Double-end surface mechanical seal monitoring device of fluid centrifugal pump

A technology of mechanical seals and monitoring devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, liquid fuel engines, etc., can solve the problems of volume reduction, easy to cause harm, and vaporization, so as to avoid vaporization and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

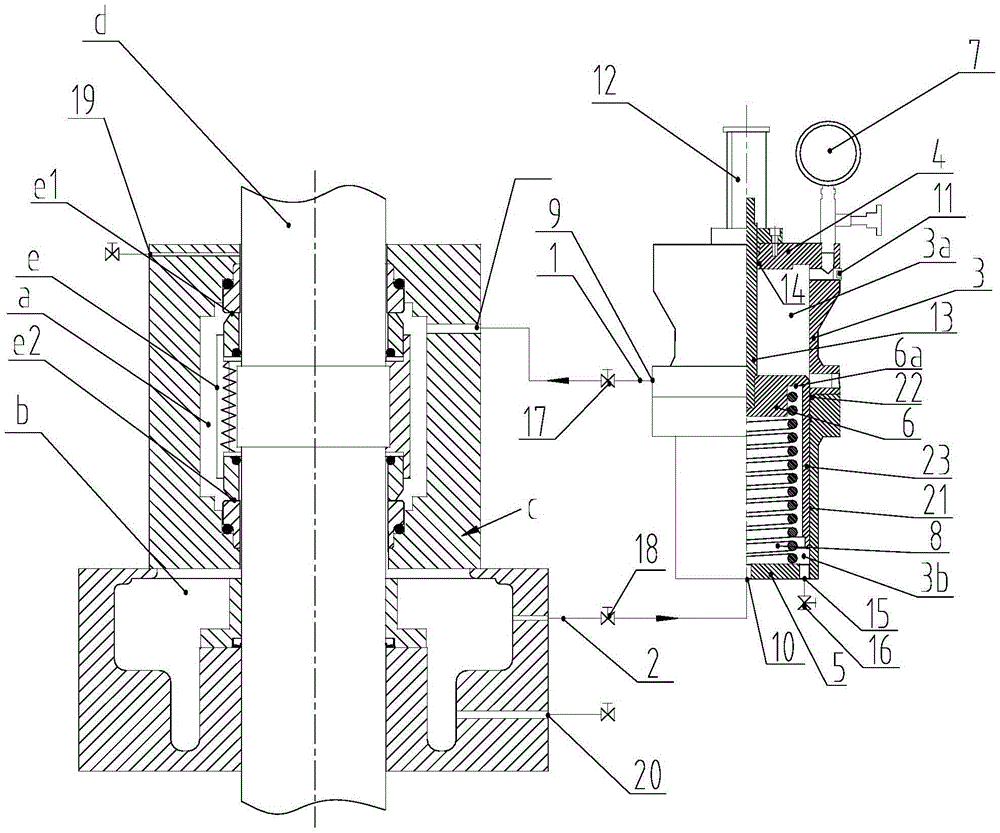

[0022] In order to clearly understand the double-end mechanical seal monitoring device of the fluid centrifugal pump provided by the embodiment of the present invention, such as figure 1 As shown, the following briefly introduces the structure of the double-end mechanical seal of the fluid centrifugal pump. Specifically, the double-end mechanical seal e of the fluid centrifugal pump is installed on the pump shaft d through the seal seat c, and the double-end mechanical seal of the fluid centrifugal pump e and the sealing seat c form a sealed chamber a, a liquid collecting chamber b is provided in the liquid collecting shell of the fluid centrifugal pump, and the pressure in the liquid collecting chamber b is the same as the pressure at the outlet of the fluid centrifugal pump. In addition, in this embodiment, the fluid centrifugal pump may be a liquefied petroleum gas pump.

[0023] The embodiment of the present invention provides a double-end mechanical seal monitoring device of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com