Method for improving development of coal underground gasification gas cavity by applying double-pinniform horizontal well

A technology for horizontal well and gasification gas, applied in coal gasification, underground mining, earth-moving drilling, etc., can solve problems such as affecting the formation and development of gasification cavity, difficult to form far-field effects, damage to horizontal wells, etc., to reduce drilling The number of holes, the increase in the recovery rate, the effect of improving the convection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

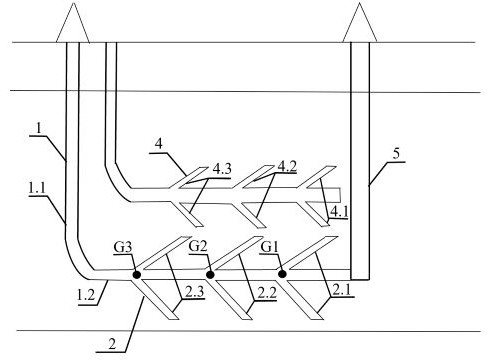

[0039] like figure 1 As shown, the body structure of a double-horizontal plume underground coal gasifier provided by the embodiment of the present invention includes: air inlet hole 1 of gas injection well, horizontal branch well 2 of gas injection well, gas production hole 3 of production well, horizontal branch well of production well 4. Auxiliary hole 5; the air inlet hole 1 of the gas injection well includes a vertical section 1.1 and a connected horizontal section 1.2, the vertical section 1.1 is connected to the surface and the target coal seam, and the horizontal section 1.2 is located near the bottom of the coal seam; the gas production hole of the production well 3 includes a vertical section 3.1 and a connected horizontal section 3.2, the vertical section 3.1 is connected to the surface and the target coal seam, and the horizontal section 3.2 is located near the bottom of the coal seam; the horizontal branch well 2 of the gas injection well and the horizontal branch w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com