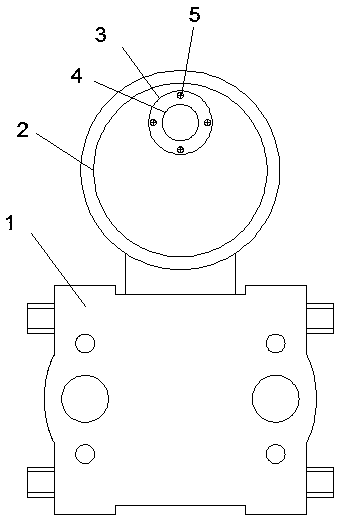

Anti-breakage differential pressure transmitter

A differential pressure transmitter and transmitter technology, used in instruments, measuring fluid pressure, pressure difference measurement between multiple valves, etc., can solve problems such as wear and tear of connecting lines, improve service life and improve sealing , the effect of easy threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

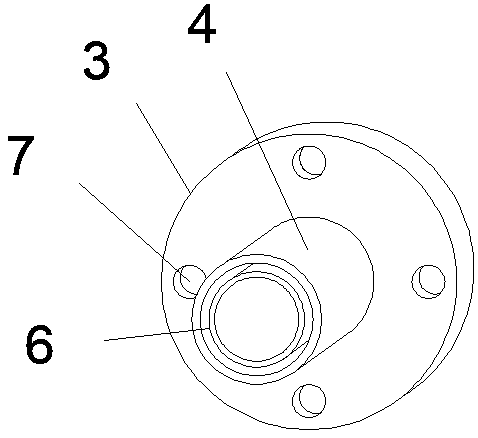

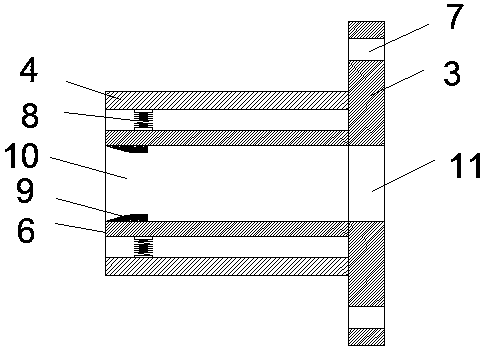

[0023] As a preferred embodiment of the present invention, the cable fixing plate 3 , the connecting pipe 4 and the inner pipe 3 are arranged concentrically.

[0024] As a preferred embodiment of the present invention, the sealing ring 9 is made of silicone material, and is vulcanized as one piece with the inner tube 6 .

[0025] As a preferred embodiment of the present invention, the inner tube 6 is made of soft rubber material, and is integrated with the fixing plate 3 .

[0026] As a preferred embodiment of the present invention, the front end of the sealing ring 9 is an inclined plane, and the angle of the inclined plane is 30-45 degrees.

[0027] As a preferred embodiment of the present invention, the number of the spring columns 8 is four, and they are symmetrically arranged in pairs on the outer surface of the inner tube 6 at equal intervals.

[0028] When this anti-break differential pressure transmitter is used, a cable fixing plate is arranged on the rear side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com