Anti-polymer adsorbent and preparation method thereof

A polymer and adsorbent technology, applied in the field of anti-polymer adsorbent and its preparation, can solve the problems of poor anti-adsorption effect, large amount of addition, short validity period, etc., and achieve strong adhesion, strong film-forming property and long validity period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

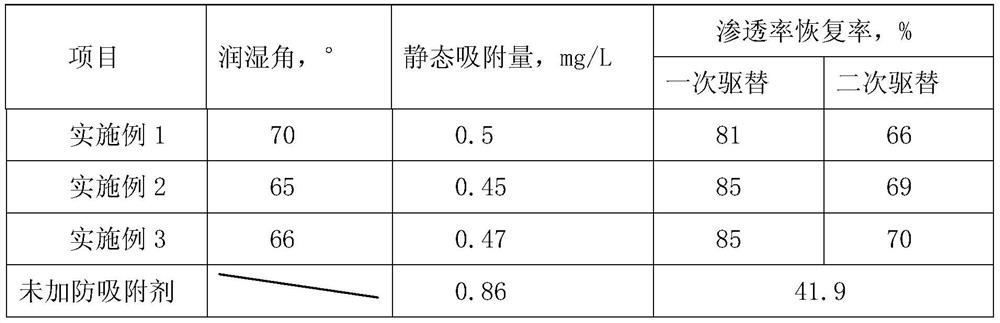

[0034] Embodiment 1: preparation anti-polymer adsorbent

[0035] The raw materials are as follows: bentonite nanoparticles 2.25g; OP-10, 1.5g; epoxy resin E-44, 20g; acrylic acid 5g, butyl acrylate 10g; styrene 6g; ammonium persulfate 0.6g; Ammonium chloride 10g; Aminopropyltriethoxysilane 5g.

[0036] The preparation method is as follows:

[0037] (1) Nanoparticles are placed in water to obtain 150 g of nanoparticle aqueous dispersions;

[0038] (2) adding the OP surfactant to the aqueous nanoparticle dispersion to obtain an aqueous surfactant solution;

[0039] (3) epoxy resin, acrylic acid monomer and styrene are added in surfactant aqueous solution, disperse 30 minutes with high-speed dispersing emulsifying machine, and stirring speed is 3000 rev / mins, obtains pre-emulsion;

[0040] (4) ammonium persulfate is mixed with the ammonium persulfate aqueous solution that mass concentration is 10%;

[0041] Take 1 / 4 of the pre-emulsion, heat it to 80°C and keep it warm, add 1...

Embodiment 2

[0046] Embodiment 2: preparation anti-polymer adsorbent

[0047]The raw materials are as follows: hectorite nanoparticles 3 g; OP-13, 1.5 g; epoxy resin E-44, 20 g; methacrylic acid 5 g, butyl acrylate 10 g; styrene 6 g; ammonium persulfate 0.6 g; Trimethylammonium chloride 12g; Aminopropyltriethoxysilane 5g.

[0048] The preparation method is the same as in Example 1.

[0049] Take the anti-polymer adsorbent prepared above, and measure its wetting angle to be 65°, which can spread rapidly on the surface of sand grains.

[0050] Add polyacrylamide to the quartz sand soaked in the above-mentioned anti-polymer adsorbent, and measure the static adsorption amount of polyacrylamide on the surface of quartz sand to be 0.45mg / L (the static adsorption of polyacrylamide on the surface of untreated quartz sand The amount is 0.8mg / L).

[0051] Take a certain amount of the above-mentioned anti-polymer adsorbent, dilute it to a concentration of 1000mg / L with Shengli brine type II (salin...

Embodiment 3

[0052] Embodiment 3: preparation anti-polymer adsorbent

[0053] The raw materials are as follows: silica nanoparticles 3.6 g; OP-15, 2.0 g; epoxy resin E-44, 30 g; methacrylic acid 10 g, methyl acrylate 15 g; styrene 10 g; ammonium persulfate 1.0 g; dodecane Trimethyl ammonium chloride 15g; Aminopropyltriethoxysilane 5g.

[0054] The preparation method is the same as in Example 1.

[0055] Take the anti-polymer adsorbent prepared above, and measure its wetting angle to be 66°, which can spread rapidly on the surface of sand grains.

[0056] Add polyacrylamide to the quartz sand soaked in the above-mentioned anti-polymer adsorbent, and measure the static adsorption amount of polyacrylamide on the surface of quartz sand to be 0.47mg / L (the static adsorption of polyacrylamide on the surface of untreated quartz sand The amount is 0.8mg / L).

[0057] Take a certain amount of the above-mentioned anti-polymer adsorbent, dilute it to a concentration of 1000mg / L with Shengli brine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static adsorption capacity | aaaaa | aaaaa |

| Static adsorption capacity | aaaaa | aaaaa |

| Static adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com