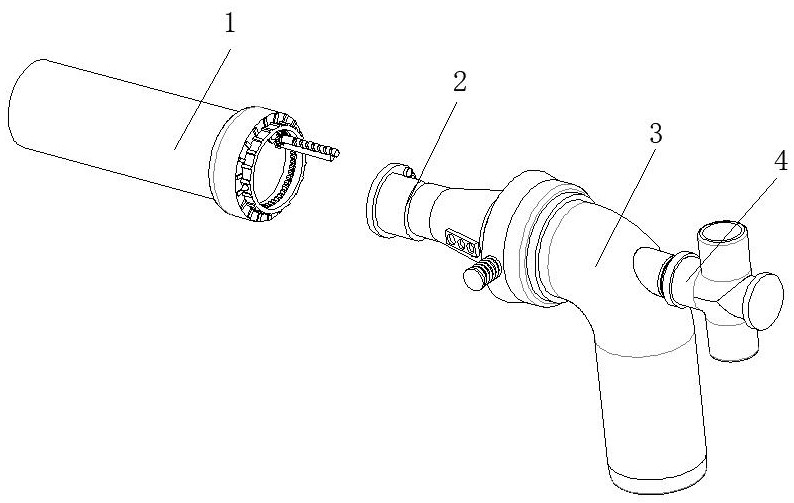

A device for adjusting the air flow of the edge suction thread of the laminating machine

A technology of airflow adjustment and laminating machine, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials. It can solve problems such as blockage in pipelines, achieve the effects of improving reliability, ensuring reliability, and accurately adjusting the size of the wind force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

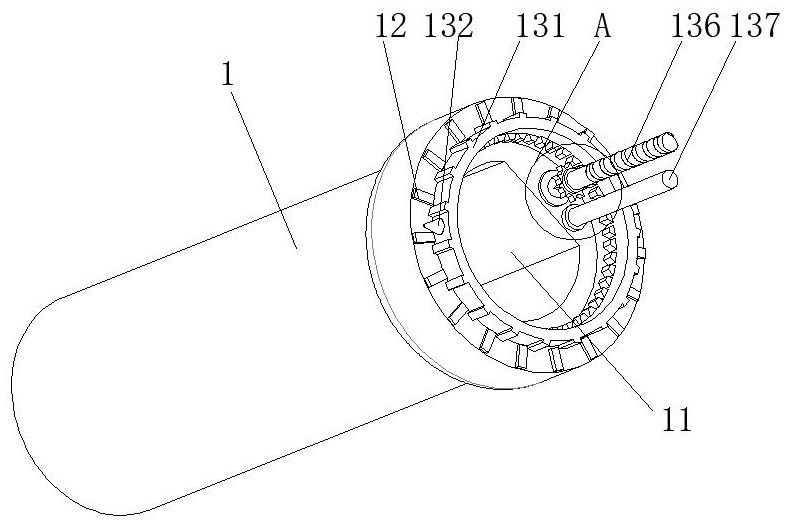

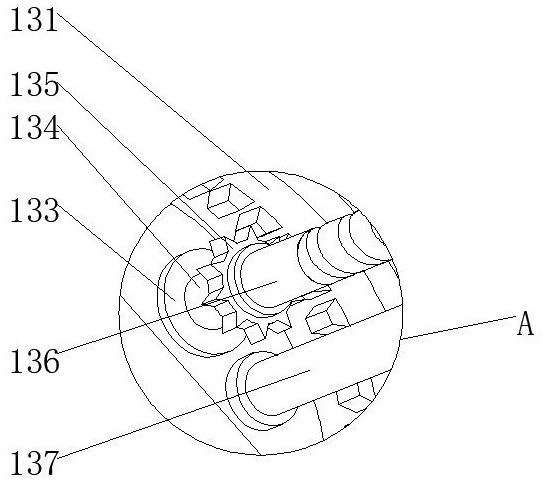

[0032] Such as figure 1 , 4As shown in , 5, the embodiment of the present invention provides a device for adjusting the air flow of the edge suction thread of the laminating machine. The outer surface of the first cone section 23 is fixedly installed with a limiting plate 231, and the outer surface of the limiting plate 231 is provided with holes. The first Both sides of the inner wall of the cone section 23 are fixedly equipped with a guide structure 232, the guide structure 232 includes a sleeve 2321, the inside of the first cone section 23 is fixedly installed with a sleeve 2321, the inner wall of the sleeve 2321 is slidably connected with a slide rod 2322, and the slide The outer surface of the rod 2322 is fixedly sleeved with a buffer spring 2323 , and the end of the slide rod 2322 away from the casing 2321 is rotatably connected to a guide wheel 2324 through the shaft 134 .

Embodiment 2

[0034] Such as figure 1 , 4 As shown in , 5, the embodiment of the present invention provides a device for adjusting the air flow of the edge suction thread of the laminating machine. The outer surface of the first cone section 23 is fixedly installed with a limiting plate 231, and the outer surface of the limiting plate 231 is provided with holes. The first Guide rails are fixedly installed on both sides of the inner wall of the cone section 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com