Cement grinding mill reducer

A technology of reducer and cement mill, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of large starting load, affecting service life, and easy damage to bearings, so as to avoid hard extrusion force and prolong service life Lifespan, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment for further explanation,

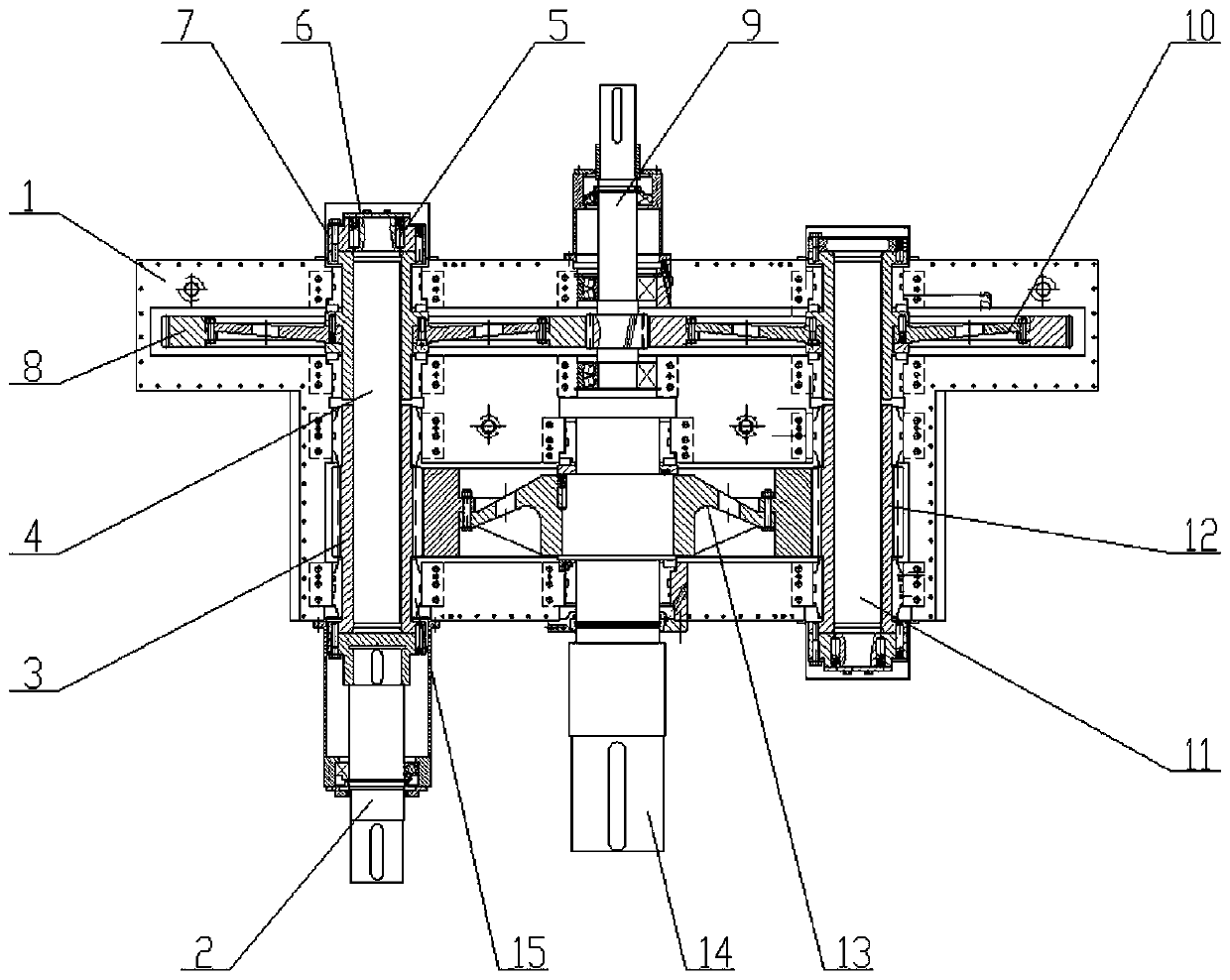

[0010] figure 1 As shown: a cement mill reducer includes a box body 1, an input shaft 2, an equalizing gear 3, an input transmission shaft 4, a positioning pin 5, a positioning pin pressing plate 6, a connecting block 7, an input gear 8, an intermediate gear shaft 9, an input Transmission gear 10 , output transmission shaft 11 , output transmission gear 12 , output gear 13 , output shaft 14 and eccentric bearing bush 15 . One end of the input shaft 2 extends out of the box body 1, and the other end is fixedly connected to one end of the input drive shaft 4 and the equalizing gear 3, the equalizing gear 3 is sleeved on the input drive shaft 4, and the other end of the input drive shaft 4 is connected through the connecting positioning pin 5 The connection block 7 is crimped by the positioning pin pressure plate 6, and the connection block 7 is connected to the end face of the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com