Method of improving production capacity of super-deep low-permeability heavy oil single well by radial drilling and auxiliary thermal recovery

A radial drilling, single-well productivity technology, applied in earth-moving drilling, drilling with liquid/gas jet, and fluid production, etc., can solve the problems of affecting fracturing process, long investment return period, and difficult to control fracture direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

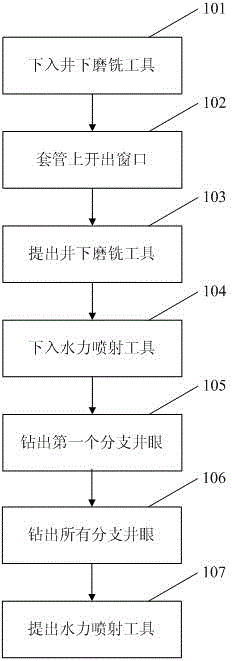

[0031] In the embodiment 2 of applying the present invention, comprise the following steps:

[0032] 1) Calibrate the target reservoir, the effective thickness of the reservoir is 5.1m, and the buried depth is 1622.9m;

[0033] 2) Lower the milling tool, and open a window with a diameter of 24mm on the casing of the target reservoir;

[0034] 3) Bring out the milling tool, and run it into a 12.7mm diameter water jet nozzle with coiled tubing;

[0035] 4) Pump high-pressure fluid from the surface to start drilling the first branch wellbore with a diameter of 50mm and a length of 96m;

[0036] 5) Continue the construction after changing the nozzle angle, and form 4 borehole branches after drilling, and the angle between the boreholes is 90°;

[0037] 6) After the construction is completed, steam is injected. The steam injection temperature is 336.1°C, the dryness is 73.2%, the pressure is 14.9MPa, and the steam injection is 1100t.

Embodiment 3

[0038] In the embodiment 3 of applying the present invention, comprise the following steps:

[0039] 1) Calibrate the target reservoir, the effective thickness of the reservoir is 4.2m, and the buried depth is 1604.4m;

[0040] 2) Lower the milling tool, and open a window with a diameter of 22mm on the casing of the target reservoir;

[0041] 3) Bring out the milling tool, and run it into a 12.7mm diameter water jet nozzle with coiled tubing;

[0042] 4) Pump high-pressure fluid from the surface to start drilling the first branch borehole with a diameter of 48mm and a borehole length of 102m;

[0043] 5) Continue the construction after changing the nozzle angle, and form 6 wellbore branches after drilling, and the angle between the wellbore is 60°;

[0044] 6) After the construction is completed, steam is injected. The steam injection temperature is 327.9°C, the dryness is 74.1%, the pressure is 14.2MPa, and the steam injection is 1400t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com