Coiled tubing clamping device and injection head using same

A clamping device and tubing technology, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems of short service life, unfavorable automatic adjustment, complicated replacement, etc., and achieve the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

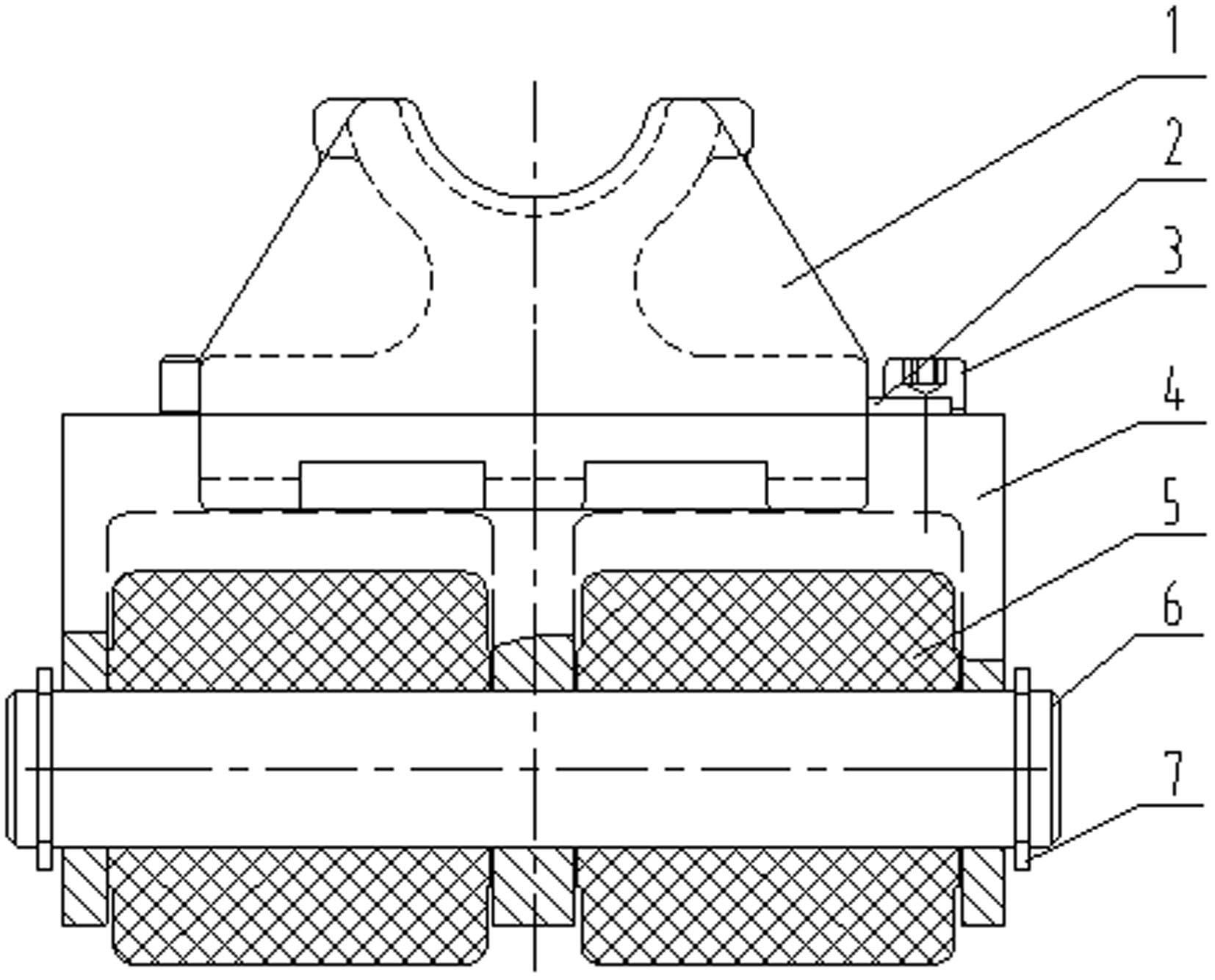

[0027] like figure 1 — Image 6 Shown: a coiled tubing clamping device, including a saddle-type clamping block 1 and a clamping block seat 4, the saddle-type clamping block 1 is fixed on the clamping block seat 4 with a gap, that is, a saddle-type clamping block The block 1 can have a certain left and right movement clearance on the clamping block seat 4 along the vertical direction of the oil pipe to be clamped.

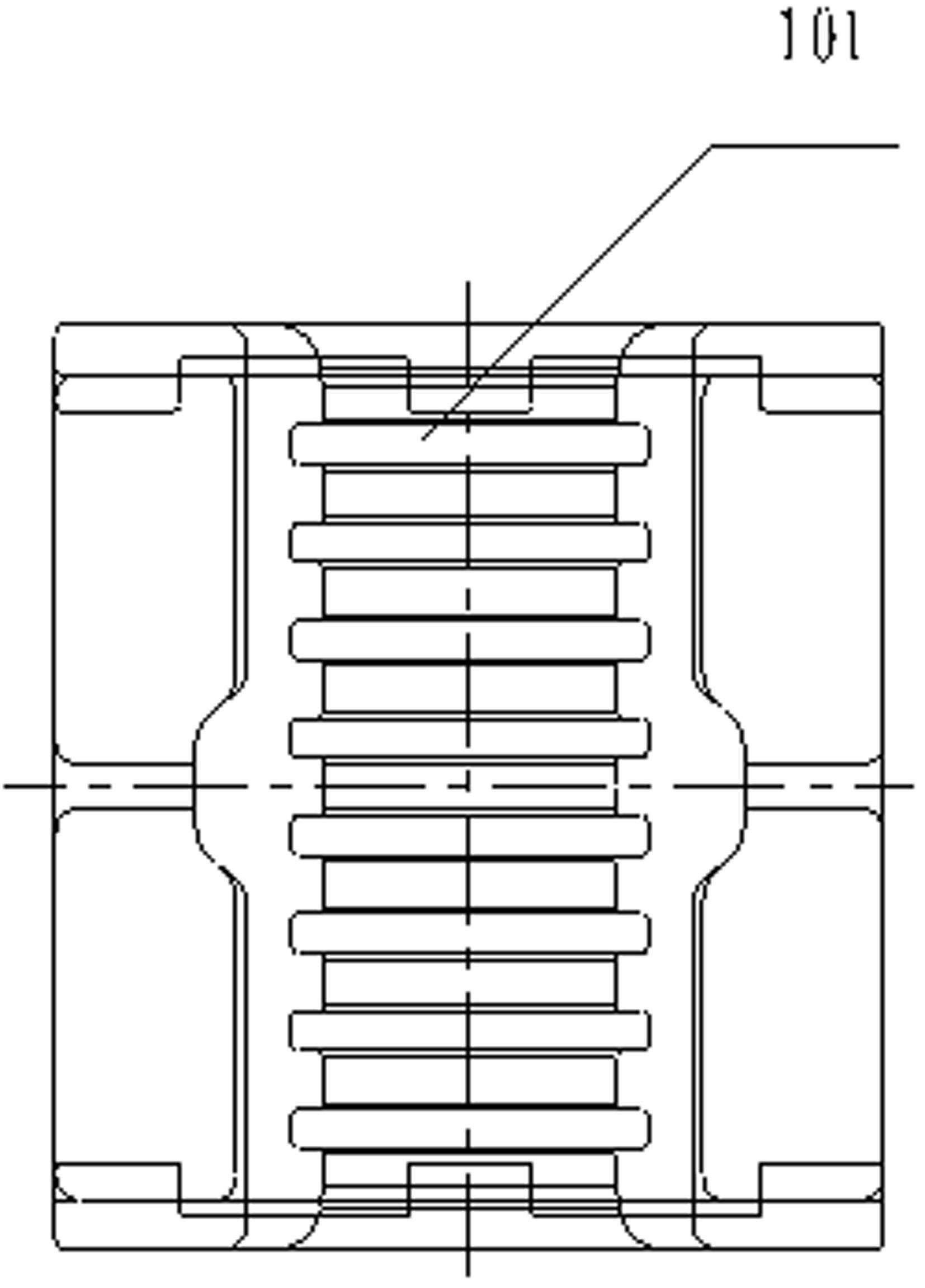

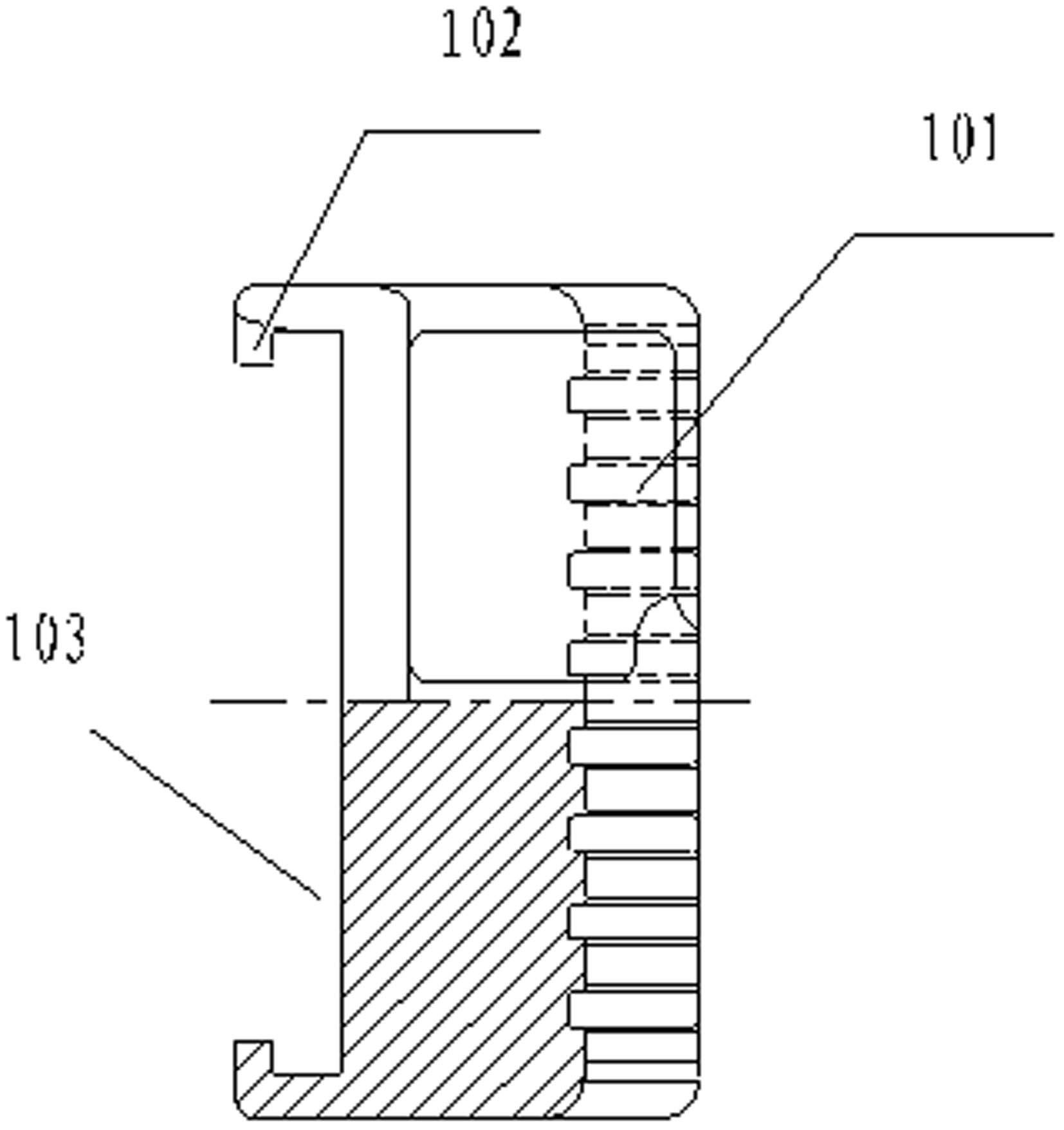

[0028] The clamping block seat 4 includes a pin shaft 6 and a ceramic rolling sleeve 5 sleeved on the pin shaft 6. The clamping block seat 4 is along the direction of the pin shaft 6, and is provided with two connecting rods for connecting with the injection head chain. The through holes 402 are provided with three partitions 406 on the upper part of the clamping block base 4 , and through holes 401 for installing the pins 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com