Installation device, installation method, and disassembly method of a looper angle encoder

An angle encoder and installation device technology, which is applied in the direction of length measuring device, metal rolling, manufacturing tools, etc., can solve the problems of unguaranteed service life and reliability, difficulty in disassembly, damage of encoder, etc., and achieve equipment maintenance Work is convenient, the overall structure design is ingenious, and the effect of simplifying the replacement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

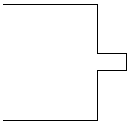

[0042] Embodiment 1: see figure 1 , an installation device for a looper angle encoder, the installation device includes a looper body dummy shaft 11, a dummy shaft side disc 1, an encoder side disc 2, and an encoder 3, and the looper body dummy shaft 11 Connect the disk 1 on the dummy shaft side, the encoder disk 2 is connected to the encoder 3, the encoder 3 is provided with a clamp 4, the installation device also includes a slide bar 5, a slider 7 and a bracket 8, the The slider 7 is arranged between the slide bar 5 and the bracket 8 .

Embodiment 2

[0043] Example 2: see figure 1 As an improvement of the present invention, one end of the sliding bar 5 is provided with a bolt hole, which is connected with the clip through a hexagonal bolt; the sliding block is provided with a chute 9, and the other end of the sliding bar is inserted into the sliding in the chute on the block. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0044] Embodiment 3: see figure 1 , as an improvement of the present invention, the bracket is set as an L-shaped bracket, and the two sides of the L-shaped bracket are respectively provided with left and right adjustment grooves 6 and front and rear adjustment grooves 10, and the slider 7 is inserted into the left and right adjustment grooves of the bracket , and fixed on the bracket with hex bolts. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com