Strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure

An end face mechanical seal and enhanced heat transfer technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of high frictional heat generation, weak heat transfer capacity, and poor ability to adapt to solid content media, etc., to improve stiffness and tightness, reduce leakage rate, and improve the effect of sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

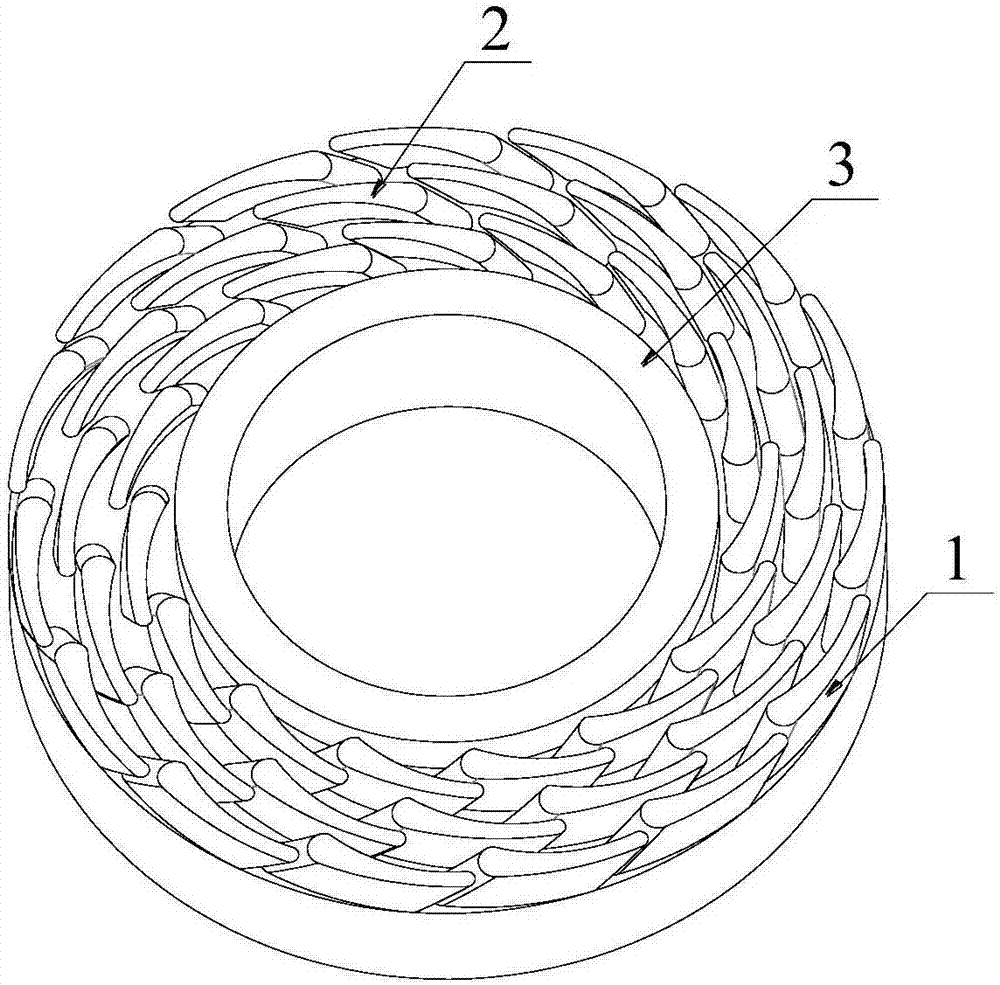

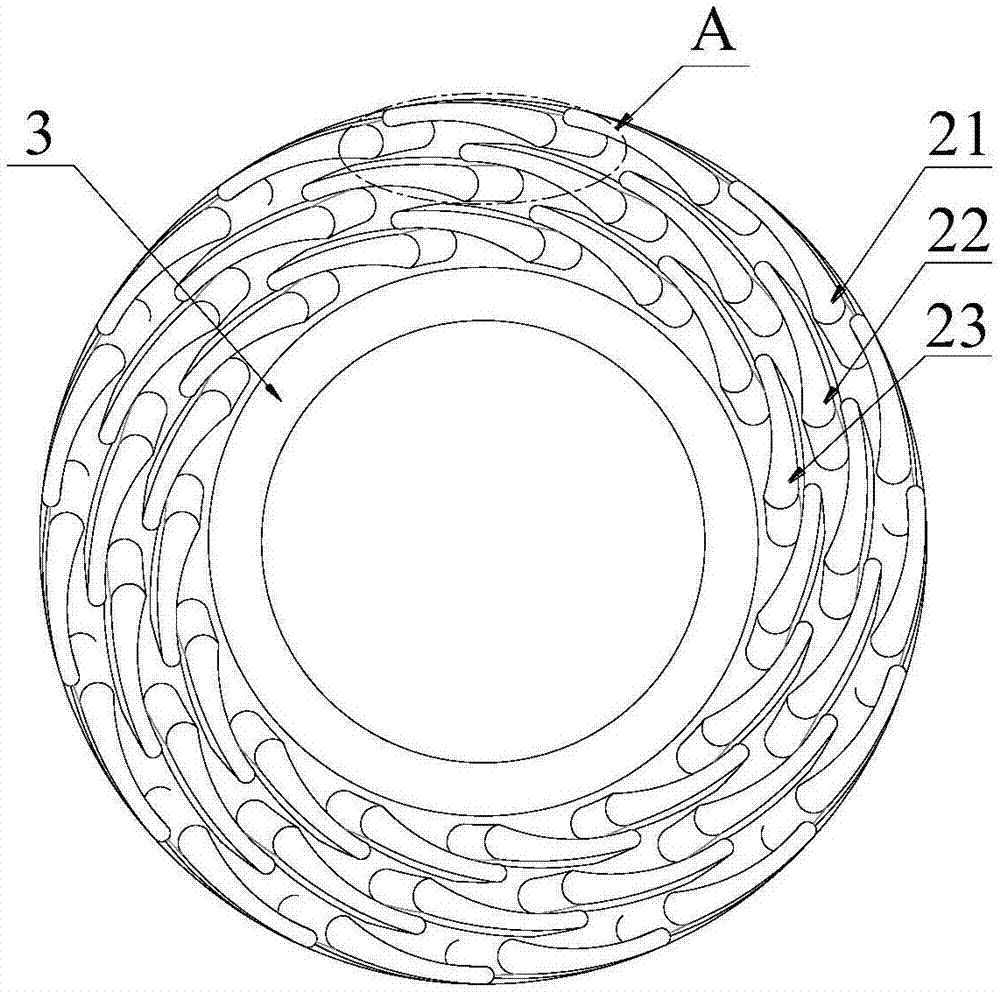

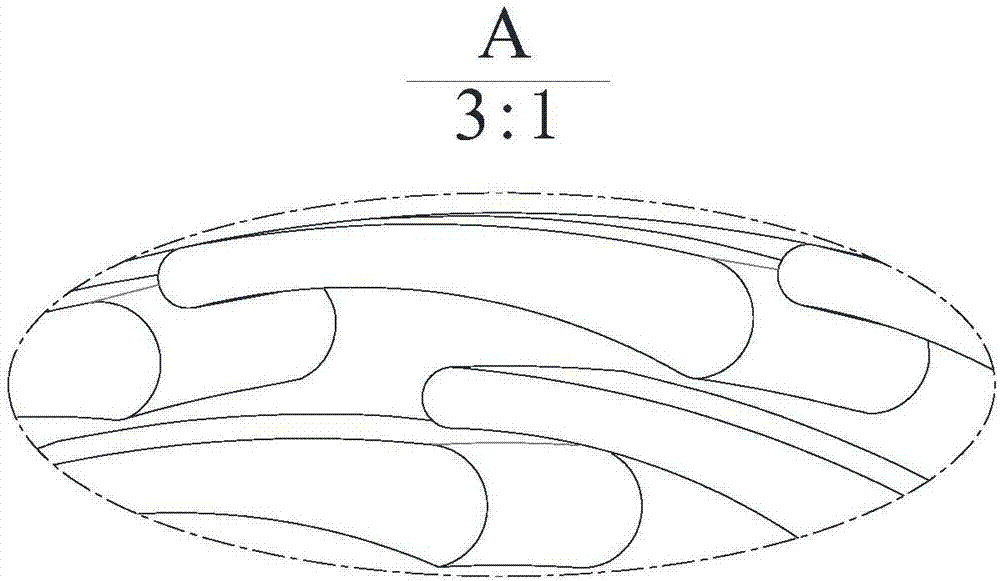

[0028] refer to figure 1 , 2 and 3, 4, 5, a heat transfer-enhanced ternary bending and torsion micro-convex body end face mechanical seal structure, the end faces of the moving ring or the static ring of the mechanical seal are processed along the circumferential direction according to the center of the end face to form an annulus 2 There is a ternary bending and twisting asperity 1, and the ternary bending and twisting asperity 1 is a micro-pillar whose cross-sectional shape is an airfoil, and there is a relative cross section between two adjacent ternary bending and twisting asperities 1 twist, each asperity on the same asperity ring is arranged at the same relative position relative to the center of the end face, which can improve the shear failure resistance of the asperity and improve the wear resistance of the end face ; The major axis of the cross section of the ternary bending and twisting asperity 1 is arranged along the circumferential direction of the end face, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum radial dimensions | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com