Coal bed methane recovery method

A recovery method and coalbed methane technology, applied in the direction of mining fluid, earth drilling, wellbore/well components, etc., can solve problems such as environmental pollution, time-consuming and financial resources, poisoning, etc., to increase the control area and improve gas production Efficiency, improve the effect of desorption environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

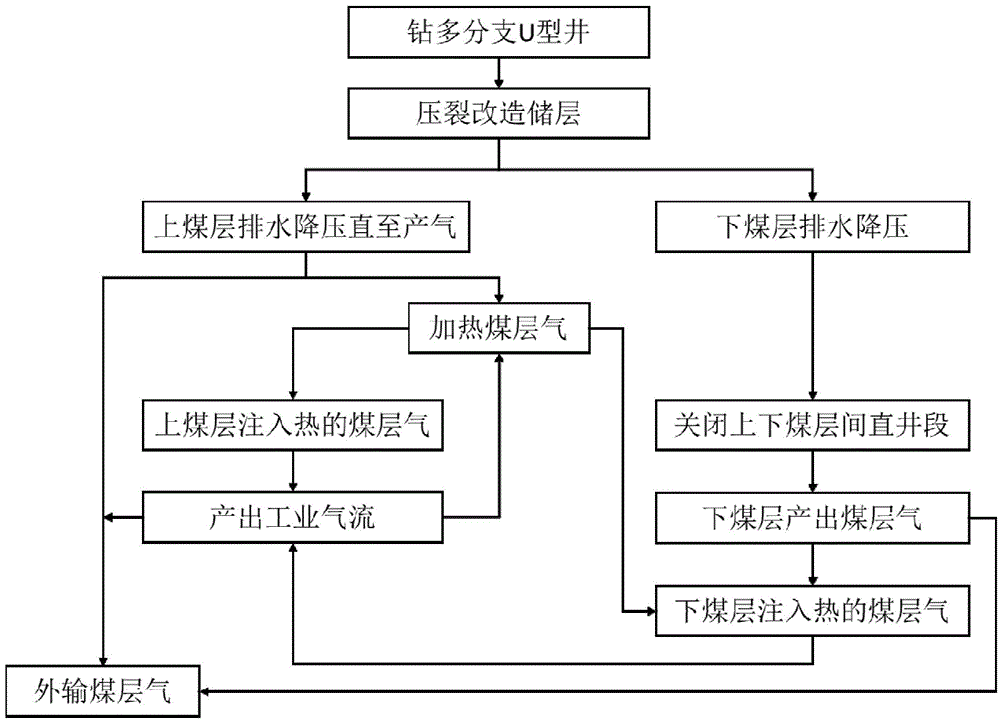

[0029] Such as image 3 As shown, the method for recovering coalbed methane disclosed in the present invention performs the following operations in sequence:

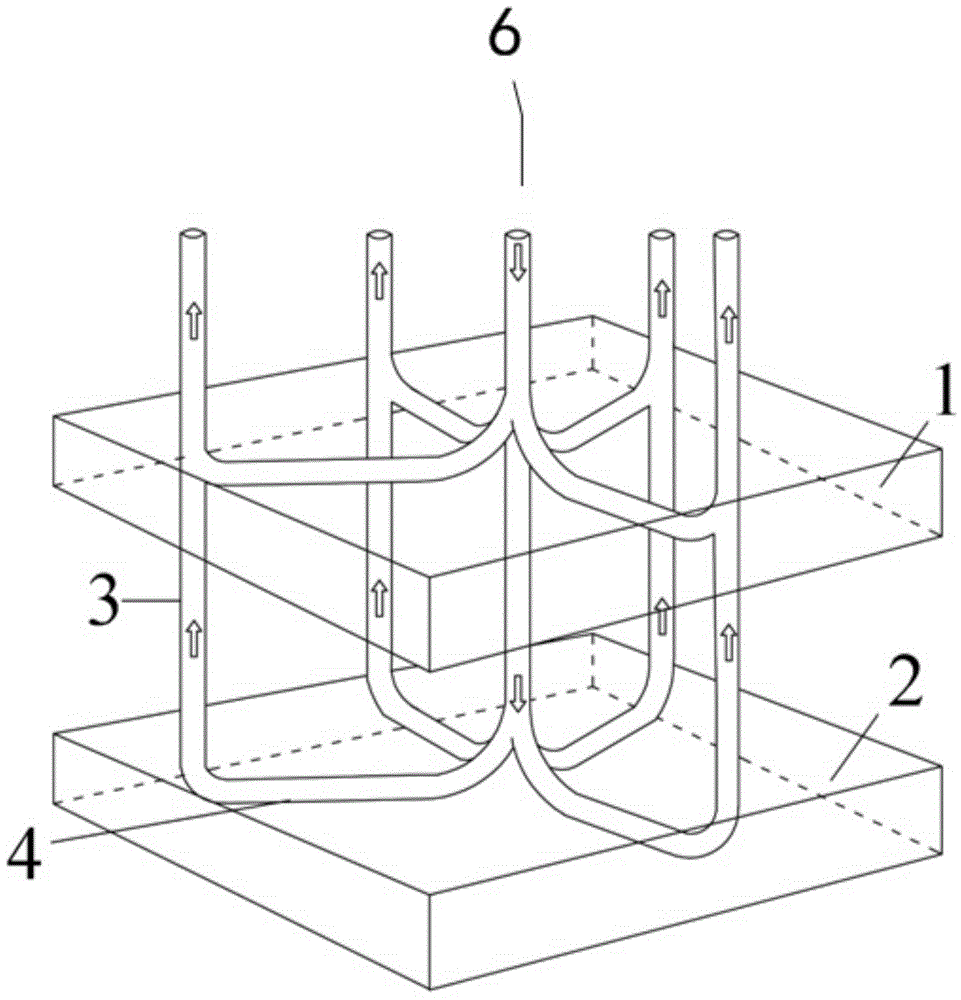

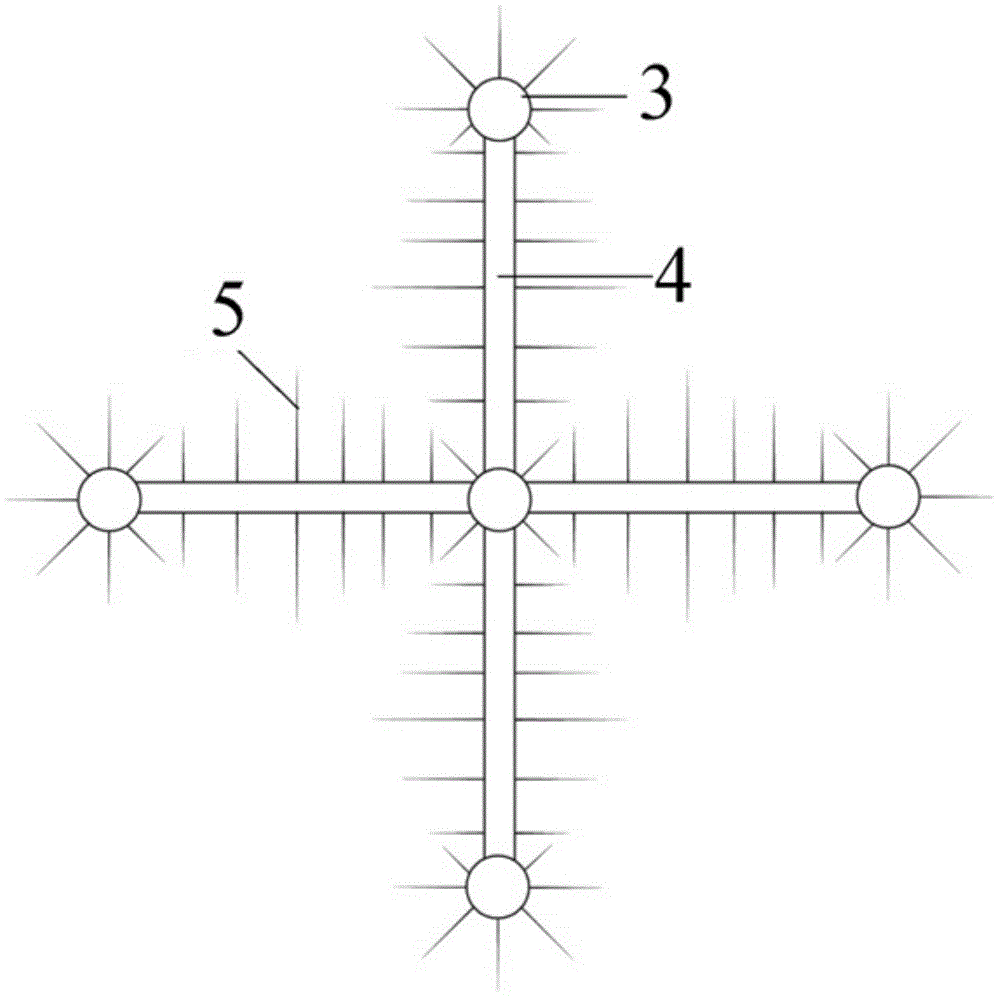

[0030] Step 1: Drill multi-lateral U-shaped wells, multi-lateral U-shaped wells such as figure 1 , figure 2 As shown, it includes 1 middle vertical well 6 and 4 peripheral vertical wells 3, and the 4 peripheral vertical wells 3 are respectively located on the 4 vertices of the rhombus centered on the middle vertical well 6. During the drilling process, the upper coal seam 1 and the lower coal seam 2 are drilled simultaneously. The middle vertical well 6 communicates with each peripheral vertical well 3 in the upper coal seam 1 and the lower coal seam 2 through horizontal shafts 4 respectively.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com