Replaceable chemical device fixing steel frame

A steel frame and chemical technology, which is applied in the field of replaceable chemical equipment fixing steel frame, can solve the problems of inconvenient pipeline pushing, inconvenient replacement work, inconvenient horizontal fixing of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

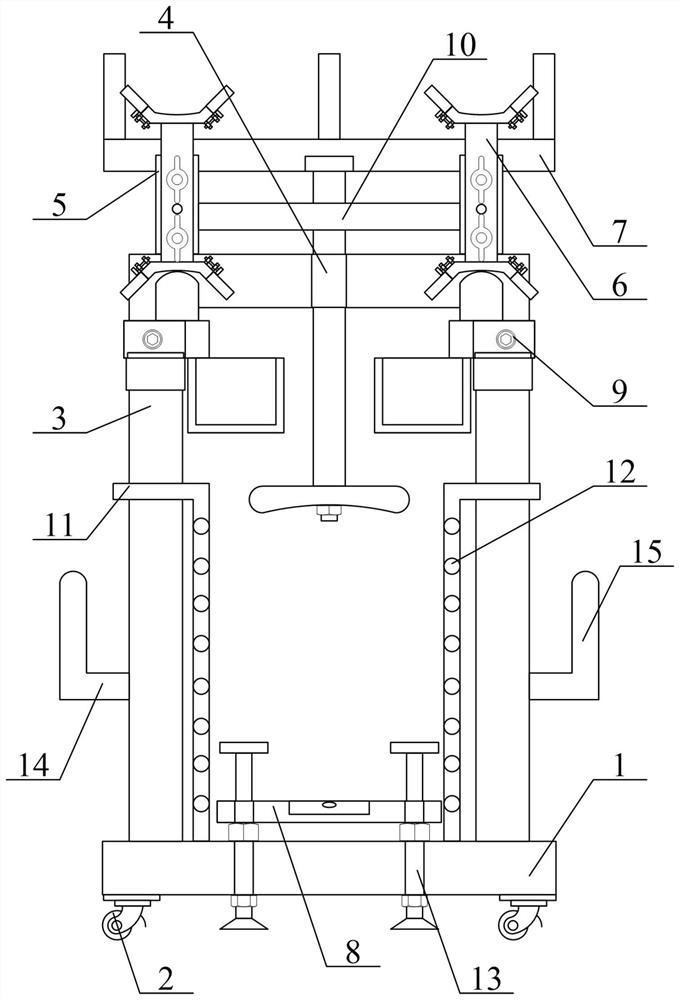

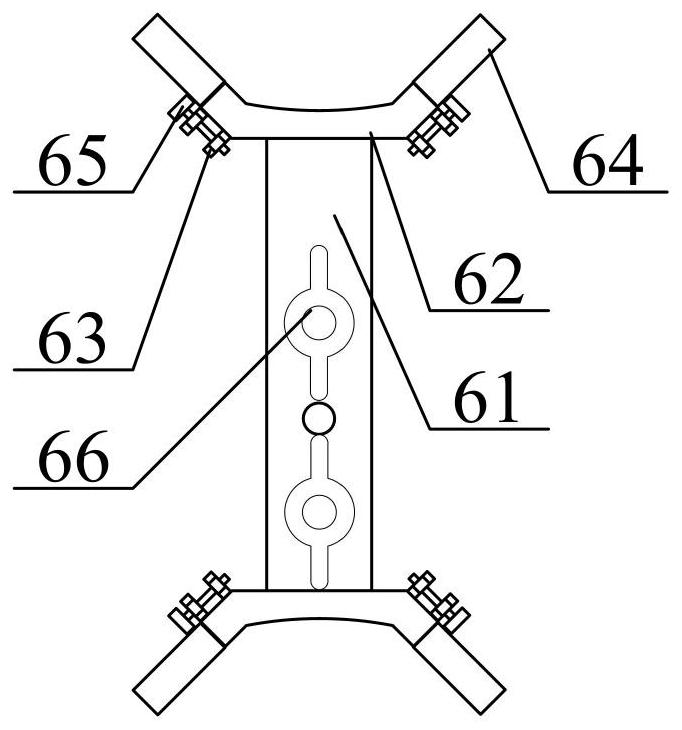

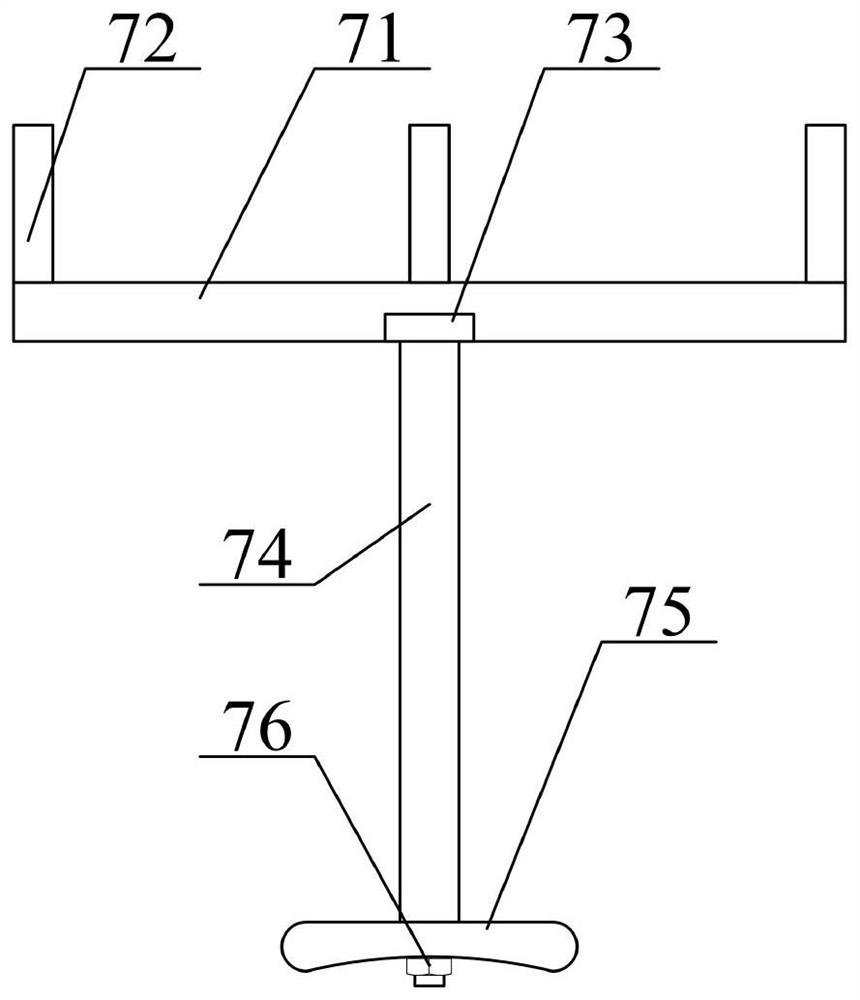

[0023] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a replaceable fixed steel frame of a chemical plant includes a moving seat 1, a moving brake wheel 2, an inverted U-shaped gantry 3, a first threaded hole 4, a fixed support rod 5, and a structure that can be plugged into a rotating support seat 6. The anti-skid plate structure can be lifted and pushed 7, the fixed rod structure can be detected horizontally 8, the fixed and reinforced storage seat structure 9, the lateral support rod 10, the inverted L turret 11, the climbing rod 12, the second threaded hole 13, the connecting rod 14 and a push rod 15, the moving brake wheels 2 are respectively bolted to the four corners of the lower end of the moving base 1; the lower end of the inverted U-shaped gantry 3 is bolted to the upper end of the moving base 1; A threaded hole 4 is provided in the middle position of the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com