Method for manufacturing nano titanium dioxide thin film through photocuring

A nano-titanium dioxide and titanium dioxide technology, which is applied in photosensitive equipment, photovoltaic power generation, capacitor electrodes, etc., can solve the problems of inability to effectively control the surface morphology of nano-titanium dioxide thin films, affecting the photoelectric conversion efficiency of dye-sensitized solar cells, and difficulty in entering dyes. Achieve the effect of improving photoelectric conversion efficiency, high specific surface area, and enhancing light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

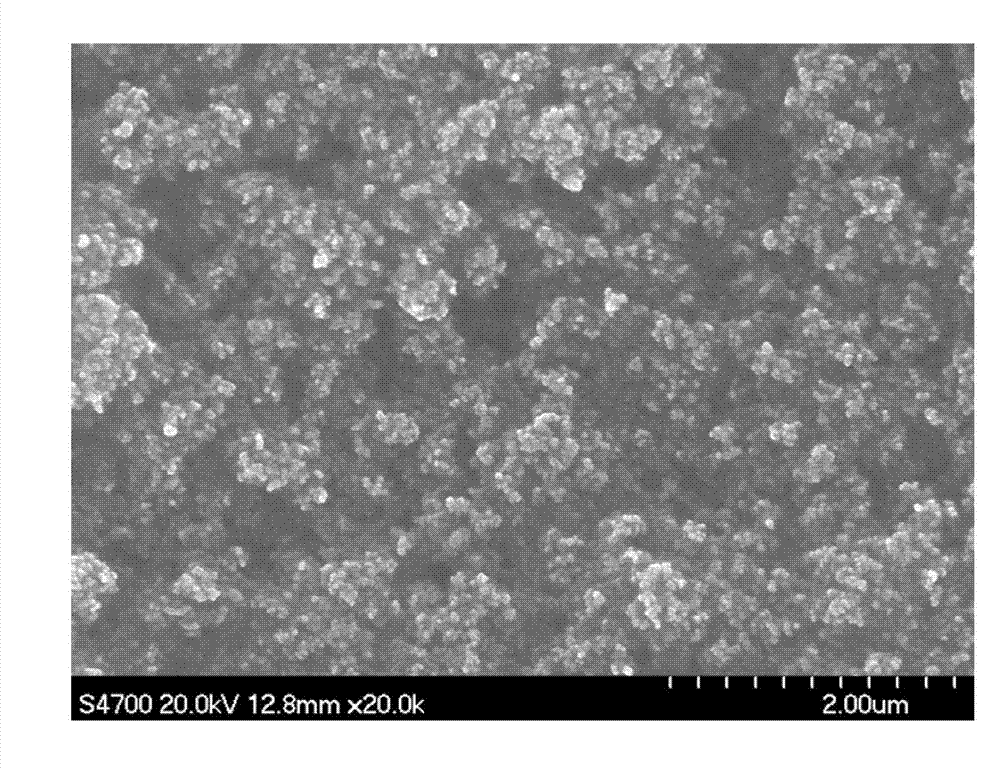

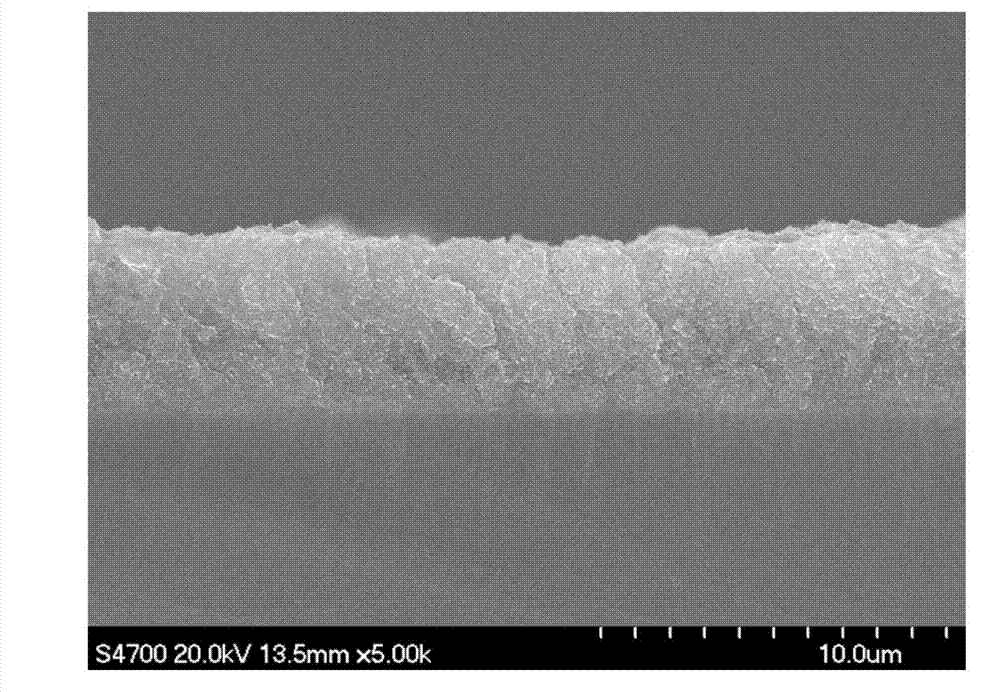

[0026] Clean the FTO transparent conductive glass ultrasonically for 15 minutes in the order of blue moon detergent, deionized water, acetone, deionized water, 95% (v / v) ethanol and deionized water, and finally soak in isopropanol solution for later use . 1.0g titanium dioxide nanoparticles were uniformly dispersed in a mixed solution of 6.0mL ethanol and 15.0mL isopropanol to obtain a; 2.0g monomer pentaerythritol triacrylate (PETA) and 0.025g photoinitiator 2-hydroxyl-2-methyl - Dissolve 1-phenylacetone (HMPP) in a mixed solution of 6.0mL ethanol and 8.0mL N,N-dimethylformamide (DMF) to obtain b. Then add b dropwise into a, and mix uniformly to prepare a colloidal titanium dioxide dispersion for film coating. The FTO transparent conductive glass soaked in the isopropanol solution was blown dry with nitrogen gas, and the colloidal dispersion was evenly coated on the cleaned FTO transparent conductive glass by the scraper coating method to obtain a layer of uniform thickness ...

Embodiment 2

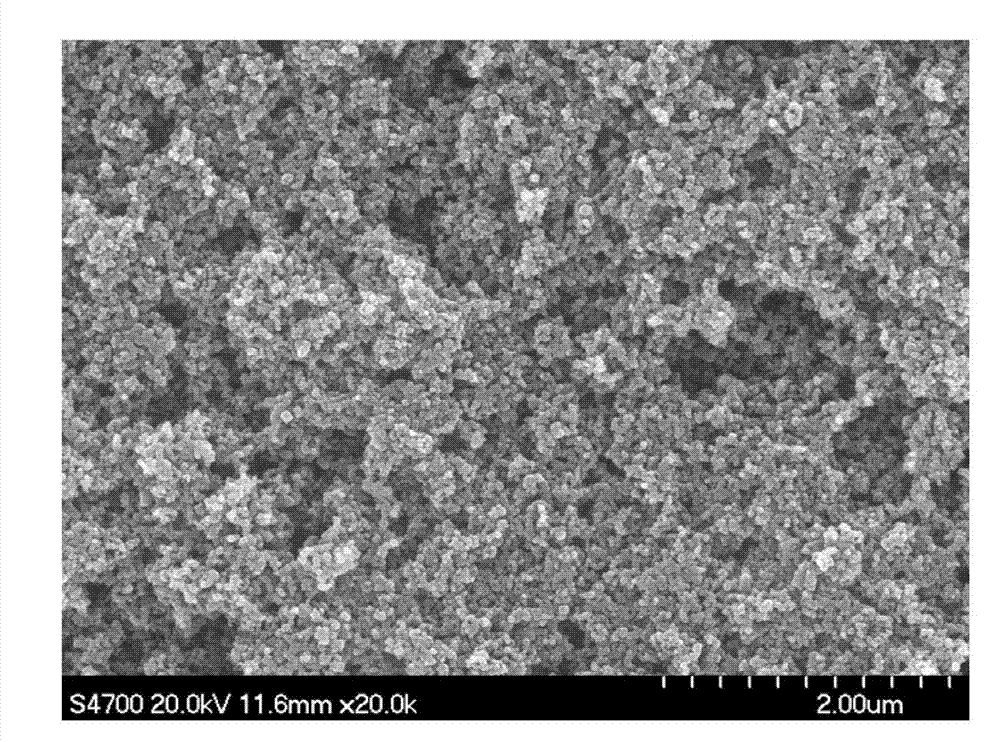

[0028] The FTO conductive glass was ultrasonically cleaned for 15 minutes in the order of five cleaning powder, deionized water, acetone, deionized water, 95% (v / v) ethanol and deionized water, and finally soaked in isopropanol solution for later use. 1.0g titanium dioxide nanorods were uniformly dispersed in a mixed solution of 6.0mL ethanol and 15.0mL isopropanol to obtain a; 2.0g monomer pentaerythritol triacrylate and 0.03g photoinitiator 2-hydroxyl-2-methyl-1- Dissolve phenylacetone in a mixed solution of 6.0mL ethanol and 8.0mL N,N-dimethylformamide to obtain b. Then add b dropwise into a, and mix uniformly to prepare a colloidal titanium dioxide dispersion for film coating. Nitrogen gas was blown to dry the FTO conductive glass to obtain the substrate of the loaded film, and a layer of colloidal dispersion coating evenly distributed on the surface of the substrate was prepared by dipping and pulling method. The coating coated on the FTO conductive glass is placed under...

Embodiment 3

[0030] The FTO conductive glass was ultrasonically cleaned for 20 minutes in the order of hand sanitizer, deionized water, acetone, deionized water, 95% (v / v) ethanol and deionized water, and finally soaked in isopropanol solution for later use. 0.75g titanium dioxide nanoparticles were uniformly dispersed in a mixed solution of 5.0mL ethanol and 12.0mL isopropanol to obtain a; 1.0g monomer pentaerythritol triacrylate and 0.02g photoinitiator benzophenone were dissolved in 5.0mL ethanol and 7.0 mL N, N-dimethylformamide mixed solution to obtain b. Then add b into a, and mix uniformly to prepare a colloidal titanium dioxide dispersion for film coating. Dry the FTO conductive glass with nitrogen gas, and apply the prepared colloidal dispersion evenly on the cleaned substrate surface by scraping coating method. The colloidal titanium dioxide dispersion coating coated on the FTO conductive glass is placed under a UV lamp, and undergoes a polymerization reaction through ultraviole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com