A pumping type bridge plug

A bridge plug and pumping technology, which is applied in the field of large-scale multi-stage and segmented fracturing operations in unconventional horizontal wells. Sand settling effect, the effect of less injection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

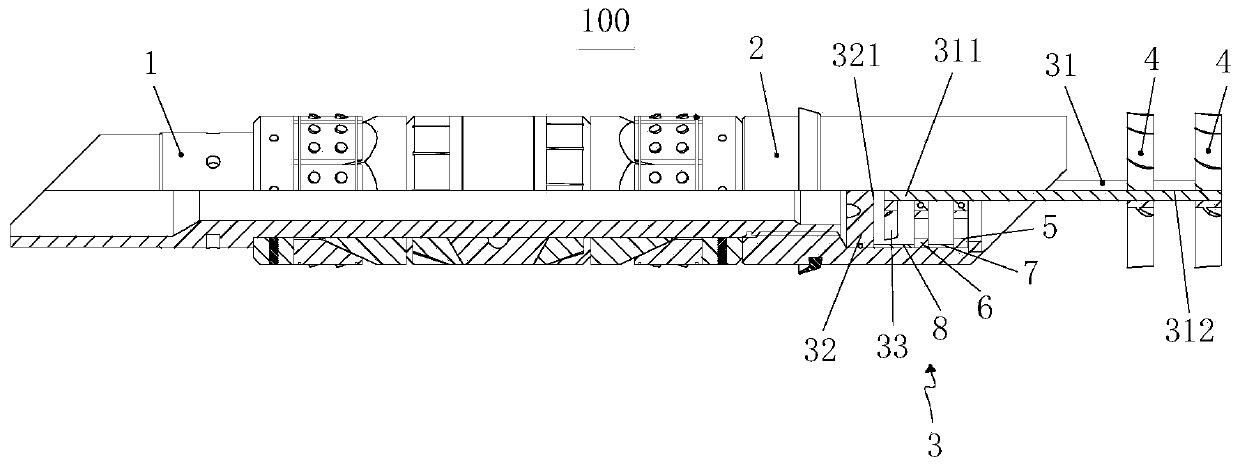

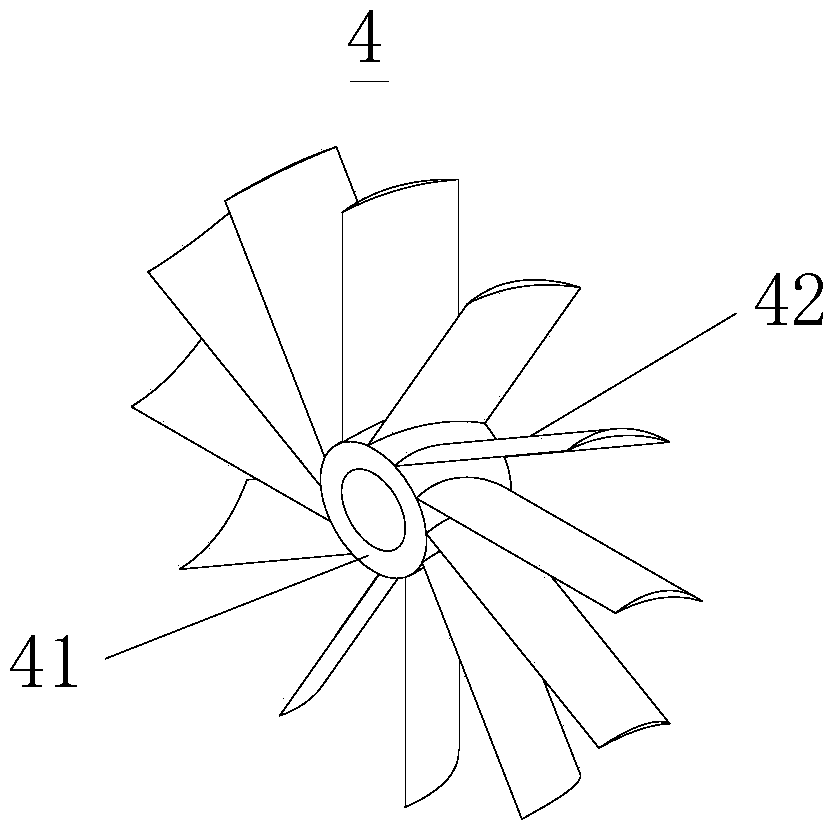

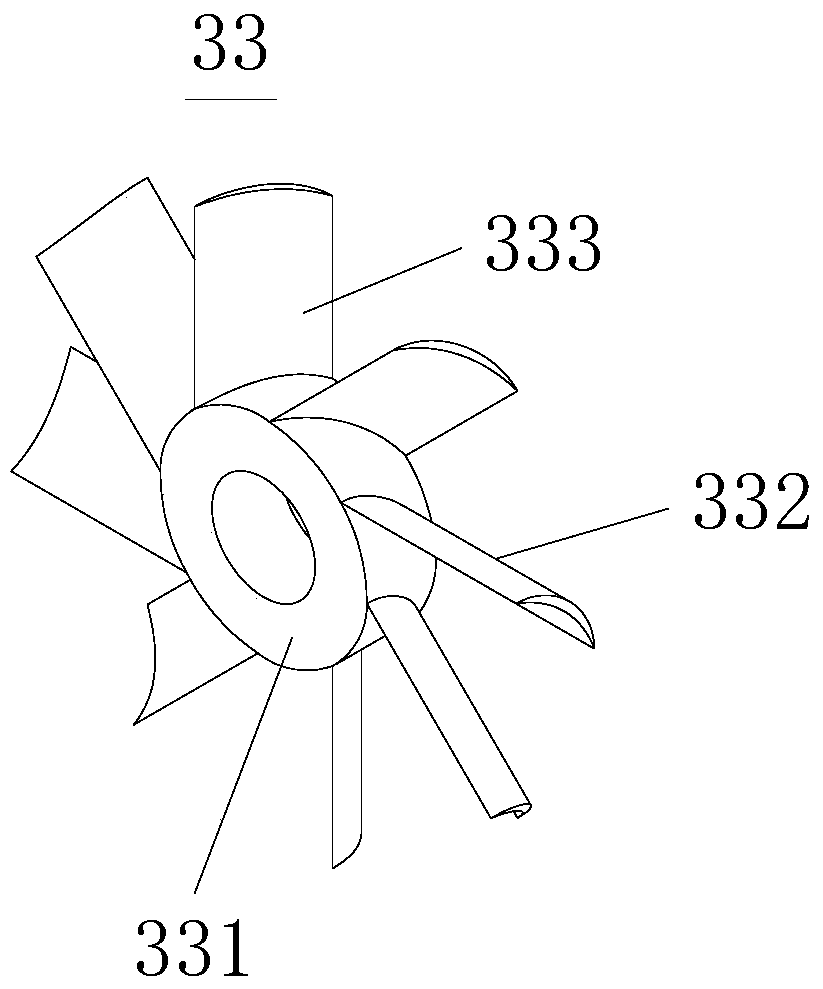

[0023] Such as figure 1 as shown, figure 1 It is schematically shown that the pumping type bridge plug 100 includes a central tube 1 , a guiding head 2 , a driving assembly 3 and a cleaning head 4 .

[0024] In the embodiment of the present application, the center pipe 1 is substantially cylindrical and hollow inside. Wherein, the upper end of the central tube 1 is configured with a milling butt joint surface which forms a certain angle with the shaft end surface. In this way, the milling operation of the pumping bridge plug 100 is facilitated.

[0025] In a specific embodiment, the range of the certain angle is greater than or equal to 45 degrees and less than or equal to 60 degrees. Among them, preferred angles are 45 degrees, 50 degrees, 55 degrees and 60 degrees.

[0026] The guide head 2 is connected with the central pipe 1, specifically, the guide head 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com