A liquefied petroleum gas-carbon dioxide water-enhanced composite fracturing method

A technology of liquefied petroleum gas and liquid carbon dioxide, which is applied in the direction of chemical instruments and methods, earthwork drilling and production, drilling compositions, etc., can solve the problems of tight oil and gas reservoir development, water sensitivity, water lock pollution, shale reservoir Pollution and other problems, to achieve the effect of reducing water lock effect, good fluidity, and ideal crack scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

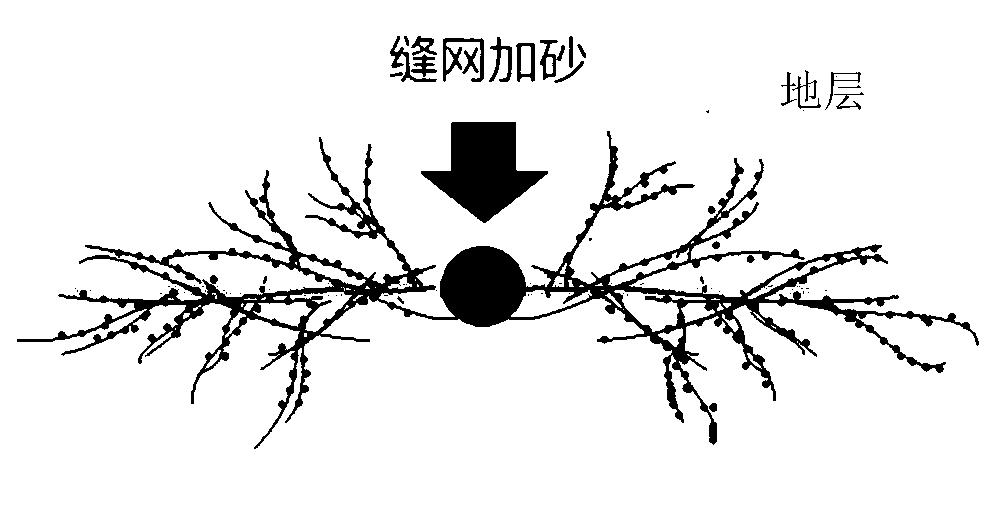

[0036] This embodiment provides a liquefied petroleum gas-carbon dioxide anhydrous energized composite fracturing method. The working fluid used in this method is divided into liquefied petroleum gas fracturing fluid without proppant added, liquid carbon dioxide fracturing fluid without proppant There are four types of fracturing fluid, liquid carbon dioxide fracturing fluid carrying proppant and liquefied petroleum gas fracturing fluid carrying proppant.

[0037] Wherein, the composition of the liquefied petroleum gas fracturing fluid without proppant added is (based on the total weight of the fracturing fluid): 0.6% dialkyl phosphate viscosifier (the thickener can be low-carbon Hydrocarbon anhydrous fracturing fluid system and rheological properties research (Hou Xiangqian, East China University of Science and Technology master's degree thesis, 2014) product GA-14), 1.2% complex iron crosslinking agent (this crosslinking agent can be low carbon Hydrocarbon anhydrous fracturi...

Embodiment 2

[0050] This embodiment provides a liquefied petroleum gas-carbon dioxide water-free energized composite fracturing method, and the four working fluids used in this method are the same as those in Embodiment 1.

[0051] The method includes the following steps:

[0052] (1) Use nitrogen gas to check the tightness of the entire pipeline. After confirming that the pipeline is completely sealed, use liquefied petroleum gas fracturing fluid without proppant 3 Squeeze out the liquid in the wellbore to avoid polluting the formation;

[0053] (2) Inject liquefied petroleum gas fracturing fluid without proppant into the formation at an injection speed of 3.8-4.2m 3 / min, the injection pressure is controlled at 35~38MPa, and a total of 38m is injected 3 , make the reservoir rock hold pressure until it breaks, and produce main fractures with a certain width;

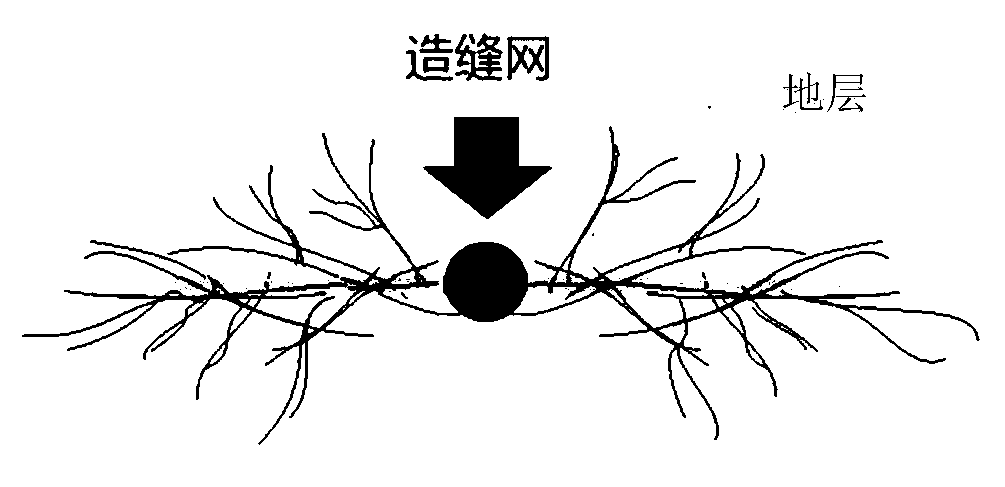

[0054] (3) Stop injecting liquefied petroleum gas fracturing fluid without proppant, and then inject liquid carbon dioxide frac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com