Patents

Literature

200 results about "End face mechanical seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An end-face mechanical seal, or a mechanical end-face seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing (otherwise known as gland packing) to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications.

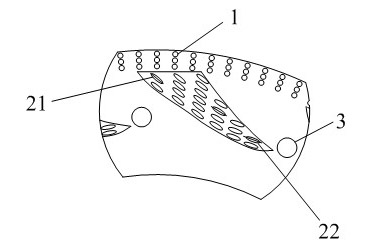

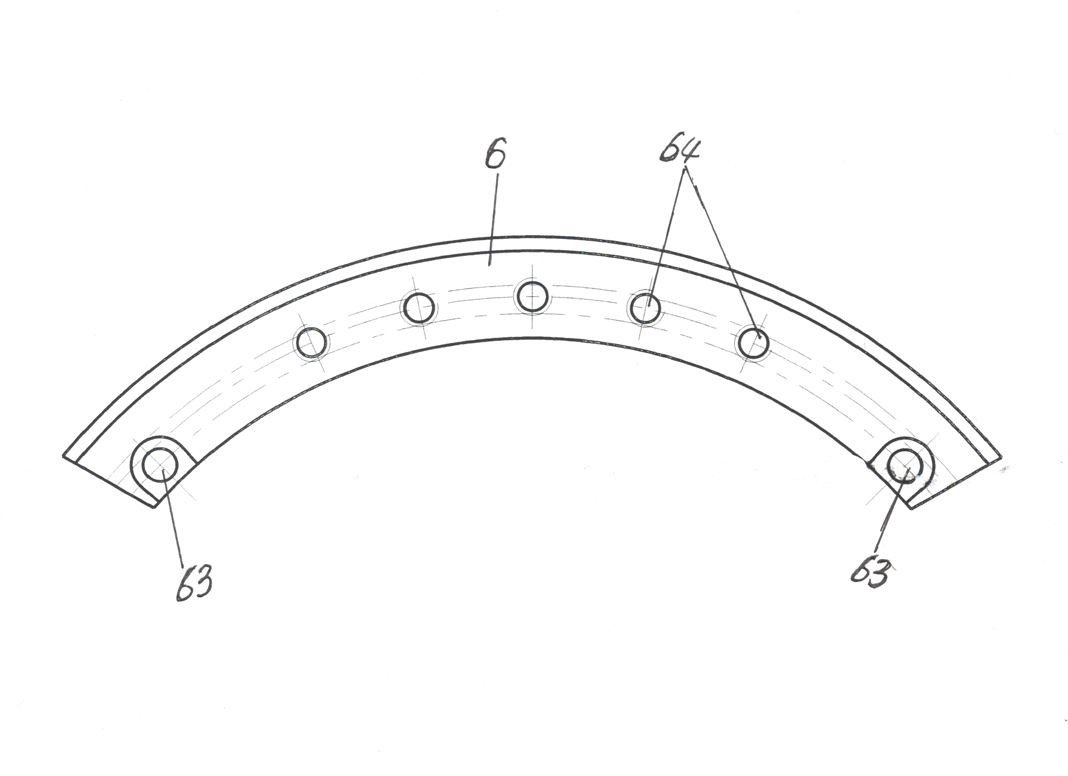

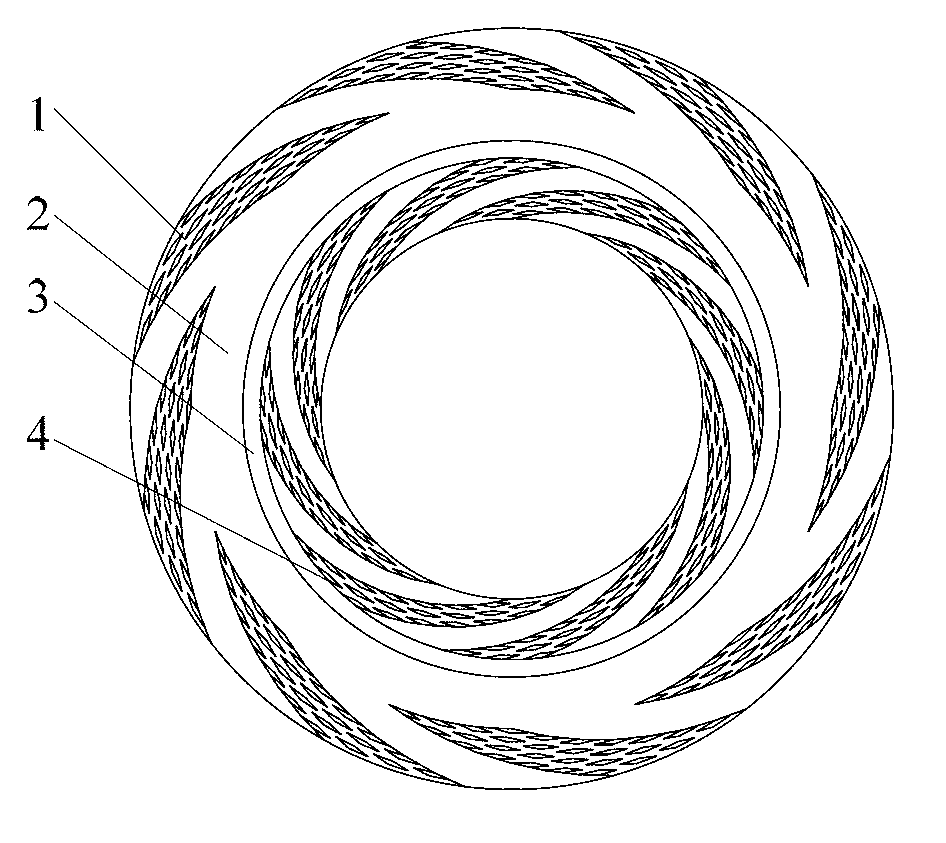

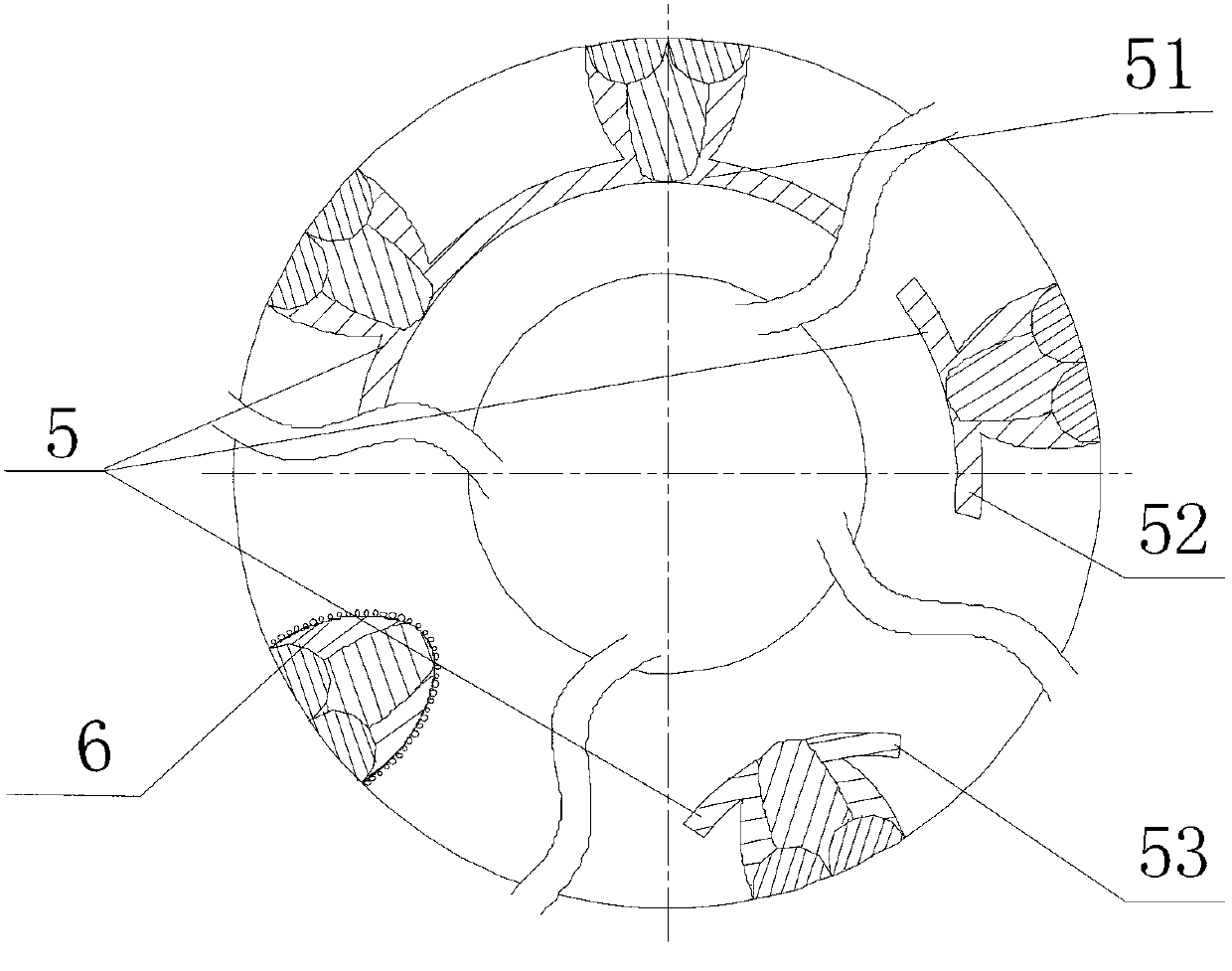

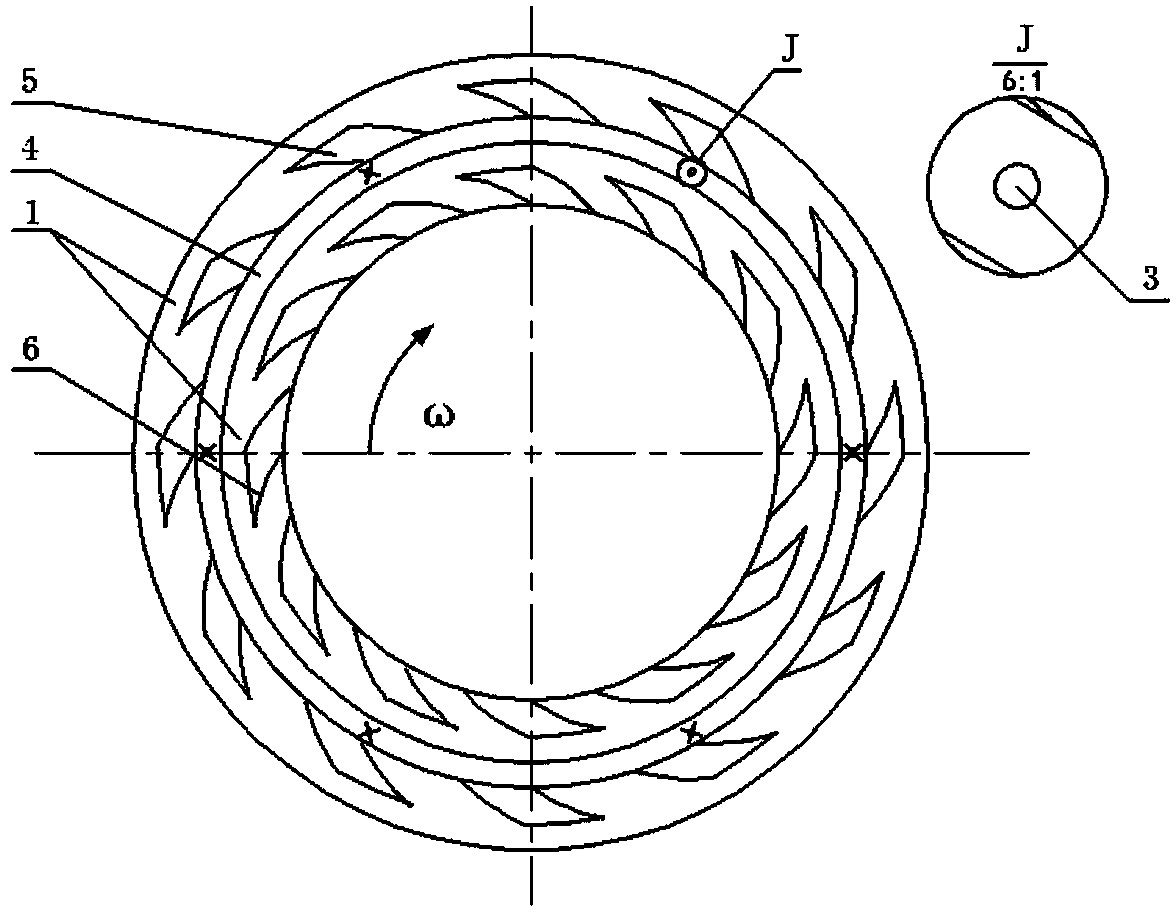

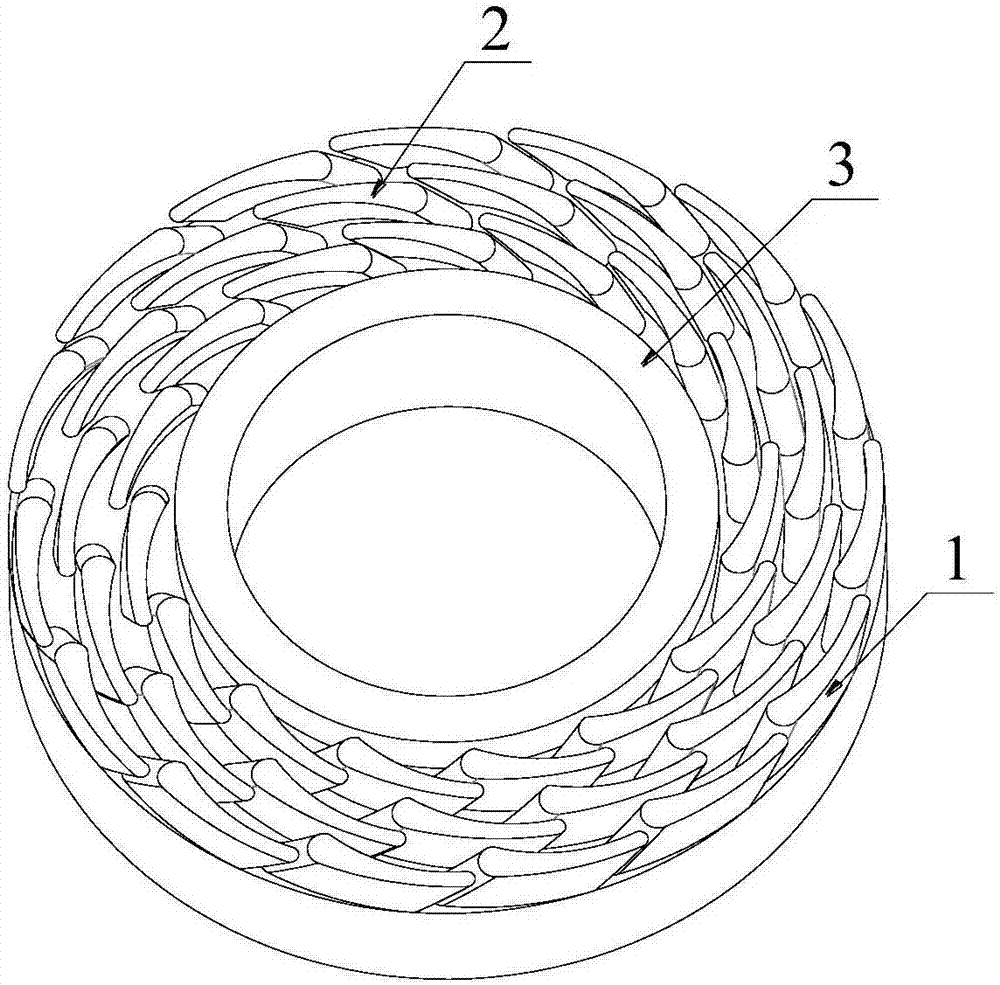

Variable distribution porous end face mechanical sealing structure

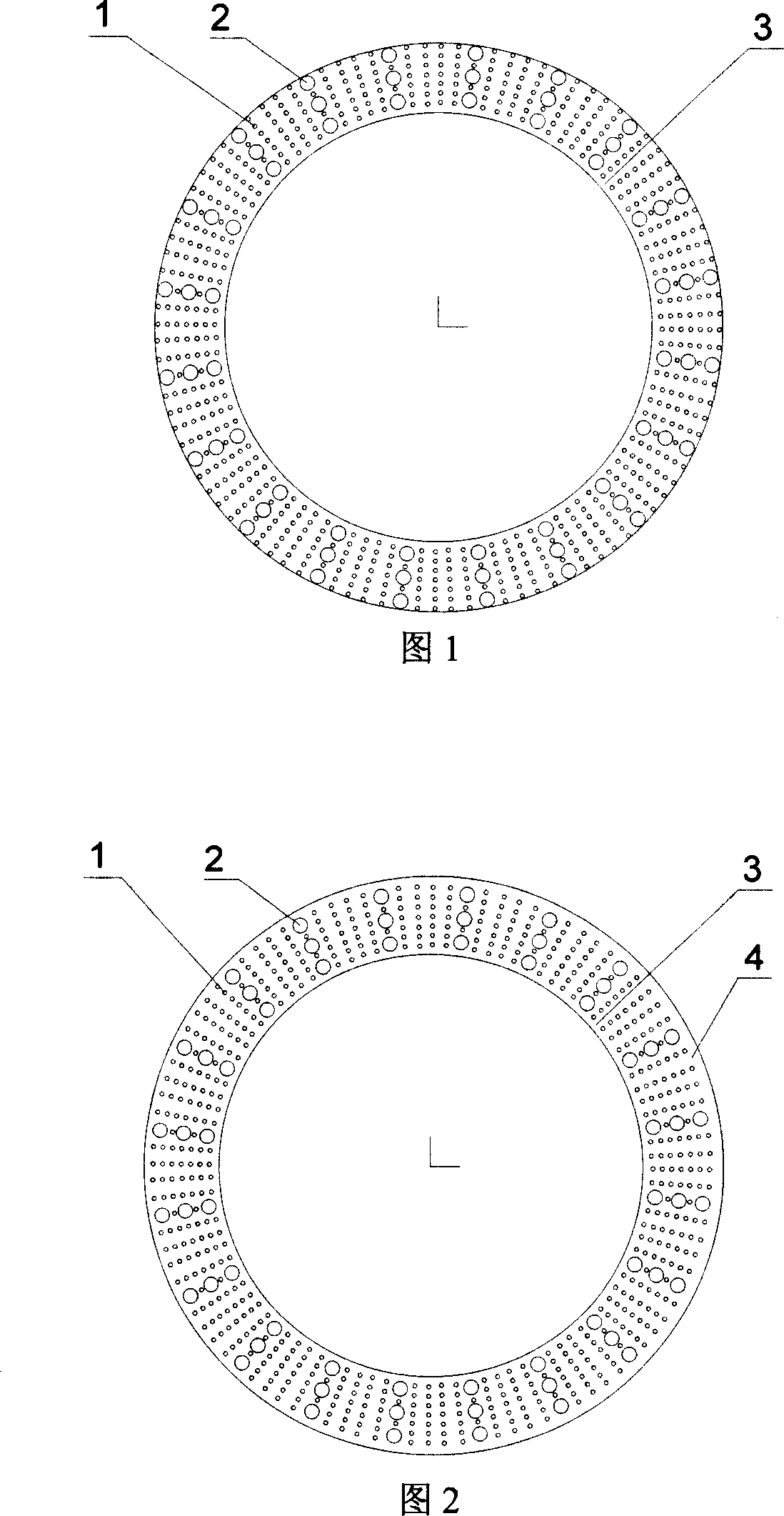

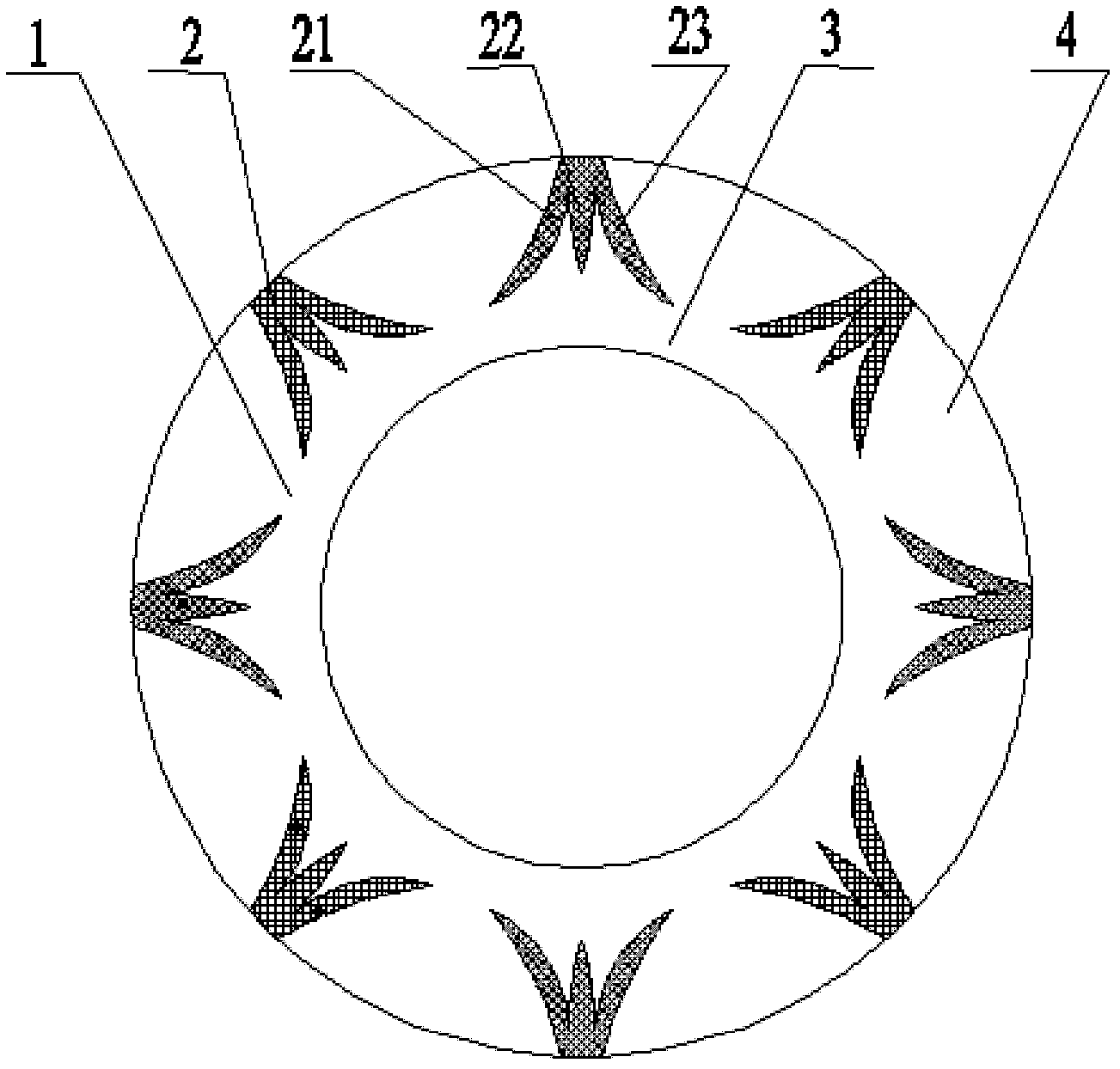

ActiveCN101016949AImprove wear resistanceImproved opening/stopping performanceEngine sealsHigh pressureWear resistance

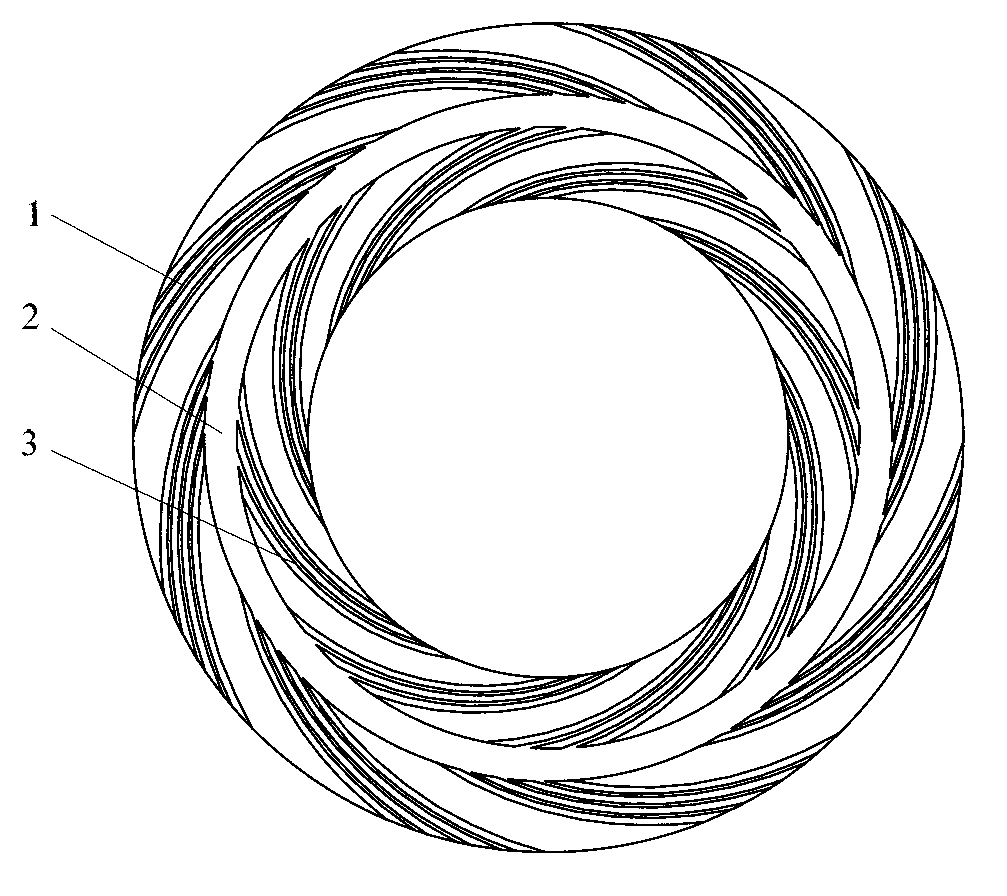

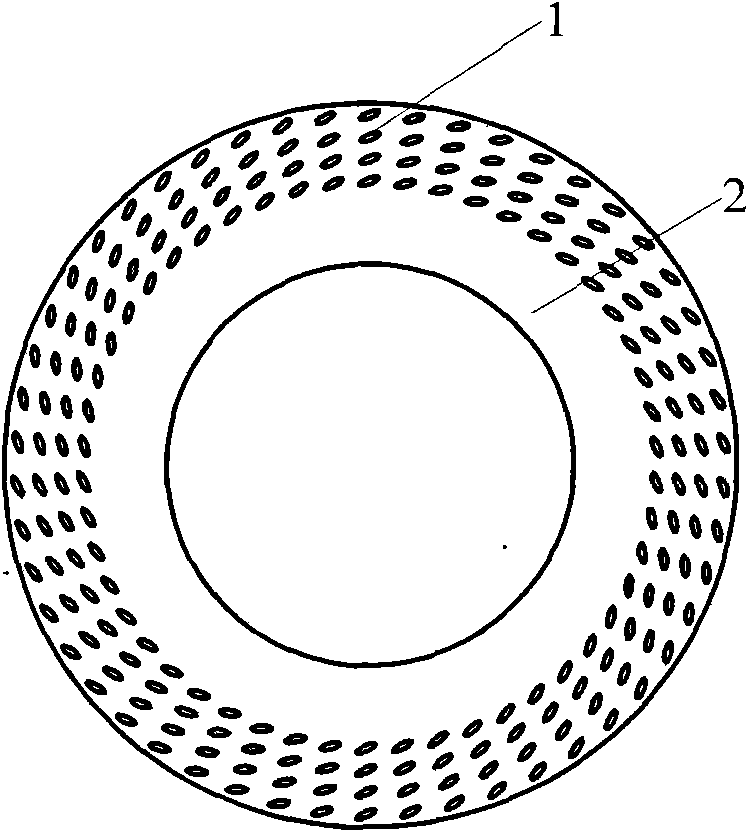

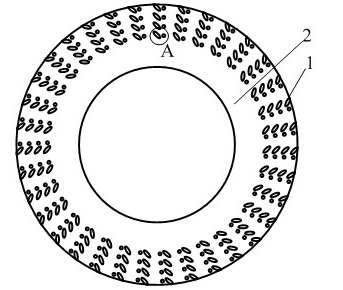

The invention relates ton a variable-distribution porous end mechanical sealing structure, comprising a movable ring and a stable ring which are mechanically sealed, to form an annular sealing end. One side of the sealing end is high pressure side as ascending, while another end is low pressure side as descending, at least one sealing end is disposed with porous structure in different sizes symmetry distributed on the sealed end. Compared with present screw or groove mechanical sealing structure, the invention has better pressure resistance, abrasion resistance and better dynamic pressure effect on fluid membrane, to improve the carrier ability of fluid membrane.

Owner:ZHEJIANG UNIV OF TECH

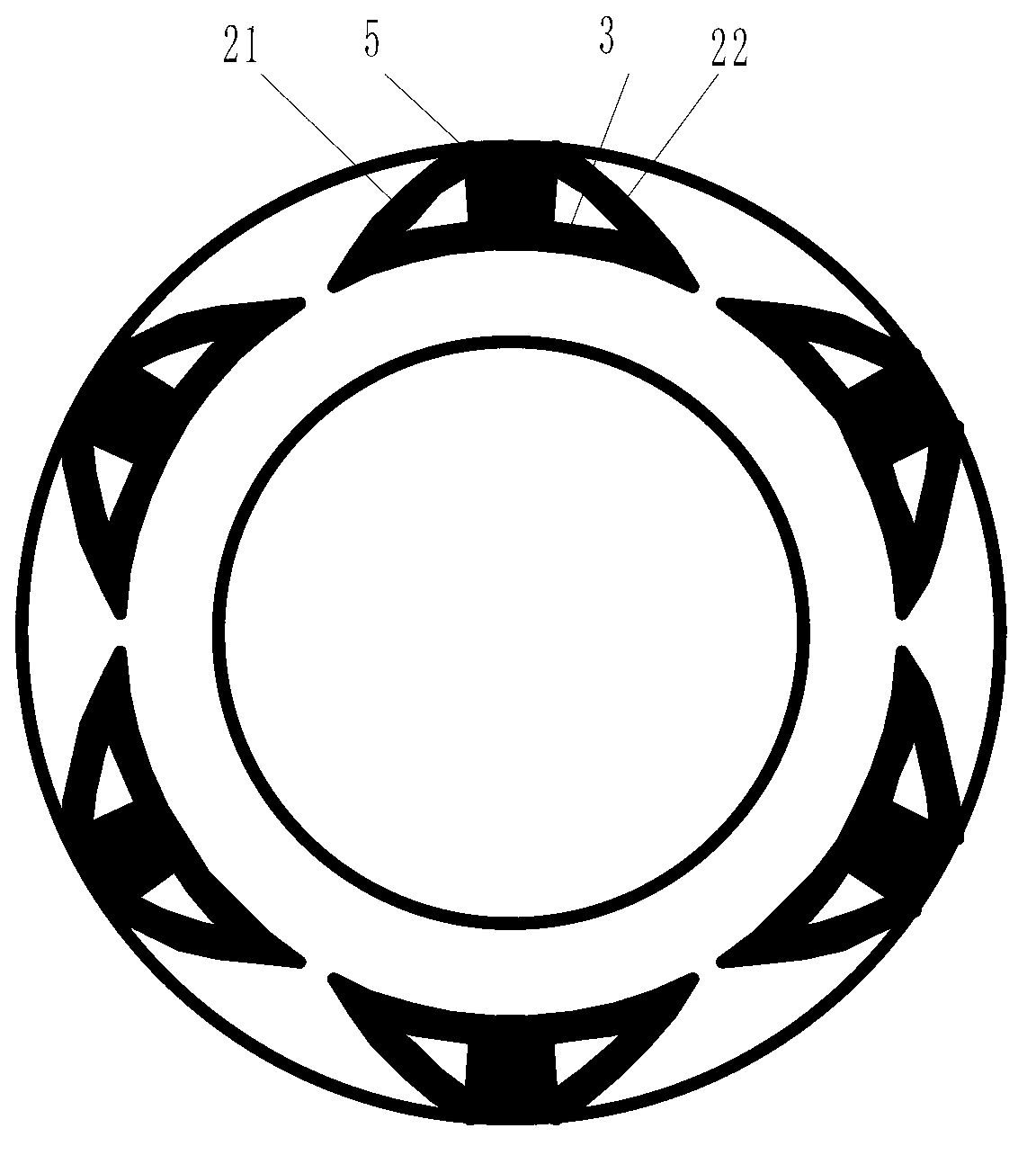

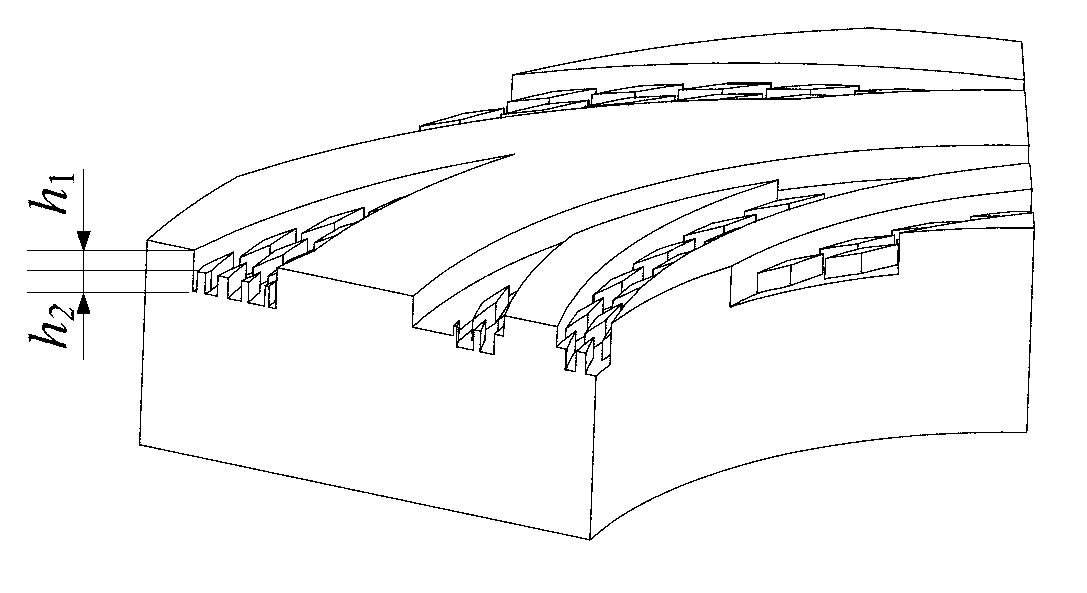

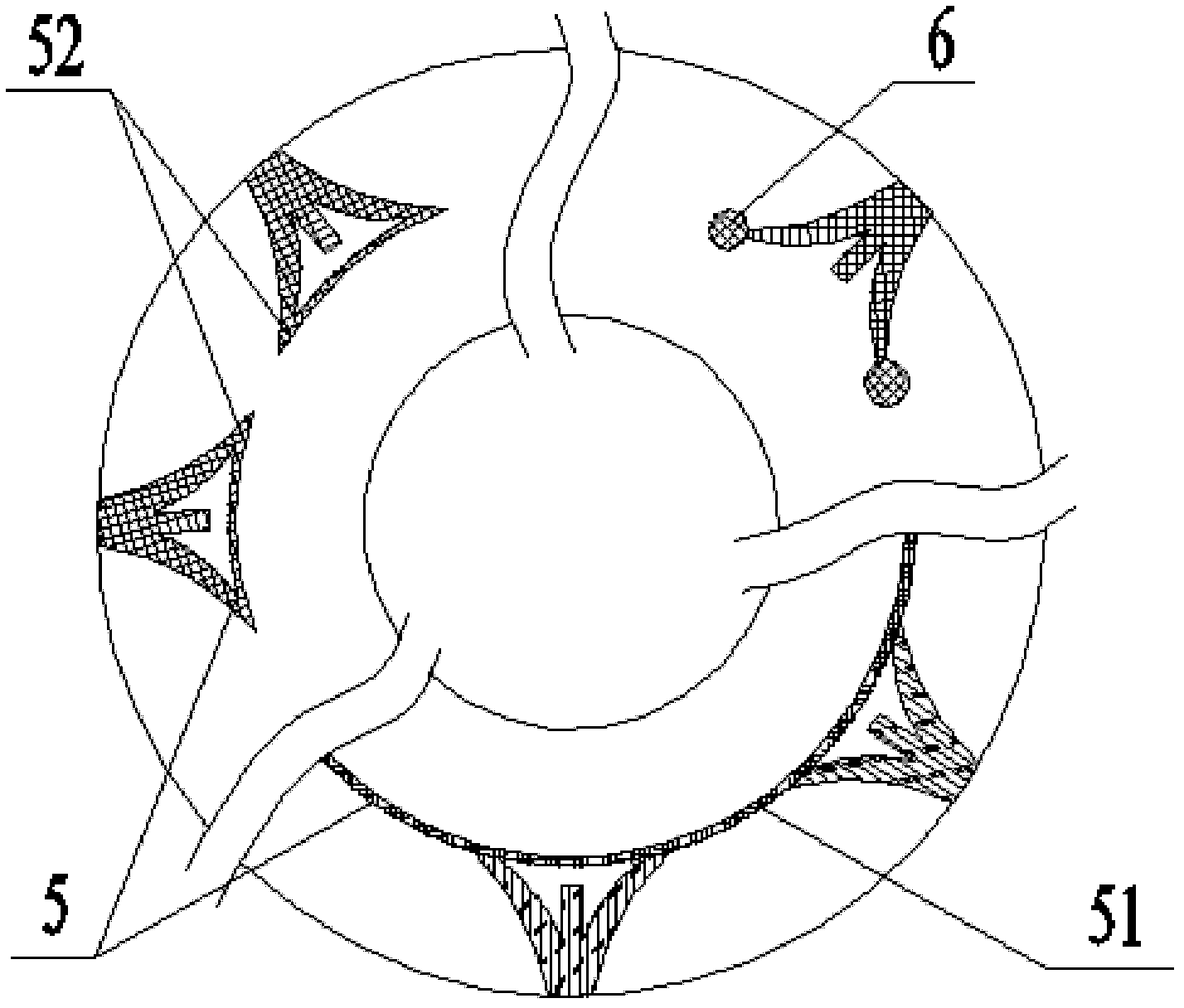

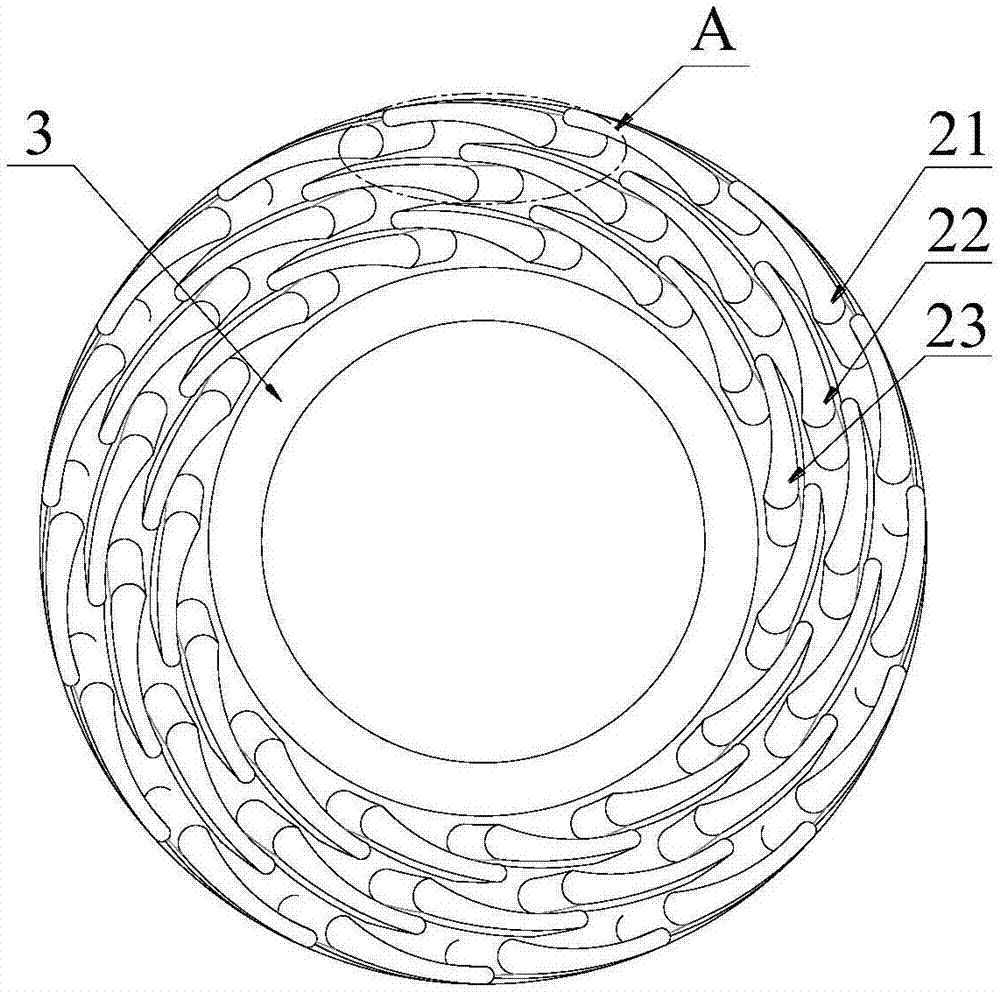

Microgroove double-layer composite groove deep end surface mechanical seal structure

ActiveCN103062411AEnhance the dynamic pressure effectImprove adsorption capacityEngine sealsEngineeringHigh pressure

The invention discloses a microgroove double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a microgroove double-layer composite groove deep dynamical pressure groove, a ring groove and a microgroove double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, the upper layer of the dynamical pressure groove is hollow, and a microgroove shape line on the lower layer of the dynamical pressure groove forms an upstream texture and is same to a dynamical pressure groove shape line on the upper layer; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, the upper layer of the pumping groove is hollow, and a microgroove shape line on the lower layer of the pumping groove forms a downstream texture and is same to a shape line on the upper layer of the pumping groove; the upstream texture and the downstream texture are connected through the ring groove; and the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove.

Owner:山东誉中新材料股份有限公司

Contact-seal inverted type gas wave refrigerating machine

ActiveCN103868269APrevent internal leakageOvercoming the drawbacks of adiabatic isentropic efficiencyEngine sealsCompression machinesEngineeringMachine

The invention relates to a contact-seal inverted type gas wave refrigerating machine, and belongs to the technical field of pressure gas expansion refrigeration. According to the gas wave refrigerating machine, mechanical seals with good sealing performance are applied to a refrigerating machine, the inner-flow balanced-type double-end-face mechanical seal is located between an intake pipe of an upper machine body and an exhaust pipe of a main machine body, the long-narrow-type single-end-face mechanical seal is arranged at the position, underneath an upper embedded bearing box, in an upper transition box base, and the thin-ladder-type single-end-face mechanical seal is arranged at the position, above a lower embedded bearing box, in the middle of the main machine body. Cooling and lubricating systems are all of a combined structure, so that the complexity, trouble and waste caused by repeated arrangements are reduced, and the reliable work of bearings and the sealing devices is guaranteed. The mechanical seals have the advantages of being good in sealing performance, small in leakage amount, high in vibration resistance, long in service life and the like, so that the defect that the adiabatic efficiency of the refrigerating machine is affected seriously due to the internal leakage of the pressure gas is effectively overcome, and the refrigerating efficiency can be enhanced by more than 10 percent. The inverted type structure is simple, the gas wave refrigerating machine is convenient to disassemble and assemble, labor intensity is relieved, and meanwhile crucial hidden hazards can be reduced.

Owner:DALIAN UNIV OF TECH

Negative pressure groove end face mechanical seal structure

The invention relates to a negative pressure groove end face mechanical seal structure, comprising a mechanically sealed moving ring and a mechanically sealed static ring, one side of the end faces of the moving ring and the static ring is a high pressure side namely upstream, the other side of the end faces of the moving ring and the static ring is a low pressure side namely downstream, at leastone end face of the moving ring or the static ring is provided with negative pressure groove groups which are symmetrically distributed with the center of rotation, the upstream of each negative pressure groove group is provided with a micropore annular band, each negative pressure groove group is composed of micropore dynamic pressure grooves with spiral deformation and inclination and relief grooves, the micropore dynamic pressure grooves and the relief grooves are distributed at intervals, the relief grooves are close to the terminals of the dynamic pressure grooves, and the downstream of each negative pressure groove group is provided with an annular sealing dam with a smooth plane. The invention has the beneficial effects of enhancing antijamming capability of sealing in operation athigh speed, improving dynamic pressure opening capability of a high speed seal face under the low speed working condition, realizing non-contact stability of the seal face under the high speed working condition, reducing end face contact wear, prolonging service life and improving sealing reliability.

Owner:海宁市黄湾镇资产经营有限公司

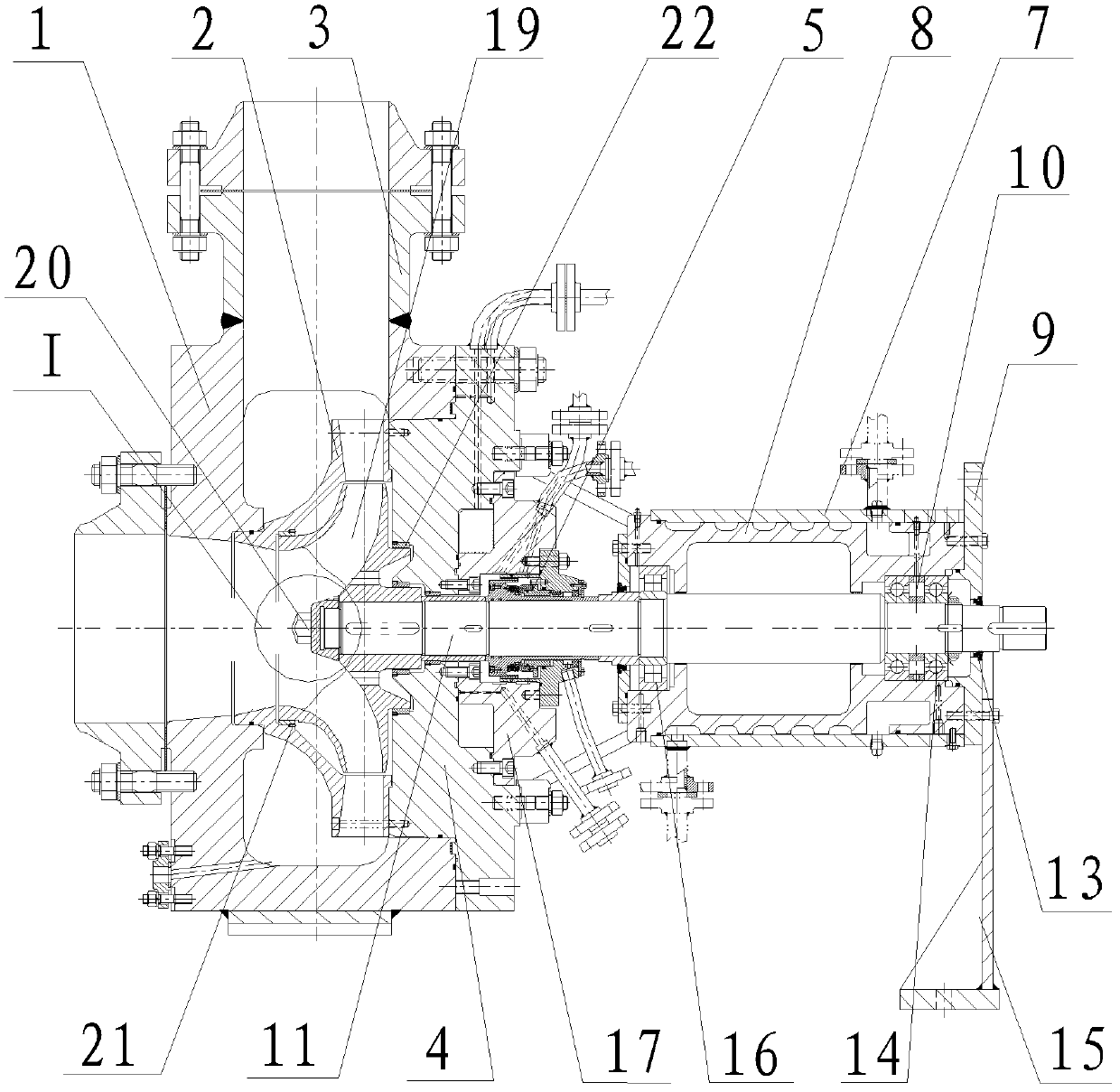

Waste heat discharge pump for nuclear power plant

The invention discloses a waste heat discharge pump for a nuclear power plant, which comprises a stator component, a rotor component, a bearing component and a shaft seal device. The stator component comprises a pump casing, guide vanes arranged in the cavity of the pump casing, a pump cover connected at the front end of the pump casing and a sealing box body connected at the front end of the pump cover. The rotor component comprises a pump shaft and vane wheels sleeved on the pump shaft through vane wheel nuts and located in the cavities of the guide vanes. The bearing component comprises a bearing body, bearing pressing covers, a driving end bearing and a non-driving end bearing, wherein the front portion and the rear portion of the bearing body are respectively provided with bearing cavities, the bearing pressing covers are covered at two ends of the bearing body, and the driving end bearing and the non-driving end bearing are arranged in the bearing cavities one by one. The shaft seal device is a containerization balanced type single end face mechanical seal and is arranged in the cavity of the sealing box body. The rotor component further comprises a retainer gasket which is arranged between the vane wheel nuts and the vane wheels in a mode that a tongue piece of the retainer gasket is covered on the planes of the vane wheel nuts. The bearing component further comprises a cooling water jacket and a cooling water pipeline, and a bearing protector is respectively arranged in cavities of the bearing pressing cover at two ends.

Owner:SHANGHAI APOLLO MACHINERY

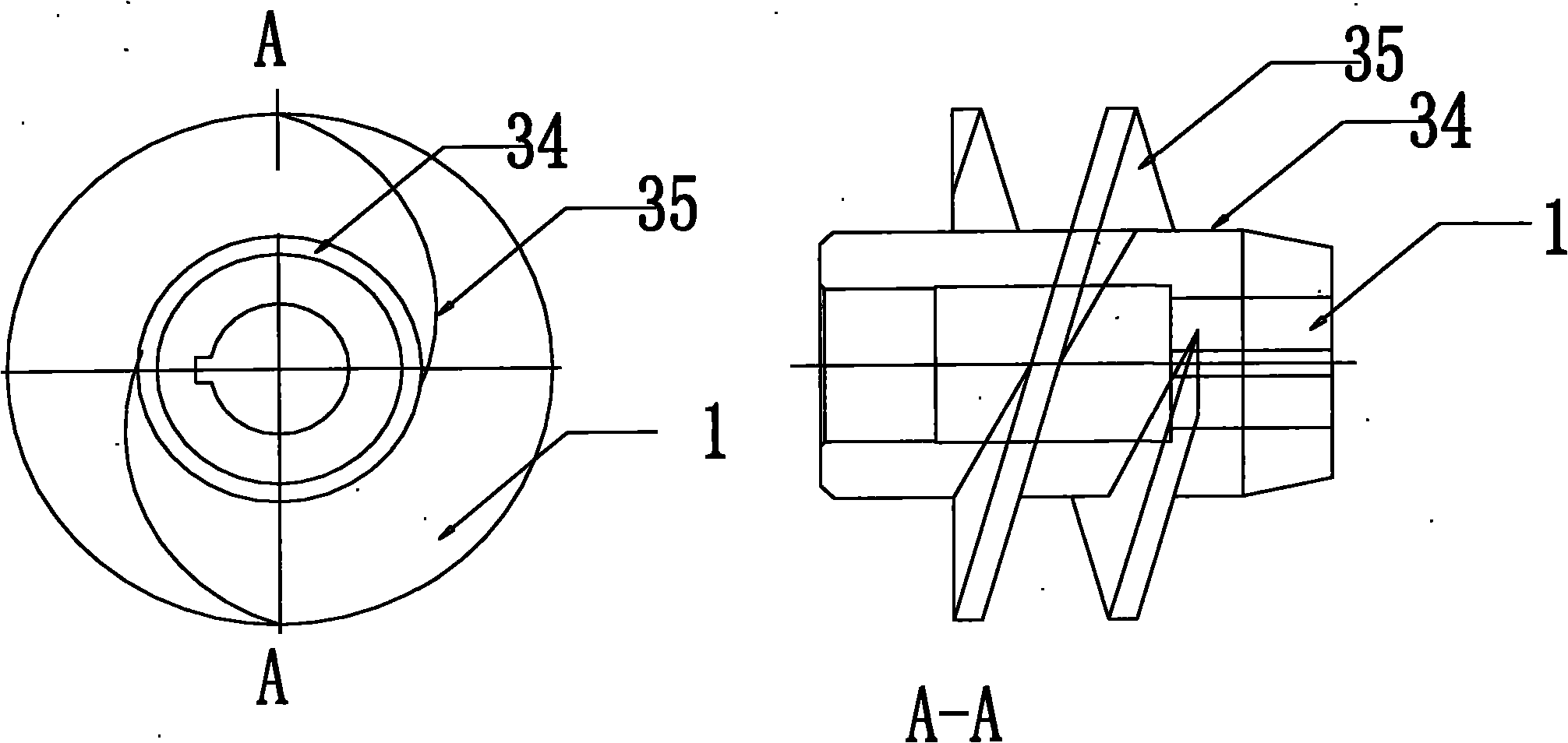

Bilaterally rotatable end surface mechanical sealing structure with dovetail grooves

ActiveCN103133697AImprove compression performanceImprove carrying capacityEngine sealsEngineeringHigh pressure

Owner:ZHEJIANG UNIV OF TECH

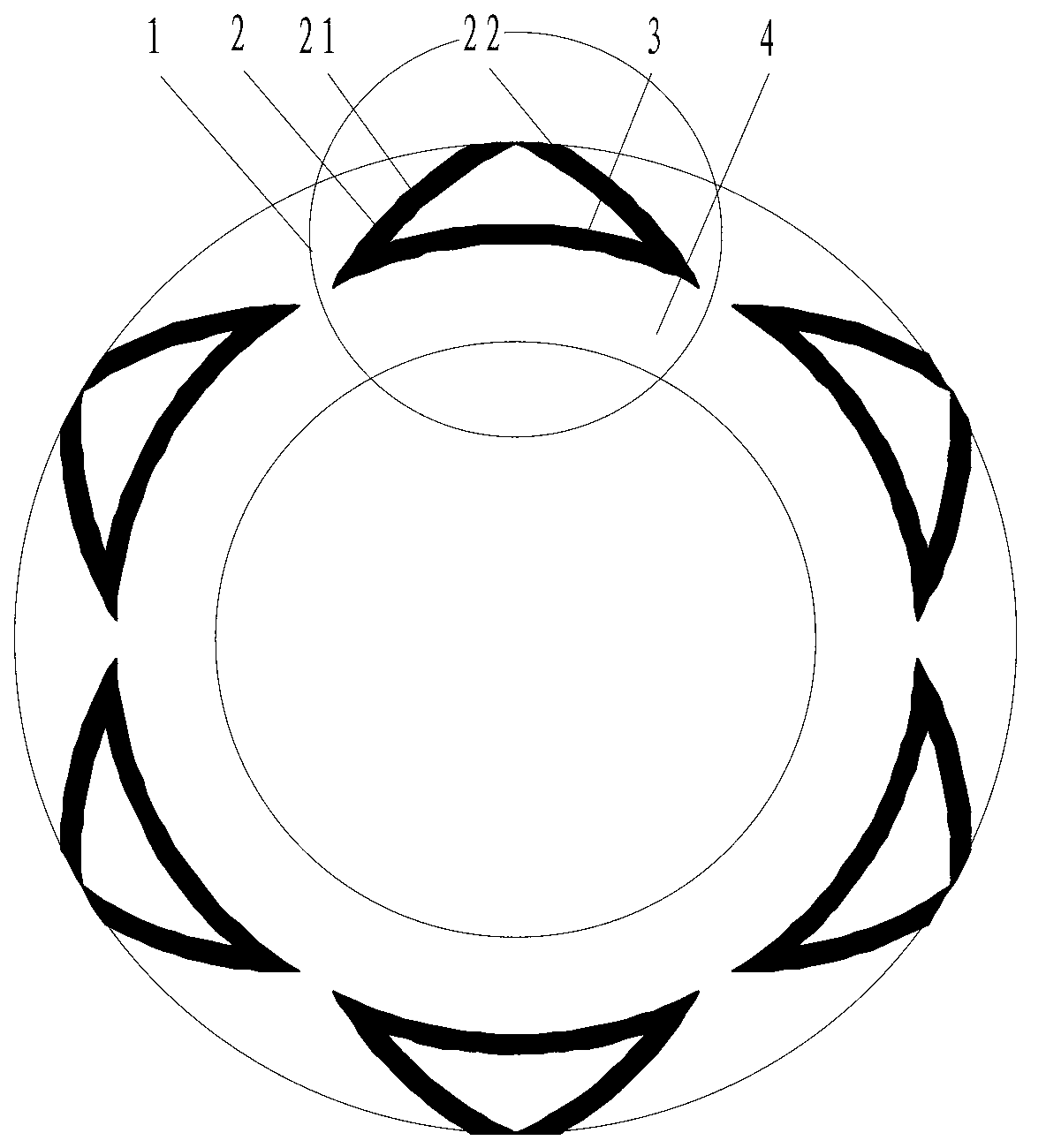

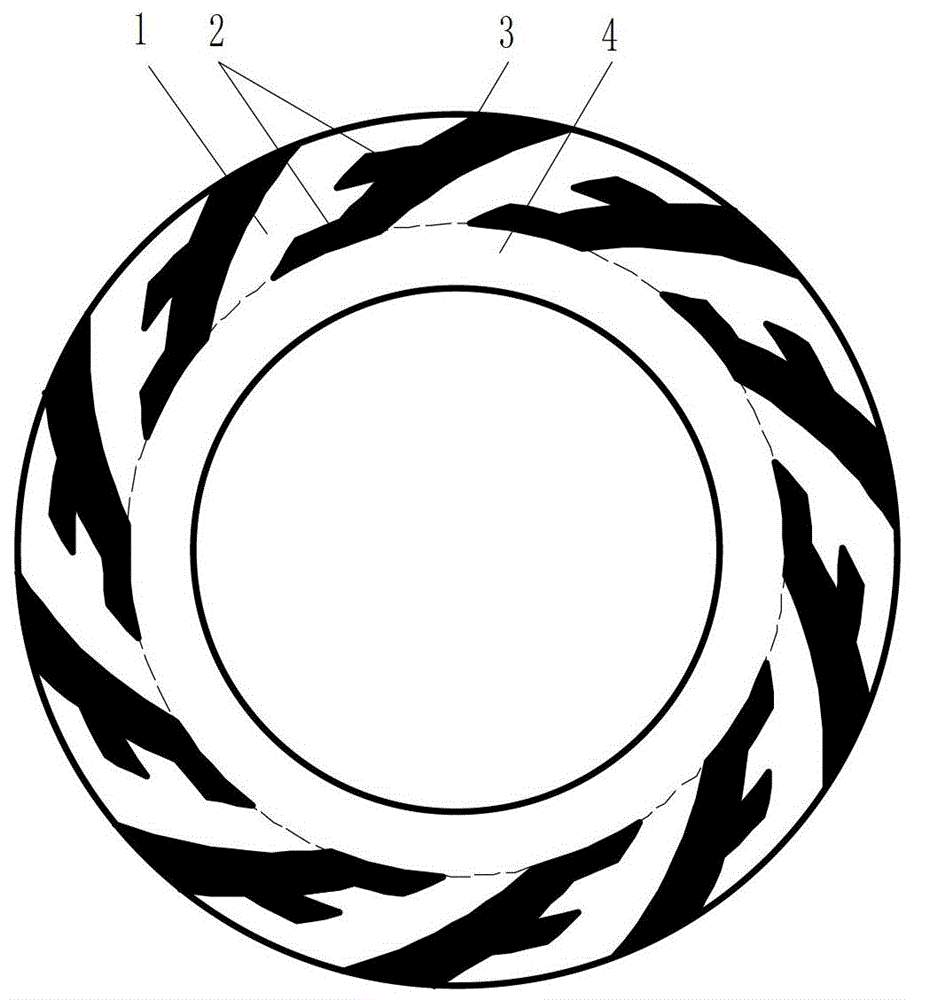

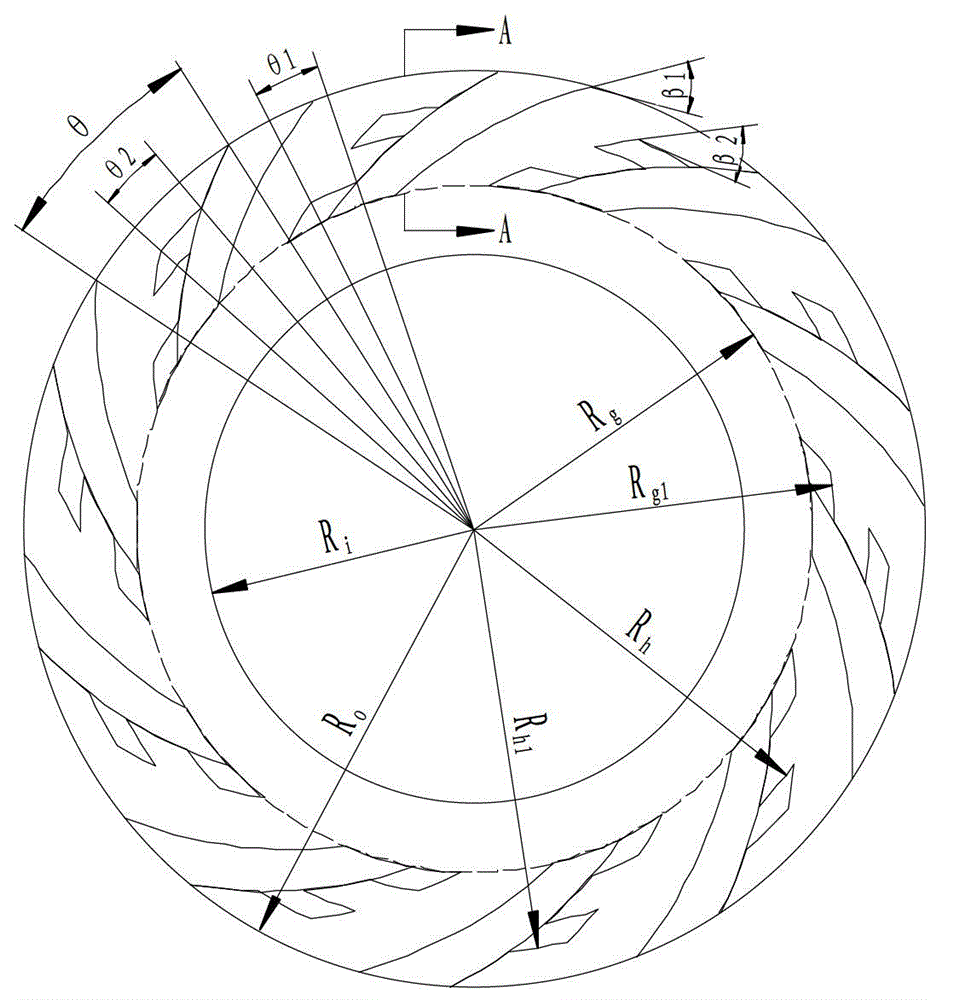

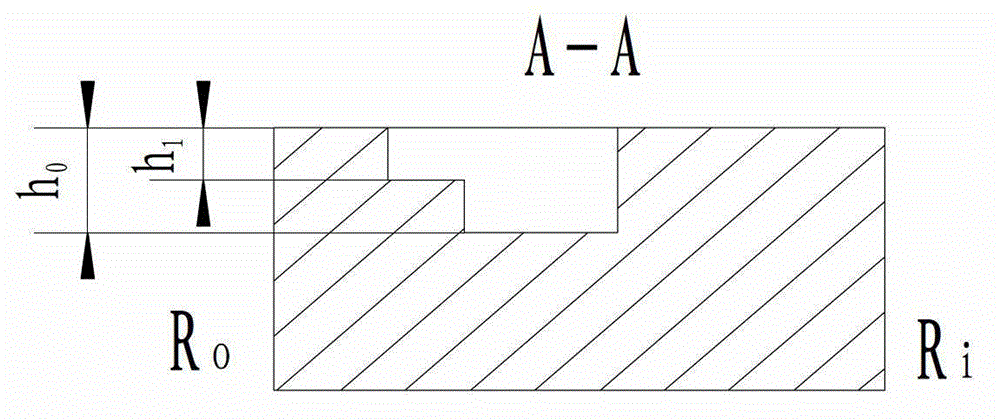

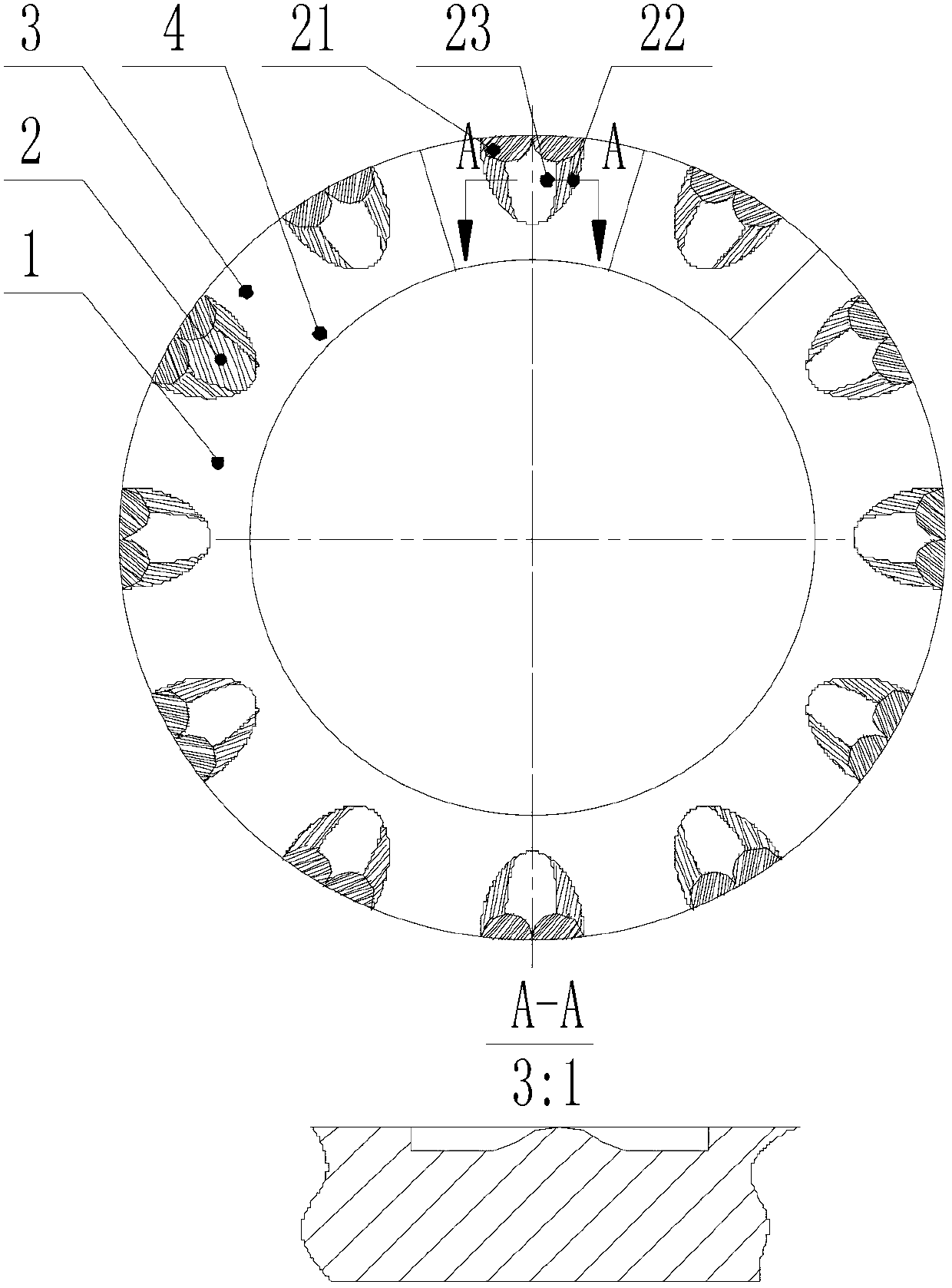

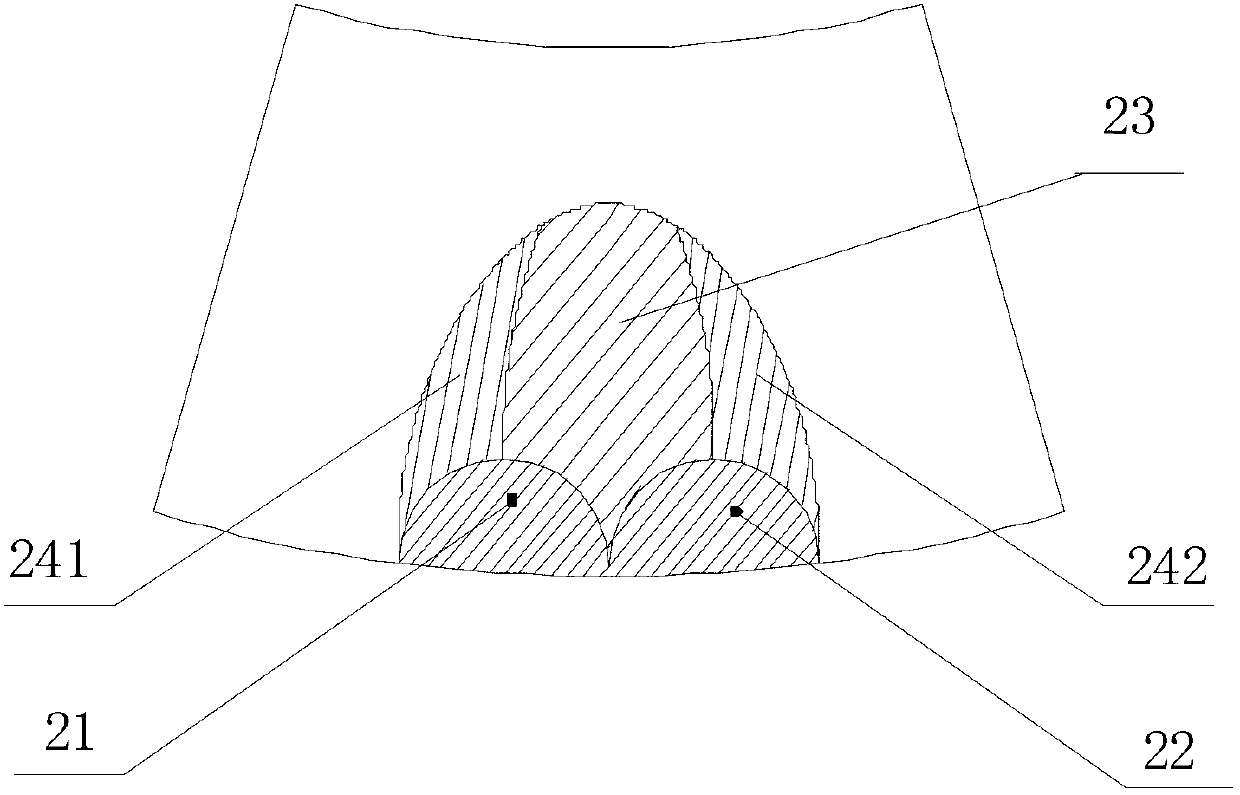

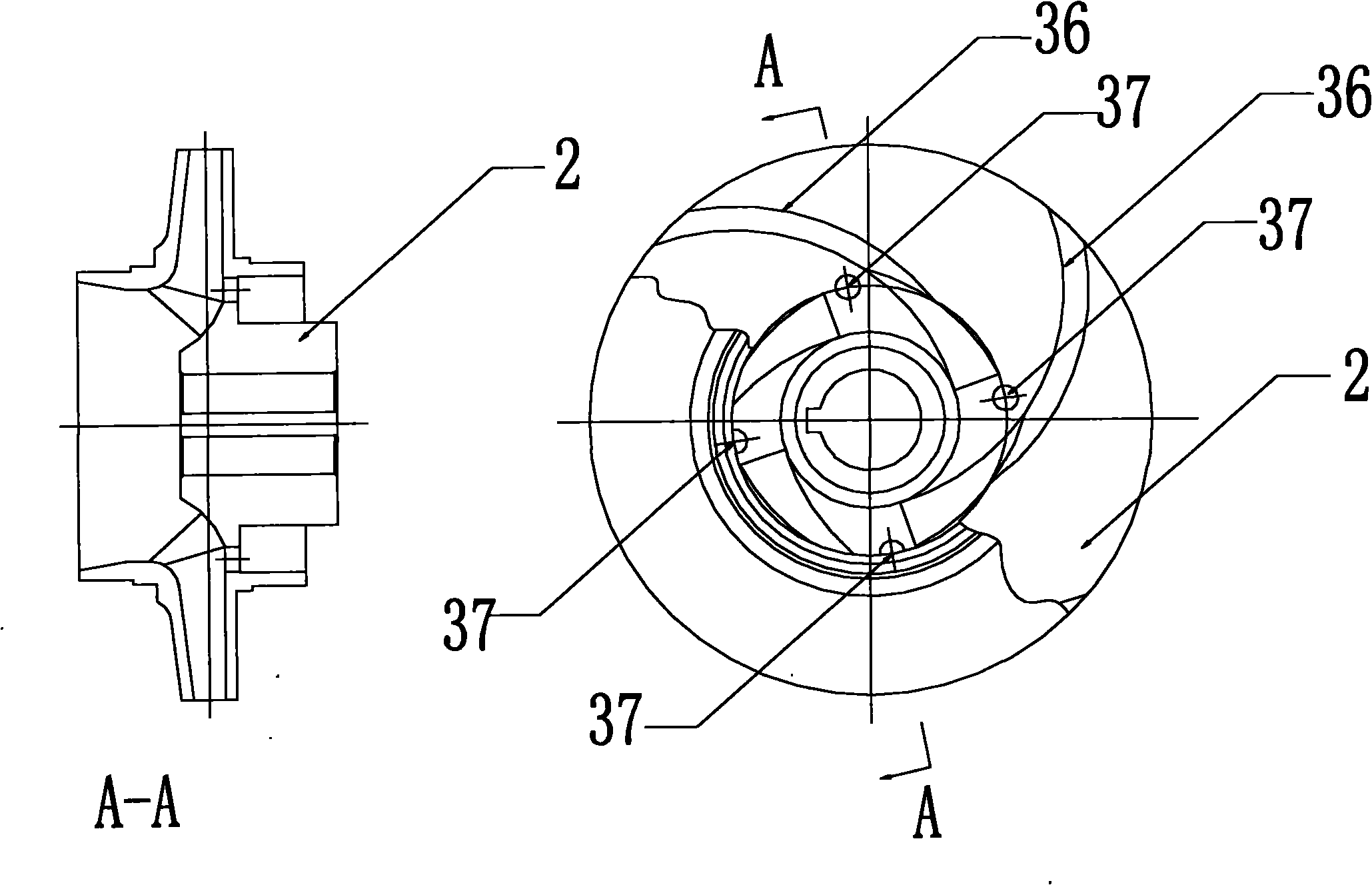

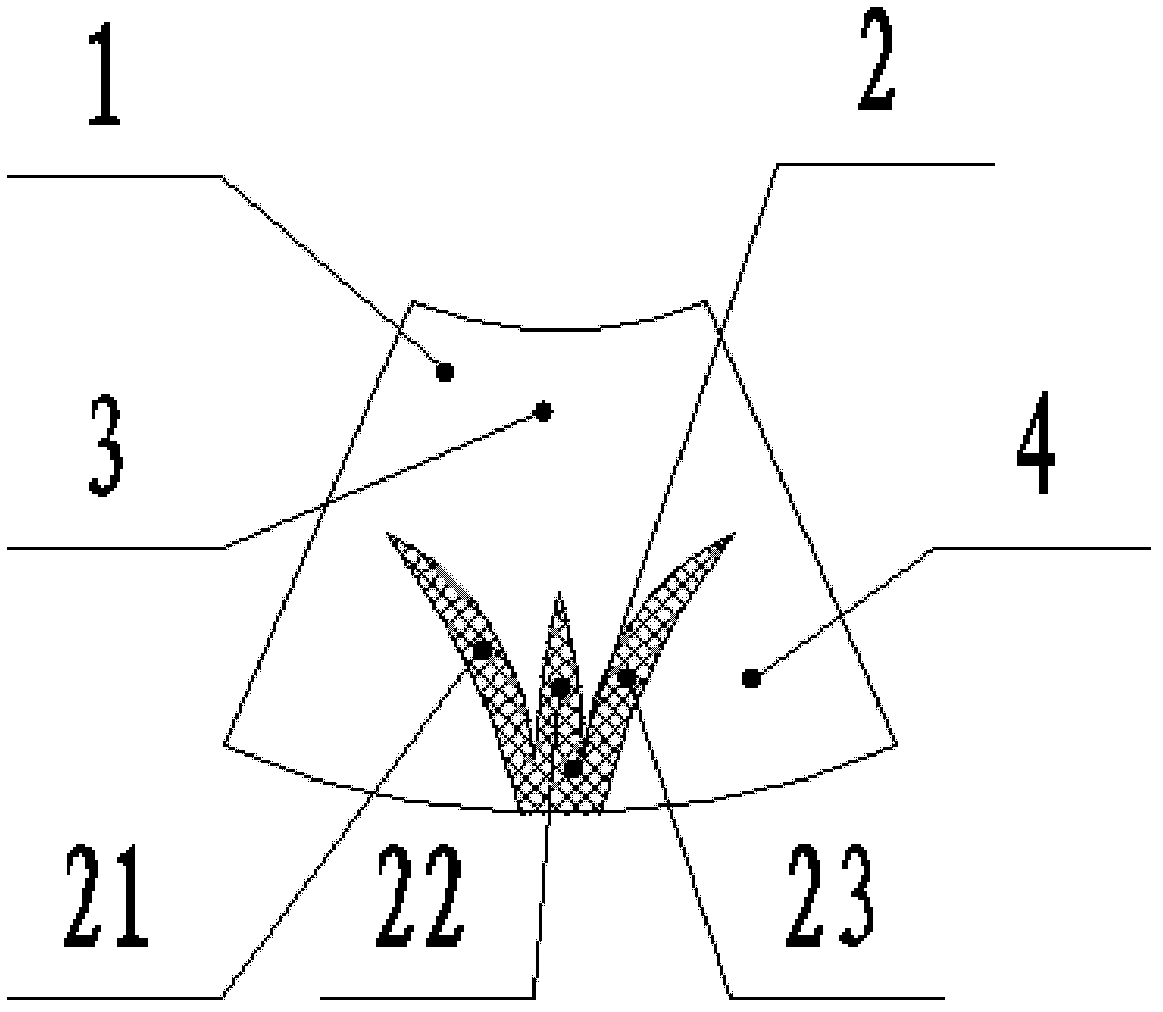

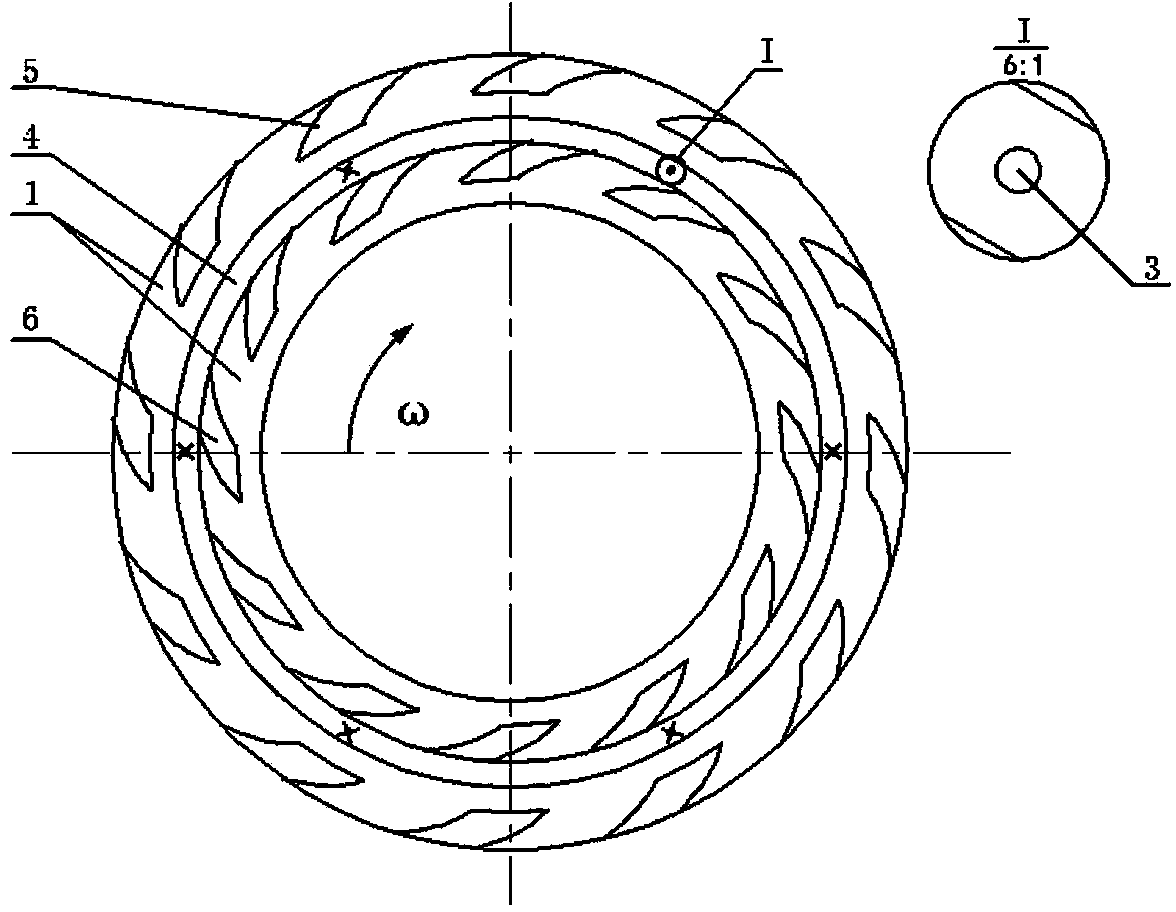

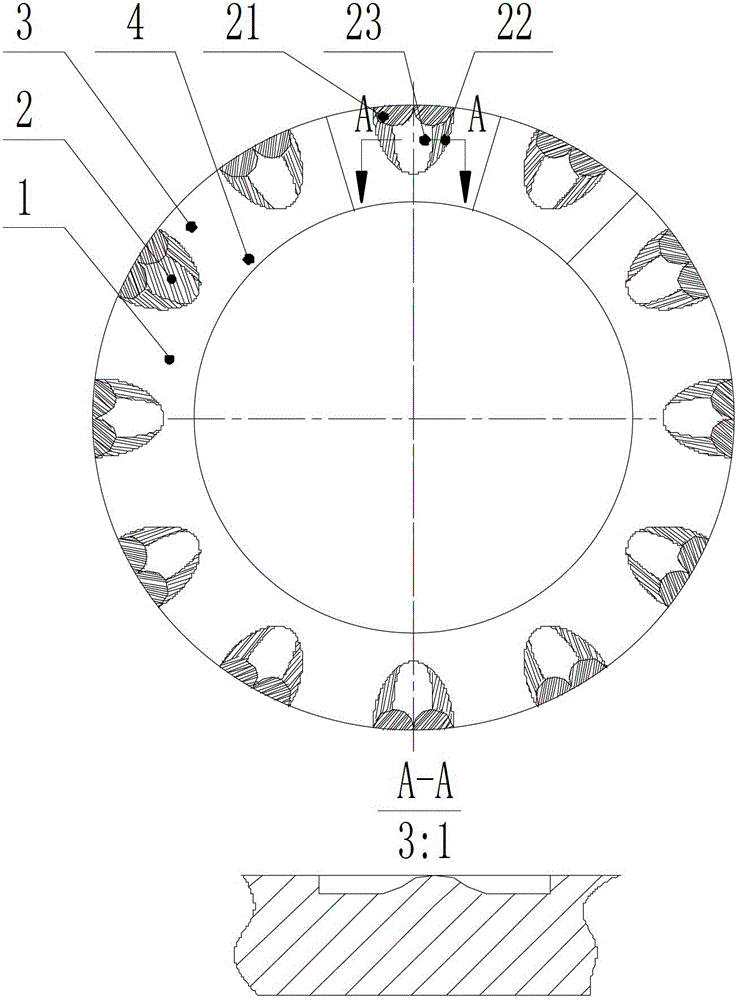

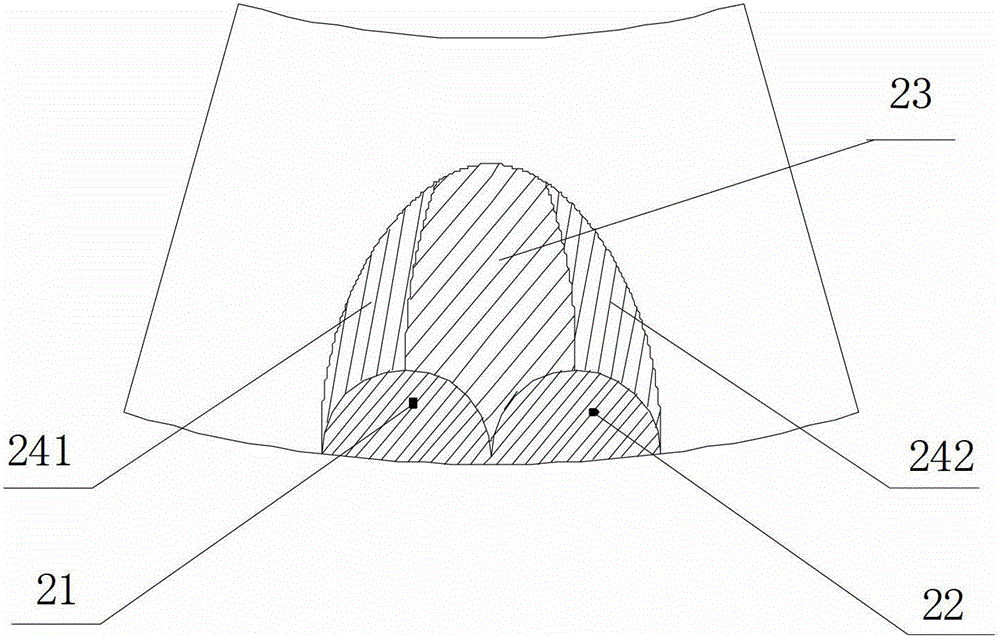

Mechanical sealing structure for radial shunt type groove end faces of pinion-like grooves

ActiveCN103185140AGood fluid diversion effectHas superimposed effectEngine sealsEnd face mechanical sealEngineering

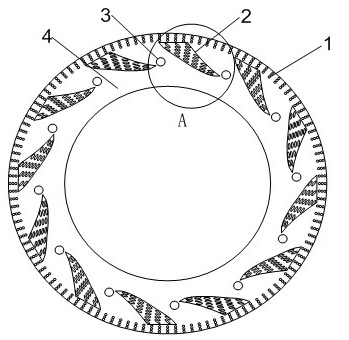

The invention discloses a mechanical sealing structure for radial shunt type groove end faces of pinion-like grooves. The mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a stationary ring, wherein a plurality of radial shunt type grooves of pinion-like grooves are distributed along peripheries and formed in the end surface of at least one mechanical sealing ring of the moving ring and the stationary ring; the radial shunt type grooves of pinion-like grooves are located at a high-pressure side of a medium, namely upstream; the radial shunt type grooves of pinion-like grooves comprise a drain groove and more than two shunt grooves adopting pinion-like groove structures; the drain groove is connected with the shunt grooves and is located on leeward sides of the shunt grooves; the shunt grooves are formed radially and stretch in a circumferential direction; uncut groove areas among the radial shunt type grooves of bird-wing-simulated grooves are sealing weirs; a ring belt which is formed in a circumferential uncut groove area on an end surface is a sealing dam; and the sealing dam is located on a low-pressure side of the end surface, namely downstream.

Owner:ZHEJIANG UNIV OF TECH

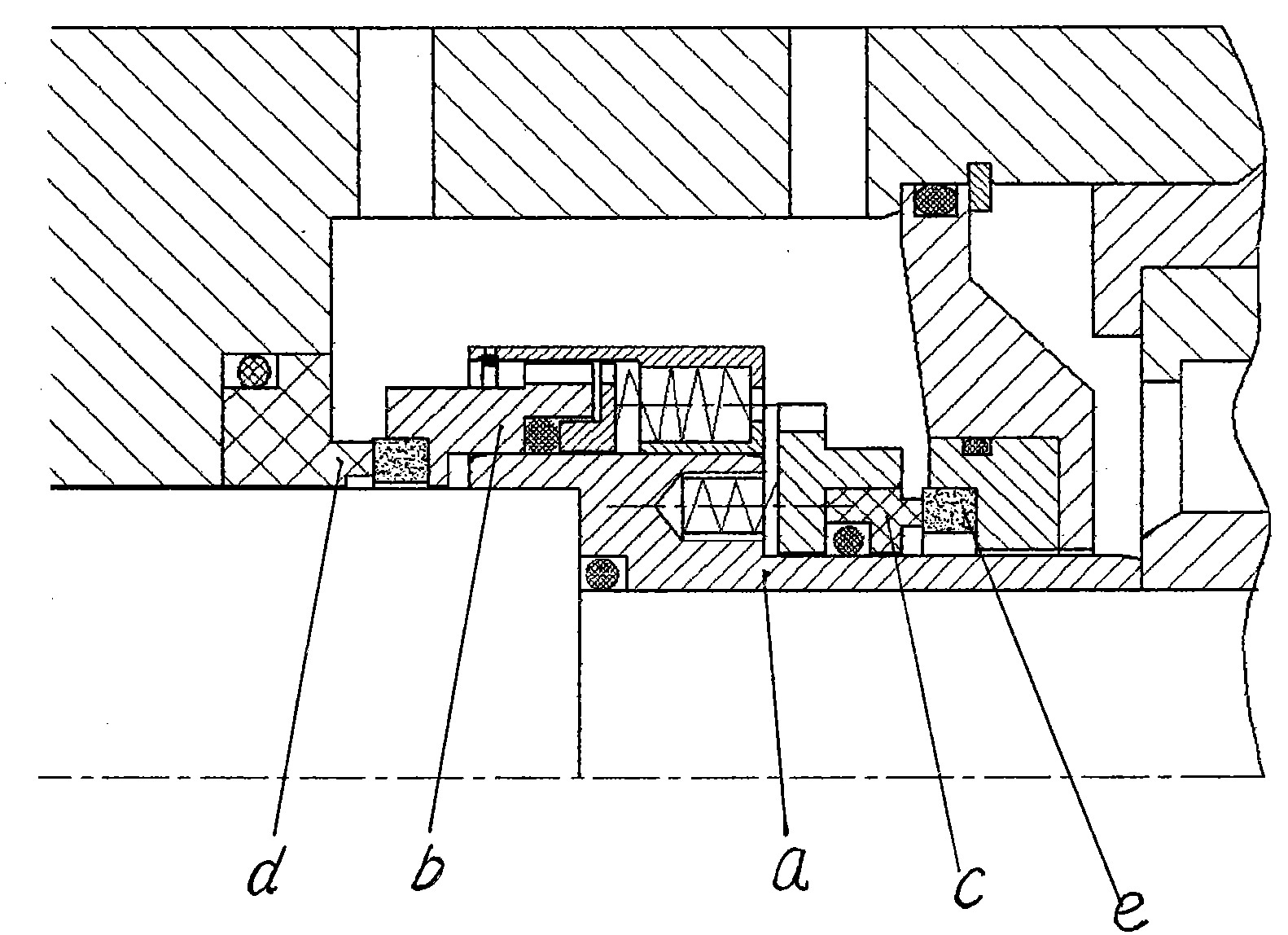

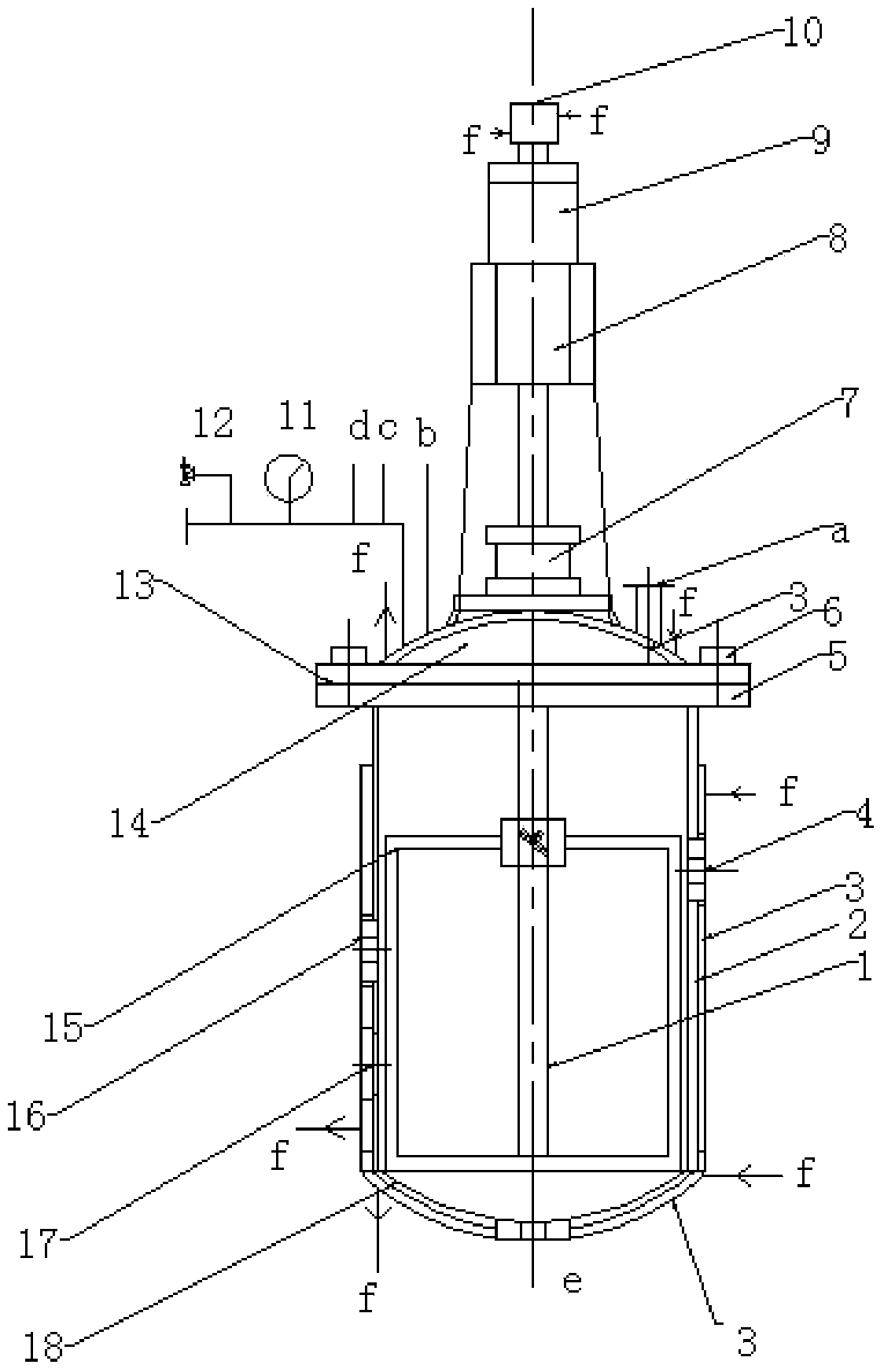

Double mechanical sealing method and double mechanical sealing device for kettle gas films

The invention discloses a double mechanical sealing method and a double mechanical sealing device for kettle gas films, and belongs to the field of machine manufacture. The double mechanical sealing device mainly comprises a shaft sleeve, a moving-ring seat, a stationary ring, a stationary-ring press plate, a moving ring, a bearing, a stationary-ring seat, an auxiliary seal and the like. The double mechanical sealing method is characterized in that a back-to-back rotating double-end-face structure is adopted for sealing to realize non-contact operation, and a fluid dynamic-pressure groove is formed in the end face of the seal stationary ring; high-pressure isolating gas is injected between two sealing structures, and a spring is not affected by solid particles and impurities in media as not contacting with the media; the stationary ring which is supported by two O-shaped rings and is positioned by the press plate can bear back pressure; a cartridge structure is adopted. The double mechanical sealing method and the double mechanical sealing device have the advantages that an auxiliary system is simple in structure and can ensure technological media to be prevented from pollution, leakage and overflow of sealed media can be completely avoided, and no environmental pollution is caused; through the cartridge structure, accuracy, convenience and rapidness in overall mounting are realized, and demounting is facilitated. The device is applicable to various blenders, reactors, dryers, reaction kettles, polymerizers and the like in the fields of petroleum, chemical engineering, pharmacy, rubber, oil refining and the like.

Owner:DONGYING HISCIEN SEALING TECH

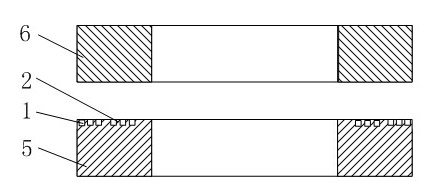

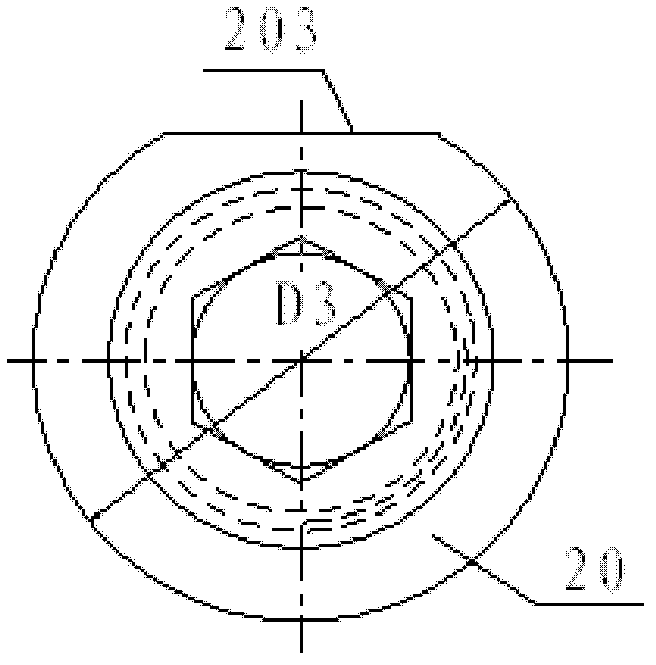

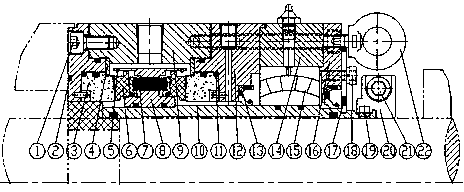

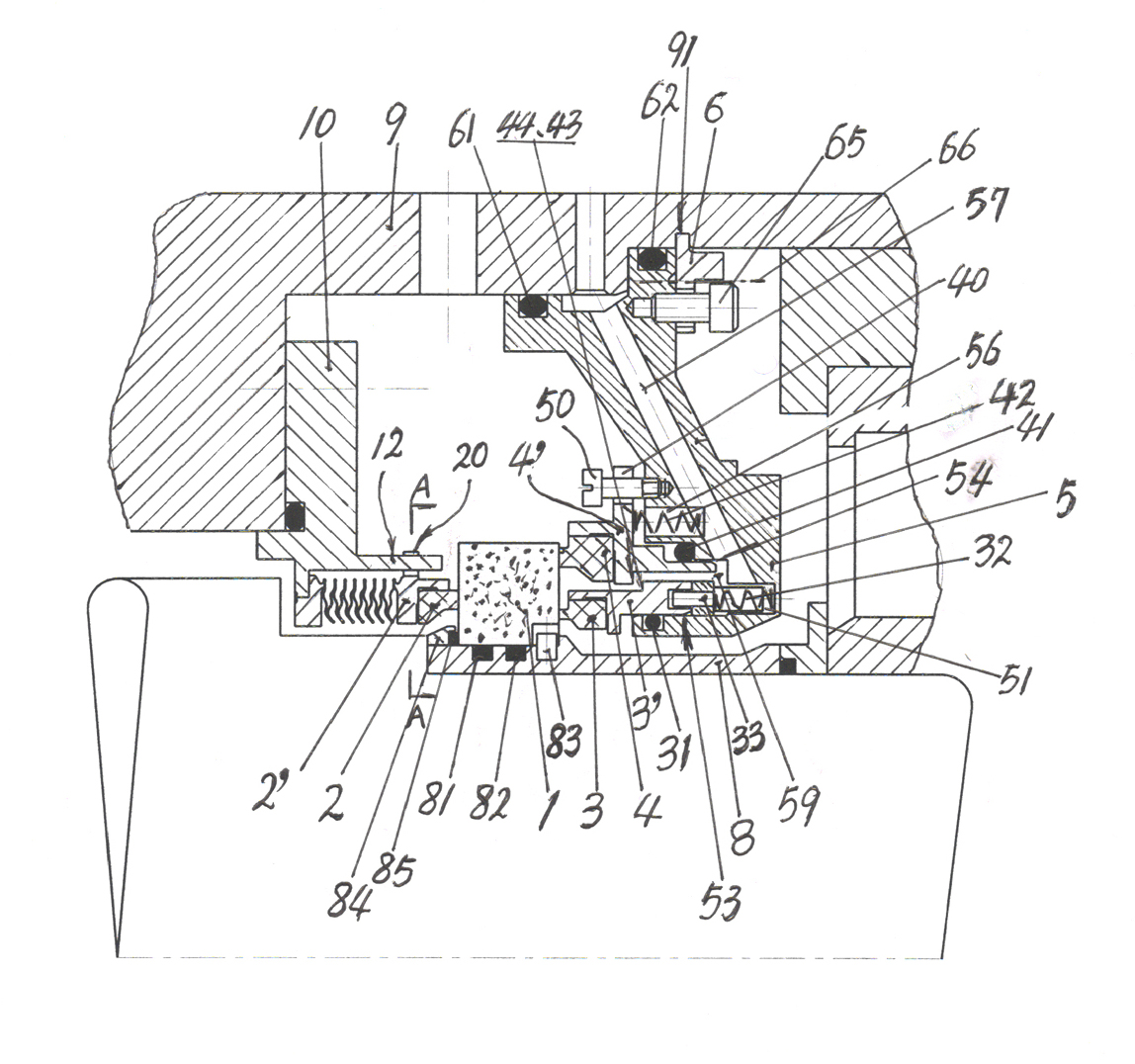

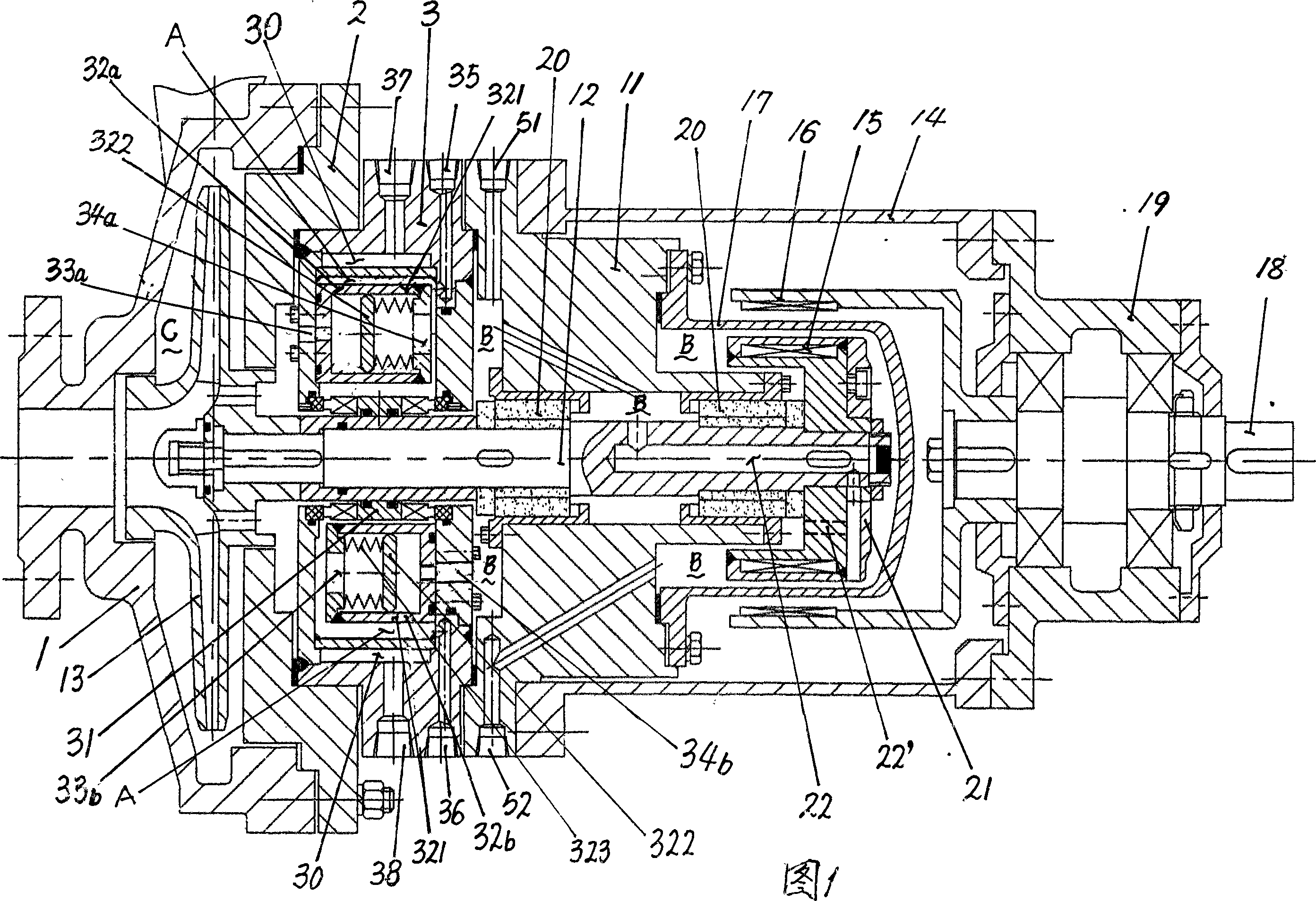

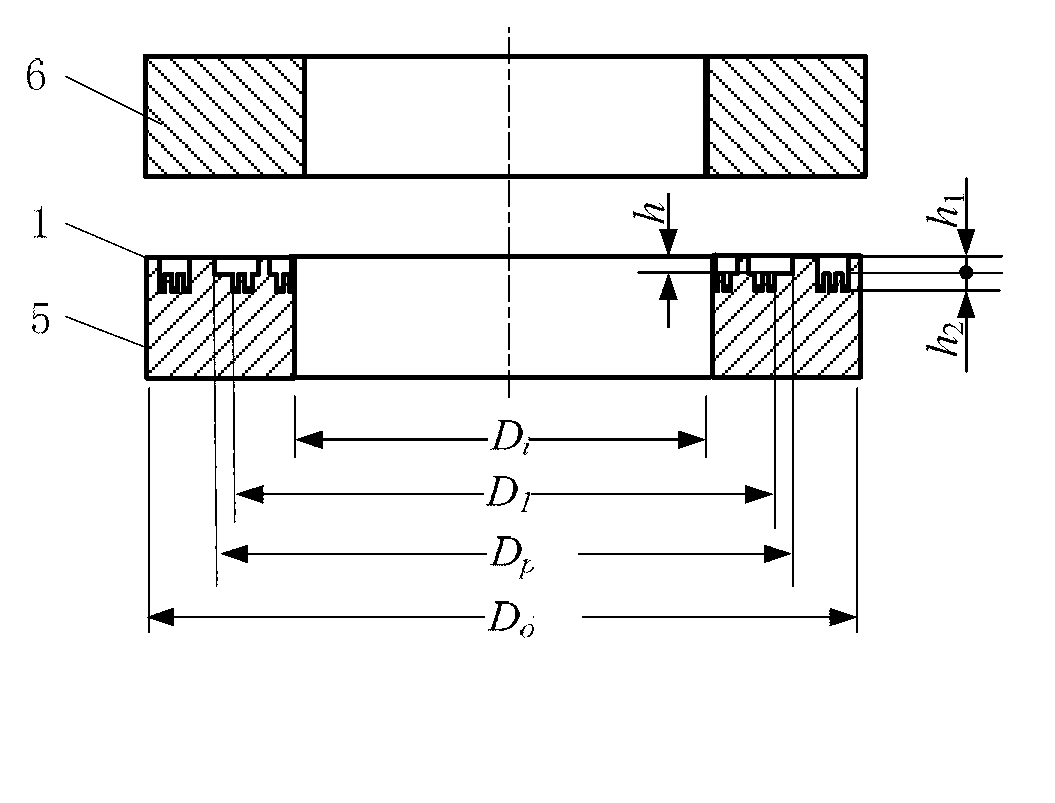

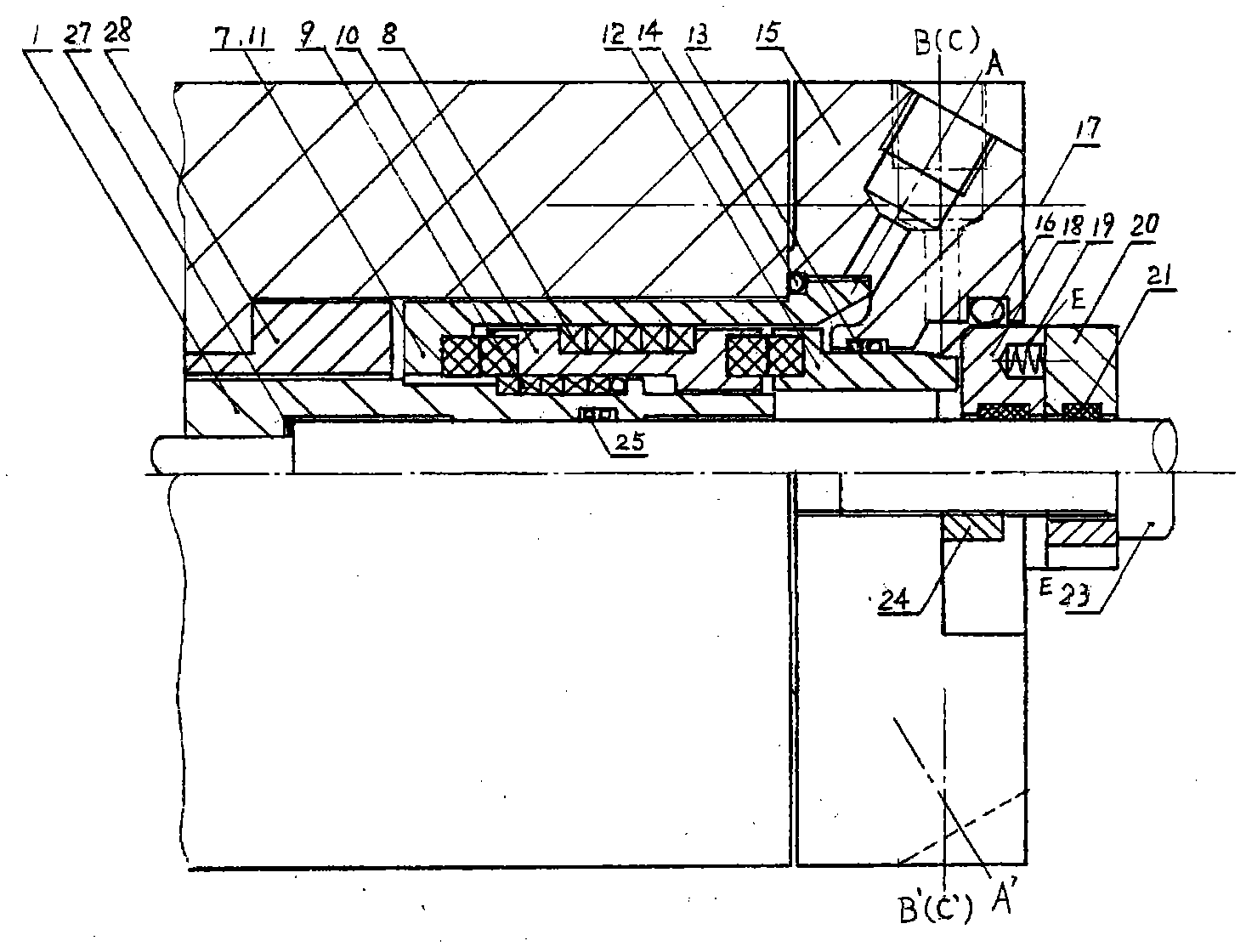

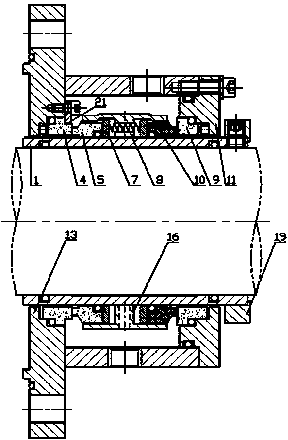

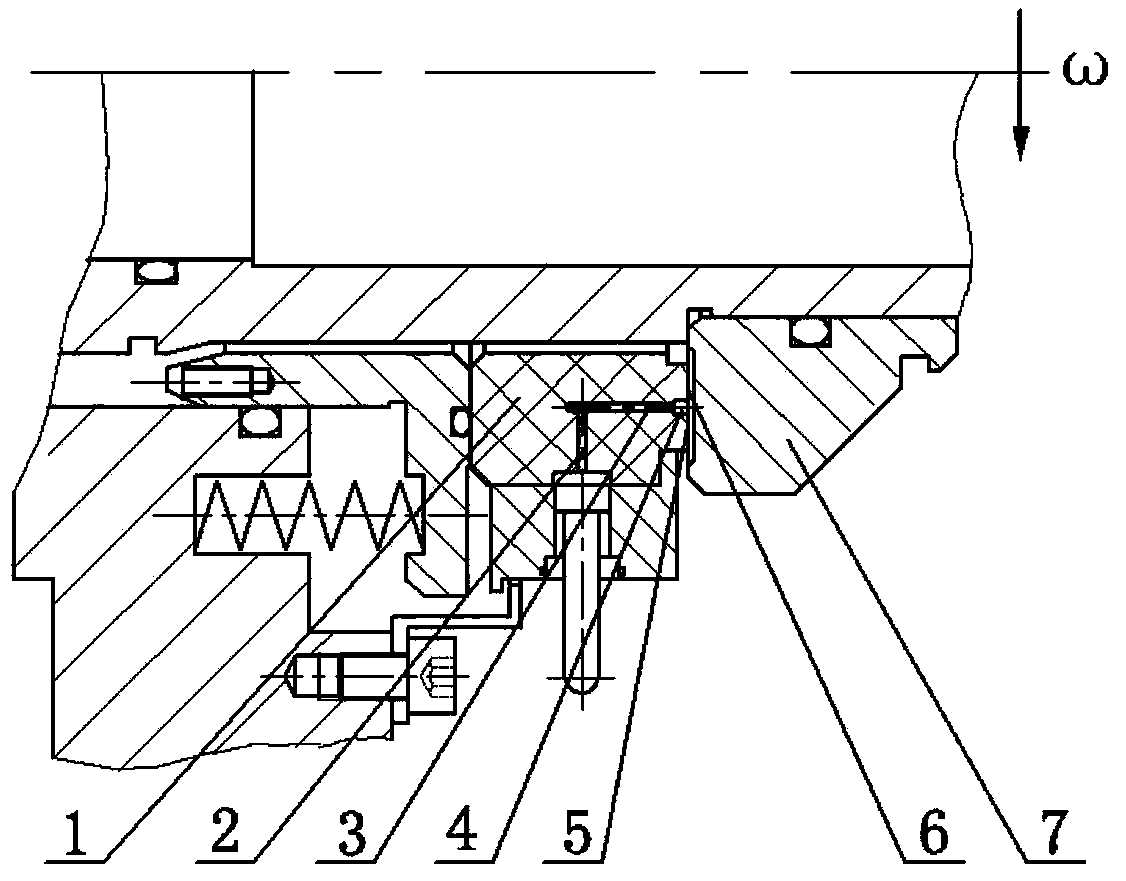

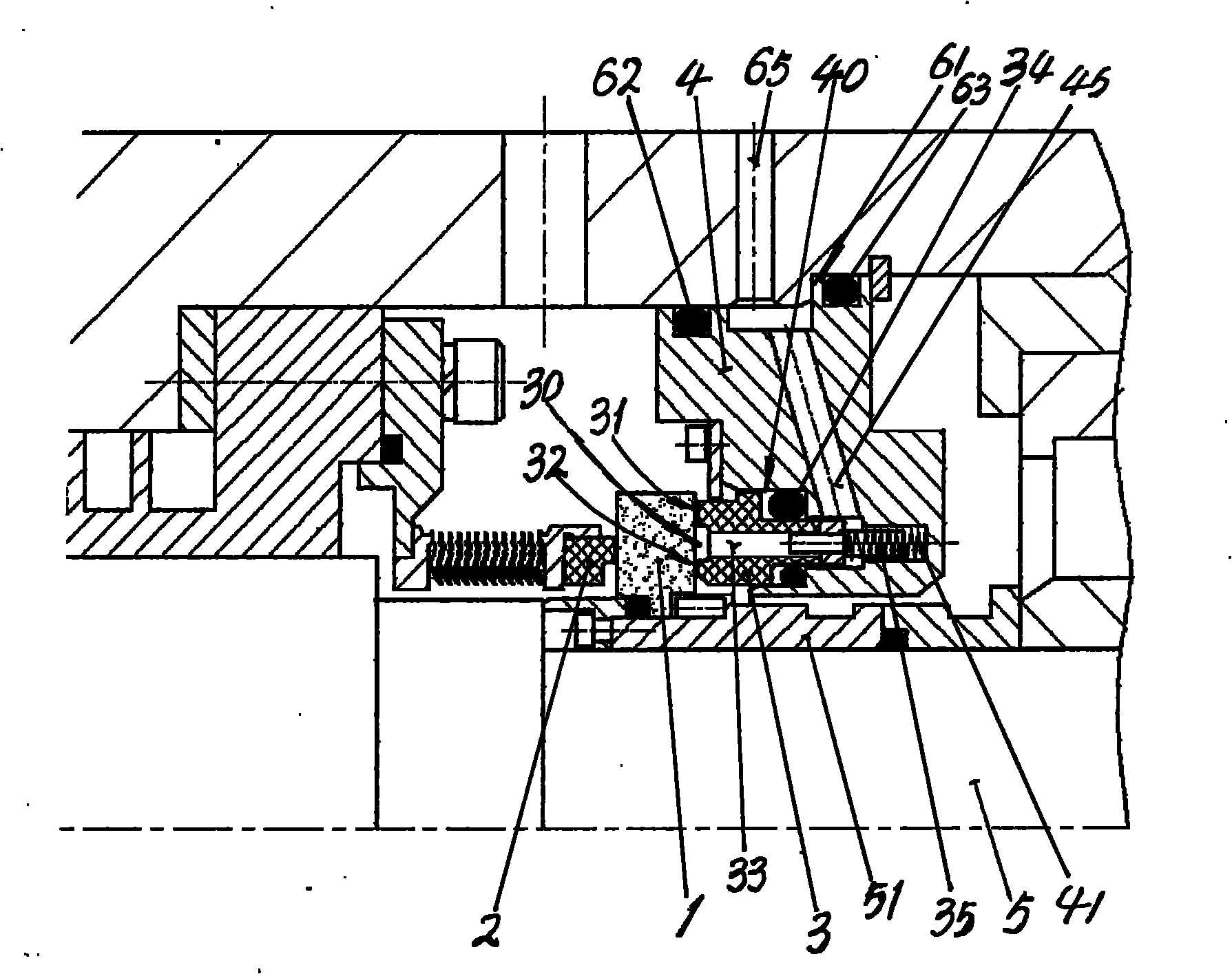

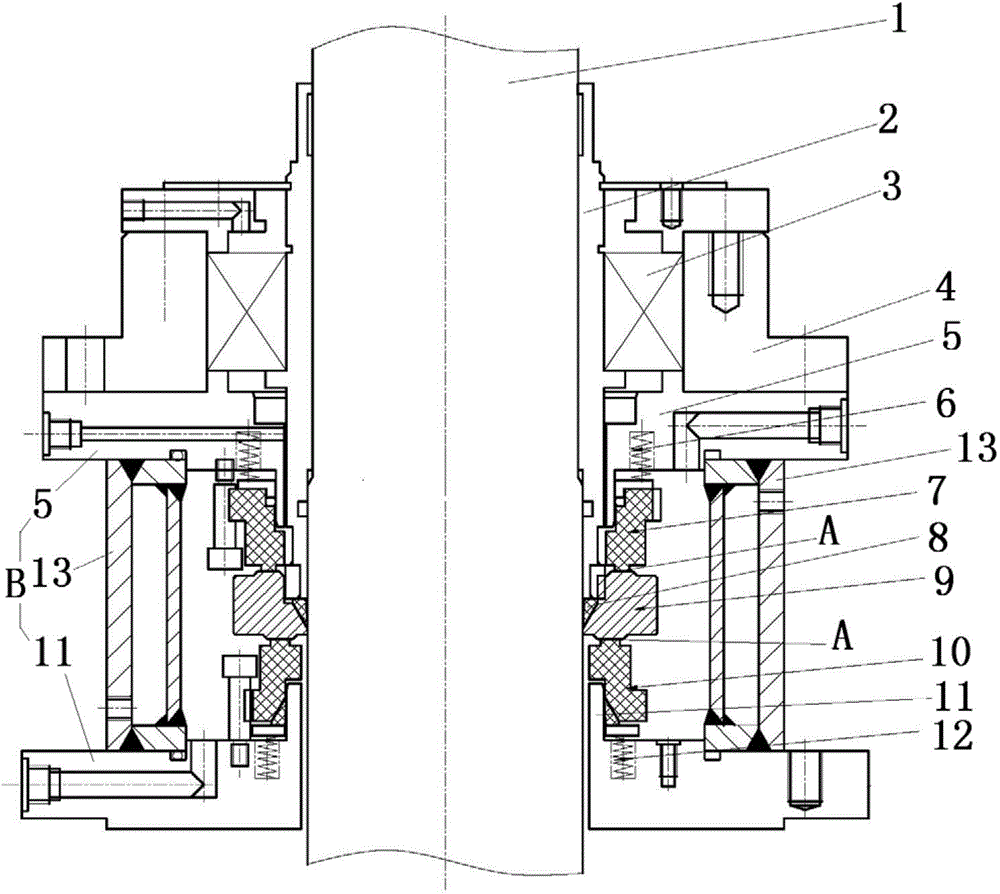

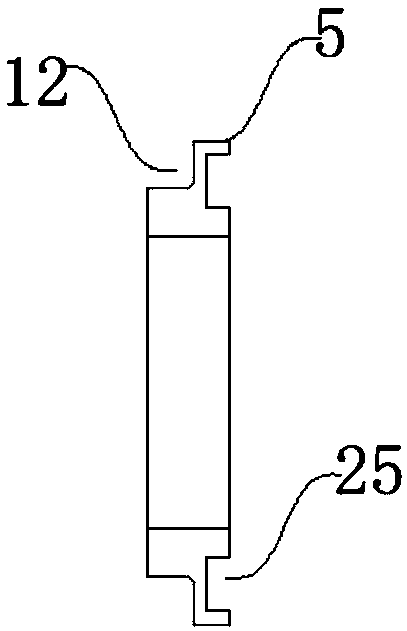

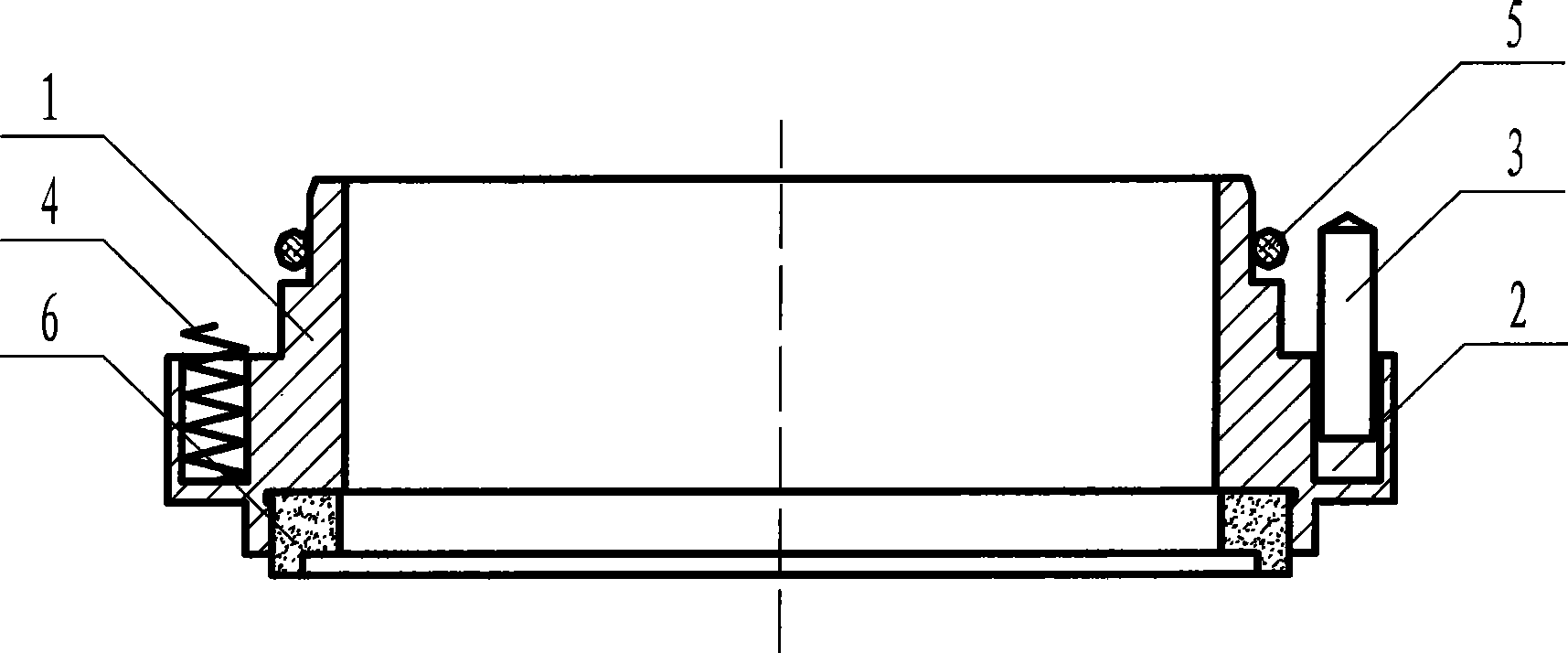

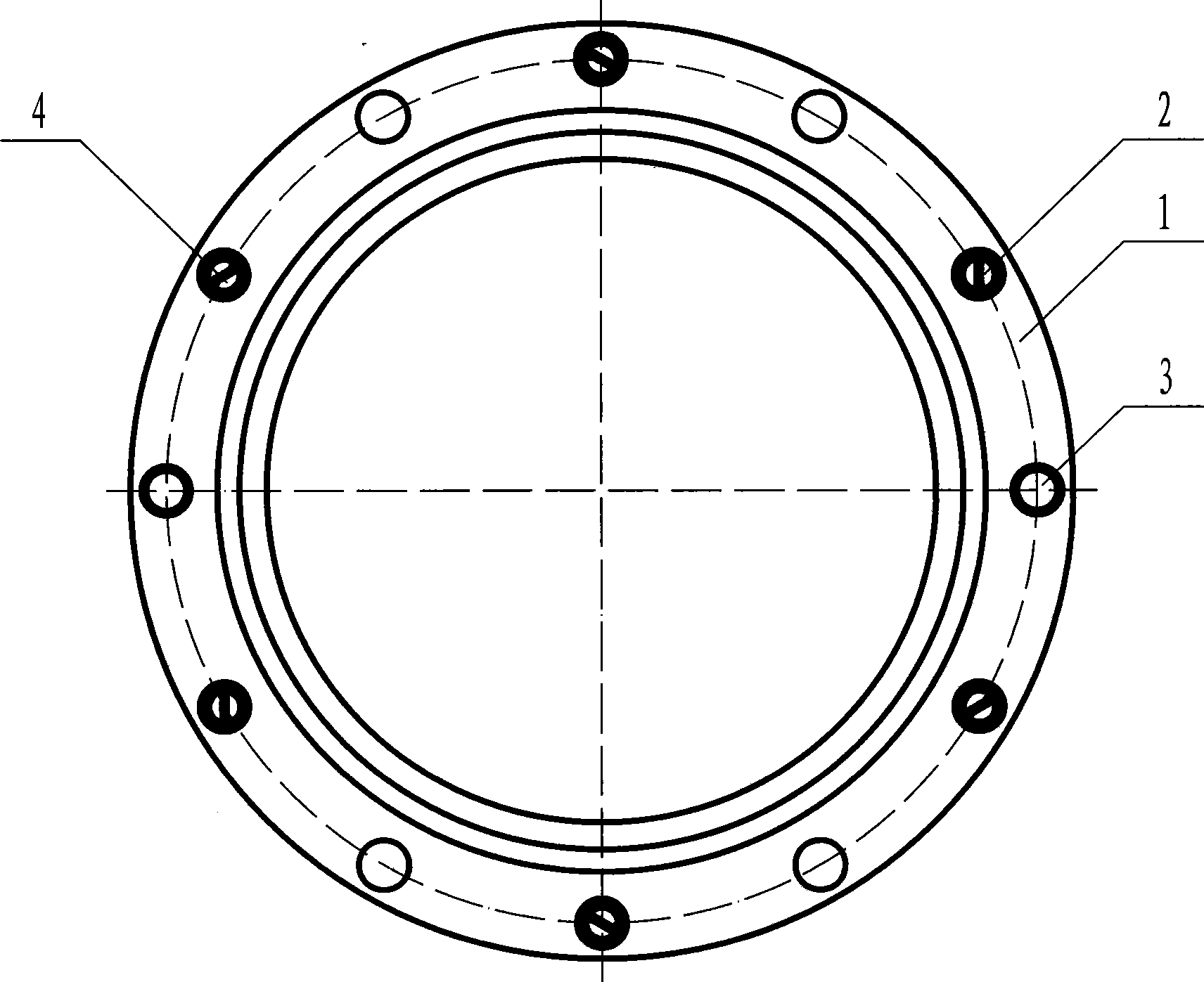

Mechanical seal device of screw power machine

ActiveCN102072321ASolve the problem of different expansion coefficientsSolve the effect of blockageEngine sealsEngineeringMachine

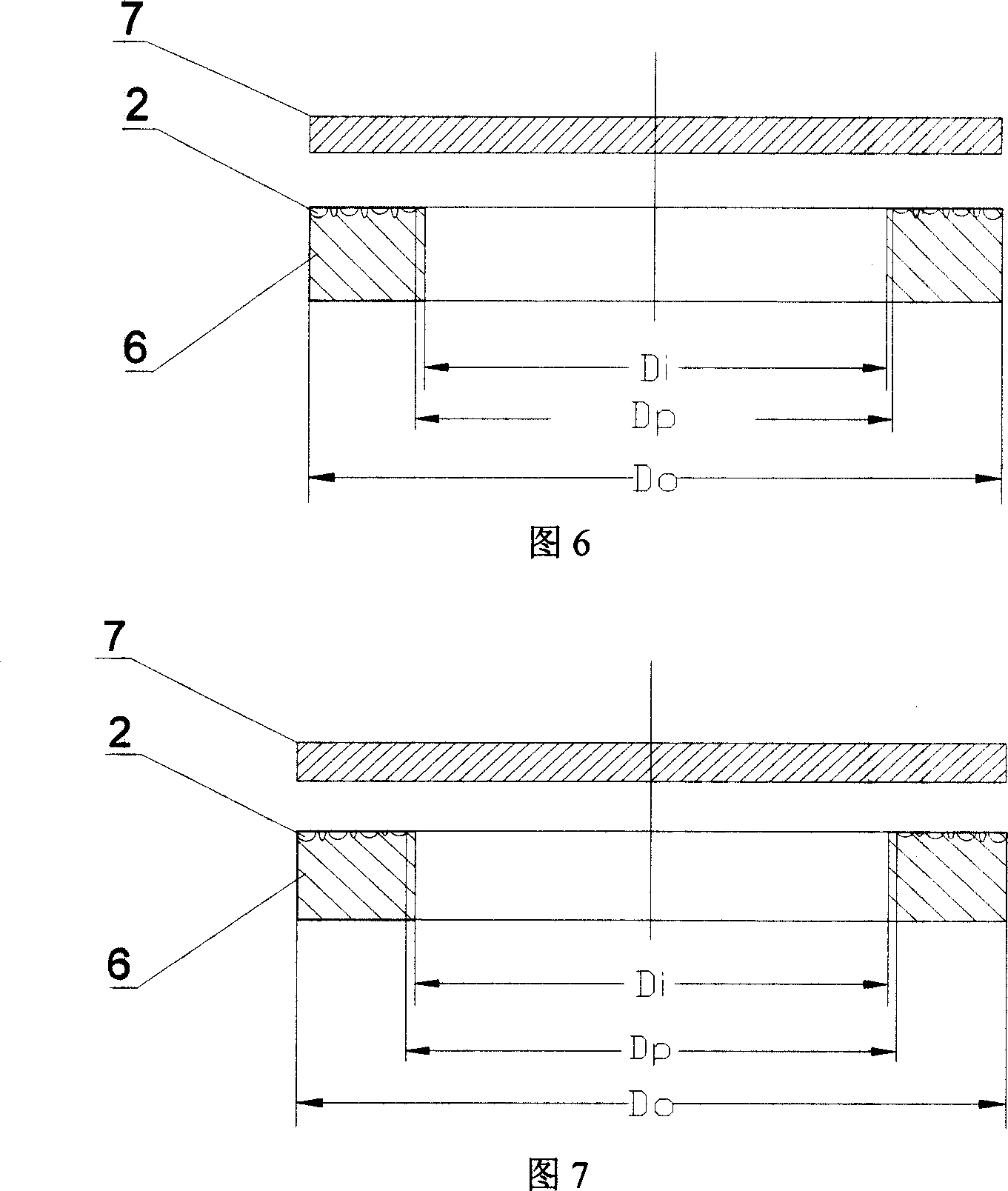

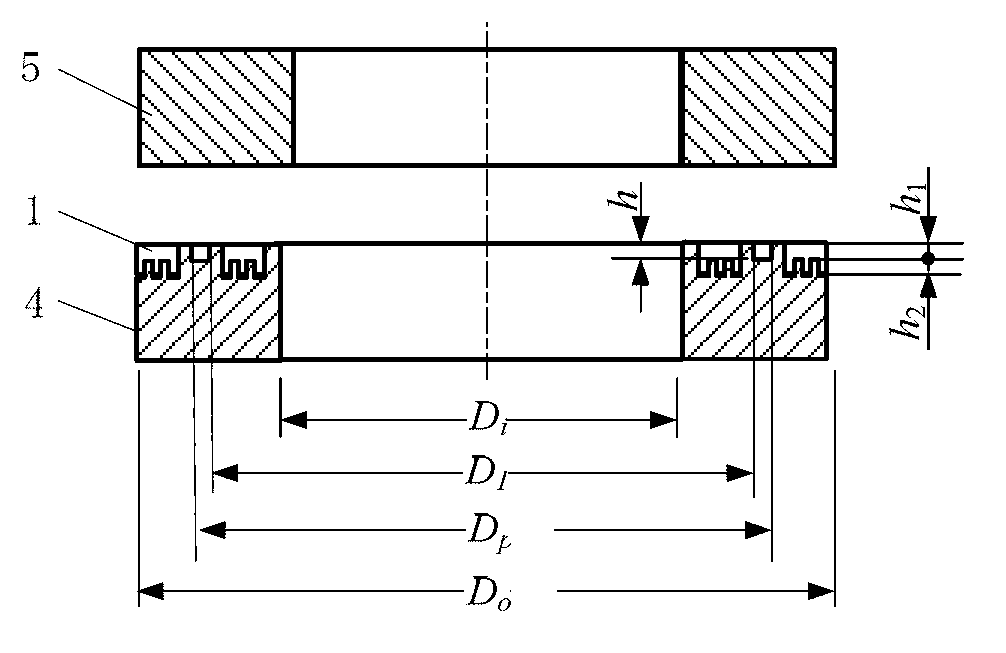

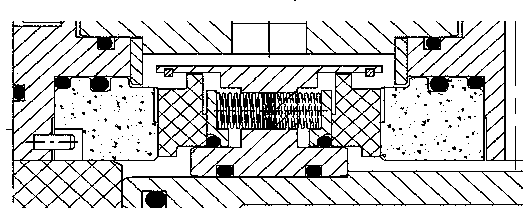

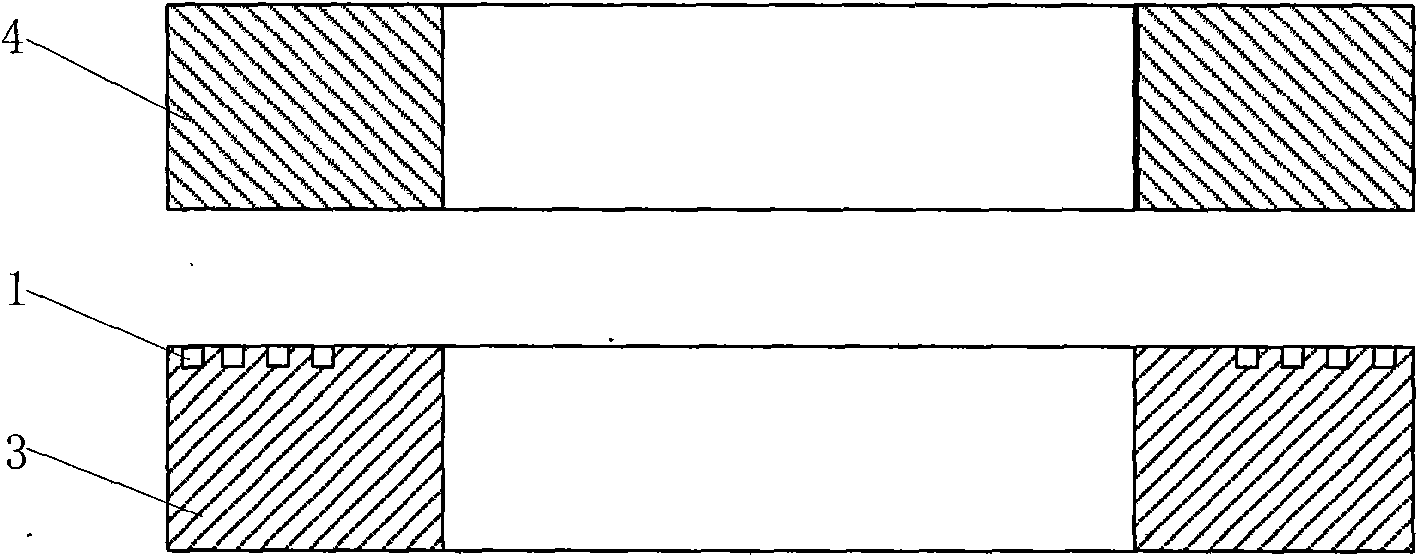

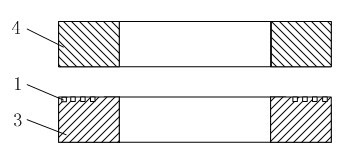

The invention discloses a mechanical seal device of a screw power machine, which is composed of a moving ring (1), a metal corrugated pipe compensation stationary ring (2), a spring-compensated radial inner stationary ring (3), a spring-compensated radial outer stationary ring (4) and a stationary ring seat (5), wherein the moving ring (1) is fixedly installed on a rotor shaft sleeve (8), the metal corrugated pipe compensation stationary ring (2) is arranged on the left side of the moving ring (1), and the spring-compensated radial inner stationary ring (3) and the spring-compensated radial outer stationary ring (4) are arranged on the right side of the moving ring (1). A mechanical seal mechanism with radial double end surfaces and axial double end surfaces is formed. The mechanical seal device has the advantages of being simple in structure, reliable in use, good in stability and convenient in assembly.

Owner:丹东隆强科技有限责任公司

High performance magnetic pump

ActiveCN101089401APrevent seepageNot affected by differential pressurePump componentsPumpsMagnetic tension forceDrive shaft

The present invention relates to a high-performance magnetic drive pump. Said high-performance magnetic drive pump includes the following several portions: pump body, pump cover, pump shaft, blade wheel, coupling frame, internal magnetic rotor, external magnetic rotor, isolation sleeve, drive shaft and drive shaft bearing. Said invention also provides its working principle and concrete method.

Owner:DANDONG COLOSSUS GROUP

Micro-bulge double-layer composite groove deep end surface mechanical seal structure

The invention discloses a micro-bulge double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a micro-bulge double-layer composite groove deep dynamical pressure groove, a sealing dam, a ring groove and a micro-bulge double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the dynamical pressure groove; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the pumping groove; the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove; the sealing dam is an unprocessed smooth plane; and the ring groove is communicated with the pumping groove and arranged on the upstream of the pumping groove.

Owner:JINTUO PETROLEUM MACHINERY MANUFACTRING CO LTD

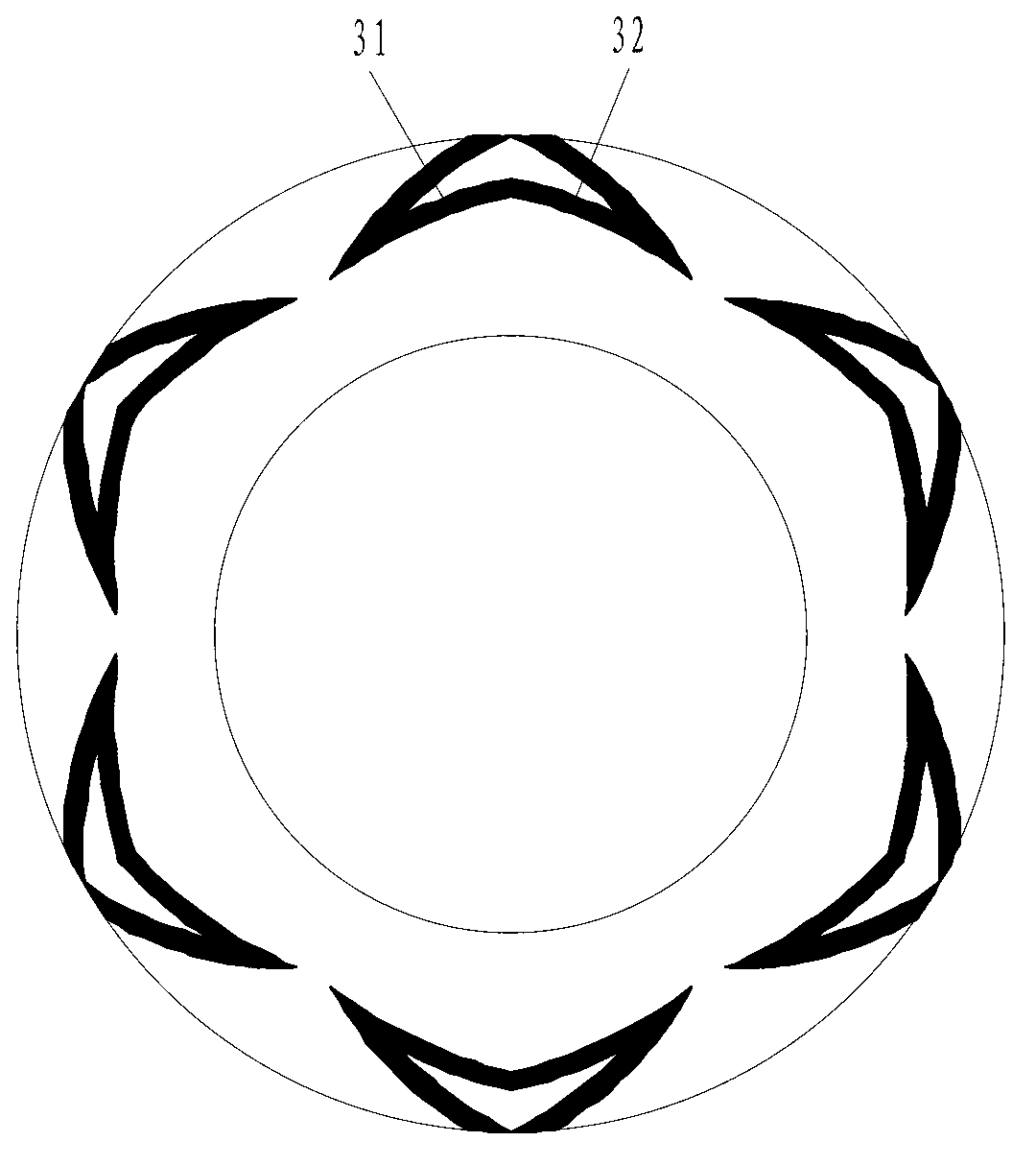

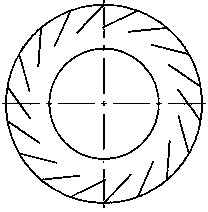

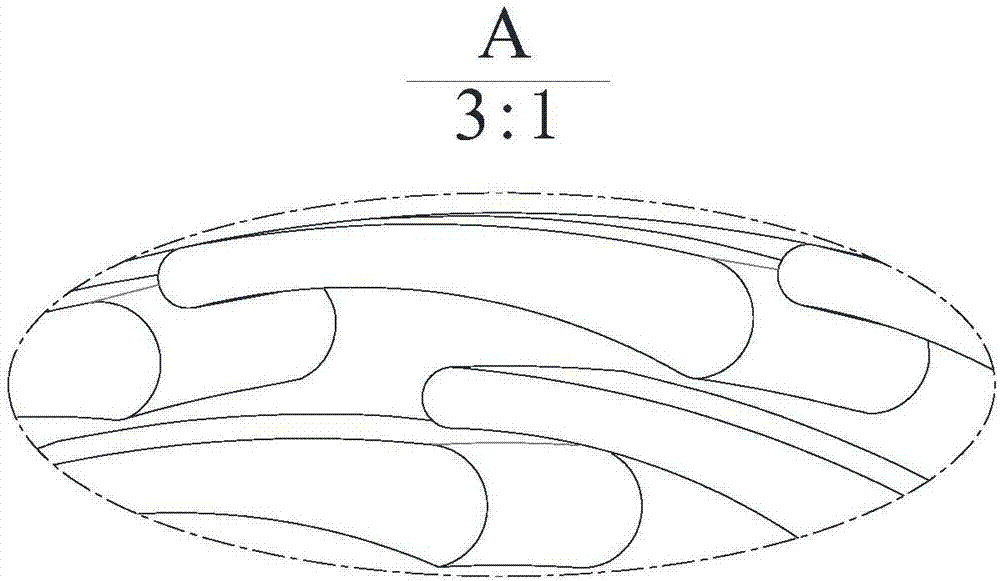

Sharkskin imitation streamline groove end face mechanical sealing structure

ActiveCN103122998ALarge dynamic pressure effectGreat effect of increasing resistance and reducing voltageEngine sealsEngineeringHigh pressure

Disclosed is a streamline groove end face mechanical sealing structure imitating a creased appearance of the surface of sharkskin. The streamline groove end face mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a static ring, plural groups of streamline grooves imitating the creased appearance of the surface of the sharkskin and arranged along the peripheral direction are arranged at least one end face of the sealing rings of the moving ring and the static ring. Each biomimetic groove comprises a left circular groove and a right circular groove, a convex platform along the pressure drop direction in the groove and transitional parts between two sides of the convex platform and an outer contour line of the groove, so that the streamline grooves, namely sharkskin imitation streamline grooves, with the appearance imitating the creased surface of the sharkskin are formed. The sharkskin imitation streamline grooves are arranged on a high pressure side of an end face medium, namely an upper stream. The whole outlines of the sharkskin imitation streamline grooves are in a contracting shape along the pressure drop direction. The sharkskin imitation streamline grooves are arranged to form a groove annular belt along the circumference of the end face, and a plane annular belt area without grooves on the outer end face other than the groove annular belt is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

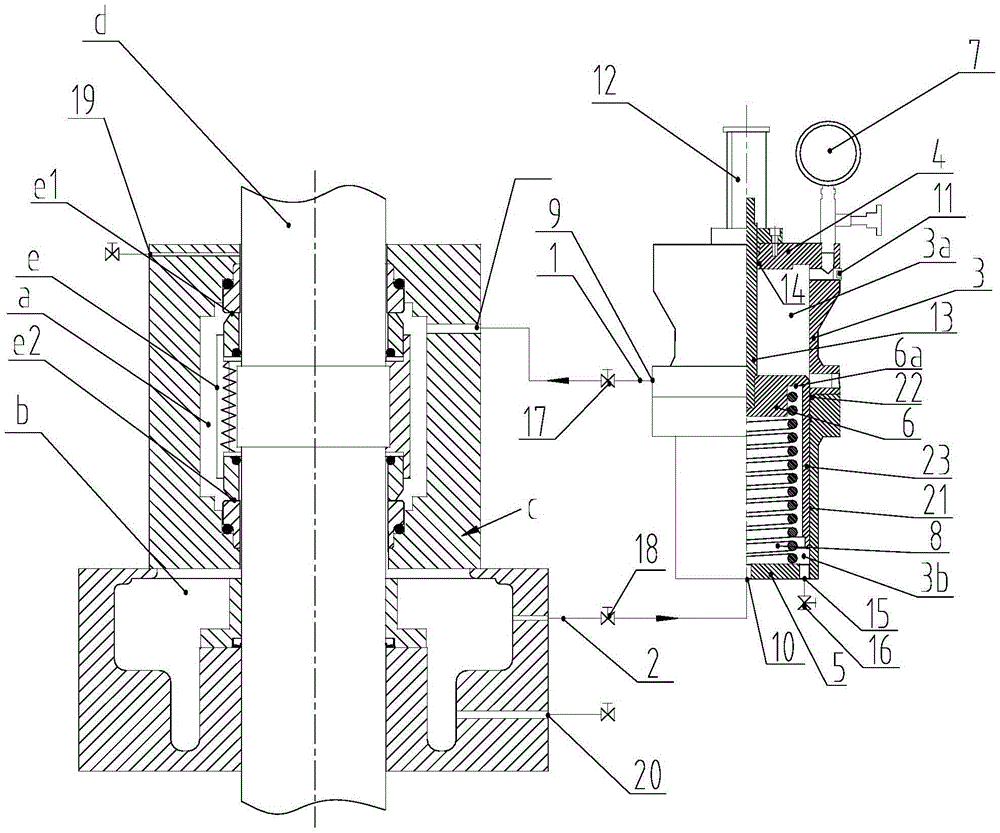

Double-end surface mechanical seal monitoring device of fluid centrifugal pump

ActiveCN105485038AIncrease pressureAvoid vaporizationPump componentsPump controlEngineeringEnd face mechanical seal

The invention discloses a double-end surface mechanical seal monitoring device of a fluid centrifugal pump. The device comprises a pressure stabilizer, a first connecting pipe and a second connecting pipe; the pressure stabilizer includes a shell, a top cover, a bottom cover, a piston, a compression spring, an observing cover and a piston rod; the piston is positioned in the shell, and divides a cavity in the shell into a first cavity and a second cavity; the observing cover is tightly mounted on the top cover; one end of the piston rod is positioned in the first cavity, and is mounted on the piston; the other end of the piston rod extends out of the top cover, and extends in the observing cover; the first cavity is filled with a sealing medium; the shell is respectively provided with a first connecting port and a second connecting port; one end of the first connecting port is communicated with the first cavity; the other end of the first connecting pipe is communicated with a sealing cavity chamber formed by a double-end surface mechanical seal of the fluid centrifugal pump and a sealing base; one end of the second connecting port is communicated with the second cavity; and elastic force of the compression spring and the pressure of a liquid collecting chamber are equal to the pressure in the first cavity. The device can guarantee accuracy of monitoring data.

Owner:WUHAN MARINE MACHINERY PLANT

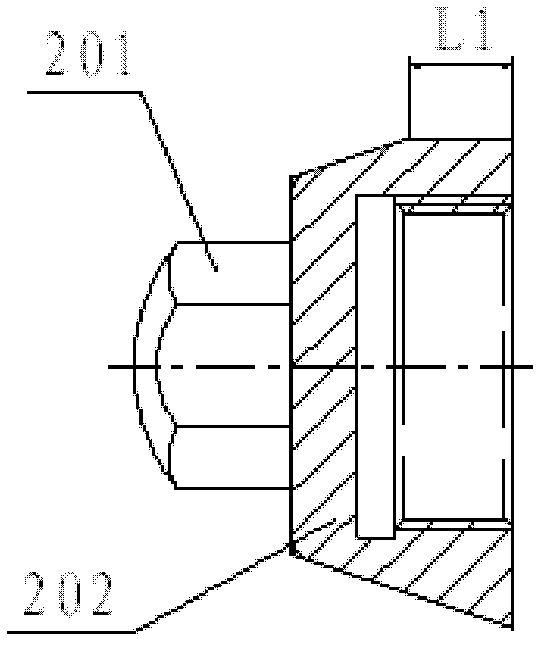

Double-end-surface mechanical seal

InactiveCN102913475ARealize online repair functionEffective filteringPump componentsPumpsEnd face mechanical sealEngineering

The invention provides a double-end-surface mechanical seal. The standard structure of the double-end-surface mechanical seal comprises a positioning packing structure, a double-end-surface sealing structure and a positioning and locking structure. A movable ring (10) rotates along with a shaft sleeve (1) under the action of a shifting fork and can simultaneously slide along an excircle surface of the shaft sleeve front and back (or left and right) in the axial direction, so that the movable ring can be permanently kept in place when the shaft sleeve moves front and back, axial floating of the movable ring is realized and a left end surface clearance and a right end surface clearance formed by the movable ring with a static ring (7) and a compensating ring (12) throughout keep working states. The double-end-surface mechanical seal has the advantages of good sealing effect and wide use range, can realize safe, reliable and long-life operation without using sealing oil or by using little sealing oil, and can simultaneously reduce use costs and maintenance costs of the double-end-surface mechanical seal and bring great social benefits to a user.

Owner:韩乐工

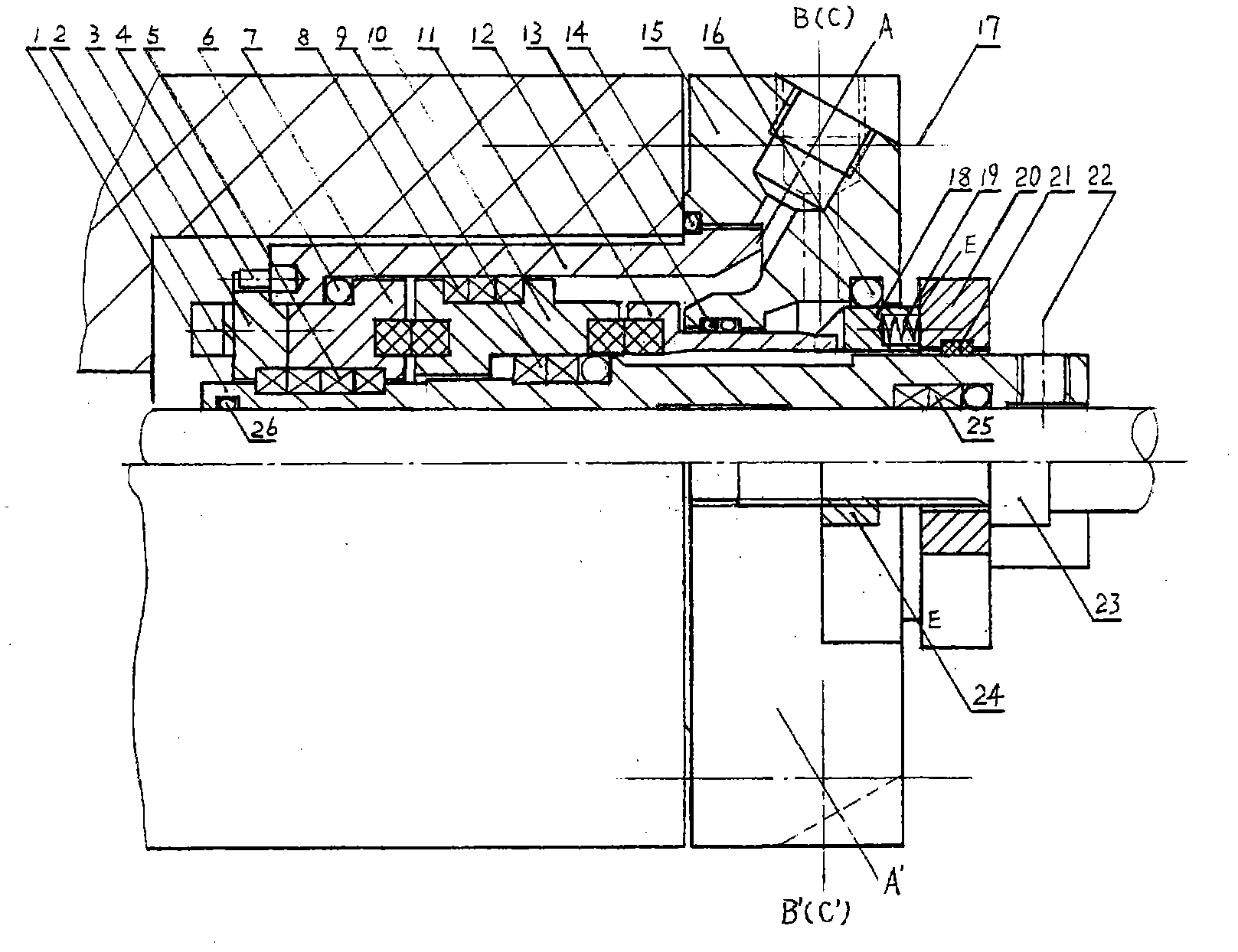

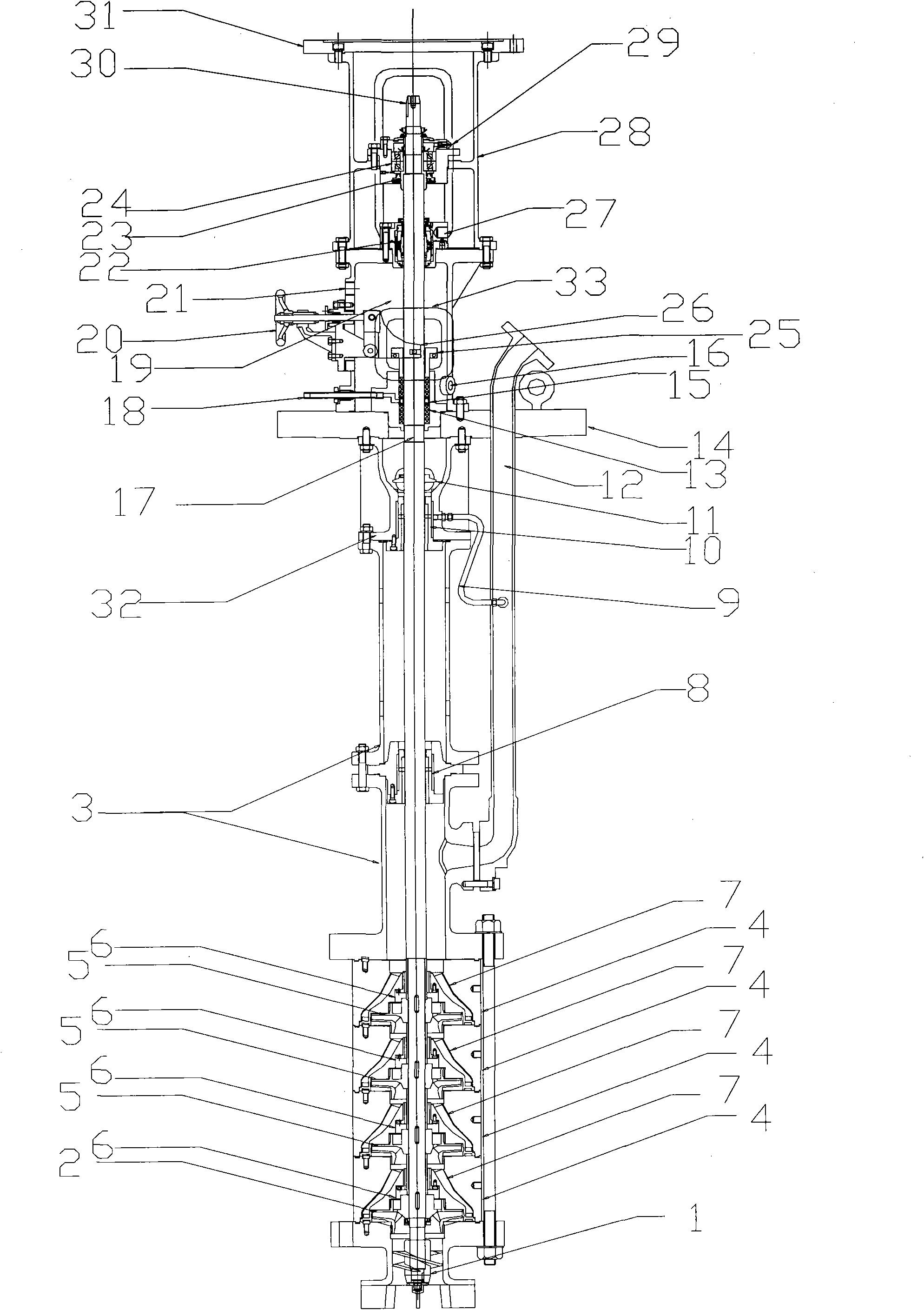

Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

InactiveCN102062107AExtended use timeExtended service lifeSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a multi-stage axial flow submerged pump with a long shaft and a method for conveying phosgene, which are mainly used for pressurizing and conveying the phosgene or chlorine gas. The submerged pump is provided with an inducer (1), a primary impeller (2), a secondary impeller (5), an auxiliary sliding bearing and shaft sleeve (6), a lower main sliding bearing and shaft sleeve (8), an upper main sliding bearing and shaft sleeve (10), a seal cavity (19) and a bearing bracket (28). The lower end of a packing box (13) is provided with an emergency seal rubber pneumatic bag (17); a double-end face mechanical seal (22) is sleeved on a pump shaft (30); a radial balancing hole (37) is arranged on the impeller; and the auxiliary sliding bearing and shaft sleeve (6) is made from silicon carbide. When both of the mechanical seal and the packing seal become invalid, high pressure nitrogen gas ensures that the emergency seal rubber pneumatic bag (17) is inflated to clasp the shaft so as to quickly block leakage of the conveyed phosgene.

Owner:甘肃银光聚银化工有限公司 +1

Mechanical sealing structure with flower and plant simulating fluid type groove end surfaces

The invention discloses a mechanical sealing structure with flower and plant simulating fluid type groove end surfaces. The mechanical sealing structure comprises a mechanical sealing movable ring and a mechanical sealing stationary ring; one sides of the end surfaces of the movable ring and the stationary ring are high-pressure sides, i.e. advanced positions; the other sides of the end surfaces of the movable ring and the stationary ring are low-pressure sides, i.e. backward positions; the backward positions of the end surfaces are provided with circular sealing dams with smooth flat surfaces; the mechanical sealing structure is characterized in that a plurality of fluid type grooves, which are uniformly distributed along the circumference direction, are formed by drainage grooves, left profiled grooves and right profiled grooves centering around the drainage grooves and take the shape of flowers and plants in appearance, are arranged on at least one of the end surfaces of the movable ring and the stationary ring, the drainage grooves are radial grooves; the fluid type grooves are distributed on an annular belt in accordance with the centers of the end surfaces, the circular belt is arranged at the advanced positions of the end surfaces; and no slotting regions between the flower and plant simulating fluid type grooves form a sealing weir. The mechanical sealing structure has better fluid guiding effect; the pressures of the root regions of the fluid type grooves are higher and more uniformly distributed; and the bearing capacity of a seal and the rigidity of a fluid membrane are increased.

Owner:ZHEJIANG UNIV OF TECH

Auto-boost mechanical seal for slurry pumps

The invention relates to the technical field of seals, in particular to an auto-boost mechanical seal for slurry pumps. The auto-boost mechanical seal comprises a shaft sleeve and a flange with which the shaft sleeve is sleeved. The shaft sleeve is sleeved with a seal component. The seal component comprises a front fixed ring and a front moving ring; the front fixed ring and the front moving ring fitting each other are disposed on one side of the flange; a spring holder is disposed on the other side of the front moving ring; a spring is disposed inside the spring holder; push rings are disposed on two sides of the spring; a rear moving ring and a rear fixed ring fitting each other are disposed on one side of the push ring disposed on the other side of the spring. A transmission sleeve is mechanically sealed from two end faces, so that the sealed end is boosted by circulating water inside a sealed cavity, and bearing pressure of the seal can be more than four times as high as the normal seal; high pressure is introduced to the bottom of a deformed groove, a boss can tightly hold a seal ring inside the groove through automatic boosting of an auxiliary impeller, unbalanced moving ring and fixed ring pressure of the seal can be balanced ingeniously, the ends of the seal can be effectively protected from abrasion, and the service life of the seal is prolonged.

Owner:WUHU ZHONGTIAN SEALS

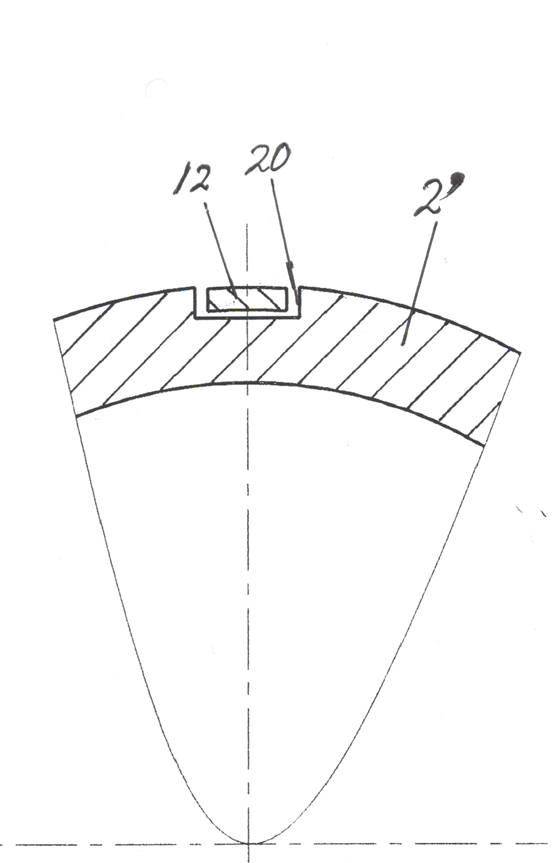

Tilting directional microporous end surface mechanical sealing structure

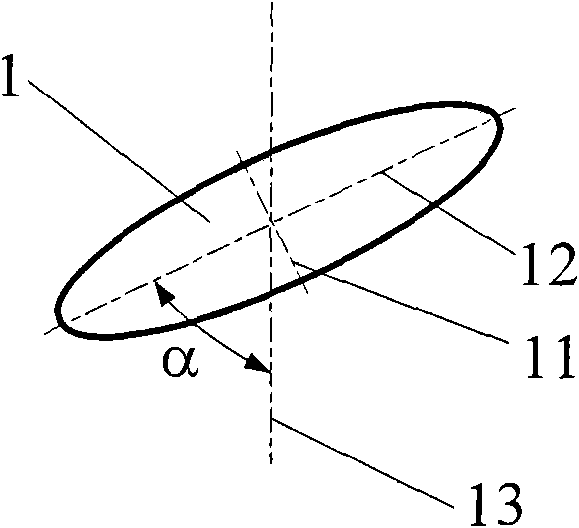

ActiveCN101672366AImprove reliabilityEnhanced hydrodynamic effectEngine sealsStart stopLiquid medium

The invention relates to a tilting directional microporous end surface mechanical sealing structure comprising a dynamic ring and a static ring which are sealed mechanically, one side of the end surface of the dynamic ring and the static ring is a high-voltage side, namely, an upstream part, and the other side thereof is a low-voltage side, namely, a downstream part; the end surface of the dynamicring or the static ring is provided with a microporous ring belt which is arranged on the upstream part of the end surface; the downstream part of the microporous ring belt is provided with a continuous ring-shaped sealing dam; and a long shaft of the micropore forms a tilting angle with the diameter of the sealing end surface passing through the center of the micropore. The tilting directional micropore end surface mechanical sealing structure has the beneficial effects of: greatly improving hydrodynamic effect of the microporous end surface, leading the sealing to have good starting-stopping effect under low-voltage condition, being capable of being applied in a liquid medium and a gas medium by setting the depth of the micropore, being capable of fully exerting the capabilities and advantages of microporous solid particles, realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

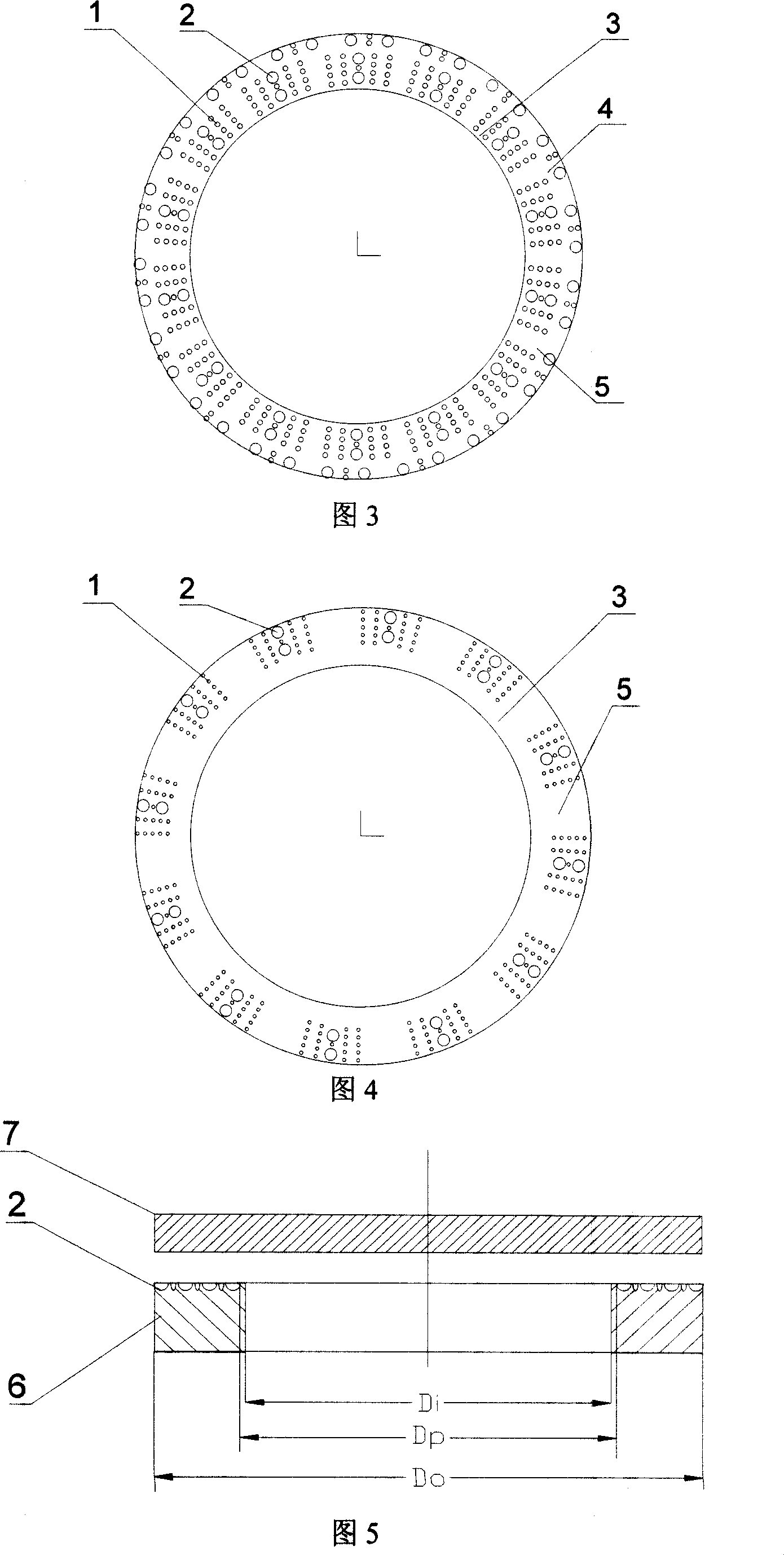

Mechanical seal structure of spike-shaped distribution microporous end surface

ActiveCN102022548AImprove non-contact stabilityImprove wear resistanceEngine sealsCentre of rotationSolid particle

The invention provides a mechanical seal structure of a spike-shaped distribution microporous end surface, comprising a moving ring and a static ring which are mechanically sealed, wherein the one side of the end surface of the moving ring and one side of the end surface of the static ring are high pressure sides, namely upstream; the other side of the end surface of the moving ring and the otherside of the end surface of the static ring are low pressure sides, namely downstream; at least one end surface of the moving ring or static ring is provided with a group of spike-shaped micropores which are symmetrically distributed based on a rotation center and composed of inclined hydrodynamic micropores and nondirectional decompressed micropores, wherein the decompressed micropores are arranged at the tail ends of the hydrodynamic micropores; the spike-shaped micropore group forms a ring belt which is arranged on the upstream of the end surface; and the downstream of the ring belt is provided with an annular seal dam with a smooth plane. The mechanical seal structure has the beneficial effects that seal disturbance-resistant capability and stability are improved by controlling fluid hydrodynamic effect of the microporous end surface and increasing damp; the capability and advantage that micropores can prevent solid particles can be fully performed; and the fluid hydrodynamic effect and disturbance resistivity are enhanced so that noncontact stability and wear resistivity of seal are improved, the service life is prolonged, and the reliability of the seal is improved.

Owner:海宁市黄湾镇资产经营有限公司

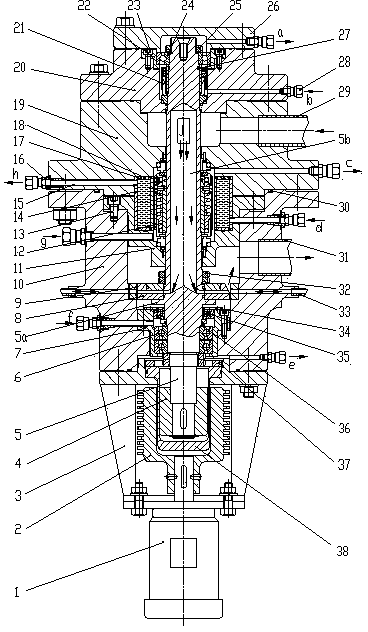

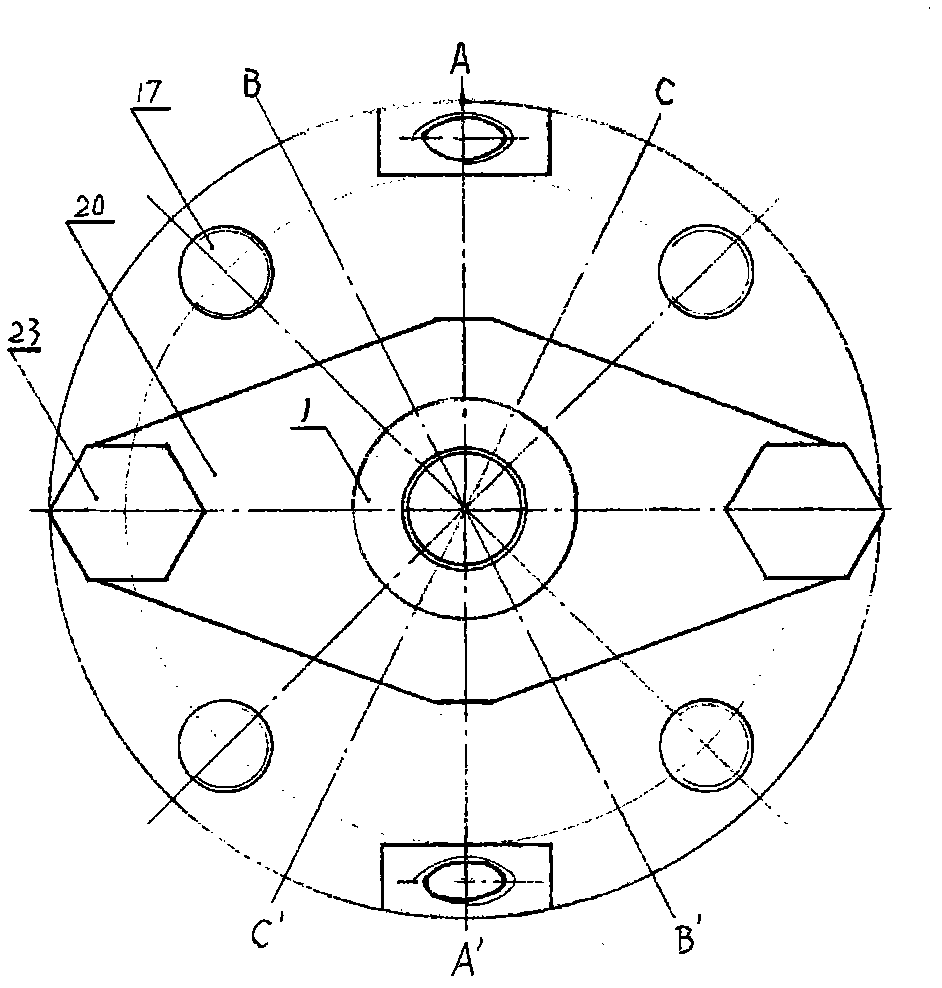

Direct and reverse flow pumping combined radial double-end-surface mechanical sealing device

ActiveCN103912685AReduce leakageProduce dynamic pressure effectEngine sealsEnvironment effectEngineering

The invention discloses a direct and reverse flow pumping combined radial double-end-surface mechanical sealing device which comprises sealing movable rings capable of rotating along shafts. Fixed rings which are flexibly fixed to sealing cavities are used as compensation rings; external liquid pressure lead-in channels are arranged in the fixed rings and are peripherally uniformly distributed in the fixed rings; annular grooves are formed in the end surfaces of the fixed rings 1, and small holes which are communicated with the channels are formed in the annular grooves; outer-side dynamic pressure grooves and inner-side dynamic pressure grooves are formed in two sides of each annular groove, and dynamic pressure effects can be realized by the outer-side dynamic pressure grooves and the inner-side dynamic pressure grooves; direct and reverse flow pumping effects can be respectively realized by inputted external liquid on the outer-side dynamic pressure grooves and the inner-side dynamic pressure grooves relative to external liquid, and the inputted external liquid is inputted via the small holes, so that leakage rates of externally fed liquid on the inner and outer sides of the sealing rings can be respectively controlled, and leakage rates of sealing media can be reduced. The direct and reverse flow pumping combined radial double-end-surface mechanical sealing device has the advantages that leakage rates of sealing joint surfaces can be reduced by the aid of the direct and reverse flow pumping effects, and the direct and reverse flow pumping combined radial double-end-surface mechanical sealing device is applicable to places where sealing media can significantly affect environments.

Owner:TSINGHUA UNIV

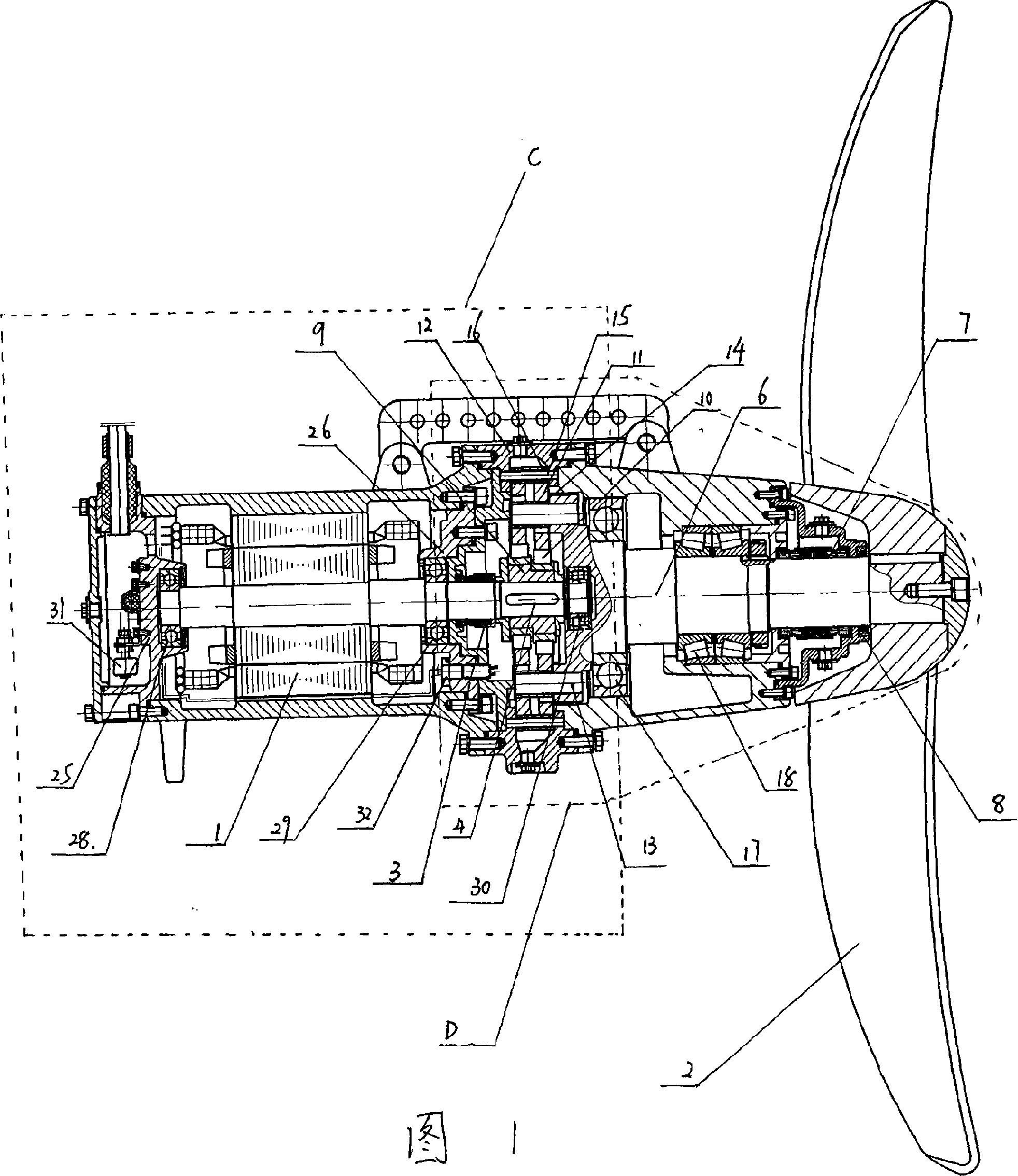

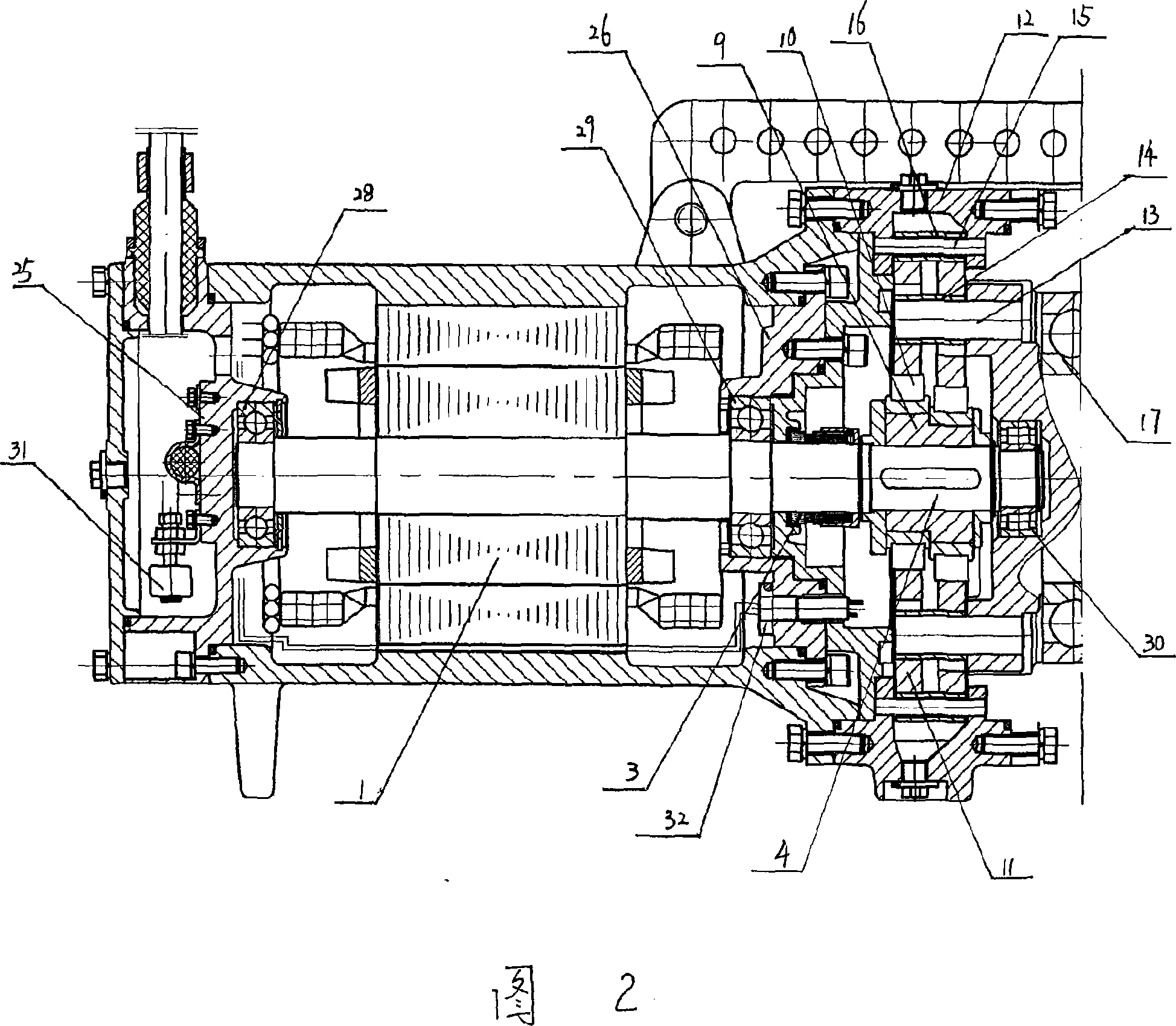

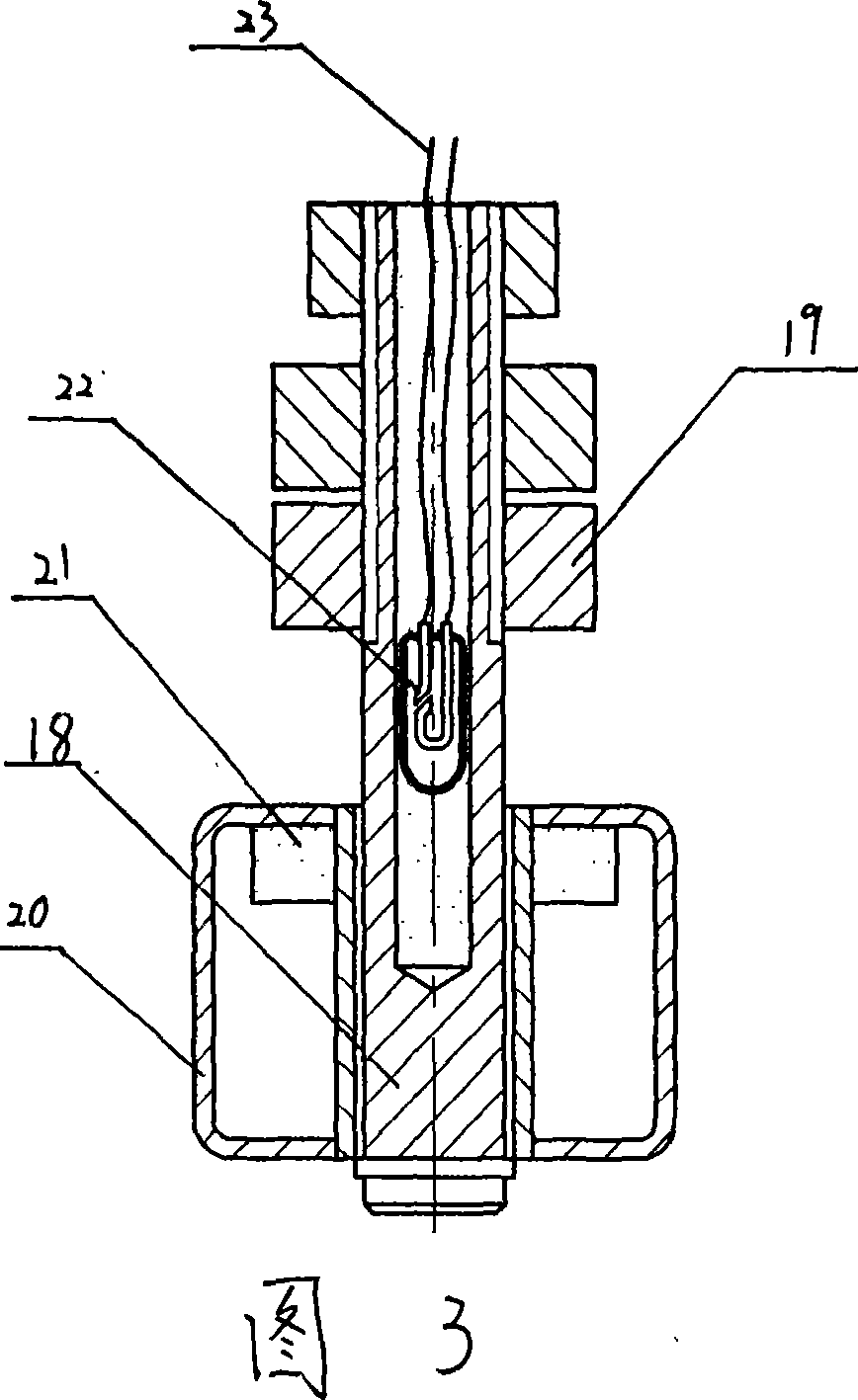

Direct-connected swing spider immersible impeller of motor

InactiveCN101028581AExquisite structureReduce volumeRotary stirring mixersToothed gearingsImpellerPropeller

A submerged propeller has a directly coupled motor-cycloidal spider driver system consisting of a motor with single-end mechanical seal on its mainshaft, a cycloidal spider type speed reducer with dual-end mechanical seal and multi-lip seal on its output axle, a propeller, and a leakage alarm protecting system for the front and back bearing covers of said motor.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

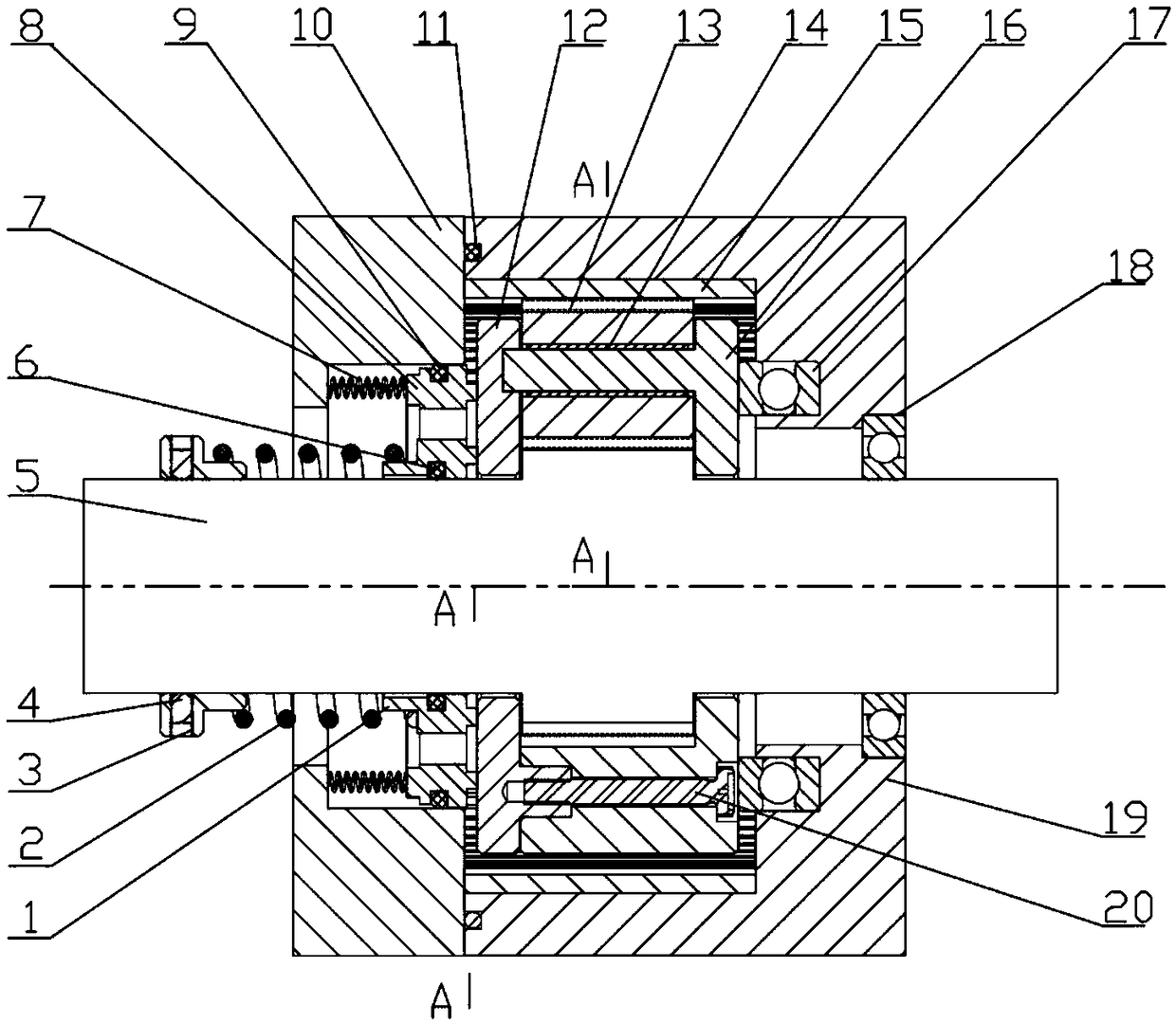

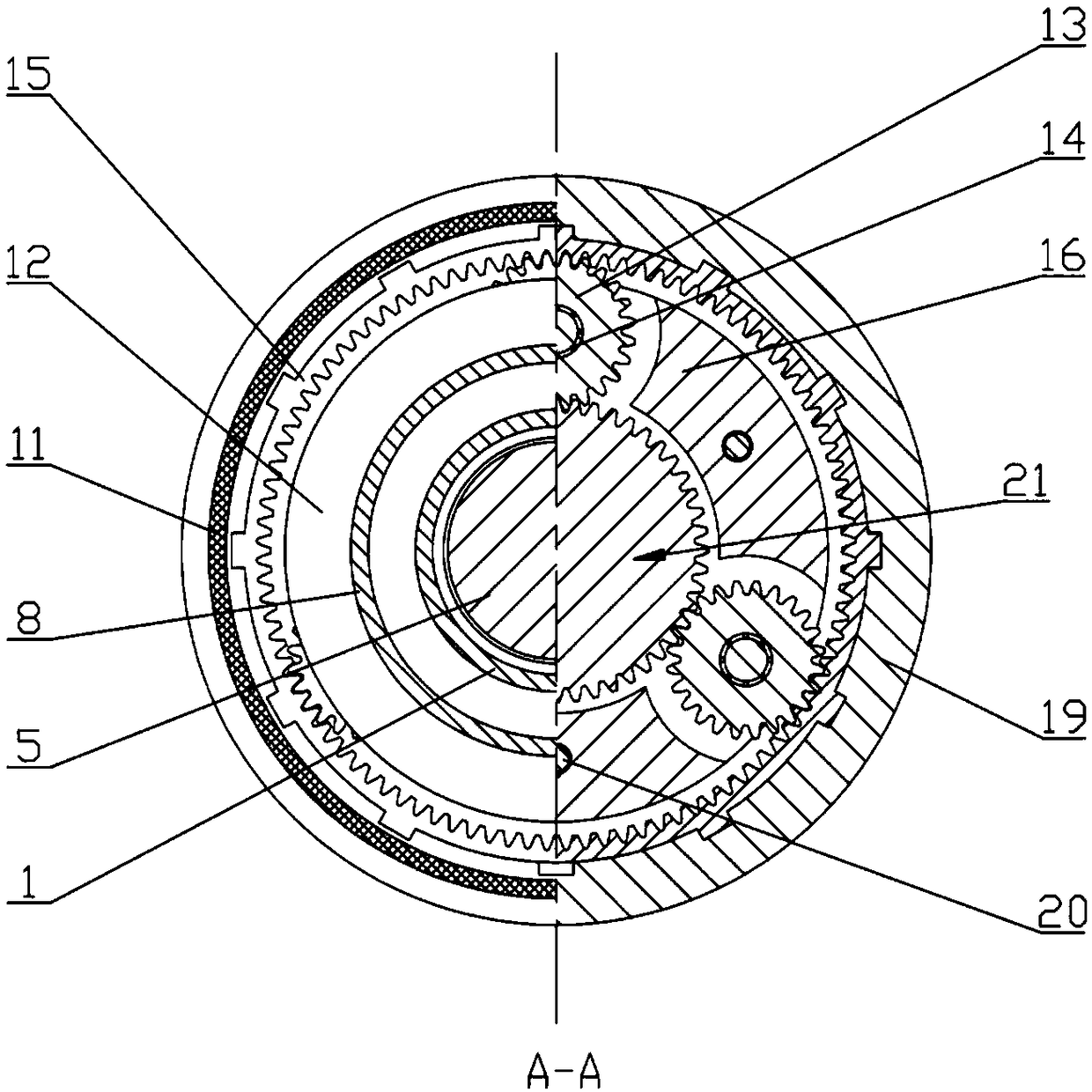

Planetary differential radial dual-end-face mechanical seal

PendingCN108799444AShorten speedAvoid pressure lossDifferential gearingsGearing detailsThrust bearingEngineering

The invention discloses a planetary differential radial dual-end-face mechanical seal. The left end is a medium side, the right end is an air side, the seal is composed of a planetary gear train and two friction pairs, the two friction pairs include a seal pair composed of a rotating seal ring next to a rotating shaft and a differential ring and a seal pair composed of a fixed seal ring away fromthe rotating shaft and a differential wheel, and a blocking medium is leaked to the air from the differential wheel. The rotating seal ring and the rotating shaft synchronously rotate, a back spring provides thrust to keep attaching to the end face of the differential wheel, the rotating seal ring and the differential wheel rotate in the same direction with different rotating speeds, the fixed seal ring is arranged in a fixed ring base, the back spring generates thrust to keep attaching to the end face of the differential wheel, the rotating seal ring and the fixed seal ring are flexible rings, and axial micro-amplitude sliding can be generated. The planetary gear train is composed of a center sun wheel, a planetary wheel, the differential wheel and an inner gear ring. The center sun wheelrotates along with the rotating shaft, the inner gear ring is connected with a shaft end fixed shell through a spline, an air side differential wheel and the medium side differential wheel are in rigid connection with a thrust bearing and are fixed, and only circumferential motion is allowed.

Owner:ZHEJIANG UNIV OF TECH

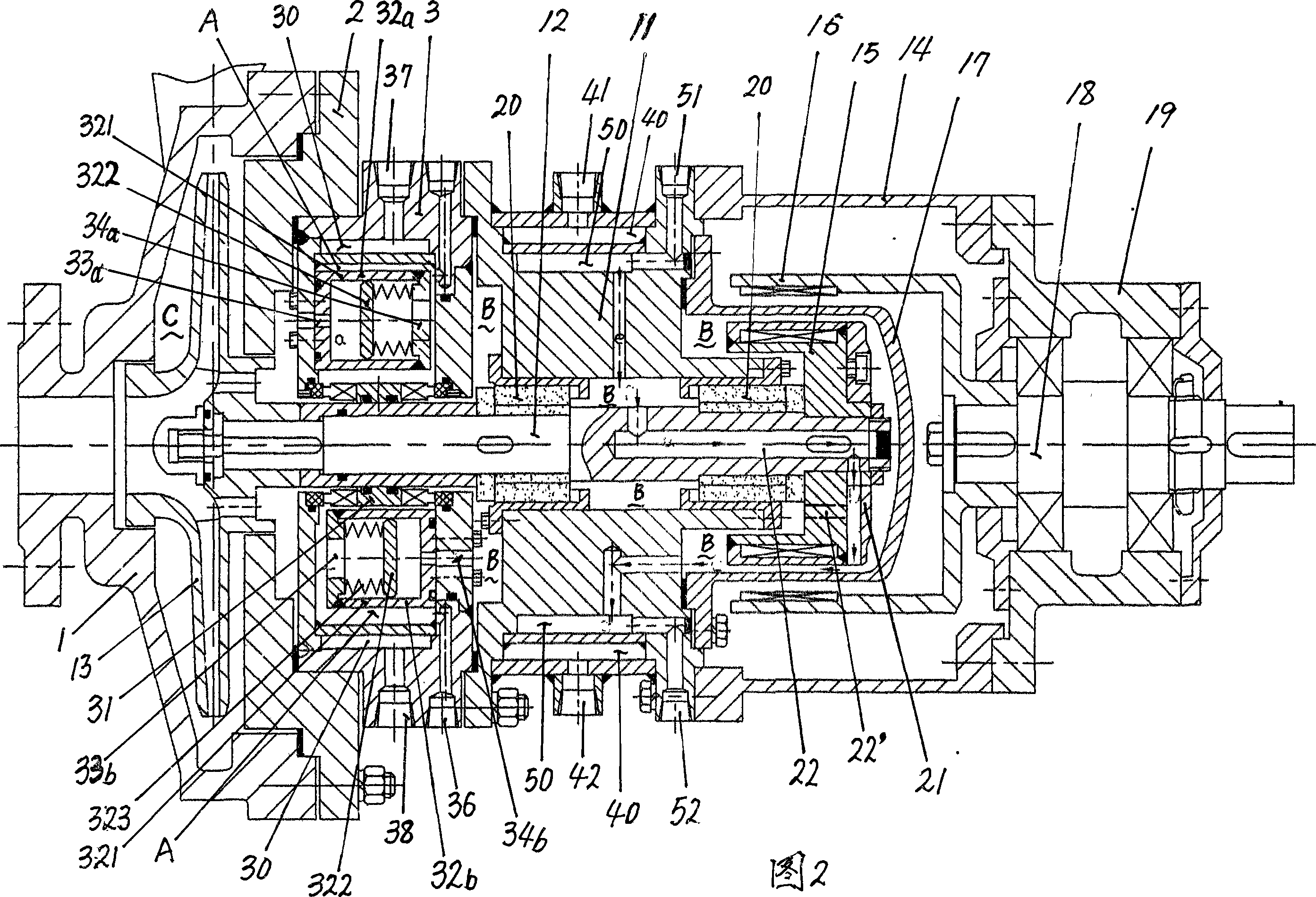

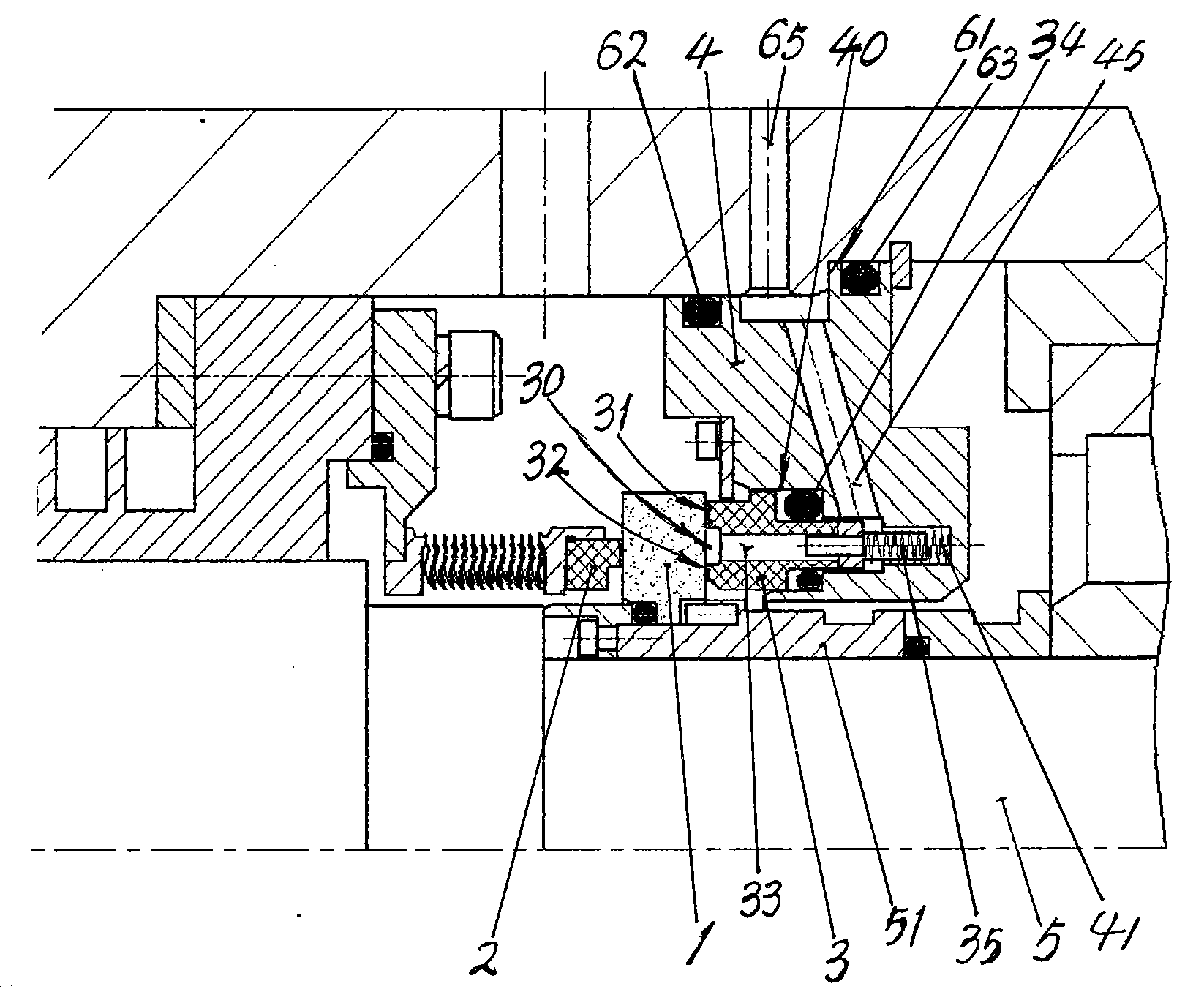

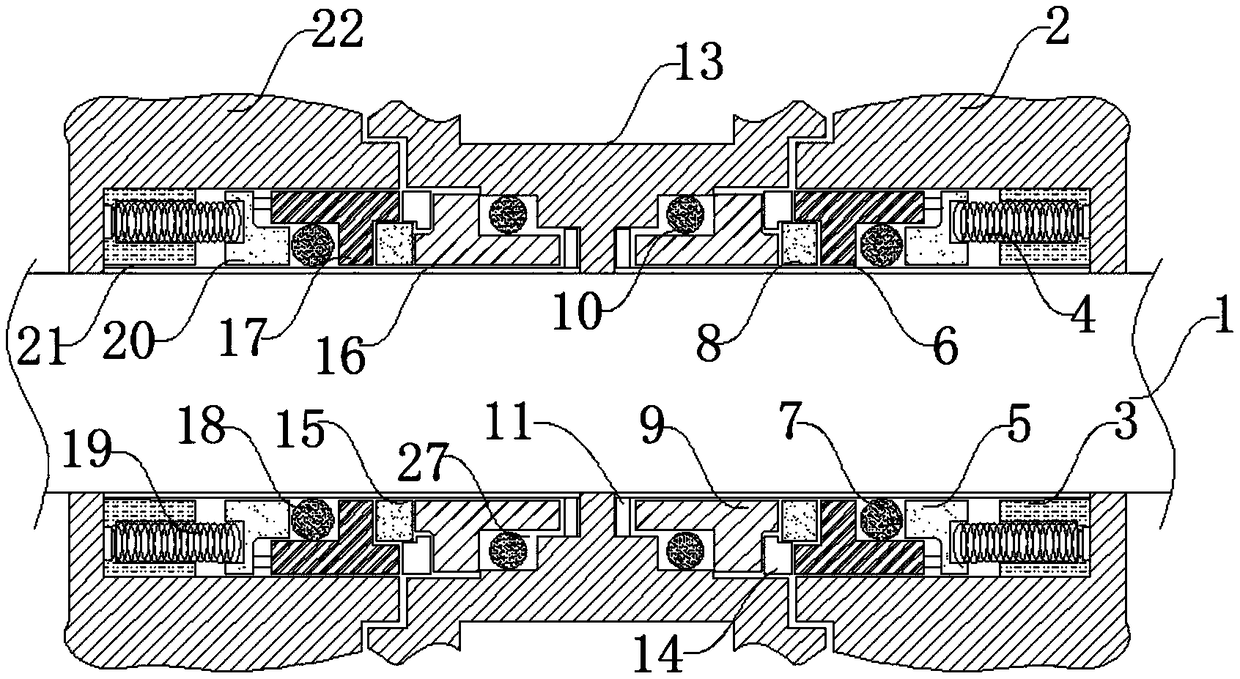

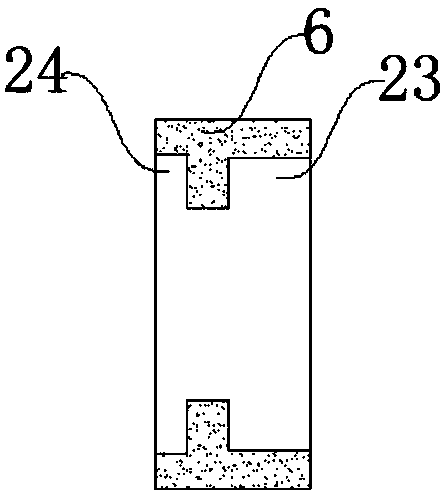

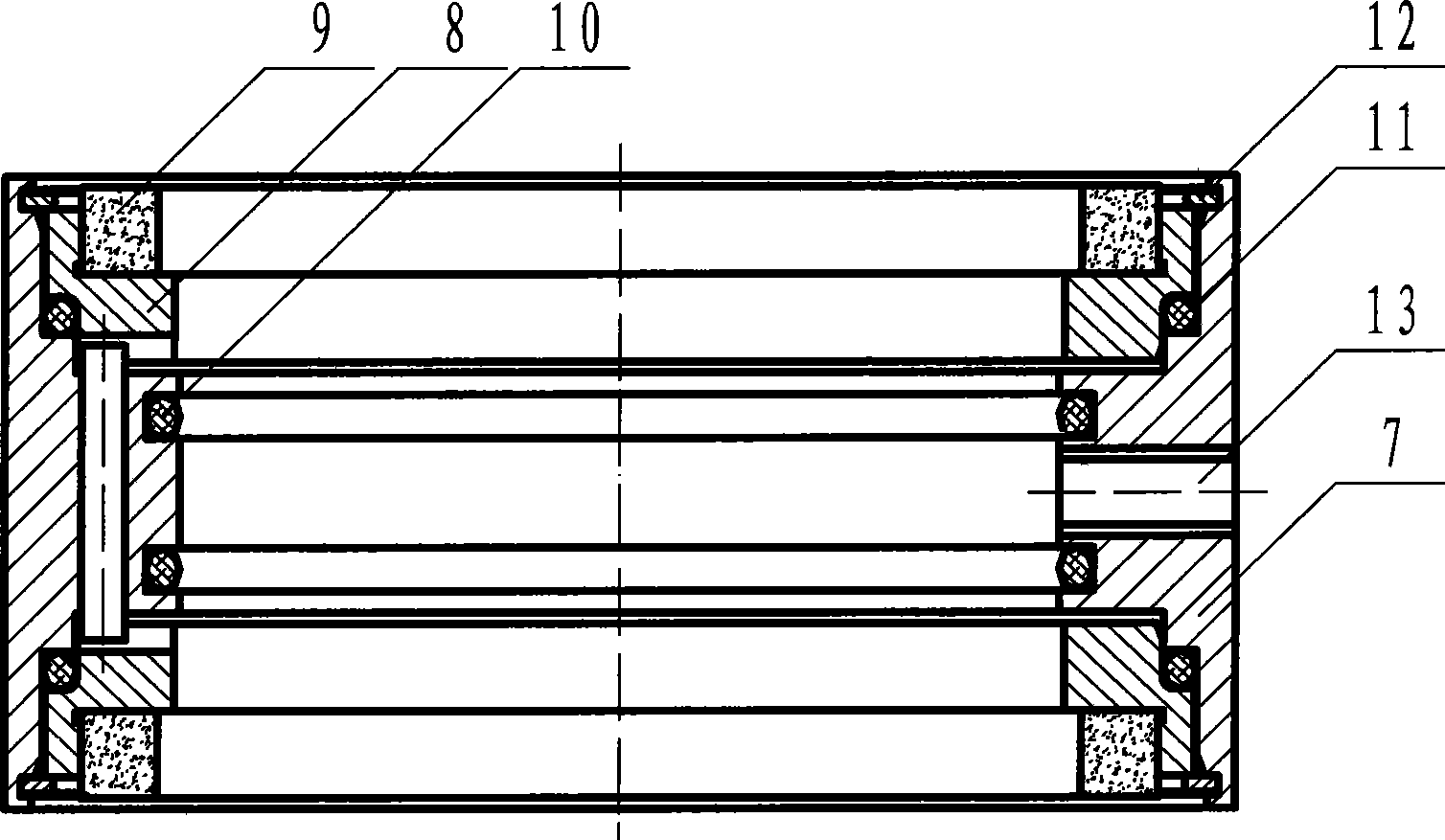

Mechanical sealing device of vapour-liquid full flow screw power machine

ActiveCN101825181AReduce the temperatureHigh working reliabilityEngine sealsEngineeringEnd face mechanical seal

The invention discloses a mechanical sealing device of a vapour-liquid full flow screw power machine, which is composed of a moving ring (1), a corrugated pipe compensation stationary ring (2) and a spring compensation radial stationary ring (3) with double end surfaces, wherein, the moving ring (1) is installed on a rotor spindle (5) or a shaft sleeve (51); the stationary ring (2) is arranged on the left side of the moving ring (1), and the spring compensation radial stationary ring (3) is arranged on the right side of the moving ring (1); and the mechanical sealing mechanism with axial double end surfaces and radial double end surfaces is formed. The mechanical sealing device has simple structure, long service life and reliable operation, improves the operation reliability of a friction sealing end surface; and the spring compensation radial stationary ring (3) with the double end surfaces fully prevents leaked medium from mixing with lubricating oil to cause emulsification.

Owner:DANDONG COLOSSUS GROUP

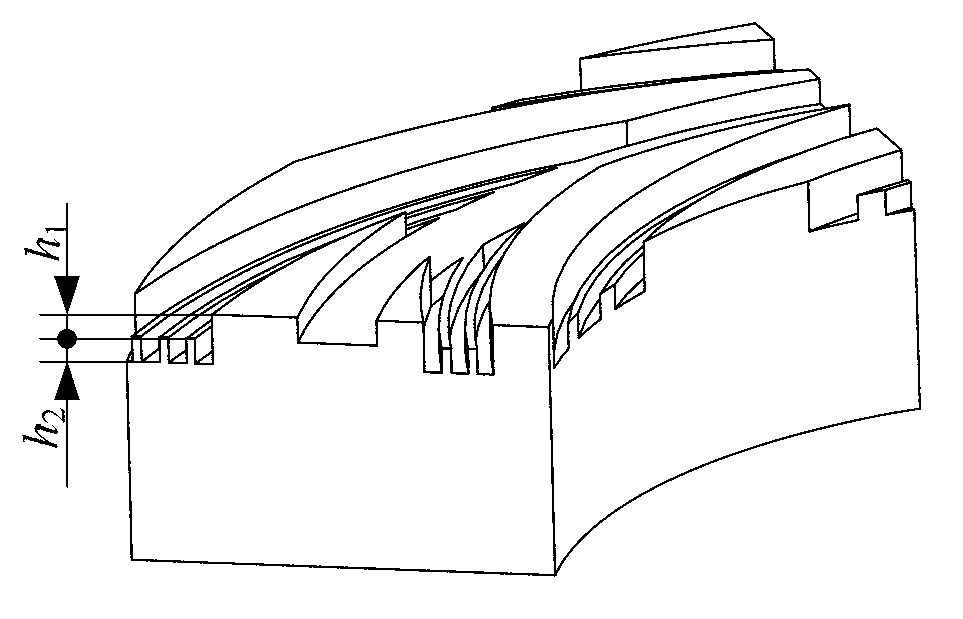

Strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure

The invention discloses a strengthened heat transfer type ternary bending torsion micro convex end face mechanical seal structure. Ternary bending torsion micro convexes arranged in the circumferential direction according to the center of the end face to form ring belts are machined on the end face of a movable ring or a static ring of a mechanical seal; each ternary bending torsion micro convex is a micro cylinder with the cross section in the wing shape; and relative torsion exists between every two adjacent cross sections on the ternary bending torsion micro convexes. The long axes of the cross sections of the ternary bending torsion micro convexes are arranged in the circumferential direction of the end face; the short axes of the cross sections of the ternary bending torsion micro convexes are arranged in the radial direction of the end face; the end face of the leeward side of the front micro convex on the ring belts is located on the inner side of the end face of the windward side of the back micro convex; a ring direction flow channel is formed between every two adjacent rows of ring belts, and fluid flows into the ring direction flow channels through the micro convexes and generates strong vortex in the ring direction flow channels; every two adjacent rows of ring belts of the ternary bending torsion micro convexes are arranged in a staggered manner; and the position, close to the leakage side, on the sealed end face is provided with an annular sealing dam; and the height of the sealing dam is equal to that of the ternary bending torsion micro convexes.

Owner:ZHEJIANG UNIV OF TECH

Static axial double-end-face mechanical sealing structure, stirrer and stirred tank

InactiveCN105276193AMeet high speed requirementsAvoid bending deformationEngine sealsMixer accessoriesChemical reactionEngineering

The invention discloses a static axial double-end-face mechanical sealing structure, a stirrer and a stirred tank and belongs to the field of chemical engineering. The static axial double-end-face mechanical sealing structure is arranged on a stirring shaft and arranged in a sealing box. The stirring shaft is sleeved with a shaft sleeve. The static axial double-end-face mechanical sealing structure comprises a first spring, a first static ring, a dynamic ring, a static sealing piece, a second static ring and a second spring which are arranged from top to bottom. The first spring is arranged below the first static ring. The second spring is arranged below the second static ring. Neither the first spring nor the second spring rotates along with the stirring shaft, the possibility of bending deformation is avoided, the mechanical sealing effect is guaranteed, and the requirement of some chemical reactions for the high rotating speed of the stirrer is met. In this way, the stirrer with the static axial double-end-face mechanical sealing structure can meet the high-rotating-speed requirement, and thus the stirrer tank with the stirrer can meet the high-rotating-speed requirement.

Owner:ZIBO SANTIAN CHEM EQUIP CO LTD

Manufacturing method of small-spring double-end-face mechanical seal device

The invention discloses a manufacturing method of a small-spring double-end-face mechanical seal device. The small-spring double-end-face mechanical seal device comprises a gland, a first housing, a second housing, a first movable ring, a first stationary ring, a second stationary ring, a second movable ring, a first spring, a first fixing base, a second fixing base, a washer, a first push ring and a second push ring, a first fixed ring, a second fixed ring, a first stationary ring seal ring, a second stationary ring seal ring, a first movable stationary ring seal ring, a second stationary ring seal ring, a waterproof ring, a rotary shaft and a second spring. Compared with the prior art, the manufacturing method of a small-spring double-end-face mechanical seal device adopts the design ofprotruding portions of the bottom sides of the first stationary ring, the second stationary ring, the first fixed ring and the second fixed ring on two sides, so that the first stationary ring seal ring, the first movable ring, the second stationary ring seal ring, the second ring, the first movable ring seal ring and the second movable ring seal ring 7 are better corresponding clamped and fixed,corresponding structures are better stabilized, and the corresponding sealing performance is better.

Owner:安徽安密机械密封有限公司

Imitation shark skin streamlined groove end face mechanical seal structure

ActiveCN103122998BImprove the lubrication effectUniform pressure distributionEngine sealsHigh pressureEnd face mechanical seal

Disclosed is a streamline groove end face mechanical sealing structure imitating a creased appearance of the surface of sharkskin. The streamline groove end face mechanical sealing structure comprises two mechanical sealing rings, namely a moving ring and a static ring, plural groups of streamline grooves imitating the creased appearance of the surface of the sharkskin and arranged along the peripheral direction are arranged at least one end face of the sealing rings of the moving ring and the static ring. Each biomimetic groove comprises a left circular groove and a right circular groove, a convex platform along the pressure drop direction in the groove and transitional parts between two sides of the convex platform and an outer contour line of the groove, so that the streamline grooves, namely sharkskin imitation streamline grooves, with the appearance imitating the creased surface of the sharkskin are formed. The sharkskin imitation streamline grooves are arranged on a high pressure side of an end face medium, namely an upper stream. The whole outlines of the sharkskin imitation streamline grooves are in a contracting shape along the pressure drop direction. The sharkskin imitation streamline grooves are arranged to form a groove annular belt along the circumference of the end face, and a plane annular belt area without grooves on the outer end face other than the groove annular belt is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

Device for preparing high-viscosity polyvinyl alcohol resin solution

InactiveCN103691334ASolve for uniformityRealize continuous productionRotary stirring mixersMixer accessoriesPolyvinyl alcoholReduction drive

The invention discloses a device for preparing a high-viscosity polyvinyl alcohol resin solution. The device is characterized by comprising a barrel unit, a stirring unit and an instrument-controlled detection unit, wherein the barrel unit is a pressure container; a jacket for circularly flowing a heat transfer medium is arranged on the outer surface of the barrel unit; the stirring unit drives a stirrer inside the barrel to rotate by connecting a motor above the barrel unit with a hollow stirring shaft stretching into the barrel through a speed reducer; a junction of the hollow stirring shaft and an upper sealing head is sealed by a double-end surface mechanical sealing structure for a kettle; the instrument-controlled detection unit comprises a thermometer, a viewing window and a liquid level detector which are arranged on the barrel, and a pressure meter and a safety valve which are arranged at a gas inlet of the upper sealing head. The device can prepare the high-viscosity polyvinyl alcohol resin solution from a high-polymerization polyvinyl alcohol resin raw material under a high-temperature and high-pressure condition; and the concentration uniformity of the solution in a high viscosity state can be ensured.

Owner:安徽皖维膜材料有限责任公司

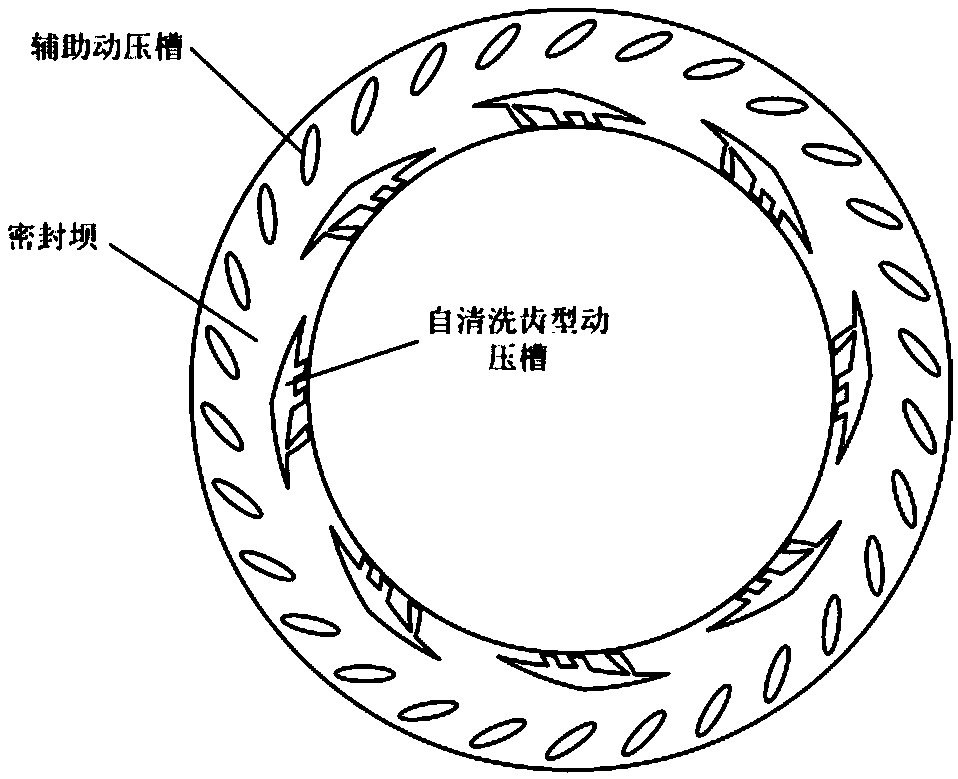

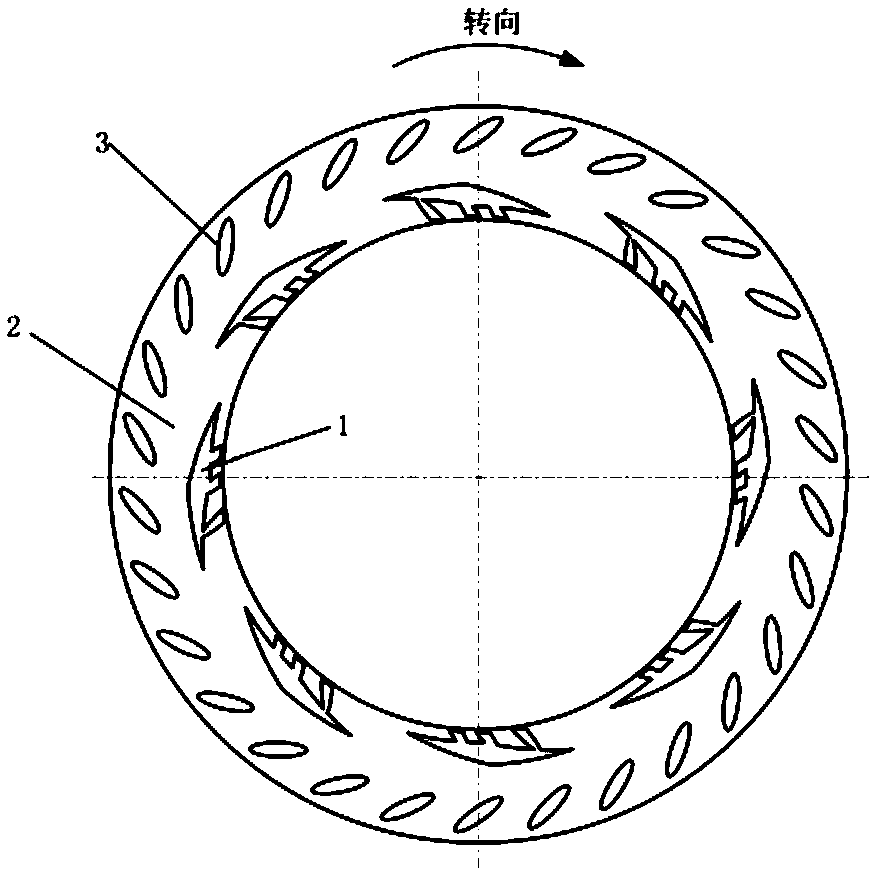

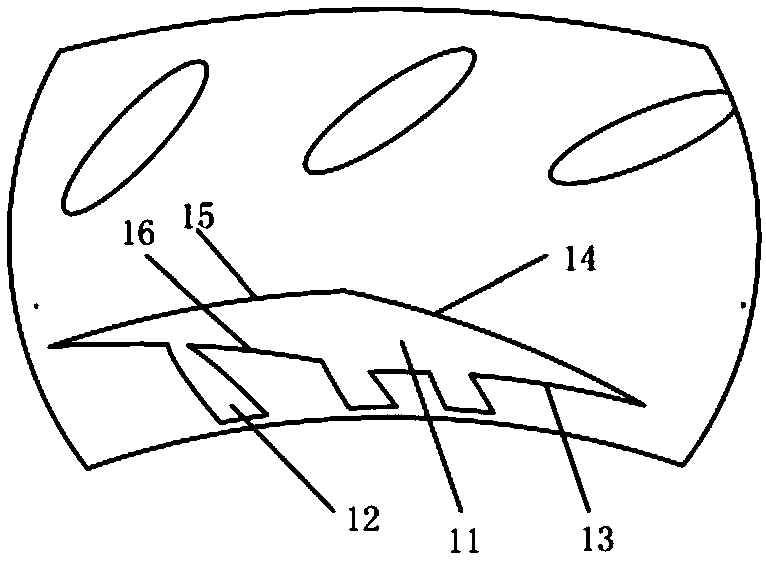

Self-cleaning toothed dynamic-pressure-type groove end face mechanical sealing structure

InactiveCN109237042AAchieve non-contact stabilityReduce contact wearEngine sealsCentre of rotationEngineering

The invention discloses a self-cleaning toothed dynamic-pressure-type groove end face mechanical sealing structure. The structure comprises a dynamic ring and a static ring which are mechanically sealed; one end face of the dynamic ring or the static ring is provided with a self-cleaning toothed dynamic-pressure-type groove ring belt and an auxiliary dynamic-pressure-type groove ring belt which are symmetrically distributed about a rotation center, self-cleaning toothed dynamic-pressure-type grooves are composed of dynamic pressure grooves and cleaning grooves, and the self-cleaning toothed dynamic-pressure-type grooves and auxiliary dynamic-pressure-type grooves are formed in the upstream and downstream portions of the end face respectively and separated by a sealed dam. The non-contact mechanical end face sealing structure prevents deposition blockage of medium particles in end face mold grooves through the cleaning groove structures, solves the blockage problem of the sealed end face mold grooves under high temperature and multi-particle medium conditions, reduces the contact wear of the sealed end face since the dynamic pressure opening force of the sealed end face decreases, and is long in service life.

Owner:BEIJING POWER MACHINERY INST

Mechanical seal stationary ring and rotating ring, and double-end mechanical seal composed of the same

InactiveCN101463902AReasonable designSimple structureEngine sealsEngineeringEnd face mechanical seal

Owner:JINING ANTAI MINING EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com