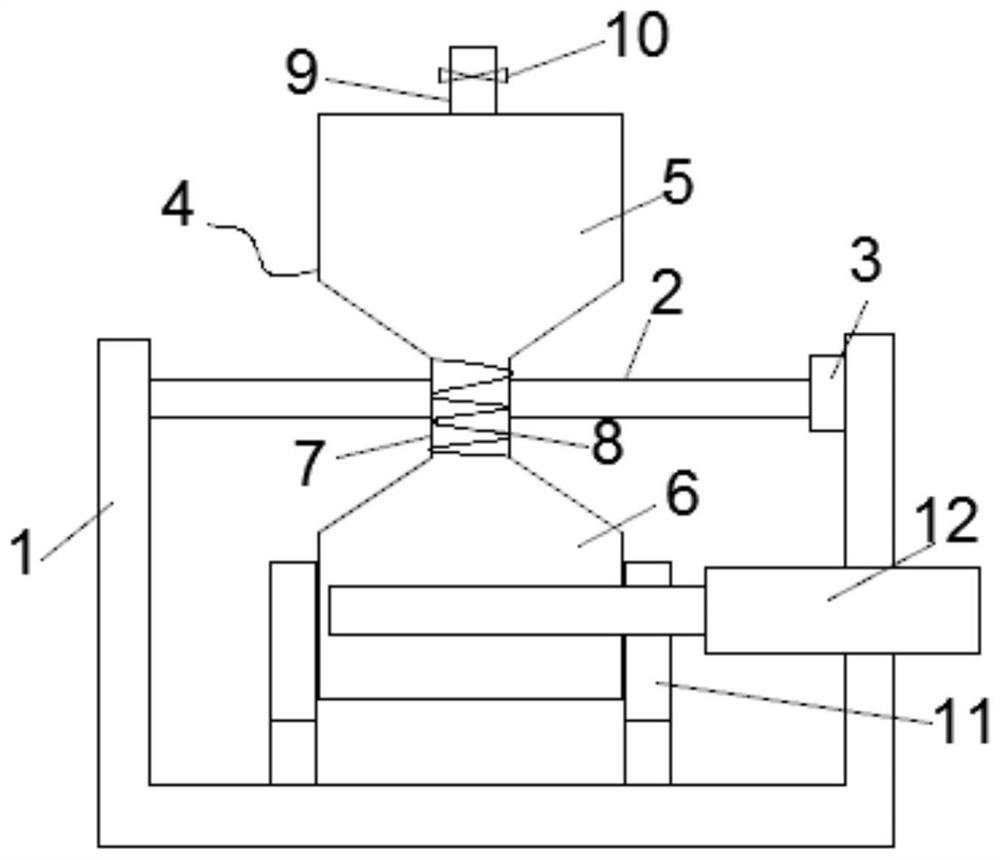

[0016] Such as figure 1 The asphalt mixing device shown includes a U-shaped frame 1, the upper axis of the U-shaped frame 1 is connected with a rotating shaft 2, the rotating shaft 2 is connected with a rotating device 3, and the rotating shaft 2 is fixedly connected with a mixing tank 4, and the mixing tank 4 includes an upper tank body 5 and the lower tank body 6; the upper tank body 5 and the lower tank body 6 are communicated through the communication pipe 7; the bolt guide piece 8 is installed in the communication pipe 7; the upper tank body 5 is equipped with an inlet and outlet material pipe 9; A valve 10 is installed on it; a heating device 11 is installed on the U-shaped frame 1 .

[0017] The rotating device 3 is a motor or a rotating cylinder. The upper tank body 5 and the lower tank body 6 are cuboids. The heating device 11 is an electric heater, and the heating device 11 is an electric heater outside the upper tank body 5 and the lower tank body 6 . The front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com