Side plate storage device of automobile reinforced beam plate

A technology for storing devices and reinforcing beams, applied in tool storage devices, manufacturing tools, etc., can solve the problems of affecting the surface quality of products, easily scratching the surface of workpieces, and occupying storage space, so as to improve convenience, facilitate access to work, Avoid the effect of hard squeeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

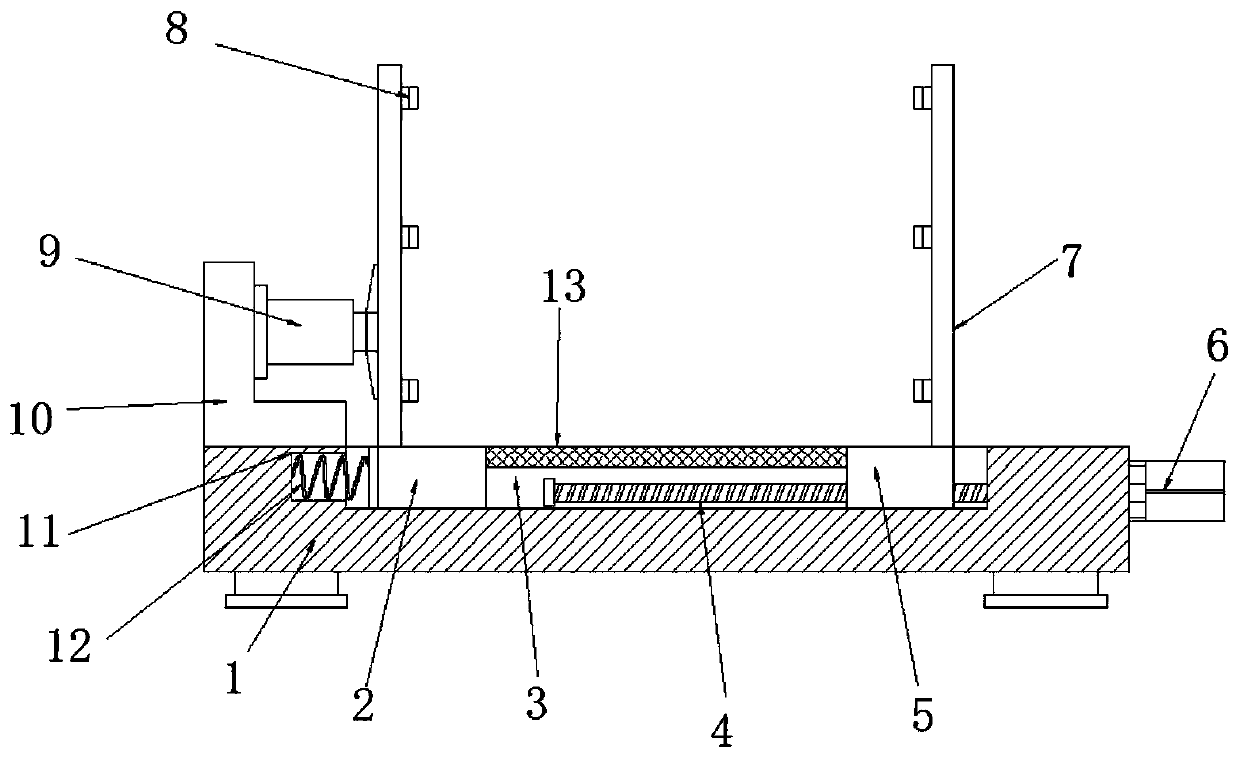

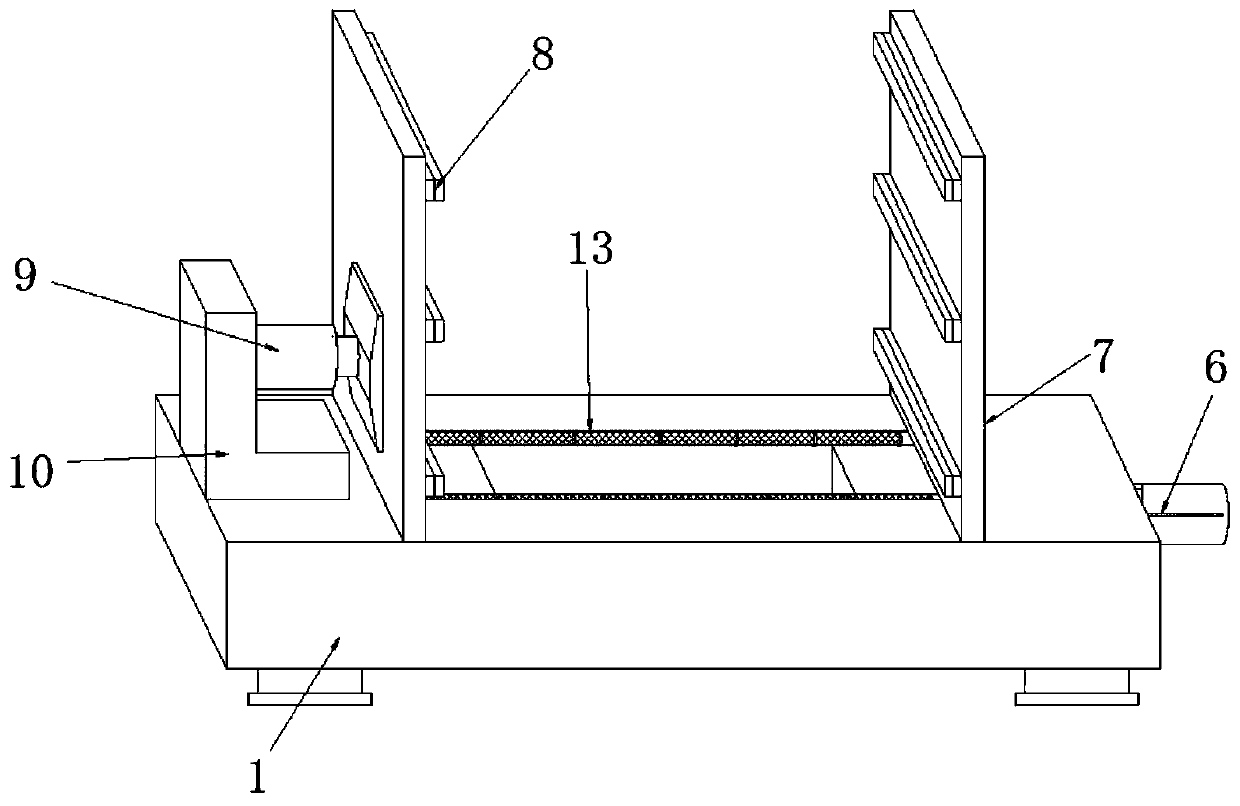

[0023] refer to figure 1 with figure 2 A side plate storage device for a reinforced beam plate of an automobile, comprising a base plate 1, a chute 3 is opened on the outer wall of the top of the base plate 1, and two rolling grooves are opened in the chute 3, and a roller 13 is installed for rotation in the rolling trough, and the sliding The first slider 2 and the second slider 5 are slidably connected in the groove 3, and the second slider 5 is connected with a drive mechanism, and the top outer walls of the first slider 2 and the second slider 5 are fixed with a clamping plate 7 , a plurality of equidistantly distributed rubber strips 8 are fixed on the outer wall of one side of the clamping plate 7 .

[0024] Wherein, the driving mechanism includes a screw rod 4 , and the screw rod 4 is threadedly inserted into the second slider 5 , and a rotating handle 6 is fixed at one end of the screw rod 4 .

[0025] Wherein, a fixed plate 10 is fixed on one side of the top outer ...

Embodiment 2

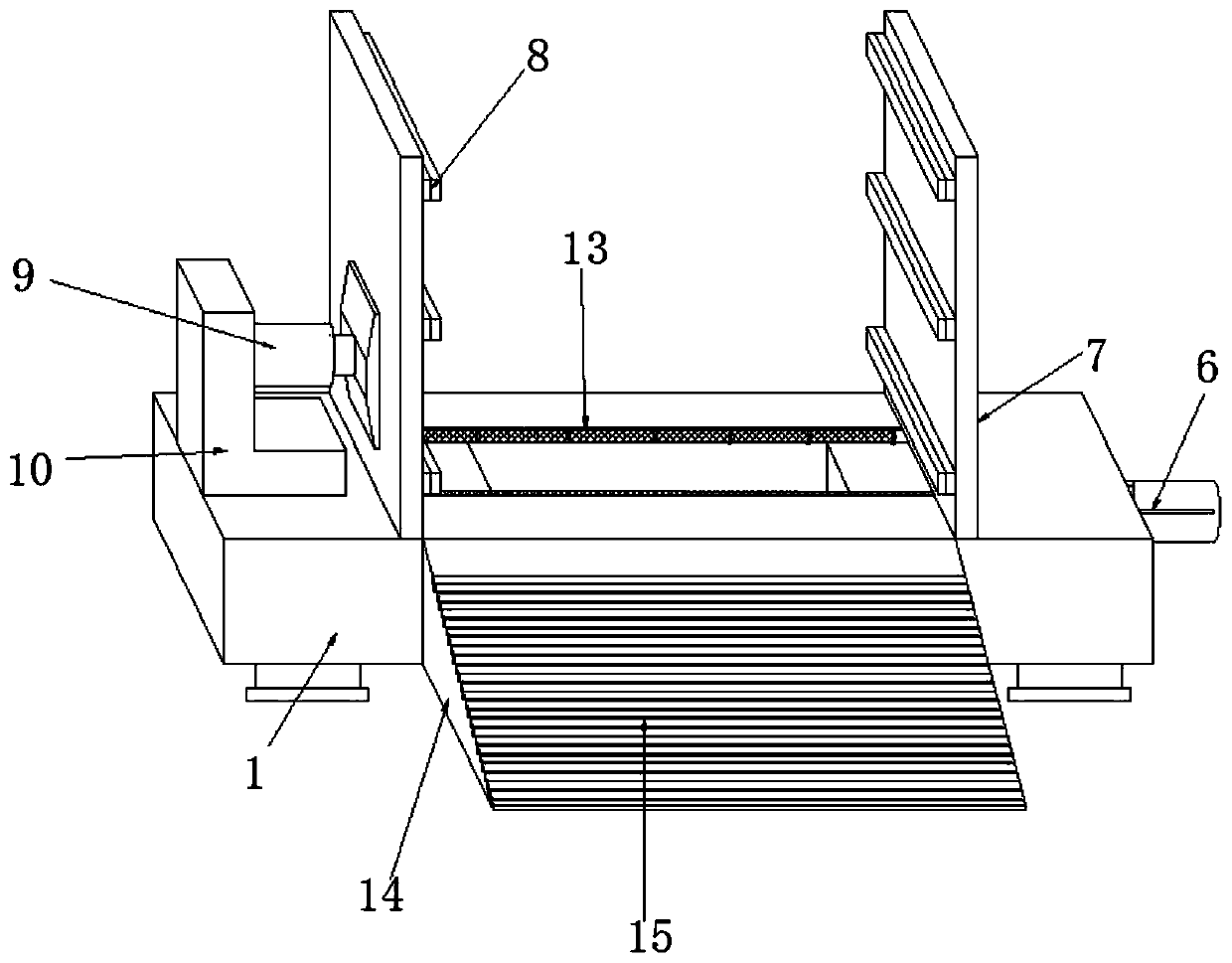

[0030] refer to image 3 , a side plate storage device for automobile reinforcement beams. The difference between this embodiment and Embodiment 1 is that a material guide plate 14 is also fixed on the outer wall of one side of the base plate 1, and the slope on the material guide plate 14 is provided with equidistant distribution. Semi-cylindrical 15.

[0031] The working principle of this embodiment: the material guide plate 14 can facilitate the unloading work on the side plate and improve the convenience of the unloading work, and the half cylinder 15 can reduce the friction between the side plate and the inclined surface of the material guide plate 14 in addition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com