Patents

Literature

35results about How to "Strong drainage ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

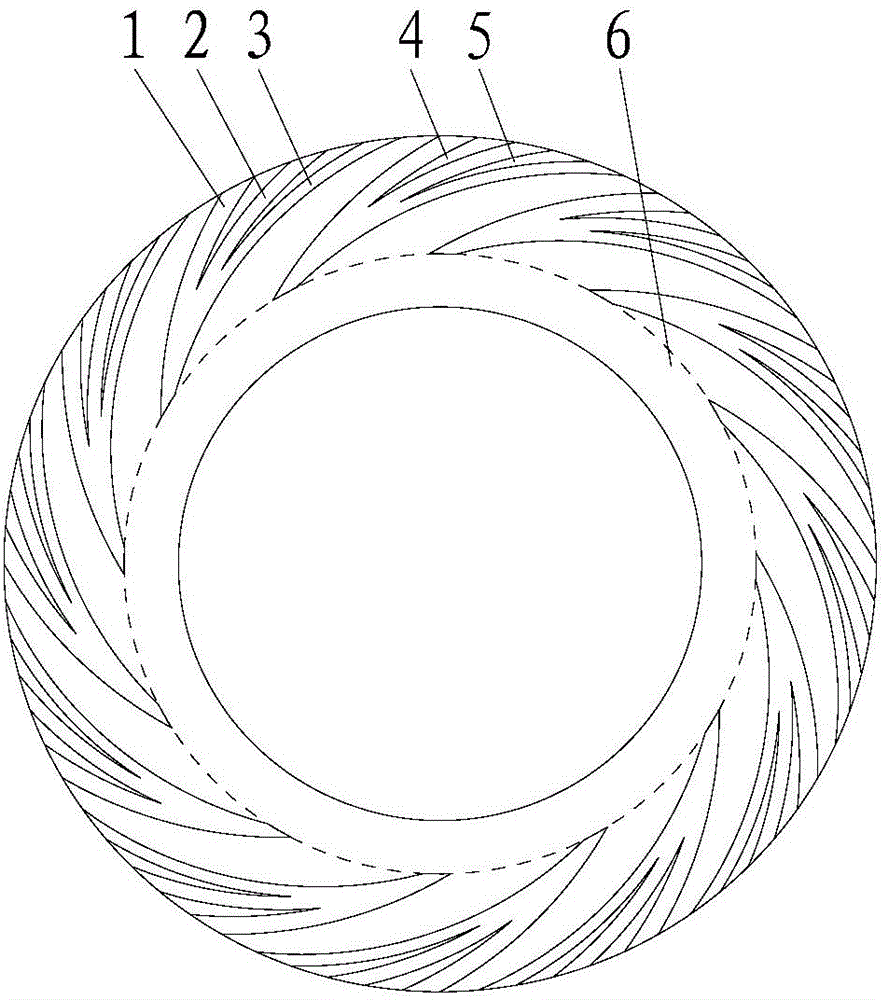

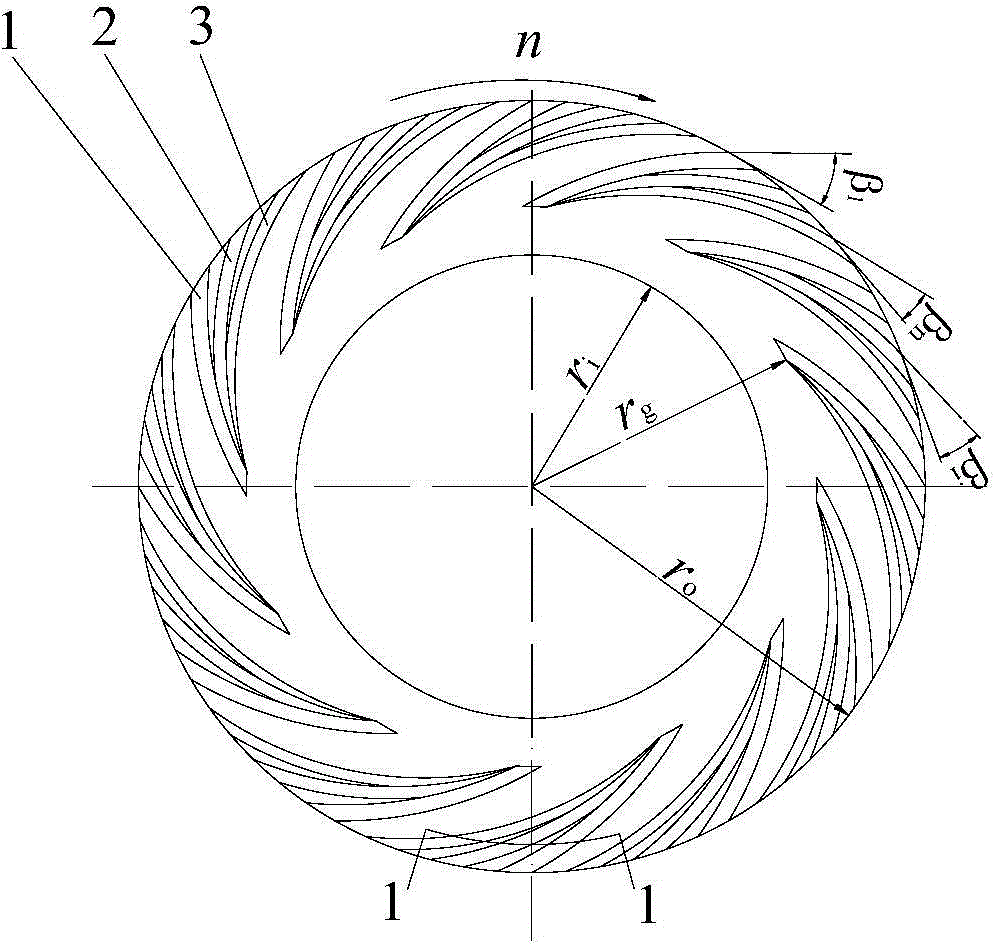

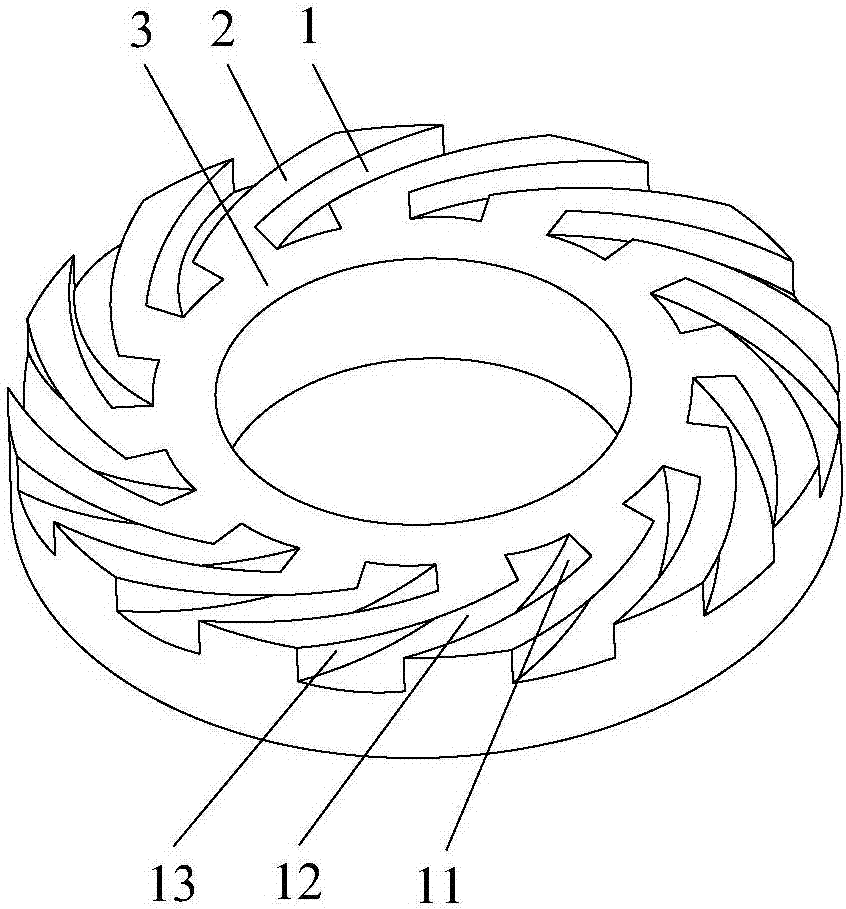

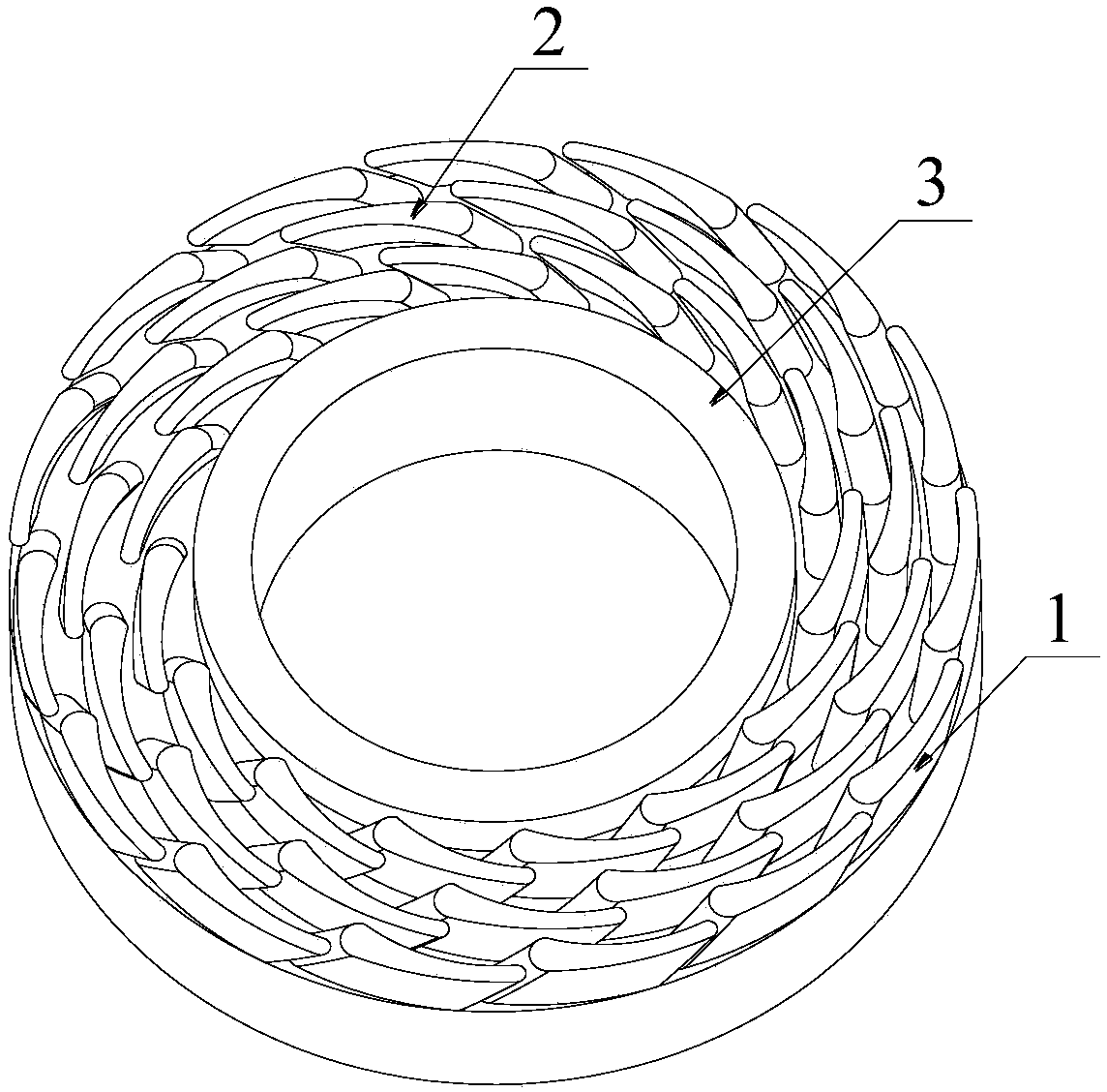

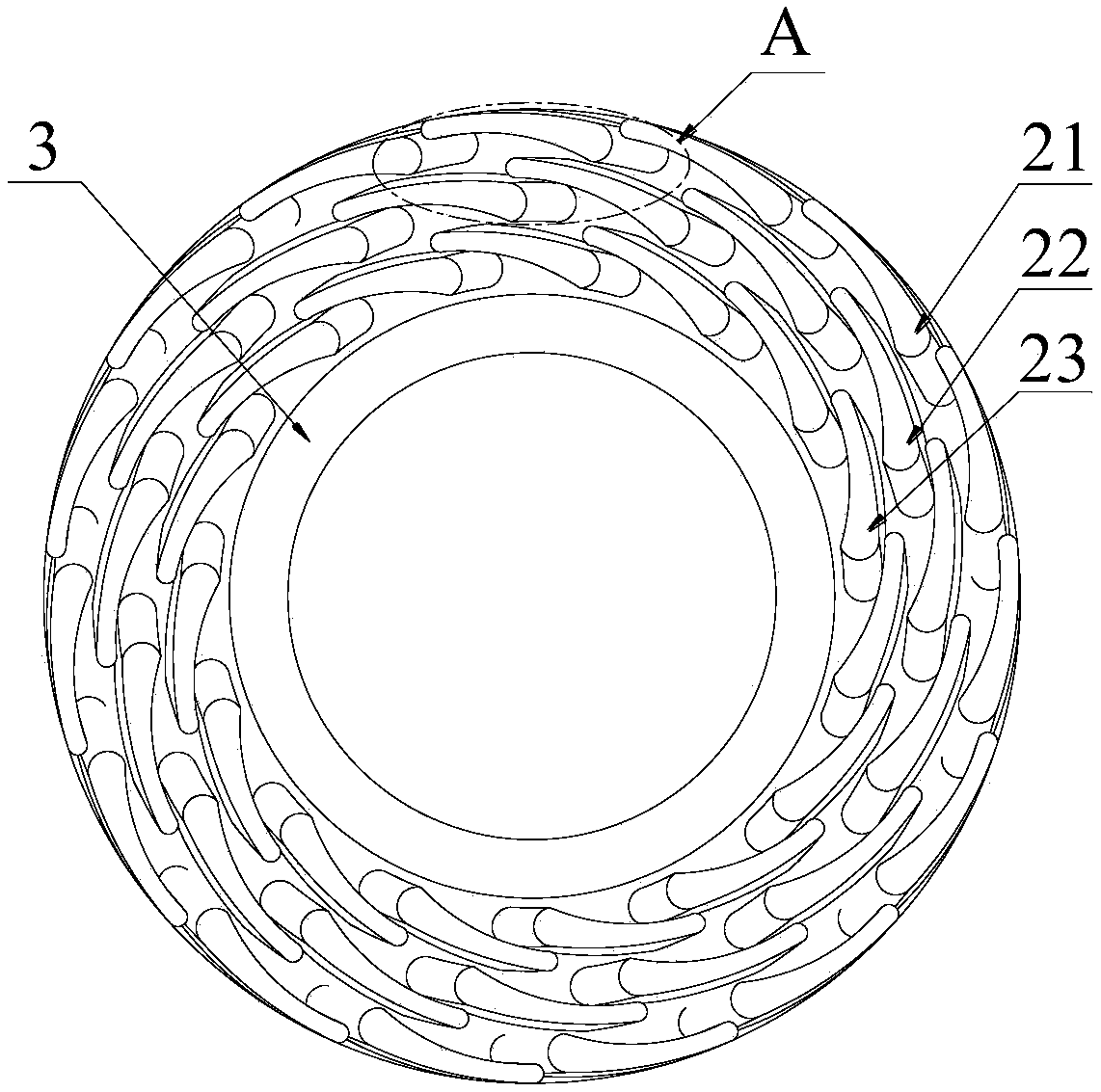

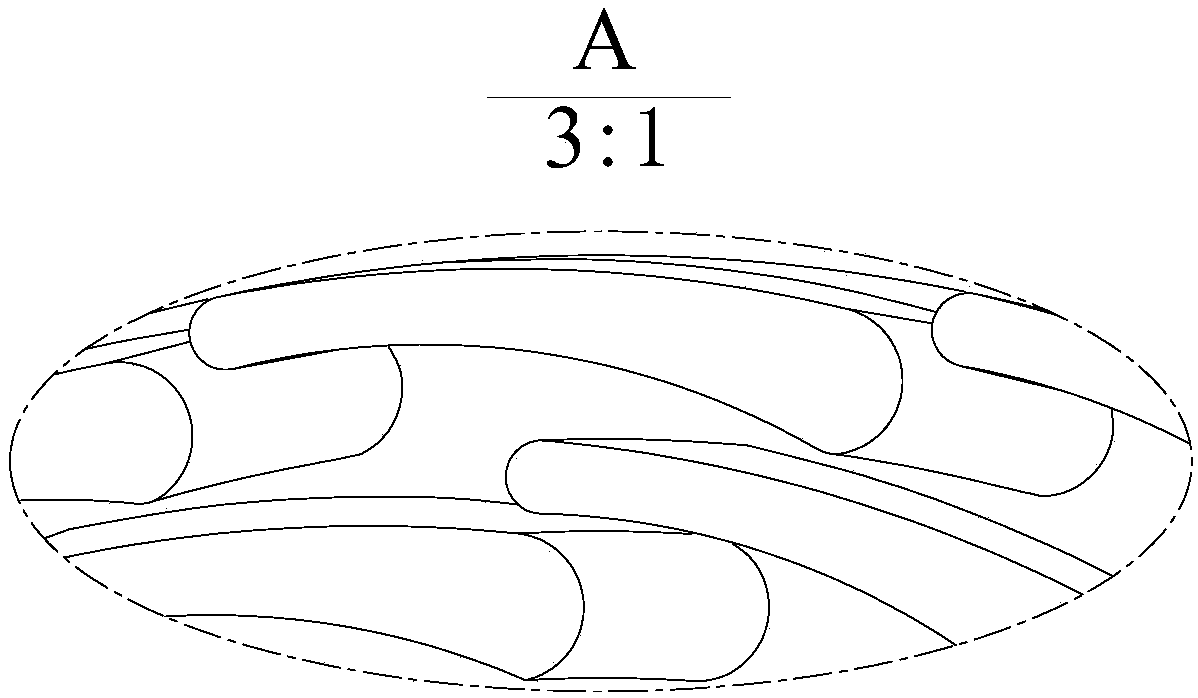

Bird-wing-imitated multichannel groove end face seal structure

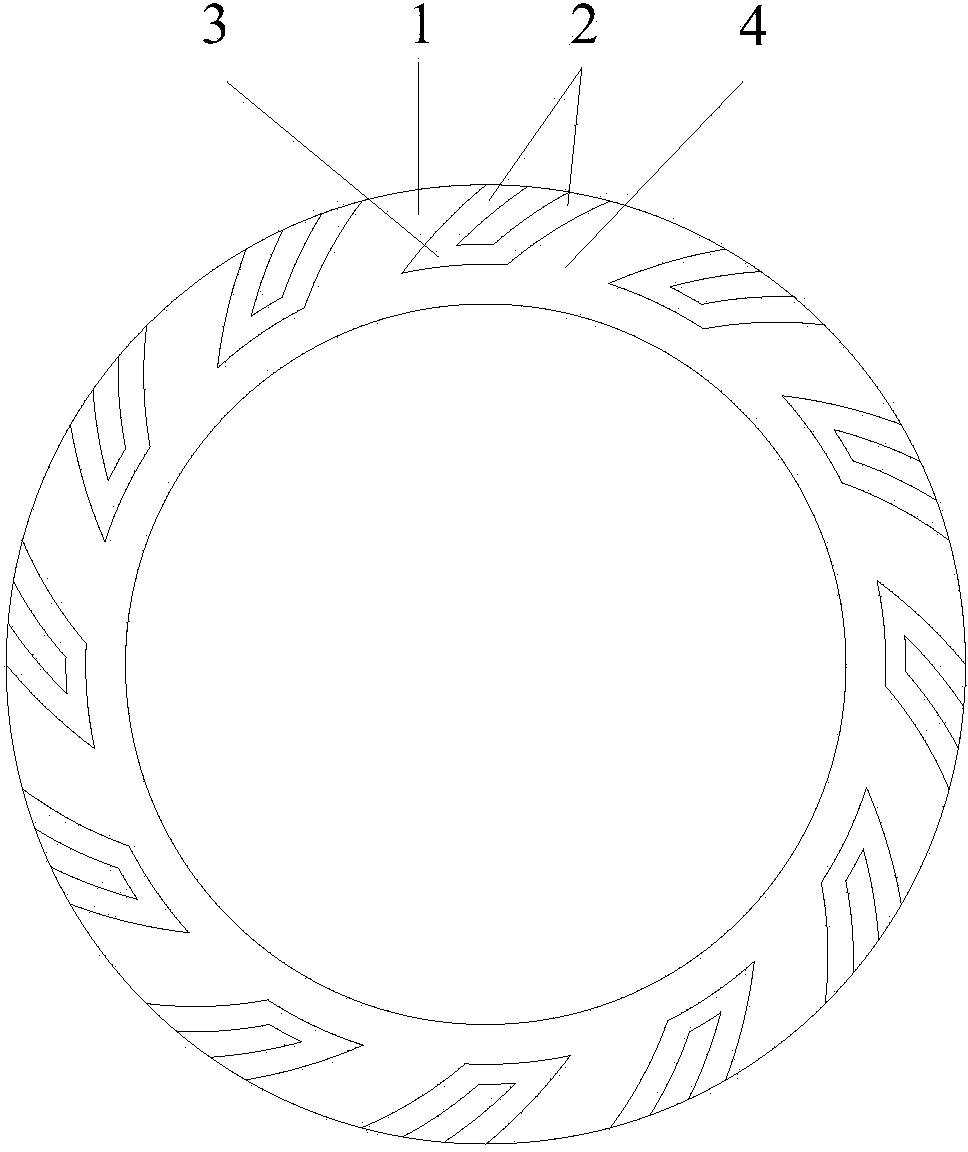

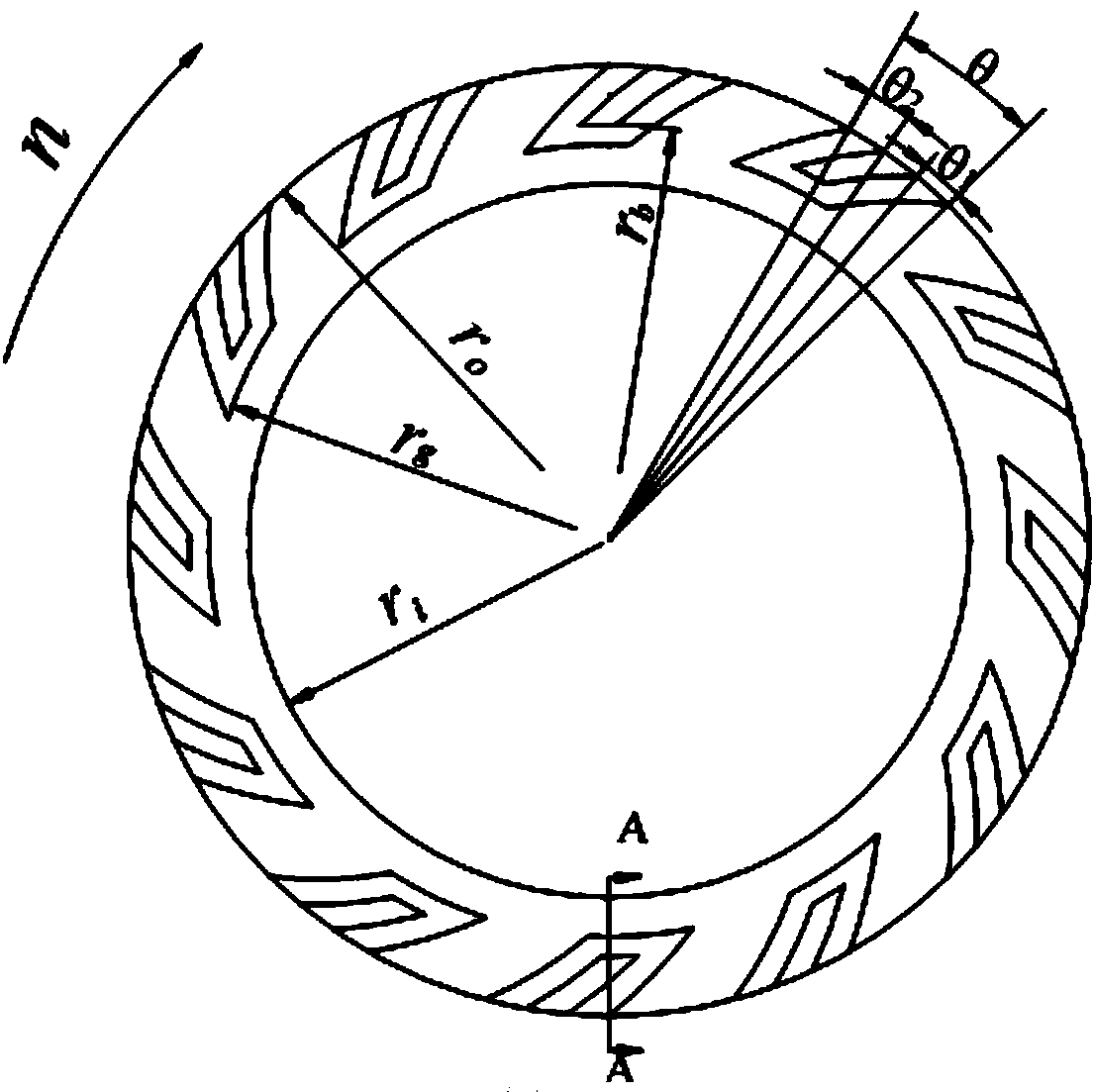

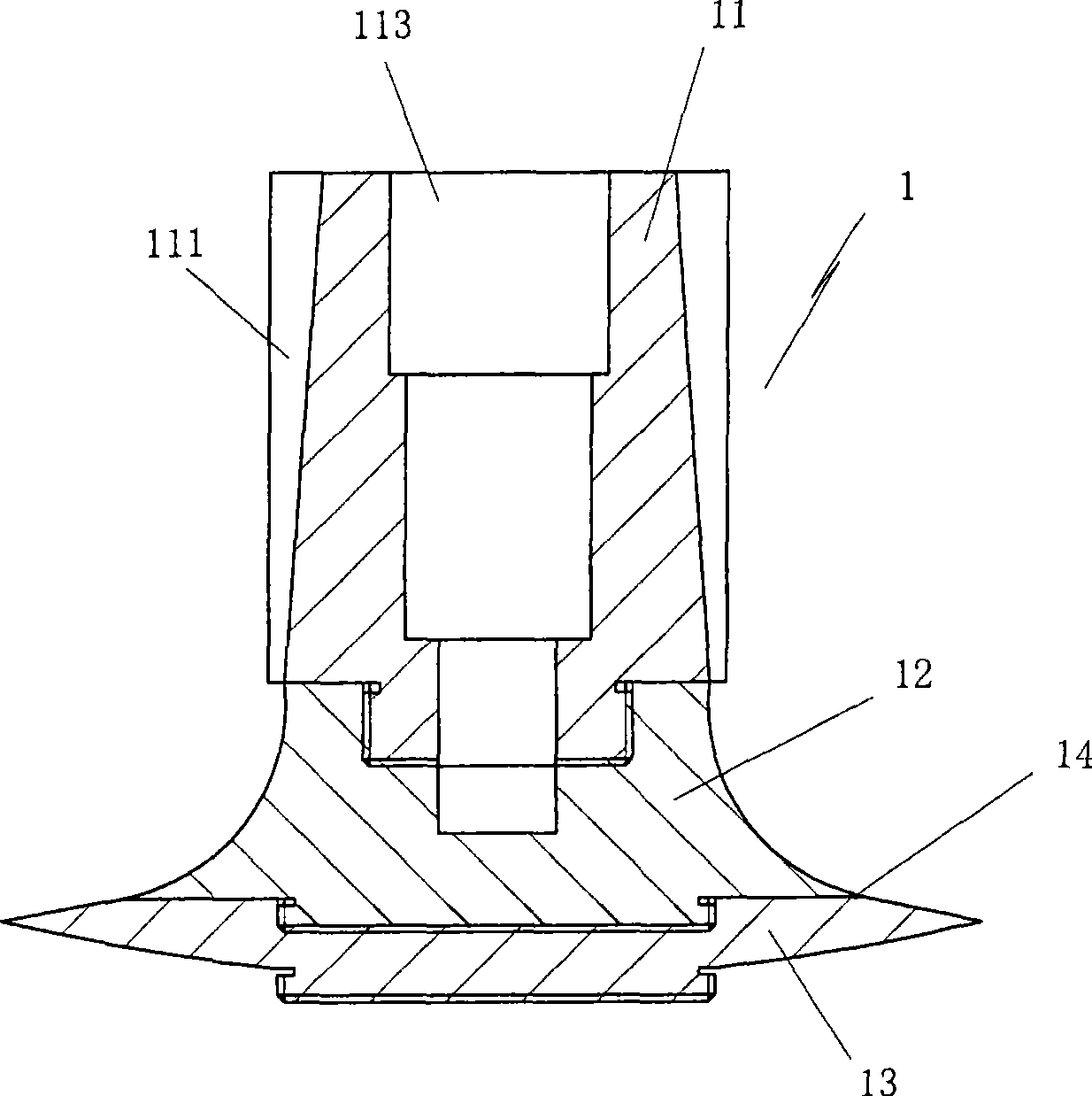

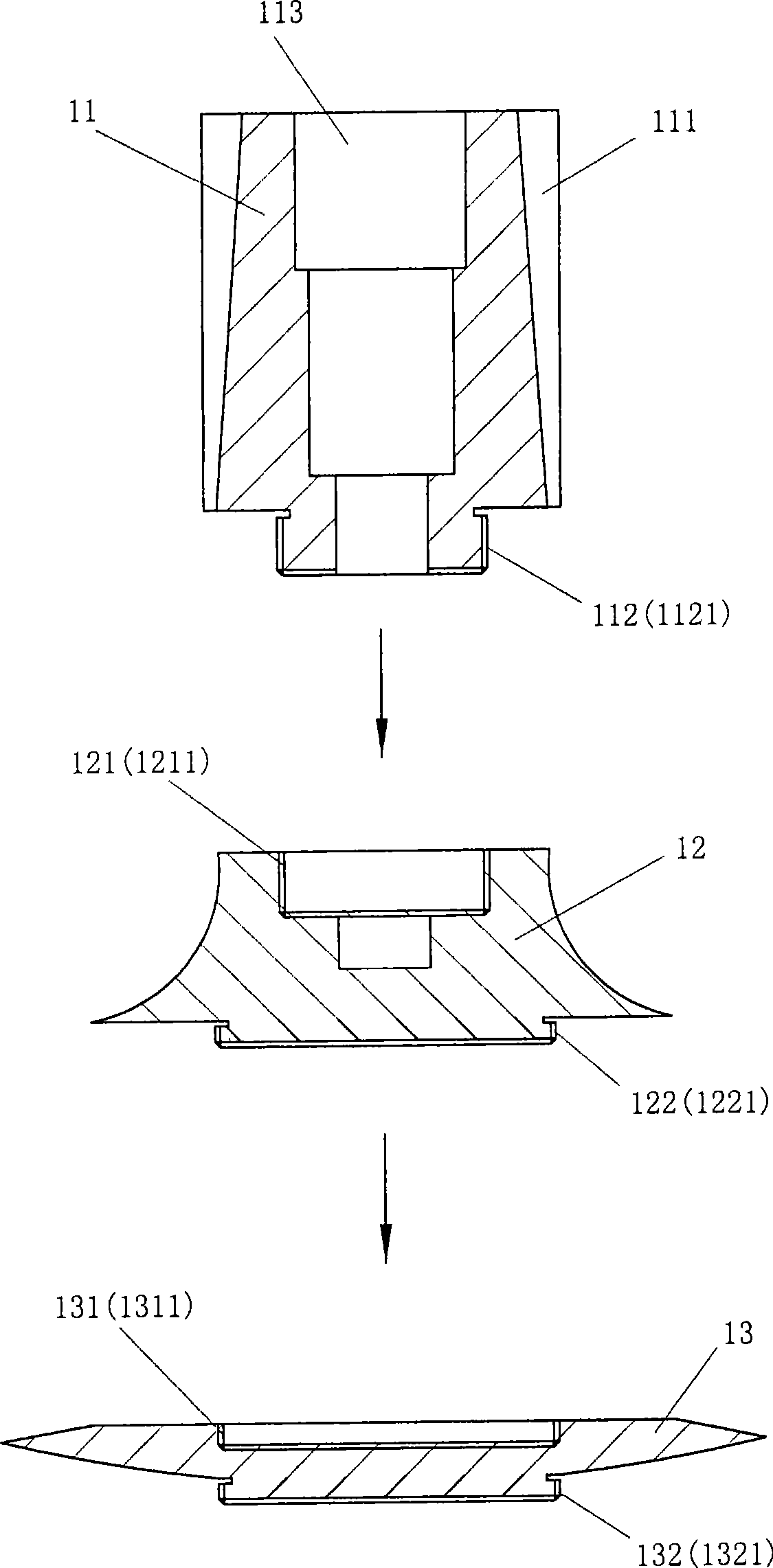

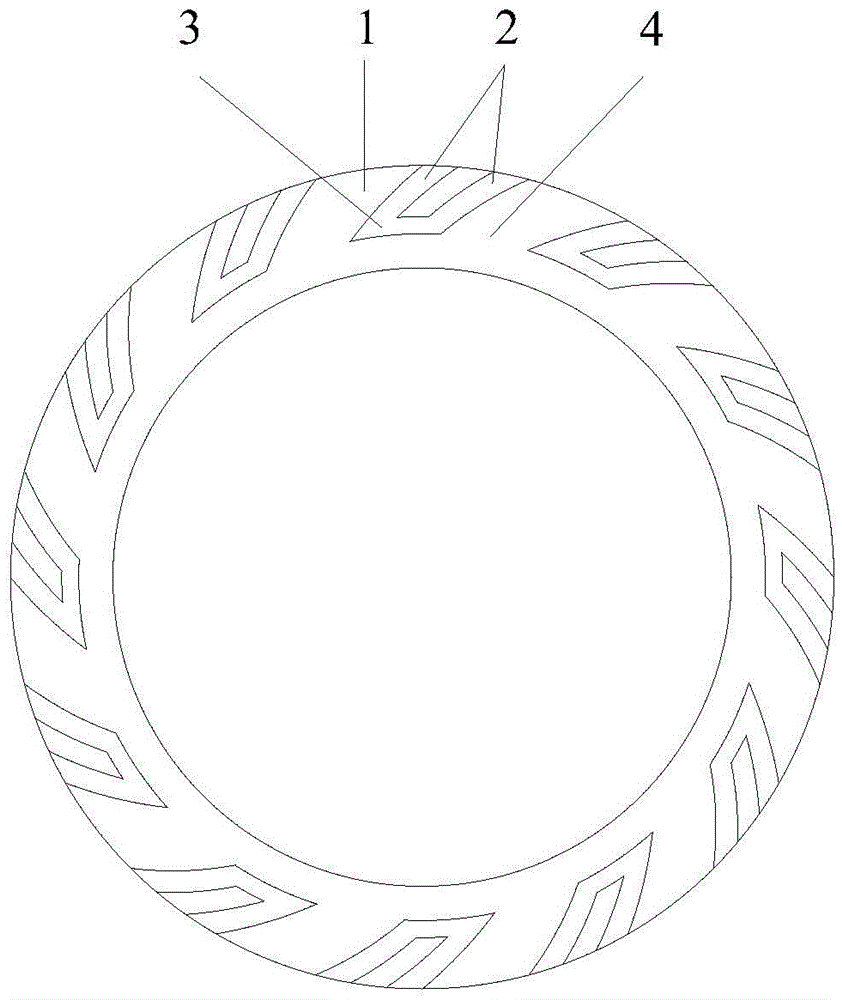

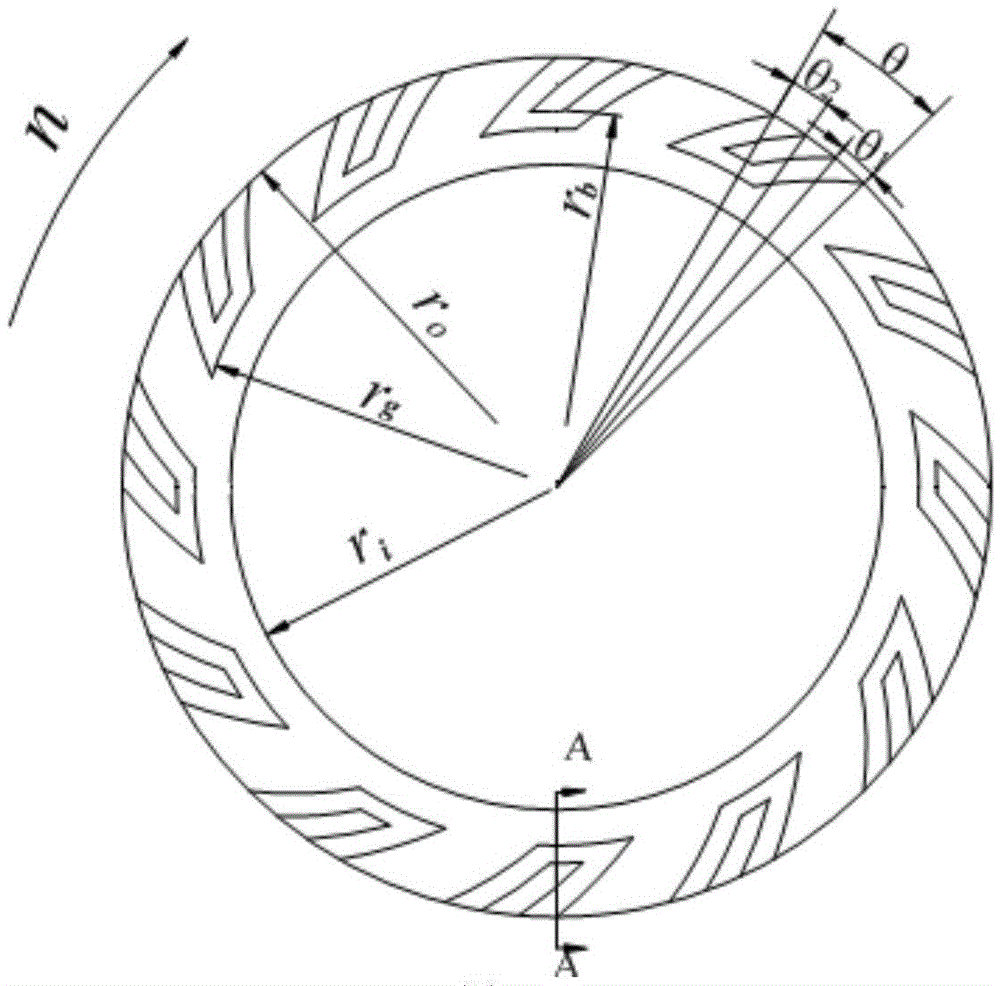

A bird-wing-imitated multichannel groove end face seal structure comprises a movable ring and a static ring which are mechanical seal rings. The end face of at least one of the movable ring or the static ring is provided with a plurality of bird-wing-imitated multichannel grooves which are evenly distributed along the circumference, and the bird-wing-imitated multichannel grooves are located on the medium high-pressure side, namely upstream. Each bird-wing-imitated multichannel groove comprises at least two draining grooves and at least one arc groove, each arc groove is located on the downstream side of the draining grooves and communicated with the same, the draining grooves are communicated with the medium high-pressure side or the upstream and evenly and circumferentially distributed, and every two draining grooves are separated by an unslotted seal weir. A ring formed on the circumferential unslotted area of the end face is a seal dam which is located on the low-pressure side of the end face, namely downstream. The bird-wing-imitated multichannel groove end face seal structure is high in end face static pressure effect, low in energy consumption, stable in operation at low speed, low in leakage amount, excellent in anti-interference performance, and especially suitable for non-contact dry gas seal of equipment such as reaction kettles and stirrers.

Owner:ZHEJIANG UNIV OF TECH

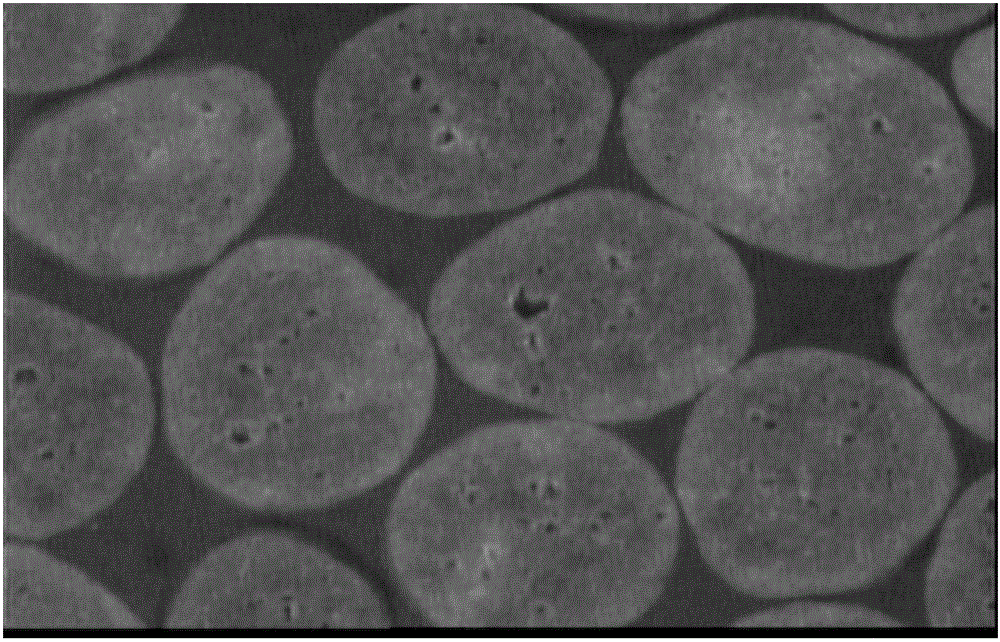

Double-layer high-strength fracturing propping agent and preparing method thereof

ActiveCN105131934AHigh compressive strengthReduce breakage rateFluid removalDrilling compositionSolubilityApparent density

The invention discloses a double-layer high-strength fracturing propping agent and a preparing method thereof and belongs to the technical field of oil (gas) extraction auxiliaries. The fracturing propping agent comprises a ceramic inner core and a silicon nitride ceramic shell wrapped on the surface of the ceramic inner core. The proportion of the diameter of the ceramic inner core and the thickness of the silicon nitride ceramic shell is 5-10:1. The ceramic inner core is mainly prepared from, by mass, 40%-50% of bauxite, 40%-50% of shale and 0-10% of gangue. The silicon nitride ceramic shell is mainly prepared from, by mass, 60%-70% of silicon nitride and 30%-40% of bauxite. The double-layer high-strength fracturing propping agent has the advantage of high tensile strength, the low breaking rate, low apparent density, the high corrosion resistance capability and the like, the breaking rate is smaller than 6% under the condition of 103 Mpa, the acid solubility is smaller than 2%, and the double-layer high-strength fracturing propping agent is particularly suitable for development of deep well and ultra-deep well oil and gas fields.

Owner:HENAN TIANXIANG NEW MATERIALS

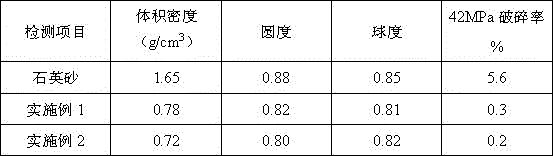

Ultralow-density petroleum fracturing propping agent and preparation method thereof

InactiveCN105567214AIncrease productionHigh strengthFluid removalDrilling compositionHigh pressureUltimate tensile strength

The invention belongs to the technical field of petroleum fracturing propping agents and preparation methods thereof, and particularly relates to an ultralow-density petroleum fracturing propping agent and a preparation method thereof. The technical problems that an existing petroleum fracturing propping agent is low in strength, poor in anti-corrosion capacity and weak in flow guiding capacity are mainly solved. The ultralow-density petroleum fracturing propping agent is prepared by taking multiple raw materials such as bauxite waste tailings, leftover materials and manganese powder as raw materials through multiple processes such as breaking, grinding, granulating and high-temperature sintering and has the advantages of resisting high temperature and high pressure, being high in strength and flow guiding capacity, resisting corrosion and the like.

Owner:沁源县元昌特材有限公司

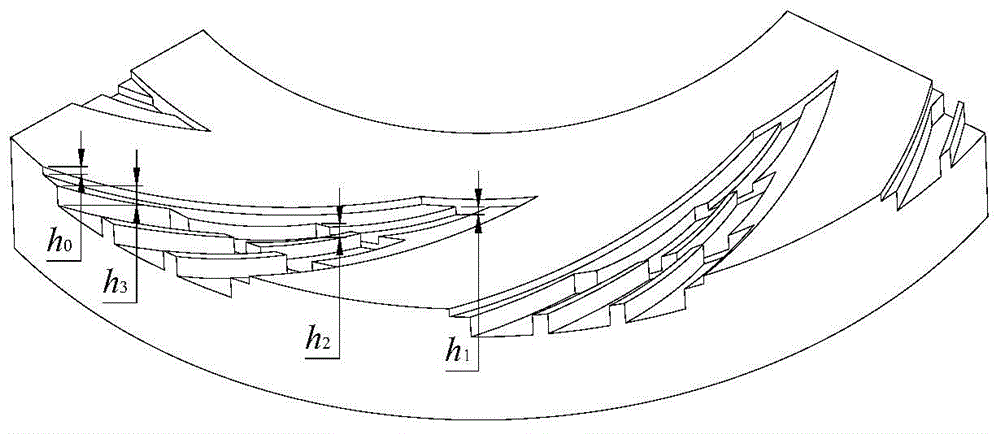

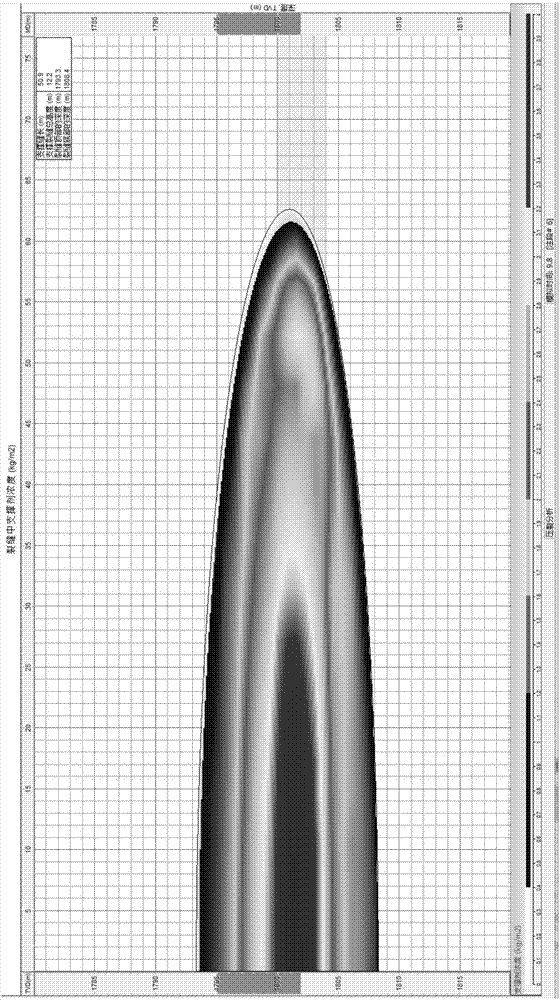

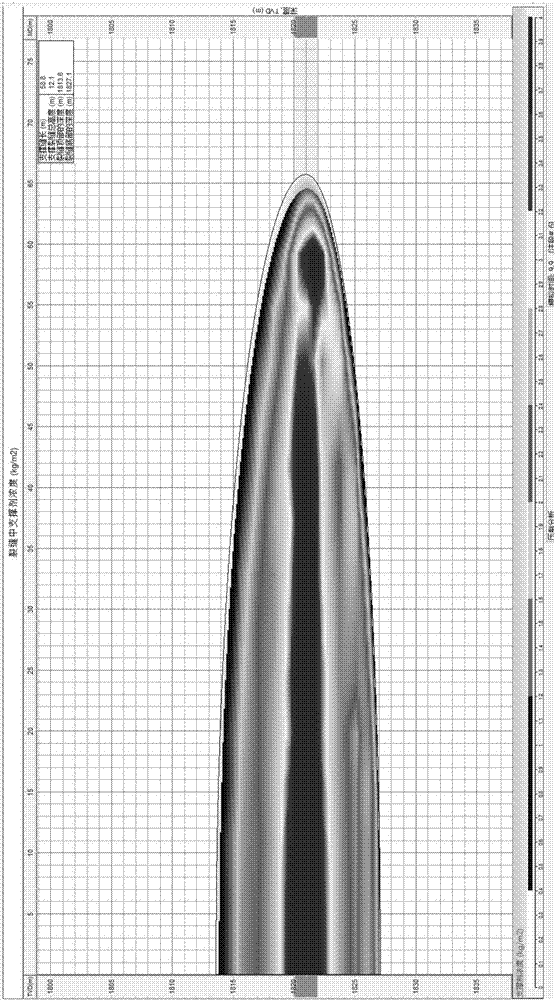

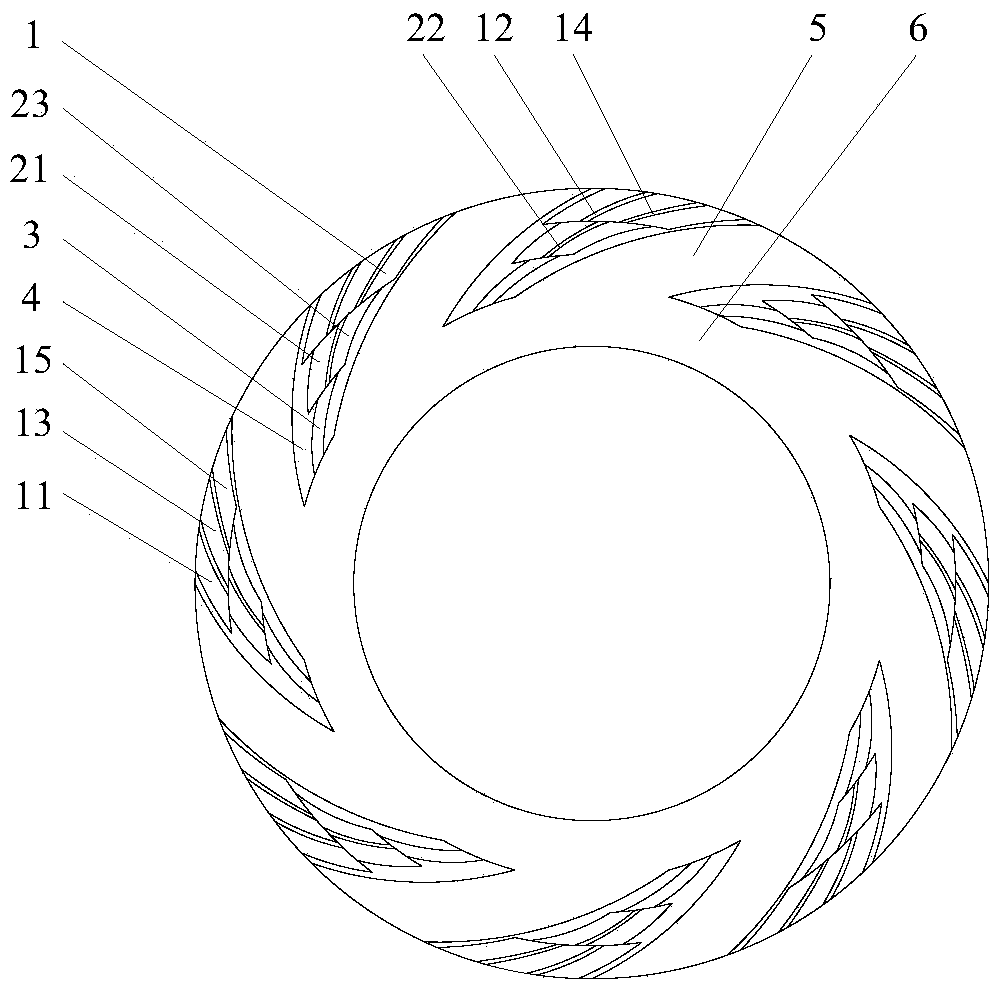

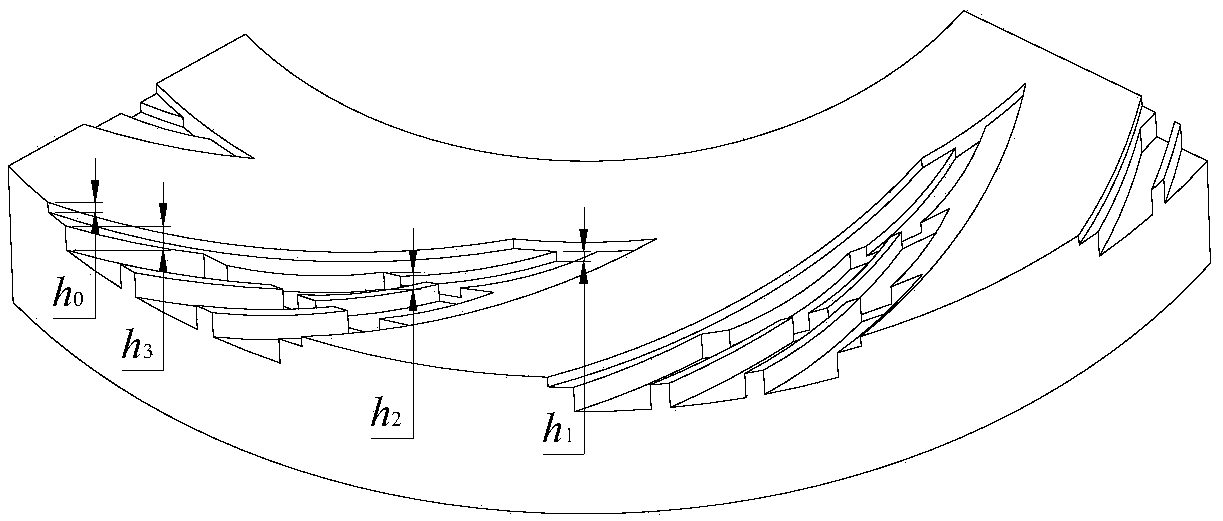

Mechanical sealing structure of gas lubricating end face with human pyramid-like combined groove deep grooves

ActiveCN104913066AStrong pumping actionLarge End Face Capacity and Fluid Film StiffnessEngine sealsEngineeringMechanical engineering

A mechanical sealing structure of a gas lubricating end face with human pyramid-like combined groove deep grooves comprises a moving ring and a static ring which are in mechanical seal. The end face of at least one seal ring between the moving ring and the static ring is provided with a plurality of human pyramid-like combined groove deep grooves spirally evenly distributed in the circumferential direction, and the human pyramid-like combined groove deep grooves are gradually narrowed from the upstream part to the downstream part. The human pyramid-like combined groove deep grooves are composed of basic dynamic pressure grooves and human pyramid-like grooves. The bottom surfaces of the basic dynamic pressure grooves are provided with the human pyramid-like grooves, and the depths of the human pyramid-like grooves become shallow gradually from the upstream part to the downstream part. The human pyramid-like grooves are formed by splicing multiple rows of sub-grooves, the adjacent sub-grooves on the same row are separated through sealing weirs with the depths equal to that of the basic dynamic pressure grooves, the sub-grooves on one downstream side stride over the sealing weirs between two sub-grooves of adjacent rows on the upstream side and are communicated with the sub-grooves on the two sides of the sealing weirs on the upstream side, and a sealing dam is arranged on the downstream part of the end face.

Owner:ZHEJIANG UNIV OF TECH

Strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure

The invention discloses a strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure. Ternary bending torsion micro convexes arranged in the circumferential direction according to the center of the end face to form ring belts are machined on the end face of a movable ring or a static ring of a mechanical seal; each ternary bending torsion micro convex is a micro cylinder with the cross section in the wing shape; and relative torsion exists between every two adjacent cross sections on the ternary bending torsion micro convexes. The long axes of the cross sections of the ternary bending torsion micro convexes are arranged in the circumferential direction of the end face; the short axes of the cross sections of the ternary bending torsion micro convexes are arranged in the radial direction of the end face; the end face of the leeward side of the front micro convex on the ring belts is located on the inner side of the end face of the windward side of the back micro convex; a ring direction flow channel is formed between every two adjacent rows of ring belts, and fluid flows into the ring direction flow channels through the micro convexes and generates strong vortex in the ring direction flow channels; every two adjacent rows of ring belts of the ternary bending torsion micro convexes are arranged in a staggered manner; and the position, close to the leakage side, on the sealed end face is provided with an annular sealing dam; and the height of the sealing dam is equal to that of the ternary bending torsion micro convexes.

Owner:ZHEJIANG UNIV OF TECH

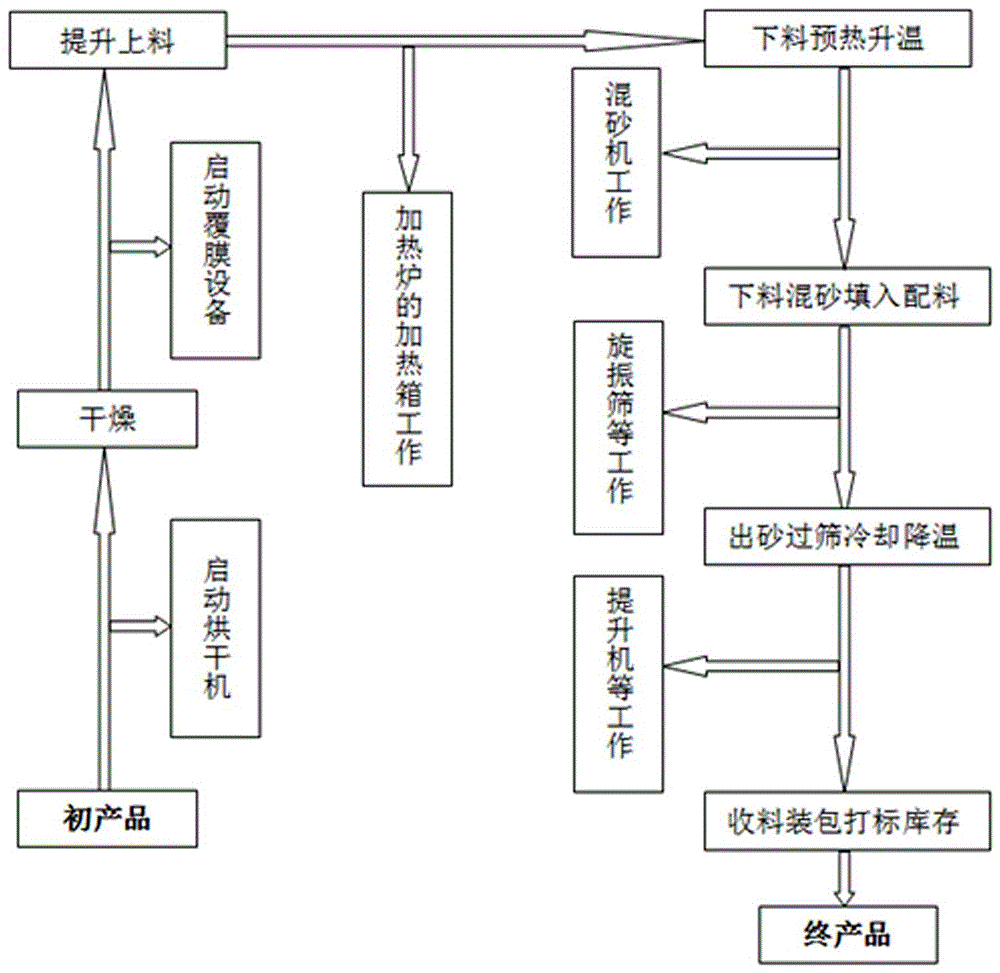

Preparation method of low-density high-intensity film covering ceramic support agent

InactiveCN106278349ALow densityIncreased crush strengthFluid removalDrilling compositionFreeze-dryingPotassium

The invention relates to a preparation method of a low-density high-intensity film covering ceramic support agent, and belongs to the technical field of fracturing support agents. By aiming the problems of high density and high crushing rate of the existing ceramic particle support agent, the invention provides the preparation method of the low-density high-intensity film covering ceramic support agent. According to the method, coal gangue with low aluminum oxide contents is used; flint clay is used for replacing high-alumina bauxite to be used as raw materials of the ceramic particle support agent; potassium feldspar is added to be used as a fusing assistant; crushing and ball milling are performed; after the sufficient mixing, the water is added to prepare slurry; the slurry is dripped into liquid nitrogen; condensing and forming are performed; freeze drying is performed to prepare ball blank particles with good sphericity and roundness; the ball blank particles are subjected to high-temperature sintering and resin coating; the low-density high-intensity film covering ceramic support agent is prepared. The prepared ceramic support agent has the advantages of low density, high intensity and low crushing rate, and has wide application prospects.

Owner:袁春华

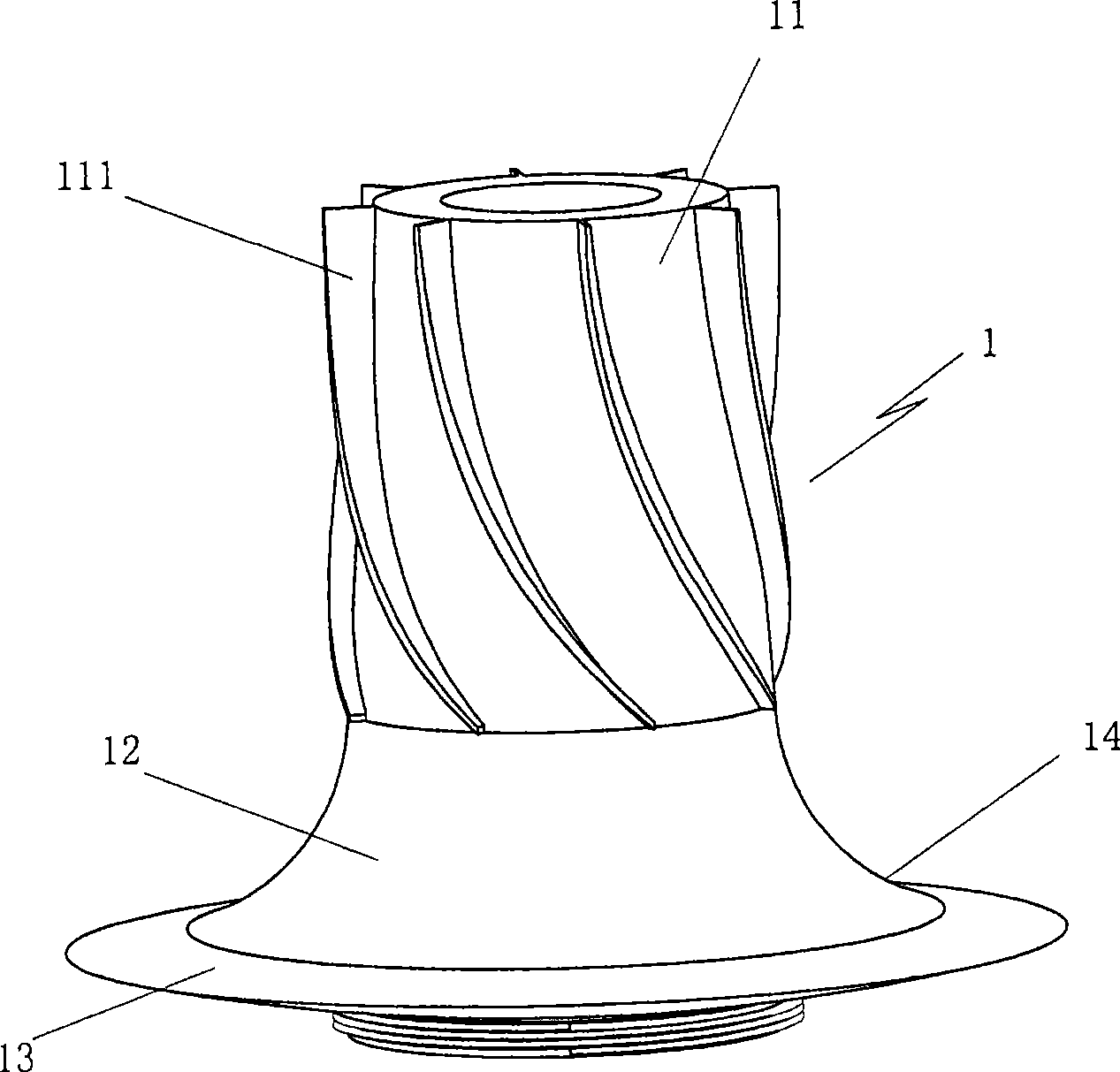

Entrance guiding cone used for vertical oil-gas mixing transmission pump

InactiveCN101532504AEffective groomingEffective rectificationPump componentsPumpsWork performanceEngineering

The invention provides an entrance guiding cone used for a vertical oil-gas mixing transmission pump, the guiding cone is arranged at the center of the cavity of the vertical oil-gas mixing transmission pump uniform blender and positioned at the entrance of the mixing transmission pump; the guiding cone is at least constructed by a guiding cone body, a round diversion pad and a guiding cone base tightly connected with each other in sequence from top to bottom; the lateral periphery of the guiding cone is distributed with diversion vanes used for diverging the direction of the multi-phase fluid; the lateral periphery of the guiding cone base and the diversion pad are consecutive streamline surface; and the lower part of the guiding cone base is connected with the shell of the mixing transmission pump uniform blender. The guiding cone uses the diversion vanes to commutate oil-gas multi-phase fluid to be fit for entering the mixing transmission pump pressurizing unit to guarantee the normal work of the pressurizing unit, thus ensuring that the oil-gas mixing transmission pump operates stably and safely, and the work performance of the vertical oil-gas mixing transmission pump can be optimal.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

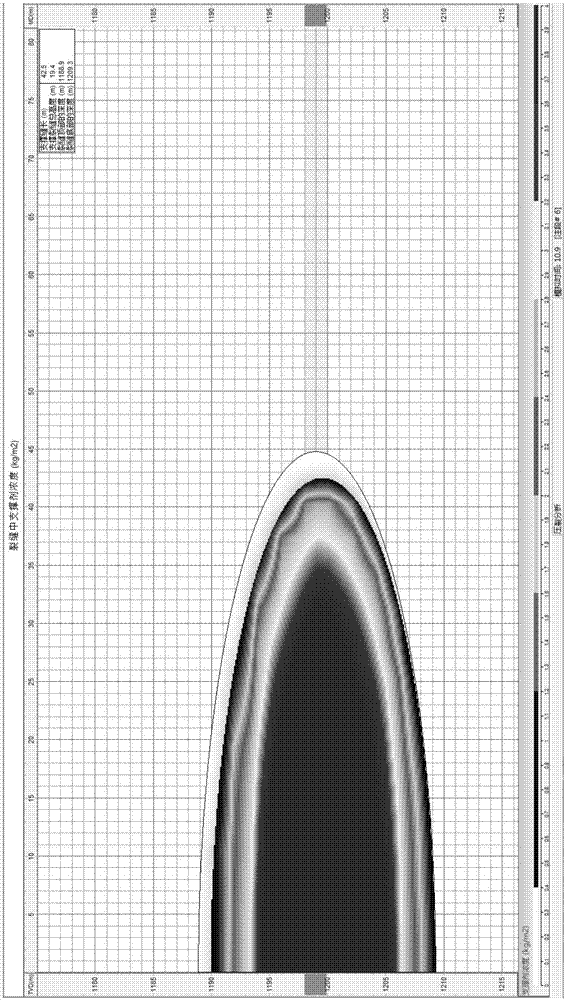

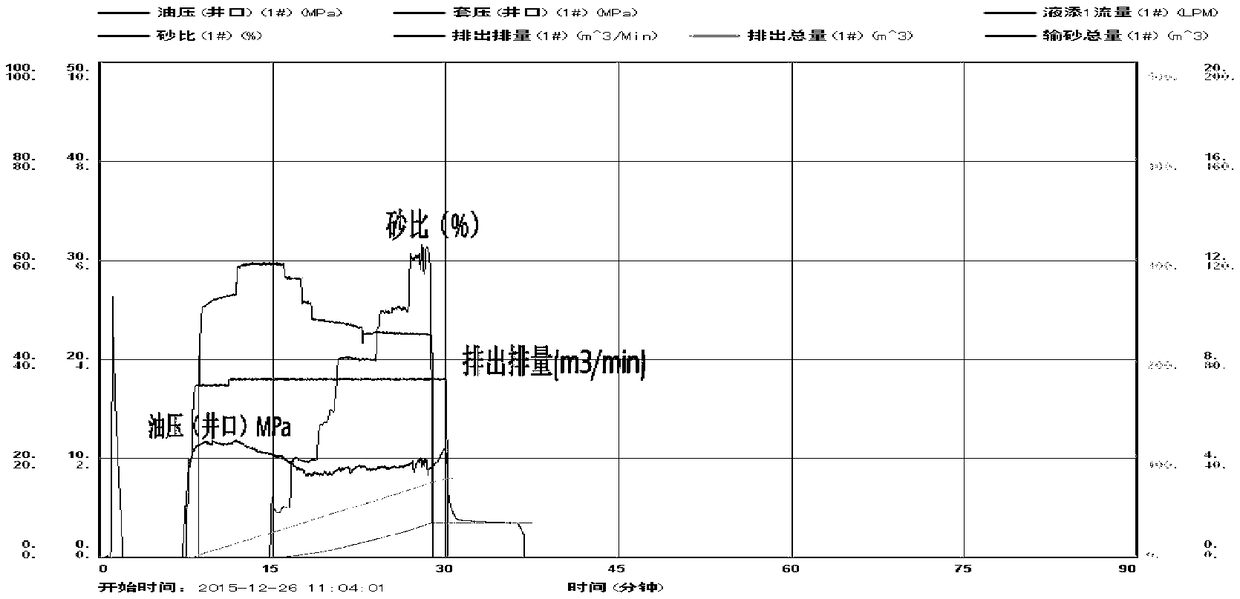

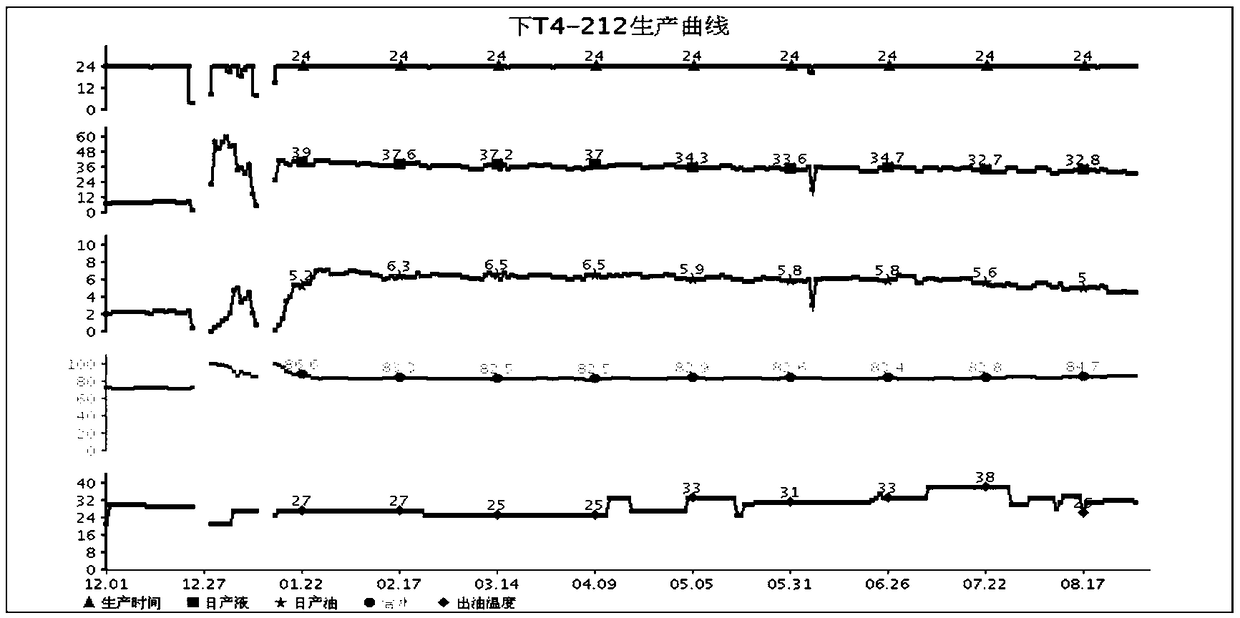

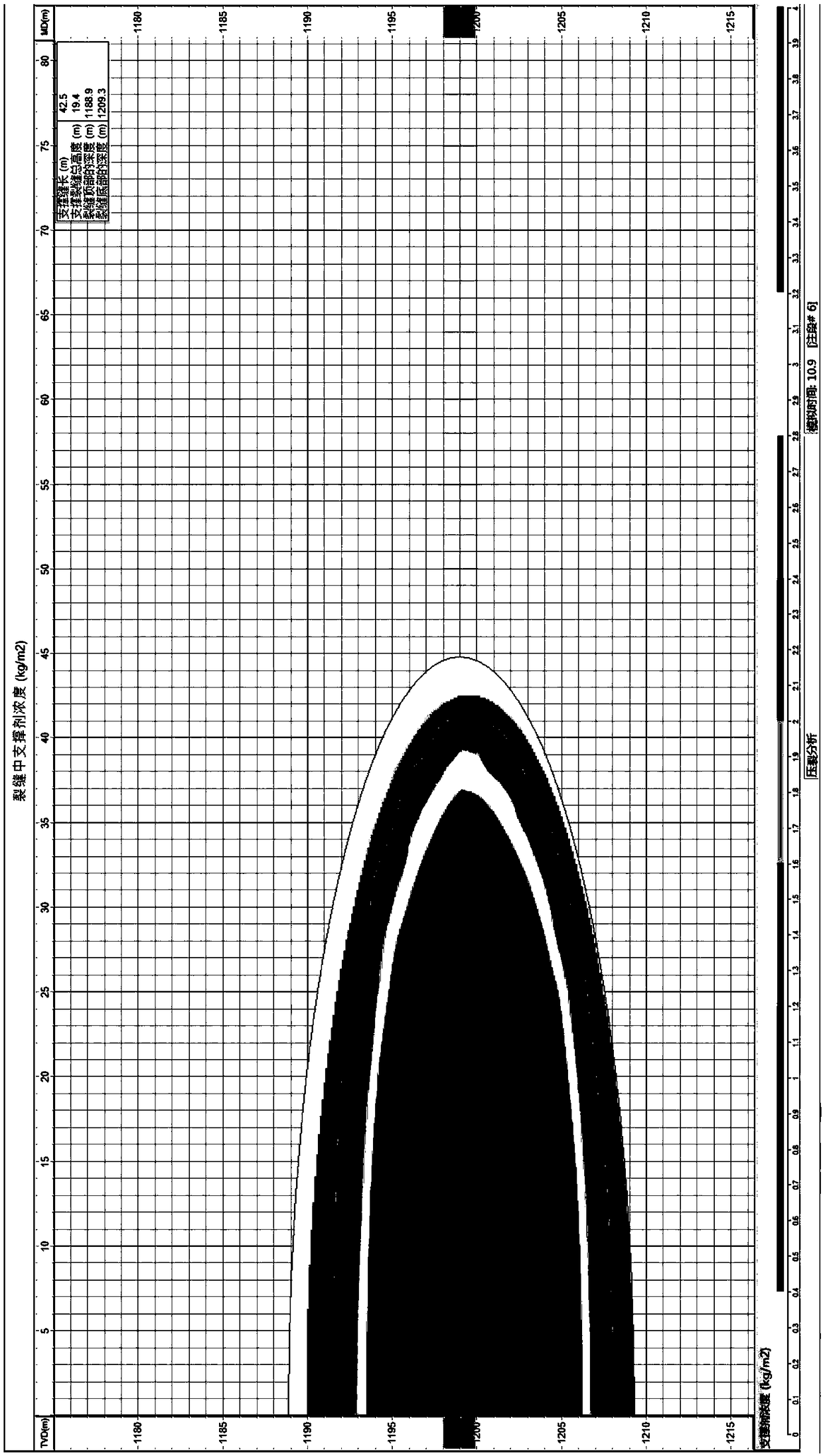

Blockage-removing method for polymer flooding blocking wells

ActiveCN106958438AReduce the impactImprove diversion capacityFluid removalDrilling compositionOil wellPolymer flooding

The invention relates to a blockage-removing method for polymer flooding blocking wells, and belongs to the field of fracturing reformation of oil wells. The blockage-removing method includes the steps of conducting fracturing construction to an blocked oil layer caused by polymer injection and controlling the length of an artificial fracture to 40-60 m, and the height to no more than 20 m, specifically, the fracturing construction is small-scale fracturing construction by sequentially injecting stratum treating fluid with a volume of 10-35 m3, injecting ahead fluid with a volume of 10-30m3, injecting particle loaded fluid with a volume of 40-60 m3, and injecting displacing fluid with a volume of 8-16m3. By reasonable selection of the polymer flooding to block wells, the pertinency and effectiveness of subsequent fracturing measure reformation are improved; by control of the length and the height of the artificial fracture, not only the permeability of a polymer blocked oil layer in near bore zones and effectiveness of the measures are improved, but also wastes of materials and labor cost caused by an excessive large construction scale are avoided, the validity of fracturing blockage-removing measures is increasingly prolonged, and the reservoir recovery is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

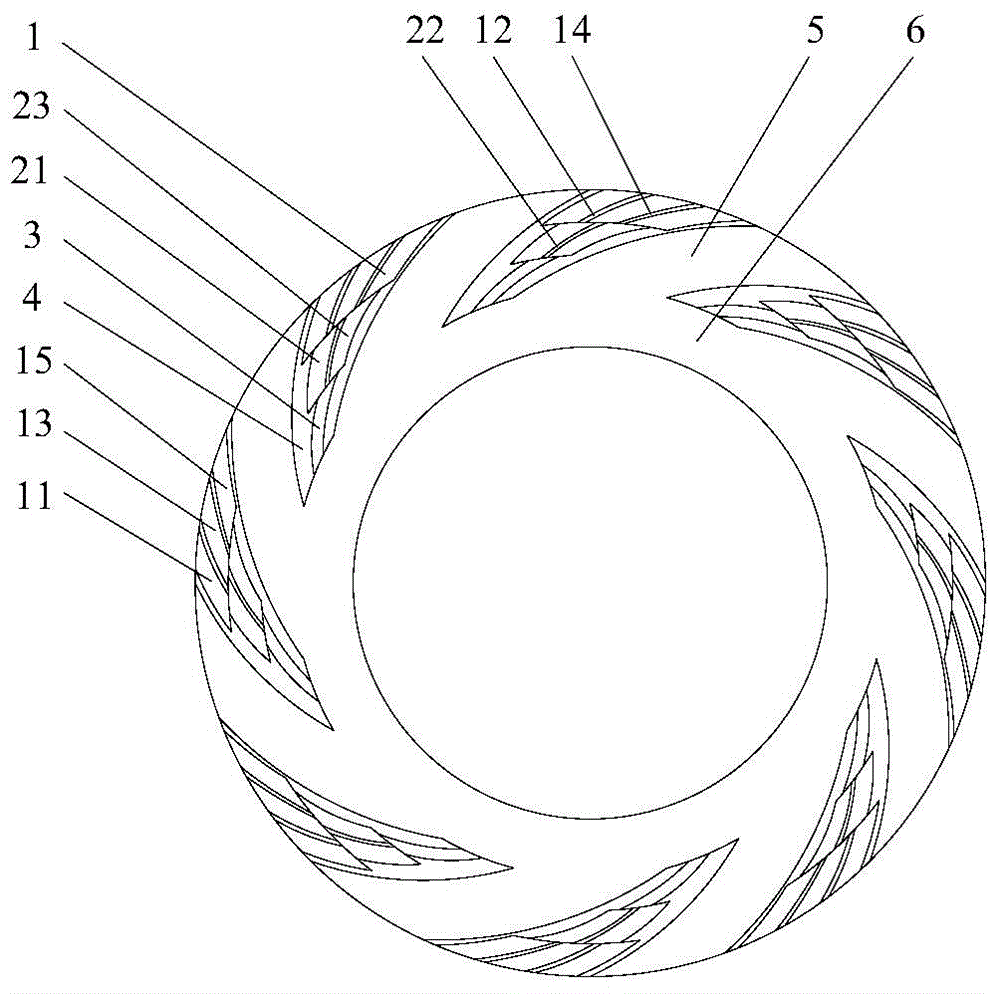

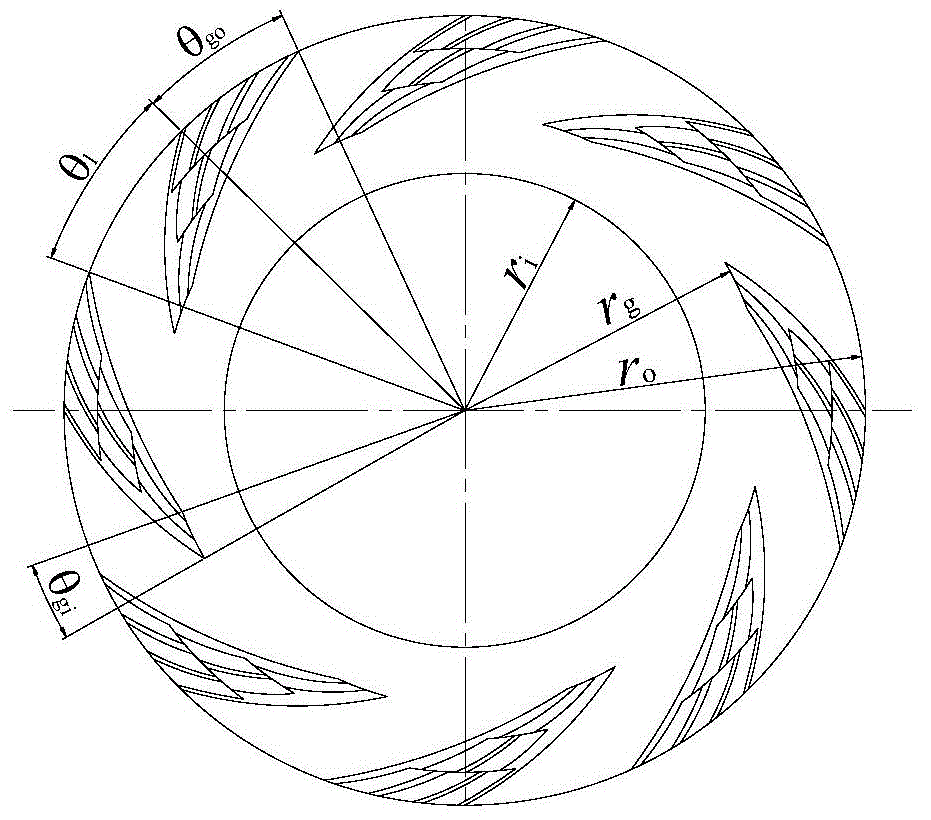

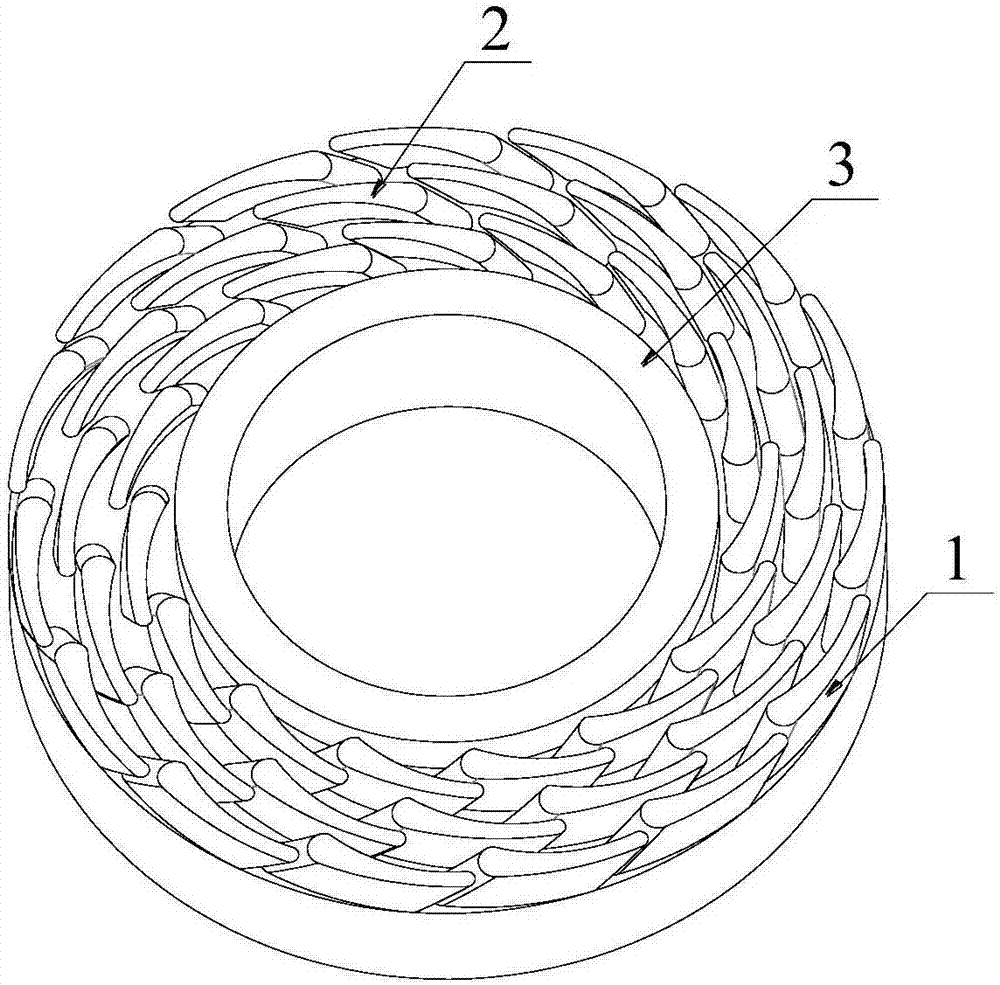

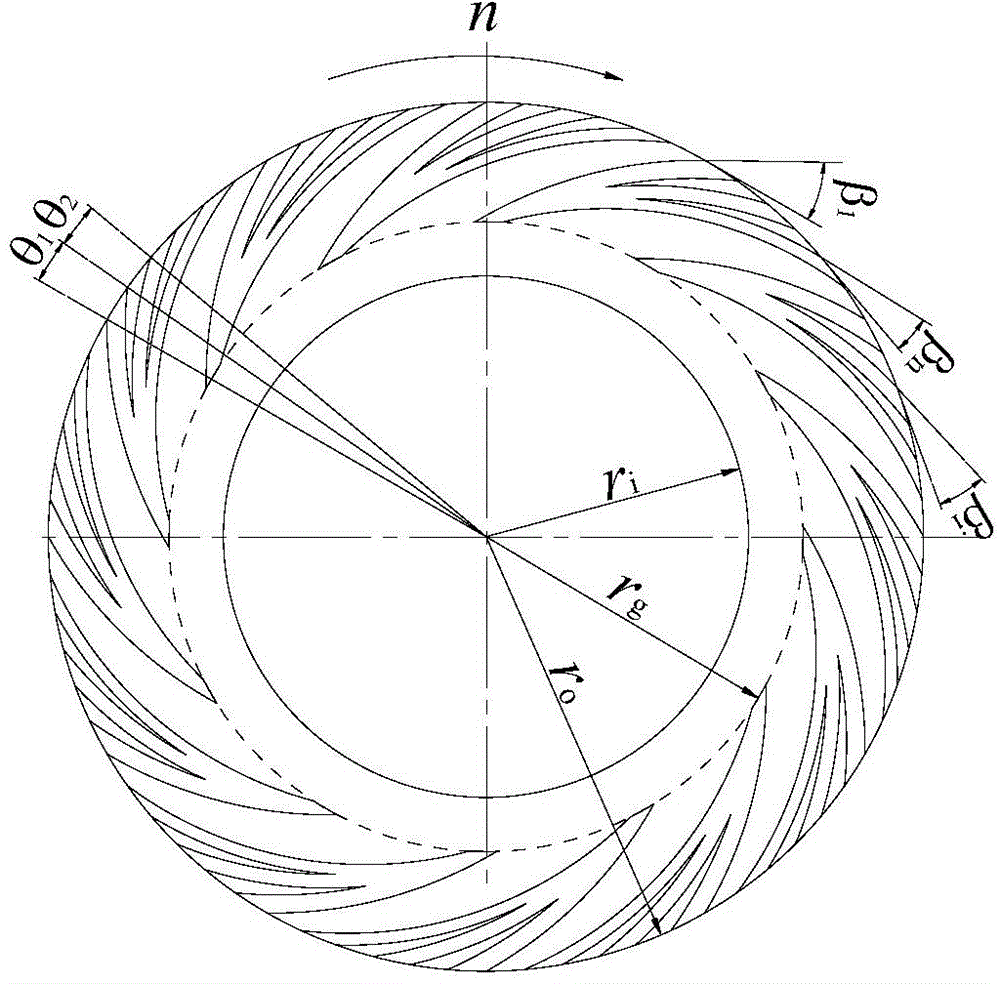

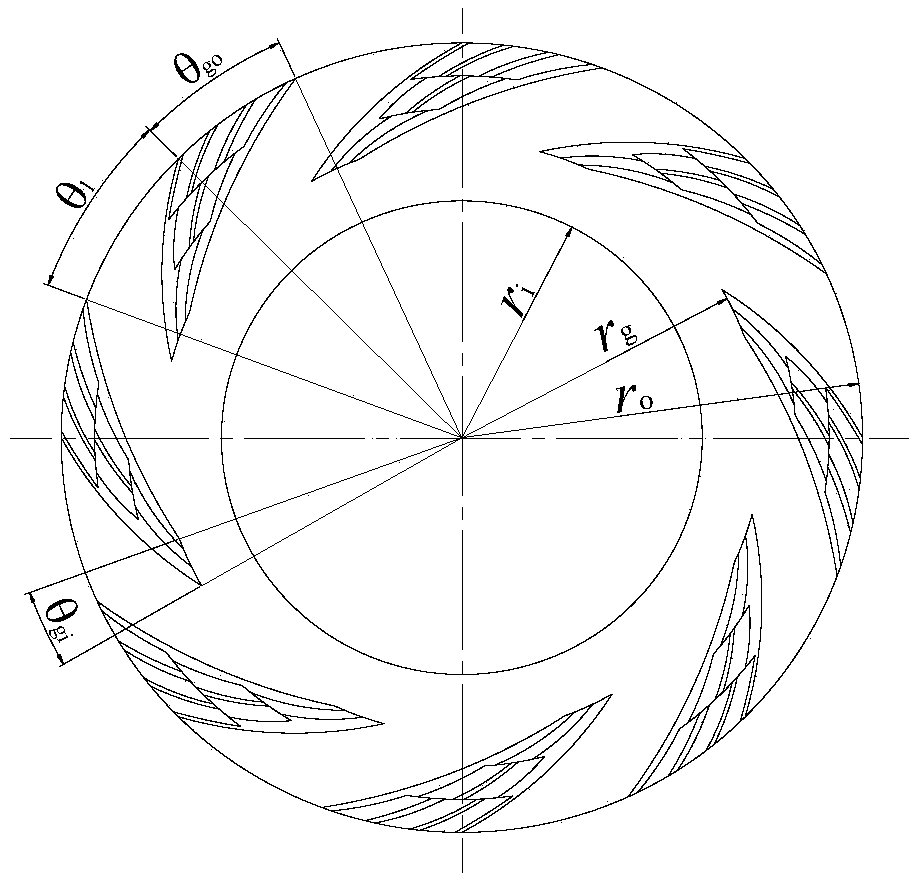

Gas lubrication cluster spiral groove end face mechanical sealing structure

InactiveCN104896099AStrong convergence propertiesImprove compression performanceEngine sealsLow speedGas lubrication

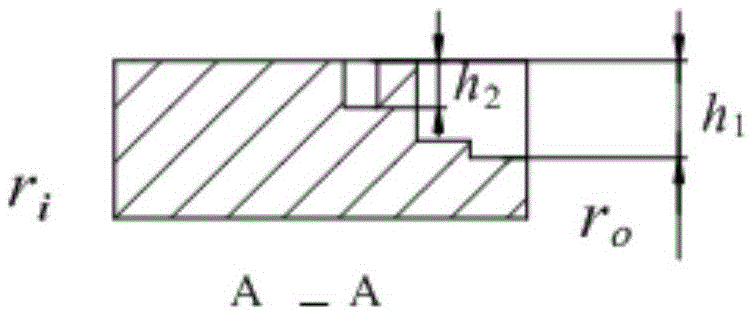

A gas lubrication cluster spiral groove end face mechanical sealing structure comprises a moving ring and a stationary ring of a mechanical seal. One side of the end face of the moving ring and one side of the end face of the stationary ring are high-pressure sides, namely, upper streams, and the other side of the end face of the moving ring and the other side of the end face of the stationary ring are low-pressure sides, namely, lower streams. A plurality of cluster spiral grooves symmetrically distributed along the circumference of the end face are formed in the end face of at least on sealing ring of the moving ring or the stationary ring, the cluster spiral grooves are formed by combining a plurality of micro spiral grooves with different spiral angles in the circumferential direction of the end face, the micro spiral grooves in the same cluster spiral groove are separated by a sealing weir free of grooves on the high-pressure side, the groove roots of the micro spiral grooves in the same cluster spiral groove are overlaid and communicated to a whole on the lower-pressure side, and sealing dams are arranged on the down streams of the cluster spiral grooves. Through the convergence configuration of bionic high-speed flyer wings and the alula structure of flyer wing front edges, the gas lubrication cluster spiral groove end face mechanical sealing structure has a high flow guide effect and compression function on fluid media, the low-speed start and stop characteristic, high-speed running stability and sealing performance of the seal can be improved, the high-speed disturbance rejection capacity of the seal is improved, and end face abrasion is avoided.

Owner:ZHEJIANG UNIV OF TECH

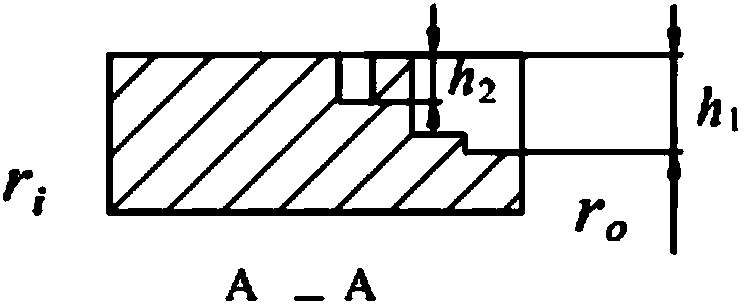

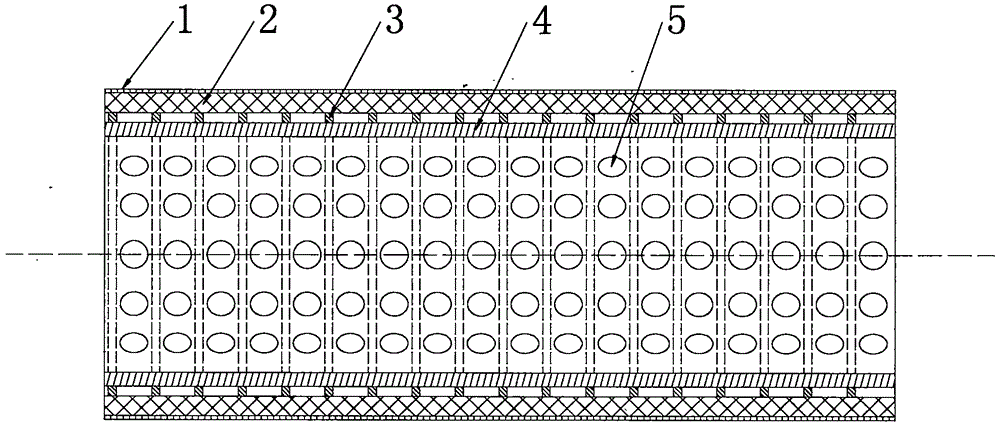

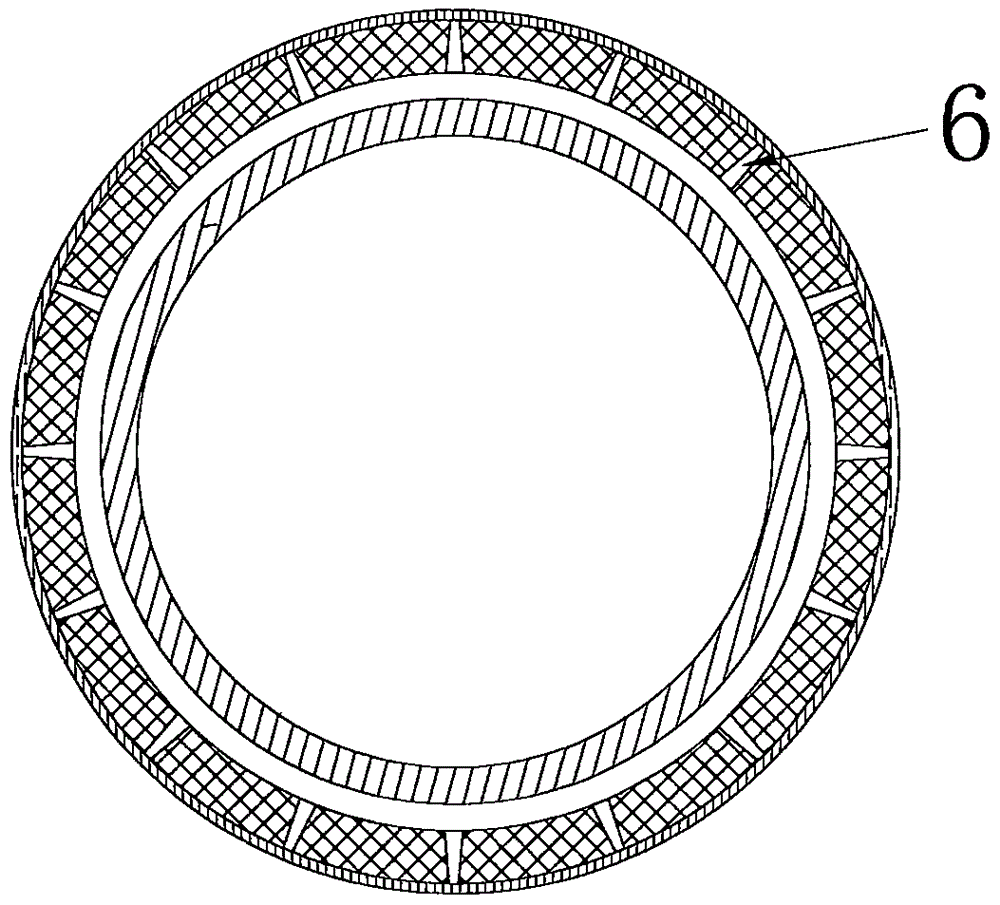

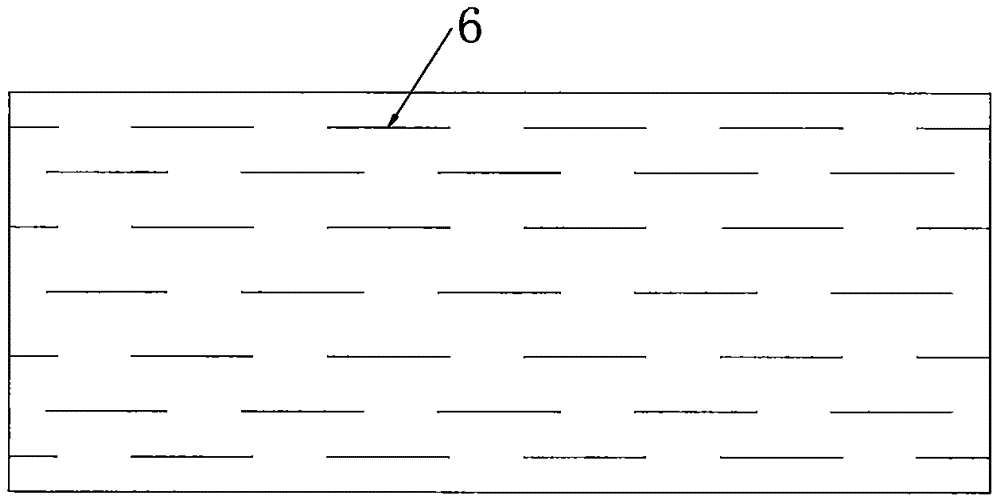

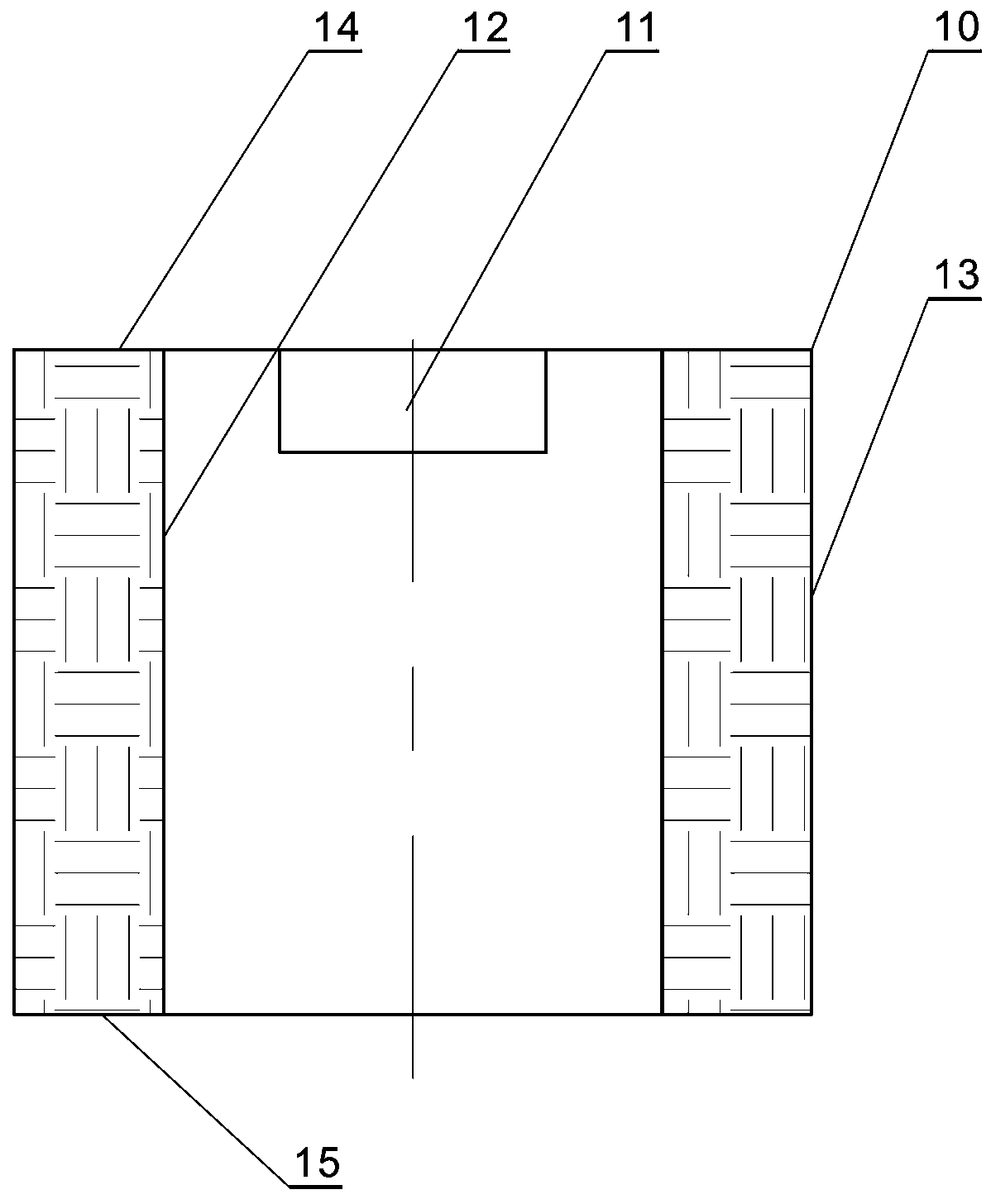

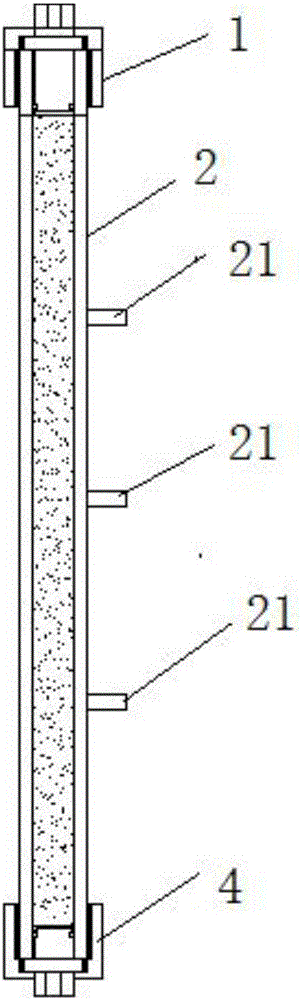

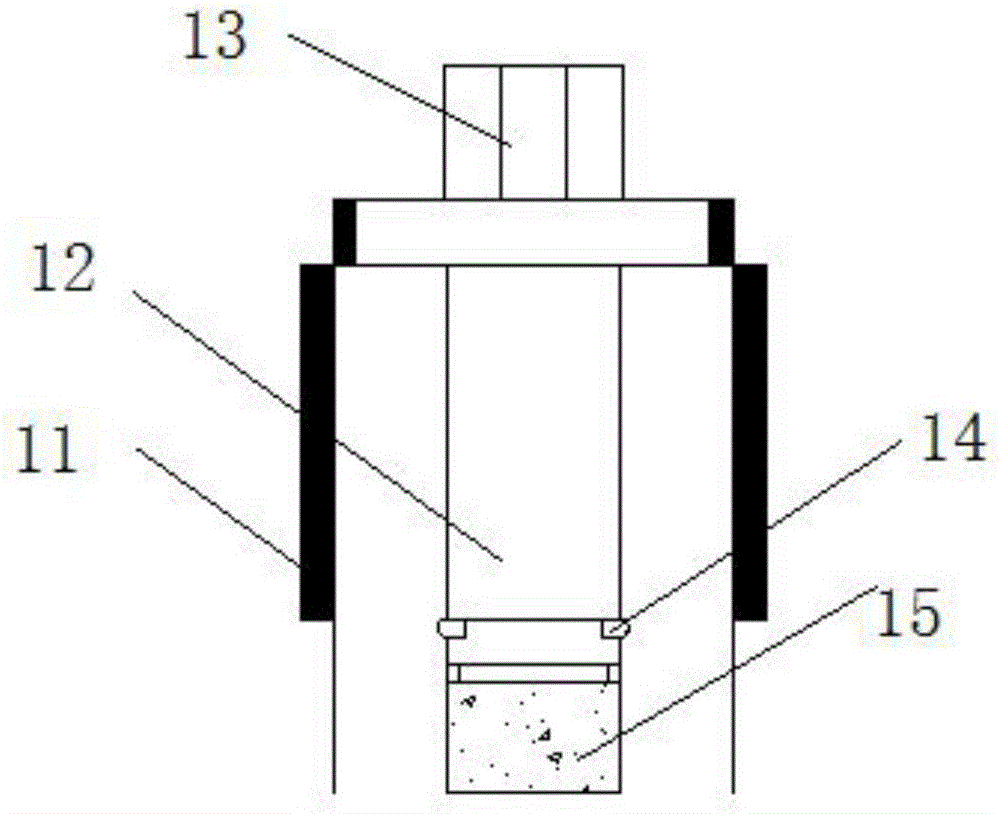

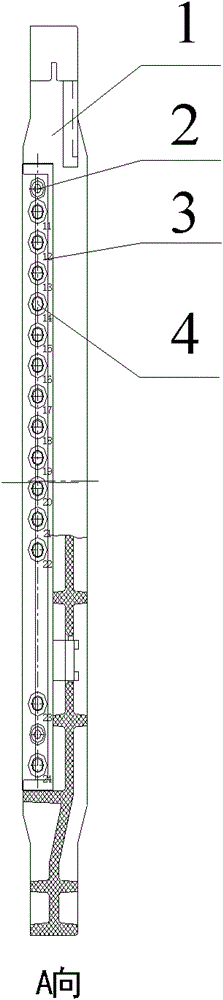

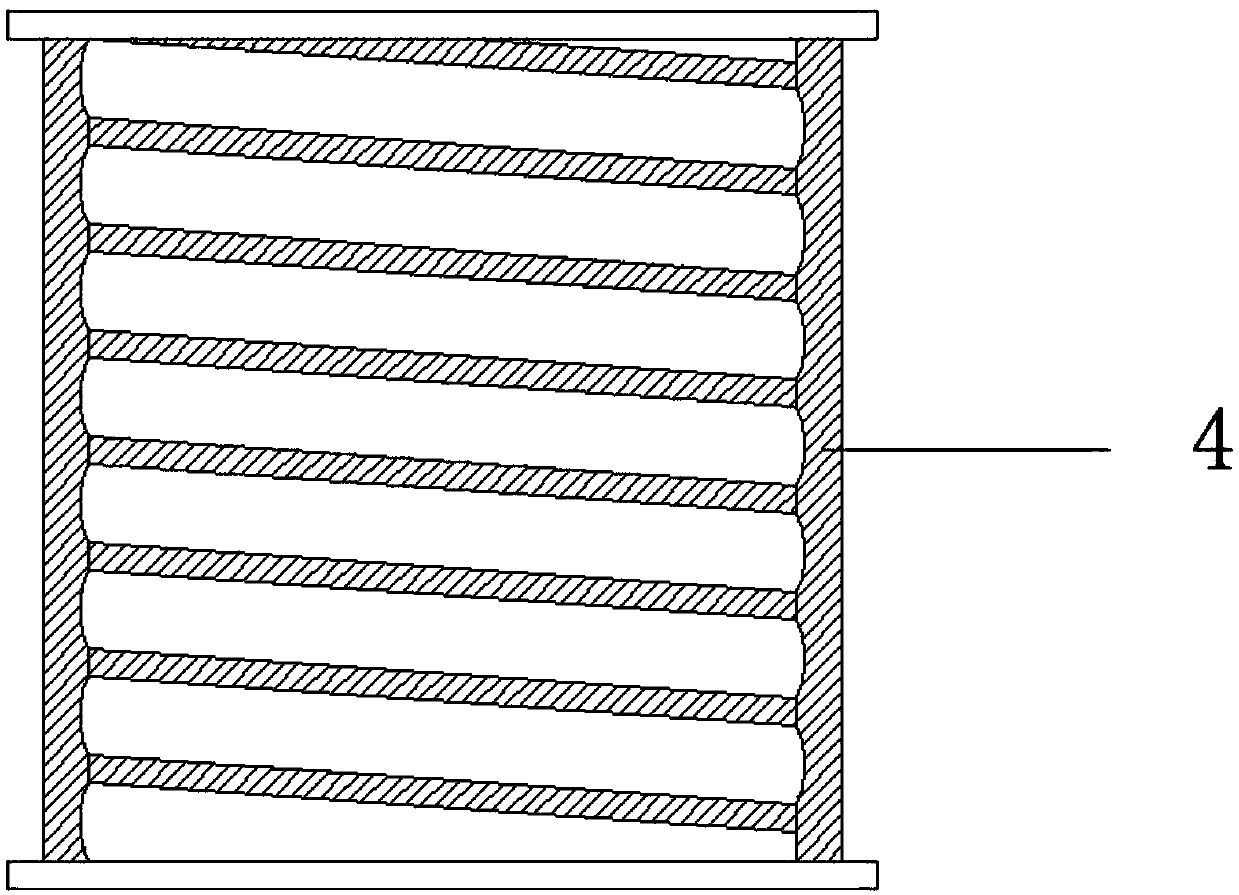

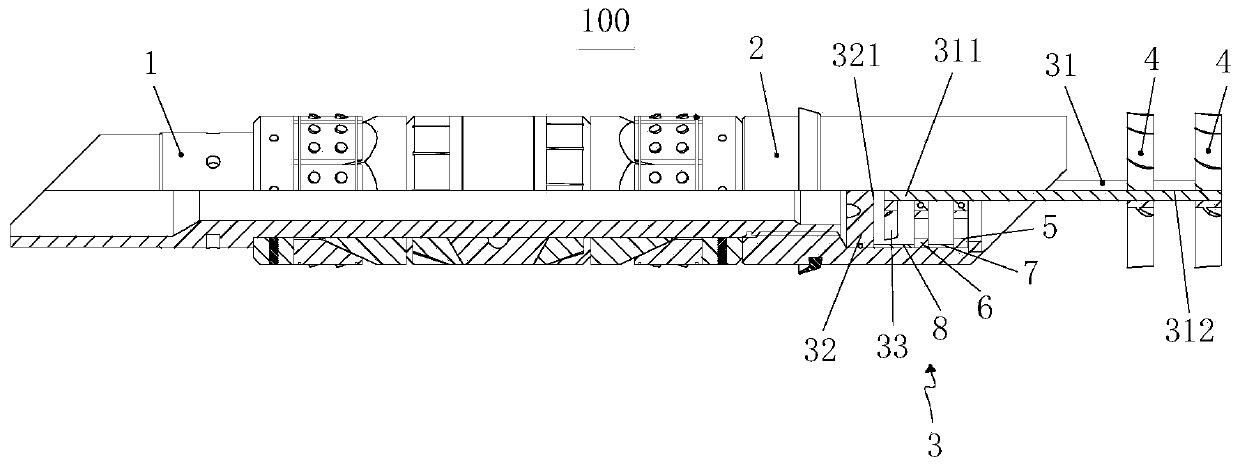

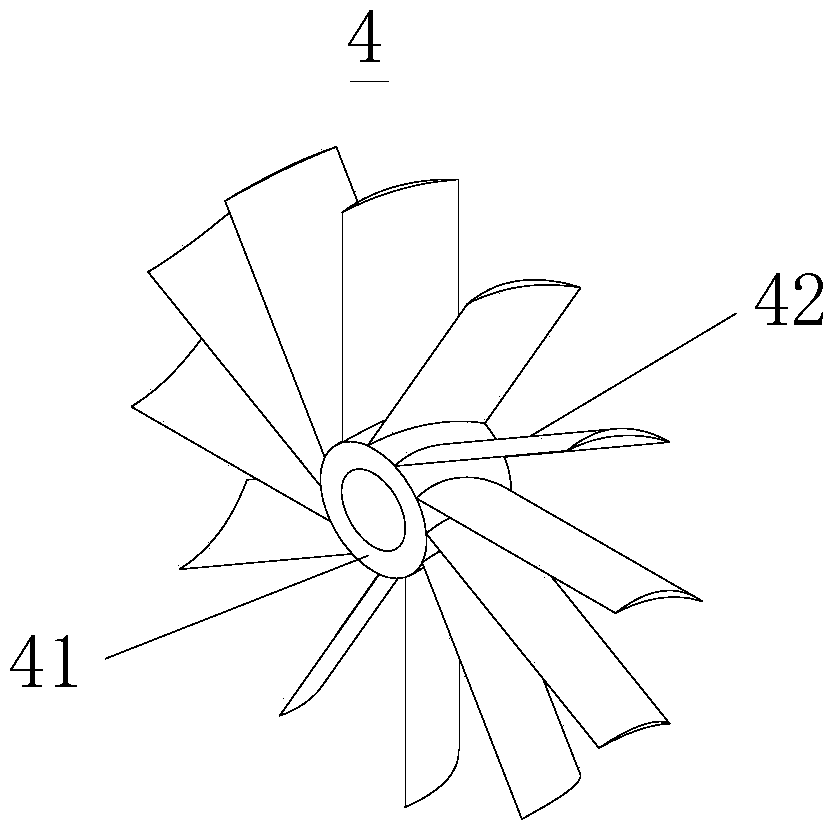

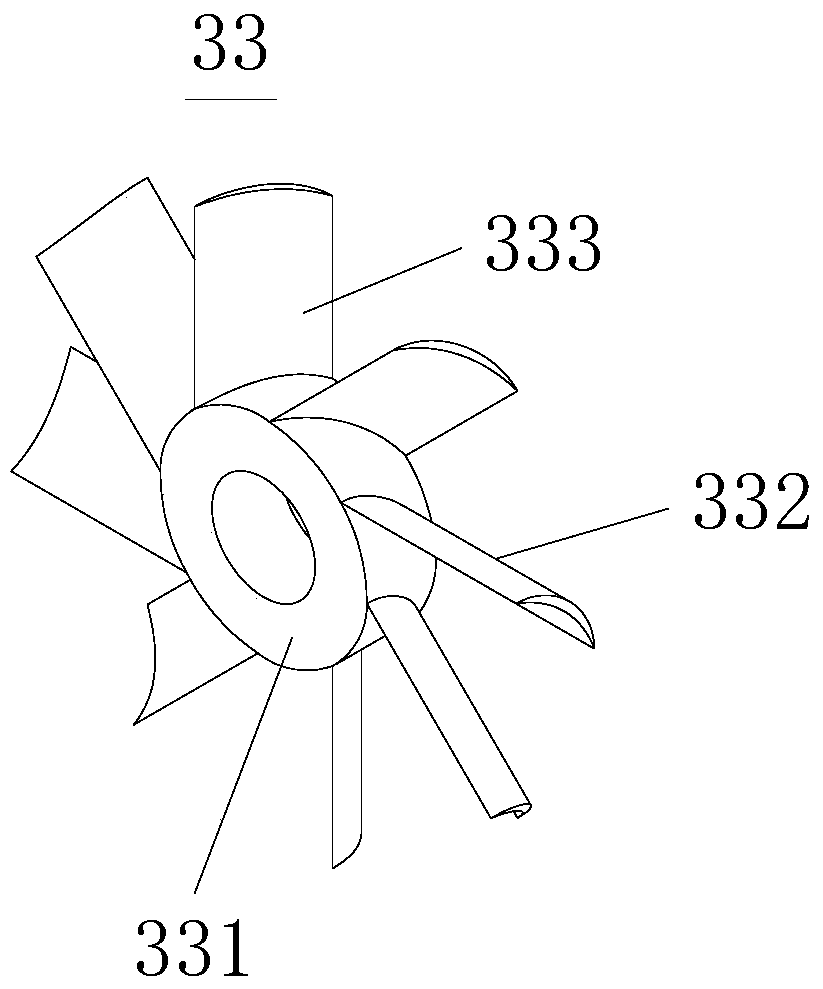

Novel foam metal sand-prevention pipe

InactiveCN105221118AStrong drainage abilityHigh sand control precisionFluid removalFiltrationEngineering

The invention relates to a novel foam metal sand-prevention pipe. The sand-prevention pipe is used for underground sand prevention for an oil and gas field and structurally comprises an outer pipe protective casing, a foam metal sand-prevention layer, wire-winding support strips and a base pipe in sequence from outside to inside, the foam metal sand-prevention layer is provided with flow guide gaps which are distributed in a staggered mode, each flow guide gap is in a trapezoidal shape with the outside narrow and the inside wide, the wire-winding support strips are welded to the outside of the base pipe, the base pipe contains parallel flow guide through holes, each flow guide through hole is located between the corresponding two wire-winding support strips, the minimum filtration diameter of the foam metal sand-prevention layer reaches 0.05 mm, the thickness of the foam metal sand-prevention layer is 0.5-1 cm, and the gap width, at the narrowest position, of each flow guide gap is greater than or equal to 01mm. The novel foam metal sand-prevention pipe is good in permeability and high in strength, each flow guide gap with the outside narrow and the inside wide has the self-cleaning function, by means of the sand-prevention pipe, sand-prevention precision is greatly improved, the service life of the sand-prevention pipe is greatly prolonged, good flow guide capability is achieved, and the liquid flow is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

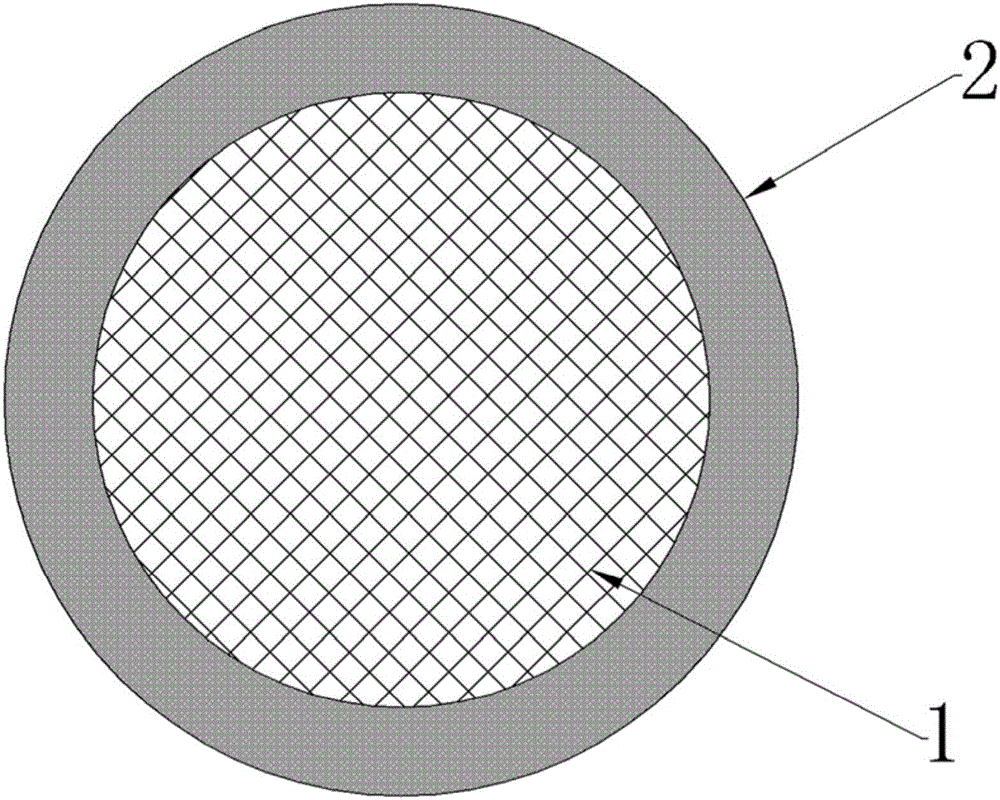

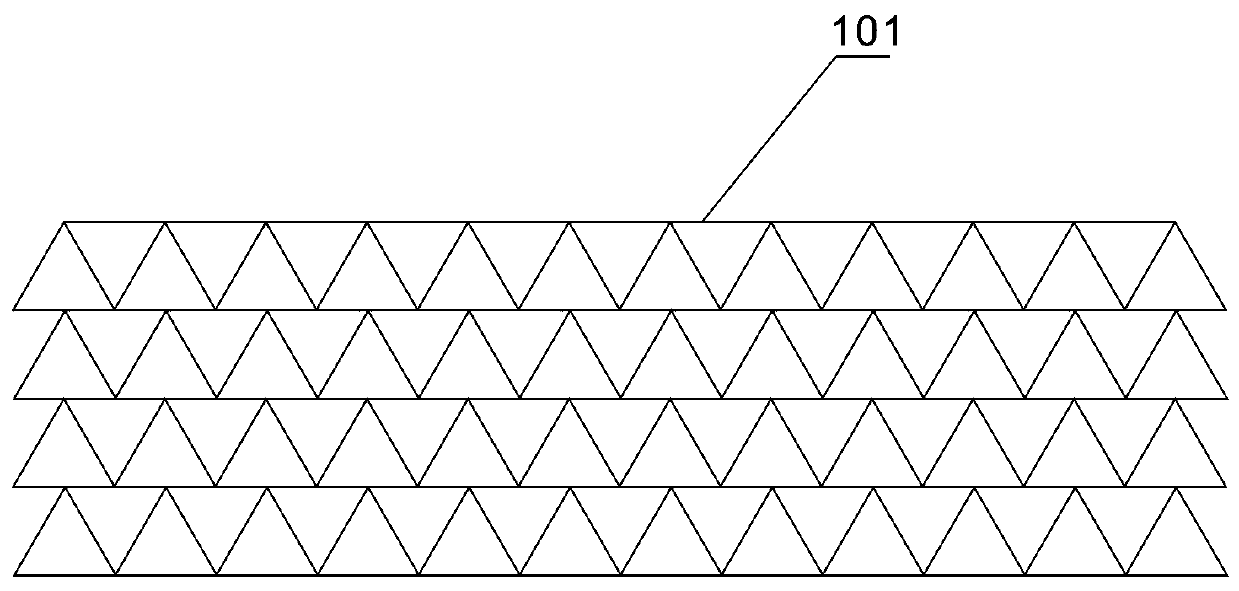

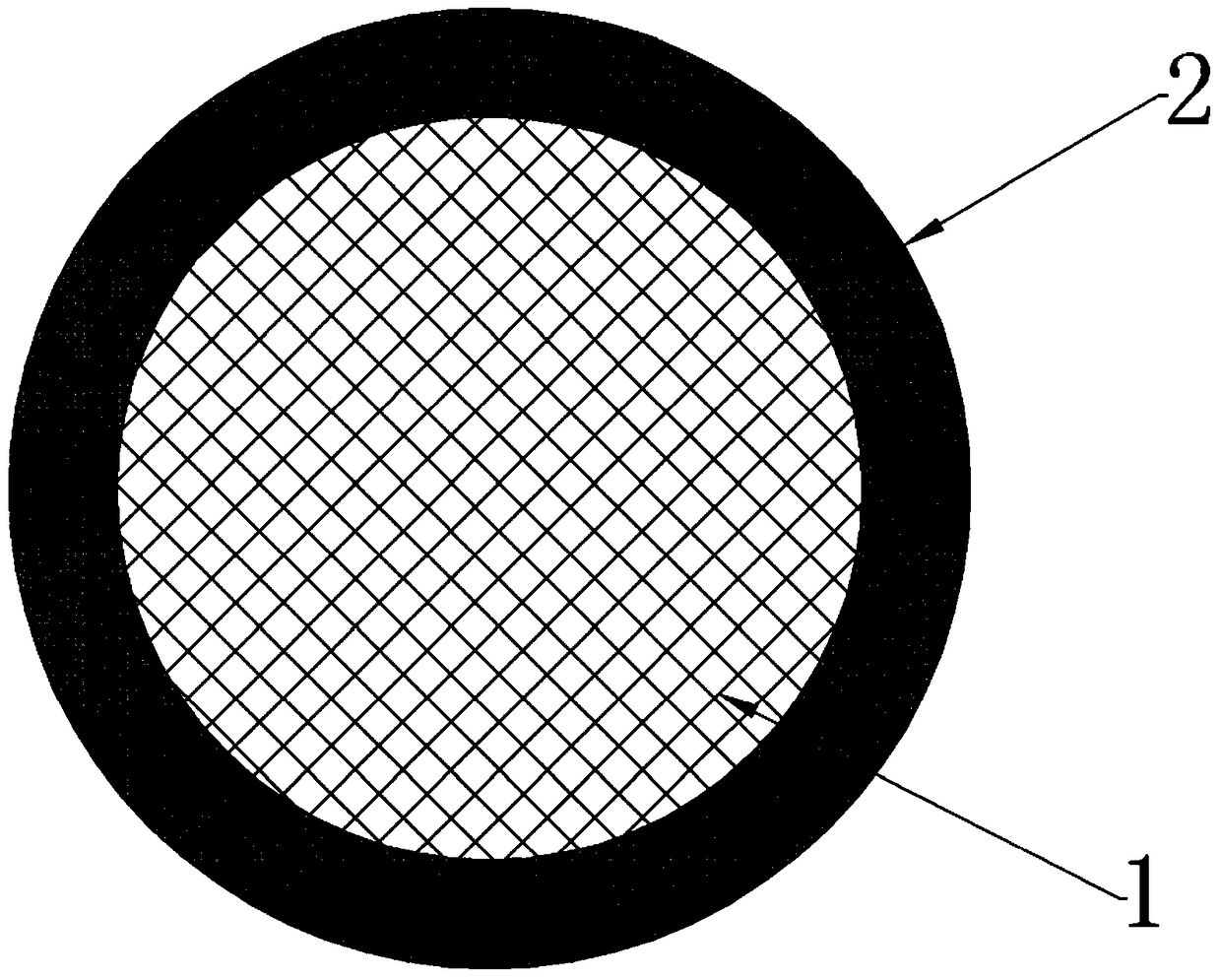

Elastic contact ring for signal transmission

InactiveCN109546377AImprove mechanical propertiesImprove consistencyFixed connectionsClamped/spring connectionsElectricityHigh density

The invention discloses an elastic contact ring for signal transmission. According to the invention, metal alloy wires are used as a base material, and a latticed sheet is formed by orderly weaving the metal alloy wires, and then the latticed sheet is coiled into a hollow cylinder shape. The triangular, quadrilateral, hexagonal or wavy latticed sheets are formed by ordered weaving, so it is convenient for strictly controlling the geometric body structure and the total material amount forming the elastic contact ring, so that the elastic contact ring with the same specification is good in mechanical property and electrical property consistency and stable and reliable in work. Compared with a contact piece formed in the prior art, the contact ring further has the advantages that the contactarea of the upper end face and the lower end face is large, the elastic force is evenly distributed, the surface contact is formed between the elastic contact ring and the PCB, and the problem of tolerance in the radial direction and the axial direction when the PCB is connected with the PCB is solved. The contact ring also has the advantages of high density, high flow conductivity and high fatigue resistance.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Road drainage structure

InactiveCN104878827AWill not damage the bearing strengthGood drainageSewerage structuresPaving detailsEngineeringUltimate tensile strength

The invention discloses a road drainage structure which comprises a permeable ground layer. More than one water collecting component is mounted on the upper surface of the permeable ground layer and is of a funnel-shaped structure, the tops of the water collecting components are fixed onto the lower surface of a drainage ground layer, the drainage ground layer is transversely arranged on the water collecting components, water guide components are vertically arranged in the permeable ground layer, correspond to the bottoms of the water collecting components and are communicated with the water collecting components, a permeable layer made of permeable concrete is arranged on the lower surface of the permeable ground layer and is connected with the permeable ground layer by cement mortar layers, a medium-sand leveling layer is arranged in the permeable layer made of the permeable concrete, and the thickness of the medium-sand leveling layer is a quarter of the thickness of the permeable layer made of the permeable concrete. The road drainage structure has the advantages that the road drainage structure is excellent in drainage performance and permeation performance and high in flow guide property and can be effectively applied to municipal road drainage; drainage devices can be prefabricated, accordingly, the construction periods can be effectively shortened, the labor intensity can be relieved, certain costs can be saved, and destruction to the bearing capacity of roads can be prevented.

Owner:CHENGDU GERUISI CULTURAL COMM

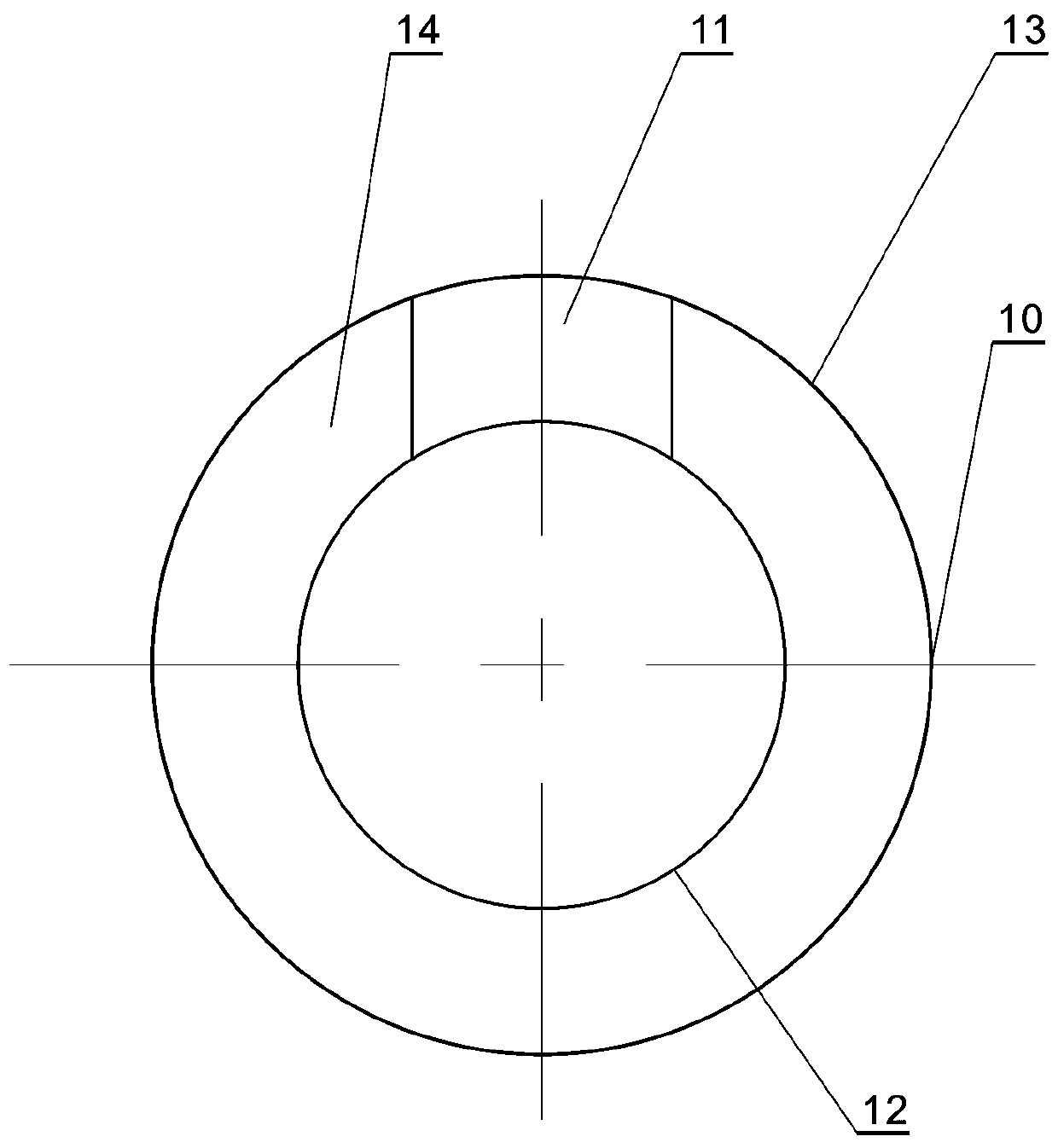

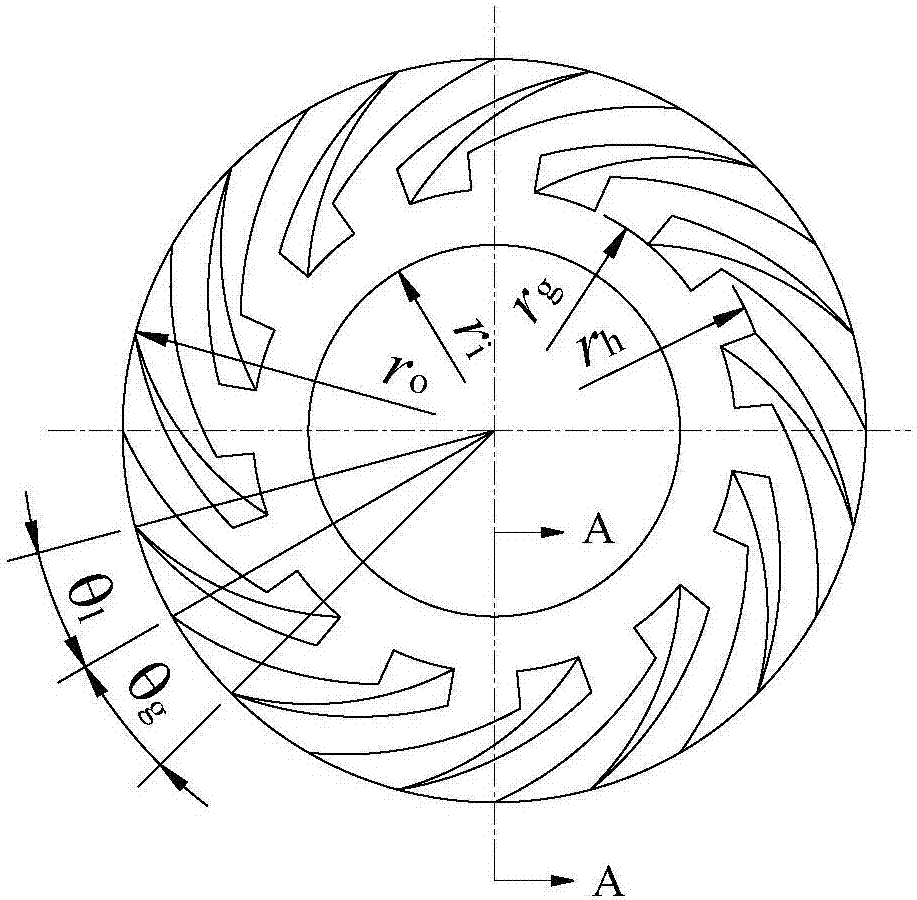

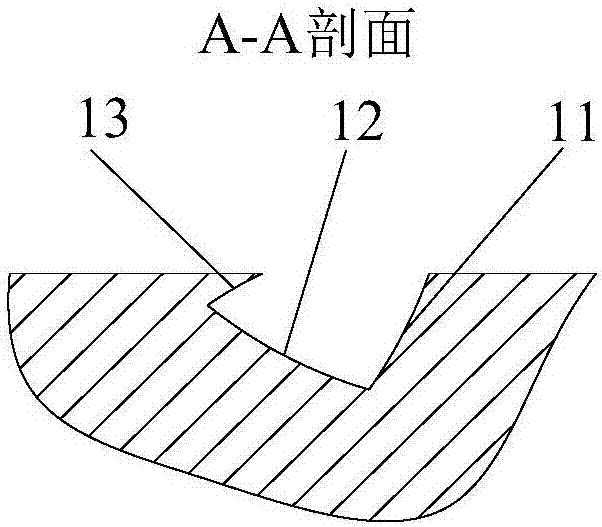

Bird-like wing-shaped multi-channel groove end face sealing structure

ActiveCN103470773BStrong drainage abilityImprove bearing capacityEngine sealsAnti jammingContact type

A bird-wing-shaped multi-channel groove end face seal structure, including a moving ring and a static ring of a mechanical seal, at least one sealing ring of the moving ring or the static ring is provided with a plurality of bird-wing-shaped multi-channels evenly distributed along the circumference The bird-wing multi-channel groove is located on the high-pressure side of the medium, that is, the upstream; the bird-like multi-channel groove includes two or more drainage grooves and one or more arc grooves, and the arc groove is located The downstream side of the drainage groove is connected with the drainage groove. The drainage grooves are connected with the medium high pressure side or the upstream and are evenly distributed along the circumference. The drainage grooves are separated by sealing weirs without slots; the end surface The annular zone formed by the ungrooved area in the circumferential direction is a sealing dam, which is located on the low pressure side of the end face, ie downstream. The invention has strong end face static pressure effect, low power consumption, good running stability at low speed, small leakage and excellent anti-interference performance, and is especially suitable for non-contact dry gas seal end face sealing devices for equipment such as reaction kettles and agitators. .

Owner:ZHEJIANG UNIV OF TECH

Gas lubrication end face mechanical seal structure for pyramid-shaped deep composite groove

ActiveCN109237039AImprove compression performanceImprove running stabilityEngine sealsGas lubricationEngineering

The invention provides a gas lubrication end face mechanical seal structure for pyramid-shaped deep composite grooves. The structure includes a moving ring and a static ring, in the moving ring and the static ring, the end face of at least one sealing ring is provided with the pyramid-shaped deep composite grooves spirally and evenly distributed in the circumference direction, and the grooves gradually become narrows from upstream to downstream; the pyramid-shaped deep composite grooves are composed of base dynamic pressure grooves and pyramid-shaped grooves, the bottom surfaces of the base dynamic pressure grooves are provided with the pyramid-shaped grooves, and the depth of the pyramid-shaped grooves gradually become narrows from upstream to downstream; the pyramid-shaped grooves are formed through splicing of several rows of secondary grooves, and the adjacent secondary grooves of the same row are separated by a sealing weir whose depth is same as that of each base dynamic pressuregroove; the secondary grooves on one side of the downstream are astride on the sealing weir between the two secondary grooves of the adjacent row on one side of the upstream and connected with the secondary grooves on the two sides of the sealing weir on one side of the upstream. The downstream of the end face is provided with a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

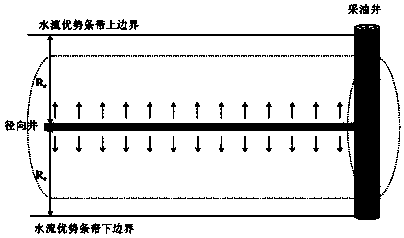

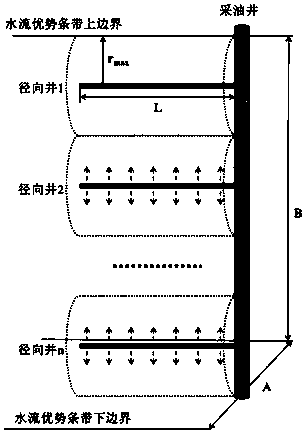

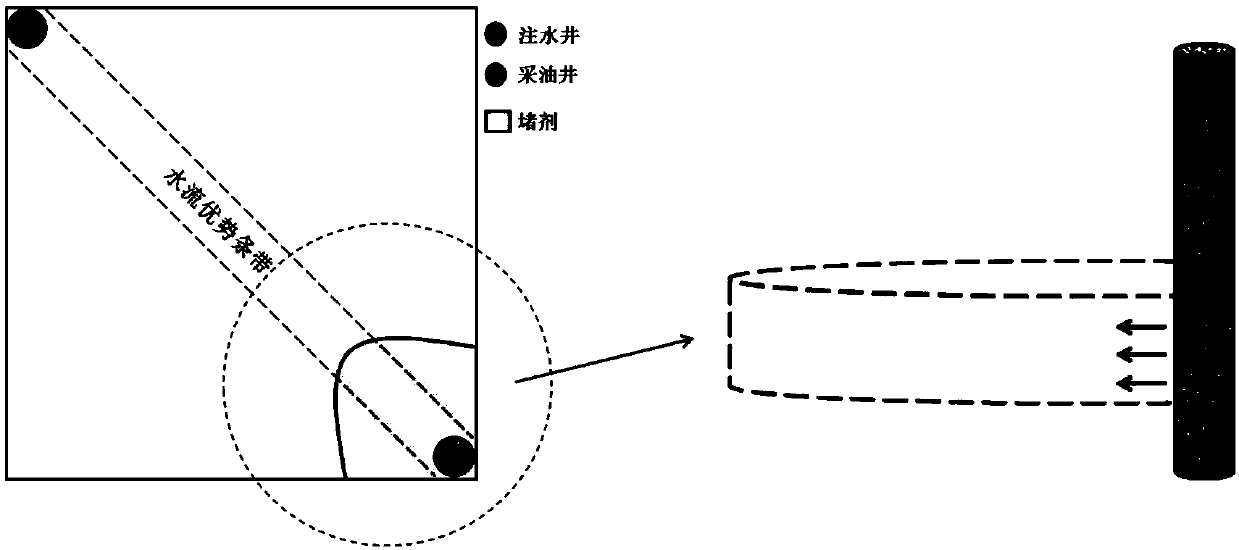

Method for guiding plugging agents into oil well for water plugging by radial well

The invention discloses a method for guiding plugging agents into an oil well for water plugging by radial wells, and belongs to the field of oil production engineering in oil development. The methodcomprises the following step that the orientation of the radial wells, the length of the radial wells, numbers of the radial wells, dosage of the plugging agents and injection displacement are determined. The method for guiding the plugging agents into the oil well for water plugging by the radial wells changes the flow line of the plugging agents along a producing well as radial flow in a traditional general injection method to the radial flow along the radial wells in a flow advantage band, the precise delivery of the plugging agents is realized, and the damage to an oil reservoir is reduced. The radial wells have high flow conductivity and can be regarded as pipe flow, compared with the formation seepage flow, the injection pressure to the depth of the formation is greatly reduced, andthe effects of decompression and increasing injection are achieved. The method for guiding the plugging agents into the oil well for water plugging by the radial wells can realize the precise deliveryof the plugging agents in the flow advantage band and the decompression and increasing injection, and is of great significance for improving the water plugging effect of the oil well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low-density laminating propping agent and preparation method thereof

InactiveCN106244132ASimple processReduce product densityFluid removalDrilling compositionShale gasChemistry

The invention discloses a low-density film-covered proppant, which consists of the following components in parts by weight: Jujube seed 280-320, resin 5.6-8.4, curing agent 1-1.4, water 5-10, dispersant 0.2-0. 0.5 and plasticized drag reducer 0.2‑0.5. The resin is a thermoplastic phenolic resin; the curing agent is an organic amine curing agent, and the low-density film-covered proppant is formed by stirring the components evenly, fully curing, uniformly dispersing, and sieving. The low-density film-coated proppant is applied to oil, coal bed gas and shale gas fracturing. The invention has the characteristics of simple process, good sphericity, low product density, good suspension performance, low breakage rate, high compressive strength, good permeability and no pollution in the manufacturing process. Widely used in oil and gas field fracturing, greatly reducing the amount of fracturing fluid, increasing the ratio of fracturing sand to liquid, increasing the concentration and breadth of proppant in fractures, improving the conductivity of fractures, and helping to increase the production of oil and gas wells. It is especially suitable for fracturing of low-permeability coalbed methane and shale gas wells.

Owner:河北易压得石油科技有限公司

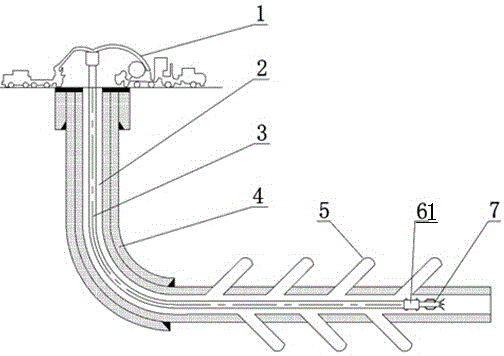

Method for improving development of coal underground gasification gas cavity by applying double-pinniform horizontal well

PendingCN113914846AReduce the number of drilled holesReduce economic costsConstructionsFluid removalThermodynamicsHorizontal wells

The invention discloses a method for improving development of a coal underground gasification gas cavity by applying a double-pinniform horizontal well. The method comprises the following steps that S1, a gas inlet hole of a gas injection well is constructed; S2, a horizontal branch well of the gas injection well is constructed; S3, a production well gas production hole is constructed; S4, horizontal branch wells of the production well are constructed; S5, auxiliary holes are constructed; S6, auxiliary devices such as an ignition device, a gasifying agent injection device and a retreating device are put down through a wellhead of the injection well; S7, a gasifying agent is injected into the horizontal branch well points for ignition; S8, after gasification cavities of the two adjacent horizontal branch wells at the finger tip communicate with each other, the auxiliary devices are arranged at the horizontal branch well points of the middle and rear section, and the steps S5-S8 are repeated till coal bed gas cavities of all the horizontal branch wells are integrally gasified and communicated; and S9, an air extractor is installed at the ground end of the production well. The using method can break through the limitation of point or line range injection and production of a vertical well and a horizontal well, a coal seam fracture system is communicated in a large range, the reaction contact area is increased, and the gas production rate is increased.

Owner:SOUTHWEST PETROLEUM UNIV

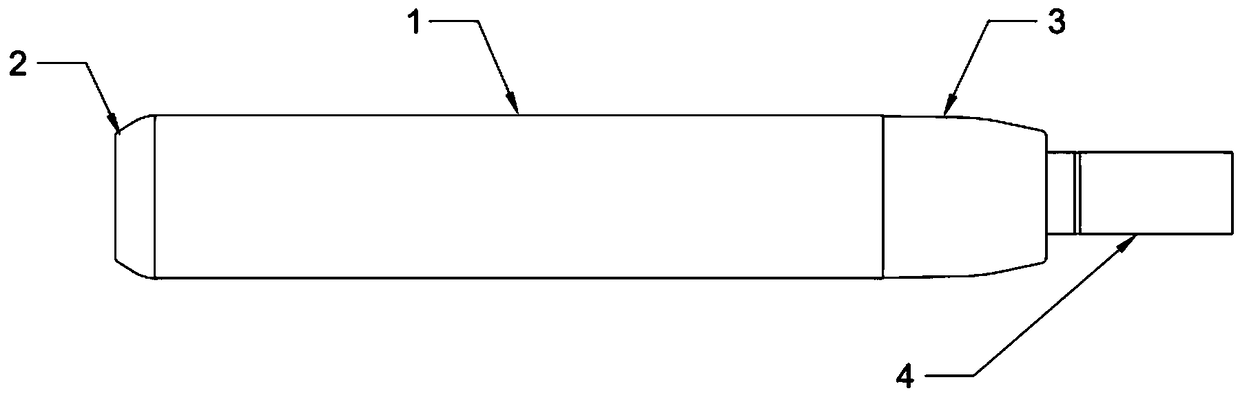

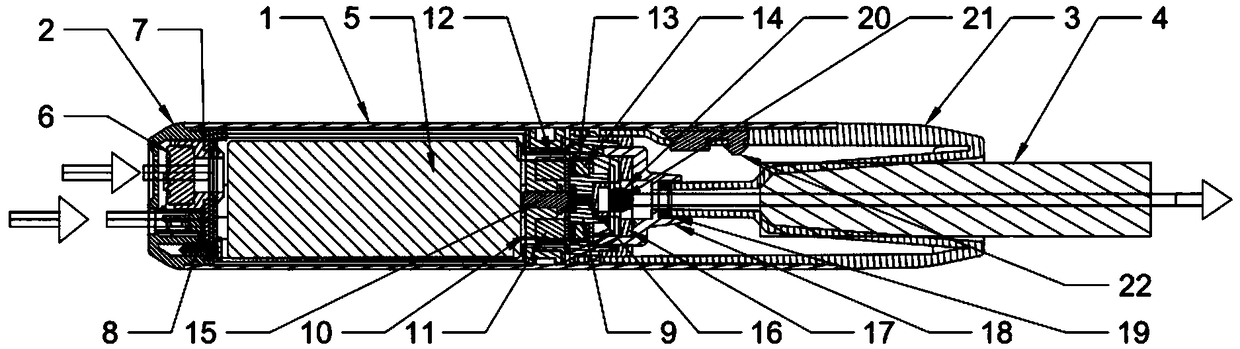

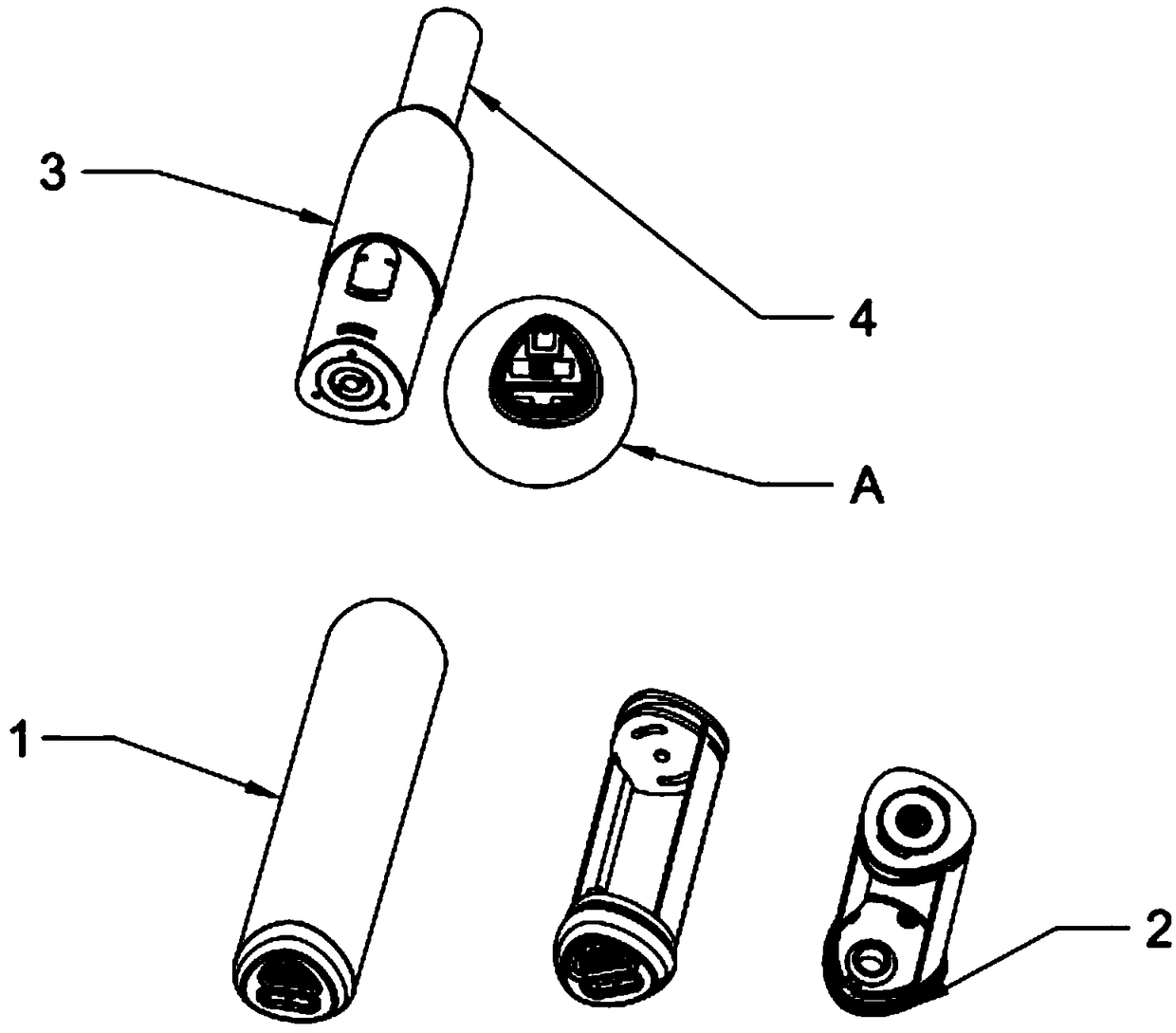

Safety electronic cigarette allowing tar recharging

PendingCN109480344AIncrease inhalationStrong absorption capacityTobacco devicesTarElectronic cigarette

The invention discloses a safety electronic cigarette allowing tar recharging, which comprises an aluminum tube. One end of the aluminum tube is provided with a battery rear cover in inserted manner;the other end of the aluminum tube is provided with a tar compartment in inserted manner; the other end of the tar compartment is provided with a filter tip in inserted manner; a microphone, microphone silica gel, a battery, a battery head, magnet I, iron shell I, iron shell II, magnet II and a tar compartment bottom cover are arranged in the aluminum tube sequentially from the battery rear coverto the tar compartment; a PCBA (printed circuit board assembly) is arranged on the lateral side of the microphone silica gel and is fixed to the battery rear cover through screws; a spring electrode is arranged in the middle of the battery head; a cartridge positive electrode is arranged in the middle of the tar compartment bottom cover; the spring electrode is in inserted connection with the cartridge positive electrode; a silica gel nebulizing chamber, a nebulizing chamber upper cover and tar-sealing silica gel are arranged sequentially from the tar compartment bottom cover to a cylindricalhollow duct in the tar compartment; a heating wire is arranged in the silica gel nebulizing chamber and is provided with a cotton stick. The safety electronic cigarette has the advantages of simple structure, prevention of tar splashing, prevention of inhaling tar and condensate, rechargeability of tar and the like.

Owner:深圳前海呼吸科技有限公司

A double-layer high-strength fracturing proppant and its preparation method

ActiveCN105131934BTemperature resistantWith pressureFluid removalDrilling compositionSolubilityApparent density

The invention discloses a double-layer high-strength fracturing propping agent and a preparing method thereof and belongs to the technical field of oil (gas) extraction auxiliaries. The fracturing propping agent comprises a ceramic inner core and a silicon nitride ceramic shell wrapped on the surface of the ceramic inner core. The proportion of the diameter of the ceramic inner core and the thickness of the silicon nitride ceramic shell is 5-10:1. The ceramic inner core is mainly prepared from, by mass, 40%-50% of bauxite, 40%-50% of shale and 0-10% of gangue. The silicon nitride ceramic shell is mainly prepared from, by mass, 60%-70% of silicon nitride and 30%-40% of bauxite. The double-layer high-strength fracturing propping agent has the advantage of high tensile strength, the low breaking rate, low apparent density, the high corrosion resistance capability and the like, the breaking rate is smaller than 6% under the condition of 103 Mpa, the acid solubility is smaller than 2%, and the double-layer high-strength fracturing propping agent is particularly suitable for development of deep well and ultra-deep well oil and gas fields.

Owner:HENAN TIANXIANG NEW MATERIALS

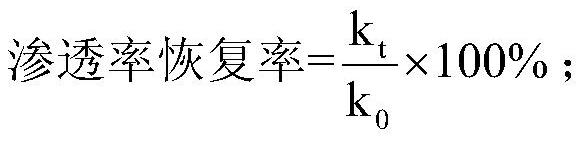

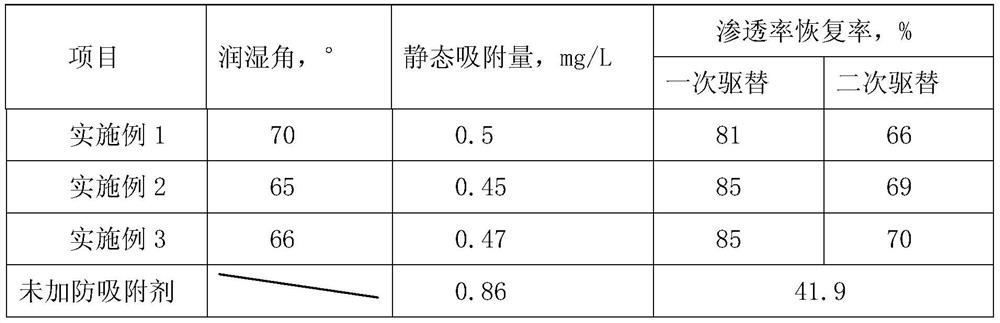

Anti-polymer adsorbent and preparation method thereof

ActiveCN112175149AStrong film formingStrong adhesionDrilling compositionActive agentSurface-active agents

The invention discloses an anti-polymer adsorbent which is prepared from the following raw materials in parts by weight: 0.75-4 parts of nanoparticles, 1.5-2.0 parts of an OP surfactant, 20-30 parts of epoxy resin, 10-25 parts of an acrylic monomer, 5-10 parts of styrene, 0.5-1.2 parts of an initiator, 10-20 parts of quaternary ammonium salt and 5-10 parts of a coupling agent. The nanoparticles are selected from any one or more than two of bentonite, hectorite, silicon dioxide and positive electricity glue. The anti-polymer adsorbent can be quickly adsorbed on the surface of quartz sand to form a layer of polymer film, and adsorption of a polymer on the surface of the quartz sand is prevented, so that the additional pressure difference of a near-well filling layer is reduced, and the flowconductivity of the near-well filling layer is improved. The anti-polymer adsorbent disclosed by the invention has the advantages of good salt resistance and scouring resistance, long validity period,high permeability recovery rate of a filling layer and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

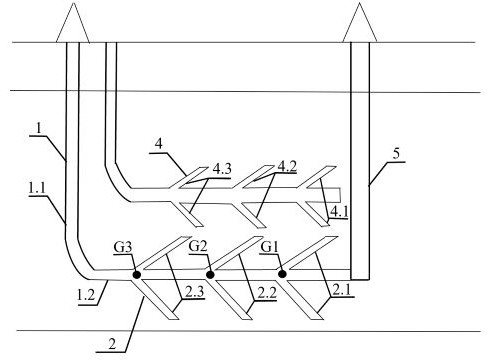

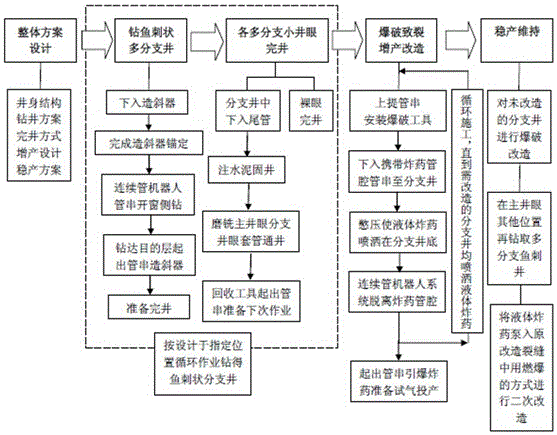

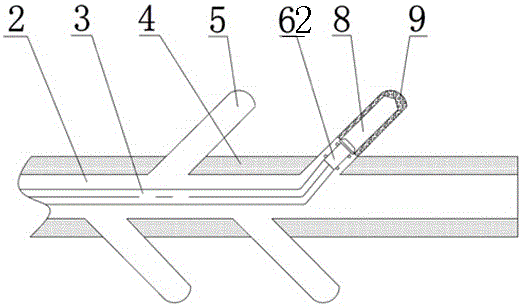

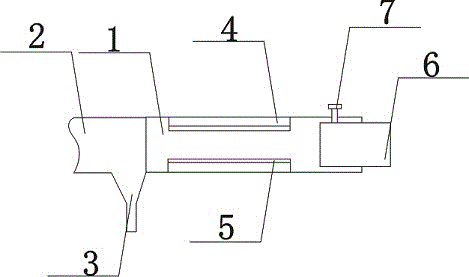

A drilling, completion and stimulation system for drilling fishbone-shaped multi-level branched horizontal wells in shale gas reservoirs

InactiveCN104533287BConvenient and fast production increase and transformation operationsSimplify preparationFluid removalDirectional drillingWell drillingCoiled tubing

The invention discloses a drilling and completion and production increasing system for a shale gas reservoir of a multilateral fishbone horizontal well. The system comprises a system for drilling the multilateral fishbone horizontal well by the matching of a continuous oil pipe and a drilling robot, a small borehole completion system for the multilateral fishbone horizontal well by the matching of the continuous oil pipe and the drilling robot, and a system for blasting and reconstructing the multilateral fishbone horizontal well; the system for drilling the multilateral fishbone horizontal well by the matching of the continuous oil pipe and the drilling robot is used for drilling the multilateral fishbone horizontal well in the shale gas reservoir so as to provide foundation for completion and blasting fracturing reconstruction; the small borehole completion system for the multilateral fishbone horizontal well by the matching of the continuous oil pipe and the drilling robot is used for performing completion construction for the drilled multilateral fishbone horizontal well. The system has the beneficial effects that the shale gas can be efficiently safely produced with low cost in a green manner; the shortages of large water and sand consumption in large-scale fracturing at the long horizontal well sections, high water pollution risk, long construction period, and failure of pressing and opening deep shale can be avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Point-contact loosening sandstone core model

PendingCN106644672AStable structureLarge pressure rangePreparing sample for investigationPermeability/surface area analysisEngineeringMechanical engineering

The invention provides a point-contact loosening sandstone core model, comprising a sand filling pipe body, an upper end head, a lower end head, and a pressing pillar; the upper end head and the lower end head are used for sealing the upper end and the lower end of the sand filling pipe body respectively; the pressing pillar is used for filling and pressing quartz sand in the sand pilling pipe; the sand filling pipe body is an integrated structure; the pressing pillar is formed by dismountably and fixedly connecting the bottom pressing block and several upper pressing blocks; the cross section area of the bottom pressing block is more than the cross section area of the upper pressing blocks, and the outside diameter of the bottom pressing block is adapted to the inside diameter of the sand filling pipe body; an air guide channel is arranged on the bottom pressing block, one end opening of the air guide channel is arranged at the bottom face of the bottom pressing block, and the other end opening is arranged at the side face of the bottom pressing block. The point-contact loosening sandstone core model provided by the application is stable in structure and big in pressure bearing scale; the model has full process of pressure application and uniform force application; the design of the pressure testing point is free from injury to the pipe wall, and simple to dismount, and convenient to operate; the flow conductivity of the inlet and outlet is strong relatively.

Owner:SOUTHWEST PETROLEUM UNIV

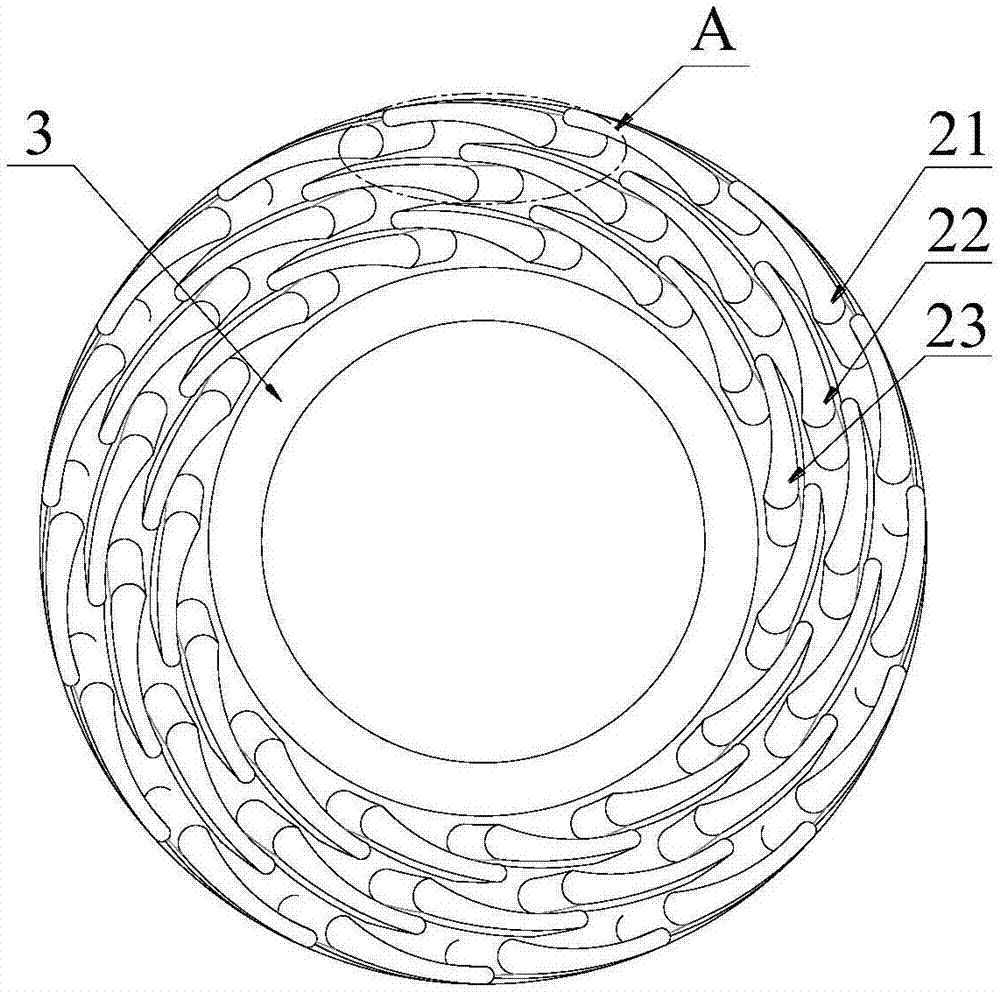

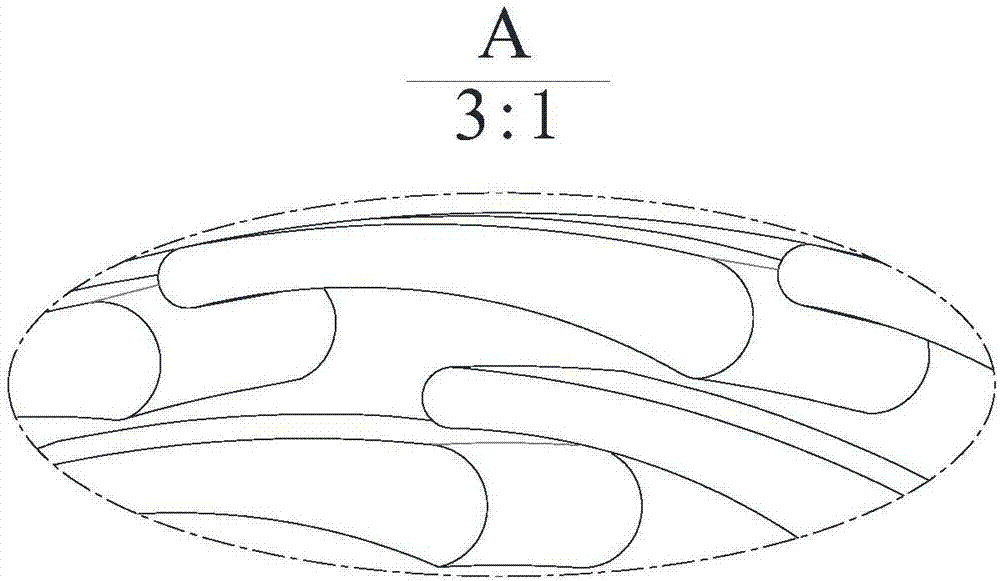

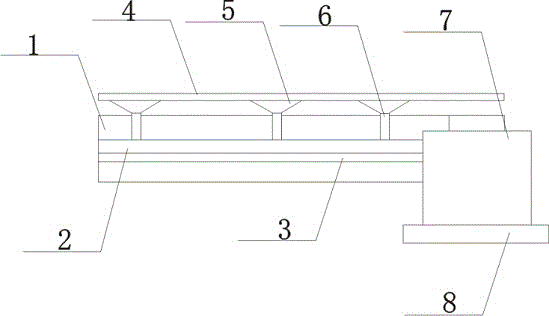

Ternary distortion-type groove end surface mechanical sealing structure

ActiveCN107218395AImprove compression performanceStrong drainage abilityEngine sealsHelical lineEngineering

A ternary distortion-type groove end surface mechanical sealing structure comprises a dynamic ring and a static ring which are used for mechanical sealing, ternary distortion-type grooves 1 evenly distributed in the circumferential direction are machined in the sealing end surface of at least one sealing ring of the dynamic ring and the static ring, and each ternary distortion-type groove is formed by two side walls and a three-dimensional distortion variable-depth groove bottom surface; the side walls of each ternary distortion-type groove comprise the windward side ternary distortion wall surface 11 and the leeward side ternary distortion wall surface 13, and the three-dimensional distortion variable-depth groove bottom surfaces 12 gradually shallow in a distortion shape from the outer circumferential side walls of the sealing rings to the centers of the sealing rings and intersect with the sealing end surfaces on the outer sides of sealing dams 3; the intersection lines of the side walls of the ternary distortion-type grooves 1 and the outer circumferential side walls of the sealing rings are perpendicular to the sealing end surfaces; the intersection lines of the side walls of the first ternary distortion-type grooves and the sealing end surfaces are each divided into two sections, the intersection lines on the medium inlet sides are helical lines, and the intersection lines on the medium leakage sides are radial straight lines.

Owner:ZHEJIANG UNIV OF TECH

Anti-blocking water conservancy pipe structure

InactiveCN105525599ACompact structureFirmly connectedConstructionsIrrigation ditchesEngineeringPiping

The invention discloses an anti-blocking water conservancy pipe structure. The anti-blocking water conservancy pipe structure comprises a water outlet pipe, a buffer table is arranged on the inner wall of the water outlet pipe, and the buffer table and the water outlet pipe are integrally connected; a wear-resisting plate is arranged on one face, opposite to the inner wall of the water outlet pipe, of the buffer table and fixed to the buffer table, a water guide pipe is arranged at one end of the water outlet pipe and connected to the water outlet pipe in a sealing manner, a flow guide opening is formed in the water guide pipe, and the flow guide opening and the water guide pipe are integrally connected; and an inner pipe is arranged at one end, opposite to the water guide pipe, of the water outlet pipe and connected with the water outlet pipe through a detachable piece. The anti-blocking water conservancy pipe structure is compact in structure, firm in connection, high in flow guide performance and not prone to generating blockage; a certain buffer and flow guide effect can be achieved; meanwhile, whether the inner tube needs to be dismounted in use or not can be selected according to actual demands on site; and the using flexibly is greatly strengthened.

Owner:CHENGDU GERUISI CULTURAL COMM

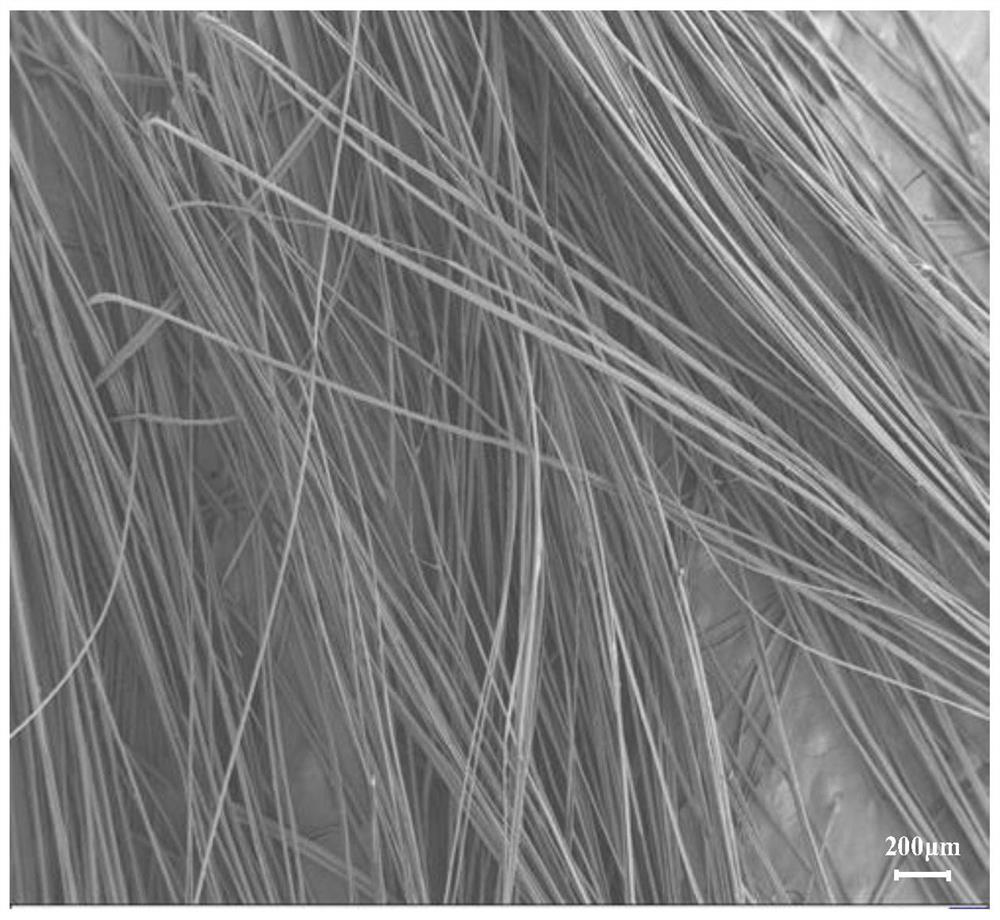

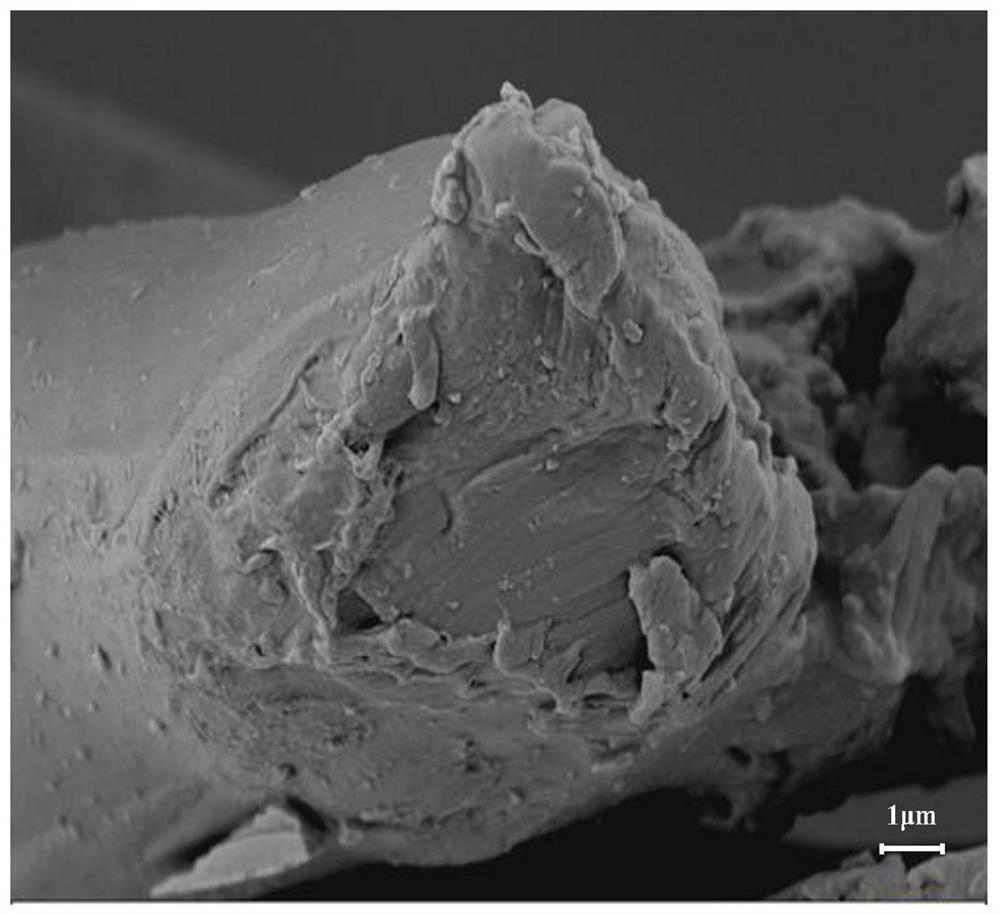

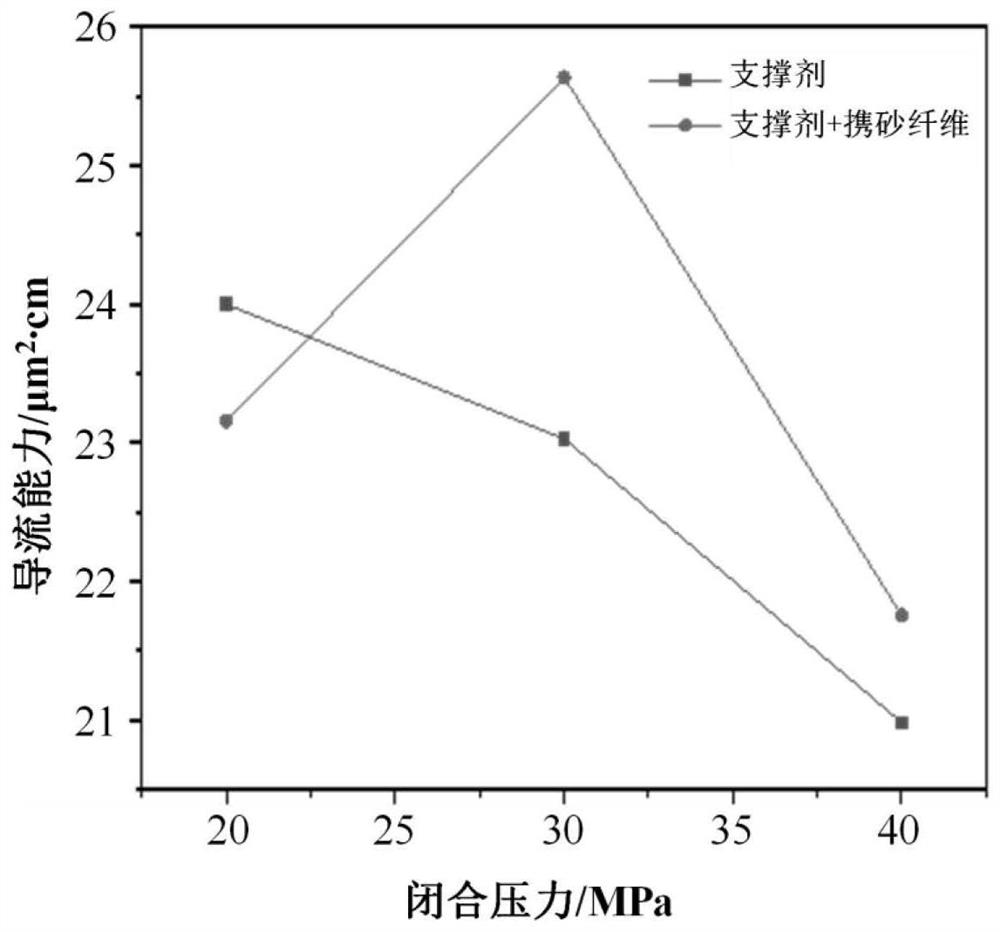

Sand-carrying fiber and preparation and application thereof

ActiveCN113981564AIncrease productionImprove conductivityGrip property fibresDrilling compositionFiberPolymer science

The invention discloses a sand-carrying fiber and preparation and application thereof. The sand-carrying fiber is a polylactic acid fiber and is prepared from the following raw materials in parts by mass: 100 parts of polylactic acid (PLA), 12 to 16 parts of poly-p-phenylene terephthamide, 3 to 5 parts of sodium dodecyl benzene sulfonate, 2 to 5 parts of citric acid, 15 to 23 parts of polyvinyl alcohol, 10 to 22 parts of glycerin monostearate, 15 to 25 parts of polyethylene glycol, 10 parts of magnesium phosphate-fibrin glue and 2 to 3 parts of zinc chloride. The sand-carrying fiber has the characteristics of simple process route, good sand-carrying performance, strong flow conductivity, excellent dispersity and the like, and the loss of fracturing fluid can be effectively reduced. Magnesium phosphate-fibrin glue and zinc chloride are added into the fiber polymer, so that the prepared sand-carrying fiber has better toughness and solubility.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Enhanced heat transfer type mechanical seal structure of ternary bending and torsion micro-convex body

ActiveCN107228196BImprove start-stop characteristicsImprove running stabilityEngine sealsEnhanced heat transferLong axis

The invention discloses a strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure. Ternary bending torsion micro convexes arranged in the circumferential direction according to the center of the end face to form ring belts are machined on the end face of a movable ring or a static ring of a mechanical seal; each ternary bending torsion micro convex is a micro cylinder with the cross section in the wing shape; and relative torsion exists between every two adjacent cross sections on the ternary bending torsion micro convexes. The long axes of the cross sections of the ternary bending torsion micro convexes are arranged in the circumferential direction of the end face; the short axes of the cross sections of the ternary bending torsion micro convexes are arranged in the radial direction of the end face; the end face of the leeward side of the front micro convex on the ring belts is located on the inner side of the end face of the windward side of the back micro convex; a ring direction flow channel is formed between every two adjacent rows of ring belts, and fluid flows into the ring direction flow channels through the micro convexes and generates strong vortex in the ring direction flow channels; every two adjacent rows of ring belts of the ternary bending torsion micro convexes are arranged in a staggered manner; and the position, close to the leakage side, on the sealed end face is provided with an annular sealing dam; and the height of the sealing dam is equal to that of the ternary bending torsion micro convexes.

Owner:ZHEJIANG UNIV OF TECH

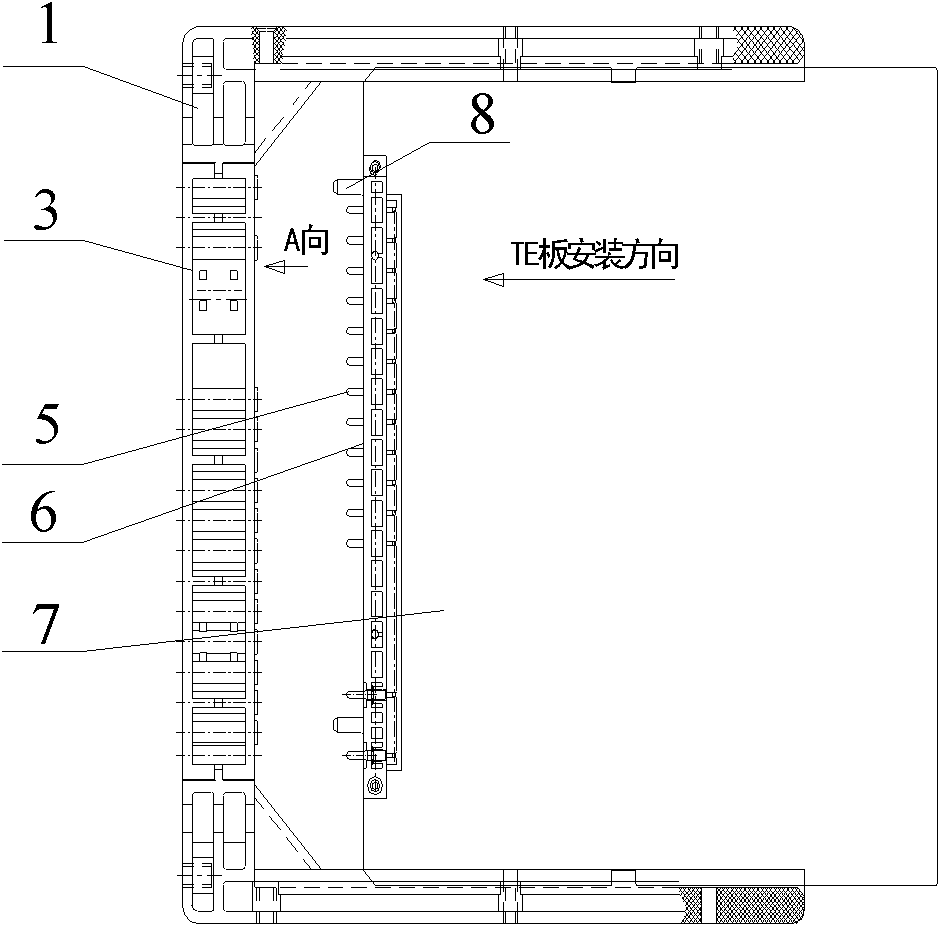

Slot type connector for high potential trigger plate

ActiveCN102544845BRealize detachable connectionReliable cooperationCoupling contact membersElectricityEngineering

Owner:CHINA EPRI SCIENCE & TECHNOLOGY CO LTD +2

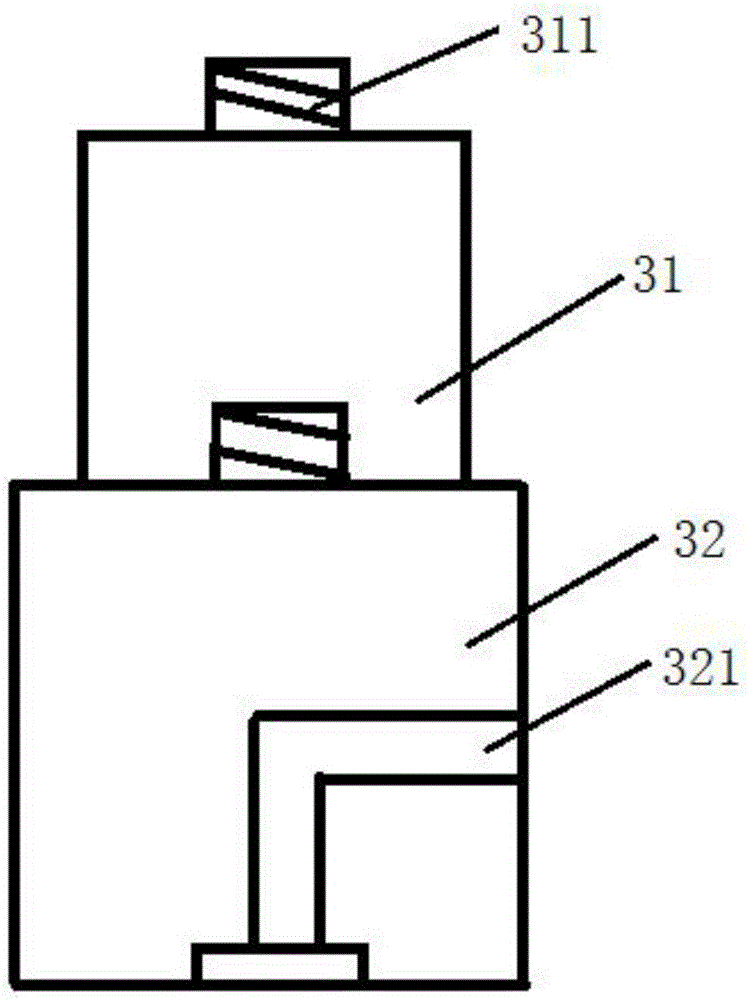

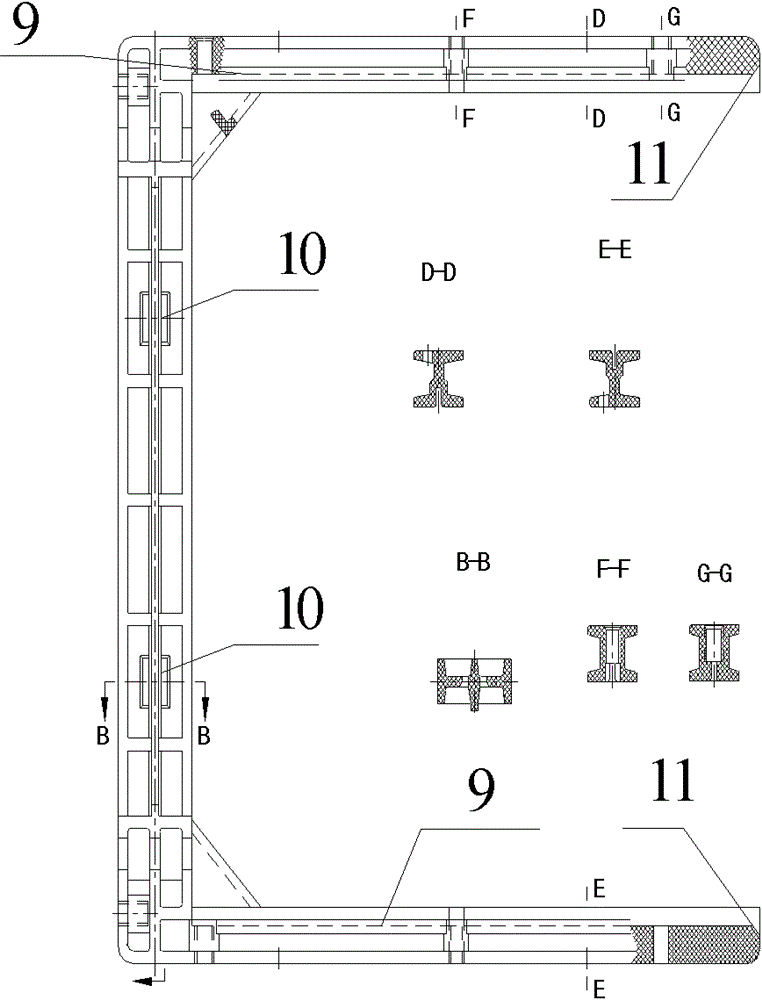

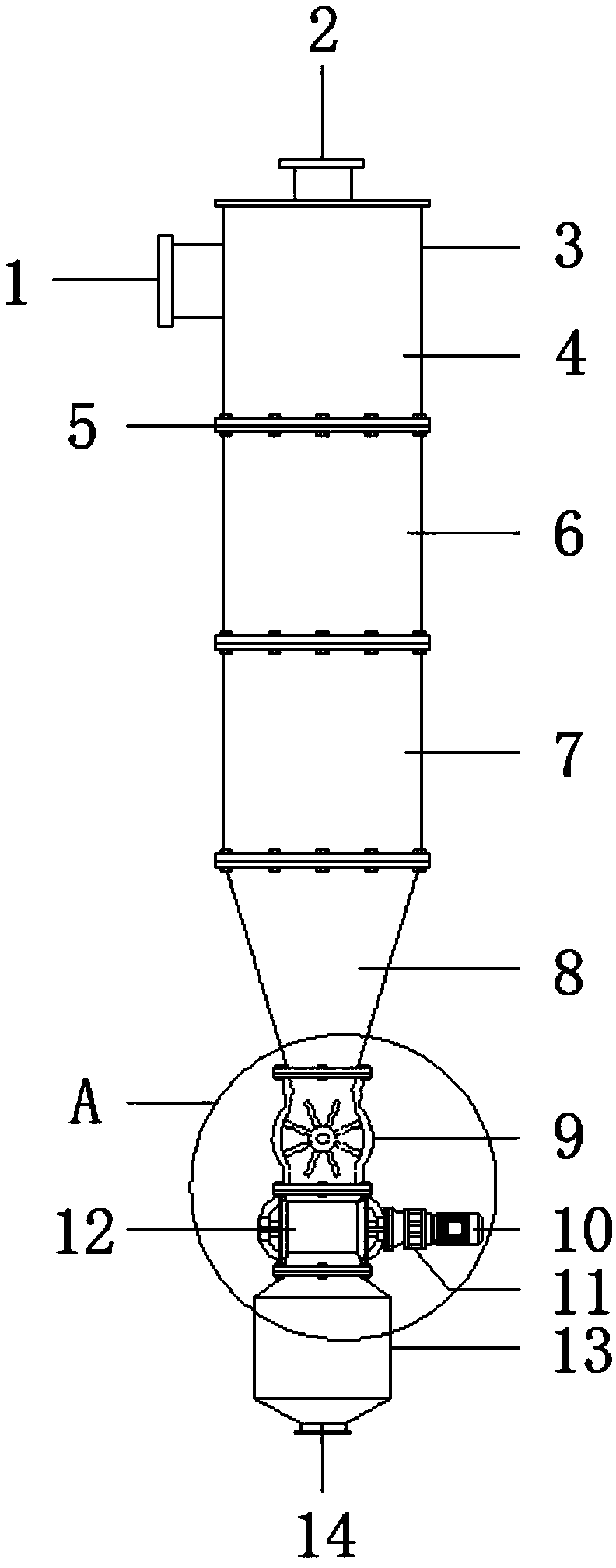

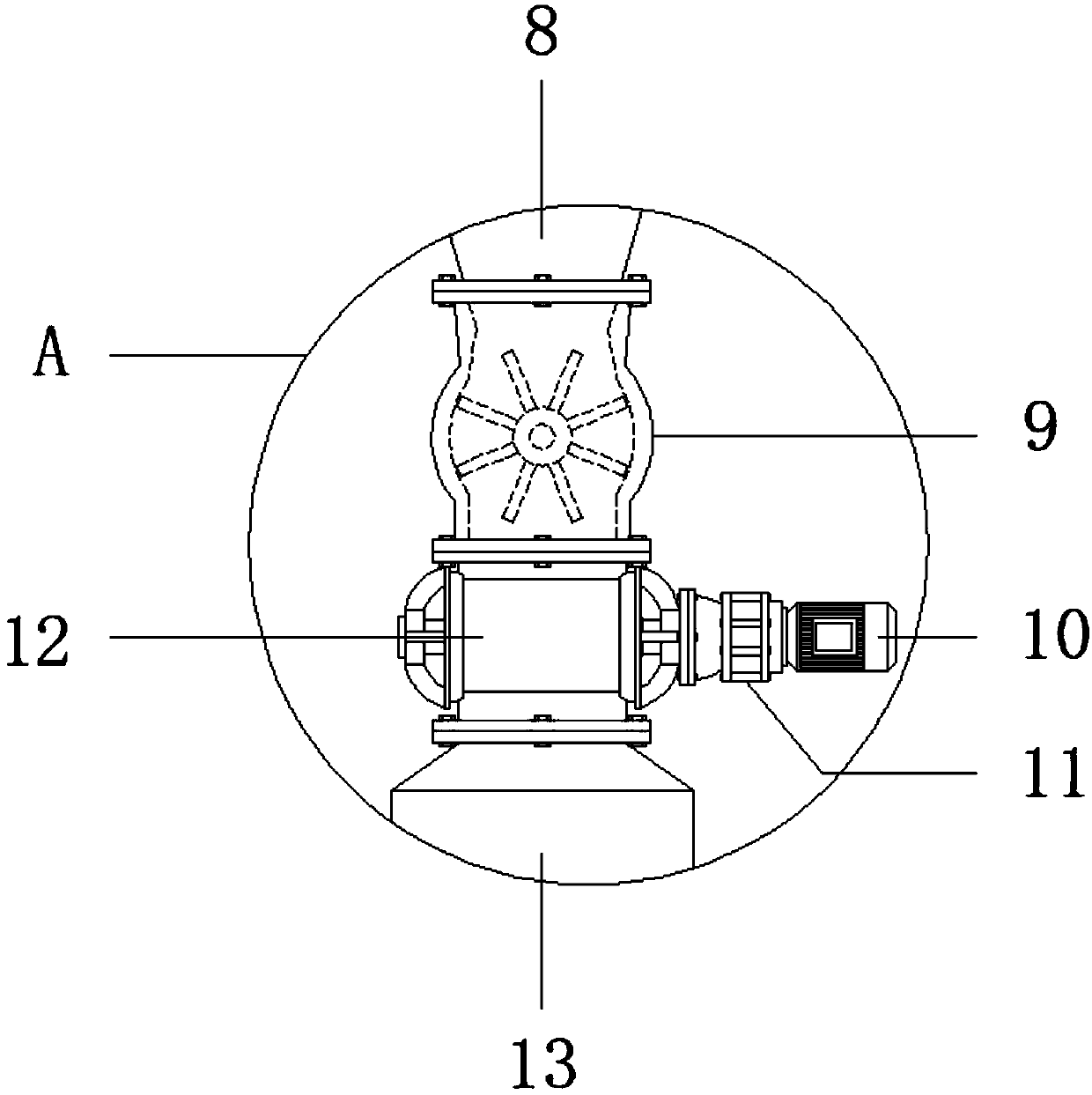

Boiler tail gas multistage cyclone dust removal purification equipment

InactiveCN109954596ARealize the effect of dust removalSimple structureReversed direction vortexCycloneEngineering

The invention relates to the technical field of tail gas treatment, in particular to boiler tail gas multistage cyclone dust removal purification equipment. The boiler tail gas multistage cyclone dustremoval purification equipment comprises a tail gas inlet, an exhaust port and a main body, wherein an upper barrel body is positioned above the main body, and the exhaust port is formed in the top of the upper cylinder body; the tail gas inlet is formed in one side of the upper cylinder body, and the tail gas inlet is connected with the upper barrel body through a penetrating mode; a middle barrel body is positioned below the upper barrel body, and the middle cylinder body is connected with the upper cylinder body through a connecting flange; and a lower cylinder body is located below the middle cylinder body, and the lower cylinder body is connected with the middle cylinder body through a connecting flange. According to the boiler tail gas multistage cyclone dust removal purification equipment, through the improvement of the structure, the structure is simple, the installation is convenient, the maintenance is easy, the dust removal effect is good, the dust removal efficiency is high, the boiler tail gas multistage cyclone dust removal purification device has the advantages of being suitable for different dust removal environments, high in practicability and the like, so that the problems and the defects existing in the existing device are effectively solved.

Owner:惠州大亚湾万圣振宇实业有限公司

A pumping type bridge plug

ActiveCN106703745BReduce grit effectImprove cleanlinessFluid removalSealing/packingMechanical engineeringEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of plugging removal method of polymer flooding plugged well

ActiveCN106958438BReduce the overall heightStrong drainage abilityFluid removalDrilling compositionOil wellPolymer flooding

The invention relates to a blockage-removing method for polymer flooding blocking wells, and belongs to the field of fracturing reformation of oil wells. The blockage-removing method includes the steps of conducting fracturing construction to an blocked oil layer caused by polymer injection and controlling the length of an artificial fracture to 40-60 m, and the height to no more than 20 m, specifically, the fracturing construction is small-scale fracturing construction by sequentially injecting stratum treating fluid with a volume of 10-35 m3, injecting ahead fluid with a volume of 10-30m3, injecting particle loaded fluid with a volume of 40-60 m3, and injecting displacing fluid with a volume of 8-16m3. By reasonable selection of the polymer flooding to block wells, the pertinency and effectiveness of subsequent fracturing measure reformation are improved; by control of the length and the height of the artificial fracture, not only the permeability of a polymer blocked oil layer in near bore zones and effectiveness of the measures are improved, but also wastes of materials and labor cost caused by an excessive large construction scale are avoided, the validity of fracturing blockage-removing measures is increasingly prolonged, and the reservoir recovery is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com