Bird-like wing-shaped multi-channel groove end face sealing structure

An end-face sealing, multi-channel technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of unsatisfactory resistance to external disturbance, large leakage rate, poor starting or stopping performance, etc., and achieve excellent comprehensive sealing performance , Improve the bearing capacity and reduce the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

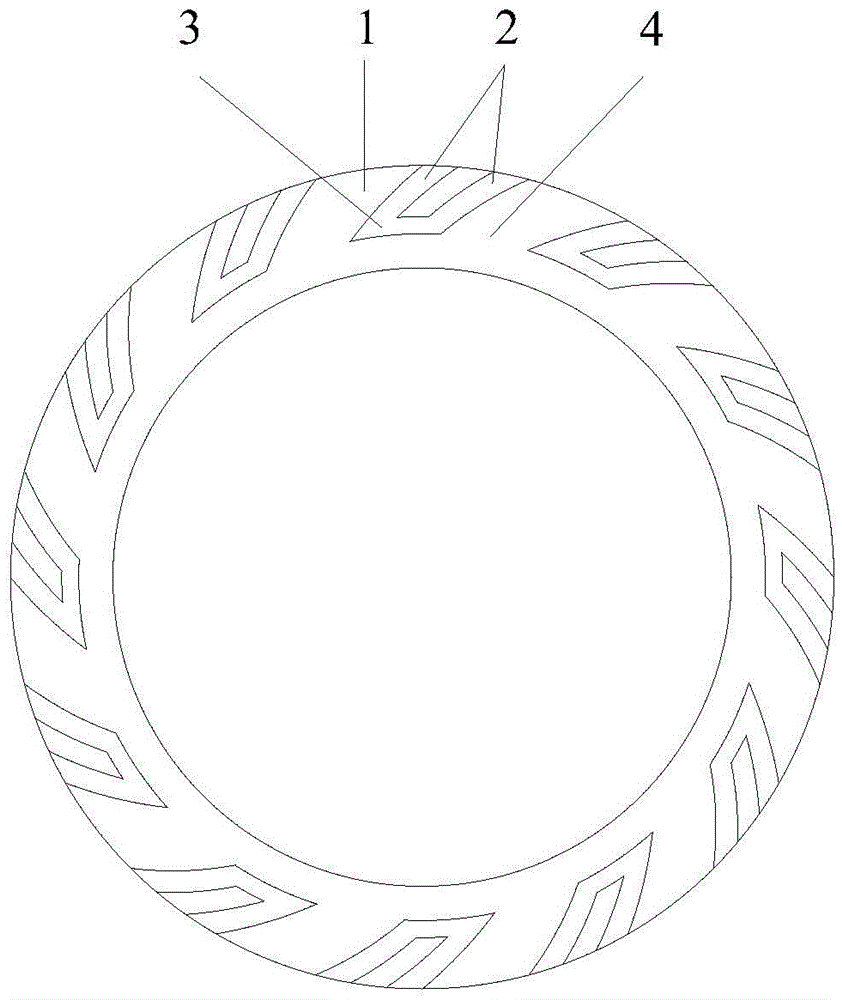

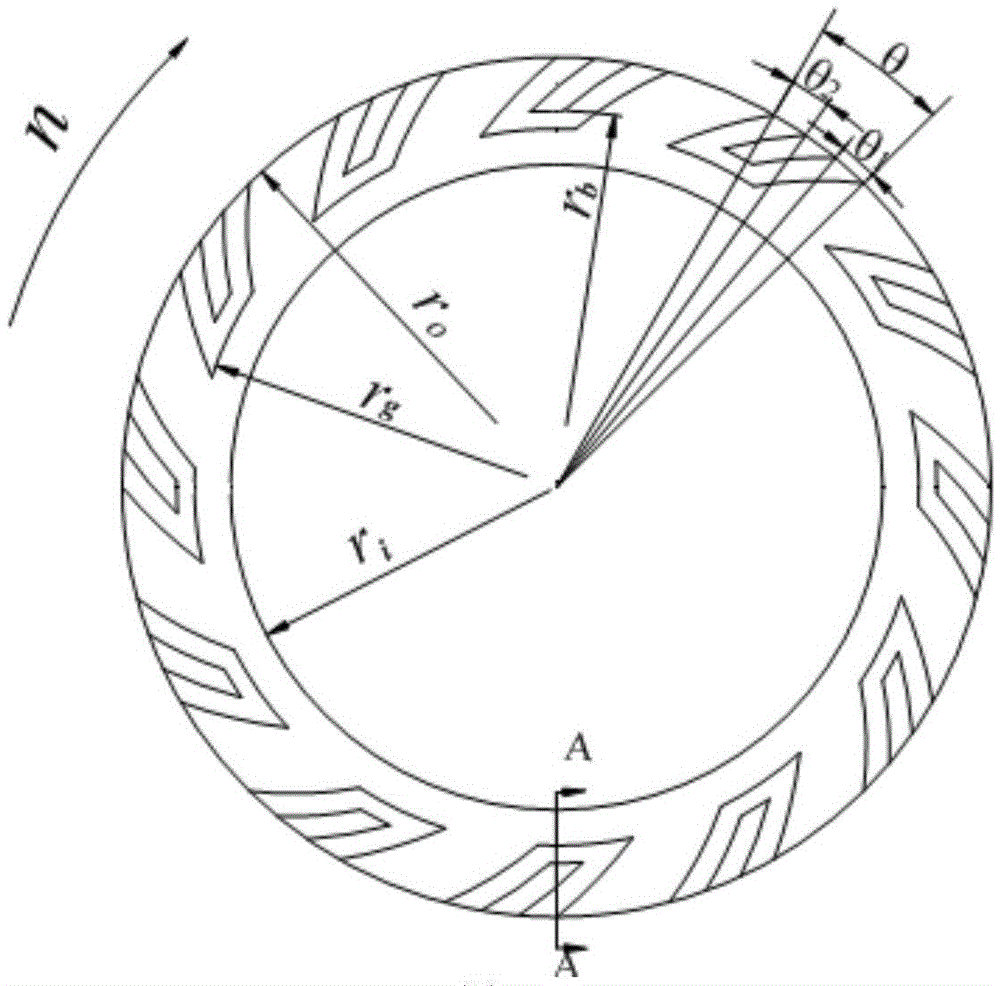

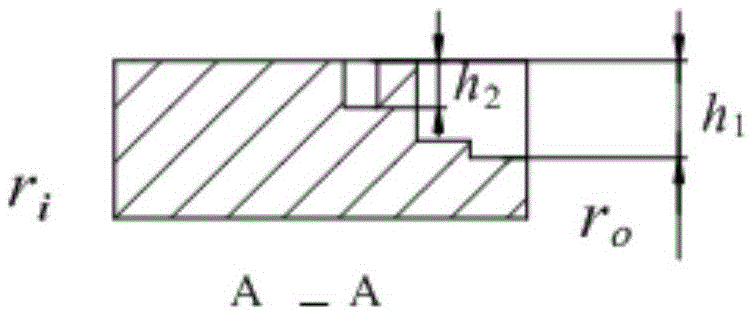

[0029] see figure 1 , Figure 2 and image 3 ,

[0030] In this example, a bird-wing-shaped multi-channel end face seal structure includes two mechanical seal rings, that is, a moving ring and a static ring. There are a plurality of imitation bird-wing multi-pass grooves evenly distributed along the circumference, and the imitation bird-wing multi-pass grooves are located on the high-pressure side of the medium, that is, upstream; the imitation bird-wing multi-pass grooves include more than two drainage grooves 2 and One or more arc grooves 3, the arc groove 3 is located on the downstream side of the drainage groove 2 and connected with each drainage groove 2, the drainage groove 2 communicates with the outer diameter of the sealing ring, the two or more The drainage grooves 2 are distributed along the circumferential direction, and the sealing weirs 1 without slots are used to isolate the drainage grooves 2. The annular zone formed by the non-grooving area on the upper surfa...

Embodiment 2

[0037] see Figure 4 The difference between this embodiment and Embodiment 1 is that the drainage groove 2 is a double-row connected spiral groove, the direction of the helix angle of the upstream spiral groove 2a is opposite to that of the downstream spiral groove 2b, and the downstream spiral groove 2b and the downstream spiral groove 2b are opposite to each other. The circular arc grooves 3 are connected, and the rest of the structure and implementation are the same as in the first embodiment.

Embodiment 3

[0039] see Figure 5 , the difference between this embodiment and embodiment one is that the number N of the drainage grooves y =3, the three drainage grooves are distributed along the circumferential direction, and the number of arc grooves N h =2, the arc grooves are distributed along the radial direction, the middle drainage groove 2c and the leeward side drainage groove 2a are connected through the upstream arc groove 3a, the middle drainage groove 2c is not connected with the downstream arc groove 3b, and the rest of the structure And the embodiment is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com