Patents

Literature

50results about How to "Large control area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

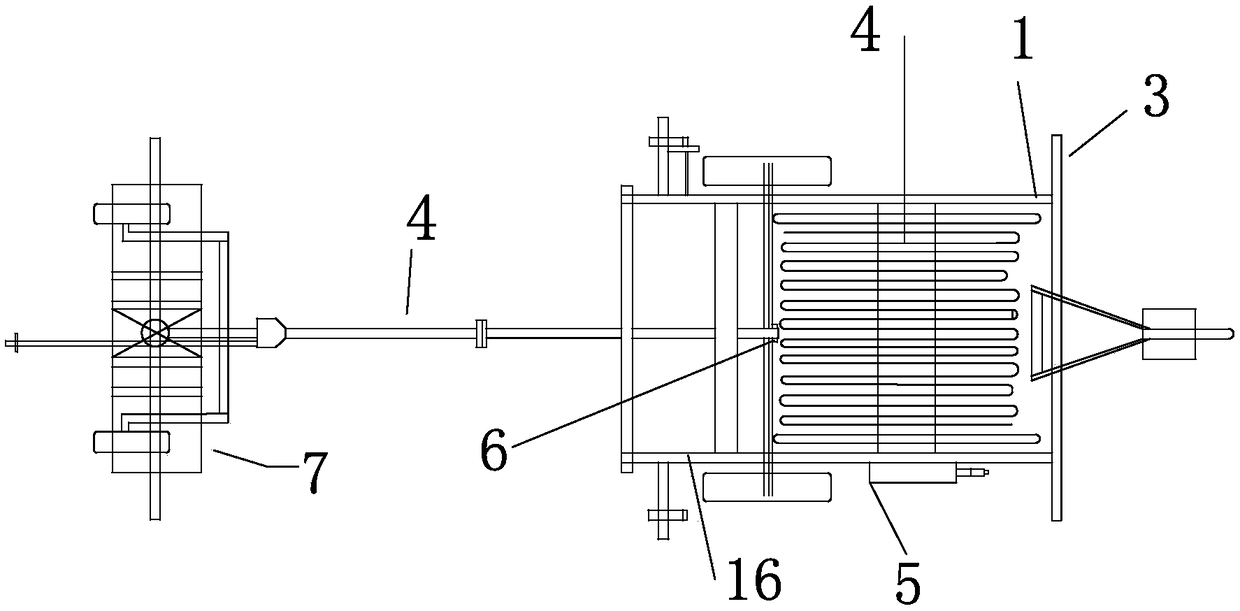

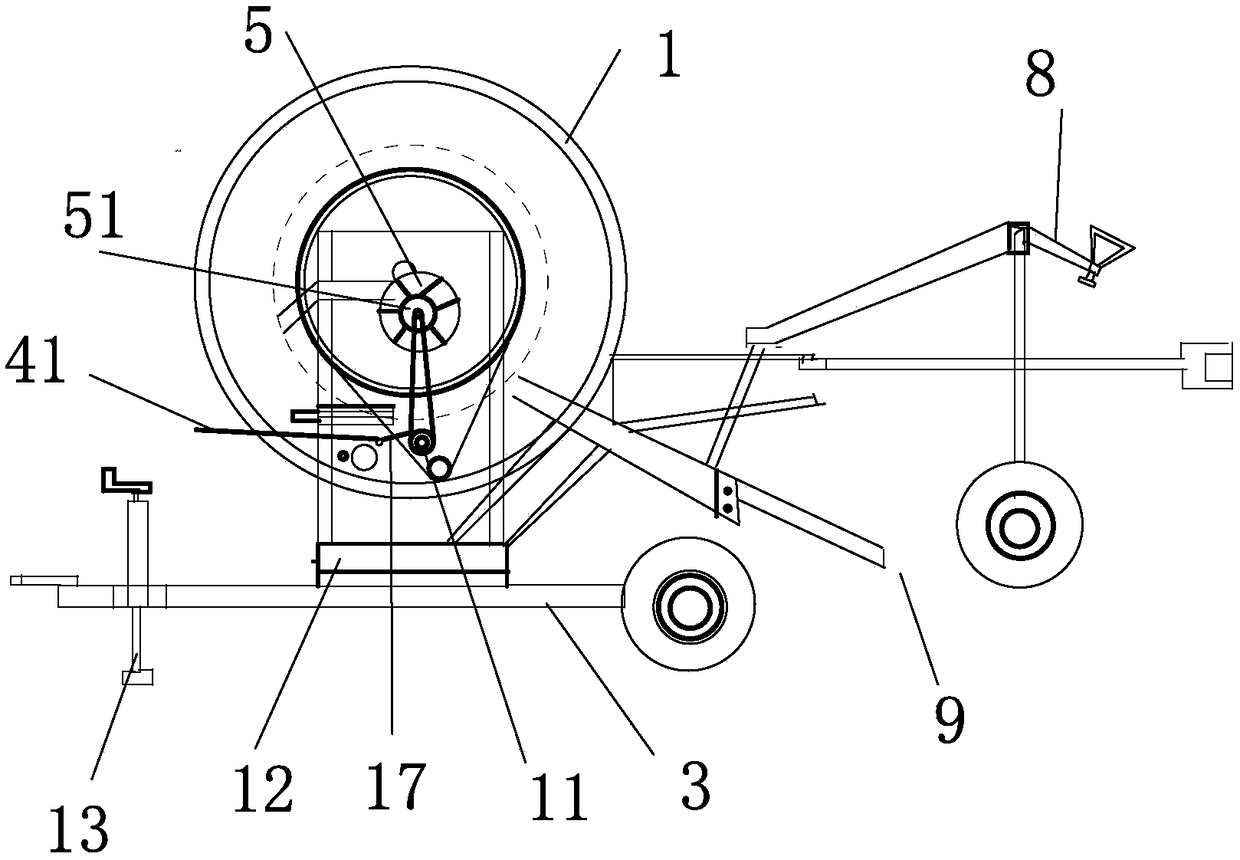

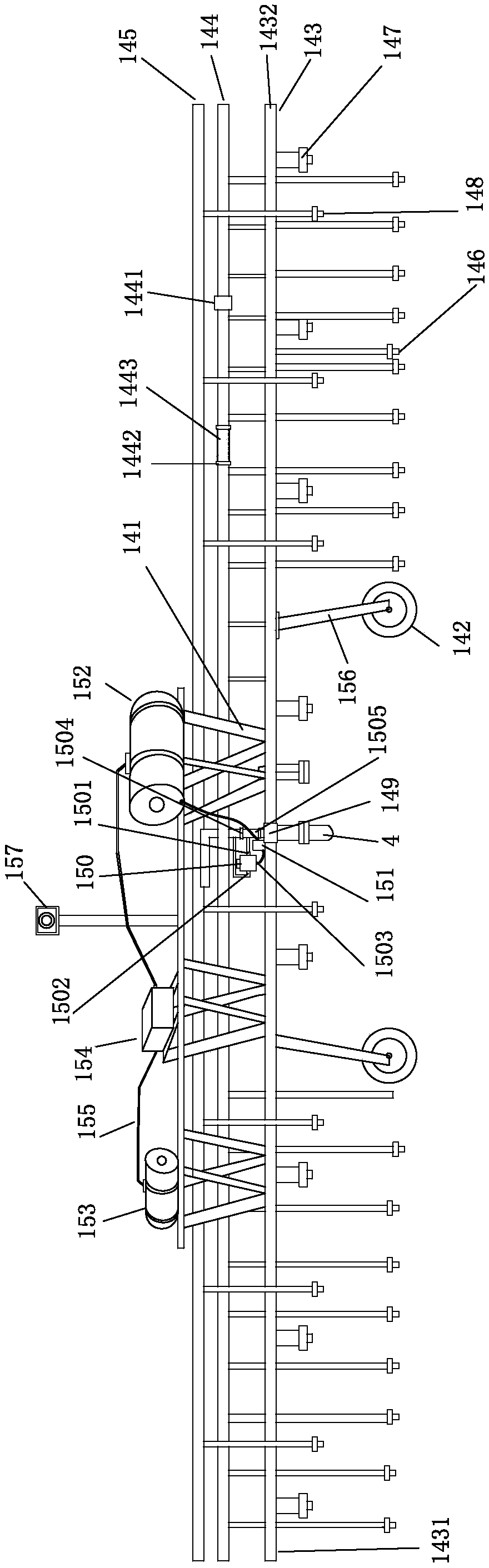

High-efficiency integrated irrigation machine of water and fertilizers

ActiveCN109275550AReliable decision-making abilityPrevent deep seepage lossWatering devicesPressurised distribution of liquid fertiliserWater turbineEngineering

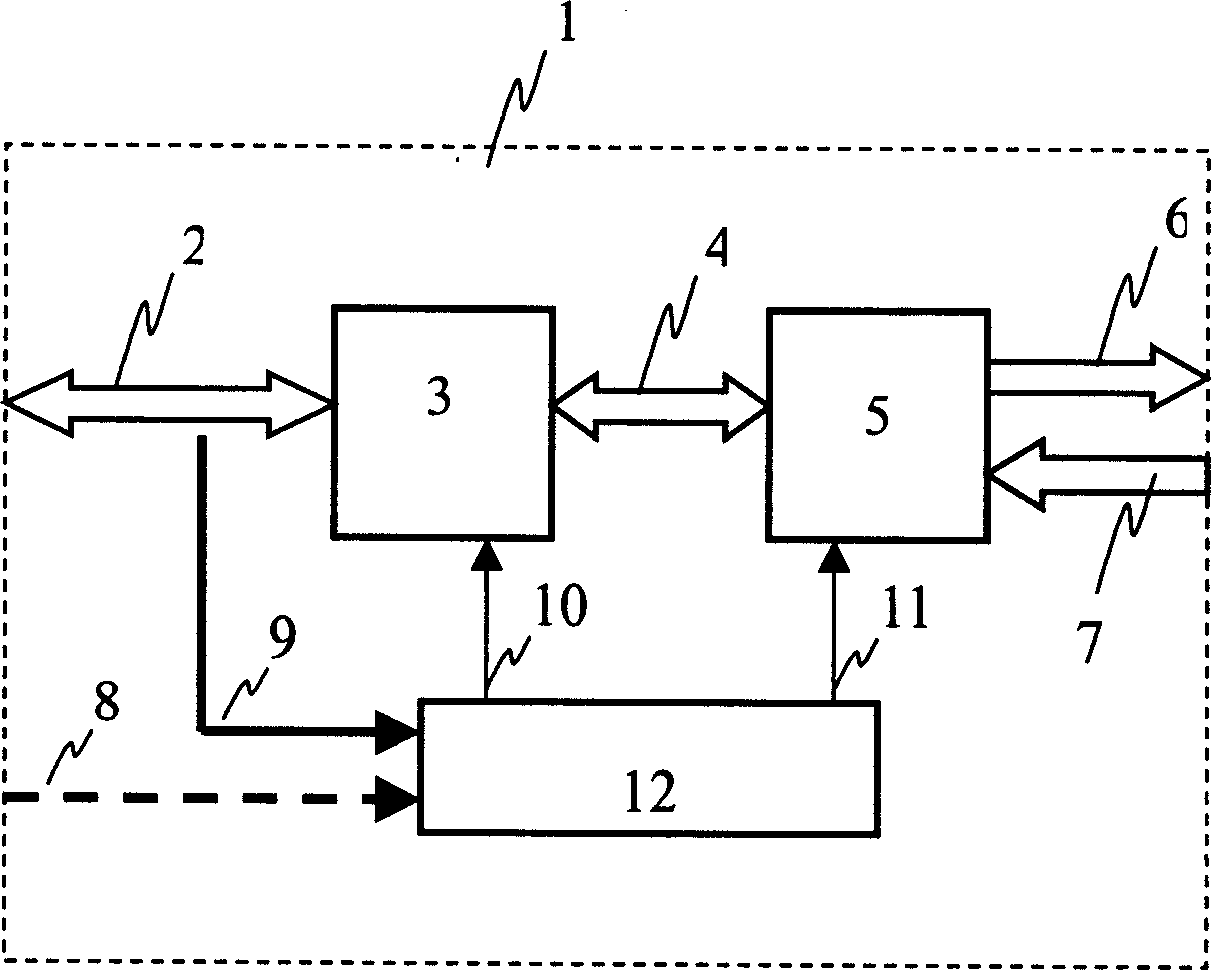

The invention discloses a high-efficiency integrated irrigation machine for water and fertilizers, comprising a reeling machine, a water-spraying walking vehicle and a water conveying pipe, and further comprising an integrated intelligent control system for water, fertilizers and pesticides; the reeling machine comprises a winch, a power transmission mechanism, a chassis and a water turbine mechanism; the integrated intelligent control system for water, fertilizers and pesticides includes a wireless soil-moisture-content sensor, a wireless transmission network, a host computer for decision making, and a lower computer for controlling an electronic control actuator, and the electronic control actuator includes an EC / PH sensor, a liquid level sensor, a fertilizer liquid pneumatic regulatingvalve, an acid-base liquid pneumatic regulating valve, a dosing metering pump and a water-pump flow control valve; the fertilizer liquid pneumatic regulating valve, the acid-base liquid pneumatic regulating valve and the dosing metering pump form a variable adjustment actuator, a reeling-machine uniform-speed recovery control structure and a water-pump stopping mechanism; and a liquid level collector and a camera are fixed on the frame of the water-spraying walking vehicle, the liquid level collector and the camera are connected to a controller through wireless transmission, and the liquid level sensor is connected with the liquid level collector.

Owner:贺州市正地发展有限公司

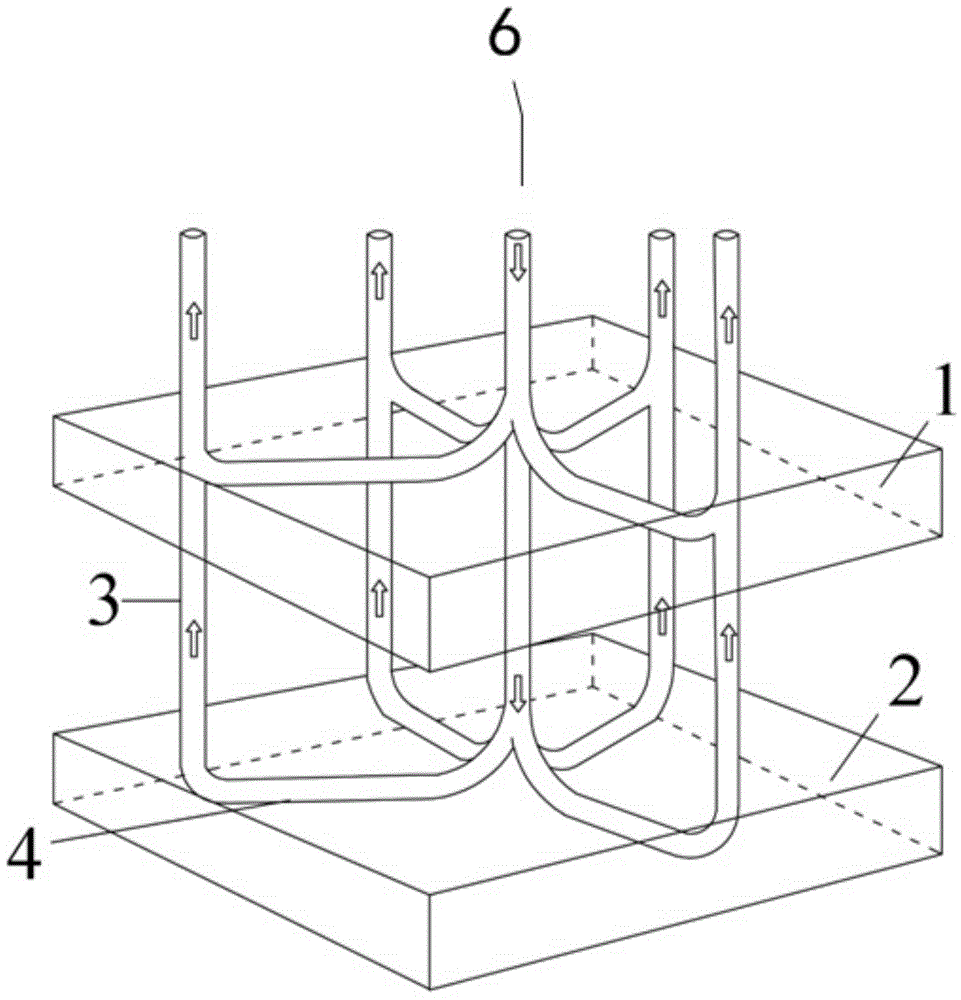

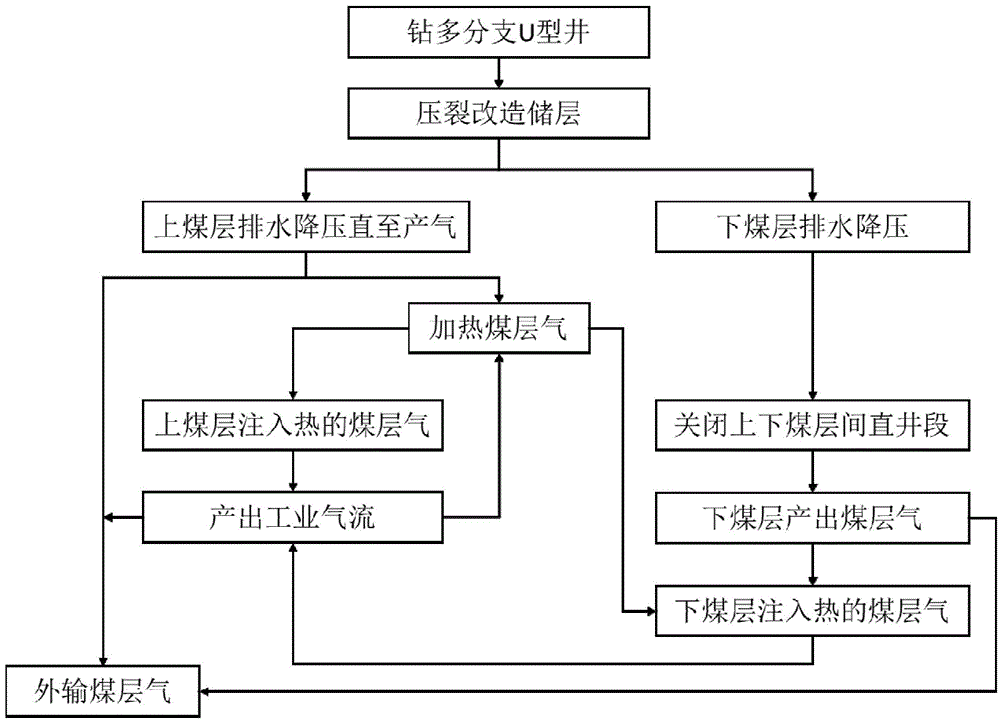

Coal bed methane recovery method

InactiveCN104790915AEnhanced overall recoveryImprove desorption environmentFluid removalRecovery methodProcess engineering

The invention discloses a coal bed methane recovery method. A multi-branch U-shaped well is used in cooperation with a coal bed methane heating injection shaft for recovering coal bed methane. By the adoption of the coal bed methane recovery method, the recovery efficiency can be improved, cost is reduced, safety and high efficiency are achieved, and operation is easy.

Owner:SOUTHWEST PETROLEUM UNIV +1

Inorganic gel profile control technology

InactiveCN104989347AImprove water flooding efficiencyImprove water absorptionFluid removalDrilling compositionActive agentCross linker

The invention discloses an inorganic gel profile control technology. Various profile control water shutoff agents are used and comprise a weak gel profile control agent, an inorganic gel profile control agent, a pre-crosslinking particle profile control agent and an oil-displacing agent, wherein the weak gel profile control agent comprises cross-linked polymers HPMA (hydroxypropyl methacrylate), a cross-linking agent, a stabilizing agent and a delay agent; the cross-linked polymers HPMA are partially hydrolyzed polyacrylamides; the cross-linking agent is a composite system of formaldehyde and resorcinol; the inorganic gel profile control agent is an inorganic mixing body using metasilicic acids as main ingredients and is matched with the pre-crosslinking particle profile control agent to be used in the profile control process; the pre-crosslinking particle profile control agent is a synthetic flexible macromolecule material containing a great number of hydrophilic groups; and the oil-displacing agent is a surfactant with amphiphiles. The inorganic gel profile control technology has the advantages that various profile control water shutoff agents using the inorganic gel as a main body extend to the inside of an oil reservoir to block a high-permeability zone, so that the direction of fluid is converted; injected water affects medium-low-permeability zones which are not affected in the prior art; the displacement effect is improved; and the recovery ratio is improved.

Owner:YANAN YUHAN PETROLEUM ENG TECH SERVICE CO LTD

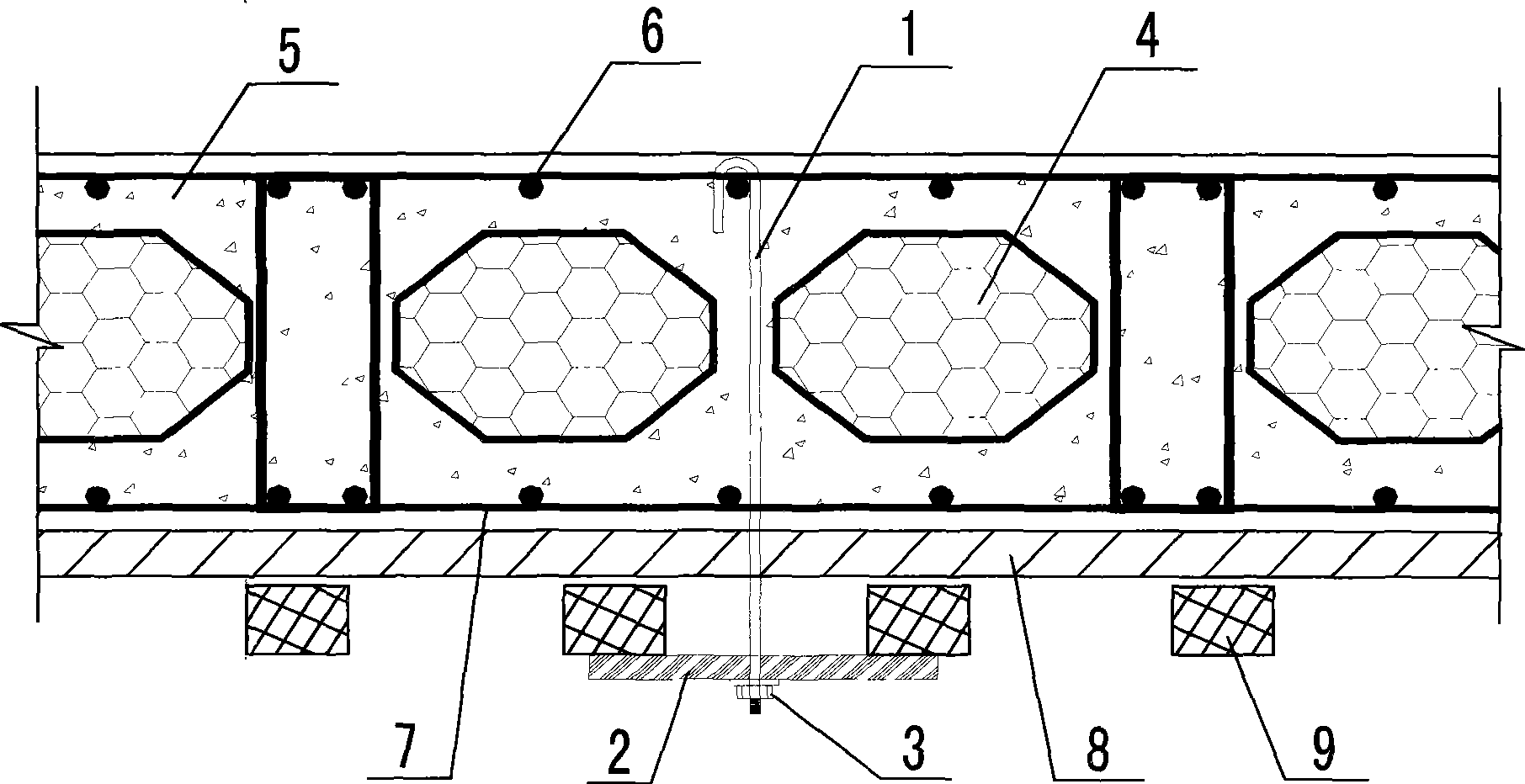

Anti-floating construction method for cast-in-place concrete hollow building roof

InactiveCN101498173AEasy to controlSave materialBuilding reinforcementsBuilding material handlingLate stageRebar

The invention relates to a floatation resistant construction method of a cast-in-site concrete hollow floor system. The cast-in-site concrete hollow floor system consists of a reinforced steel tie rod of which one end of is hooked on reinforced steel ribs while the other end is fixed on transverse bracing purlines, a load-bearing plate, nuts and gaskets. The invention can accurately control the thicknesses of cast-in-site hollow slabs and has strong floatation resistance; the invention ensures that floatation resistant points are fewer and more accurate compared with the prior floatation resistant technology, has simple construction and can ensure the construction quality. The invention is suitable for the engineering having suspended ceiling requirement and the reinforced steel tie rods can be used as tie rods of suspended ceilings at the late stage as well.

Owner:吴建辉

Well completion method for reinforcing hydrothermal type geothermal system

InactiveCN106968661ALarge displacementImprove efficiencyCollector components/accessoriesDrilling rodsMicroseismEnvironmental geology

The invention relates to the field of geothermal exploitation and provides a well completion method for reinforcing a hydrothermal type geothermal system. According to the method, a geothermal reservoir stratum is drilled through firstly, a microseism technology is utilized to conduct stratum microresistivity scanning imaging and dip angle combination logging, the stratum crack growing direction is recognized, then a branch hole is dilled in the perpendicular direction of crack growing, a hydraulic fracturing technology is adopted for fracturing a branch well section, thus a high-permeability geothermal reservoir stratum is constructed so as to enable a stratum fluid to enter a well drum along a fractured crack, the fluid is exploited to the ground through the well drum, and then power generation is conducted. According to the method, a branch well, microseism detection, a treatment system and the hydraulic fracturing technology are sufficiently utilized, the geothermal reservoir stratum crack is effectively recognized, the reservoir stratum is opened at a largest limitation, geothermal energy of the geothermal reservoir stratum is sufficiently utilized, and hydrothermal type geothermal energy exploitation efficiency is greatly improved.

Owner:CNPC DRILLING RES INST +1

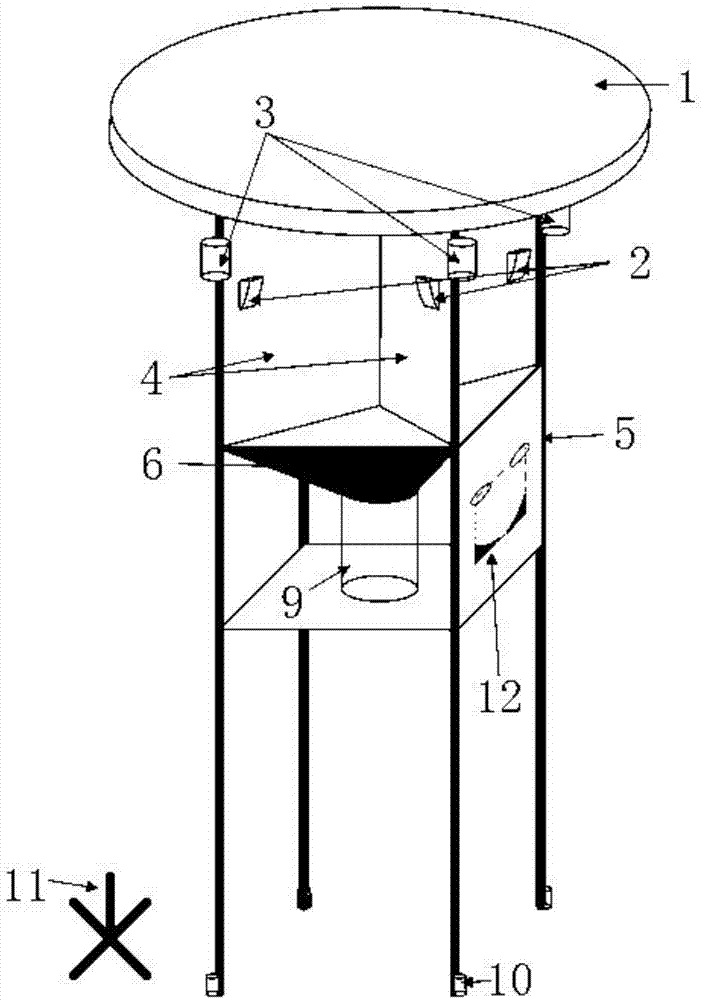

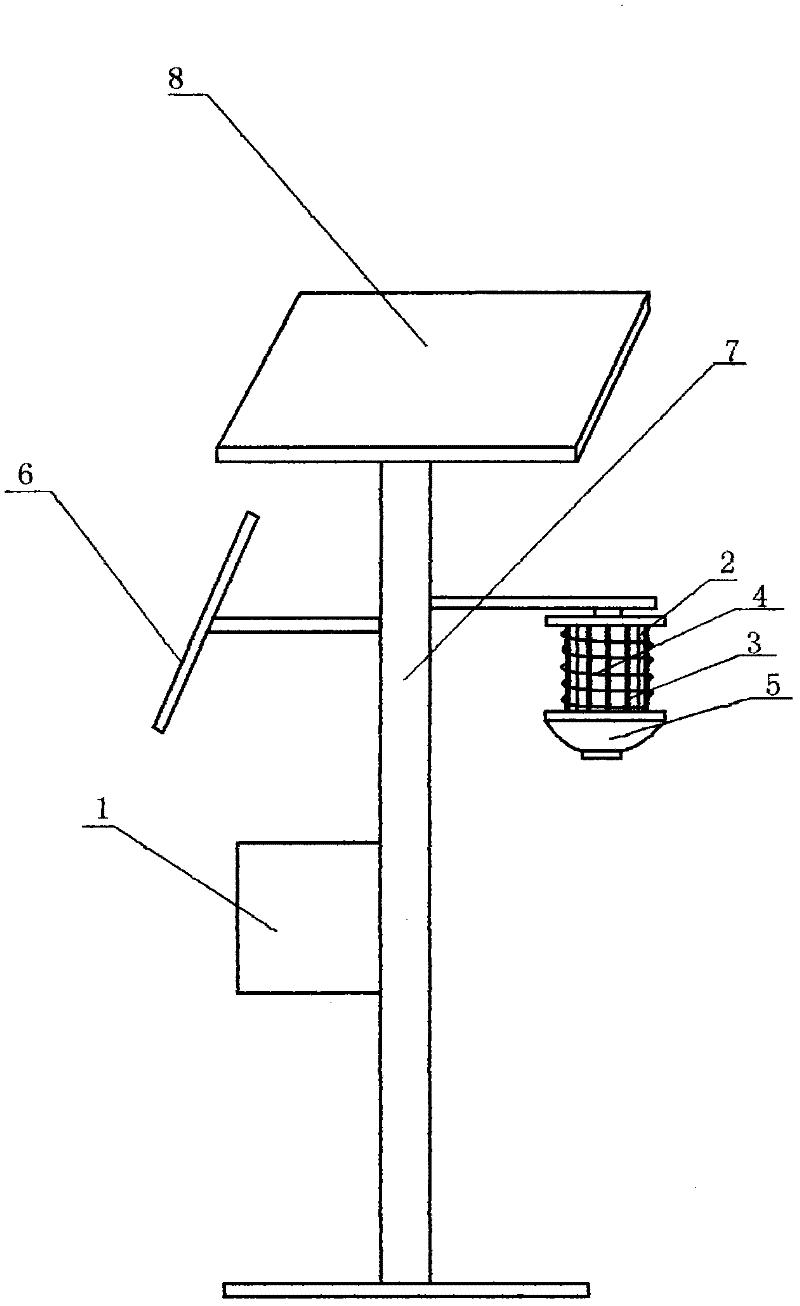

Garden pest monitoring method and large vertical garden pest monitoring device

The invention discloses a garden pest monitoring method and a large vertical garden pest monitoring device. A transparent intercepting plate with a hole is elevated through a bracket, and pests are attracted by means of a slow-release attractant, so that the insects fall into an insect collecting funnel at the bottom after colliding with the transparent intercepting plate; a pest collecting cup containing a specimen preservation solution is arranged below the insect collecting funnel to collect the fallen pests, so that garden pest monitoring can be achieved by counting the pests in the pest collecting cup; meanwhile, the garden pests are subjected to centralized trapping and killing, and the number of the garden pests can be effectively controlled.

Owner:SOUTHWEST FORESTRY UNIVERSITY +2

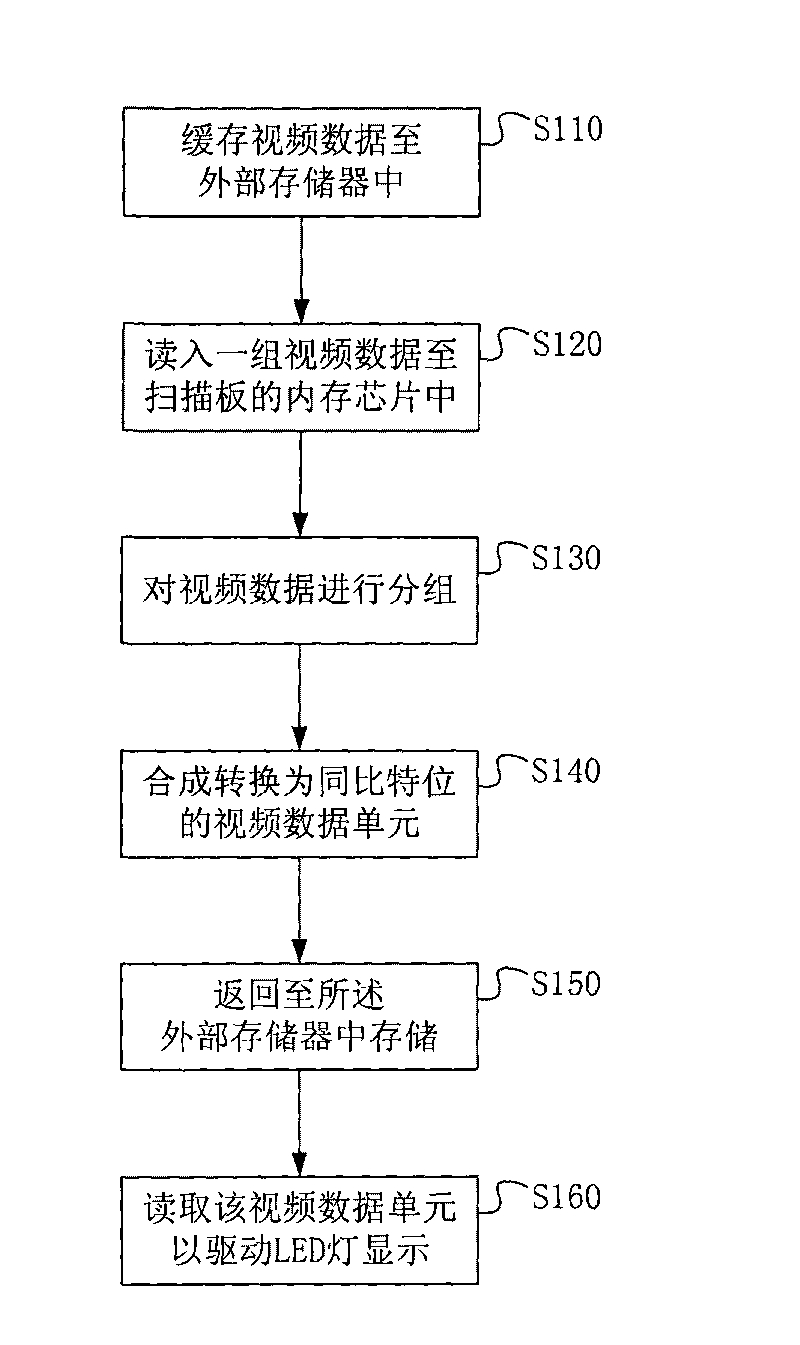

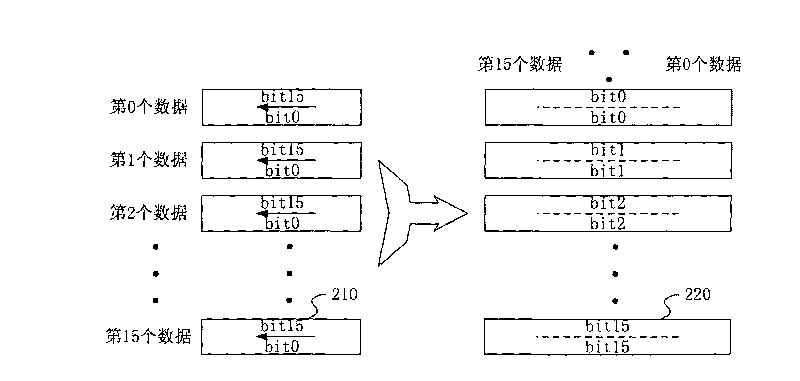

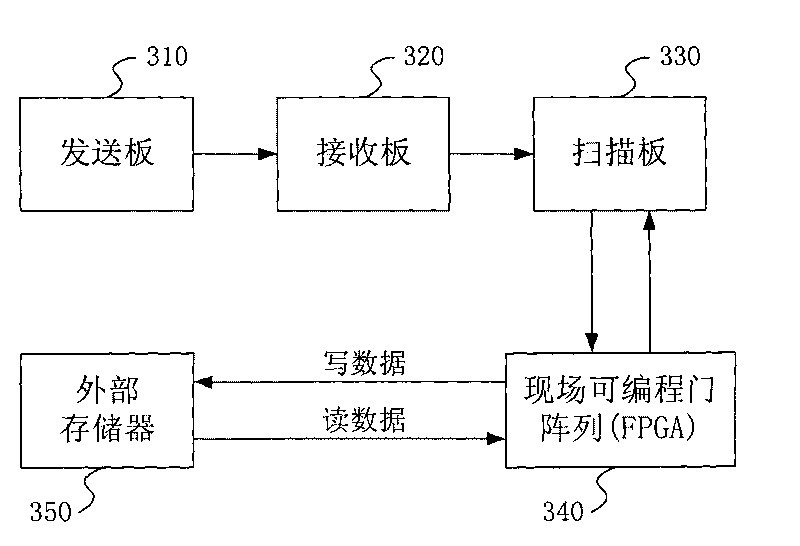

Method and system for enhancing refresh rate of video display of light-emitting diode

ActiveCN101692325AIncrease refresh rateLarge control areaStatic indicating devicesElectric light circuit arrangementData channelRefresh rate

The invention discloses a method and a system for enhancing the refresh rate of the video display of a light-emitting diode, wherein the method comprises the steps: caching video data to an external memory in a set order; reading the video data therefrom which is equivalent to the number of data channels on a scanning panel; combining and converting the same bit of the video data video data units arrayed at the same bit; reading the combined and converted video data to drive the light-emitting diode in the scanning panel to emit light so as to display the video. As the video data structure originally comprising a plurality of bits is converted into the video data structure with the same bit and the external memory having relatively low cost is utilized, the video data, with the same bit, of all the channels on the scanning panel is read out in parallel each time the video data is read when the scanning panel uses a pulse width modulation way for driving, which is to say, the control area of the scanning panel is increased in order to indirectly enhance the refresh rate of the video display of the light-emitting diode.

Owner:深圳康佳控股集团有限公司

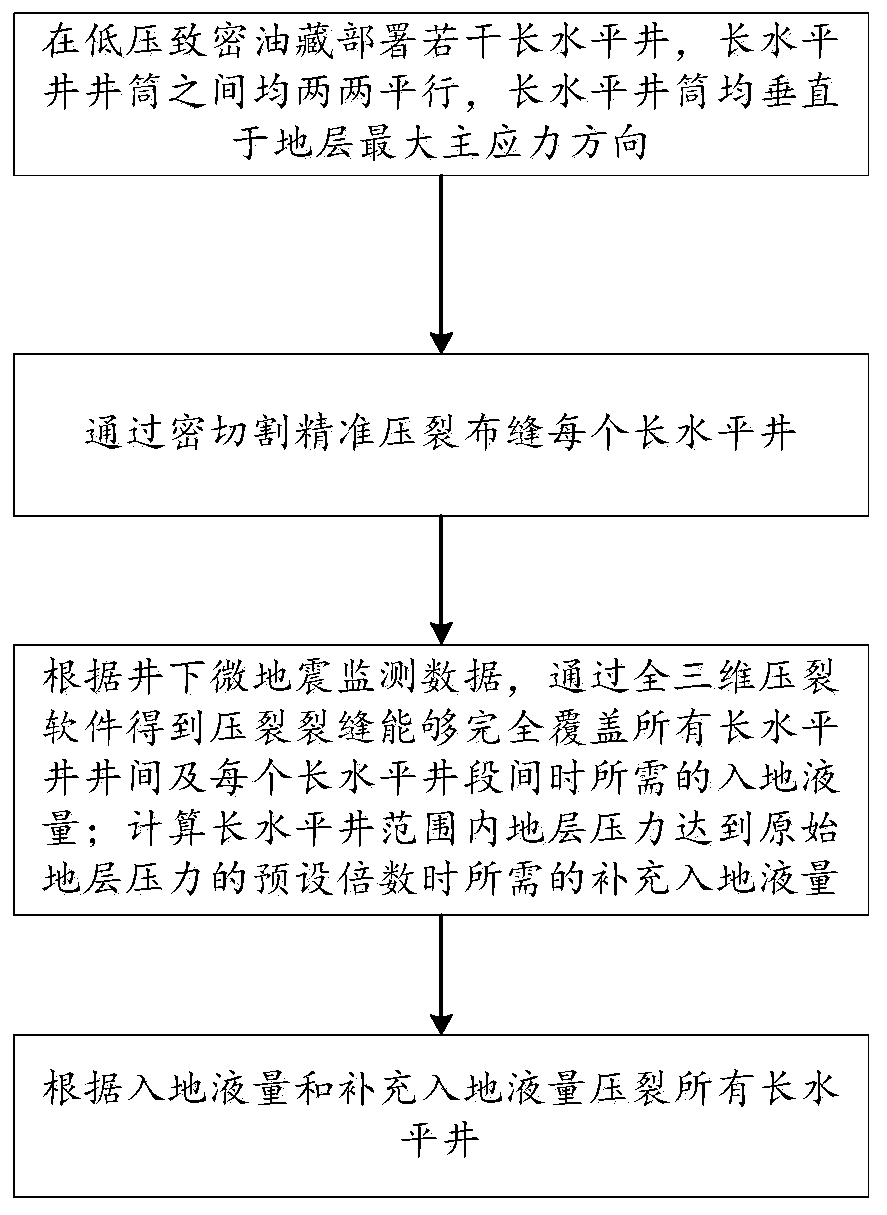

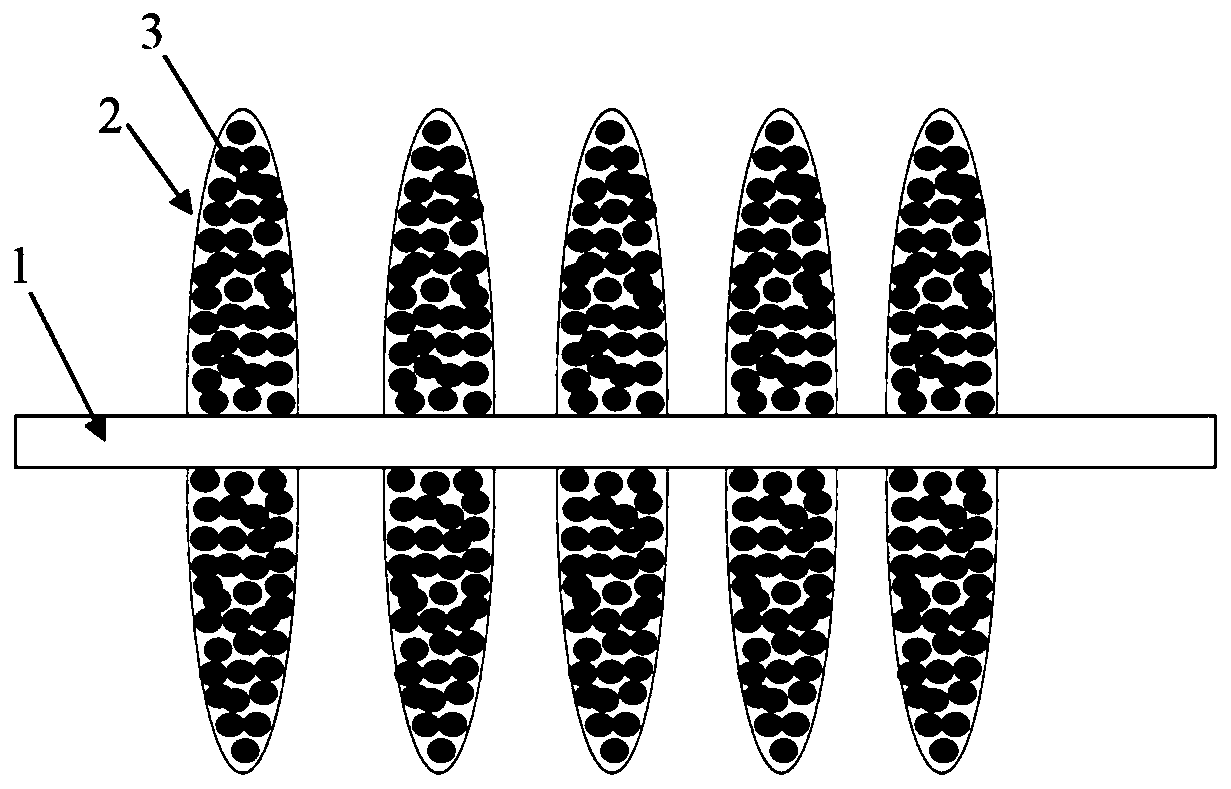

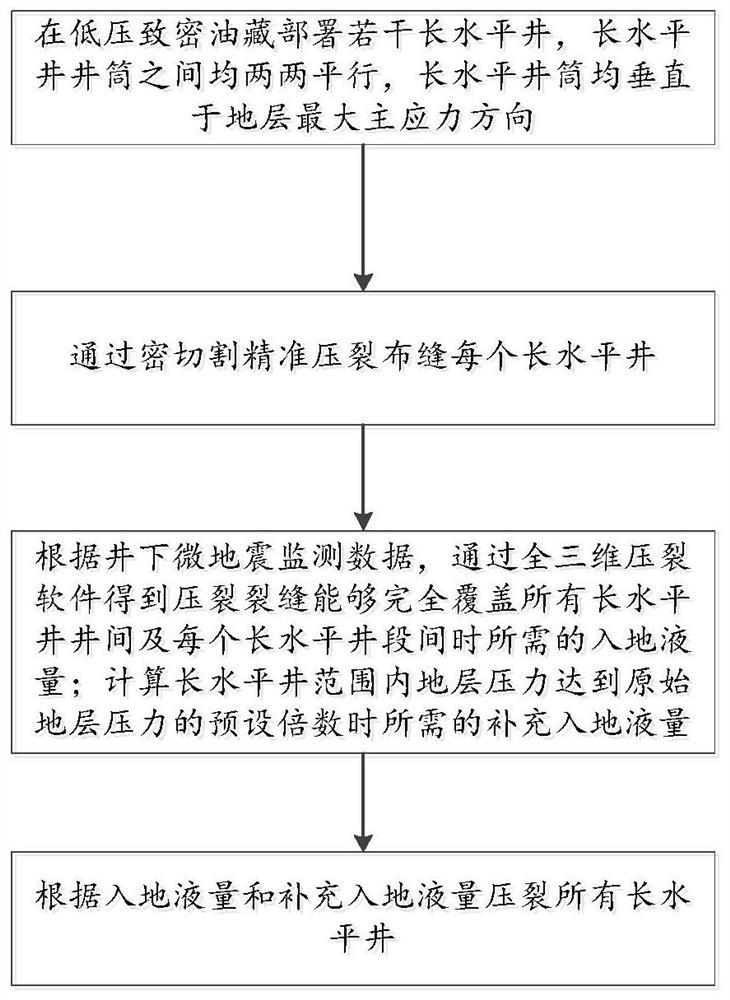

Low pressure dense oil reservoir supplementary energy fracturing method

ActiveCN110469309AProlong the stable production period of oil recoveryIncrease cumulative oil productionFluid removalPrincipal stressHorizontal wells

The invention discloses a low pressure dense oil reservoir supplementary energy fracturing method. The low pressure dense oil reservoir supplementary energy fracturing method comprises the following steps that a plurality of long horizontal wells are deployed in a low pressure dense oil reservoir, long horizontal well shafts are parallel one another, the long horizontal well shafts are perpendicular to the direction of the maximum principal stress of the formation; each long horizontal well is laid through close cutting precision fracturing; through full three-dimensional fracturing software simulation, the amount of ground-entering fluid required for fracturing fractures to completely cover spaces between all long horizontal wells and spaces between sections of each long horizontal well segment is obtained; supplementary ground-entering fluid required when the formation pressure in the range of long horizontal well reaches a preset multiple of the original formation pressure is calculated; and all the long horizontal wells are fractured according to the amount of ground fluid and the supplementary ground fluid. According to the low pressure dense oil reservoir supplementary energyfracturing method, the production decline of the low-pressure dense oil reservoir can be slowed down, the stable production period is prolonged, the recovery degree is improved, and the cumulative production of a single well in a whole life cycle of a single well is increased.

Owner:PETROCHINA CO LTD

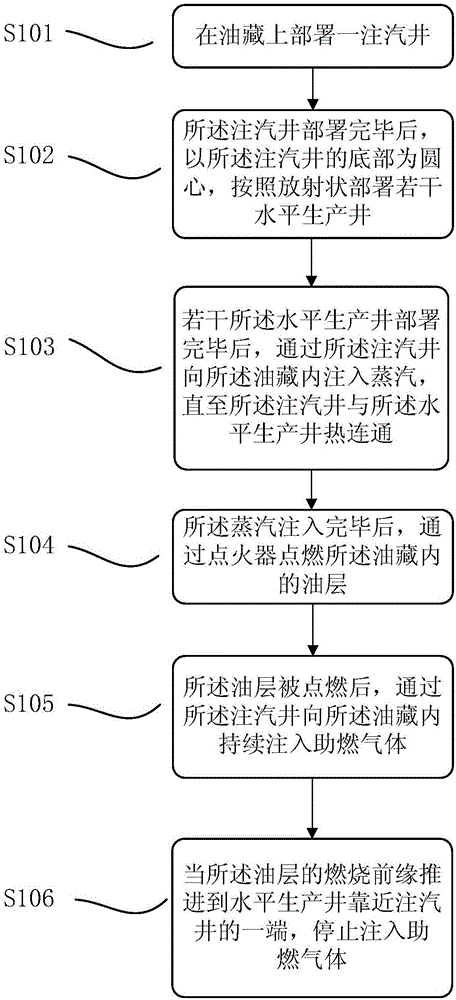

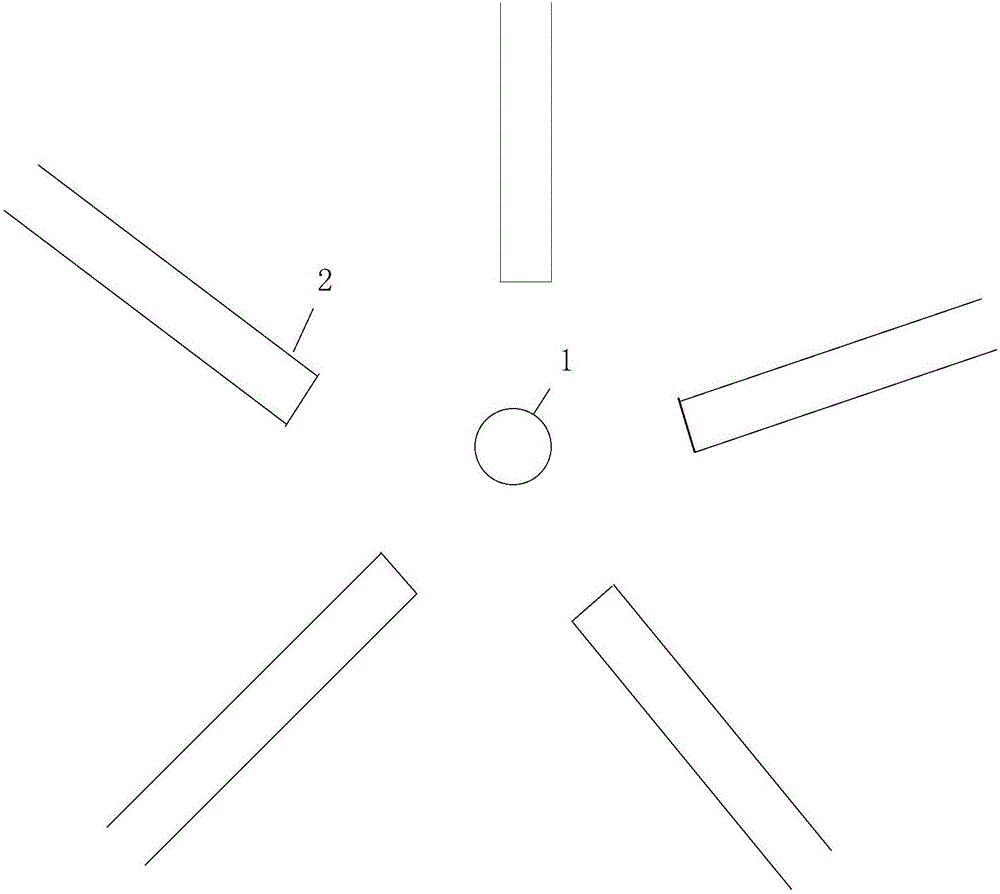

Oil production method and well pattern

ActiveCN106761631AExpand the affected volumeReduced chance of flameoutConstructionsFluid removalCombustionFlue gas

The invention discloses an oil production method and a well pattern. The oil production method includes the following steps that a steam injection well is deployed on an oil pool; the bottom of the steam injection well serves as a center of a circle, and a plurality of horizontal producing wells are deployed in a radial pattern; after deploying the plurality of producing wells, steam is injected in the oil pool through the steam injection wall; after the steam injection, oil layers in the oil pool are ignited by an igniter; after the oil layers are ignited, combustion-supporting gases are continuously injected into the oil pool through the steam injection well. According to the method, the development of a fire chamber is no longer in the direction of a single horizontal producing well, and the fire chamber is uniformly developed in the directions of the various horizontal producing wells arranged in a radial pattern, so that the firing range in the whole oil pool is gradually expanded and the probability of flame out is reduced. Meanwhile, flue gases, movable oil, firing lines and the like can move along the plurality of horizontal producing well, and therefore the firing lines uniformly advance towards multiple directions, the swept volume of combustion is enlarged, the exploiting effect is improved, and the oil production efficiency is improved.

Owner:PETROCHINA CO LTD

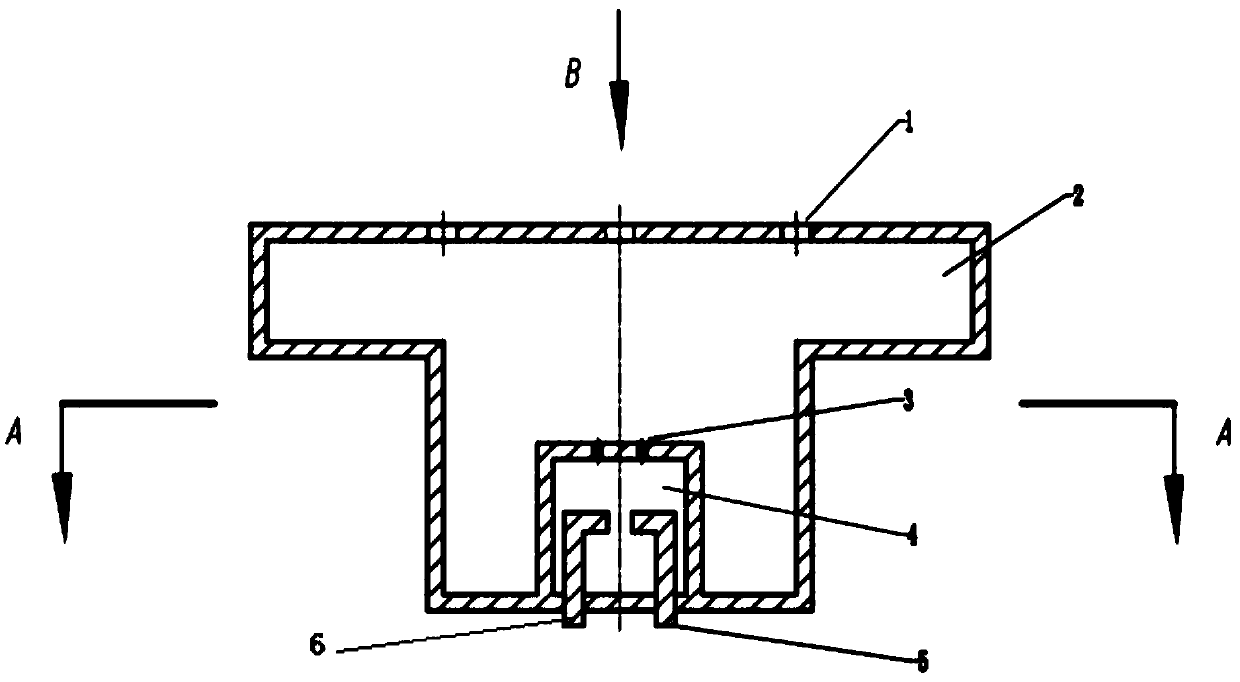

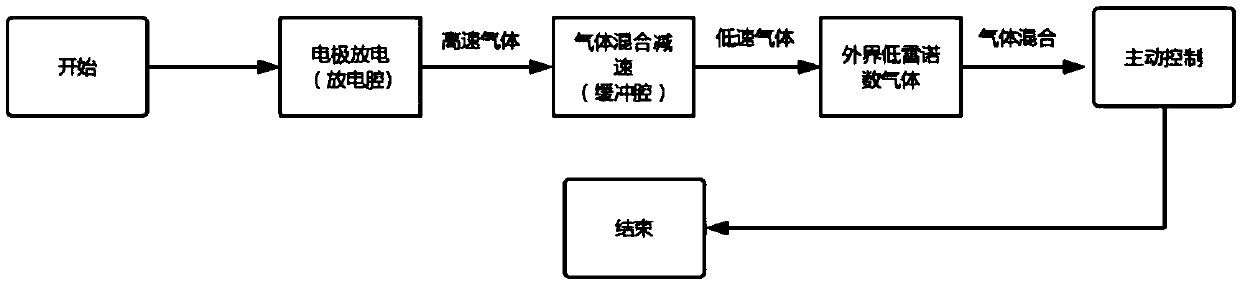

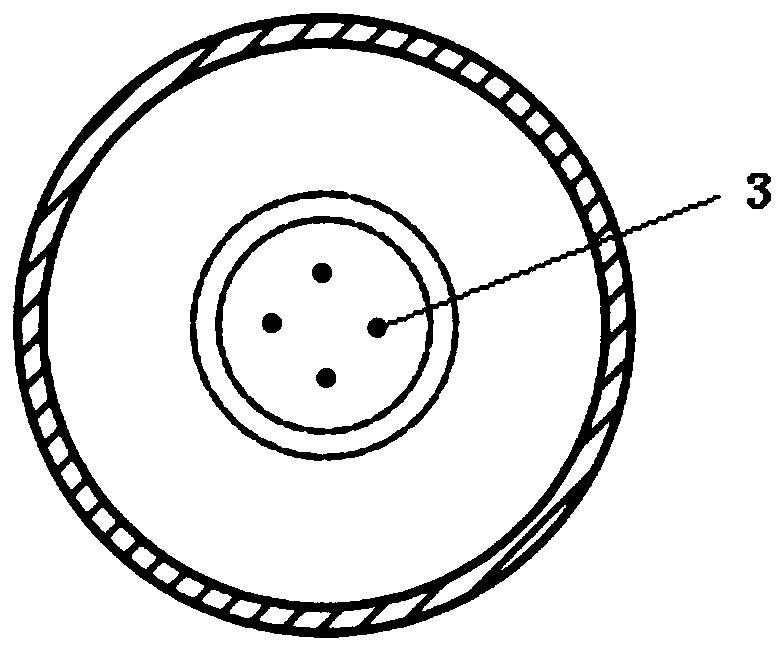

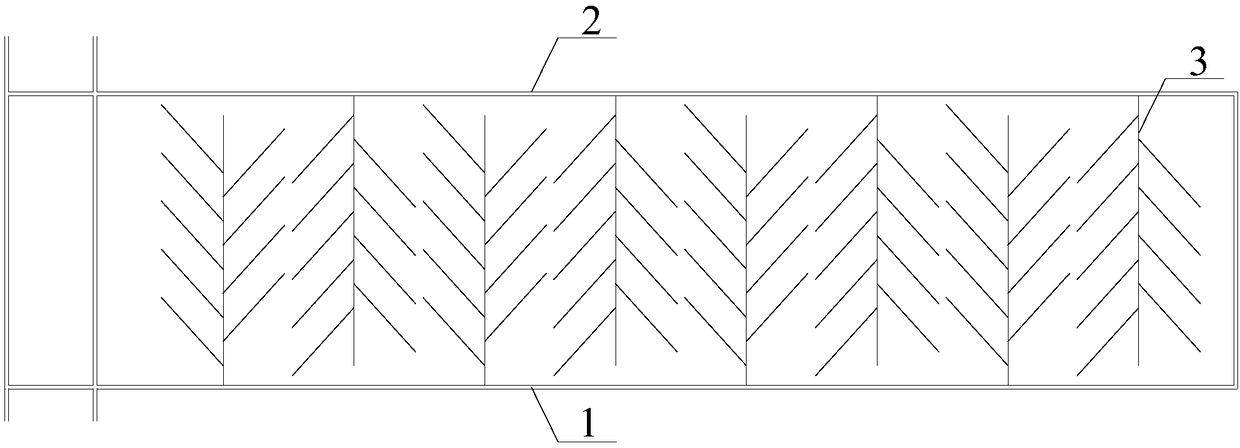

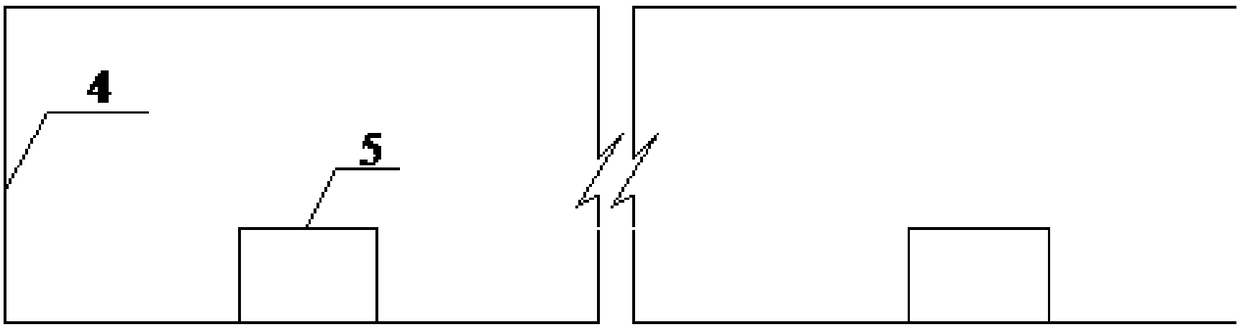

Plasma synthetic jet actuator with low Reynolds number

ActiveCN109618481ASimple structureImprove stabilityAir-flow influencersPlasma techniqueLow speedActuator

The invention discloses a plasma synthetic jet actuator with low Reynolds number. The plasma synthetic jet actuator comprises an actuator discharge cavity (4), an actuator buffer cavity (2), a cathodedischarge electrode (6), an anode discharge electrode (5) and heat-resistant silica gel. The actuator discharge cavity (4) is placed inside the actuator buffer cavity (2), and the heat-resistant silica gel is used for fixing and sealing the cathode discharge electrode (6) and the anode discharge electrode (5) at the bottom of the actuator discharge cavity (4). Under the effect of the discharge electrodes, gas inside the actuator discharge cavity (4) becomes high-speed gas, the high-speed gas is ejected into the actuator buffer cavity (2) through high-speed jet holes (3), the high-speed gas becomes low-speed gas through speed reduction, the low-speed gas is ejected to the outside through low-speed jet holes (1), and finally low-speed gas with the Re of no more than 10<-6> are ejected inside the actuator buffer cavity (2). The plasma synthetic jet actuator is simple in structure, high in stability, high in efficiency and small in volume.

Owner:HARBIN INST OF TECH

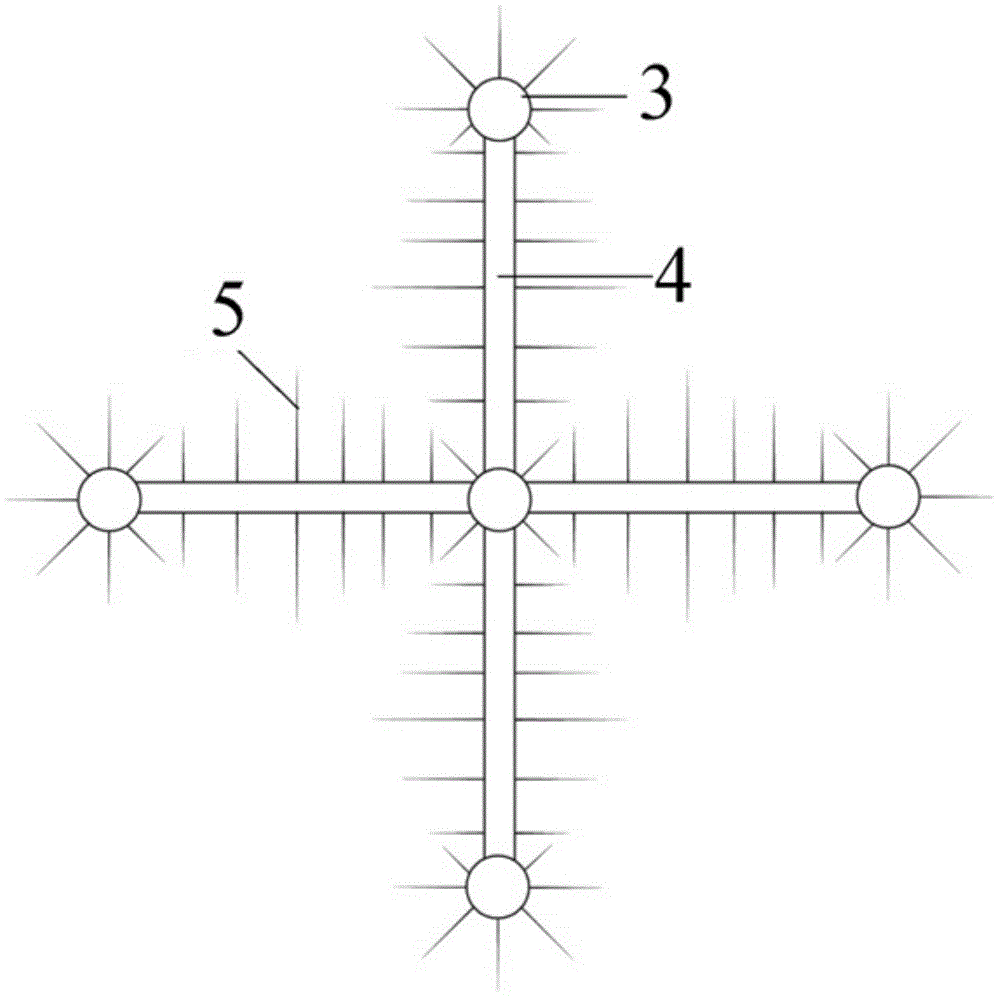

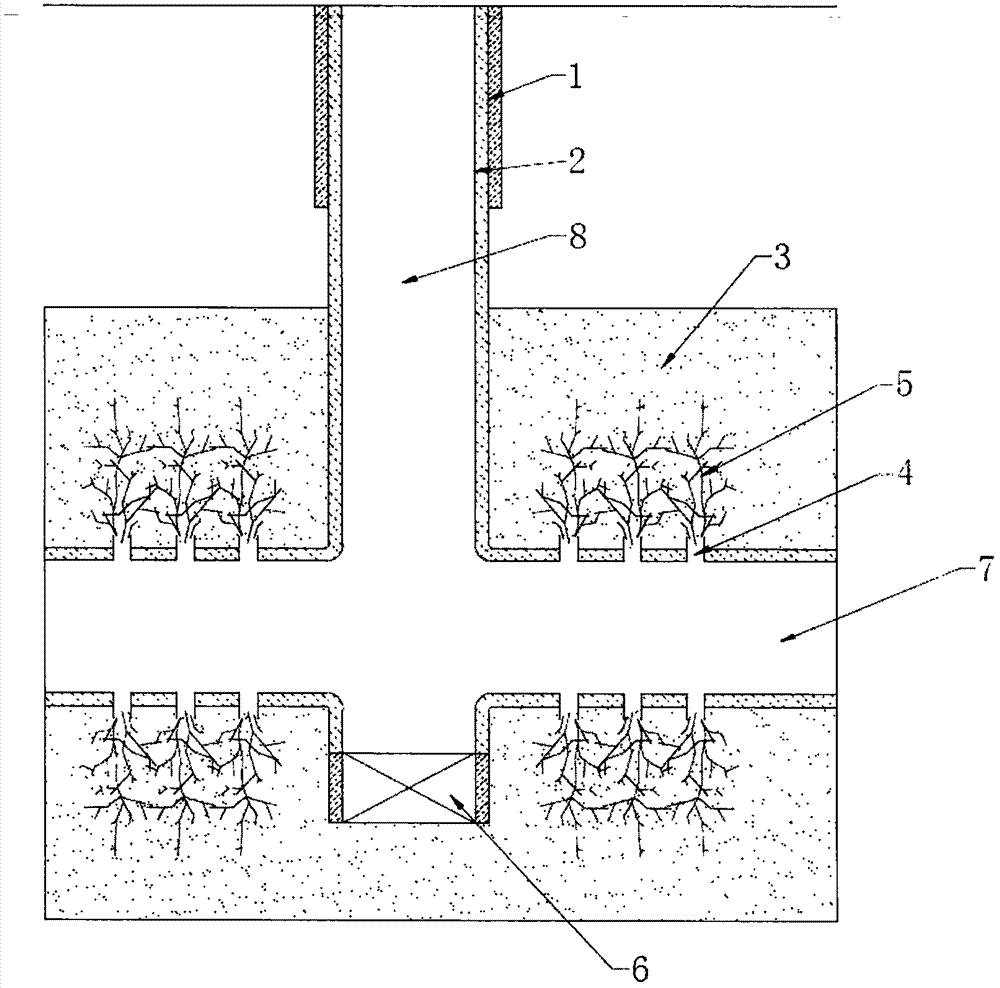

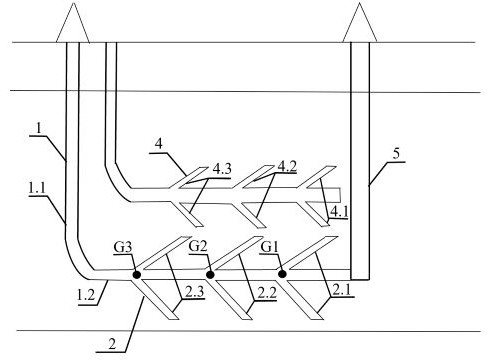

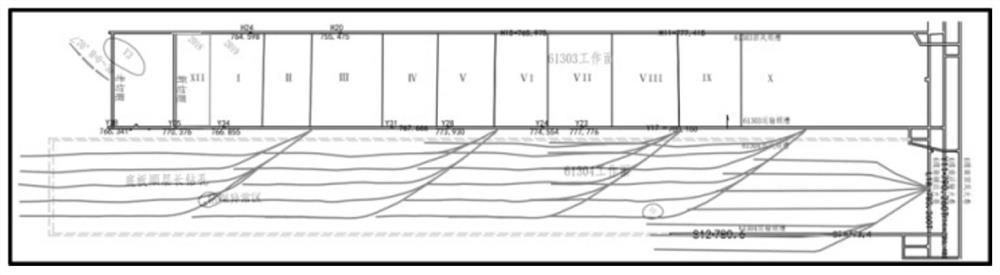

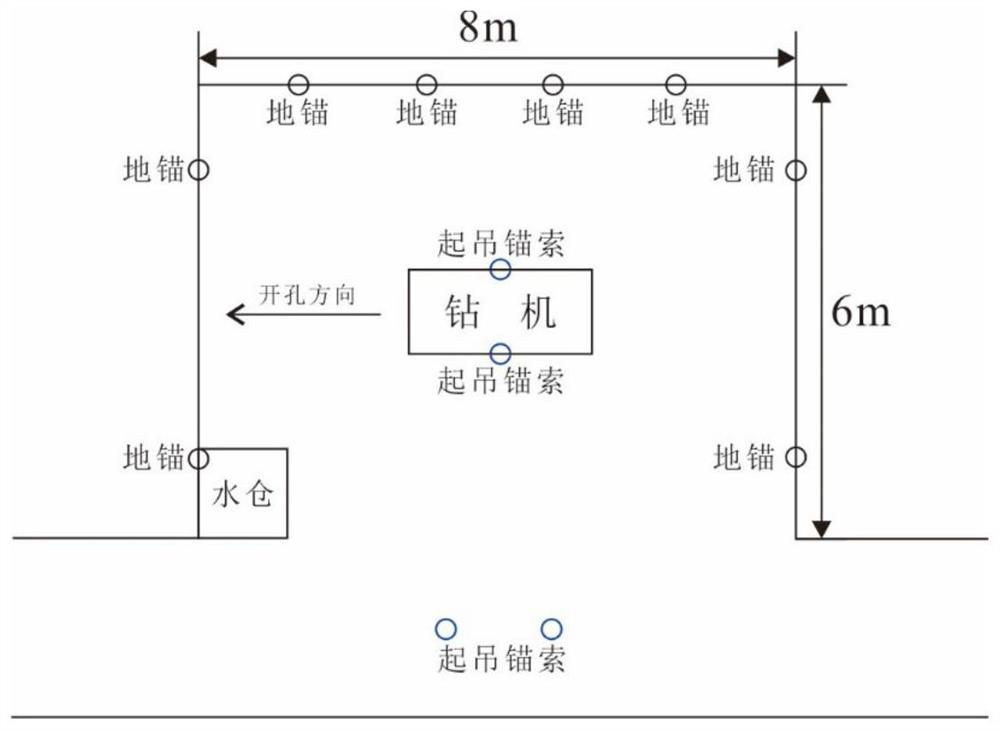

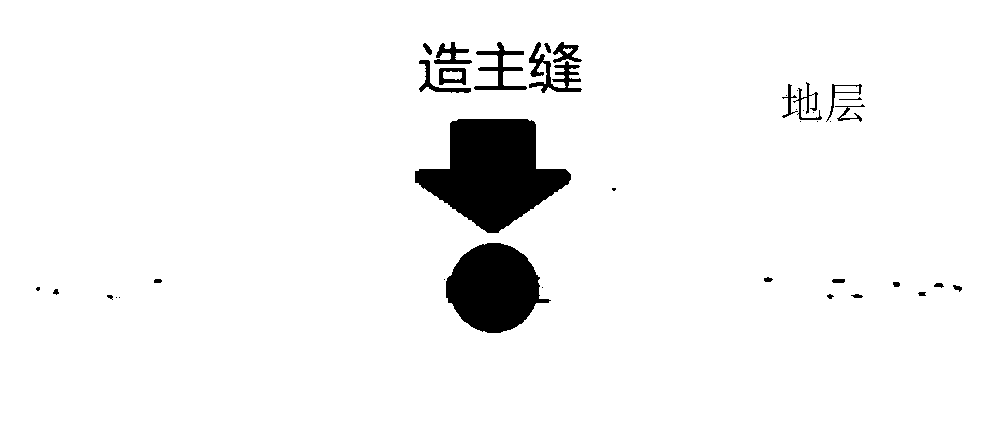

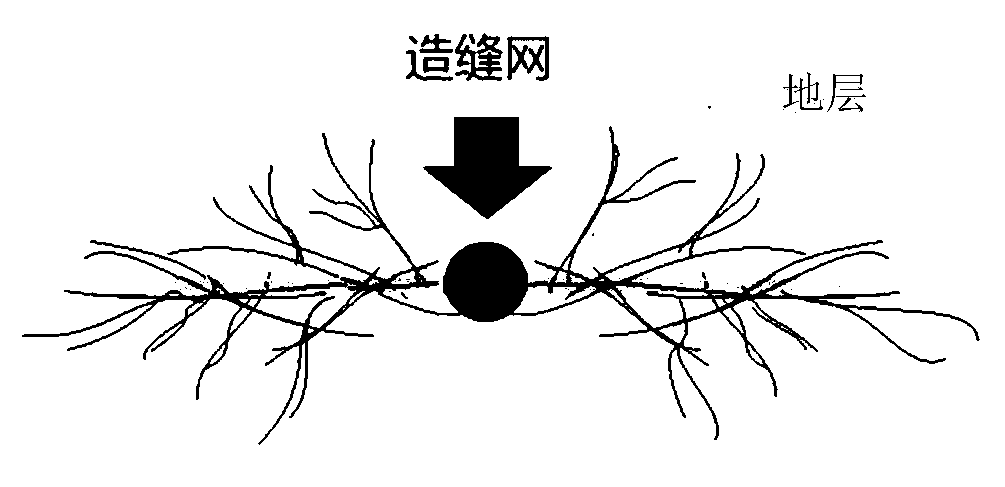

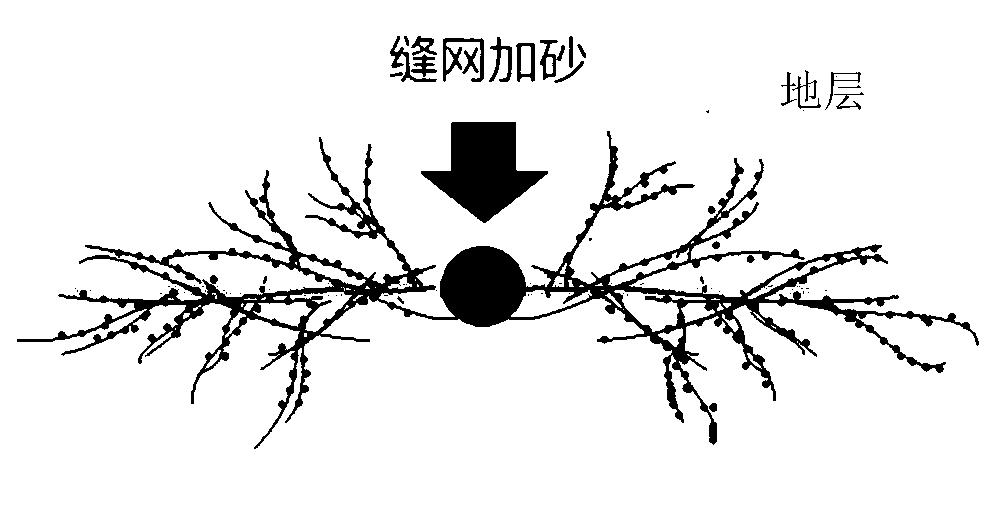

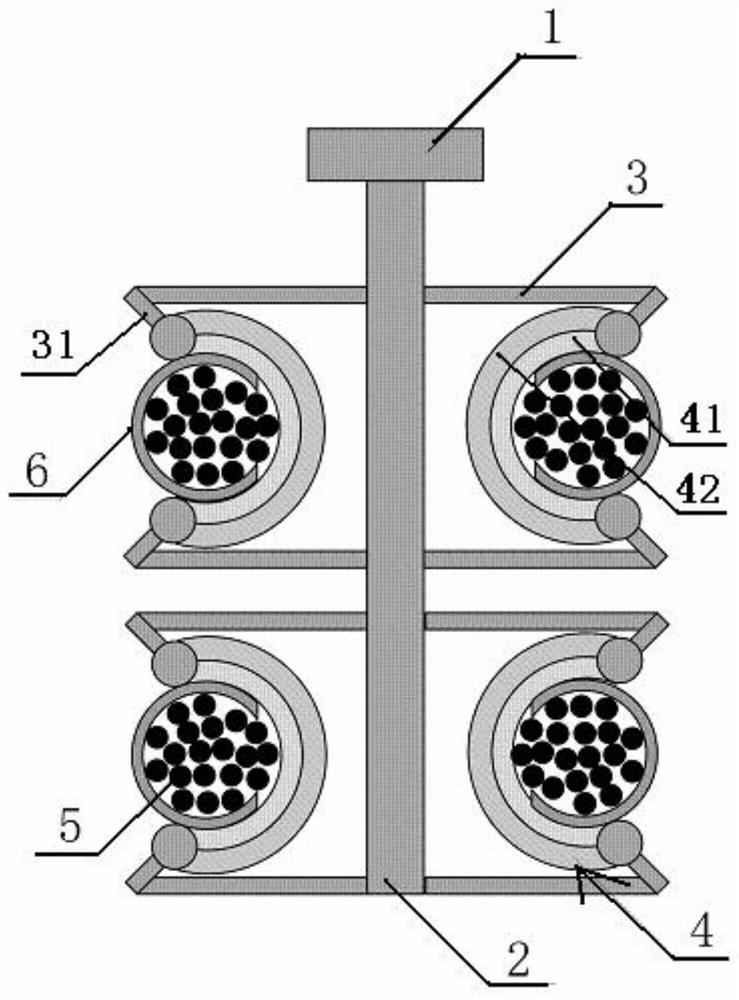

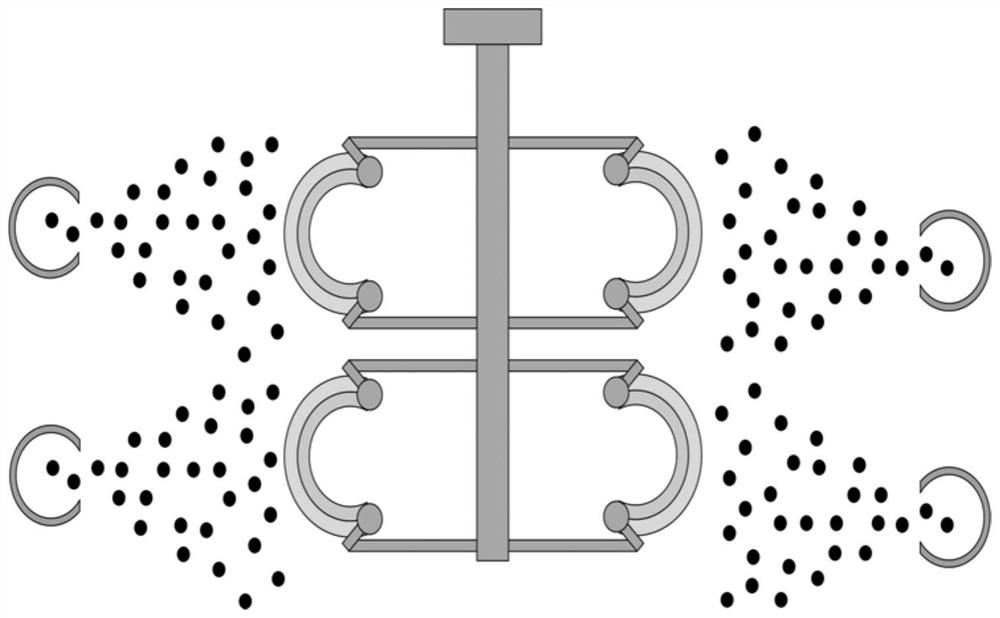

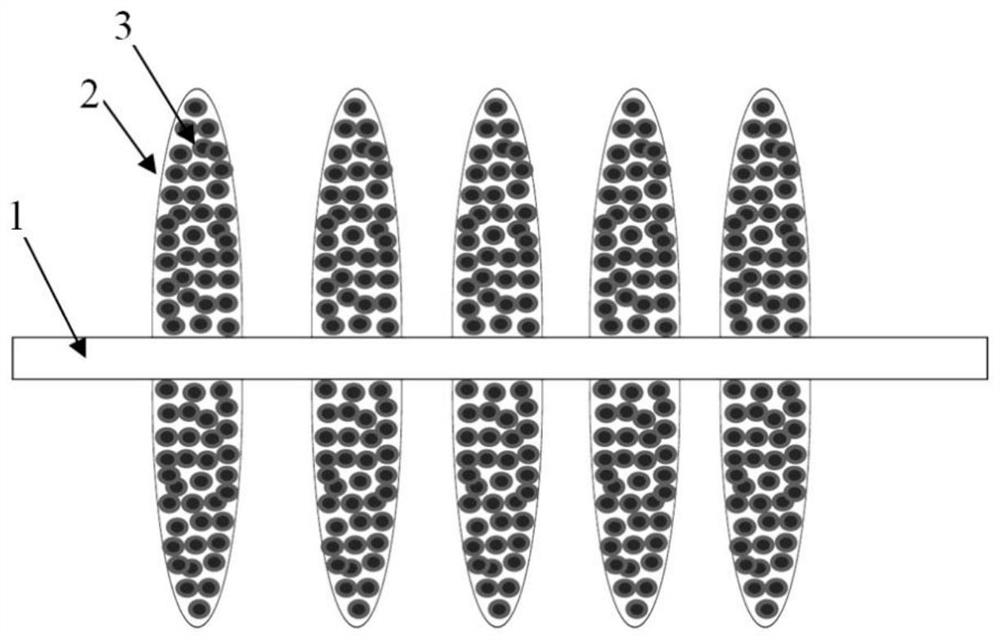

Gas drainage borehole arrangement method for extra-thick coal seam

InactiveCN108590741ALarge control areaReduce the risk of poor governanceFluid removalGas removalControl areaCoal

The invention discloses a gas drainage borehole arrangement method for an extra-thick coal seam. The method comprises the specific steps that step 1, first drill fields and second drill fields are separately arranged toward a working area on the side of an intake airflow roadway and the side of a return airflow roadway, the first drill fields and the second drill fields are arranged alternately, and the distance between the adjacent first or second drill fields on the same side is 100m-500m; step 2, gas drainage boreholes are constructed in each first or second drill field, each gas drainage borehole includes a main hole channel and a plurality of branch hole channels distributed on both sides of the main hole channel, and the gas drainage boreholes are arranged parallel to the coal seam;and step 3, the main hole channels are subjected to hole sealing treatment and connected to a gas drainage system. Two rows of gas drainage boreholes are constructed in the intake airflow roadway andthe return airflow roadway, and the control area of the gas drainage boreholes is increased. Each borehole consists of a main hole and a plurality of branch holes distributed on both sides of the mainhole, the number of borehole sealing is reduced, and the risk of the poor gas treating effect due to the hole sealing problem is reduced.

Owner:LIAONING TECHNICAL UNIVERSITY

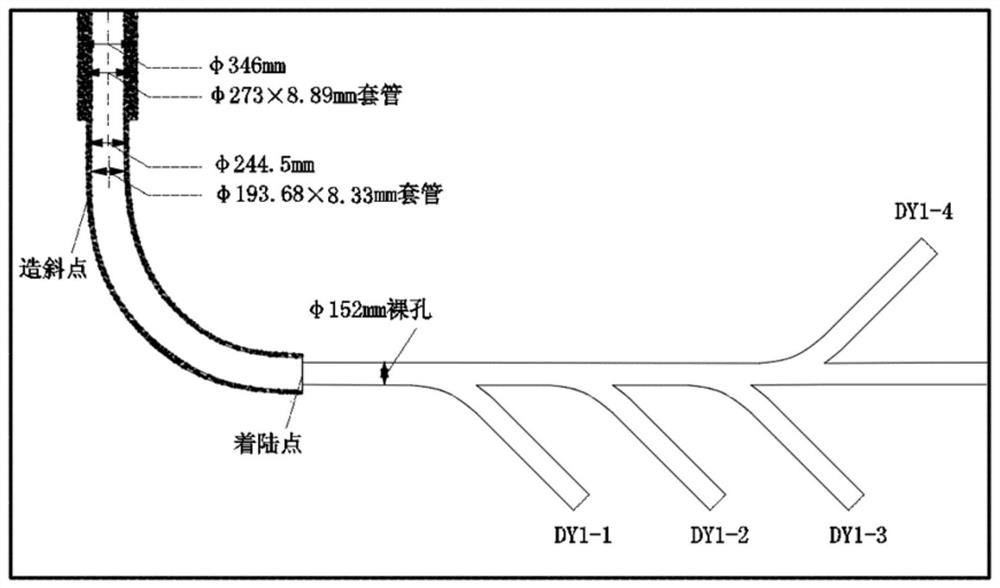

Coal-bed gas well short frontal distance from target point horizontal well integration process method

ActiveCN111706302AImprove accuracyIncrease the encounter rateFluid removalDirectional drillingGeosteeringHorizontal wells

The invention relates to the technical field of short frontal distance from target point horizontal well drilling processes, in particular to a coal-bed gas well short frontal distance from target point horizontal well integration process method. According to the coal-bed gas well short frontal distance from target point horizontal well integration process method, window sidetracking can be carried out in a minimum casing pipe of five and a half inches (the outer diameter is 139.7 mm and the inner diameter is 124 mm), new well hole drilling can be carried out, and the adaptability is wide; theangle building hole rate ranges from 0.4-1 degrees / m, and the effective footage is saved; the drilling construction is combined with geosteering, and the coal seam landing accuracy and the drilling ratio are improved; clean water is used for horizontal section well drilling construction, and the reservoir pollution is avoided; the length of a horizontal section is larger than 200 m, and a coal seam control area is enlarged; a well completion pipe string adopts a hanger, a steel casing pipe and a ball activated sliding sleeve, the well completion well cementation is carried out, an annulus below the hanger is sealed, the support is provided for follow-up transformation while a well wall is supported; and the reservoir transformation is combined with a fracturing technology, an oil and gaschannel is enlarged, and the single well yield is increased.

Owner:陕西瑞鹰国际油气工程技术服务有限公司 +1

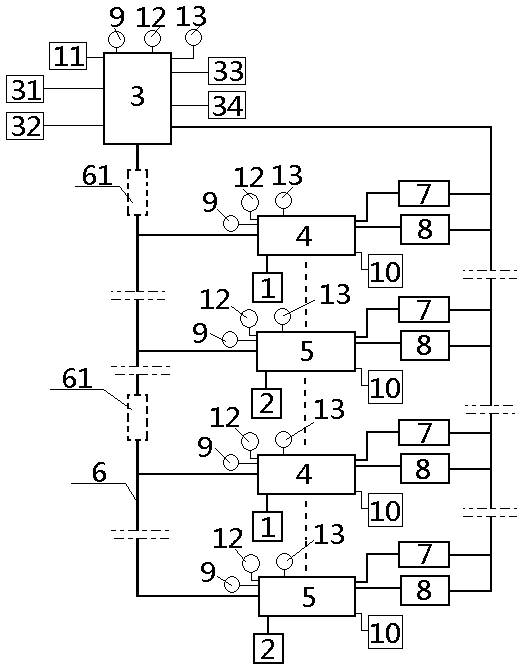

Optical fiber smoke sensing temperature fire automatic alarm linkage control system

PendingCN110298991ARealize all-fiberGuaranteed accuracyFire alarm electric actuationFire alarm smoke/gas actuationFire alarm systemControl system

An optical fiber smoke sensing temperature fire automatic alarm linkage control system is provided. The system comprises a fire linkage controller, at least one smoke fire alarm controller, and at least one temperature fire alarm controller. The fire linkage controller is in a signal connection with the smoke fire alarm controller and the temperature fire alarm controller by using the optical fiber; the fire linkage controller, the smoke fire alarm controller, and the temperature fire alarm controller are in a signal connection with a manual fire alarm button, a manual fire hydrant button, a linkage control device, and a fire extinguishing controller by using the optical fiber; and the smoke fire alarm controller and the temperature fire alarm controller are in a signal connection with a corresponding fiber-optic smoke-sensed detector and a corresponding fiber-optic temperature-sensed detector by using the optical fiber. According to the design of the present invention, not only the optical fiber technology can be used to build a fire alarm system with a better fire alarm effect, but also high precision, strong safety and a wide control area can be realized.

Owner:深圳晶点光科有限公司

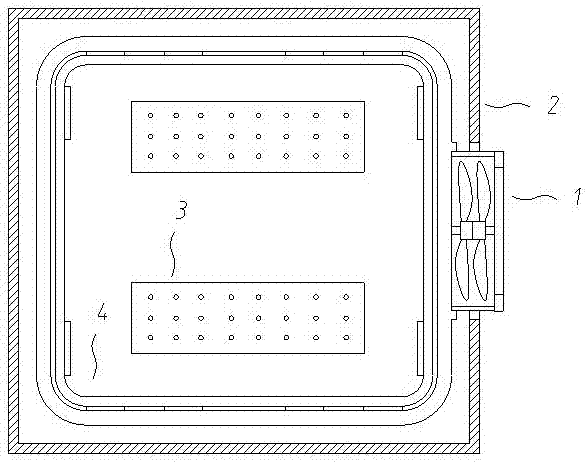

System for adjustment of temperature in curing room

InactiveCN107992116ATemperature controlThe temperature control system can control the temperature of the curing roomTemperature control using electric meansEngineeringUser control

The invention discloses a system for adjustment of temperature in a curing room, and relates to the technical field of cement curing. The system comprises a control system, an air supply device, the curing room, a support and an annular pipeline, wherein the air supply device is arranged on the side wall of the curing room and communicated with the annular pipeline, and the support is arranged inthe curing room. The overall structure is simple, the system is easy to use, and the uniformity of the temperature in the curing room is ensured; the damage degree of a cement test piece is reduced tothe minimum; the control system can effectively expand the control area of the temperature in the curing room, so that it is ensured that a user controls the temperature in a large-area curing room.

Owner:王丽霞

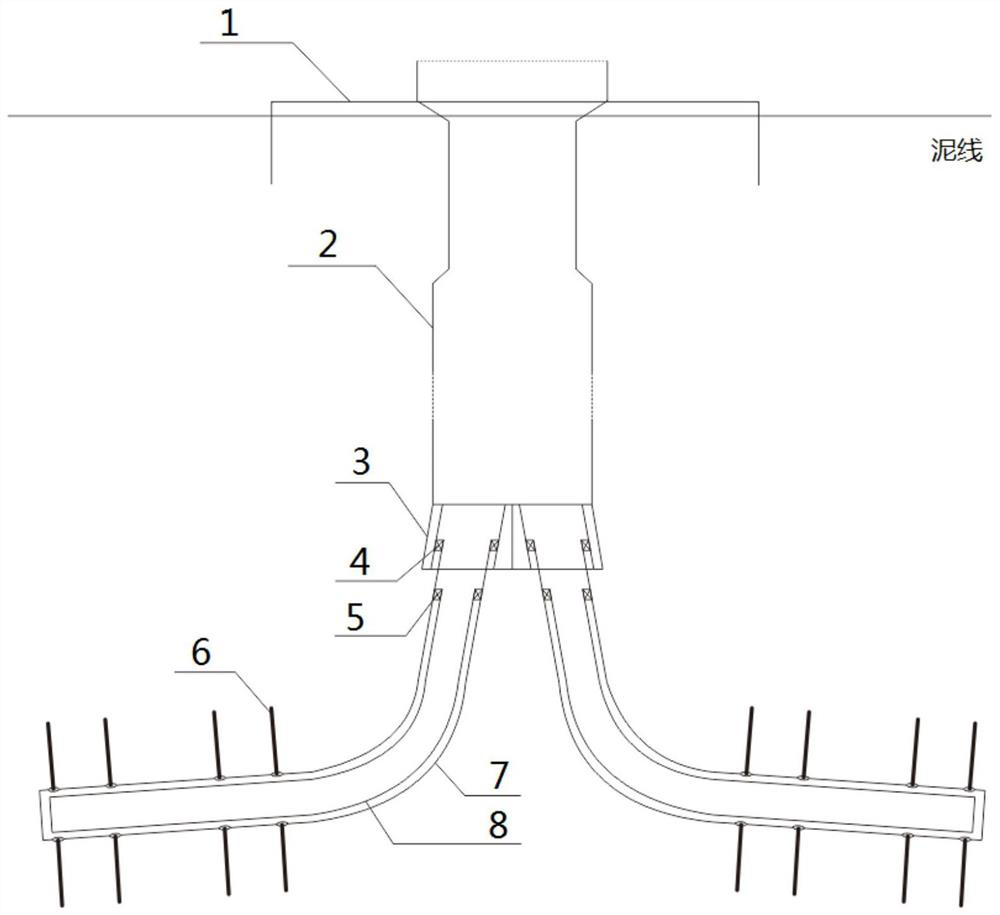

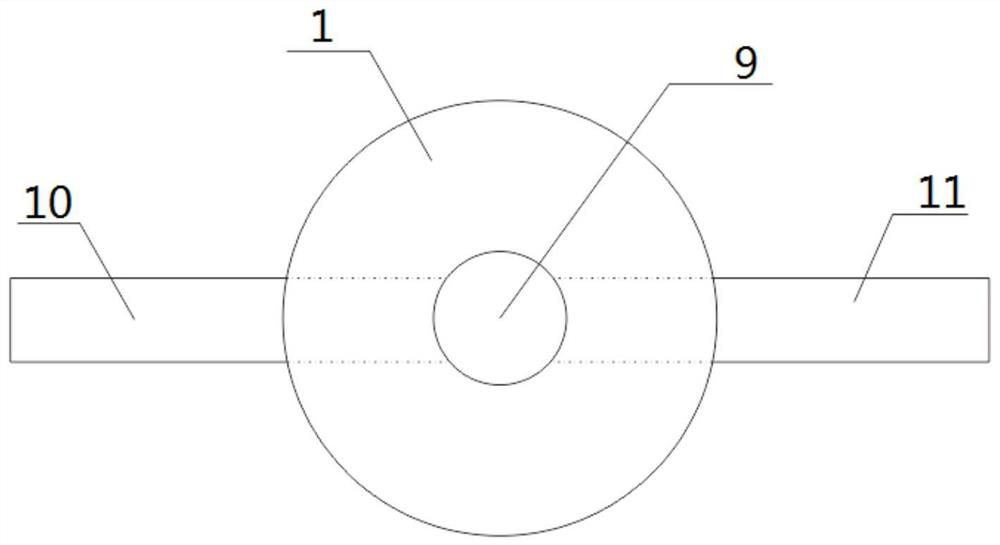

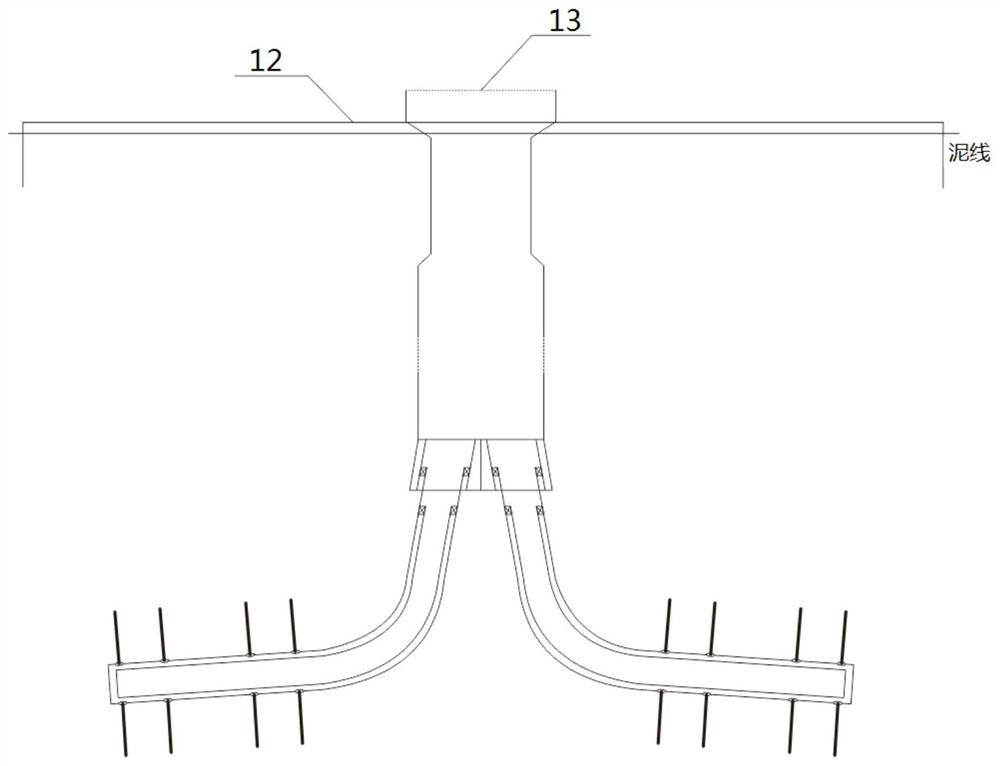

Natural gas hydrate horizontal multilateral well exploitation method based on deepwater suction anchor

The invention relates to the technical field of natural gas hydrate exploitation accessory devices, in particular to a natural gas hydrate horizontal multilateral well exploitation method based on a deepwater suction anchor. The natural gas hydrate horizontal multilateral well exploitation method can improve the single-well productivity of hydrates, reduce the single-well construction cost and improve the economic and technical indexes of hydrate exploitation. The method comprises the following steps that (1) a deepwater suction anchor wellhead is lowered into a well position, and drilling operation is carried out through a suction anchor inner barrel; (2) a casing string with a casing bifurcation system tool is tripped in, a casing bifurcation short section in a casing bifurcation systemserves as a guide, and drilling of multiple horizontal branch wells is completed; (3) a fishbone tool is used in each open hole horizontal well for performing yield-increasing transformation operationon a hydrate reservoir; (4) a sand control screen pipe is hung in a fishbone pipe column; and (5) a complete natural gas hydrate horizontal multilateral well body structure based on the deepwater suction anchor is established.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

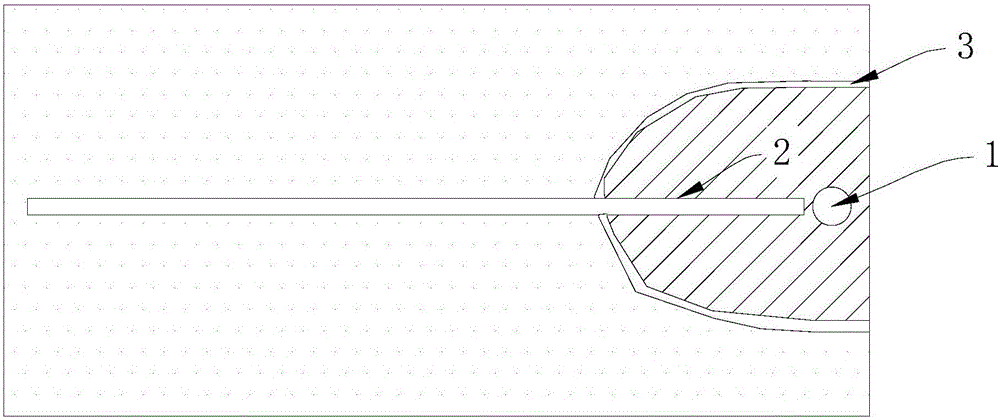

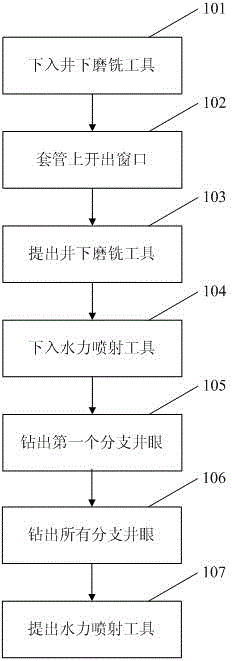

Method of improving production capacity of super-deep low-permeability heavy oil single well by radial drilling and auxiliary thermal recovery

InactiveCN104832140AReduced vapor absorption capacityIncrease vapor absorption capacityLiquid/gas jet drillingFluid removalCoiled tubingHigh pressure water

The invention provides a method of improving production capacity of a super-deep low-permeability heavy oil single well by radial drilling and auxiliary thermal recovery. The method comprises steps: 1, a downhole milling tool is tripped in; 2, a downhole motor is used for driving the downhole milling tool to open a window on a casing in a target layer position; 3, the downhole milling tool is pulled up; 4, a hydraulic jetting tool connected with a coiled tubing is tripped in; 5, high-pressure water is pumped from the ground, and water jet is used for drilling multiple branch well holes in the target layer; and 6, the hydraulic jetting tool is pulled up for steam injection production. According to the method of improving production capacity of the super-deep low-permeability heavy oil single well by radial drilling and auxiliary thermal recovery, steam injection pressure is reduced, the steam absorption ability of the ground layer is added, the steam injection dryness and the steam zone diffusion range are improved, the flowing ability of the heavy oil in the ground layer is added, and the purpose of improving the production capacity of the single well is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

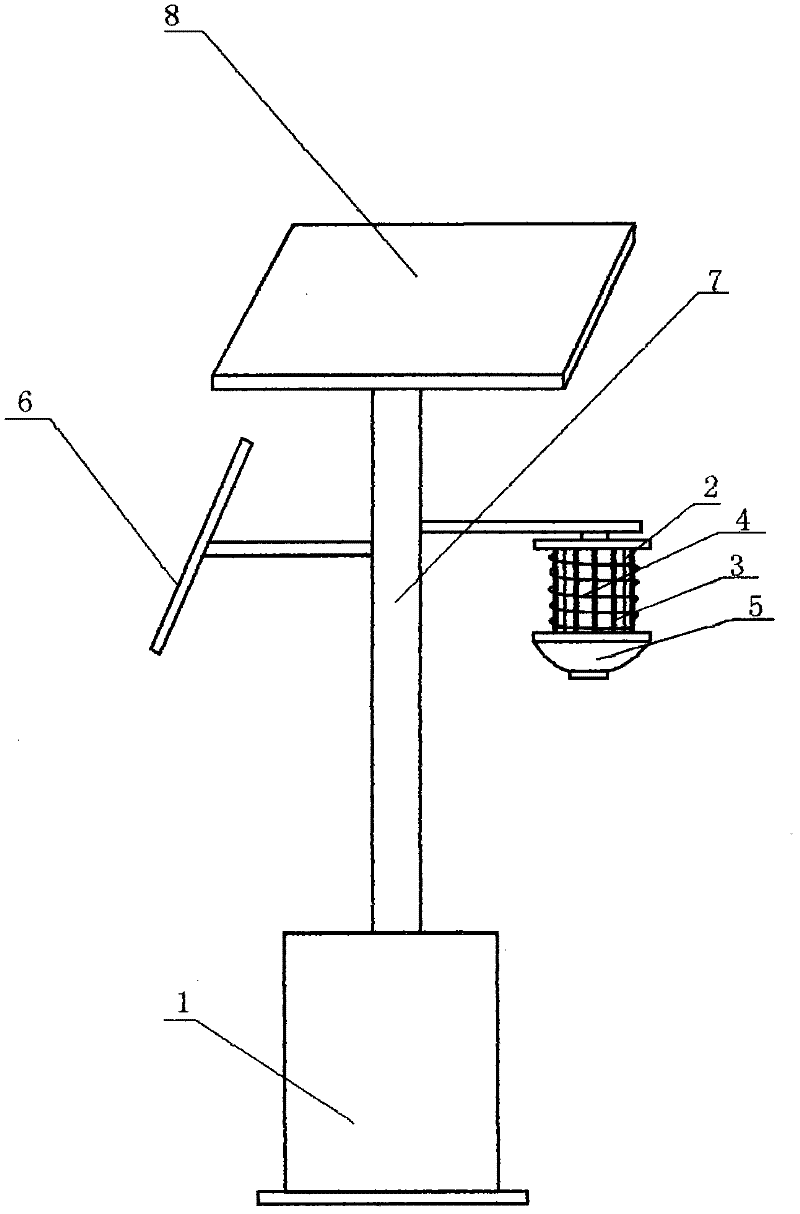

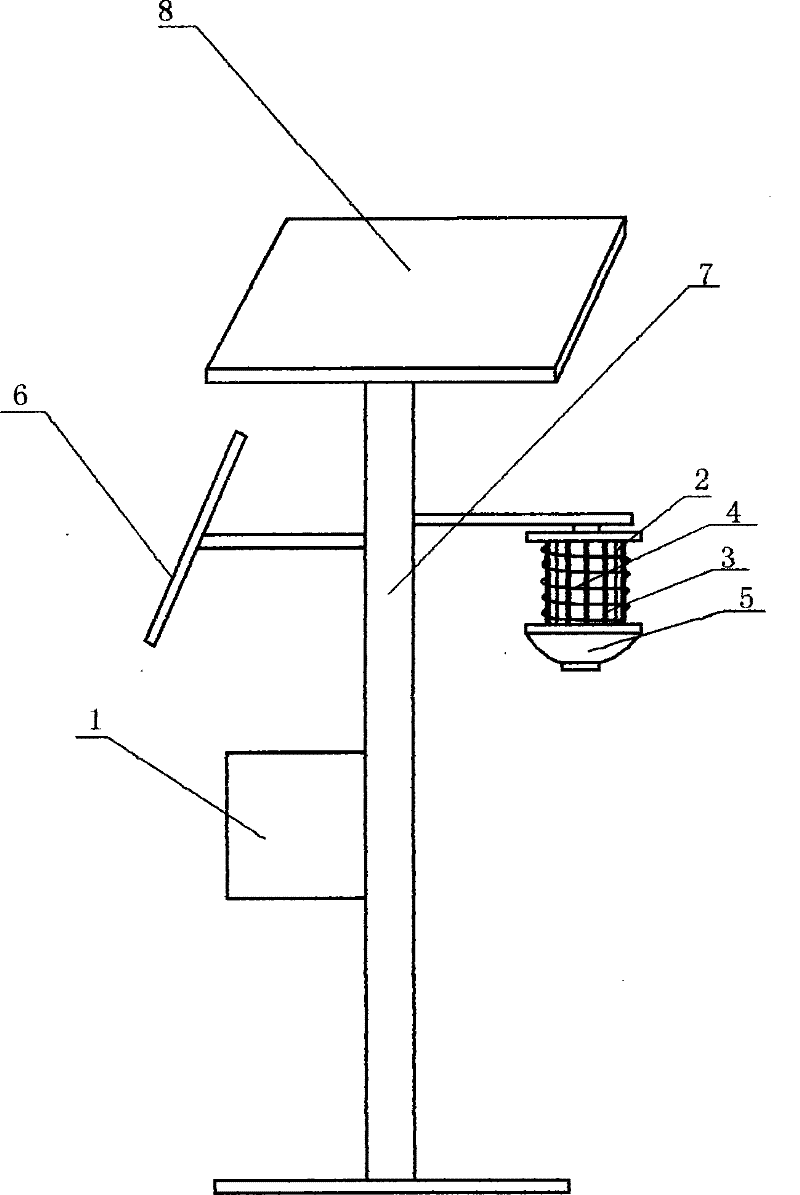

Green environmental intelligent control optical frequency media multifunctional insect zapper

InactiveCN102283189AInhibition of fertilityPromote aggregationLight radiation electric generatorInsect catchers and killersShock resistanceEngineering

Green environmental intelligent control optical frequency media multifunctional insect zapper mainly consists of power supply, intelligent controller, intelligent control protector, control box (1), spectral insect-attracting LED light source (2), insulating column (3), high voltage electric shock resistance A net (4), a pest collector (5), a mosquito and fly insect sticky catch plate (6) and a hollow support (7), is characterized in that: the solar panel (8) of the power supply is arranged on the top of the hollow support (7), The accumulator of power supply is arranged in the control box (1), and the control box (1) is arranged on the middle part of hollow support (7), and intelligent controller, intelligent control protector are arranged in the control box (1), and spectrum trap LED light source ( 2) On the auxiliary support of the hollow support (7), the insulating columns (3) are distributed and arranged around the LED light source (2) for attracting insects, and the high-voltage shock-resistant net (4) is arranged on the insulating column (3), and the pest collector (5) be arranged under the high-voltage shock-resistant net (4), the sticky catch plate (6) of mosquitoes and flies insects is arranged on another auxiliary support of the hollow support (7), to achieve the design purpose.

Owner:武俊

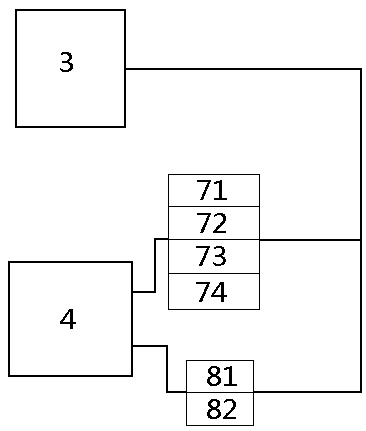

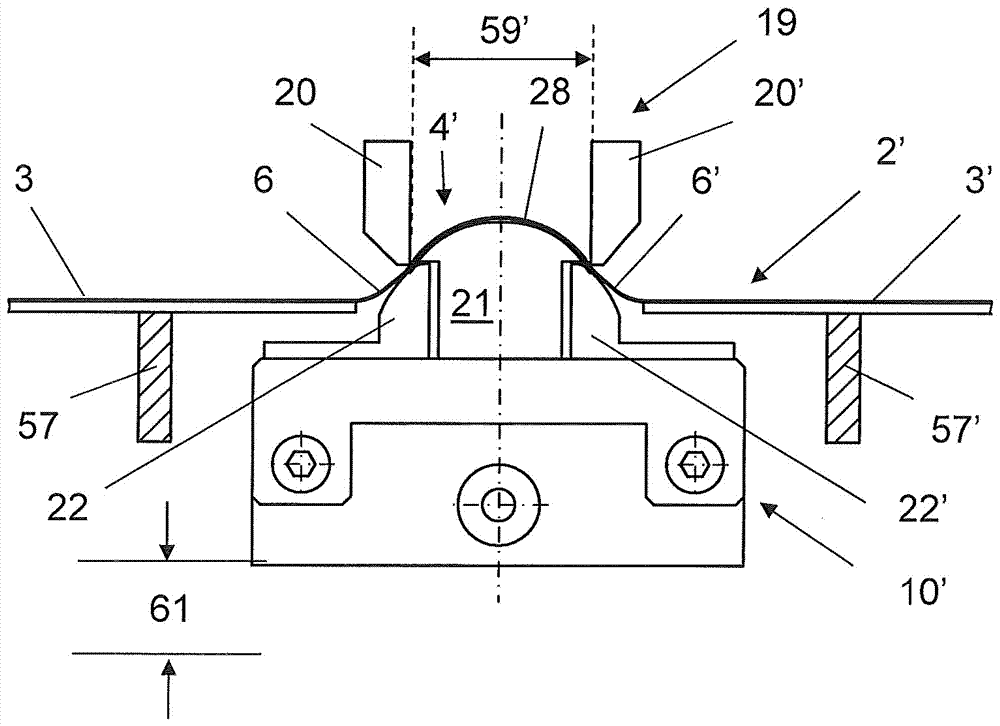

Shaping tool and device for shaping book covers

InactiveCN107303768AQuality improvementLarge control areaBookbinding casesCasing-inRoundingEngineering

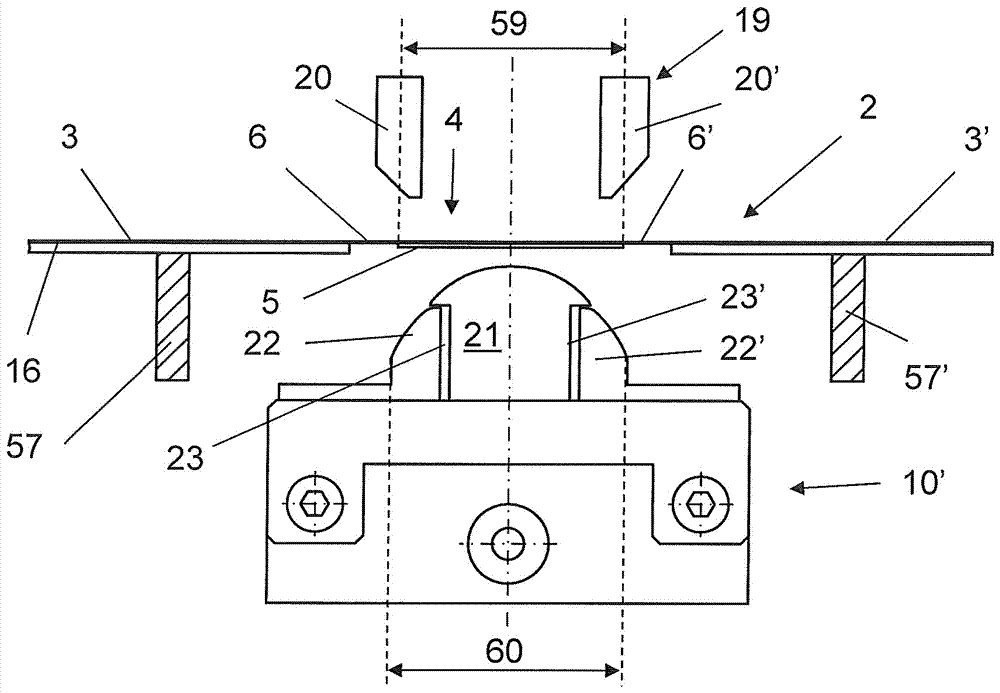

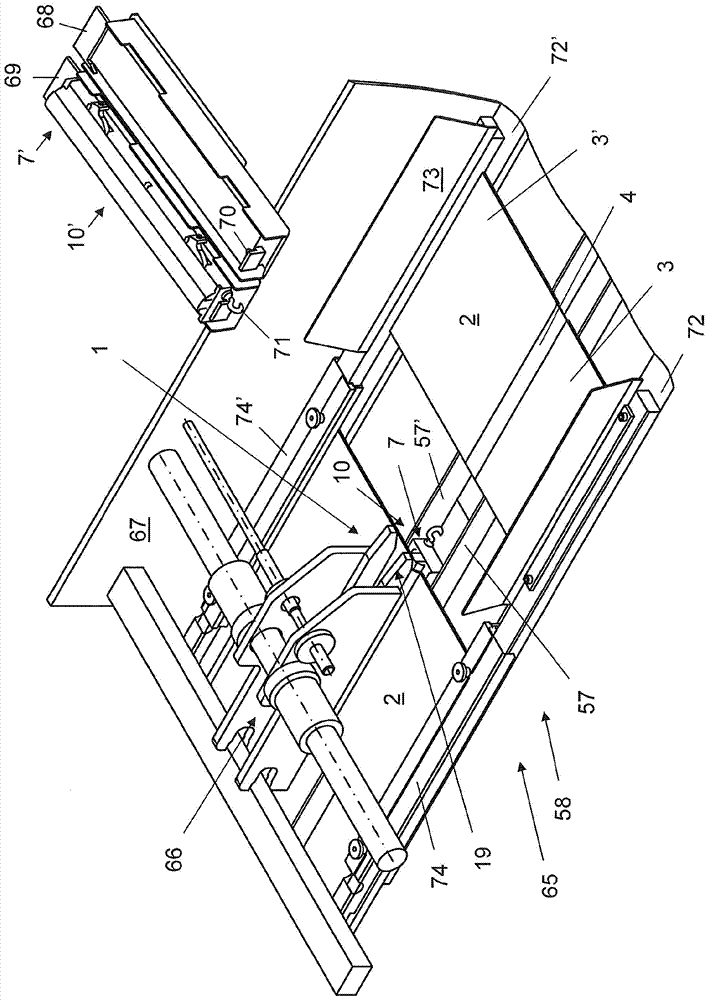

The invention relates to a shaping tool and device for shaping book covers. A shaping tool (10, 10') for a device for rounding a spine region (4) and for shaping a folding region of a lying outstretched book cover, the folding region being adjacent on either side of the spine region (4), in accordance with a shape of a spine of a book block, which subsequently forms a book together with the book cover (2), includes a fixed, convex central shaping strip (21) and two convex outer shaping rails (22, 22') laterally adjoin the central shaping strip and are laterally adjustable according to a required rounding and width of the spine region (4) of the book cover (2). In addition, the invention relates to a device (1) with at least one such deformation tool (10, 10').

Owner:MULLER MARTINI HLDG

Bus controller of light external transparent illuminating node in building

InactiveCN1681366ALarge address rangeLarge control areaElectric light circuit arrangementTransceiverTwisted pair

The invention consists of physical bus link unit, bus transceiver, embedded bus controller, power unit. It uses twisted-pair wire or power line, and makes communication, management, signal collection and driver output in large area, long distance, multi kinds and multi node through lightening node and equipment node relating to application of inner illuminant passing through outside.

Owner:上海国皓电子有限公司

Method for improving development of coal underground gasification gas cavity by applying double-pinniform horizontal well

PendingCN113914846AReduce the number of drilled holesReduce economic costsConstructionsFluid removalThermodynamicsHorizontal wells

The invention discloses a method for improving development of a coal underground gasification gas cavity by applying a double-pinniform horizontal well. The method comprises the following steps that S1, a gas inlet hole of a gas injection well is constructed; S2, a horizontal branch well of the gas injection well is constructed; S3, a production well gas production hole is constructed; S4, horizontal branch wells of the production well are constructed; S5, auxiliary holes are constructed; S6, auxiliary devices such as an ignition device, a gasifying agent injection device and a retreating device are put down through a wellhead of the injection well; S7, a gasifying agent is injected into the horizontal branch well points for ignition; S8, after gasification cavities of the two adjacent horizontal branch wells at the finger tip communicate with each other, the auxiliary devices are arranged at the horizontal branch well points of the middle and rear section, and the steps S5-S8 are repeated till coal bed gas cavities of all the horizontal branch wells are integrally gasified and communicated; and S9, an air extractor is installed at the ground end of the production well. The using method can break through the limitation of point or line range injection and production of a vertical well and a horizontal well, a coal seam fracture system is communicated in a large range, the reaction contact area is increased, and the gas production rate is increased.

Owner:SOUTHWEST PETROLEUM UNIV

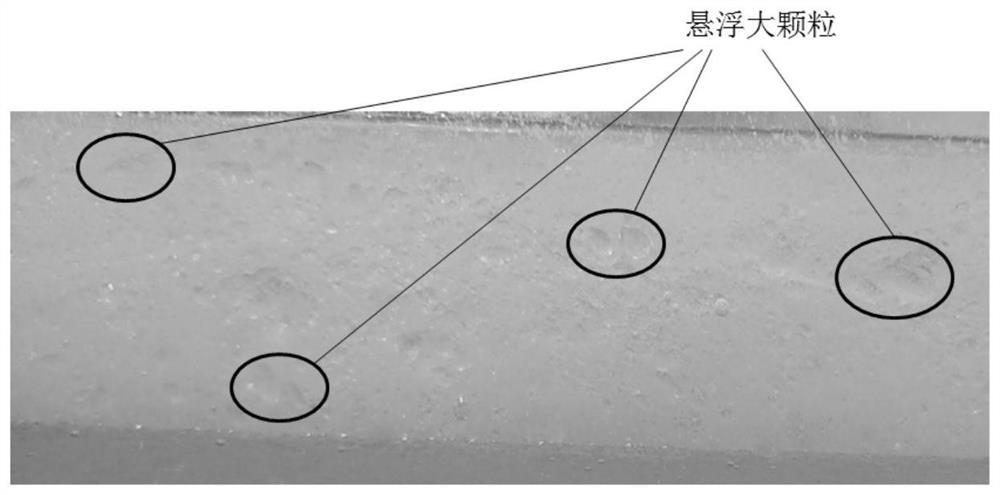

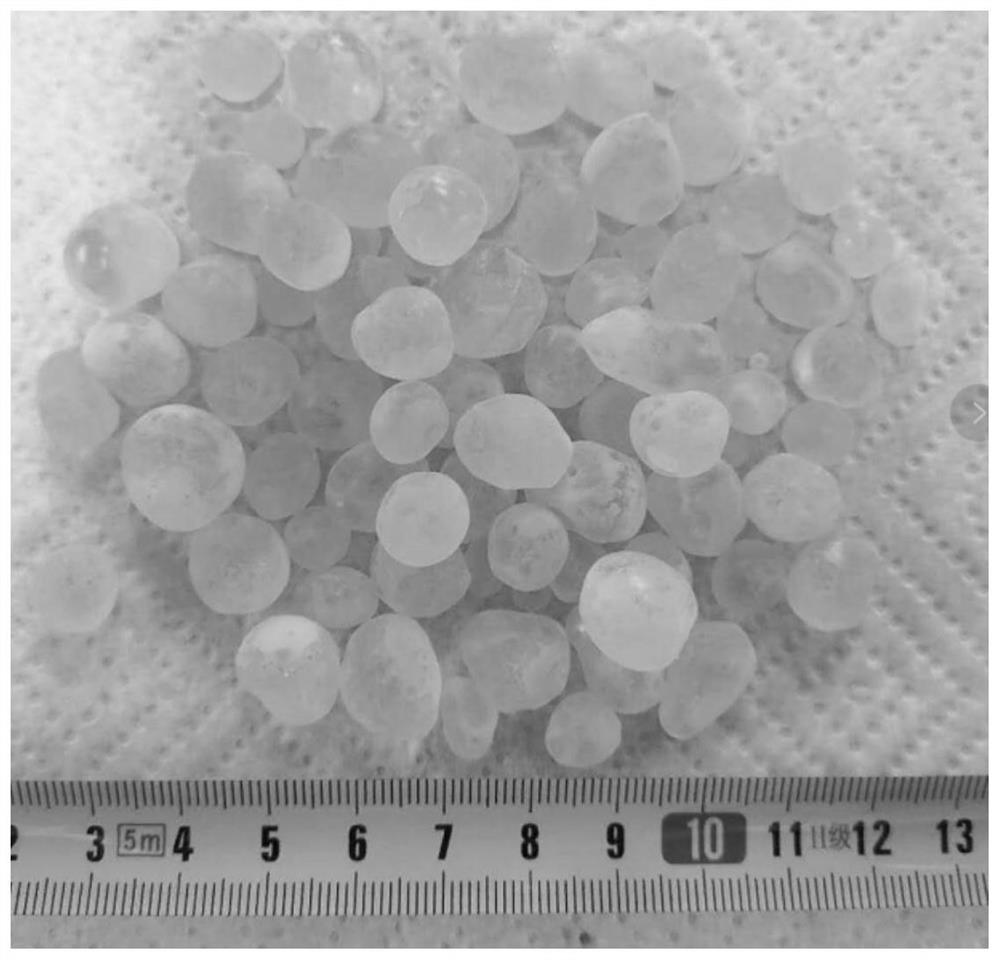

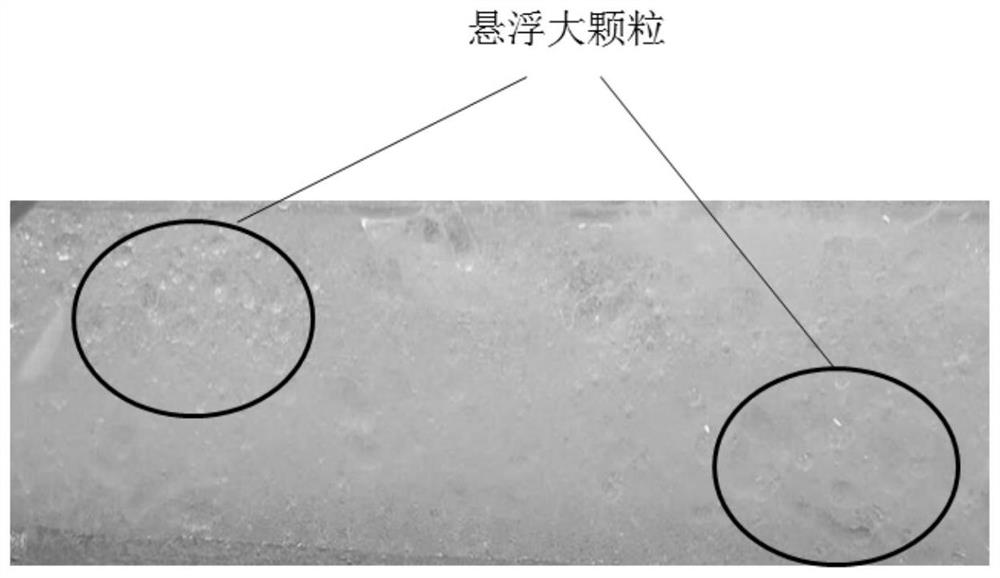

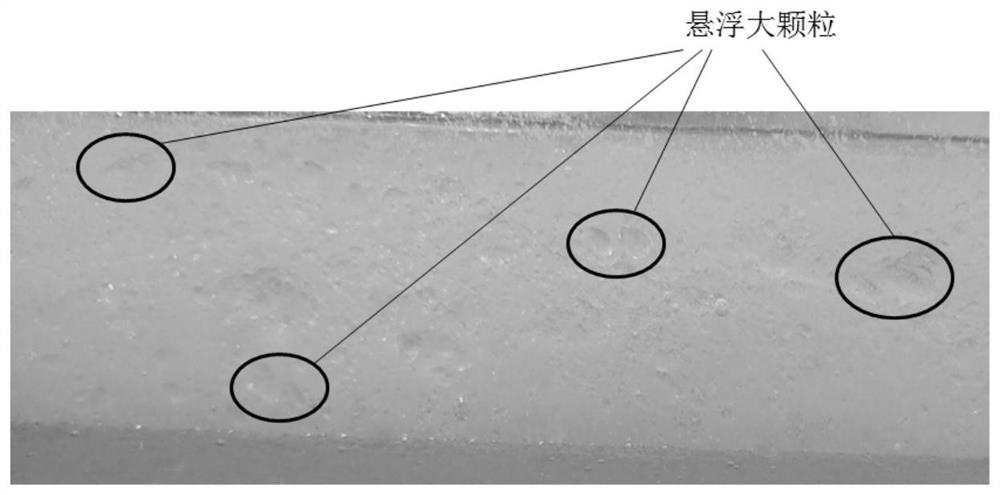

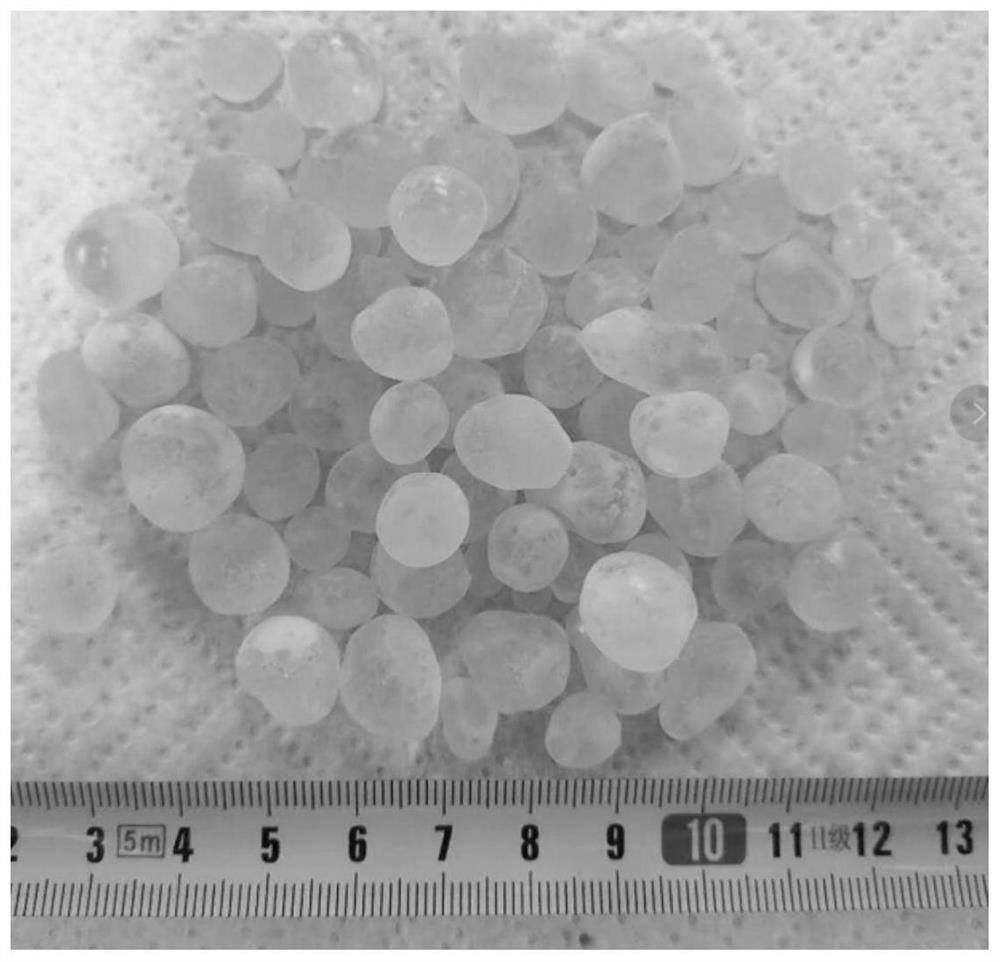

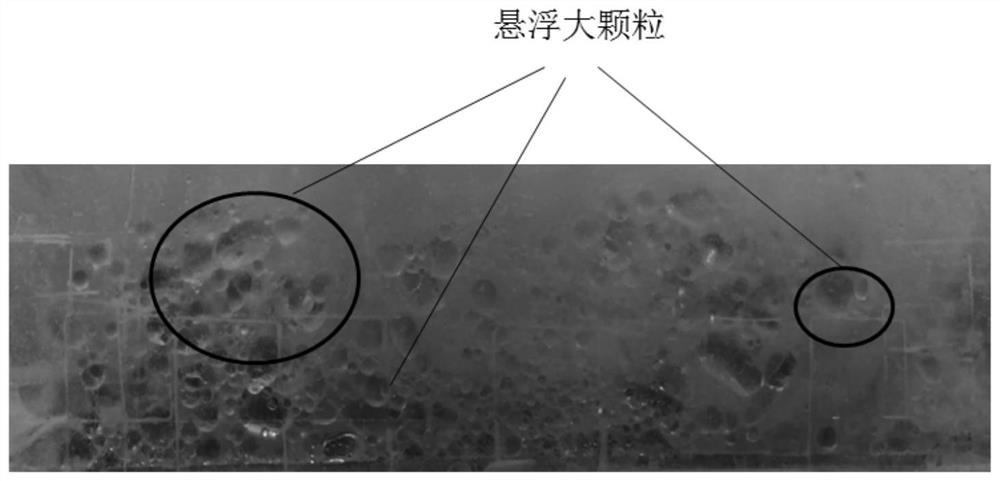

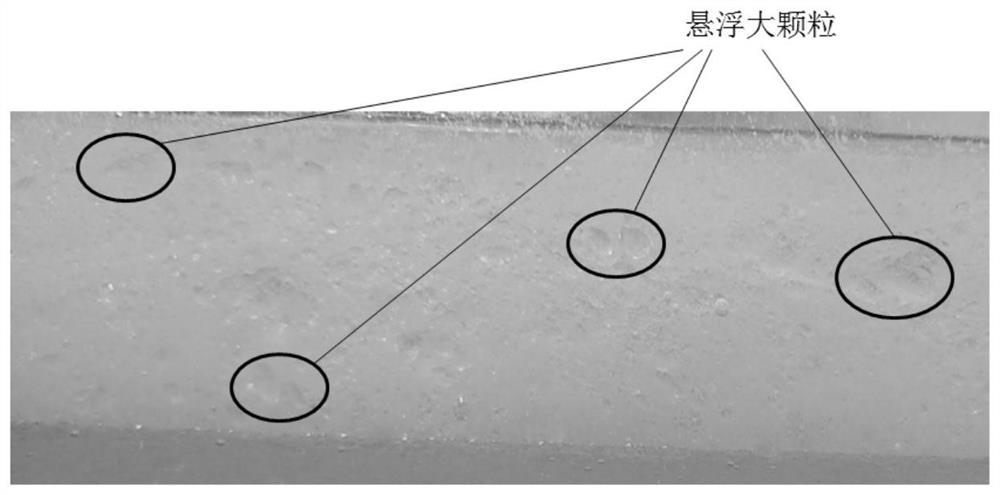

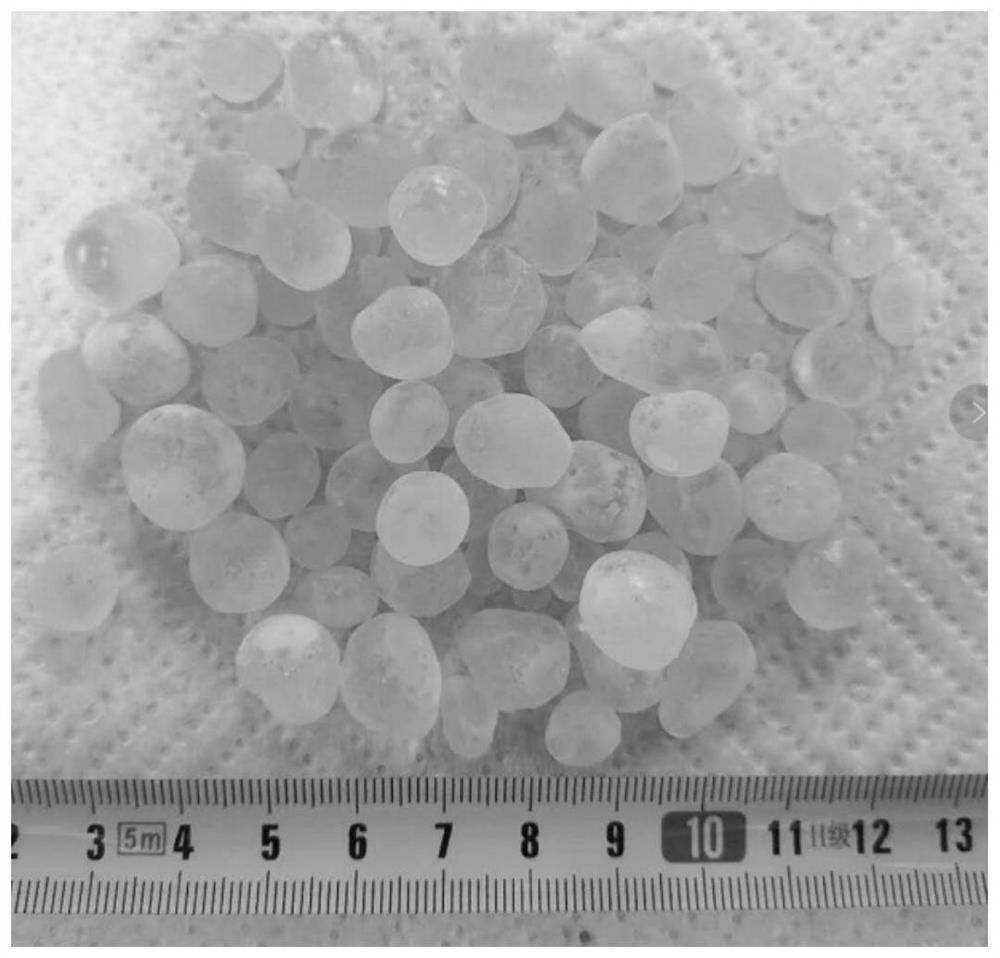

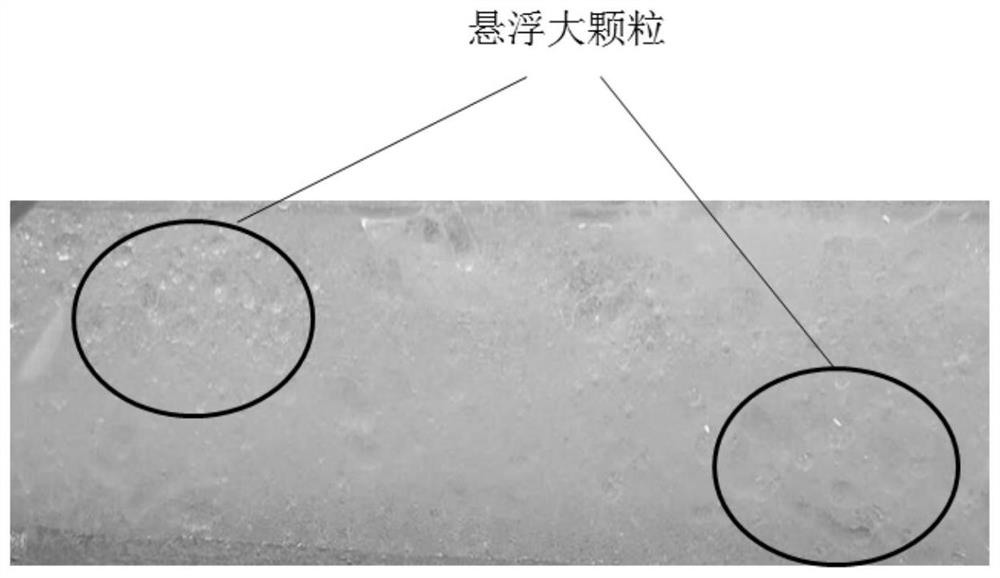

Liquid self-supporting high-speed channel fracturing fluid and experimental method

ActiveCN111718703ALow costAvoid the risk of sand pluggingFluid removalDrilling compositionFracturing fluidEconomic benefits

The invention provides a liquid self-supporting high-speed channel fracturing fluid and an experimental method. The mass ratio of a fluid A to a fluid B in the fracturing fluid is 1: (3-19), wherein the liquid A comprises resin, a curing agent and a suspension dispersing agent; the liquid B comprises conventional fracturing liquid, a density regulator and a suspension dispersing agent, and the liquid A is suspended and dispersed in the liquid B; the liquid self-supporting fracturing fluid does not need a solid-phase propping agent, an existing conventional fracturing mode is changed, the costof the solid-phase propping agent is saved, the construction process is reduced, and the sand blocking risk caused by the solid-phase propping agent is avoided. Centimeter-level cured particles can beformed, the compressive strength is high, and the defect that a traditional low-density proppant is prone to being compacted is overcome. And the solid-phase system A liquid accounts for less ratio,so that the fracturing cost can be reduced, and economic benefits can be obtained. Uniformly suspended and dispersed centimeter-level solid particles formed by the liquid self-supporting fracturing fluid can form a seepage channel with high flow conductivity, reduce the seepage resistance, enlarge the crack control area and improve the yield.

Owner:青岛大地新能源技术研究院

Ground-underground combined exploration and treatment method for mine geological anomalous body

InactiveCN113464203AImprove elimination effectEffective blockingMining devicesDirectional drillingDirectional drillingGeophysics

The invention discloses a ground-underground combined exploration and treatment method for a mine geological anomalous body. The method comprises the following steps of 1, exploration, wherein the position of the geological anomalous body is determined, that the geological anomalous body is communicated with gray water is determined, and the water burst risk exists, wherein 1.1 mine underground exploration is conducted, 1.2 three-dimensional seismic exploration is conducted, an anomalous area is delineated, and 1.3 ground exploration is conducted mainly by drilling a hole, and a three-opening well body structure is adopted for the drilled hole; and 2, treatment, wherein 2.1 ground treatment is conducted, and 2.2 underground treatment is conducted. According to the ground-underground combined exploration and treatment method for the mine geological anomalous body, directional drilling of the ground and directional long drilling of an underground bottom plate along the layer are combined according to engineering practice, exploration and treatment of the mine geological anomalous body are conducted, the effects that the exploration and treatment time is advanced, the exploration and treatment space range is large, the exploration accuracy is high, the overall elimination effect of water damage hidden danger is good, a water guide fracture channel is effectively blocked, and the treatment effect is obvious are achieved.

Owner:鄂尔多斯市华兴能源有限责任公司 +2

Pulse type fracturing construction process for liquid self-supporting highway

ActiveCN111827950ALow costAvoid the risk of sand pluggingCleaning apparatusFluid removalHigh densityPulsed mode

The invention provides a pulse type fracturing construction process for a liquid self-supporting highway. The process includes the following steps of preparing curable liquid A, low-density carrying liquid B and high-density middle-roof liquid B' on site when fractures are made, mixing the liquid A with the liquid B immediately after the fractures are made, injecting the A / B mixed liquid and the liquid B' into a stratum in a pulse mode until fracturing ends, injecting displacing liquid into a shaft to replace the A / B mixed liquid and the liquid B' in the stratum, and then stopping a pump, closing a well and holding the pressure for 40-180 min. A mixing method of the liquid A and the liquid B includes the step of jetting the liquid A into the liquid B, wherein a jet port is located below the liquid surface of the liquid B, and the liquid A forms evenly-distributed centimeter-level liquid particles in the liquid B. The process can reduce the consumption of the liquid A, further improvesthe suspension property and carrying property of the liquid B, further enhances the flow guide capacity, is beneficial for cleaning a well wall or an oil tube, omits the wall hanging property, and reduces the construction risk.

Owner:青岛大地新能源技术研究院

A liquefied petroleum gas-carbon dioxide water-enhanced composite fracturing method

InactiveCN107842351BReduce harmImprove liquidityFluid removalDrilling compositionFracturing fluidLiquid carbon

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

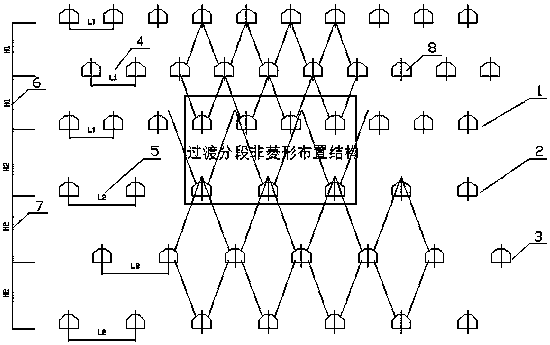

Large-spacing pillarless mining method

InactiveCN108131142AReduce the amount of quasi-engineeringReduce the number of extraction routesUnderground miningSurface miningSection planeComputer science

The invention discloses a large-spacing pillarless mining method, and relates to the technical field. The large-spacing pillarless mining method comprises the following steps: S1, dividing an ore bodyinto a plurality of sections as production level in mining level height, and dividing each section into a plurality of production ore blocks, wherein an extracting drift in the upper and lower sections is of a diamond-shaped arrangement structure, and the bottommost section is used as an upper section; S2, adopting a least common multiple method to enlarge structure parameters of a mining field,obviously increasing the structure parameters of the mining field of a mine on the original basis, forming a transition section, and forming a lower section after the structure parameters of the mining field represent a certain cyclic change rule; S3, arranging an ore discharging connection roadway, a cutting roadway and an air ventilation roadway in a section plane, and blasting and discharging ores in the cutting roadway and the extracting drift according to the requirements of a mining plan. The large-spacing pillarless mining method has the advantage that the structure parameters of the mining field are enlarged by the least common multiple method, so that the stope preparation quantity is obviously reduced.

Owner:NANJING IRON & STEEL CO LTD

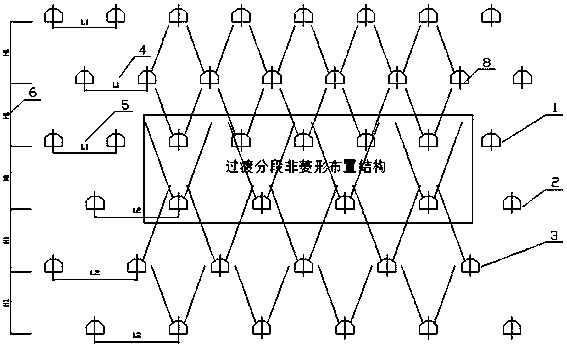

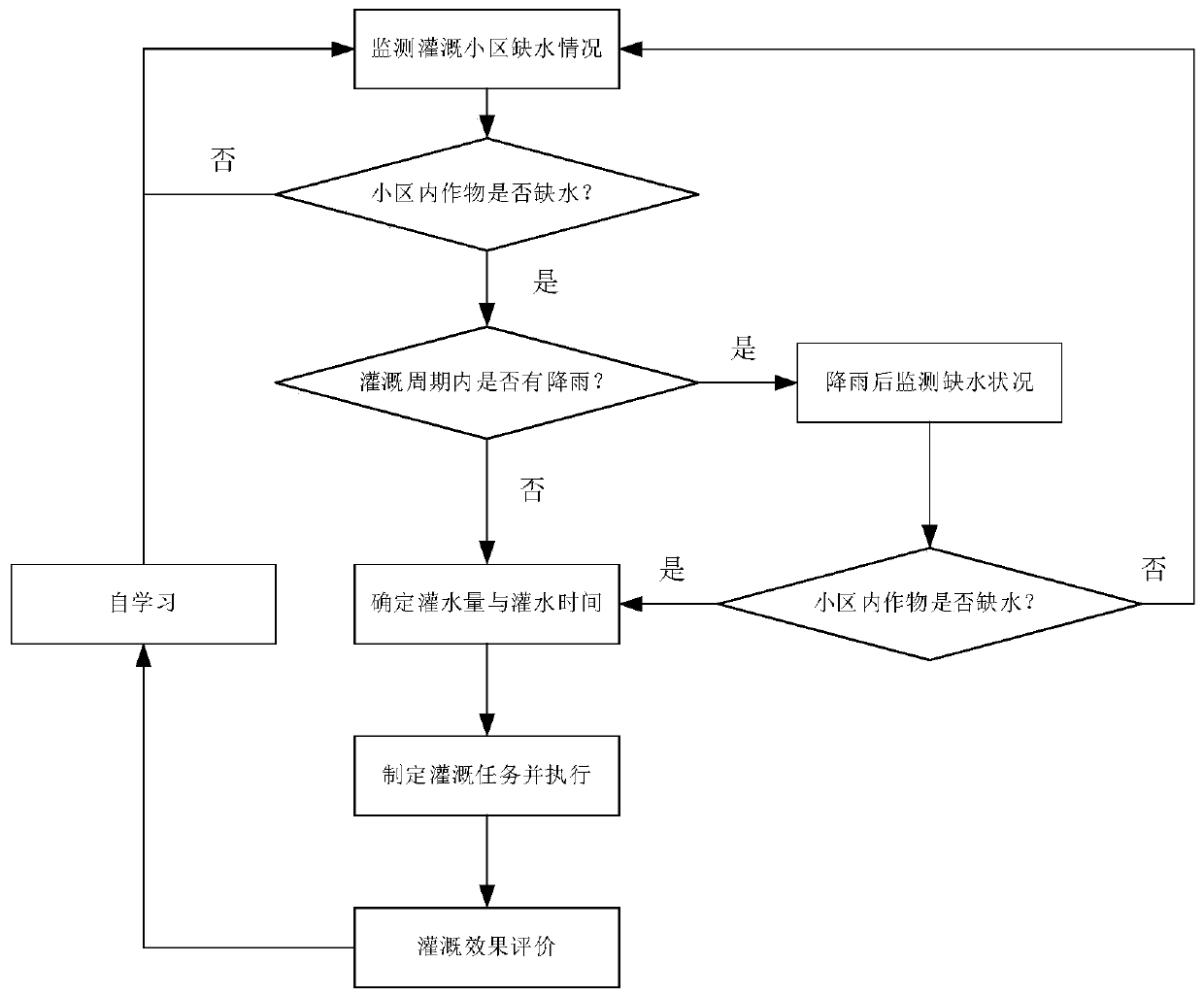

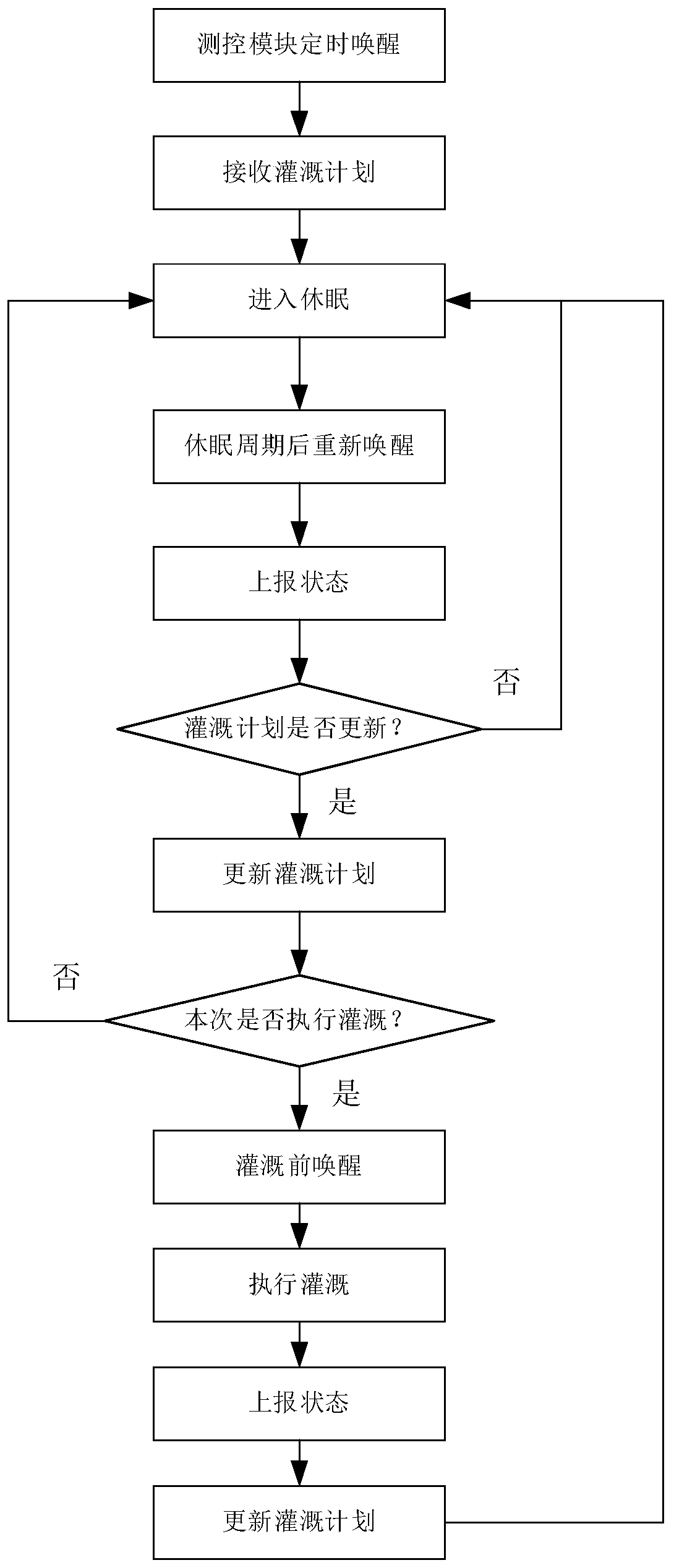

A large-scale farmland wireless Internet of things intelligent drip irrigation system and method

ActiveCN108156918BReduce construction investmentLarge control areaClimate change adaptationWatering devicesWireless controlRemote control

Belonging to the technical field of high efficiency water-saving irrigation, the invention relates to a large-scale farmland wireless Internet of things intelligent drip irrigation system and method.The large-scale farmland wireless Internet of things intelligent drip irrigation system comprises a remote control center, a number of measurement and control modules, a field drip irrigation system and a terminal. The system and method provided by the invention realize all wireless control transmission, put forward consumption reduction and dormancy measures directed at the drip irrigation fieldmeasurement and control modules, at the same time the measurement and control modules are labeled with special information, and positioning of the measurement and control modules, reading, setting andother management operations can be completed through portable terminal reading. The system and method provided by the invention solving the problems of high power consumption, difficult layout and complex management in large-scale farmland intelligent drip irrigation systems, also simultaneously lower the building investment of large-scale farmland intelligent drip irrigation systems, and improvethe management efficiency.

Owner:CHINA AGRI UNIV

A water-saving planting device for automatic seeding based on humidity strain

ActiveCN108738549BNo energy consumptionWide range of controlSeed depositing seeder partsBroadcast seedersAgricultural engineeringStructural engineering

The invention discloses a water-saving planting device based on humidity strain automatic seeding. The water-saving planting device is characterized by comprising a hanging base, wherein a hanging rodis arranged under the hanging base; at least one group of automatic seeding devices is fixedly arranged on the hanging rod; each automatic seeding device comprises two horizontal support plates in vertical and symmetrical arrangement; an arc-shaped double-layer humidity expansion body is positioned at the tail ends of the two horizontal support plates and is connected with the tail ends of the two horizontal support plates through hinging; crop seeds to be sowed are put into a cylindrical casing; the outside of the cylindrical casing is connected with the inner layer of the arc-shaped double-layer humidity expansion body; under the humidity strain driving, the arc-shaped double-layer humidity expansion body overcomes the bending rigidity of the horizontal support plates, and then generates the jumping flection around the tail ends of the horizontal support plates; the inward concave state is fast converted into the outward convex shape; the cylindrical casing is popped up; in the flying process, the crop seeds at inside are spread out. The water-saving planting device has the advantages of automatic induction, high sensitivity, simple structure, high spreading speed, large seedingarea, small occupied space, no maintenance, manufacturing convenience, lightweight and reliability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

A Completion Method of Volumetric Fracturing for Horizontal Wells in Unconventional Reservoirs

ActiveCN110578506BHigh densityDriving differential pressure reductionFluid removalThermodynamicsHorizontal wells

Owner:PETROCHINA CO LTD +3

Liquid self-supporting highway fracturing construction process

The invention provides a liquid self-supporting highway fracturing construction process, comprising the following steps: (1) preparing liquid B1 from conventional fracturing liquid and a density adjusting agent according to a certain weight ratio; (2) manufacturing cracks by using the liquid B1; (3) preparing liquid A and liquid B during the manufacturing of the cracks: mixing resin or a resin diluent with a suspension dispersant, adding a curing agent, and performing uniform mixing to obtain the liquid A; uniformly mixing the liquid B1 with the suspension dispersant or uniformly mixing the liquid B1 with the suspension dispersant and a crosslinking agent to obtain the liquid B; (4) after crack manufacturing is completed, jetting the liquid A immediately into the liquid B through a plurality of jet orifices, the jet orifices being located below the liquid surface of the liquid B, and injecting the A and B mixed liquid into a stratum; and (5) displacing all the A and B mixed liquid intothe stratum by using displacement liquid, and building the pressure for 40 to 180 min. The process solves the problem, in the prior art, that the stratum is easily damaged because the liquid A is distributed in blocks and pieces, and can achieve comprehensive crack self-supporting and highway fracturing effects.

Owner:青岛大地新能源技术研究院

A supplementary energy fracturing method for low-pressure tight oil reservoirs

ActiveCN110469309BIncrease formation pressureSuppression of diminishing yieldFluid removalHorizontal wellsTight oil

The invention discloses a low-pressure tight oil reservoir replenishment energy fracturing method, which comprises the following steps: deploying several long horizontal wells in the low-pressure tight oil reservoir, the shafts of the long horizontal wells are all parallel to each other, and the shafts of the long horizontal wells are all perpendicular to the formation The direction of the maximum principal stress; precise fracturing of each long horizontal well through dense cutting; through the full three-dimensional fracturing software simulation, the fracturing fractures can completely cover all long horizontal wells and each long horizontal well section. The amount of liquid injected into the ground; calculate the amount of additional liquid injected into the ground when the formation pressure within the range of the long horizontal well reaches the preset multiple of the original formation pressure; all long horizontal wells are fractured according to the amount of liquid injected into the ground and the amount of added ground fluid. The invention can slow down the production decline of the low-pressure tight oil reservoir, prolong the stable production period, improve the recovery degree, and increase the cumulative production of a single well in the whole life cycle of a single well.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com