Patents

Literature

217results about How to "Avoid vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

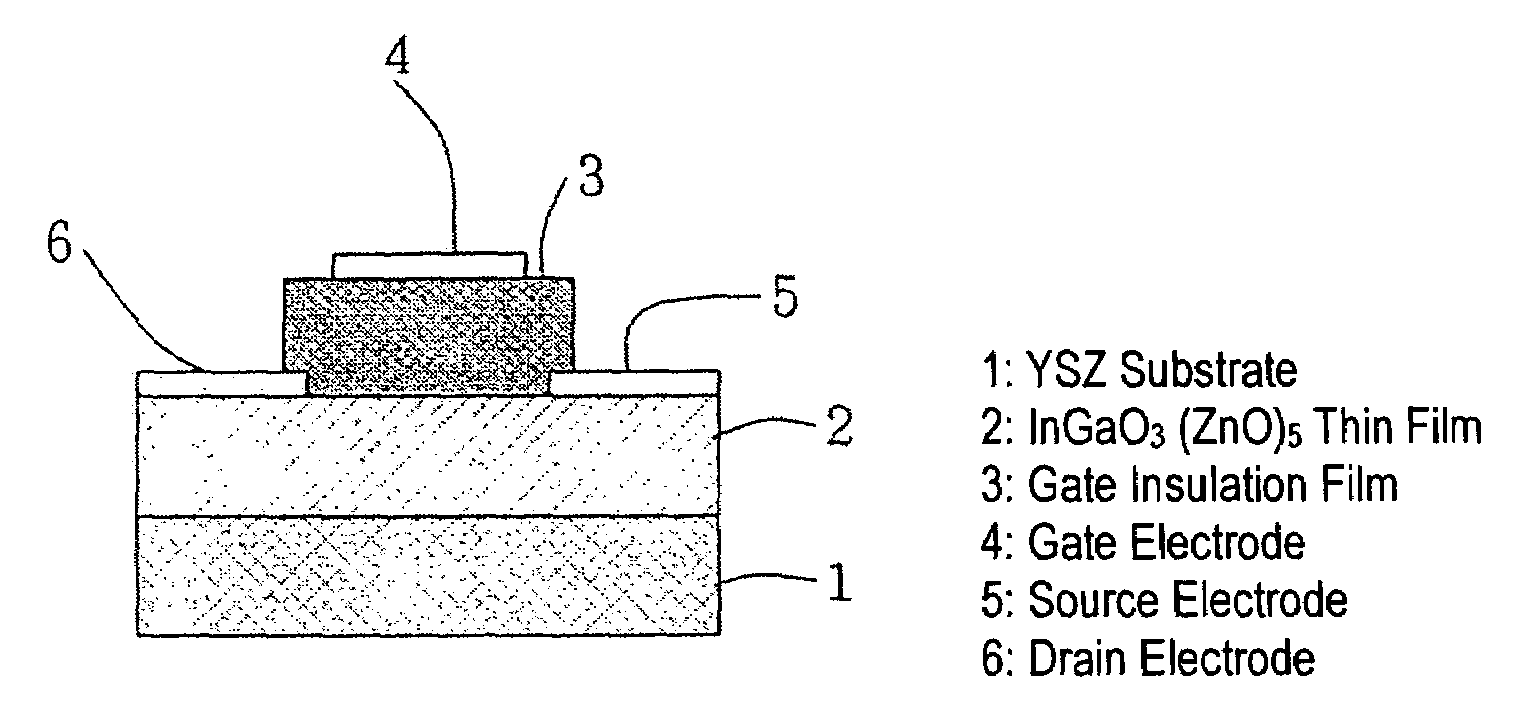

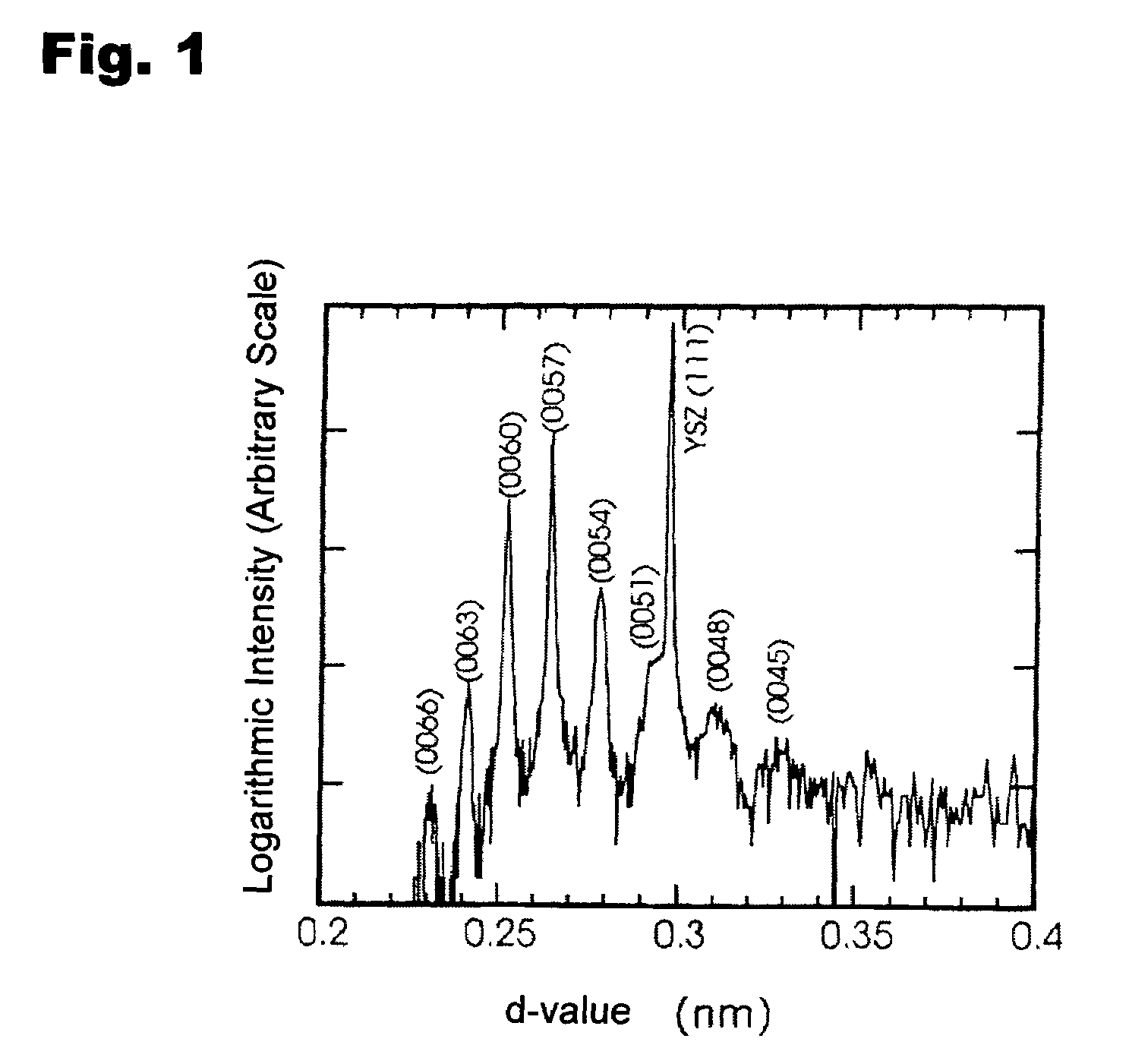

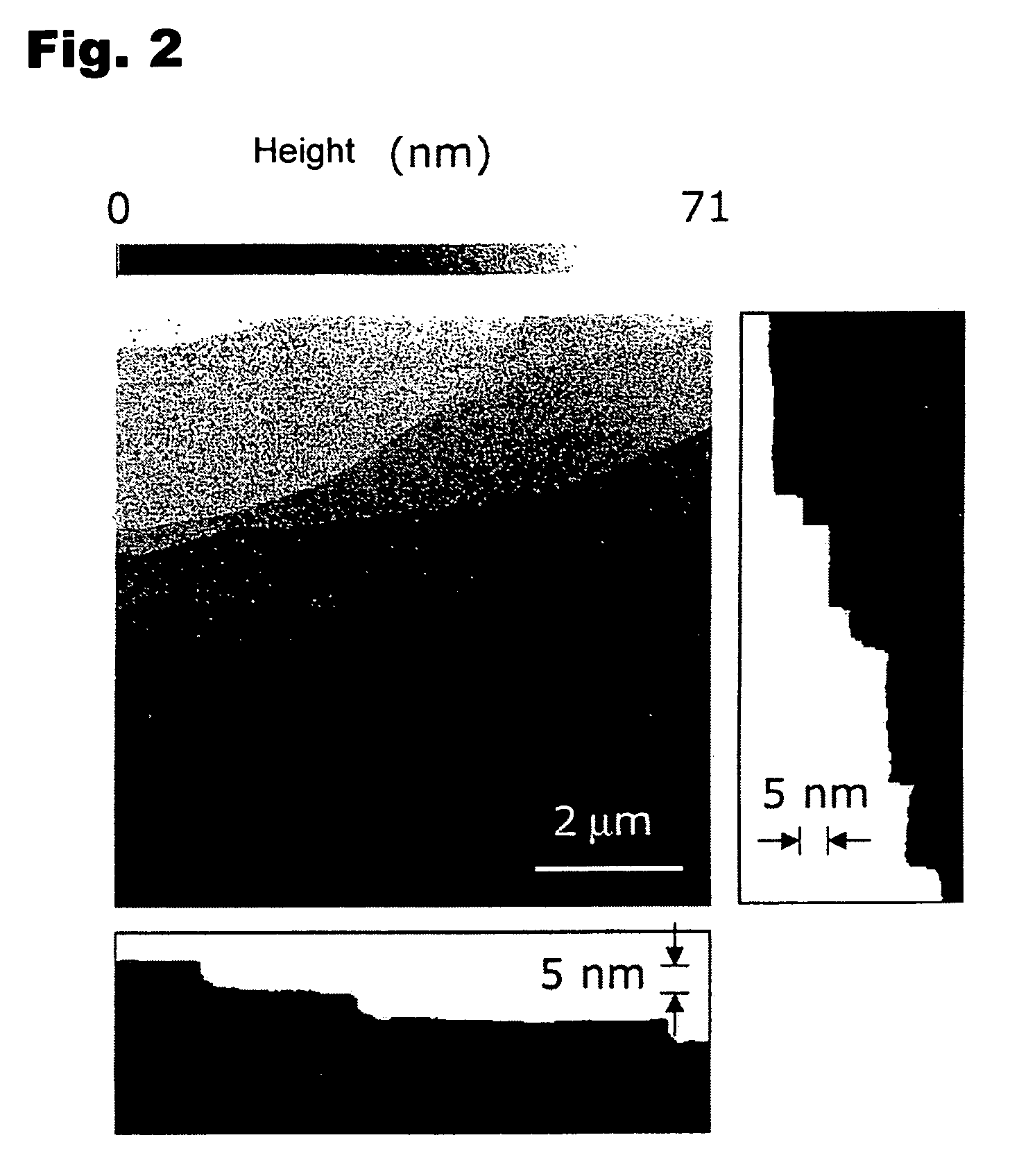

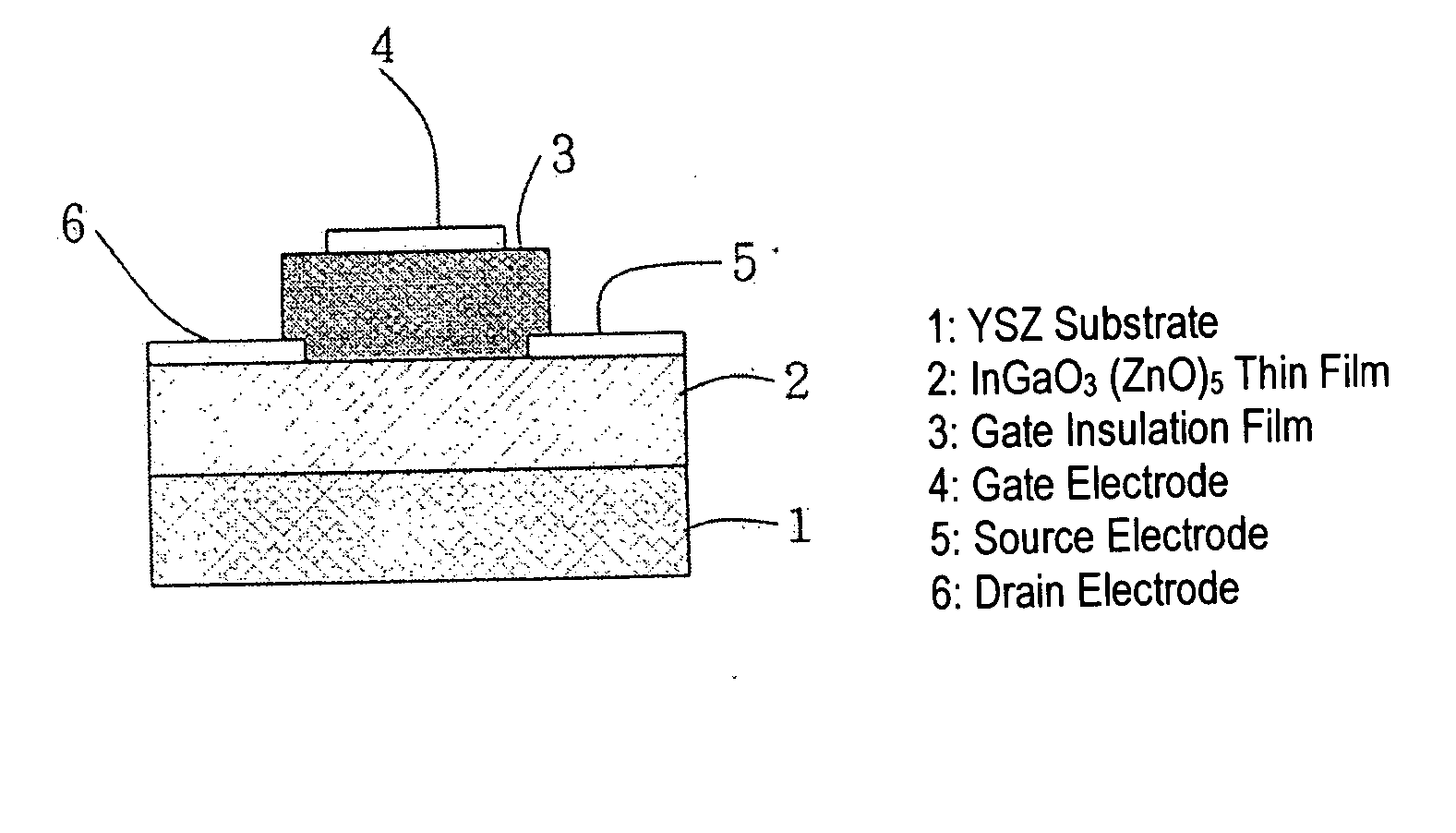

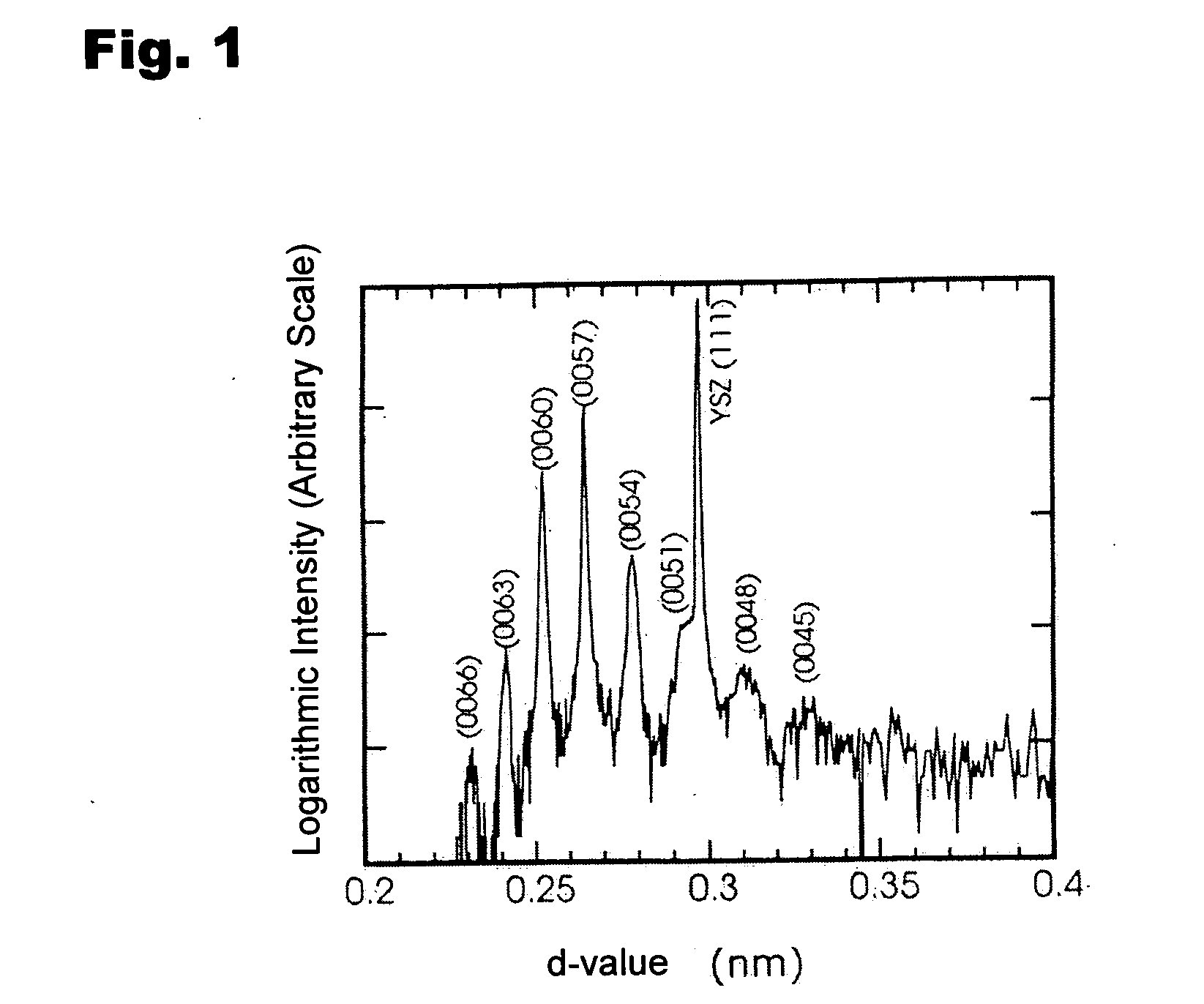

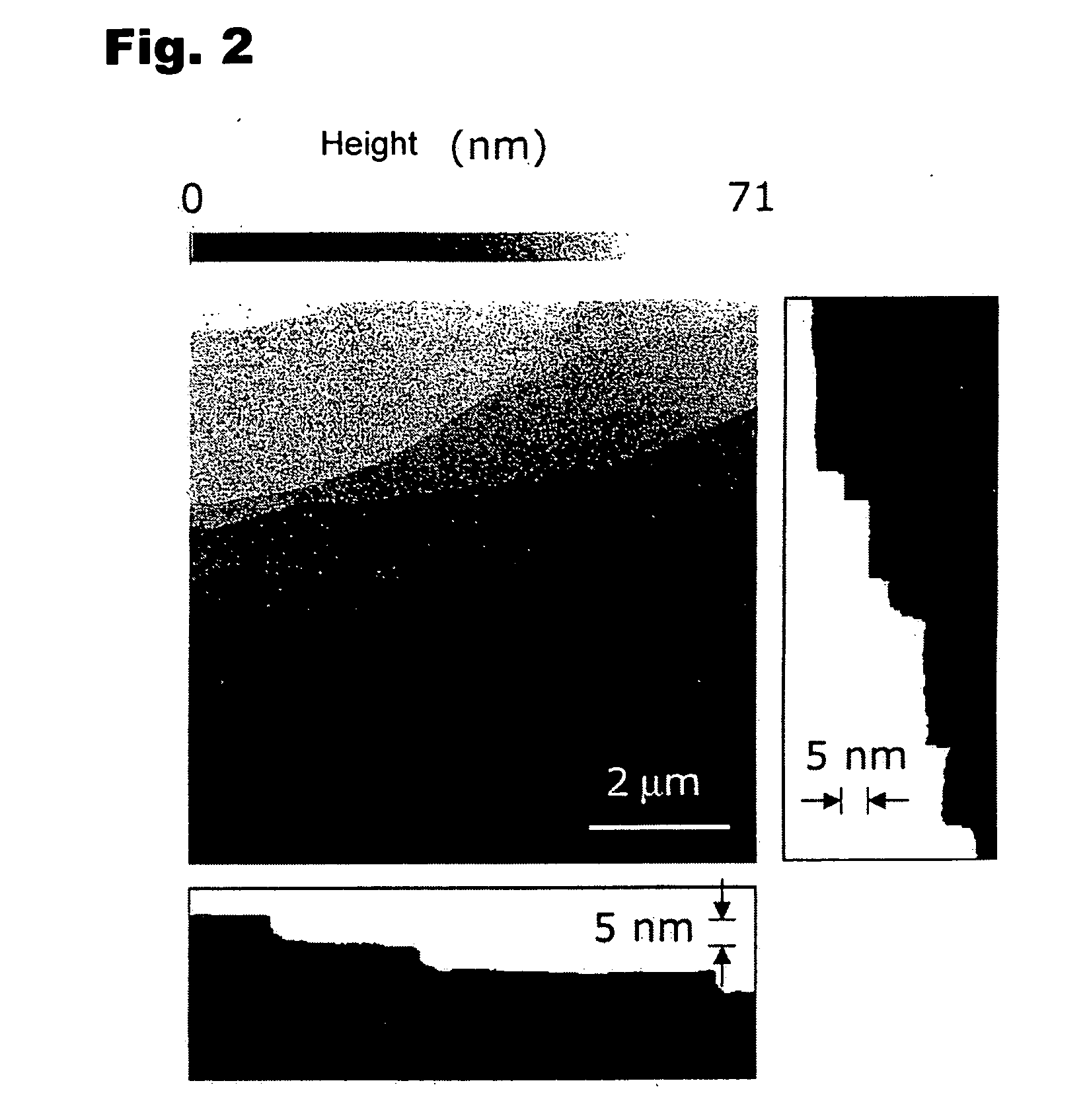

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS7061014B2Easy to controlSimple processTransistorPolycrystalline material growthSingle crystal substrateSingle crystal

Disclosed is a natural-superlattice homologous single-crystal thin film, which includes a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS20050039670A1Avoid large deviationImprove insulation performanceTransistorPolycrystalline material growthX-raySingle crystal substrate

Disclosed is a natural-superlattice homologous single-crystal thin film, which comprises a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the a formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

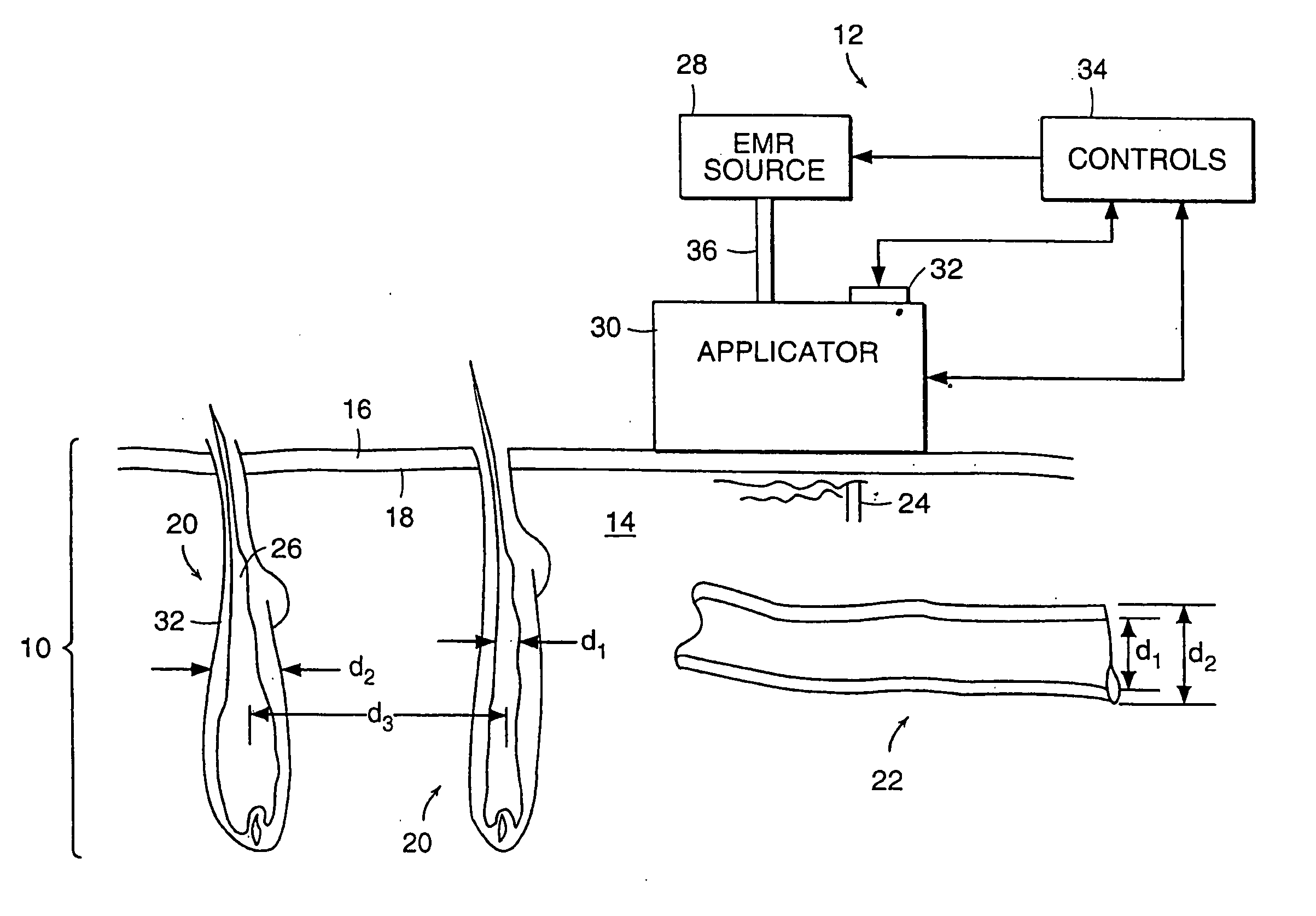

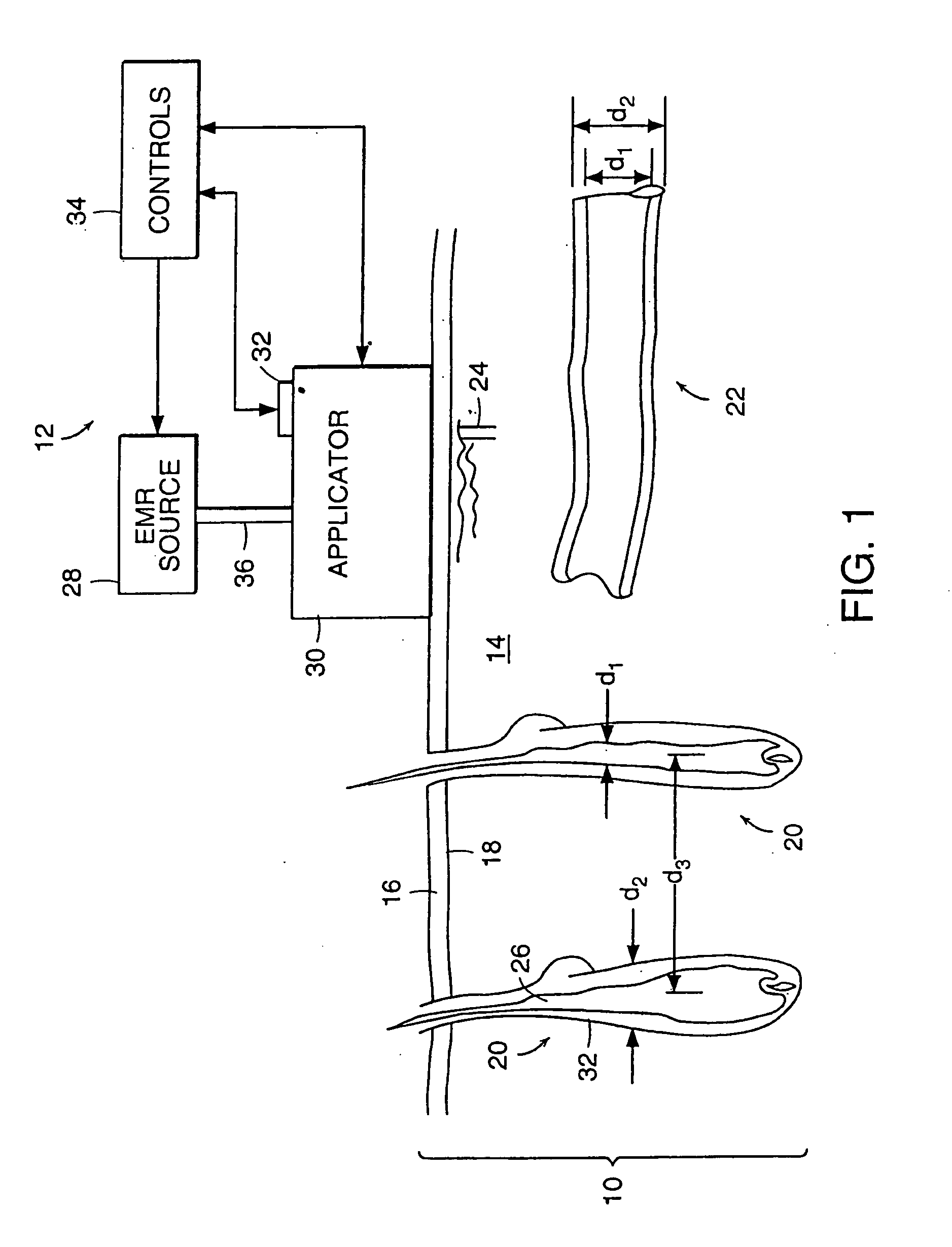

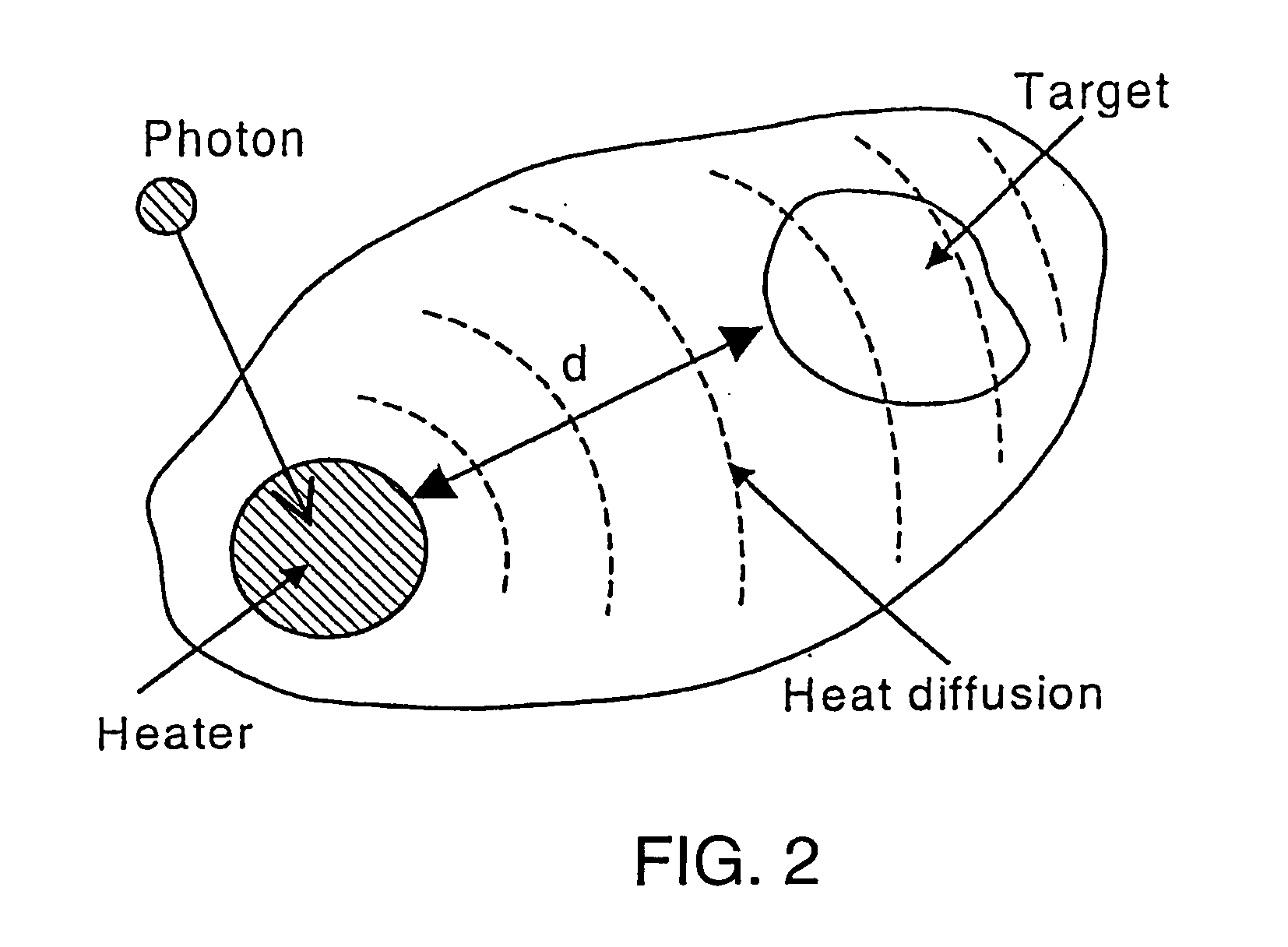

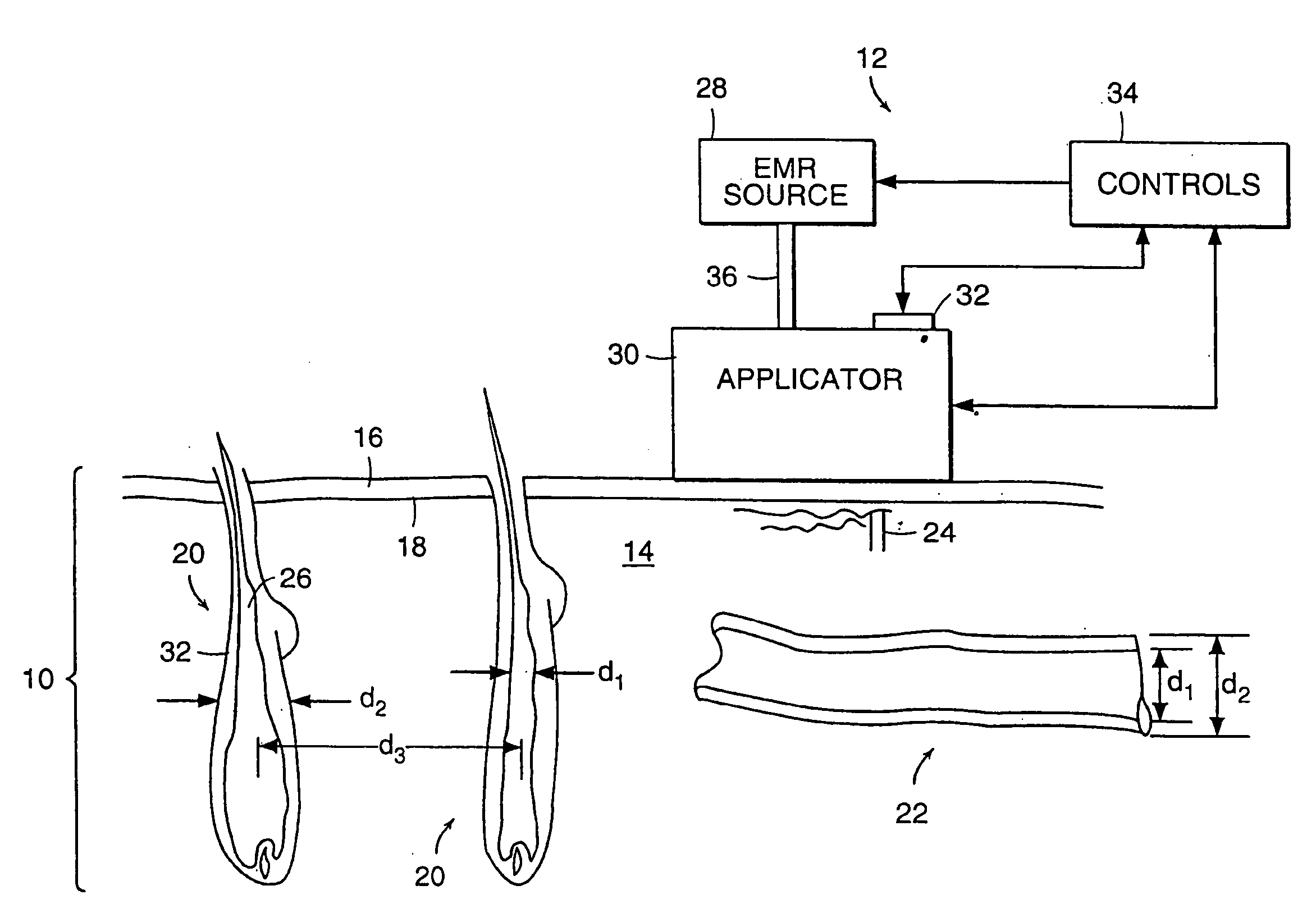

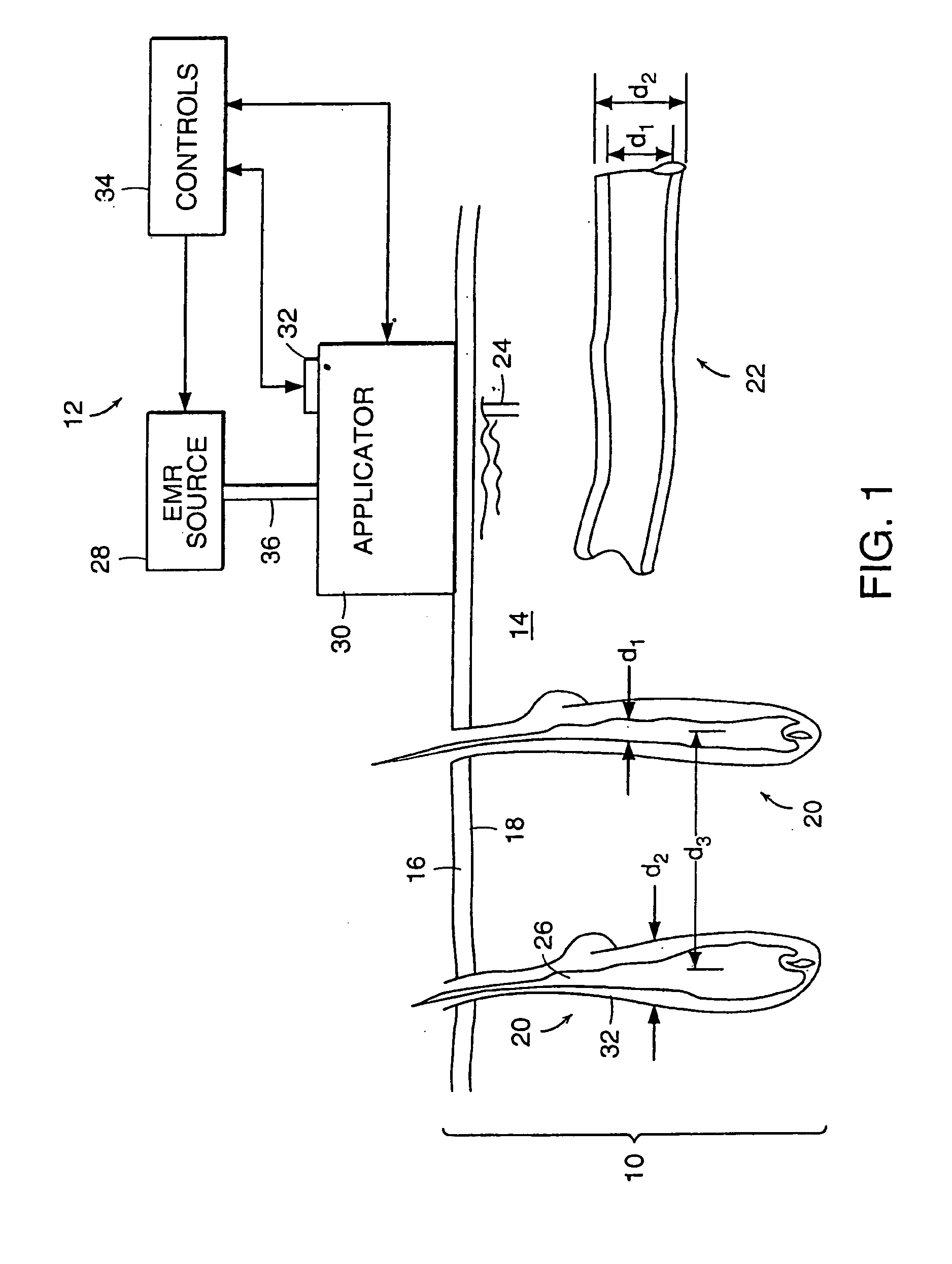

Method and apparatus for medical treatment utilizing long duration electromagnetic radiation

InactiveUS20050215988A1Suppress temperature increaseImprove cooling effectSurgical instrument detailsMicrowave therapyMedicinePeak value

A method and apparatus are provided for performing a medical procedure on a patient, for example a dermatological procedure, by use of electromagnetic radiation (EMR) having a relatively low peak power, and in particular a peak power low enough so as not to result in a phase change in the heater or chromophore absorbing radiation which would result in a significant reduction in its absorption, and of relatively long duration which is generally greater than, sometimes significantly greater than, the thermal relaxation time of the irradiated target.

Owner:PALOMAR MEDICAL TECH +1

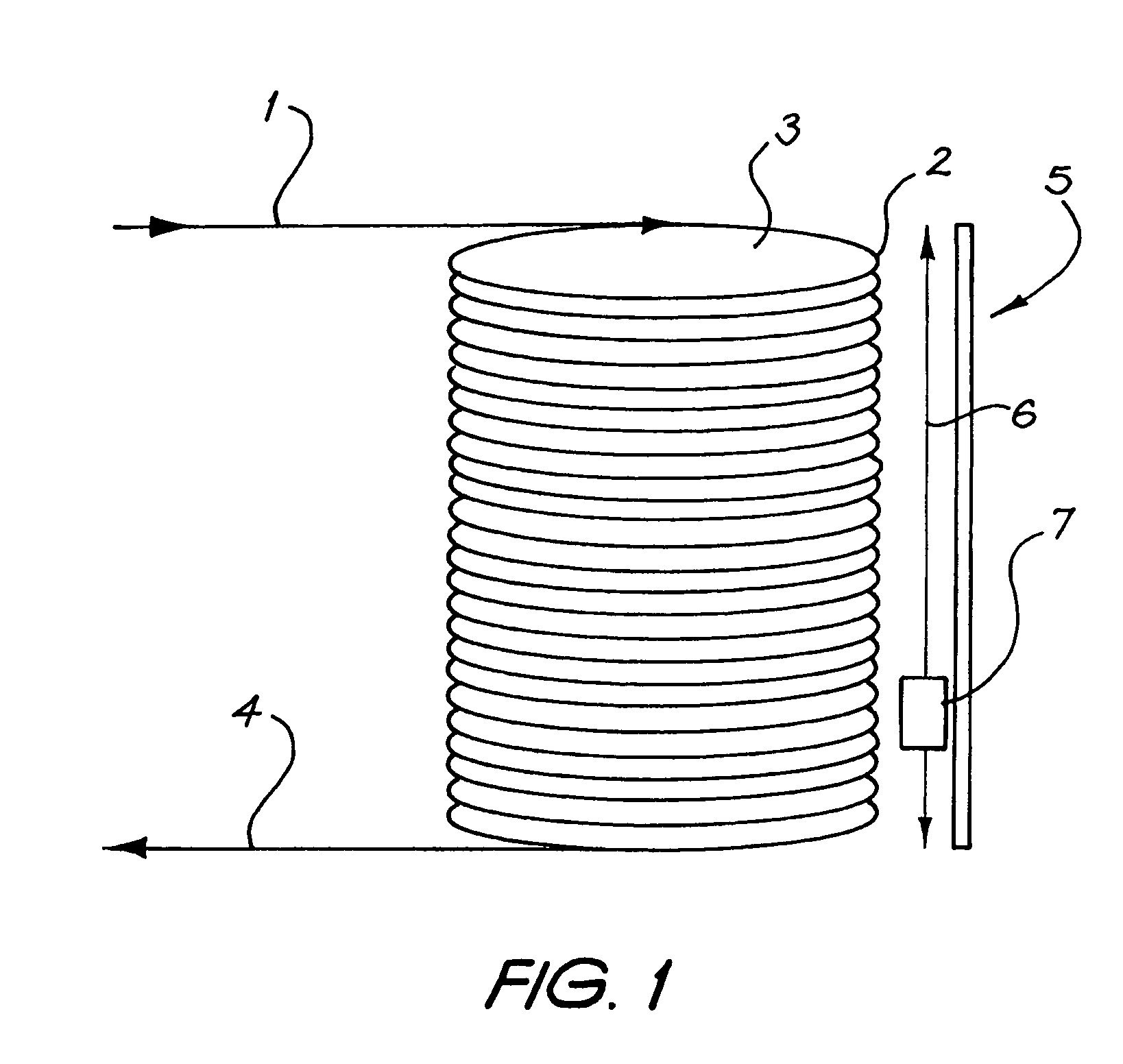

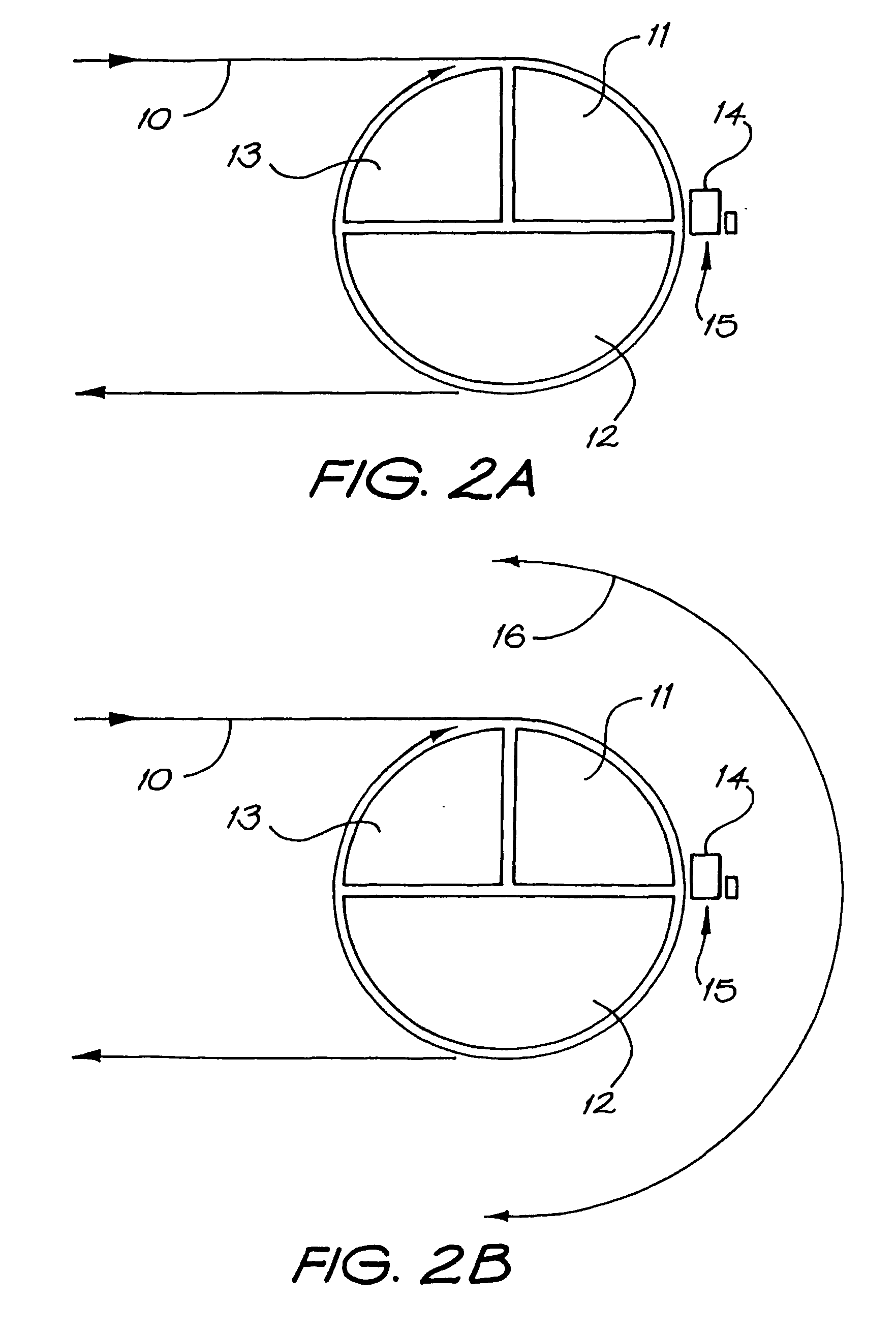

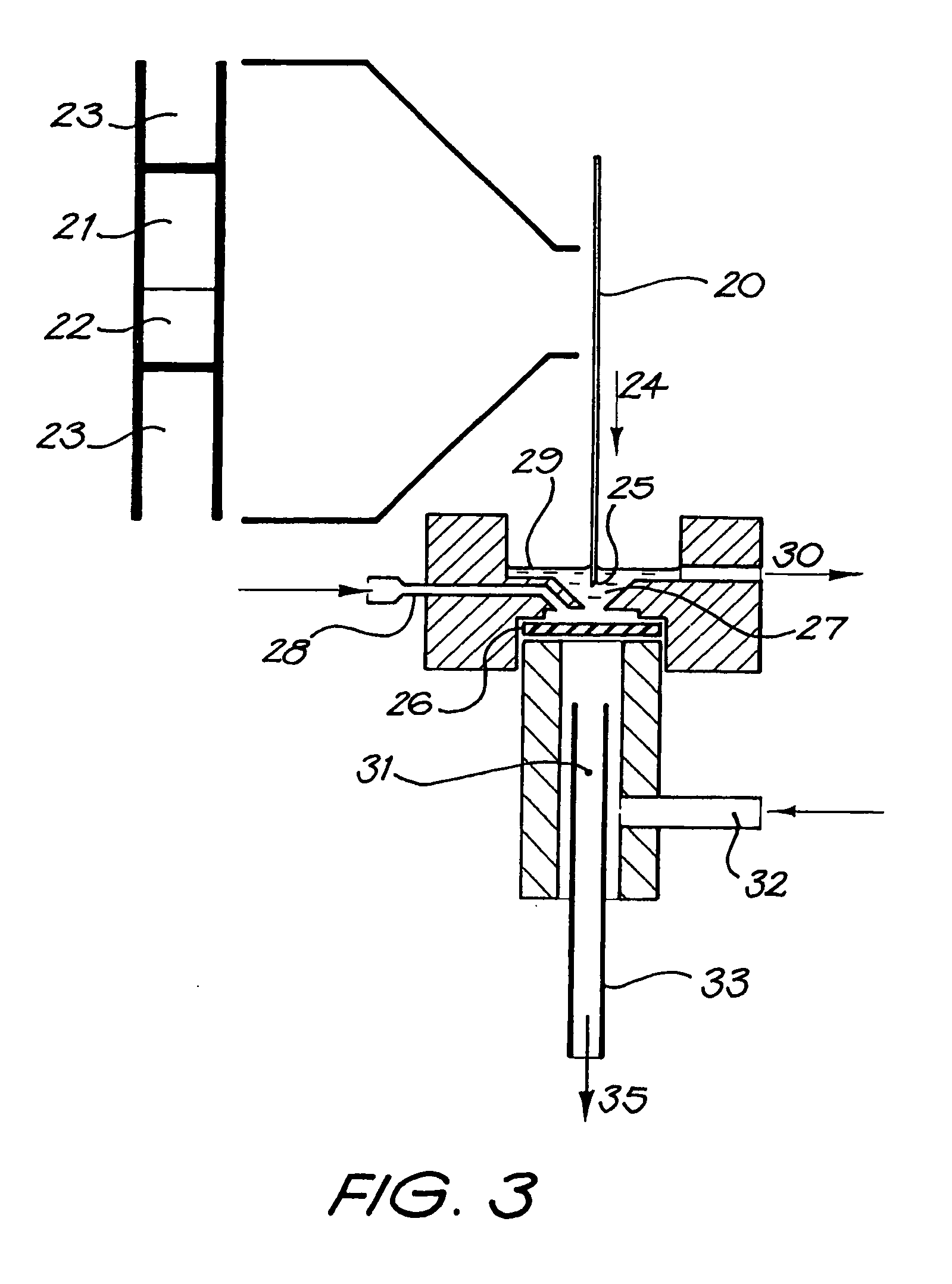

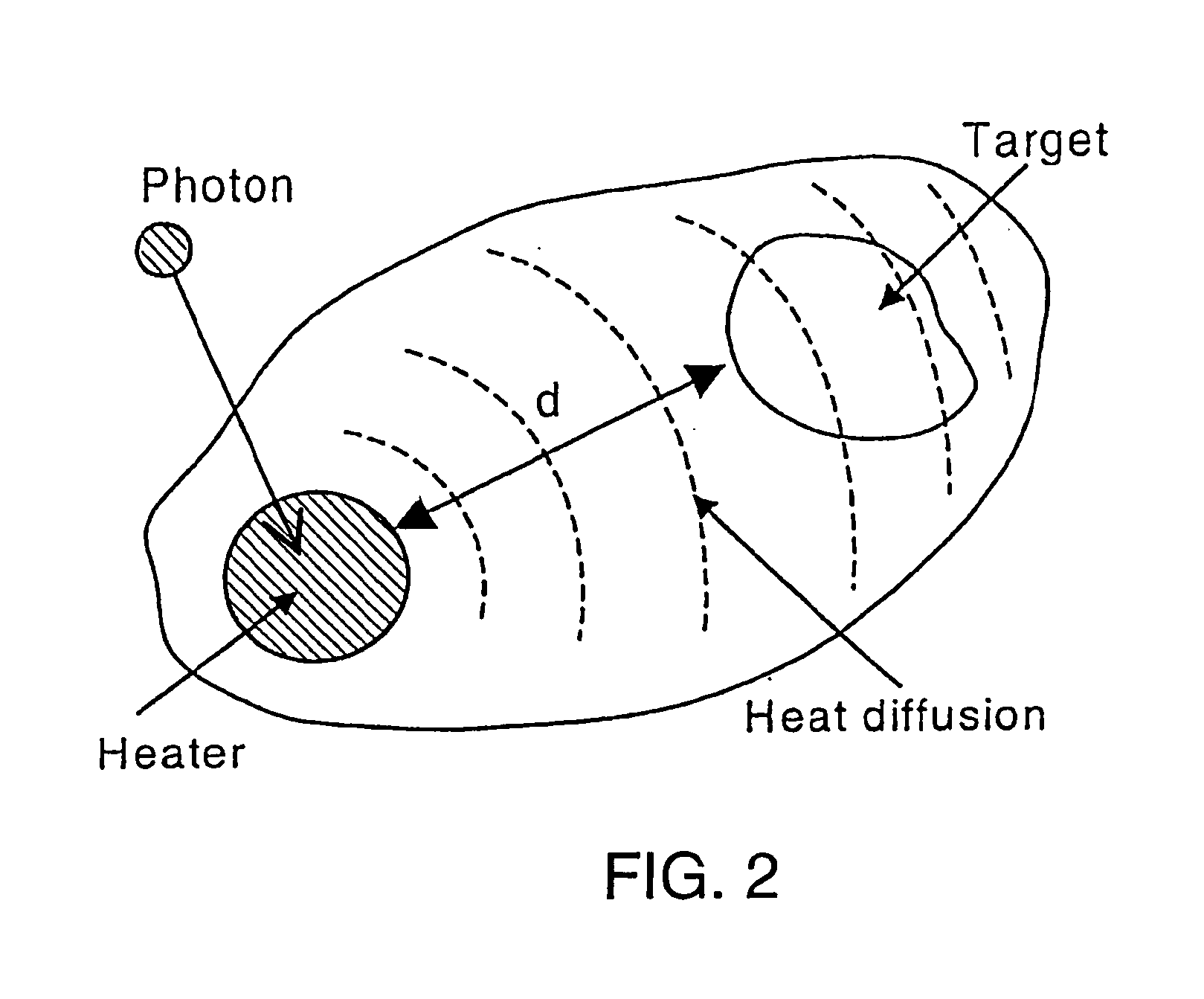

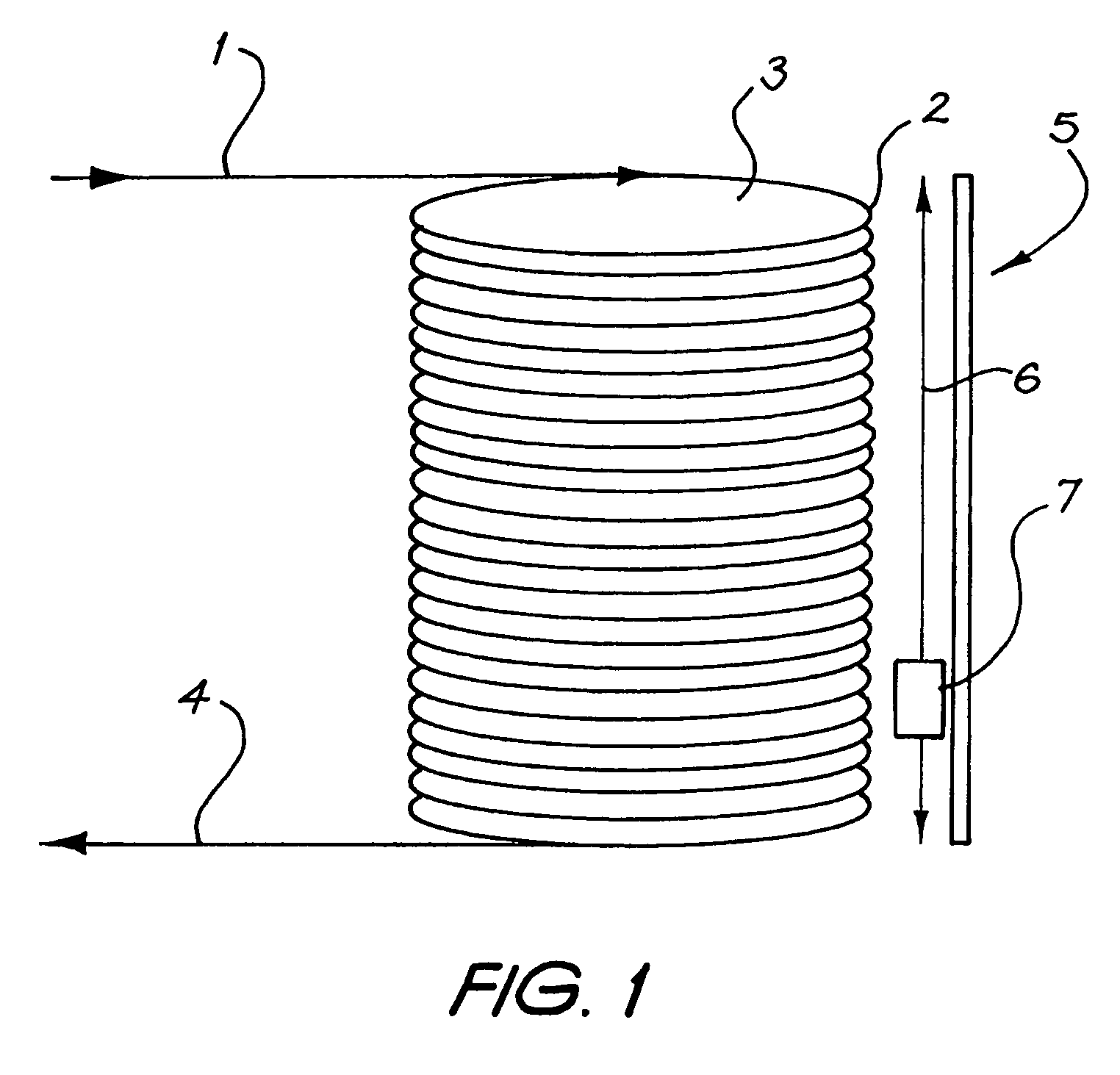

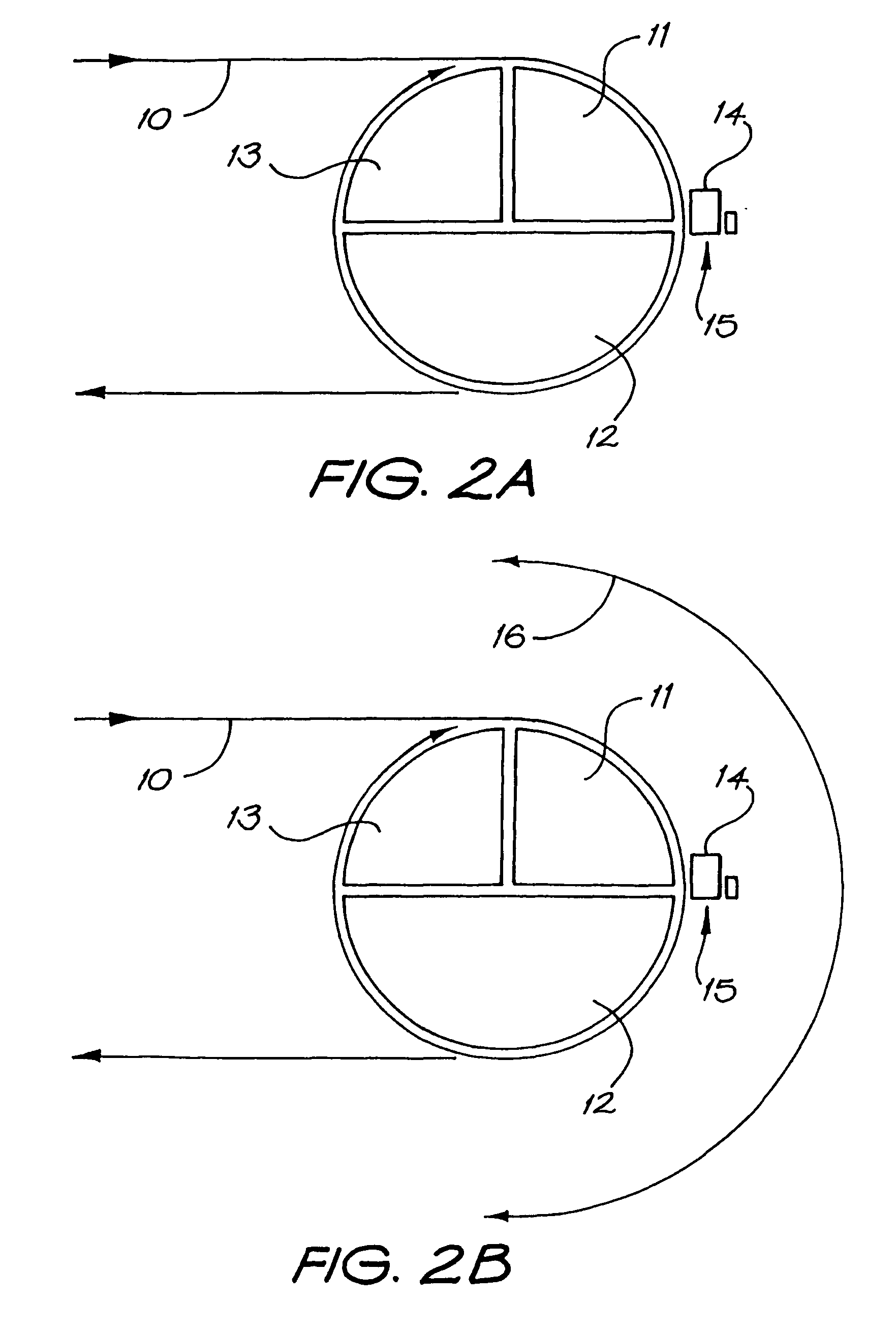

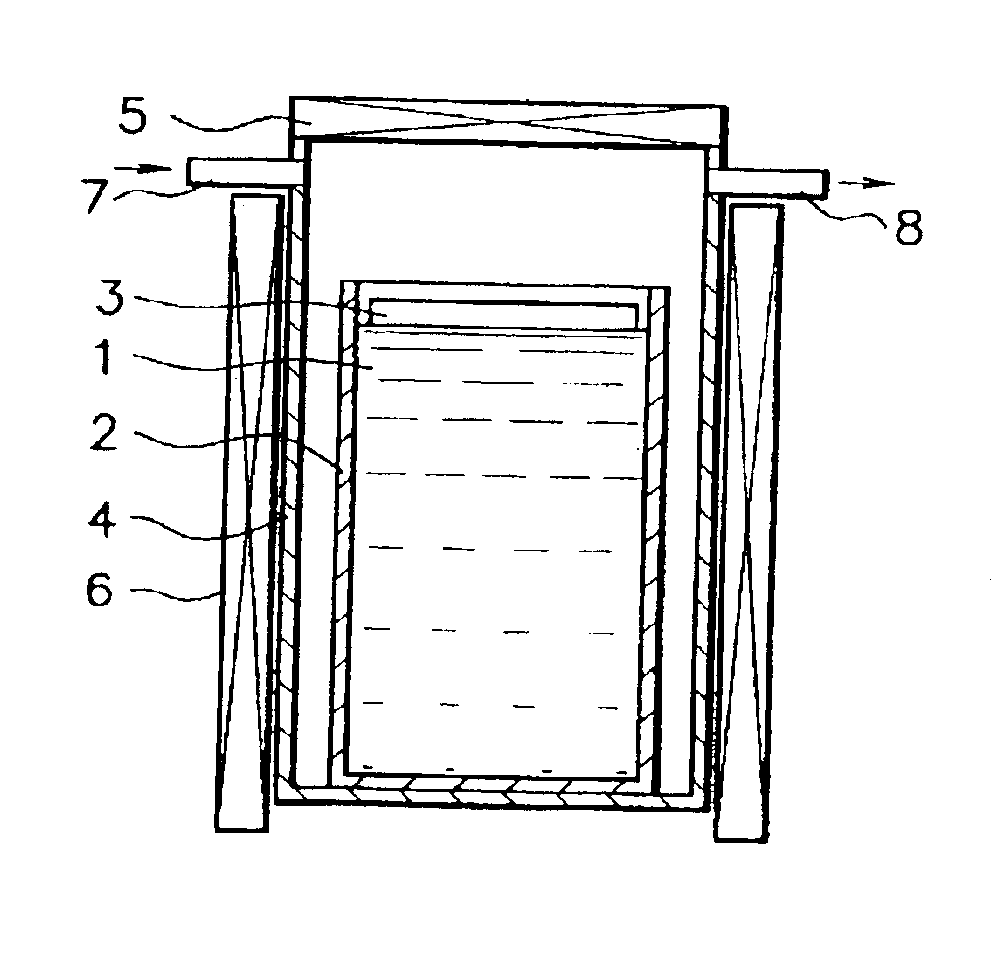

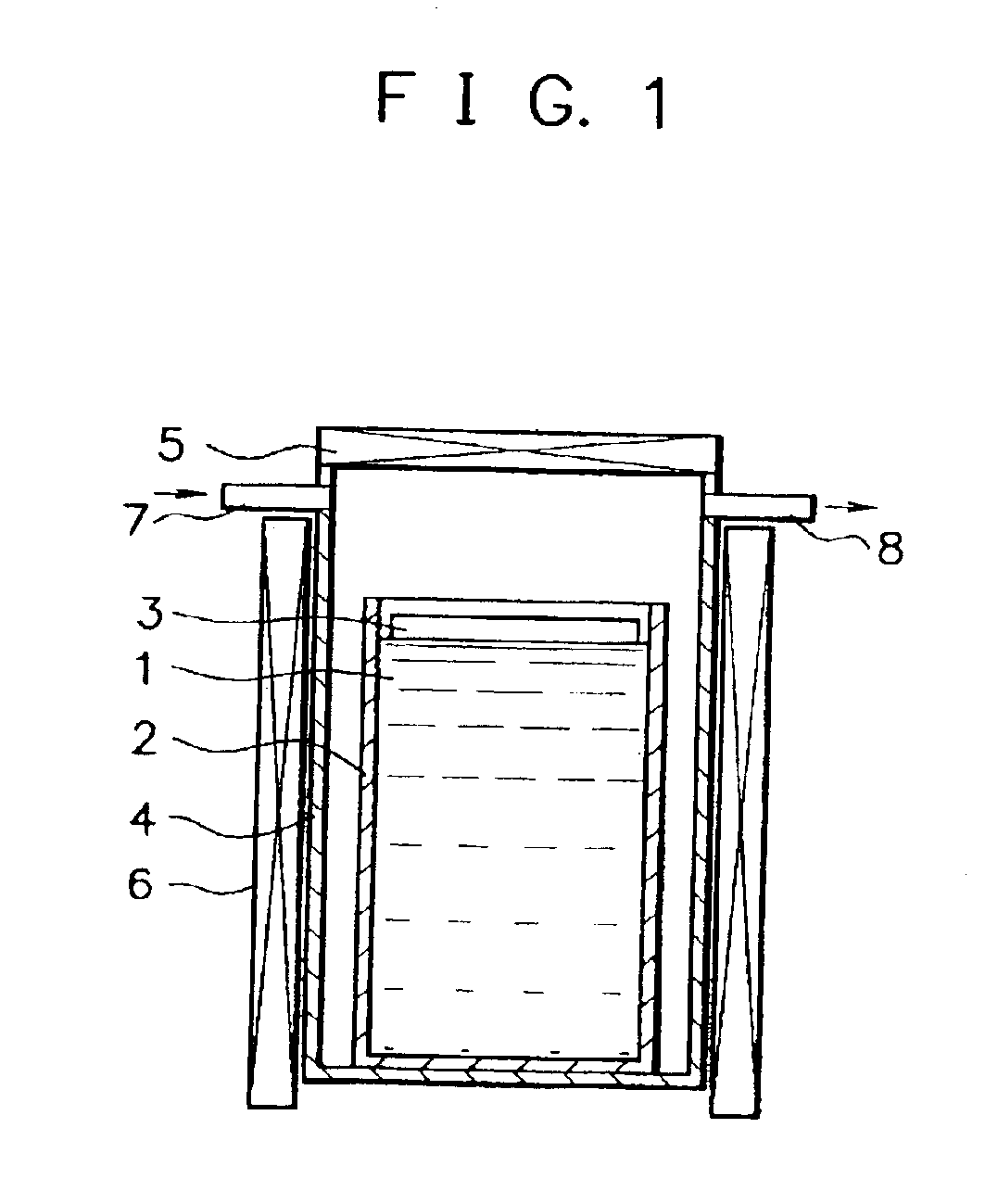

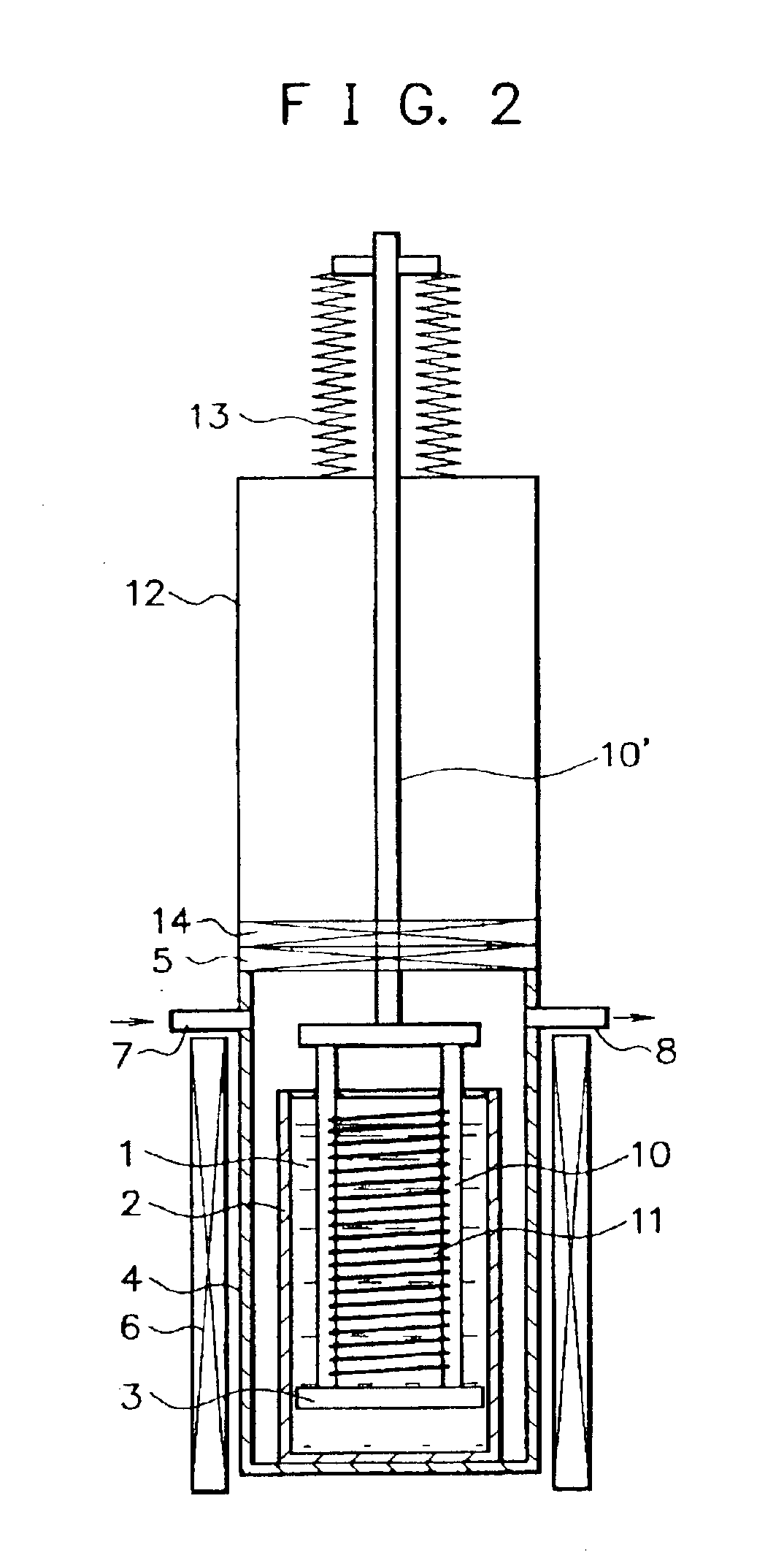

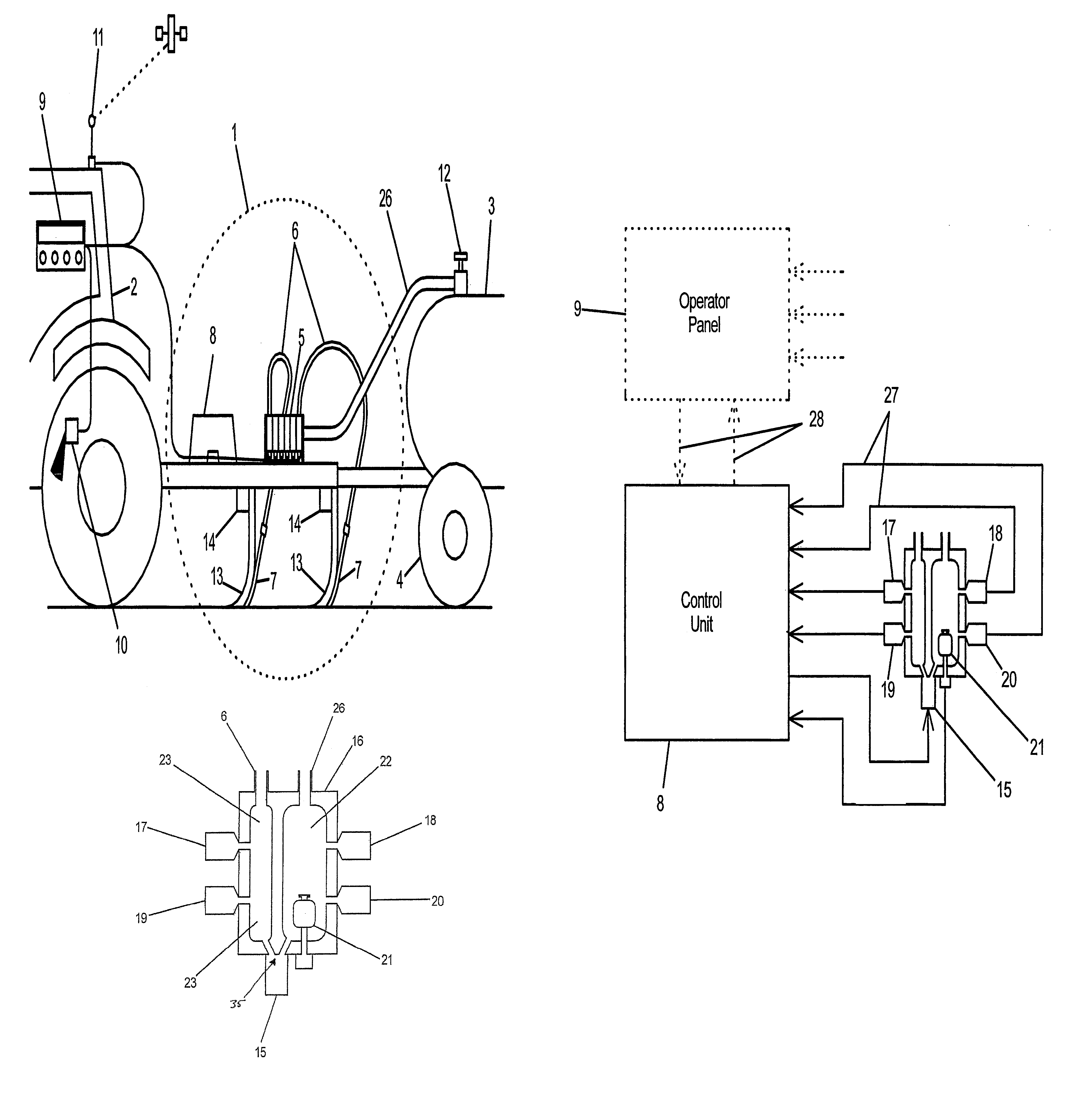

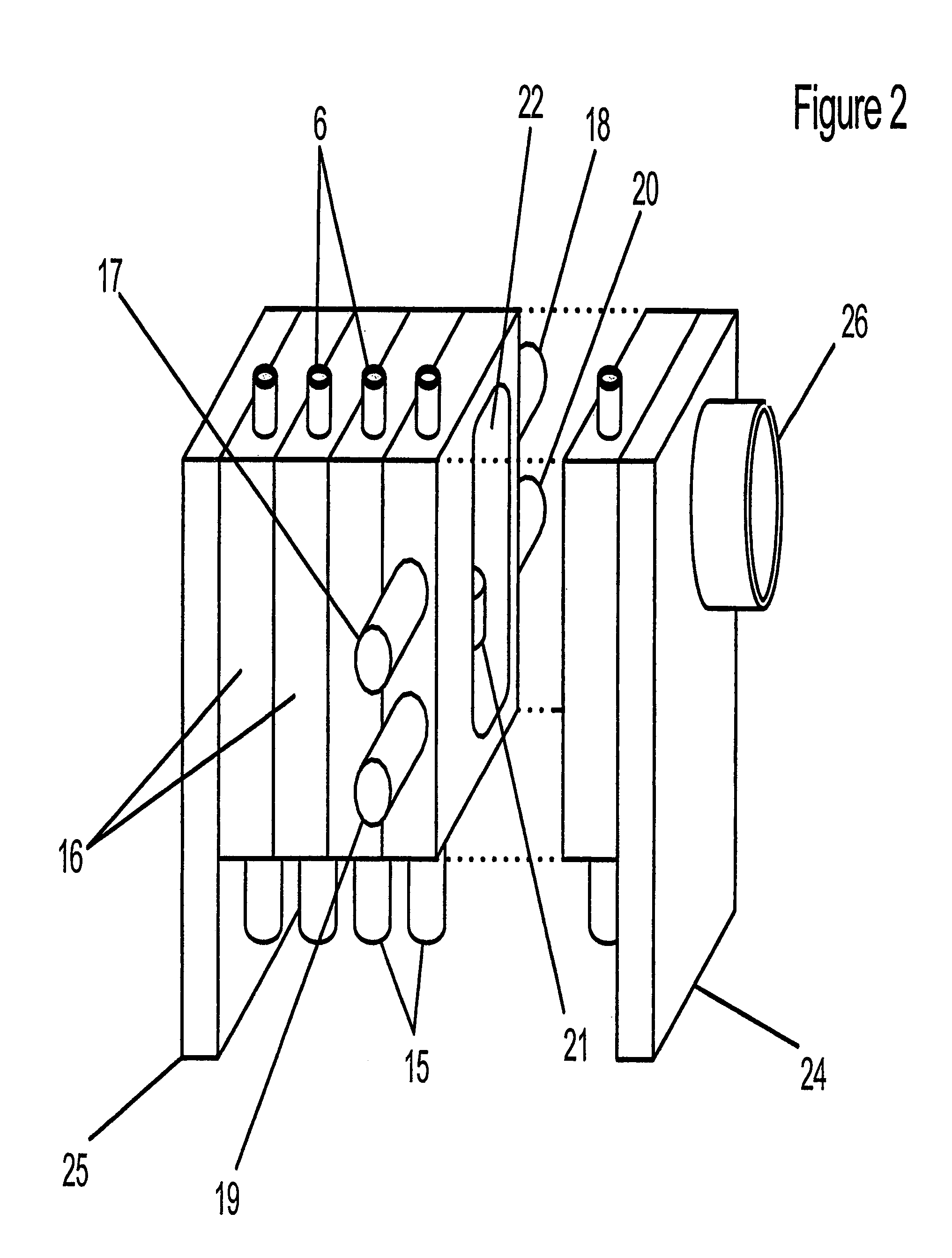

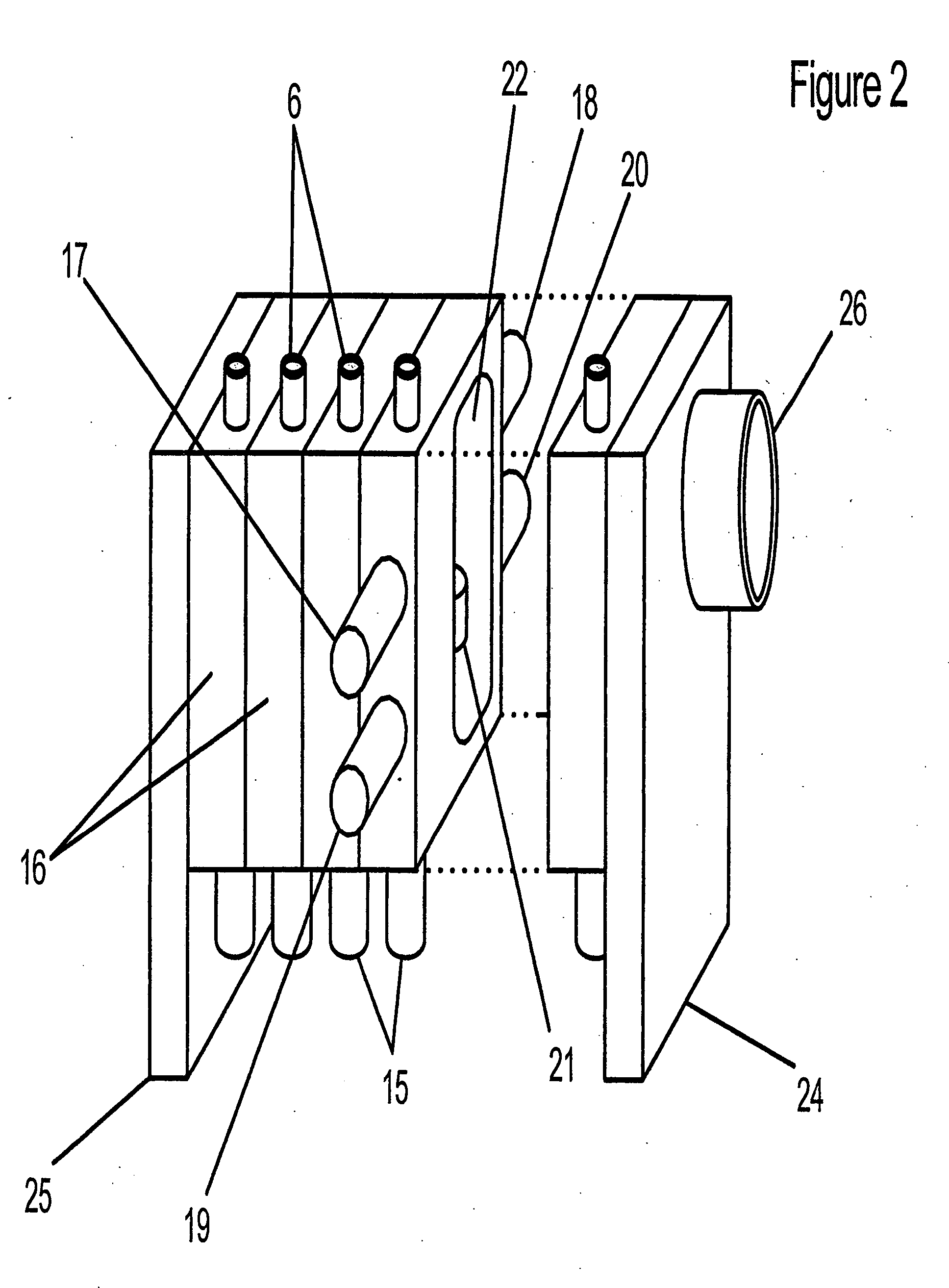

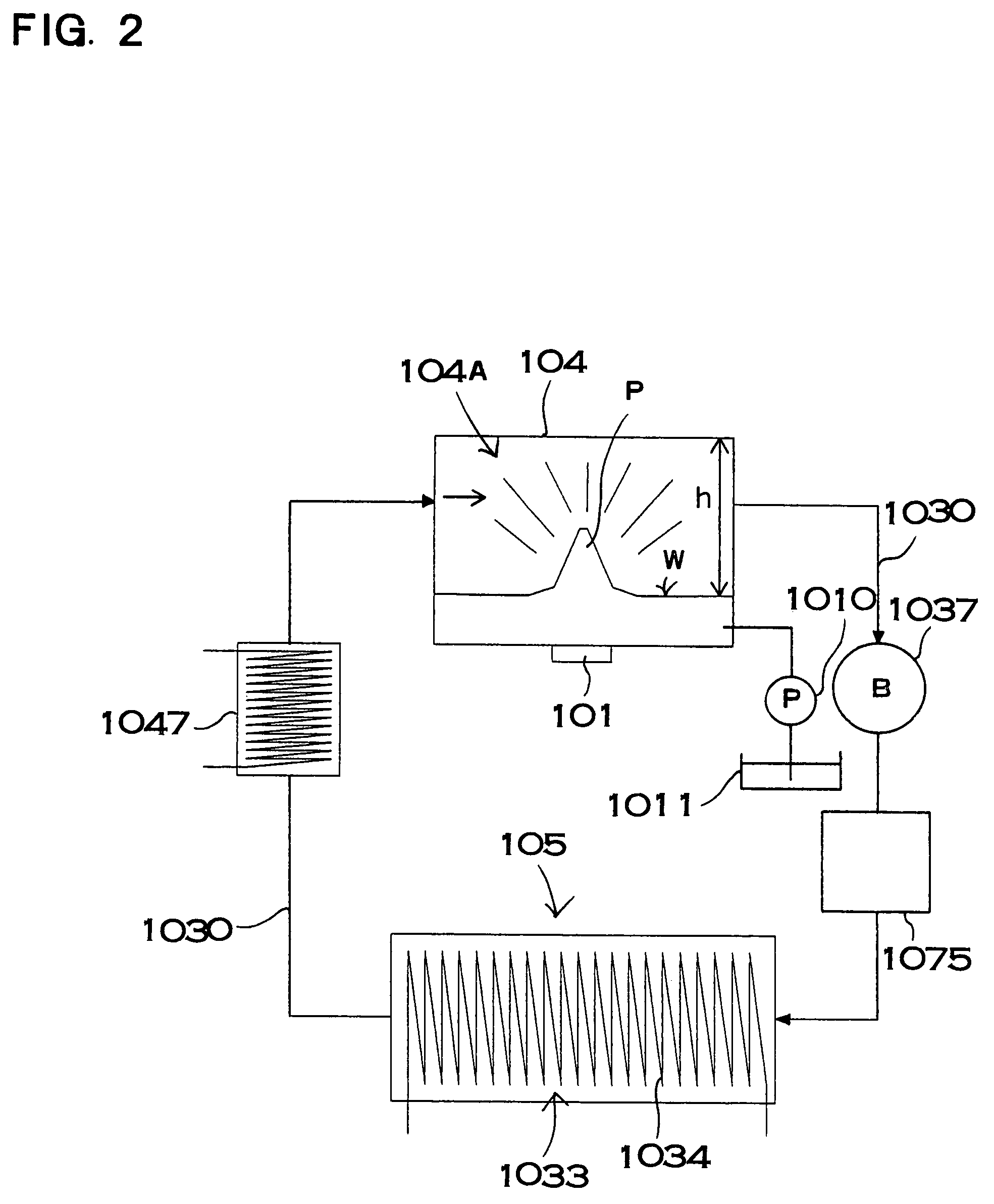

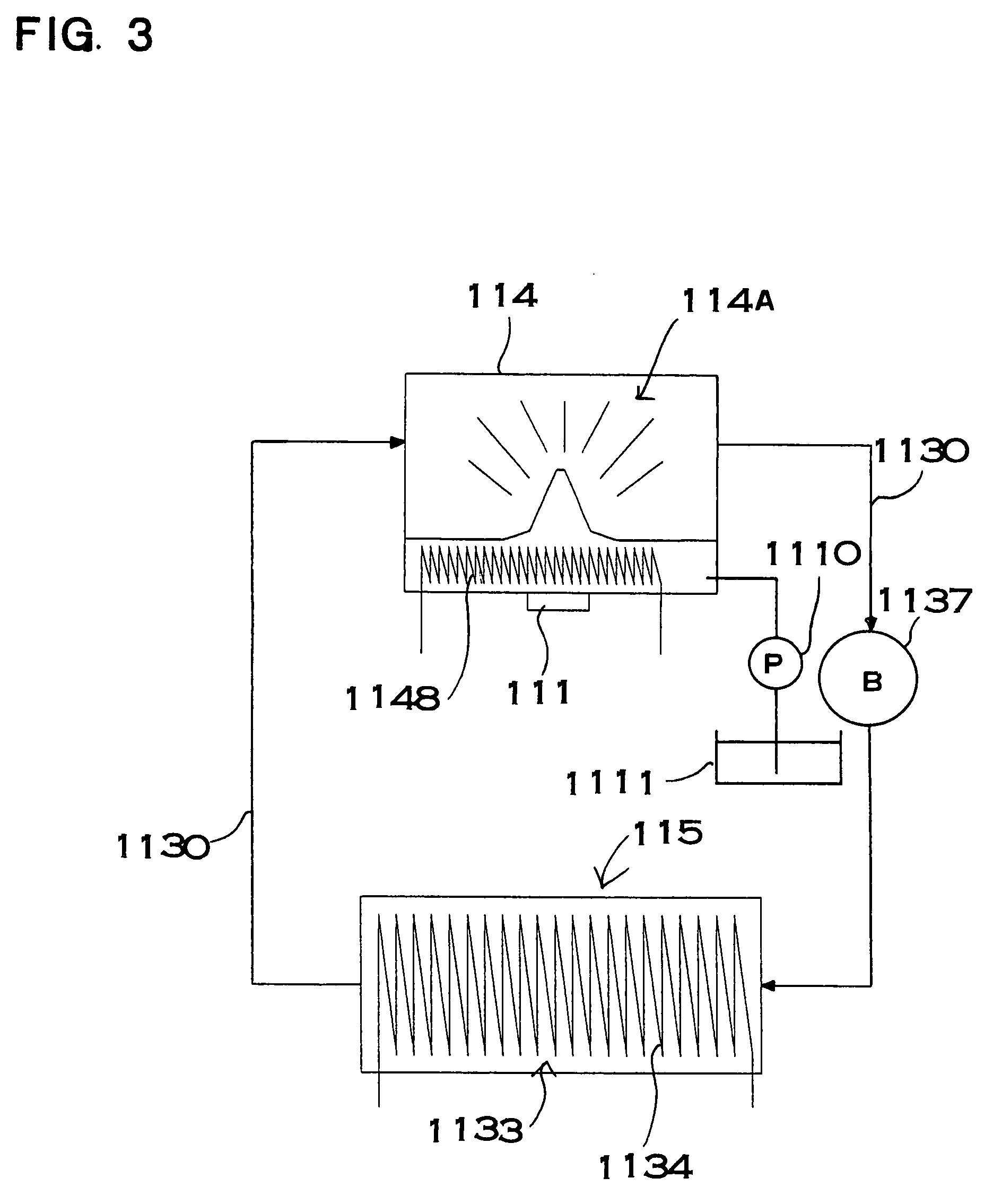

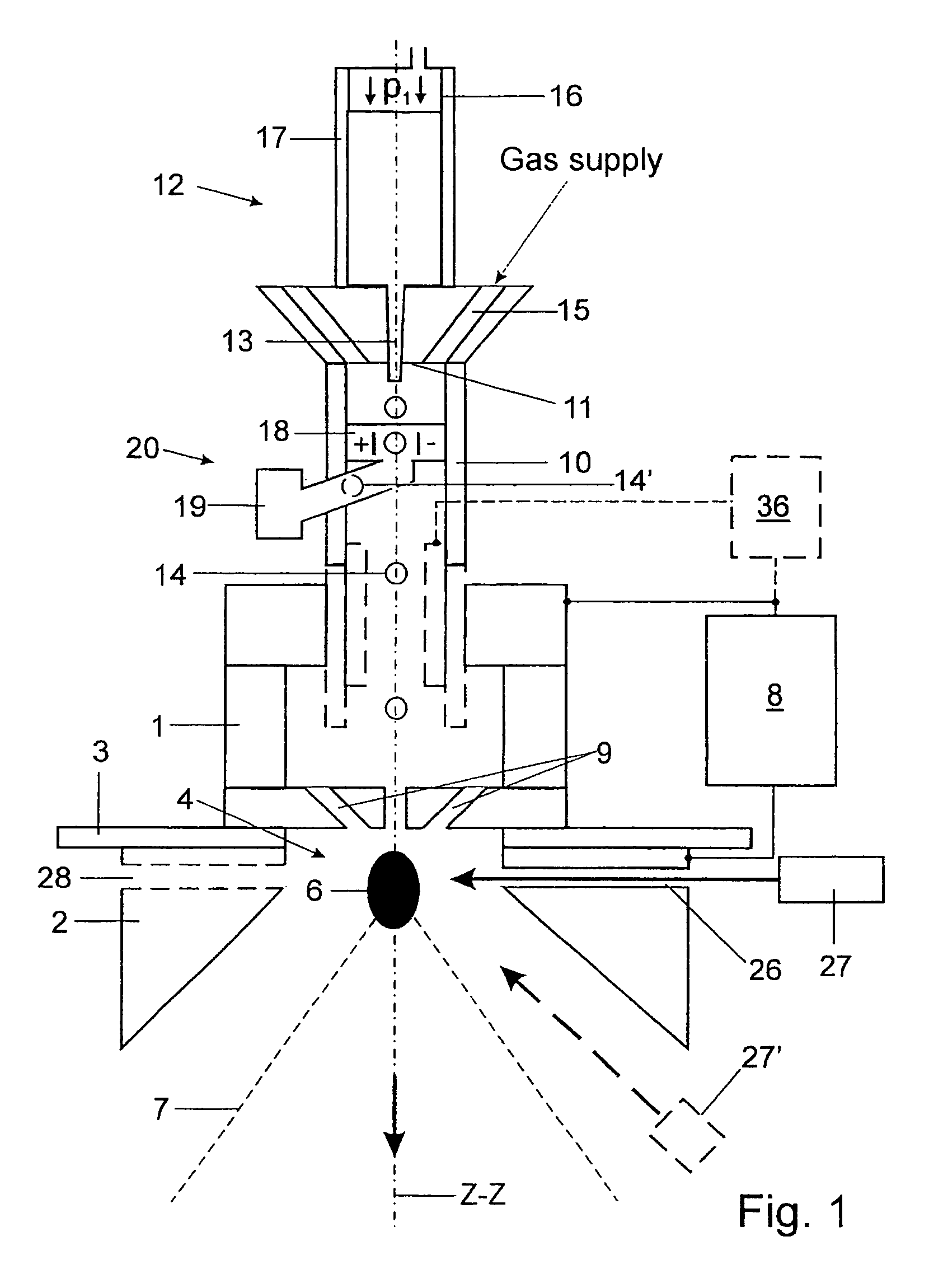

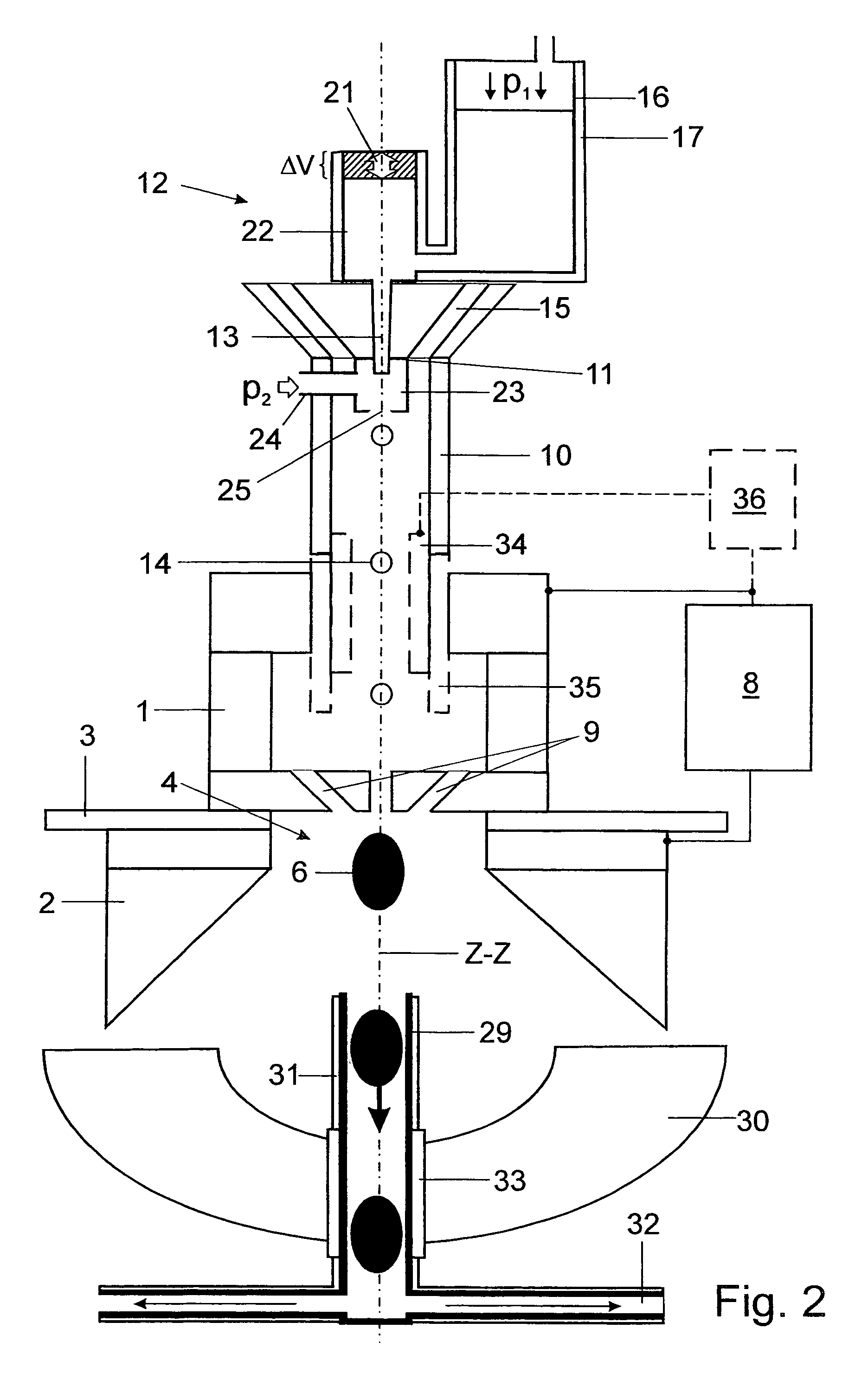

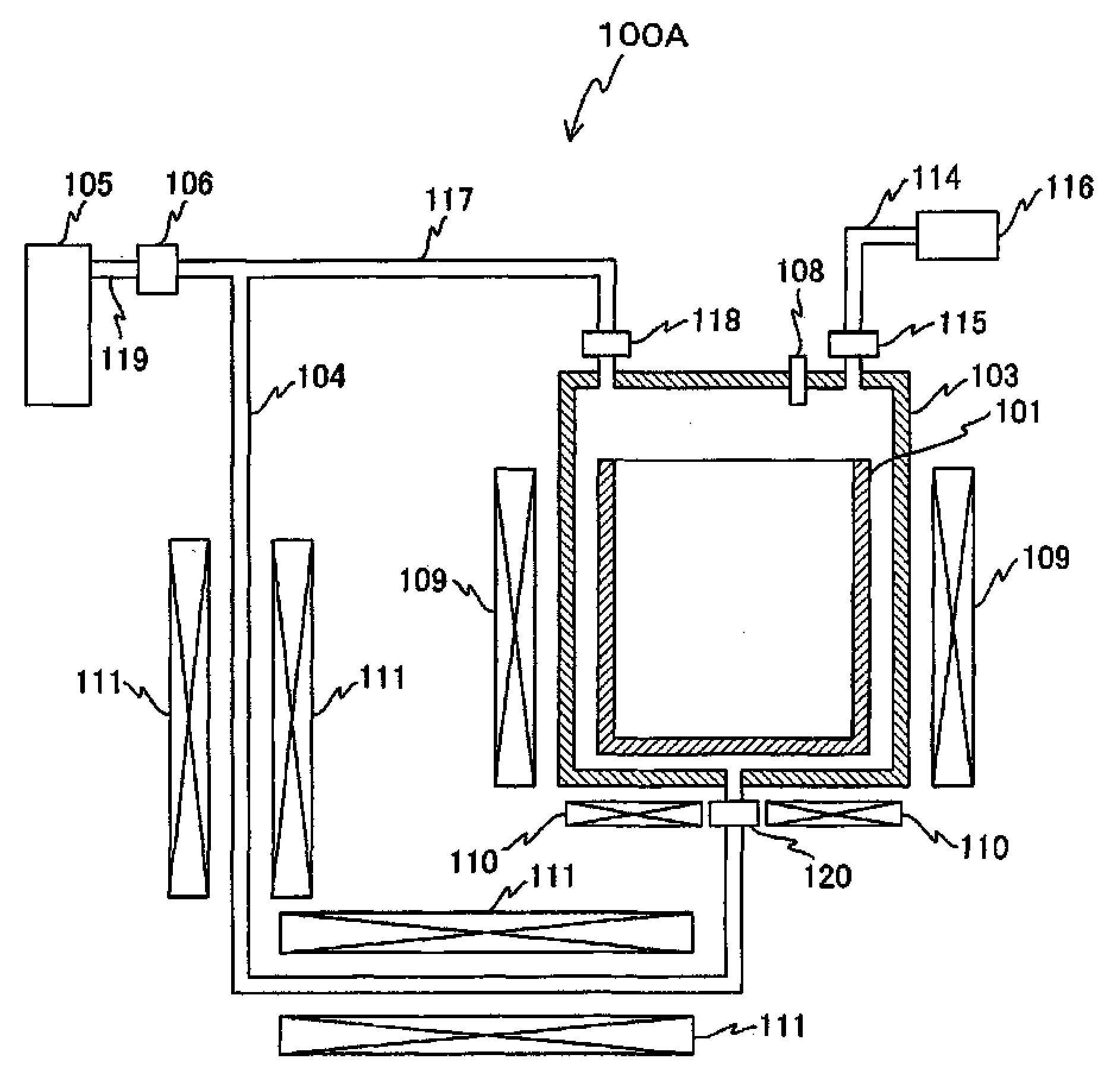

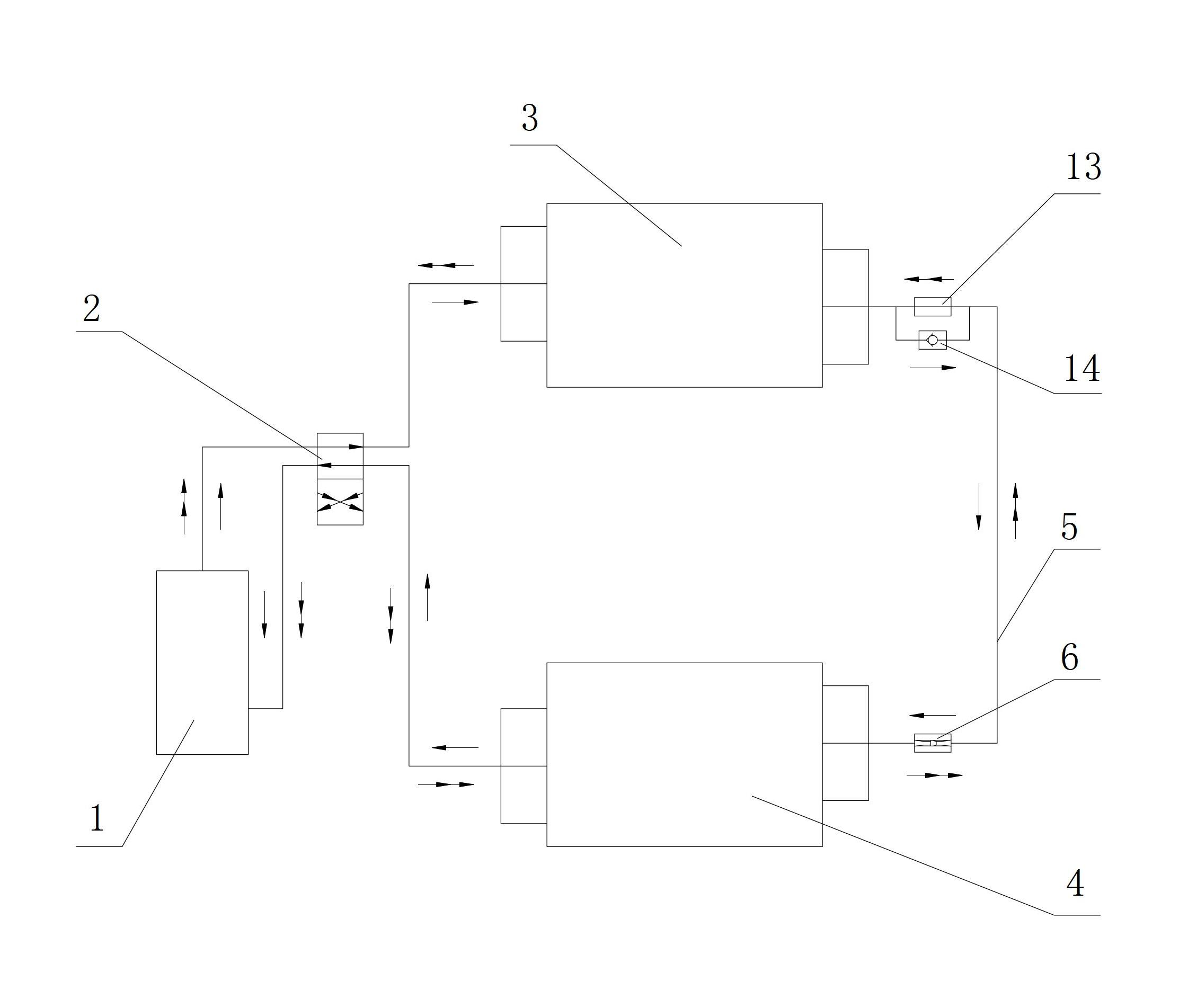

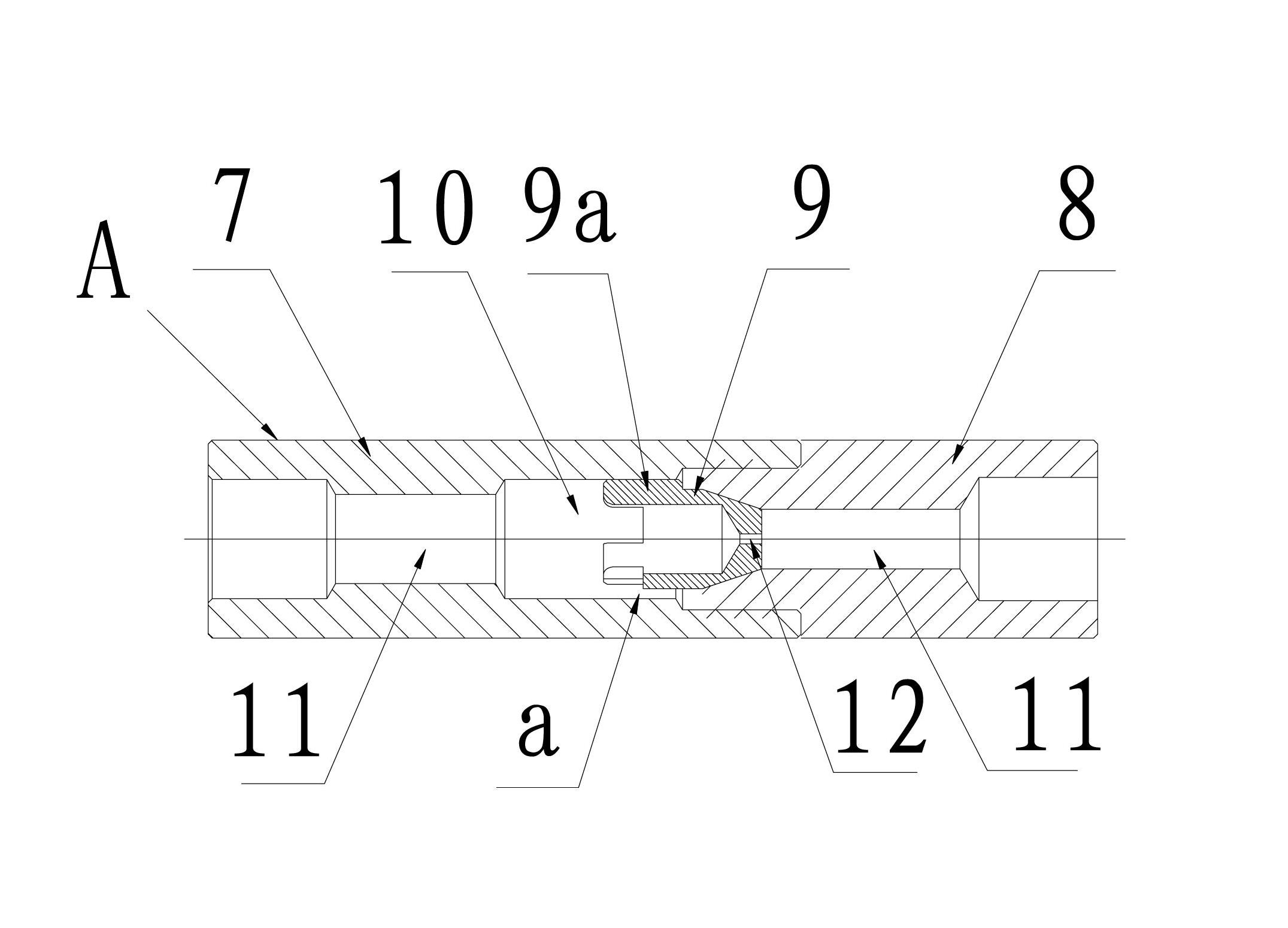

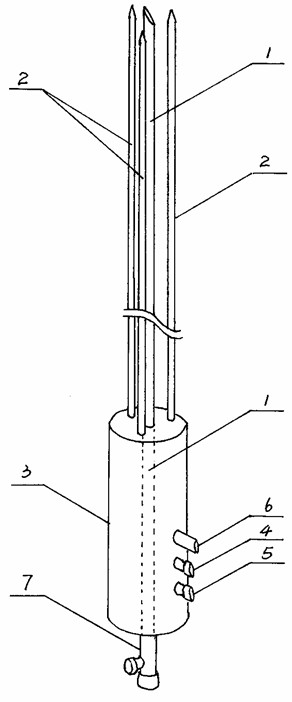

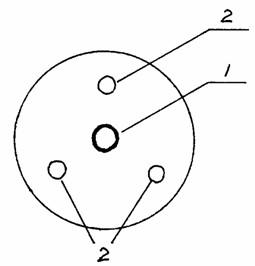

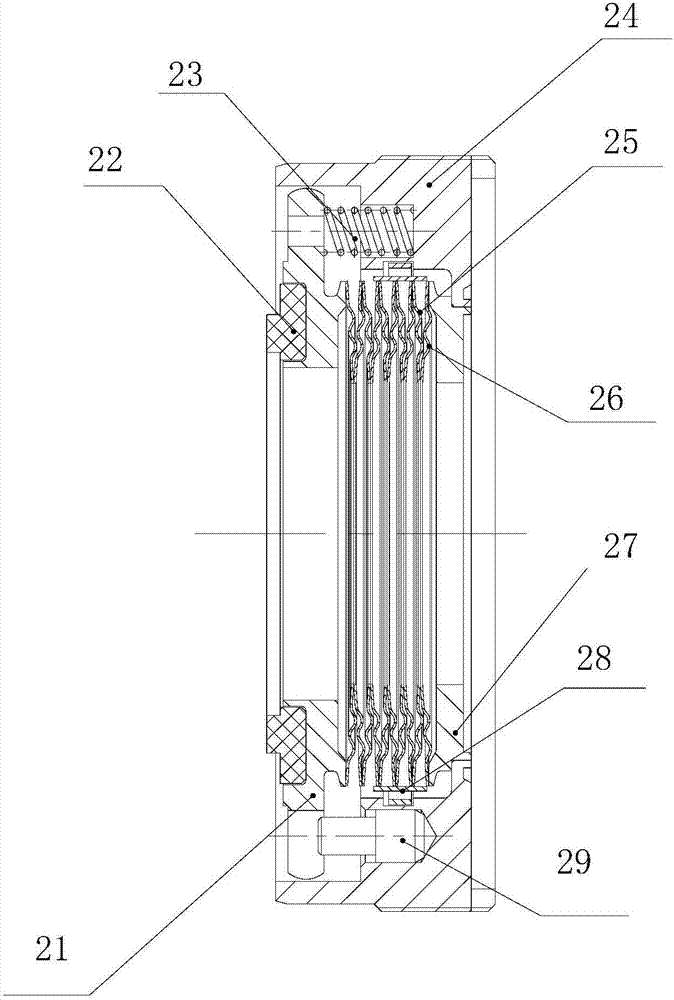

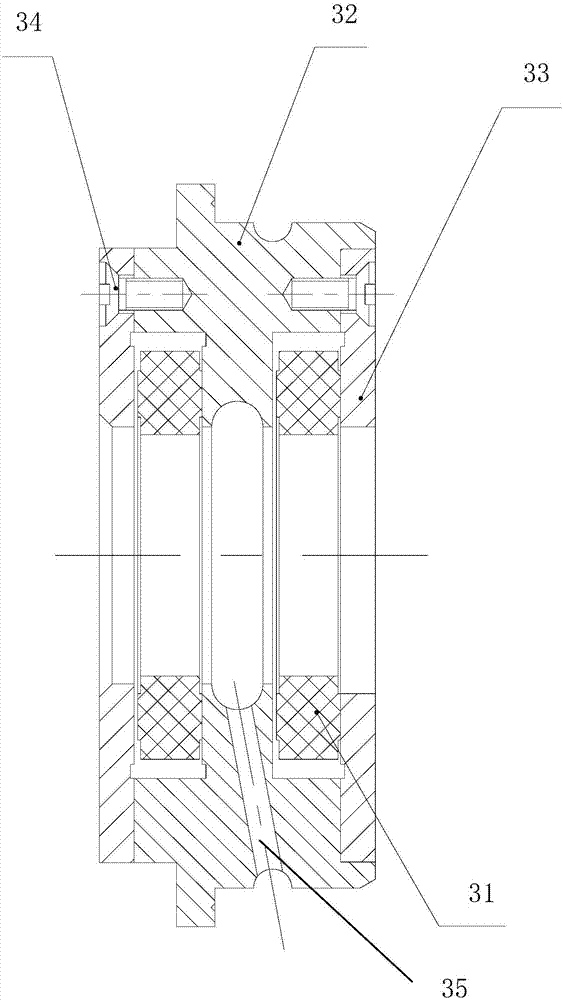

Continous flow thermal device

ActiveUS20050282206A1Avoid vaporizationMinimizing turbulent flowBioreactor/fermenter combinationsBiological substance pretreatmentsThermal contactThermal cycle

The present invention provides a thermal cycling device including: a heat exchanger body (3) having a longitudinal axis and longitudinally divided to provide at least two segments which are able to be heated to different temperatures so that said body has peripheral surfaces of different temperatures; a conduit (2) extending about said body so as to be in thermal contact with said peripheral surfaces; a first delivery device to deliver a first fluid to said conduit to cause said fluid to pass therealong and therefore change in temperature as the fluid passes said segments; and a second delivery device to deliver a second fluid to said conduit so as to flow with said first liquid and therefore also change in temperature. The fluid then leaves the device by conduit (4). The invention also is directed to an injector means for use in the thermal cycling device of this invention, comprising: a septum (26); a needle (20) which is able to pierce the septum; a reservoir (27) in fluid contact with septum (26) having an inlet (28) and an outlet (30); wherein when in use, the needle is urged through the fluid in said reservoir and then through the septum while continually purging the reservoir with said purge fluid. The present invention also includes a scanning detector (5) fitted to the outside of the heat exchange body (3) which monitors the course of reaction inside the conduit (2).

Owner:QIAGEN GMBH

Method and Apparatus for Medical Treatment Utilizing Long Duration Electromagnetic Radiation

InactiveUS20110137230A1Avoid vaporizationAvoid temperature riseElectrotherapySurgical instrument detailsCalorescenceMedicine

A method and apparatus are provided for performing a medical procedure on a patient, for example a dermatological procedure, by use of electromagnetic radiation (EMR) having a relatively low peak power, and in particular a peak power low enough so as not to result in a phase change in the heater or chromophore absorbing radiation which would result in a significant reduction in its absorption, and of relatively long duration which is generally greater than, sometimes significantly greater than, the thermal relaxation time of the irradiated target.

Owner:PALOMAR MEDICAL TECH +1

Continuous flow thermal device

ActiveUS7709250B2Improve heat transfer efficiencyAvoid vaporizationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringThermal contact

The present invention provides a thermal cycling device including: a heat exchanger body (3) having a longitudinal axis and longitudinally divided to provide at least two segments which are able to be heated to different temperatures so that said body has peripheral surfaces of different temperatures; a conduit (2) extending about said body so as to be in thermal contact with said peripheral surfaces; a first delivery device to deliver a first fluid to said conduit to cause said fluid to pass therealong and therefore change in temperature as the fluid passes said segments; and a second delivery device to deliver a second fluid to said conduit so as to flow with said first liquid and therefore also change in temperature. The fluid then leaves the device by conduit (4). The invention also is directed to an injector means for use in the thermal cycling device of this invention, comprising: a septum (26); a needle (20) which is able to pierce the septum; a reservoir (27) in fluid contact with septum (26) having an inlet (28) and an outlet (30); wherein when in use, the needle is urged through the fluid in said reservoir and then through the septum while continually purging the reservoir with said purge fluid. The present invention also includes a scanning detector (5) fitted to the outside of the heat exchange body (3) which monitors the course of reaction inside the conduit (2).

Owner:QIAGEN GMBH

Liquid-phase growth process and liquid-phase growth apparatus

InactiveUS6872248B2Efficiently formedLow costAfter-treatment apparatusPolycrystalline material growthCrucibleLiquid phase

A liquid-phase growth process comprising immersing a base substrate in a solution containing reactant species to be grown dissolved therein which is accommodated in a crucible and growing a crystal film on said substrate, characterized in that a capping member is kept afloat on the surface of said solution before said substrate is immersed in said solution and said capping member is subsided in said solution upon immersing said substrate in said solution. A liquid-phase growth apparatus suitable for practicing said liquid-phase growth process.

Owner:CANON KK

Vaporizer and apparatus for vaporizing and supplying

InactiveUS20030209201A1Reduce and stabilize pressure fluctuation in and flow rate fluctuationAvoid depositionMixing methodsUsing liquid separation agentVaporizationProduct gas

The present invention provides a vaporizer comprising a vaporization chamber for a CVD material, a CVD material feed portion supplying the CVD material for the vaporization chamber, a vaporized gas exhaust port and a heating means for heating the vaporization chamber, characterized in that the CVD material feed portion has passageways for the CVD material and for a carrier gas respectively and the passageway for the CVD material has a pressure loss-inducing means for the CVD material. At the same time, the present invention provides an apparatus for vaporizing and supplying that feeds a CVD material to a vaporizer via a liquid flow controller, and after vaporizing the CVD material that supplies the vaporized gas for a semiconductor production apparatus, characterized in having a pressure loss-inducing means for the CVD material between the liquid flow controller and the vaporizer. According to the present invention, even in the case of vaporizing and supplying with a decrease in a feed amount of a carrier gas to be supplied accompanying the CVD material employing a solid CVD material, reducing and stabilizing both the pressure fluctuation in the vaporizer and the flow rate fluctuation in the liquid flow controller and efficiently vaporizing a CVD material at a desirable concentration and flow rate without causing deposit or adhesion of the solid material in the vaporization chamber can be achieved.

Owner:JAPAN PIONICS

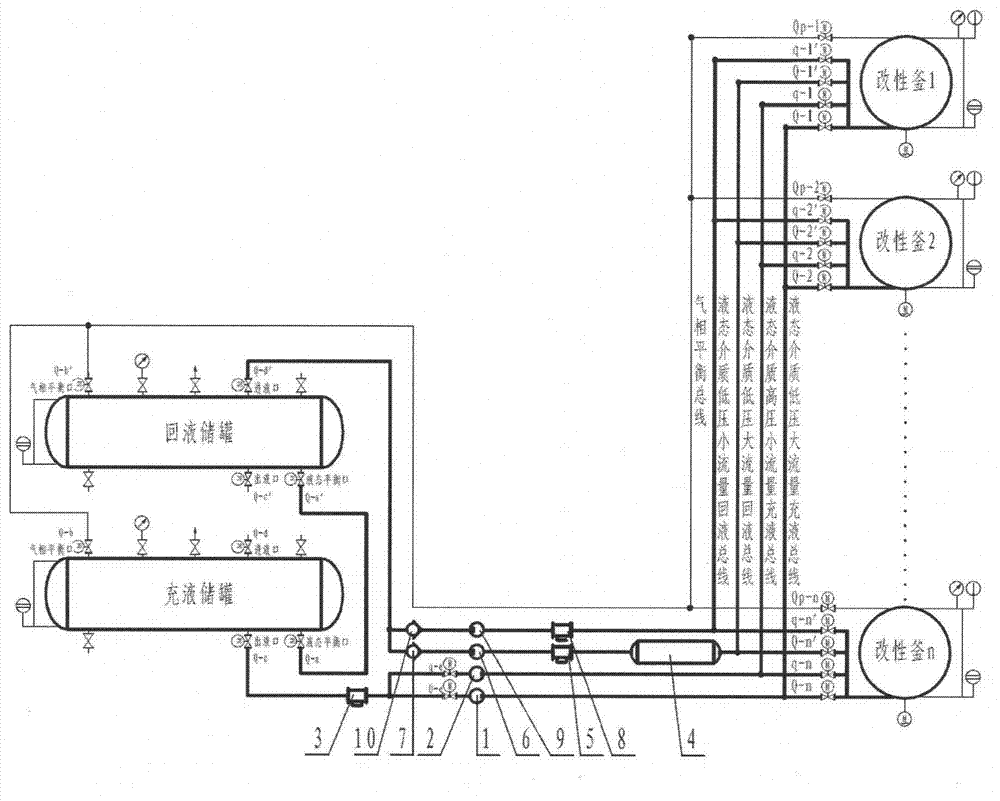

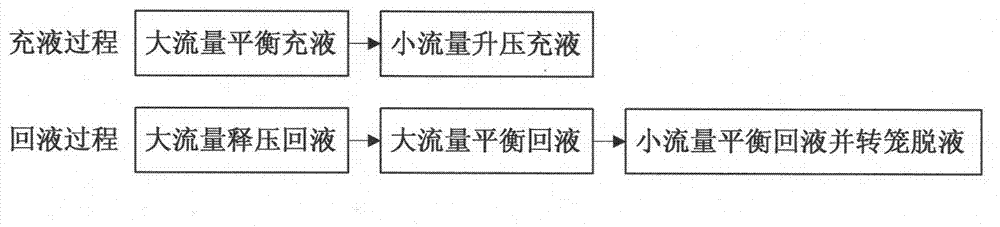

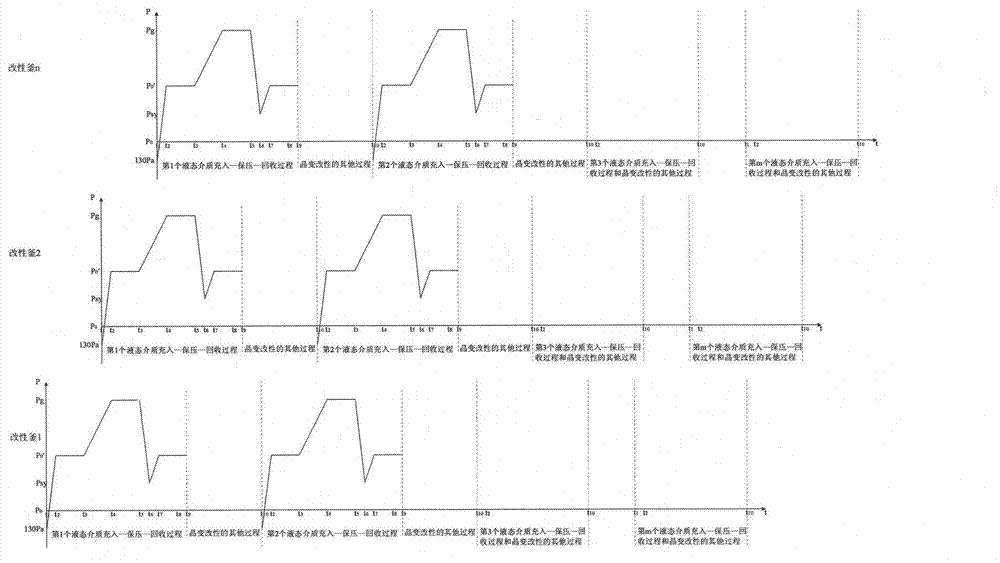

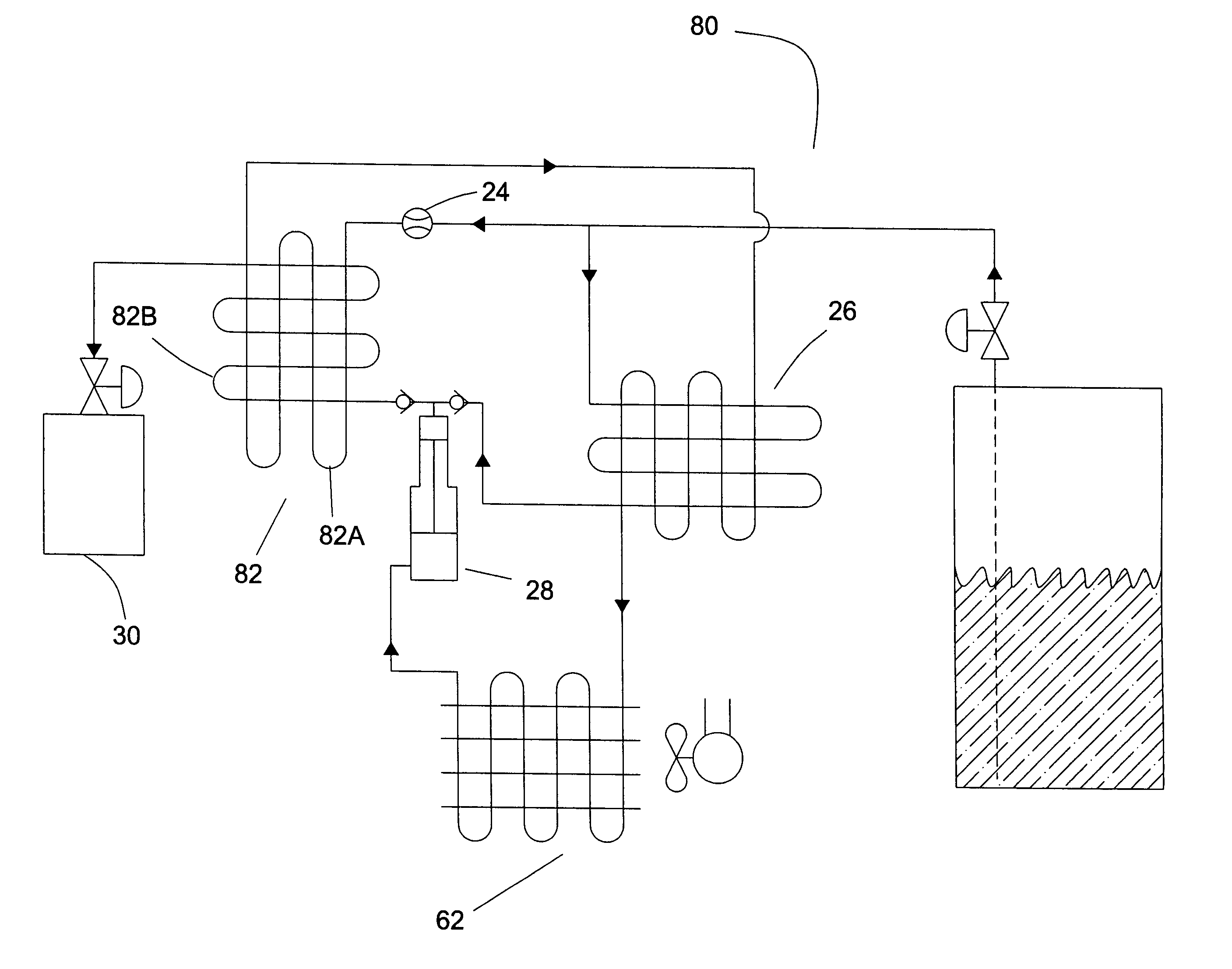

Natural fiber crystal variation modified liquid medium filling and recovery system and method based on paralleled multiple buses and multiple modified kettles

InactiveCN103161046AImprove equipment utilization and production efficiencyReduce equipment cost and production costTextile treatment machine arrangementsTraffic volumeNatural fiber

The invention provides a natural fiber crystal variation modified liquid medium filling and recovery system based on paralleled multiple buses and multiple modified kettles. The natural fiber crystal variation modified liquid medium filling and recovery system based on the paralleled multiple buses and multiple modified kettles comprises a liquid medium low-pressure mass flow liquid-filling bus, a liquid medium high-pressure small flow liquid-filling bus, a liquid medium low-pressure mass flow liquid-return bus, a liquid medium low-pressure small flow liquid-filling bus, a gas phase balance bus, and n modified kettles which are in parallel connection on the buses, and n >=1. The invention further provides a natural fiber crystal variation modified liquid medium filling and recovery method based on the paralleled multiple buses and multiple modified kettles. The liquid-filling process comprises mass flow balance liquid filling and small flow pressure boosting liquid filling, and the liquid return process comprises mass flow pressure relief liquid return, mass flow balance liquid return, small flow balance liquid return, and cage shift liquid exhaustion. The natural fiber crystal variation modified liquid medium filling and recovery system and the method based on paralleled multiple buses and multiple modified kettles are good in modified effect, small in system energy consumption, and high in production efficiency.

Owner:DONGHUA UNIV +1

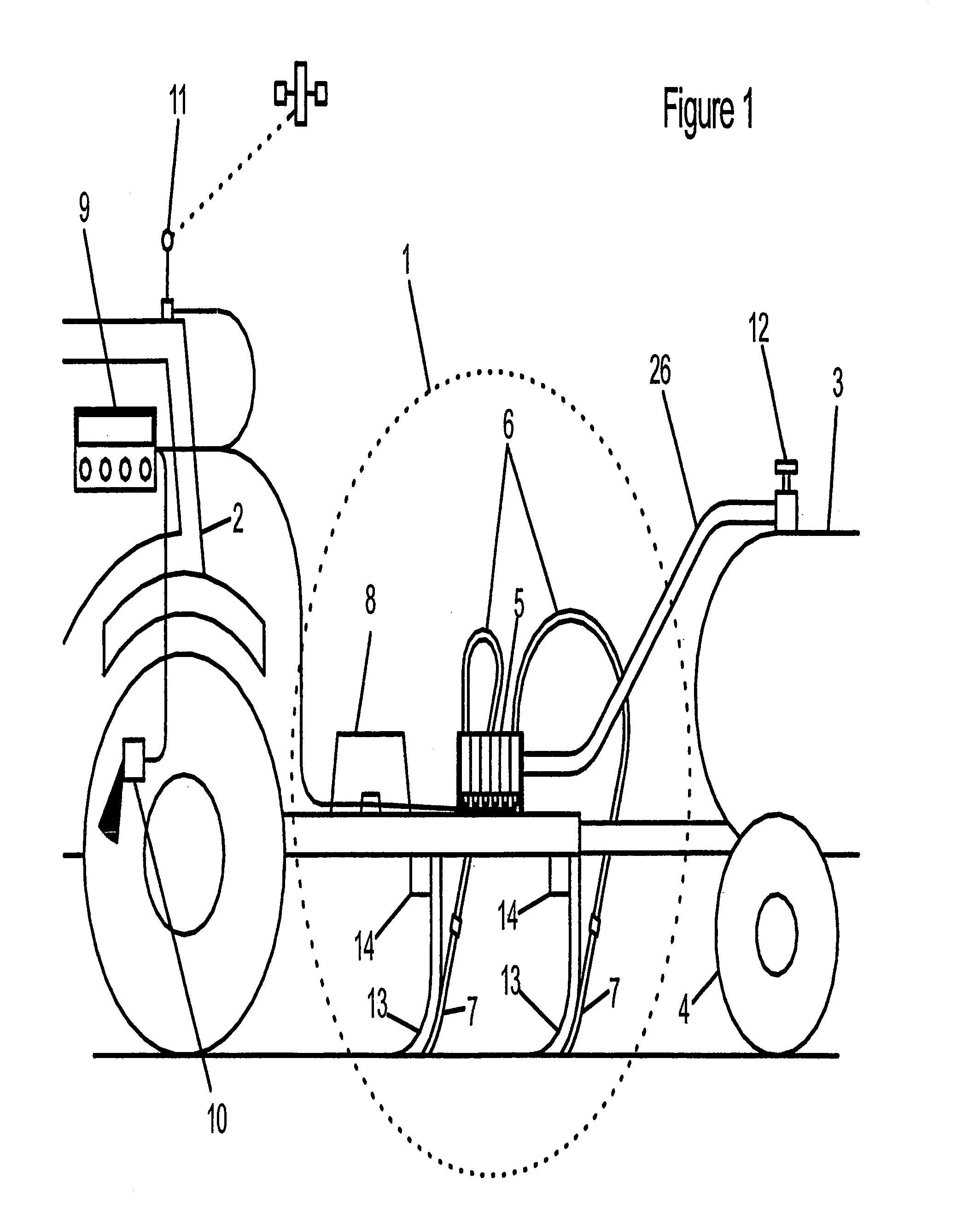

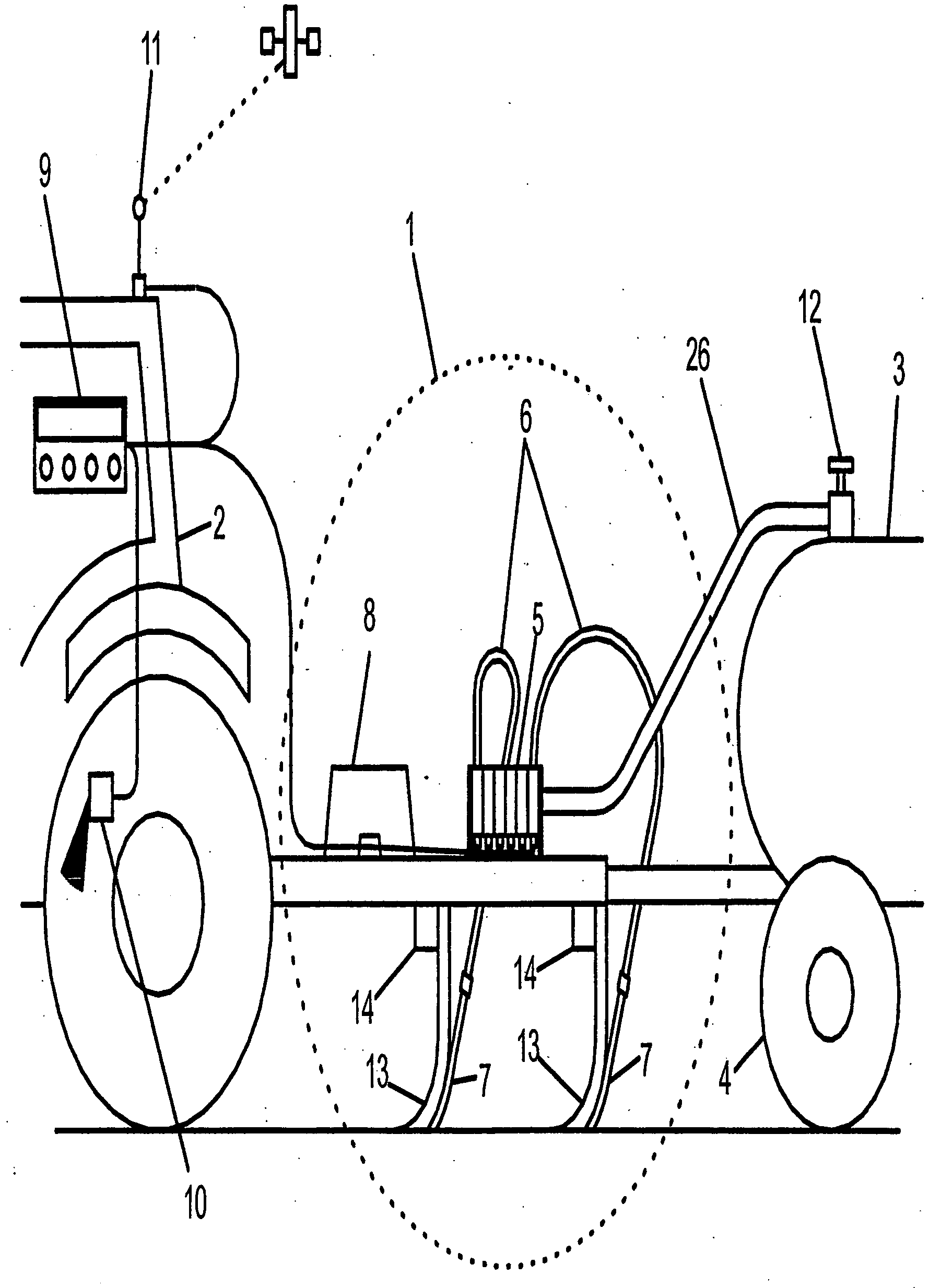

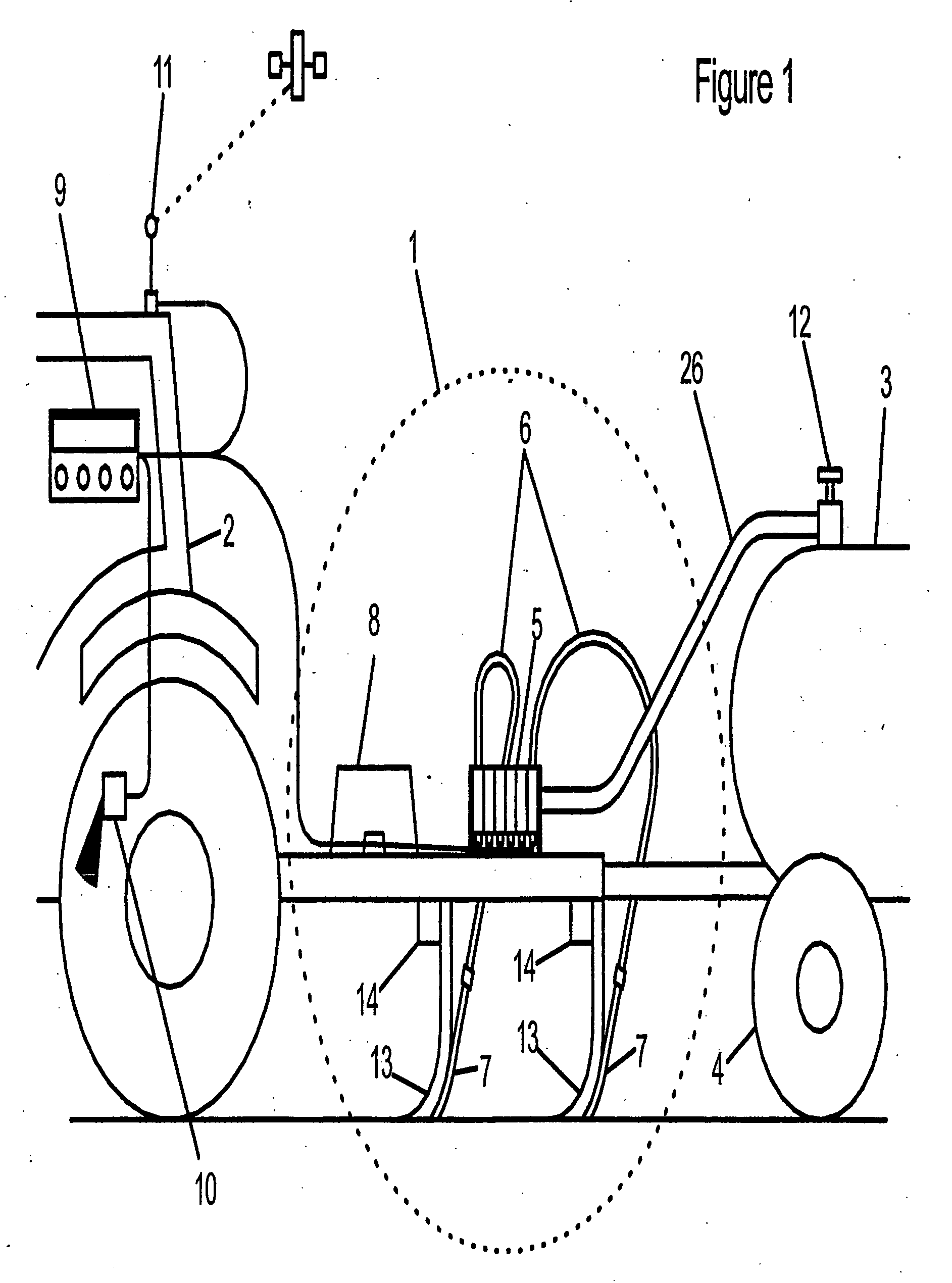

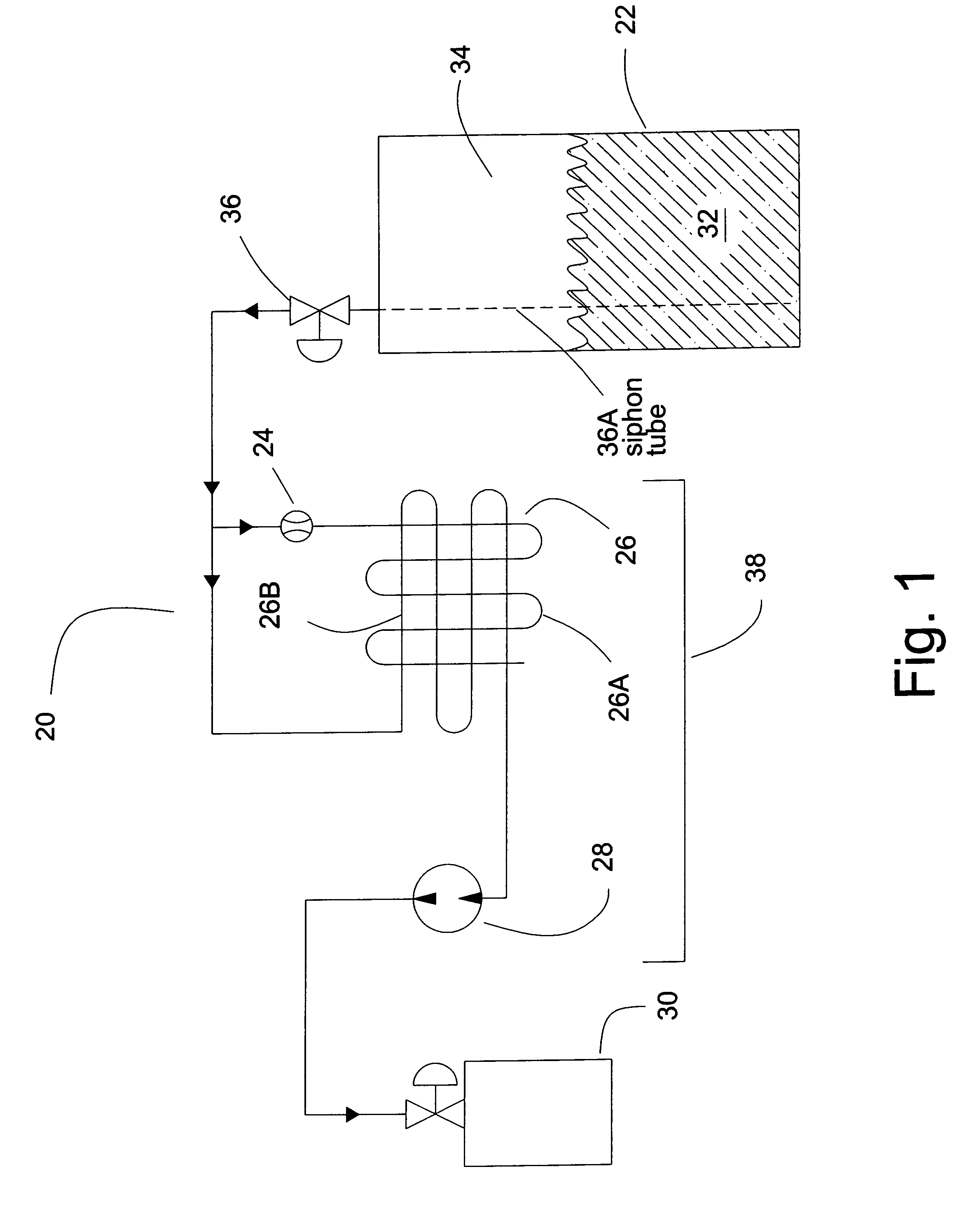

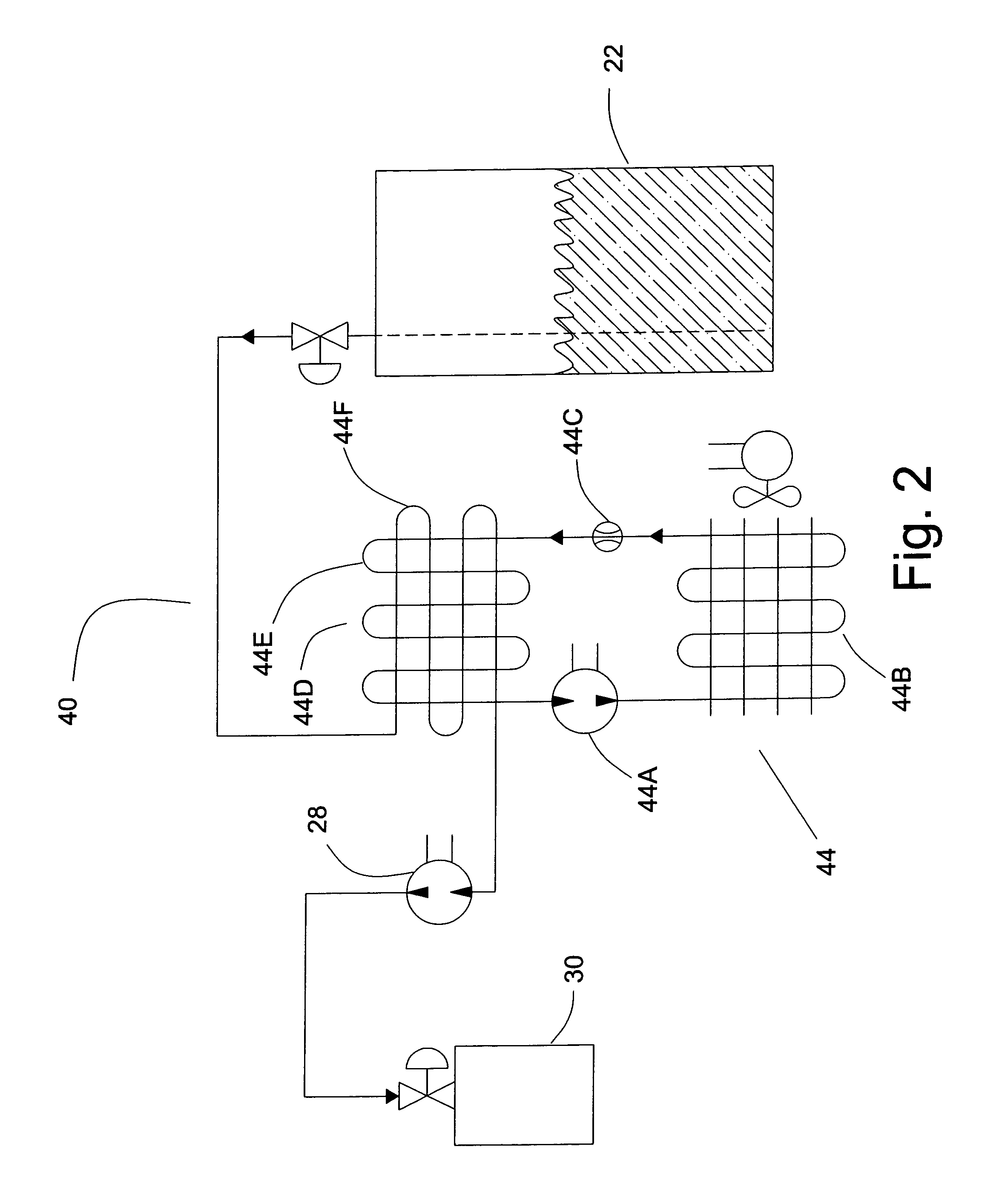

System and method for dispensing a volatile liquid fertilizer

A system and process for dispensing a liquid agrochemical such as ammonia into a field is disclosed. The ammonia is placed in a vessel under sufficient pressure to maintain a substantial portion of the ammonia in a liquid form. From the pressurized vessel, the ammonia is fed to a distribution manifold where it is ultimately injected into a soil through a plurality of dispensing tubes. A constant pressure flow rate control device is placed at each dispensing tube for metering the amount of ammonia fed to the soil. Furthermore, the outlet flow of each constant pressure rate control device is made to vaporize nearby the inlet flow path to create a heat exchange effect thereby cooling the inlet flow. In particular, the flow control devices allow ammonia to be dispensed from the system while maintaining sufficient back pressure and temperature within the distribution manifold to maintain the ammonia in a liquid form. By maintaining the ammonia in a liquid form, uniform and accurately controlled flow rates can be dispensed from the dispensing tubes.

Owner:CAPSTAN

System and method for dispensing a volatile liquid fertilizer

A system and process for dispensing a liquid agrochemical such as ammonia into a field is disclosed. The ammonia is placed in a vessel under sufficient pressure to maintain a substantial portion of the ammonia in a liquid form. From the pressurized vessel, the ammonia is fed to a distribution manifold where it is ultimately injected into a soil through a plurality of dispensing tubes. A constant pressure flow rate control device is placed at each dispensing tube for metering the amount of ammonia fed to the soil. Furthermore, the outlet flow of each constant pressure rate control device is made to vaporize nearby the inlet flow path to create a heat exchange effect thereby cooling the inlet flow. In particular, the flow control devices allow ammonia to be dispensed from the system while maintaining sufficient back pressure and temperature within the distribution manifold to maintain the ammonia in a liquid form. By maintaining the ammonia in a liquid form, uniform and accurately controlled flow rates can be dispensed from the dispensing tubes.

Owner:CAPSTAN

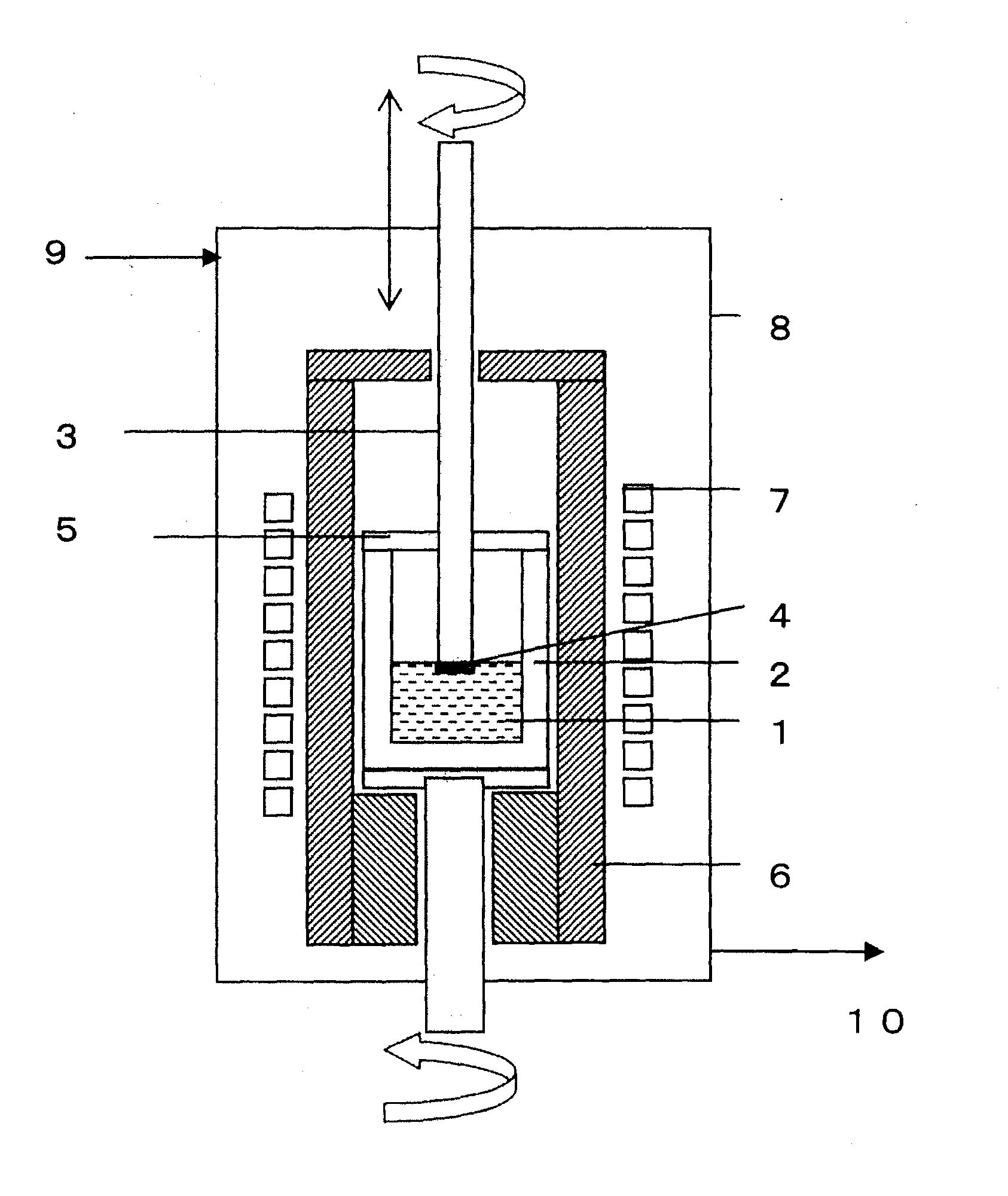

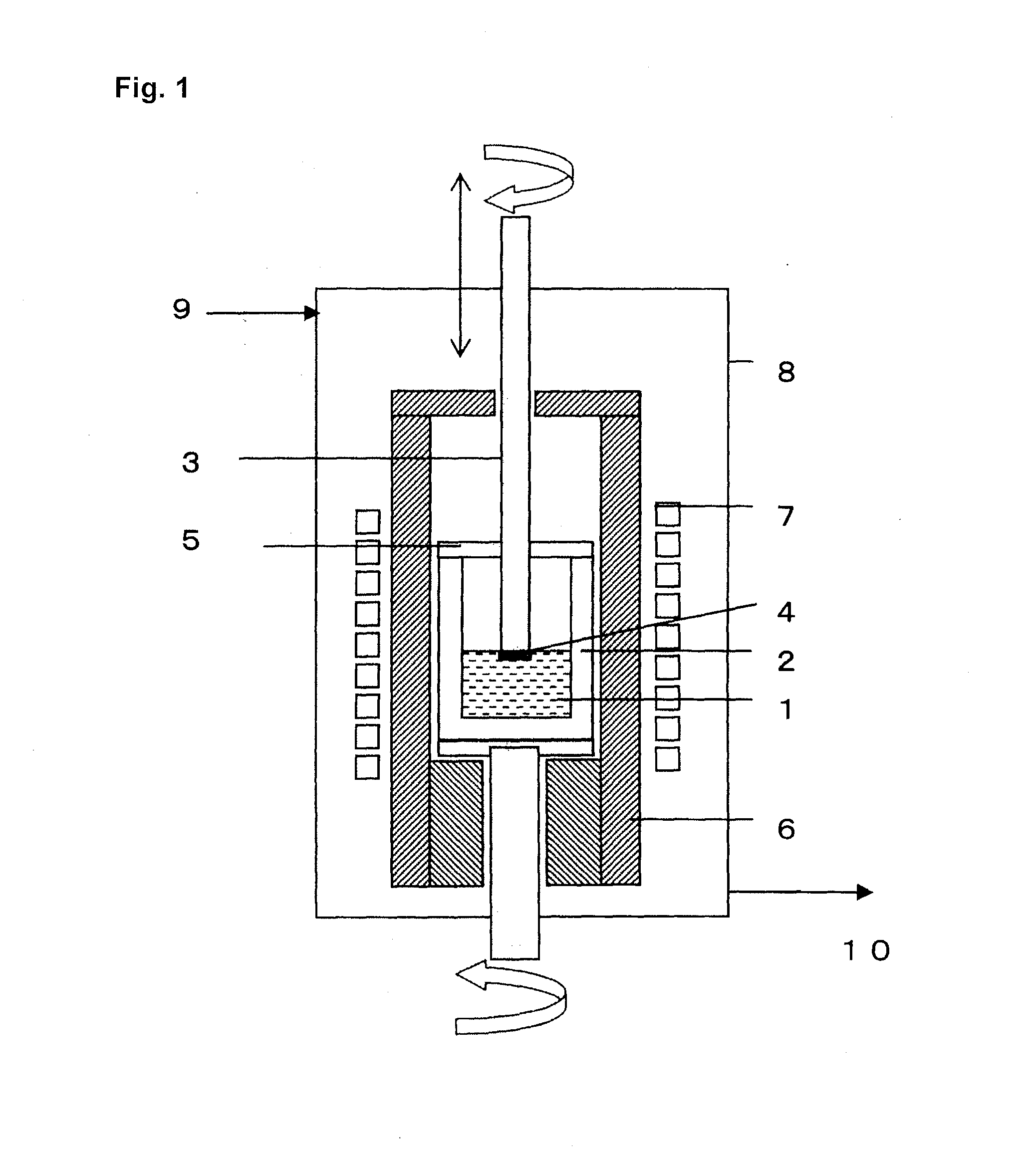

Method of manufacturing a silicon carbide single crystal

InactiveUS20110200833A1Efficient preparationReduce carrier densityPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalAlloy

A method capable of stably manufacturing a SiC single crystal in the form of a thin film or a bulk crystal having a low carrier density of at most 5×1017 / cm3 and preferably less than 1×1017 / cm3 and which is suitable for use in various devices by liquid phase growth using a SiC solution in which the solvent is a melt of a Si alloy employs a Si alloy having a composition which is expressed by SixCryTiz wherein x, y, and z (each in atomic percent) satisfy0.50<x<0.68, 0.08<y<0.35, and 0.08<z<0.35, or (1)0.40<x≦0.50, 0.15<y<0.40, and 0.15<z<0.35. (2)x, y, and z preferably satisfy 0.53<x<0.65, 0.1<y<0.3, and 0.1<z<0.3.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

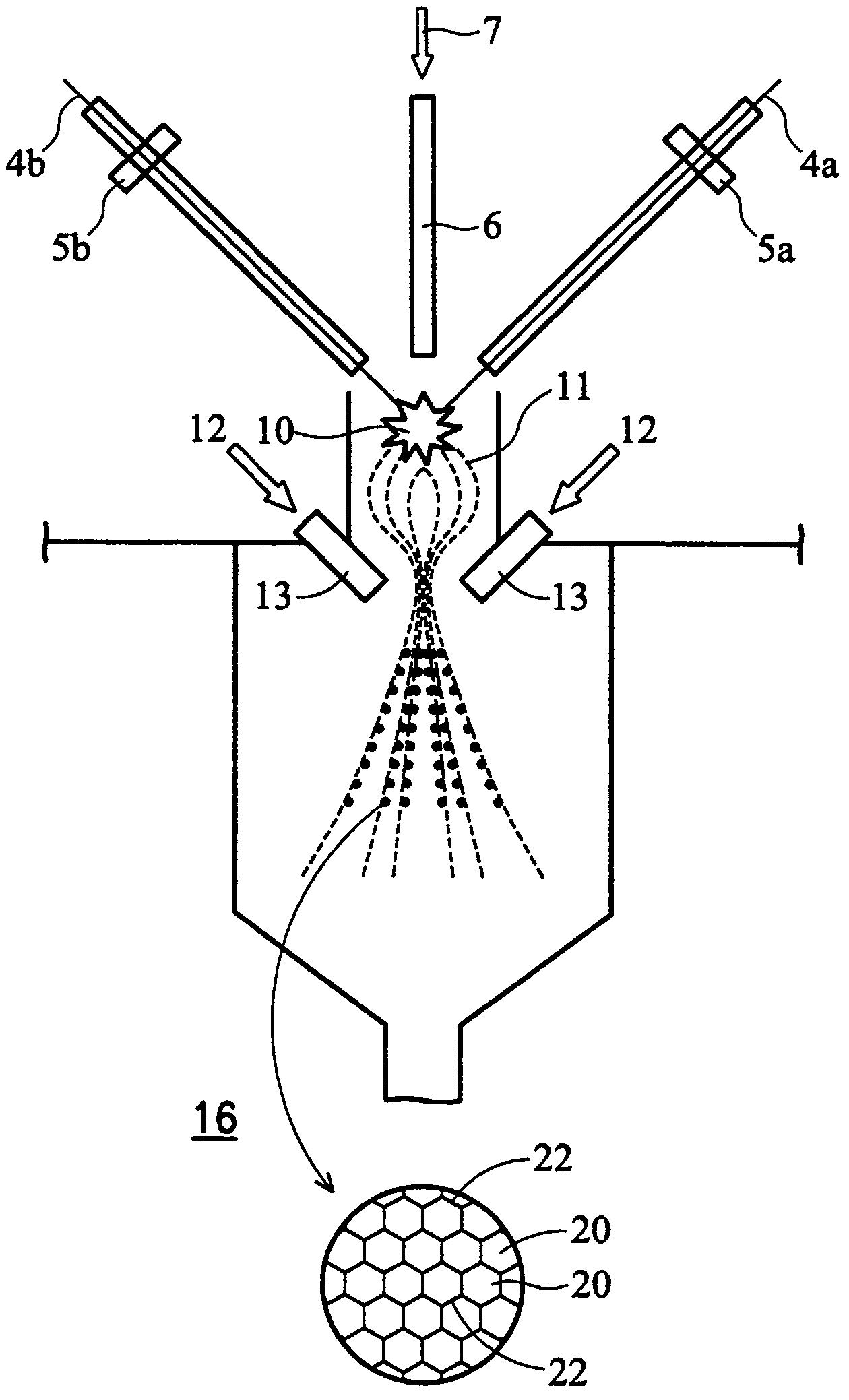

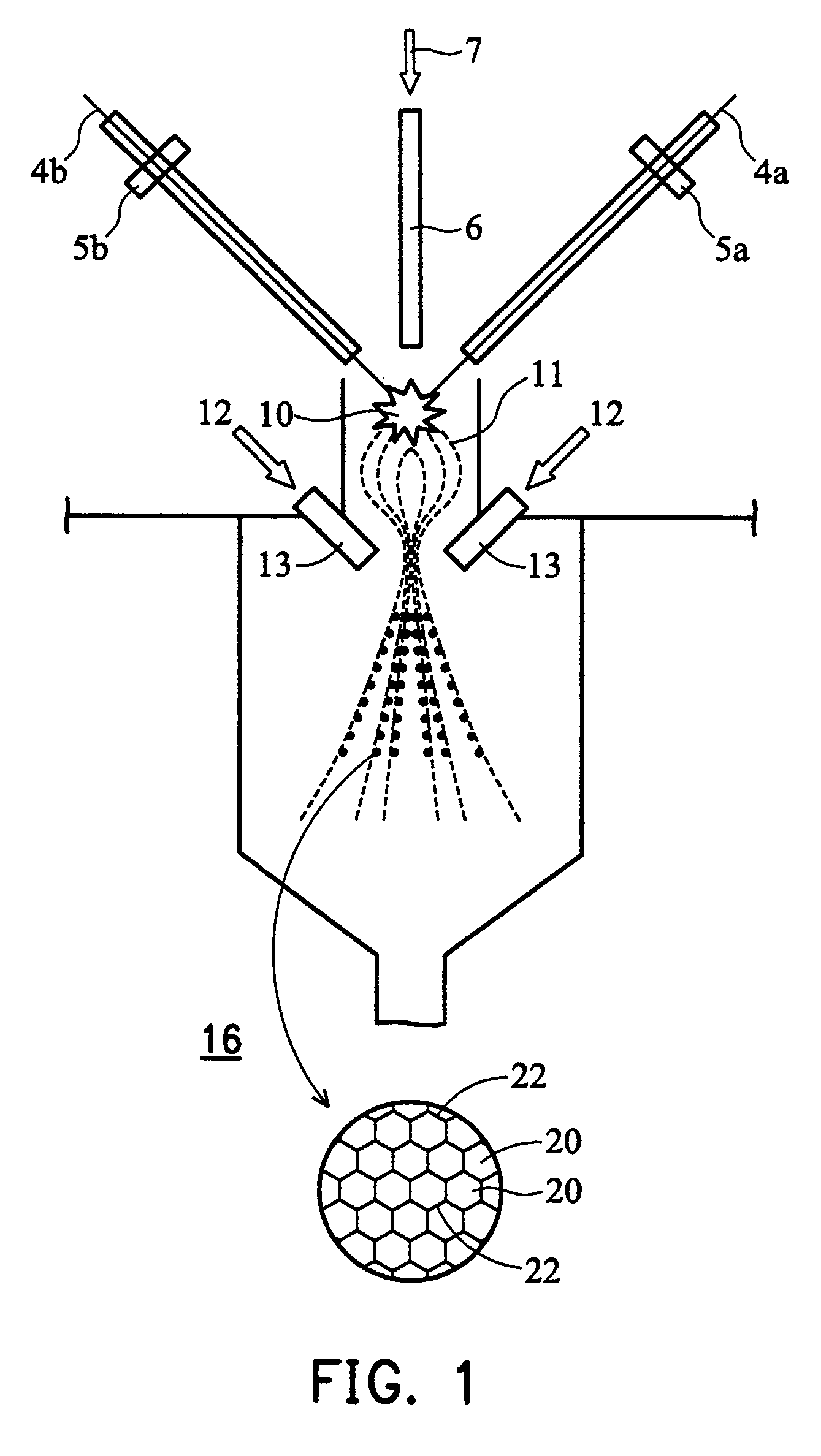

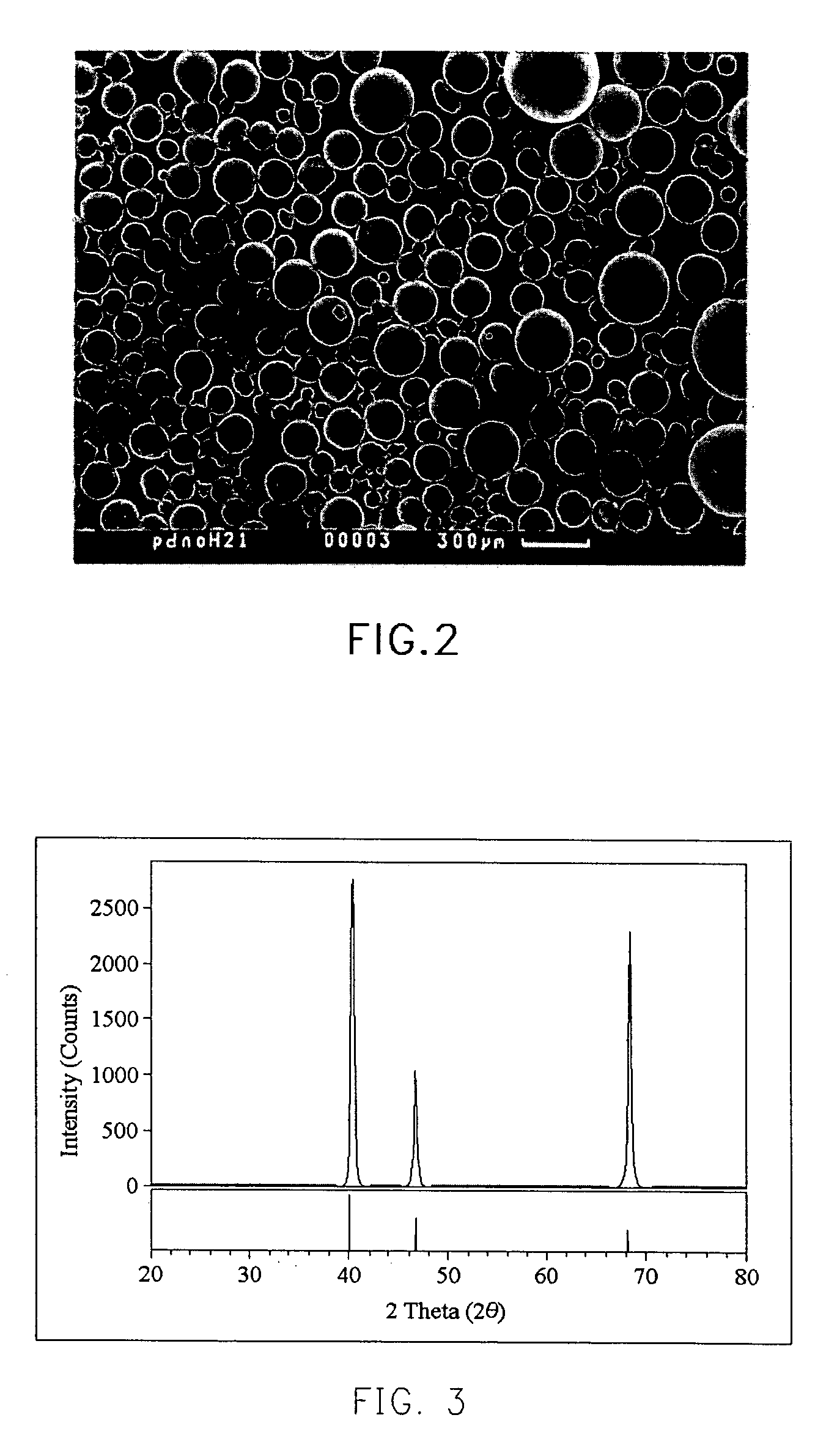

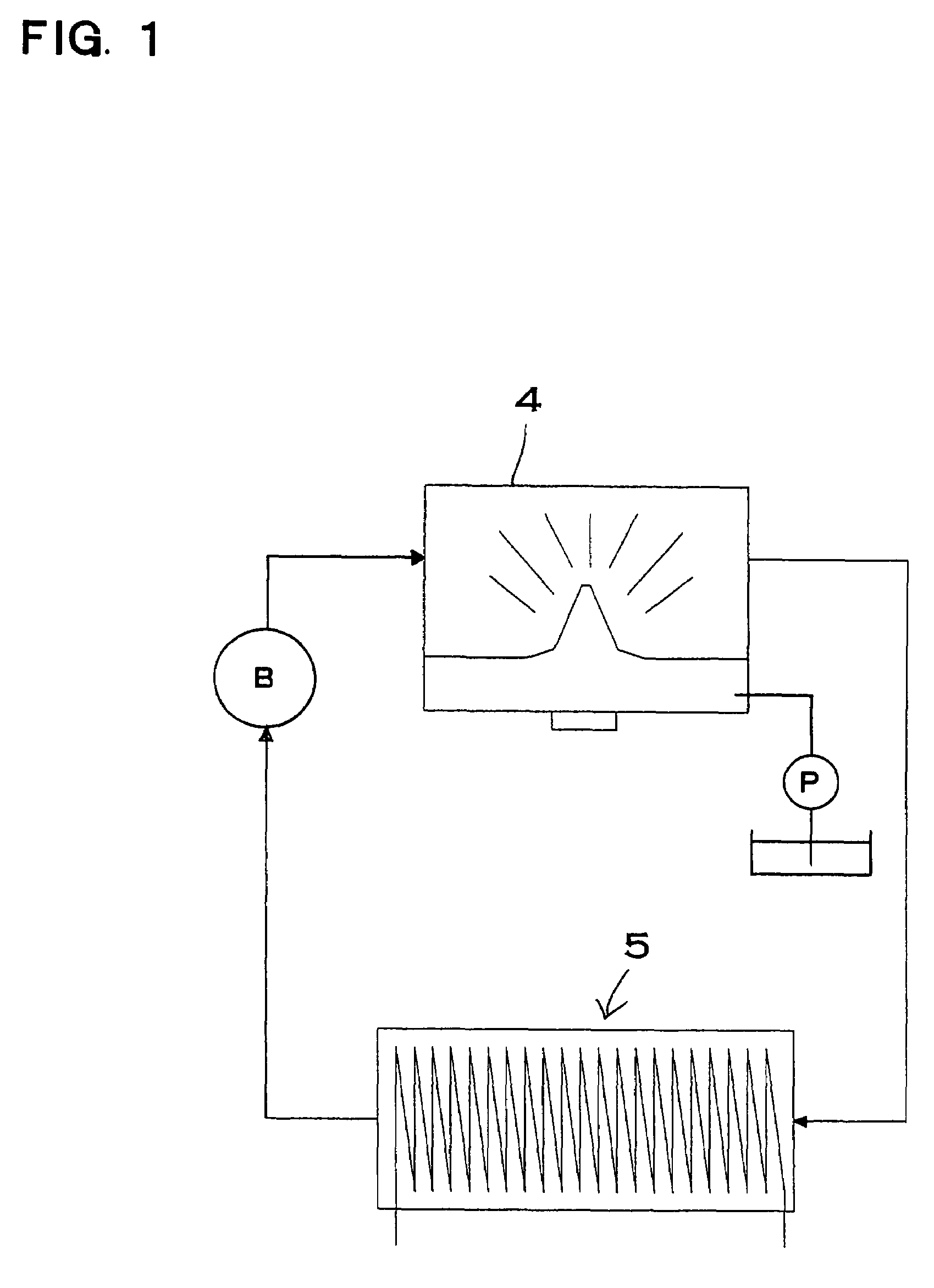

Nanostructured metal powder and method of fabricating the same

ActiveUS7431750B2High densityGood fluidityTransportation and packagingMetal-working apparatusTemperature controlMetallurgy

The present invention relates to a nanostructured metal powder and a method of fabricating the same. A twin-wire electric arc process is performed to melt the wire tips, and metal melt is formed. Simultaneously, the metal melt is broken up into melt droplets by an atomizing device. The operating temperature of the electric arc process is controlled between melting point and boiling point of the wire, to avoid vaporization of the melt droplets. Then, a fast cooling is performed to quench the melt droplets. Thus, melt droplets are solidified to μm-scaled, spherical and dense powders comprising nano-grains (d<100 nm).

Owner:IND TECH RES INST

Ultrasonic solution separator

ActiveUS7347889B2Efficient productionEfficient separationThermo-electric condensationCombination devicesHigh frequency powerUltrasonic atomization

An ultrasonic solution separator including an ultrasonic atomization chamber supplied with a solution containing a target material; an ultrasonic oscillator producing mist from the solution in the ultrasonic atomization chamber with ultrasonic oscillation; a power supply for ultrasonics connected to the ultrasonic oscillator, and a collection portion transporting the mist produced by the ultrasonic oscillator with a carrier gas and aggregating and collecting the mist included in the carrier gas. The power supply supplying high-frequency power to the ultrasonic oscillator so that the ultrasonic oscillator oscillates at an ultrasonic frequency. The ultrasonic separator aggregates and collects the mist produced in the ultrasonic atomization chamber by means of the collection portion. With this ultrasonic solution separator, the temperature of carrier gas in the ultrasonic atomization chamber is at least 5° C. higher than the carrier gas in the collection portion.

Owner:ULTRASOUND BREWERY

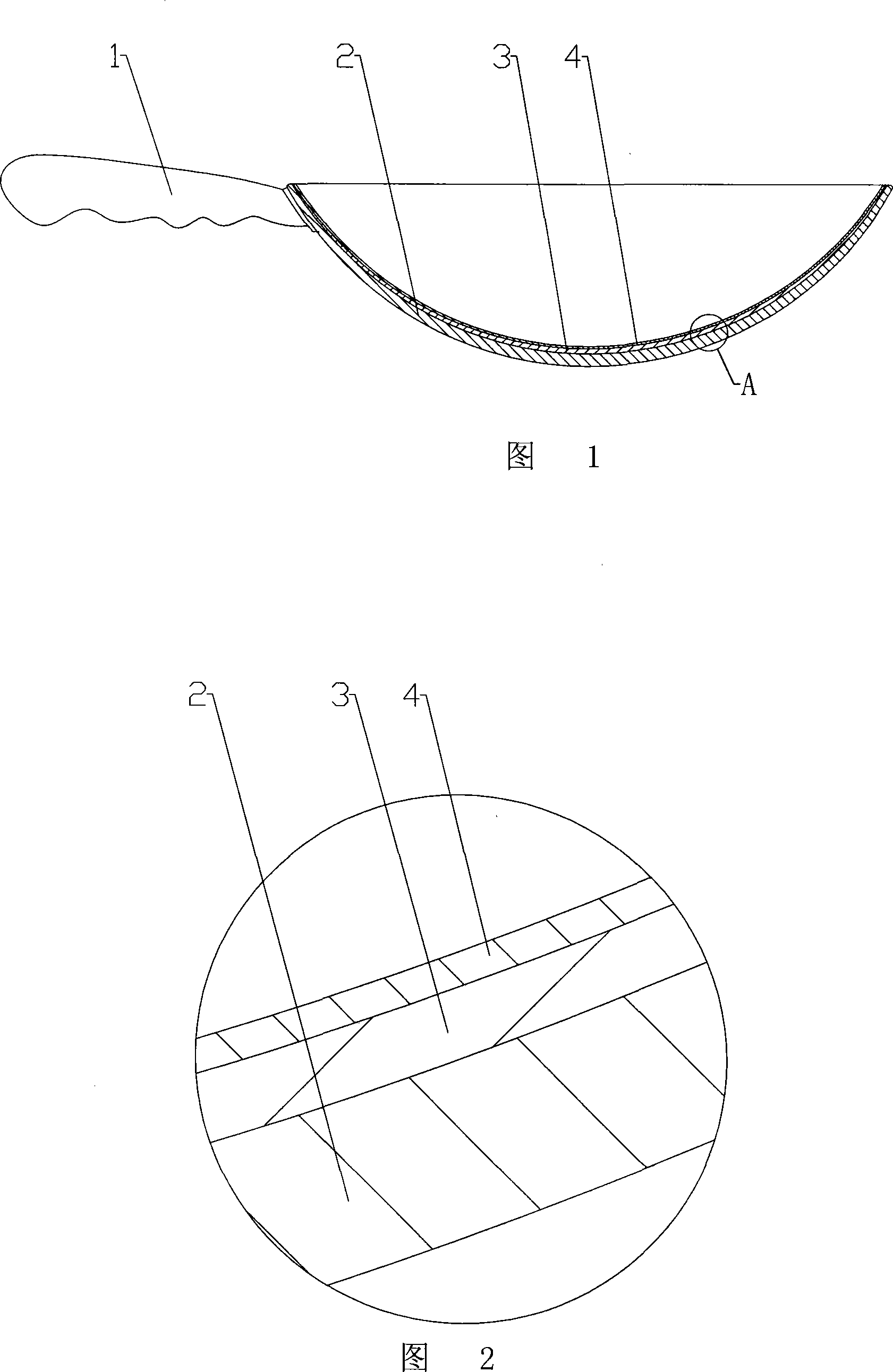

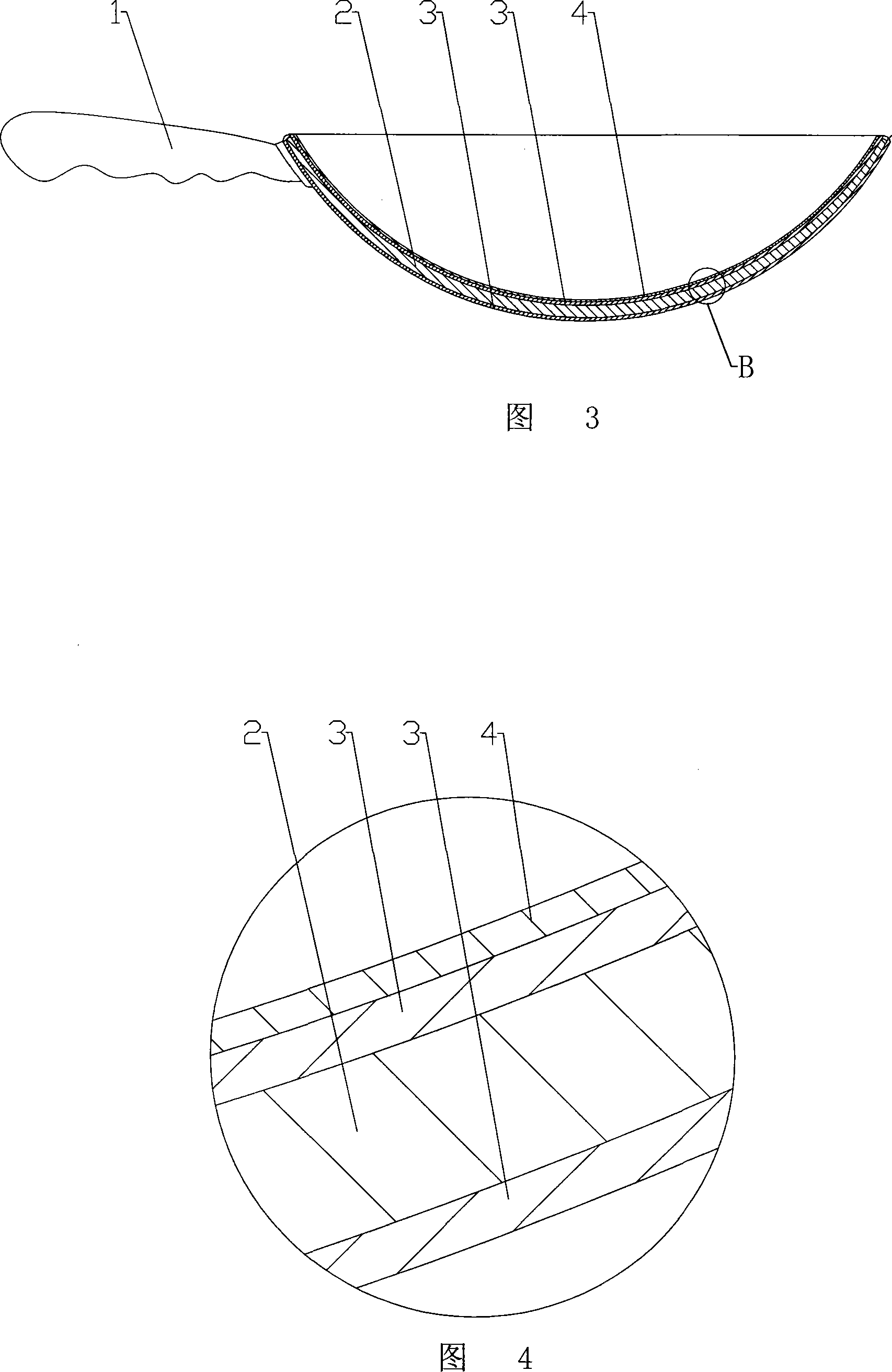

Cooker

InactiveCN101176616ADoes not cause peelingStrong adhesionCooking-vessel materialsMetallurgyCooking process

The invention relates to a pan, comprising a pan body; wherein, a handle is arranged on the pan body, which comprises a metallic layer and a ceramic layer compounded as a whole. The metallic layer and the ceramic layer are close compounded as a whole through partial fusing or fusing; the ceramic layer on the inner surface of the pan body is covered with a non-stick layer with the component of ceramic, which is bound on the ceramic layer through 200 to 420 DEG C baking. The invention has the advantages that: since the metallic layer and the ceramic layer are close compounded as a whole through partial melting or melting, and the adhesive power between the metallic layer and the ceramic layer is strong, the desquamation of the ceramic layer is avoided after the using of metallic spade in the cooking process or a long-time using of the pan; the non-stick layer and the ceramic layer are hard connected since the non-stick layer comprises the component of ceramic.

Owner:卢雄文

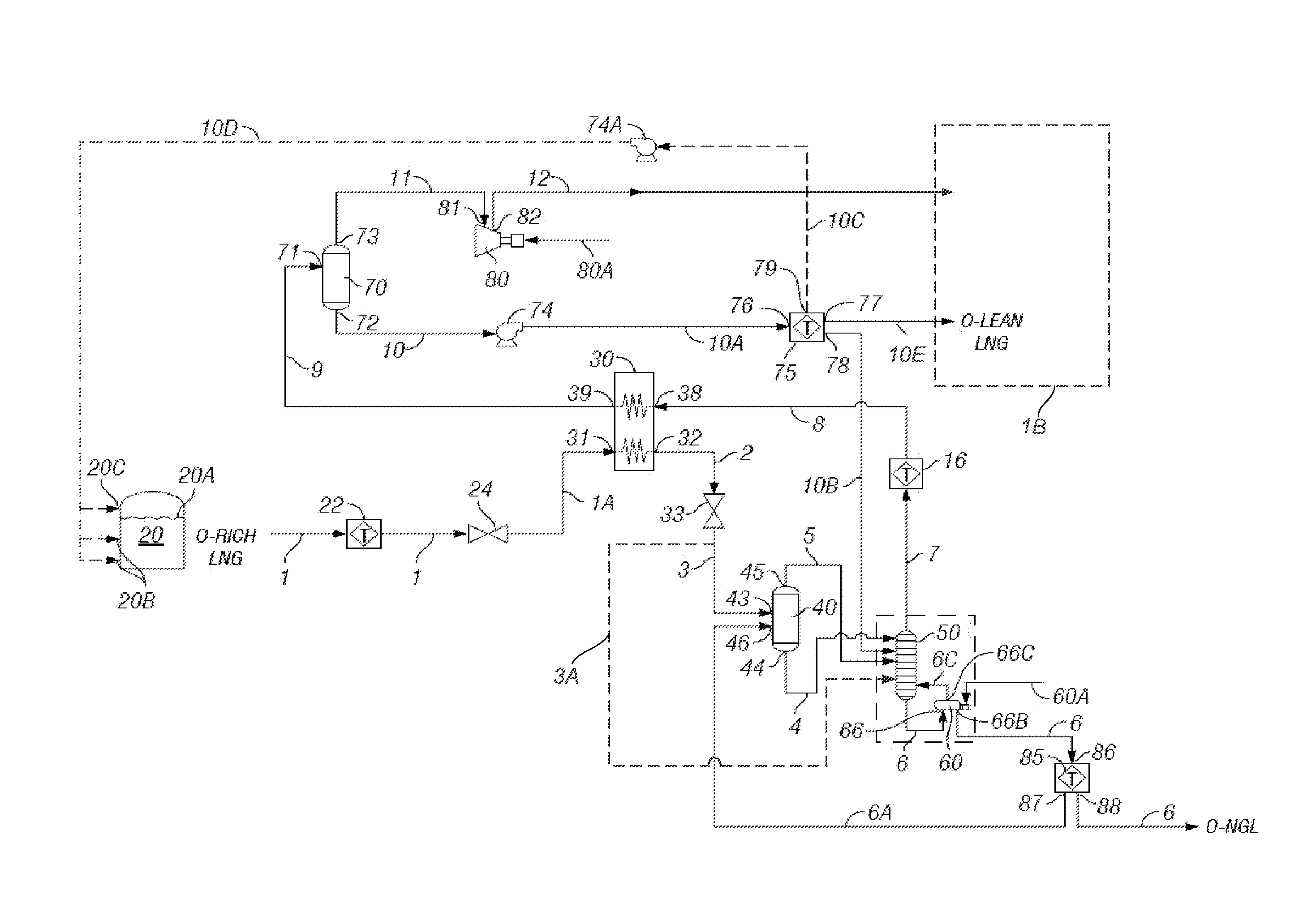

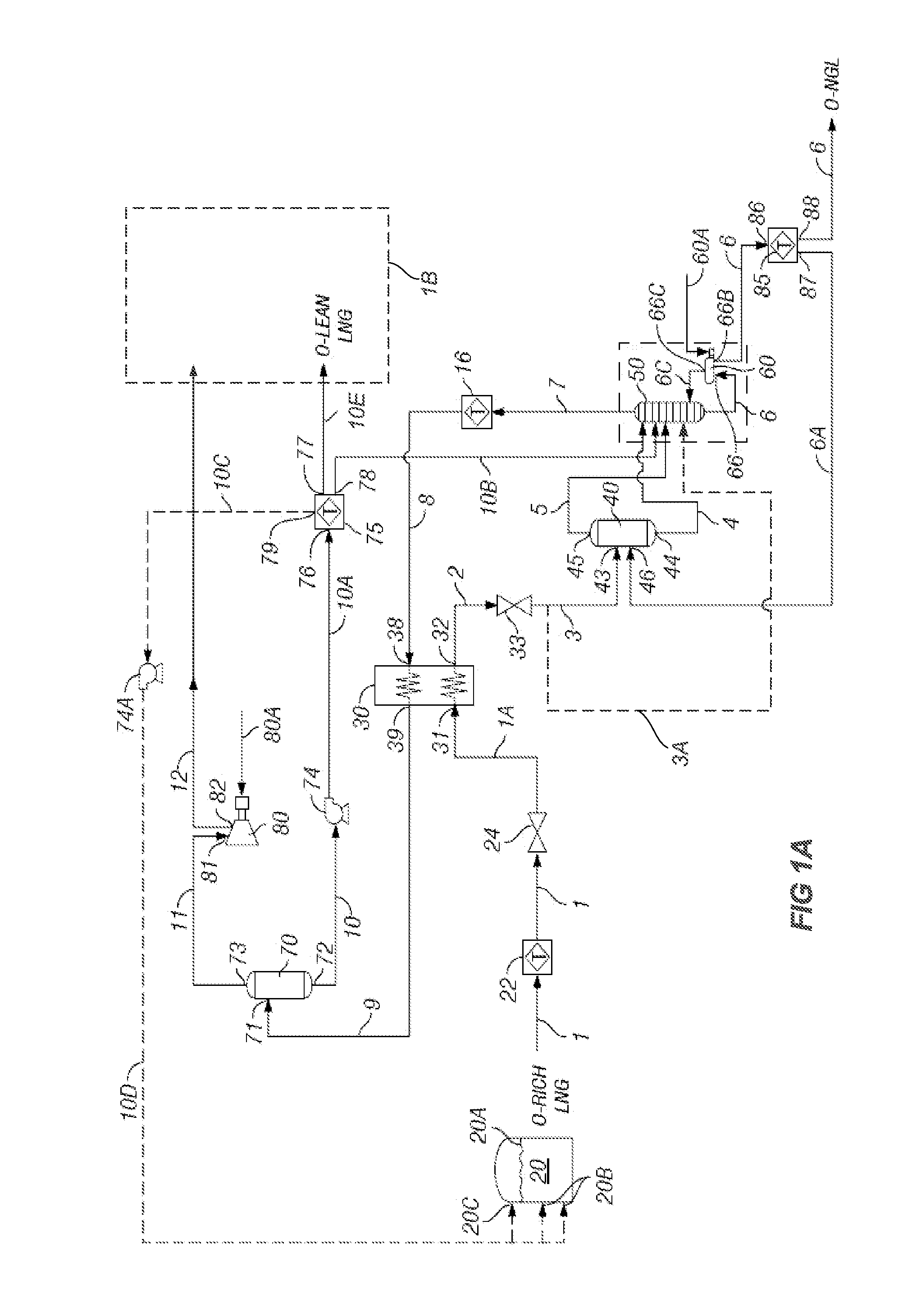

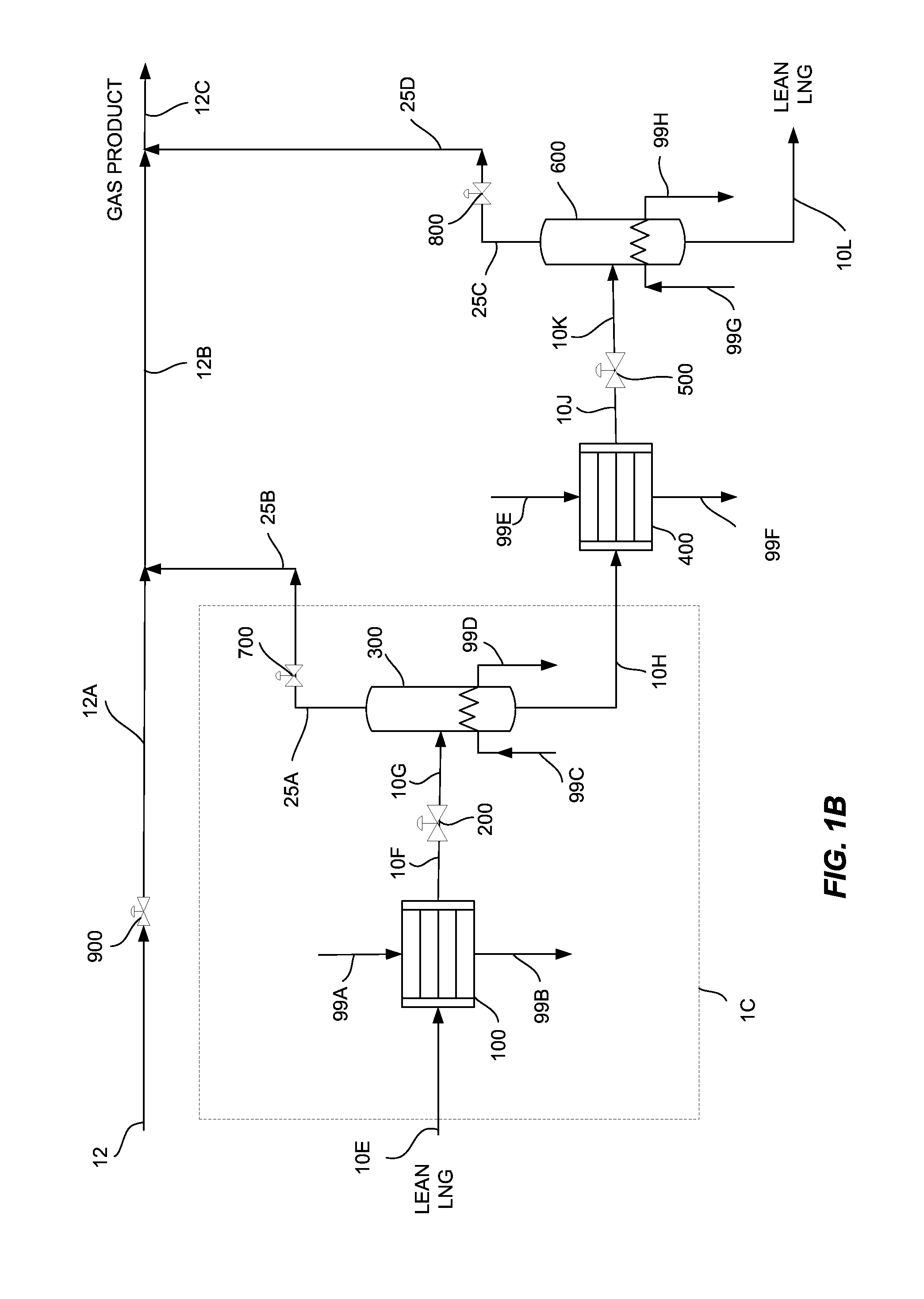

Process for separating and recovering ethane and heavier hydrocarbons from LNG

A process for extracting heavier components, e.g., NGL from liquid / fluid streams such as Rich LNG (RLNG) stream(s) with the streamlined economy. The process involves heating the RLNG stream in heat exchanger(s) (LNGX) against column overhead vapour stream; not requiring separation of Feed streams into feed and reflux by splitting either pre- or post- of heat LNGX. The source liquid RLNG is processed producing liquid NGL and at same time returning purified Lean LNG (LLNG) product in its Liquid LNG form. The process operates essentially without the need for compression equipment. The process further provides without compressors vaporized natural gas at pipeline pressure and specifications. This is a system that can flexibly change product compositions and specifications of product NGL / Lean LNG / Pipeline Gas and operate in both Pipeline Specification deep 99% Ethane (C2) Extraction and Ethane (C2) Rejection NGL recovery modes with economy of equipment and energy requirements.

Owner:PATEL KIRTIKUMAR NATUBHAI +1

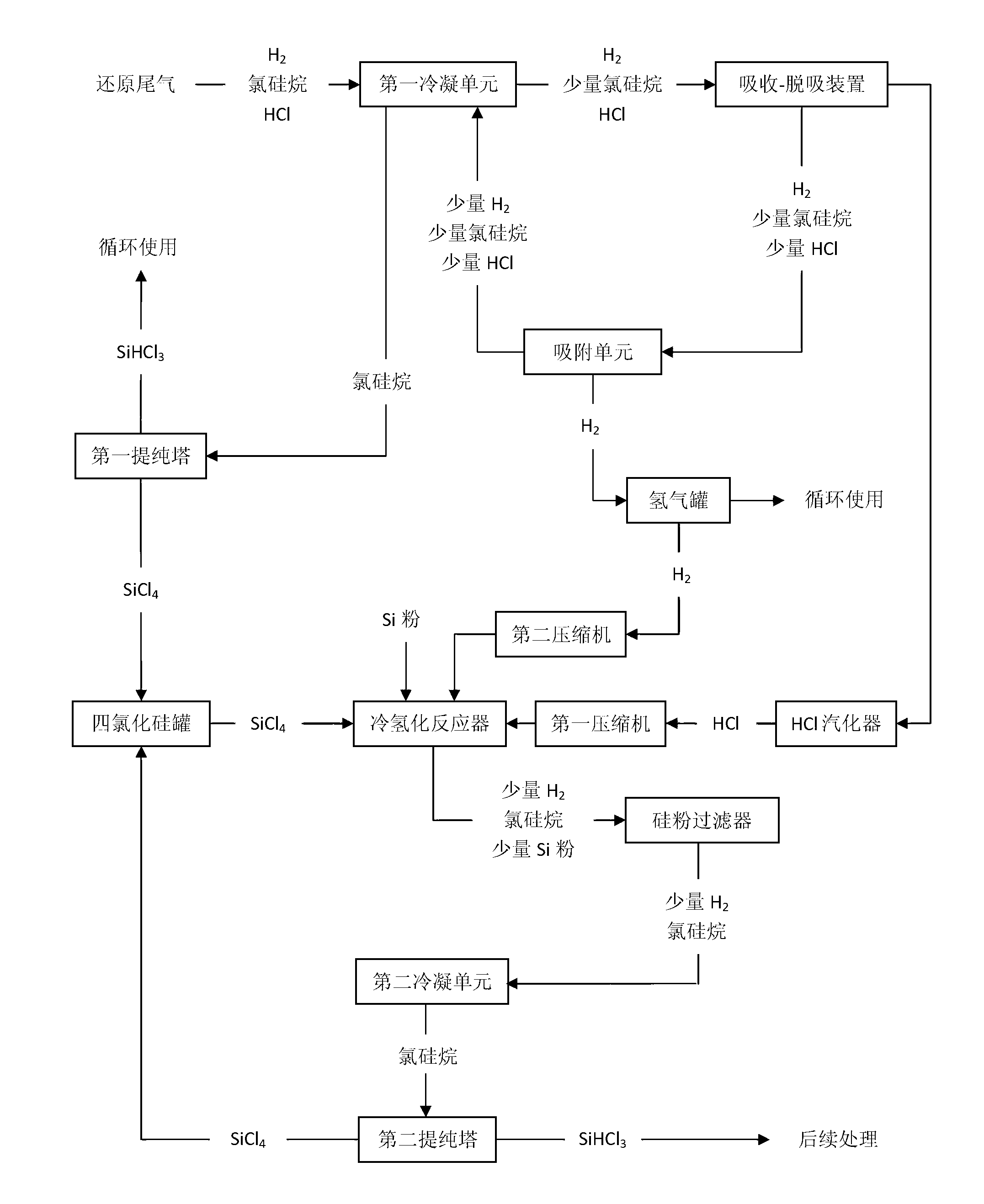

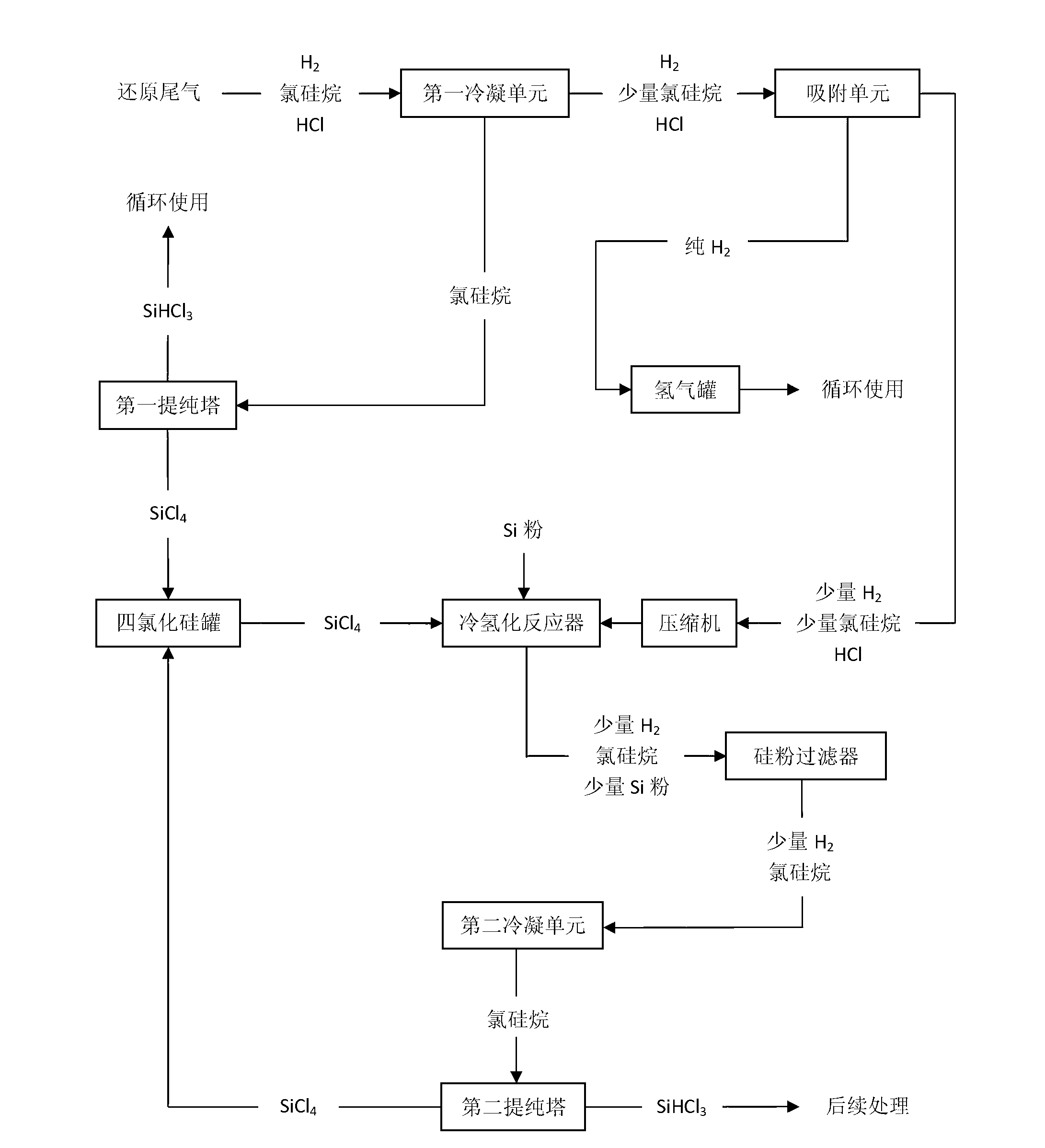

Recovery system and recovery method of by-product in polycrystalline silicon production

ActiveCN103058140ASave heat and coolSave on cooling or heatingChlorine/hydrogen-chloride purificationHydrogen separation using solid contactExhaust gasChemistry

The invention discloses a recovery system and a recovery method of a by-product in polycrystalline silicon production. The system and the method are used for recycling the hydrogen, chlorosilane and chlorine hydride gas in the reducing tail gas produced during the polycrystalline silicon production. The recovery method comprises the following steps: a condensing step for separating most of chlorosilane from the reducing tail gas; an adsorption step for removing all chlorine hydride and the rest chlorosilane from the reducing tail gas by using an absorption unit after the condensing step to obtain the pure hydrogen; a regenerating step for regenerating the absorption unit by using the hydrogen so as to remove the chlorosilane and chlorine hydride absorbed by the absorption unit, and obtaining the regenerative gas containing hydrogen, chlorosilane and chlorine hydride; and a cold hydrogenating step for directly feeding the regenerative gas as the raw material of the cold hydrogenation reaction to a cold hydrogenation reactor. According to the system and method provided by the invention, the HCl can be singly separated from the tail gas without an adsorption-de-adsorption device so as to prevent the HCl from being condensedly separated and gasified, and a great number of heat and cooling capacity is saved.

Owner:巴彦淖尔聚光硅业有限公司

System and method of pumping liquified gas

InactiveUS6923007B1Expensive to installLow costGas handling applicationsGas handling/storage effectsProcess engineeringVaporization

A system and method of pumping liquified gas. Applicants systems includes a liquified gas storage vessel and a smaller high pressure high pressure liquified gas storage cylinder. Applicant provides a pump between the two vessels for pumping the liquified gas from one vessel to the other. Applicants system also includes at least one heat exchanger through which the liquified gas passes as it is pumped from one vessel to the other, which heat exchanger cools the liquified gas that is being pumped to a temperature typically below the vaporization point of the gas.

Owner:MICHAEL D HOLT COMPANY

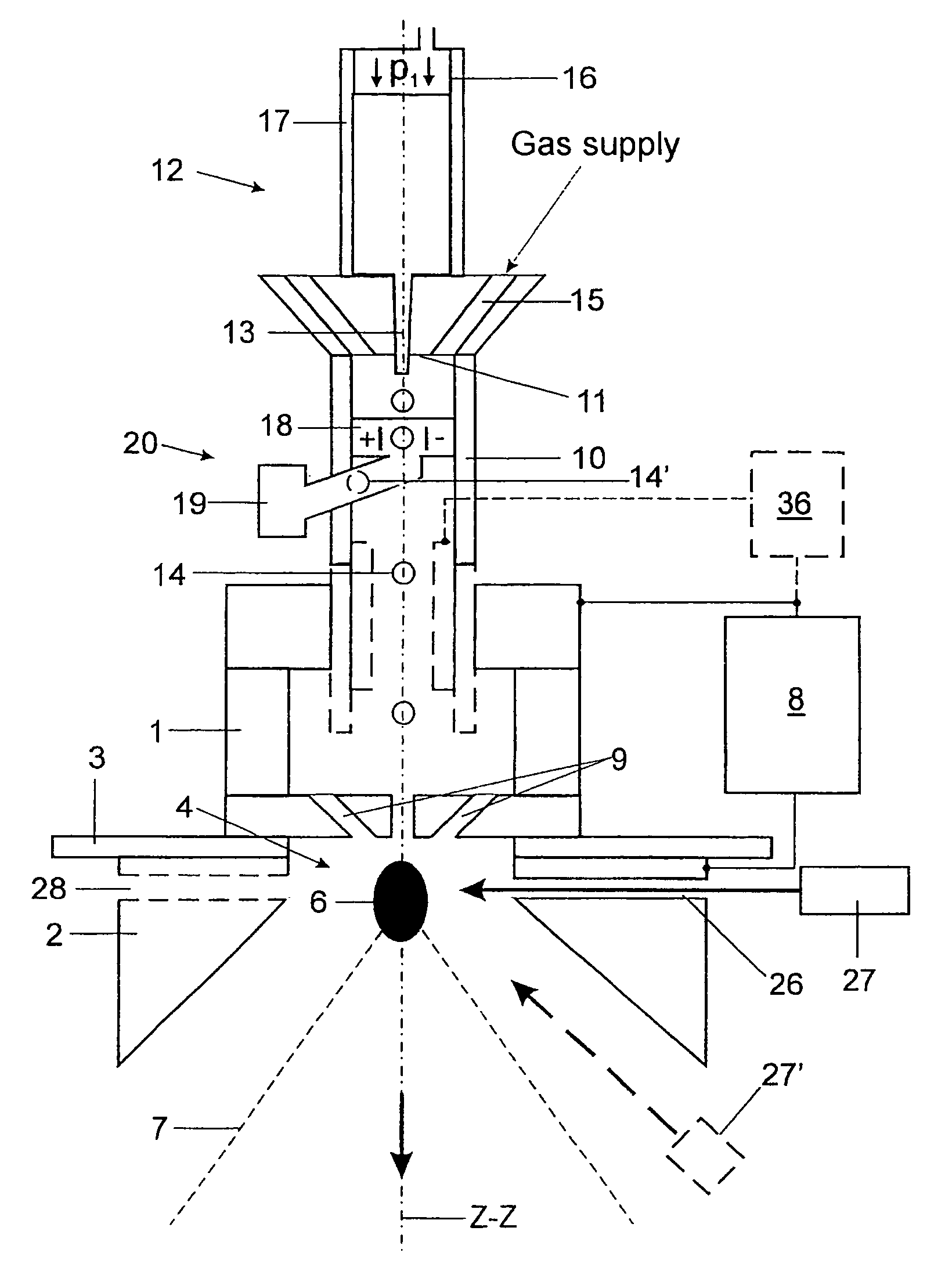

Device and method for generating extreme ultraviolet (EUV) radiation

InactiveUS7476884B2Solution to short lifeEfficient conversionRadiation pyrometryDirect voltage acceleratorsElectric dischargeSource material

It is the object of a device and method for generating extreme ultraviolet (EUV) radiation to overcome the obstacles formerly posed by the use of efficient metal emitters so that the conversion efficiency can be optimized and, as a result, the radiation output can be increased without shortening the useful life of the collector optics and electrode system. An injection nozzle of an injection device is directed to a discharge area located in a discharge chamber. The injection nozzle supplies a series of individual volumes of a source materials for the electric discharge serving to generate radiation at a repetition rate that corresponds to the frequency of the gas discharge. Further, provision is made for successively vaporizing the individual volumes in the discharge area.

Owner:USHIO DENKI KK

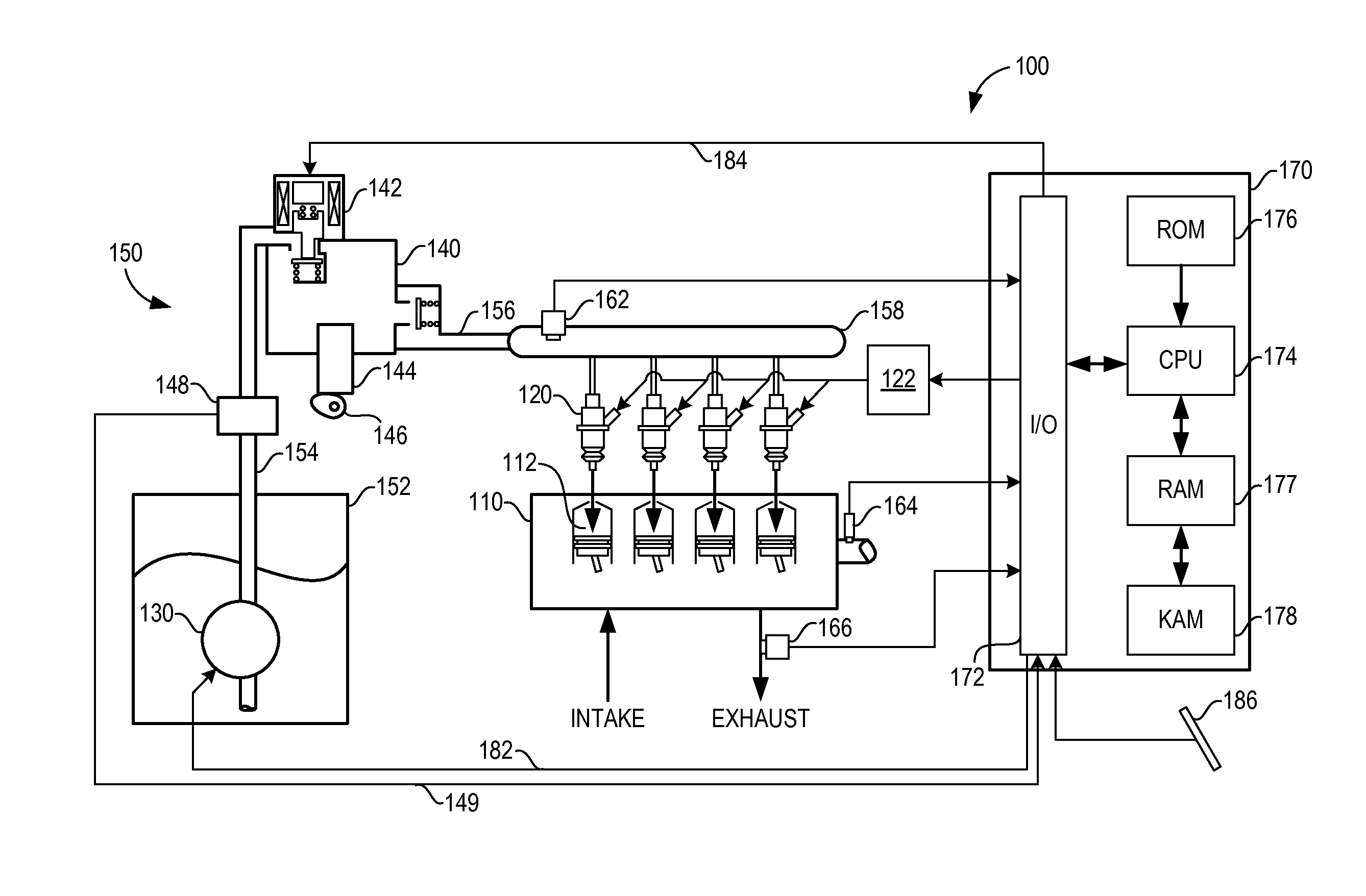

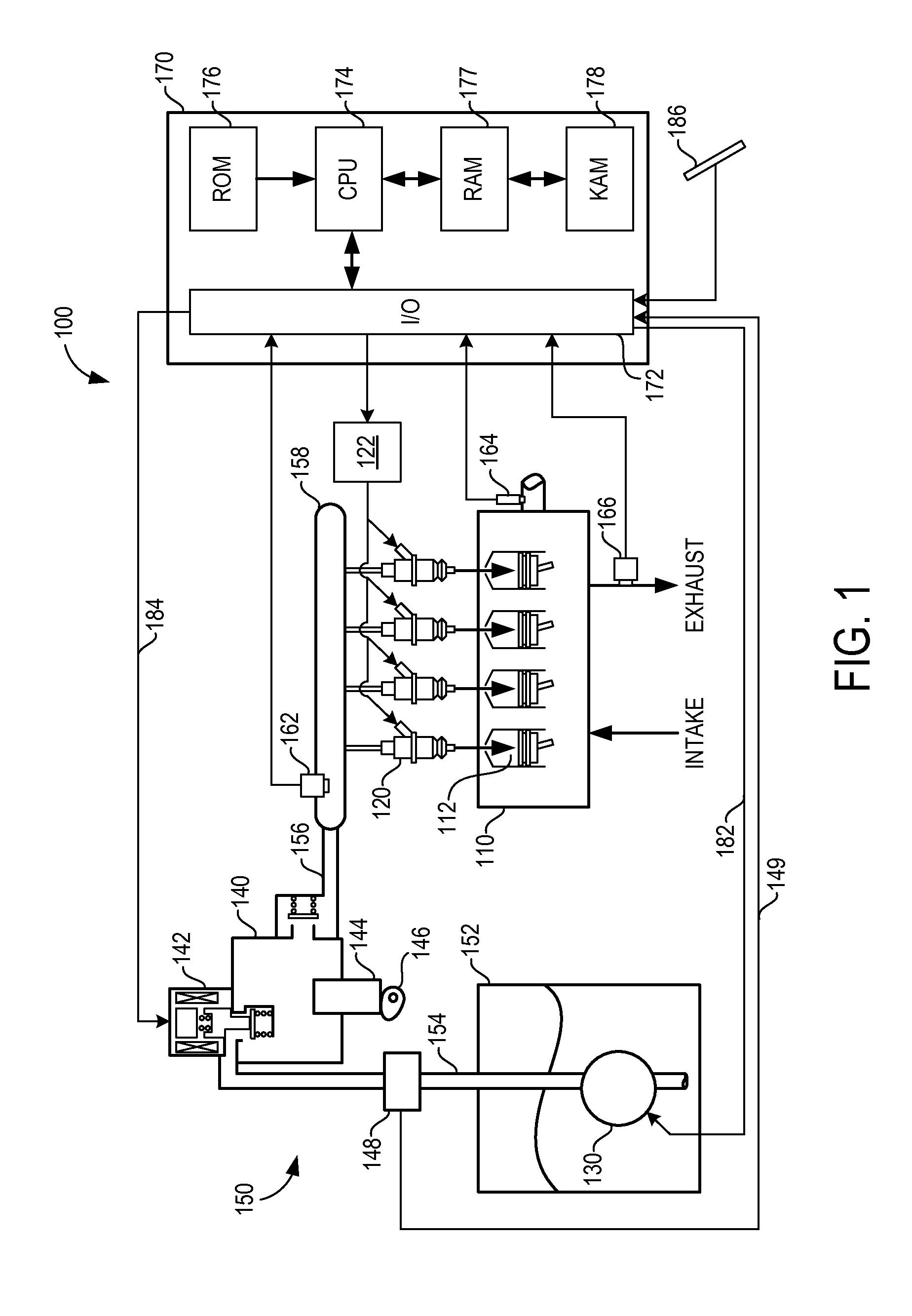

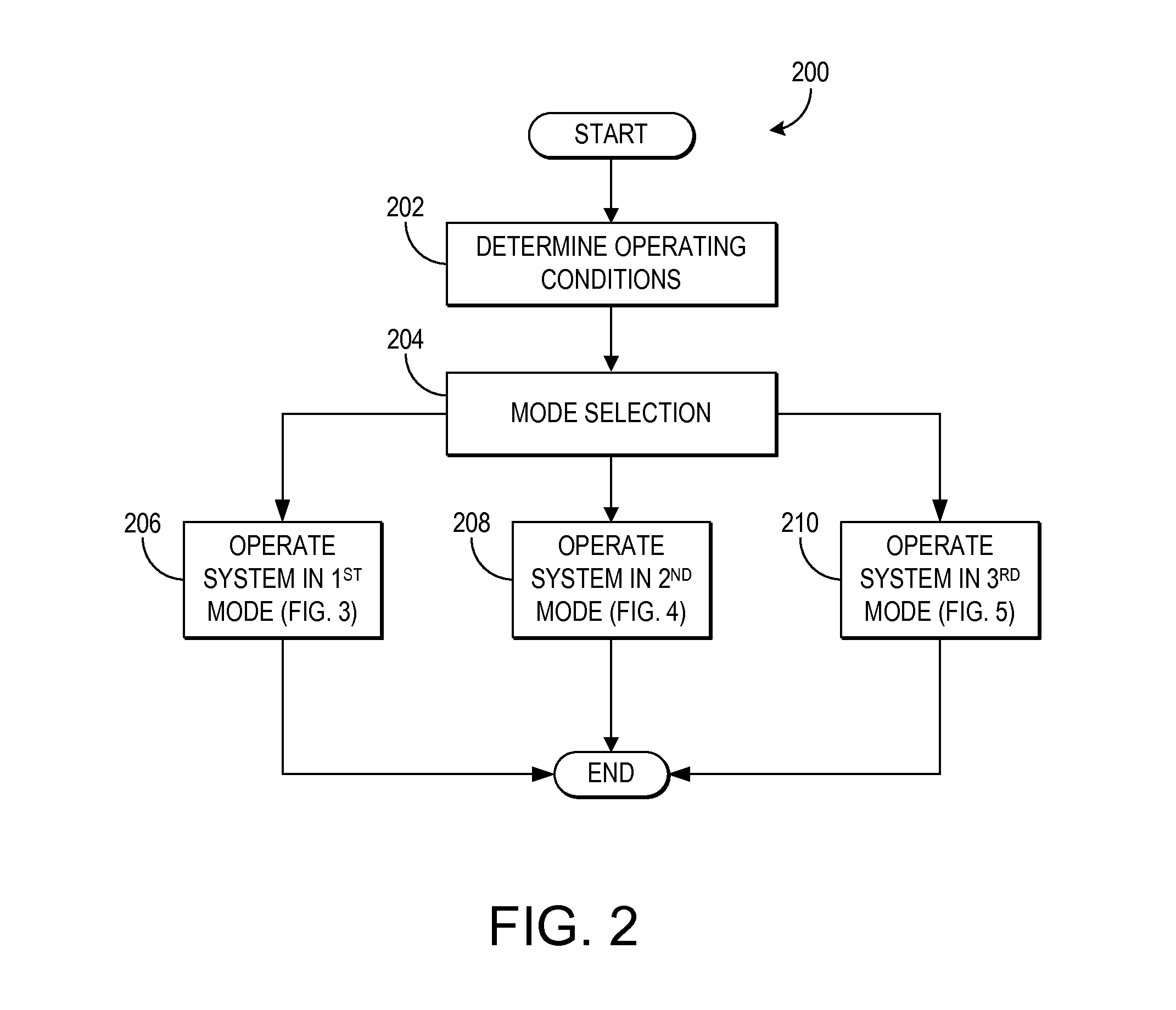

Methods and systems for a fuel system

InactiveUS20140230794A1Avoid vaporizationImprove system efficiencyElectrical controlMachines/enginesCapacitanceOperation mode

Various methods and system are described for a fuel system which includes a fuel composition sensor and a fuel lift pump disposed upstream of the sensor. The system may be operated in each of three different modes of operation. In each of the modes, a fuel lift pump voltage is adjusted responsive to a fuel capacitance output by the sensor, while a variable such as sensor temperature or fuel pump pressure is maintained depending on the mode of operation.

Owner:FORD GLOBAL TECH LLC

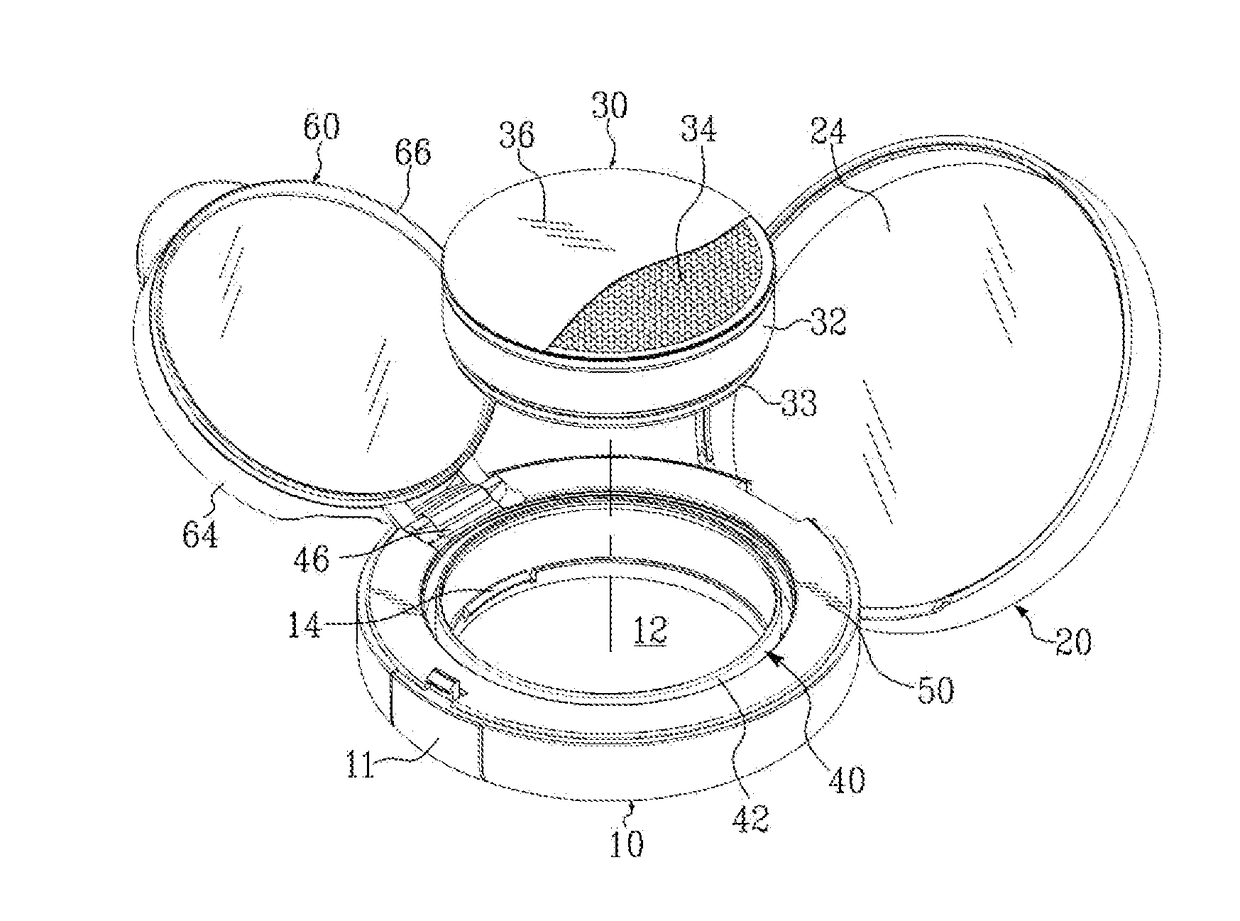

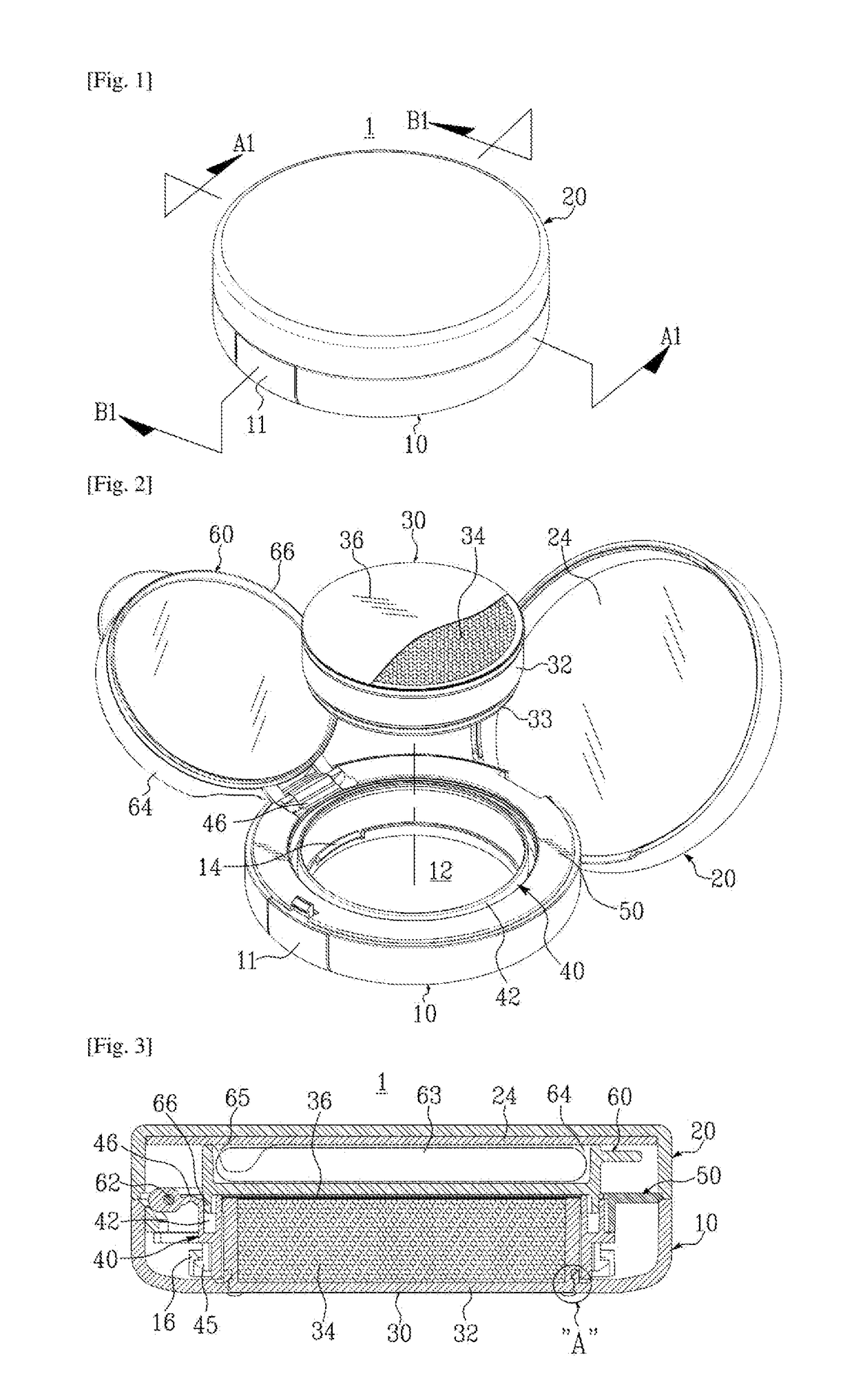

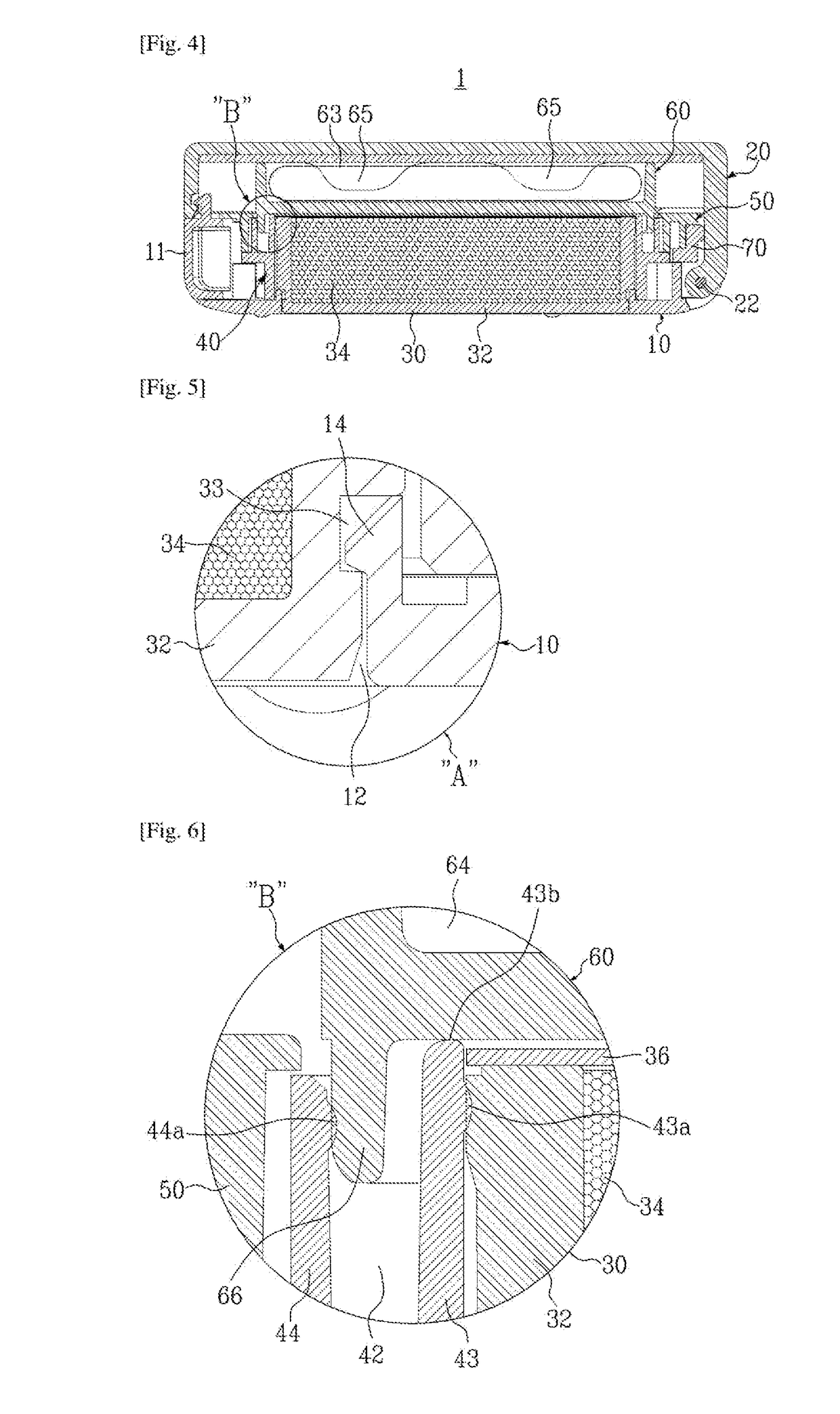

Compact case having airtight structure refillable with capsule cosmetic

InactiveUS20170127799A1Avoid vaporizationPrevent leakageLiquid surface applicatorsFlexible coversBiomedical engineeringClose contact

A compact case having an airtight structure, refillable with a capsule cosmetic includes: a lower case having a hole and an elastic locking member on a bottom; an upper case connected to the lower case by a first hinge pin to be opened and closed; a capsule cosmetic for refilling including a capsule and a liquid cosmetic material impregnated in a porous pad within a capsule, sealed with a sealing member removed upon the first makeup application, and fitted in the hole of the lower case with a bottom of the capsule exposed to the outside and a locking groove on the capsule elastically detachably locked to the locking pins; an internal container having an inner wall and an outer wall for forming a fitting groove and disposed outside the capsule cosmetic; and a lid connected to the internal case by a second hinge pin to be opened and closed, having a puff seat on a to and a fitting rib, which is fitted in the fitting move of the internal container, on a bottom, in which the capsule cosmetic and the lid are sealed by being elastically in close contact with sealing projections, respectively, on the inner wall and the outer wall of the internal container. Therefore, it is very simple to replace a capsule cosmetic in the lower case for refilling and the cosmetic material is not vaporized by the sealing structure, so it is possible to use the cosmetic, maintaining the quality of the cosmetic for a long period of time.

Owner:CTK

Method for producing silicon tetrafluoride from uranium oxyfluoride

InactiveUS6033642AReduced thermodynamic stabilityAvoid vaporizationUranium dioxideHalogenated silanesSilicon tetrafluorideSilicon dioxide

A method for producing silicon tetrafluoride includes combining uranium oxyfluoride and silicon dioxide; heating the combination below the melting point of the uranium oxyfluoride to sufficiently react the uranium oxyfluoride and the silicon dioxide to produce non-radioactive silicon tetrafluoride and an oxide of uranium; and removing the silicon tetrafluoride.

Owner:INT ISOTOPES

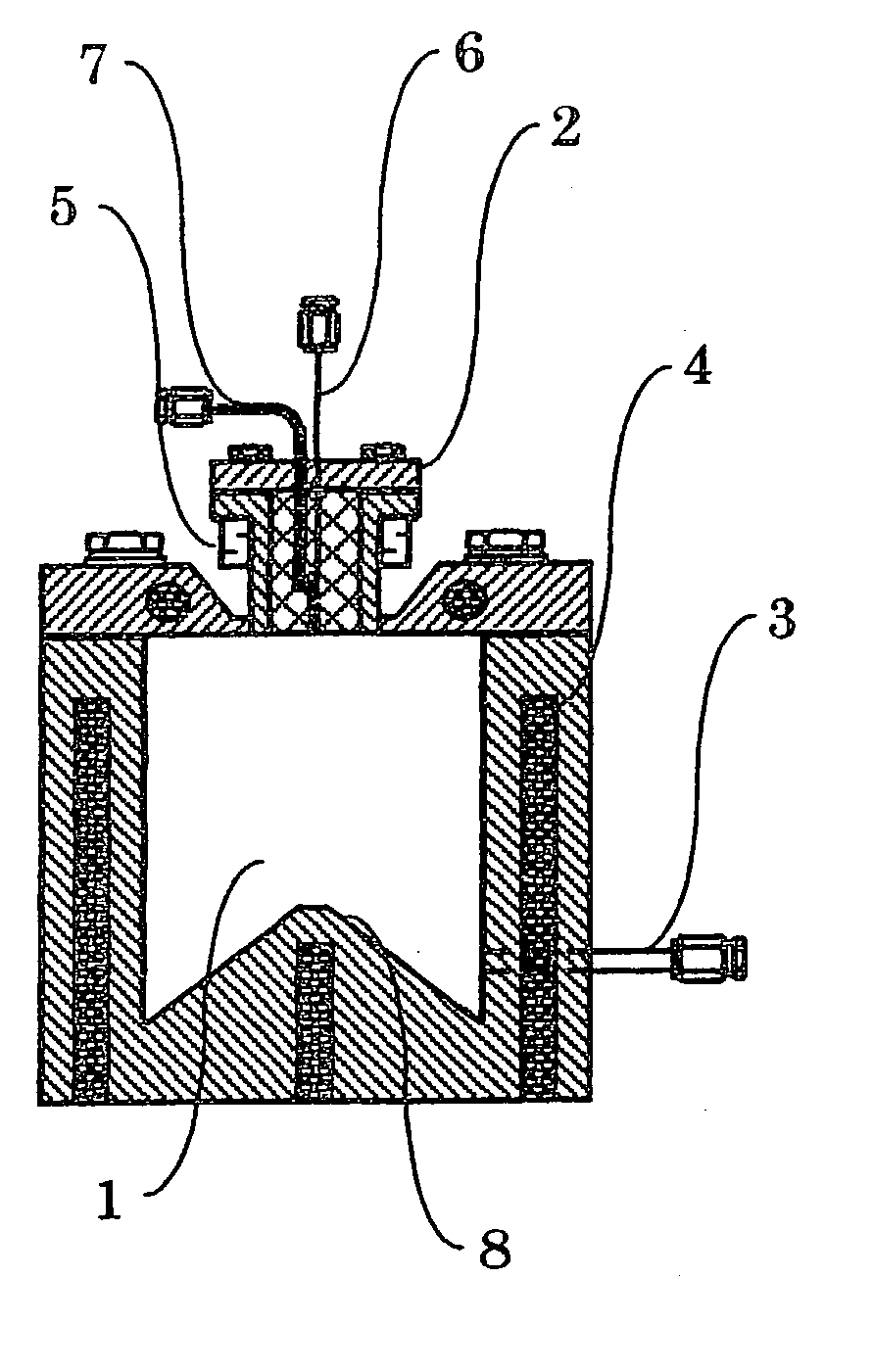

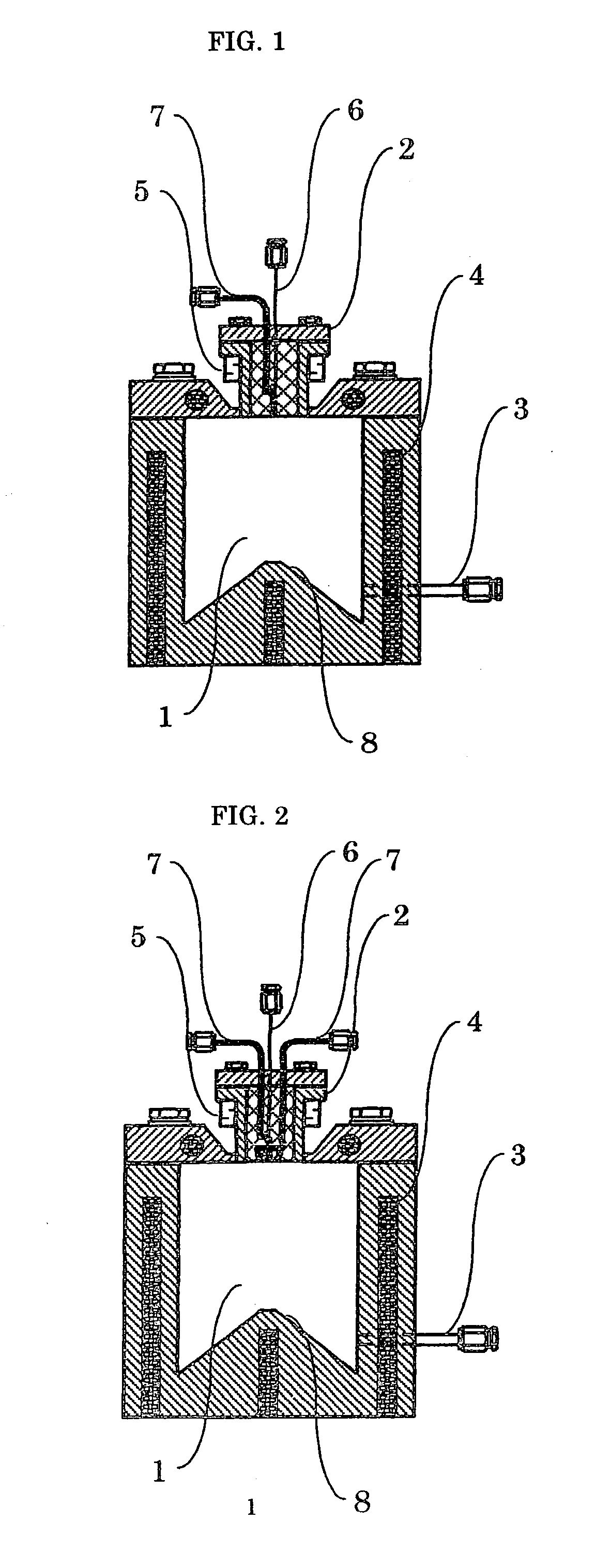

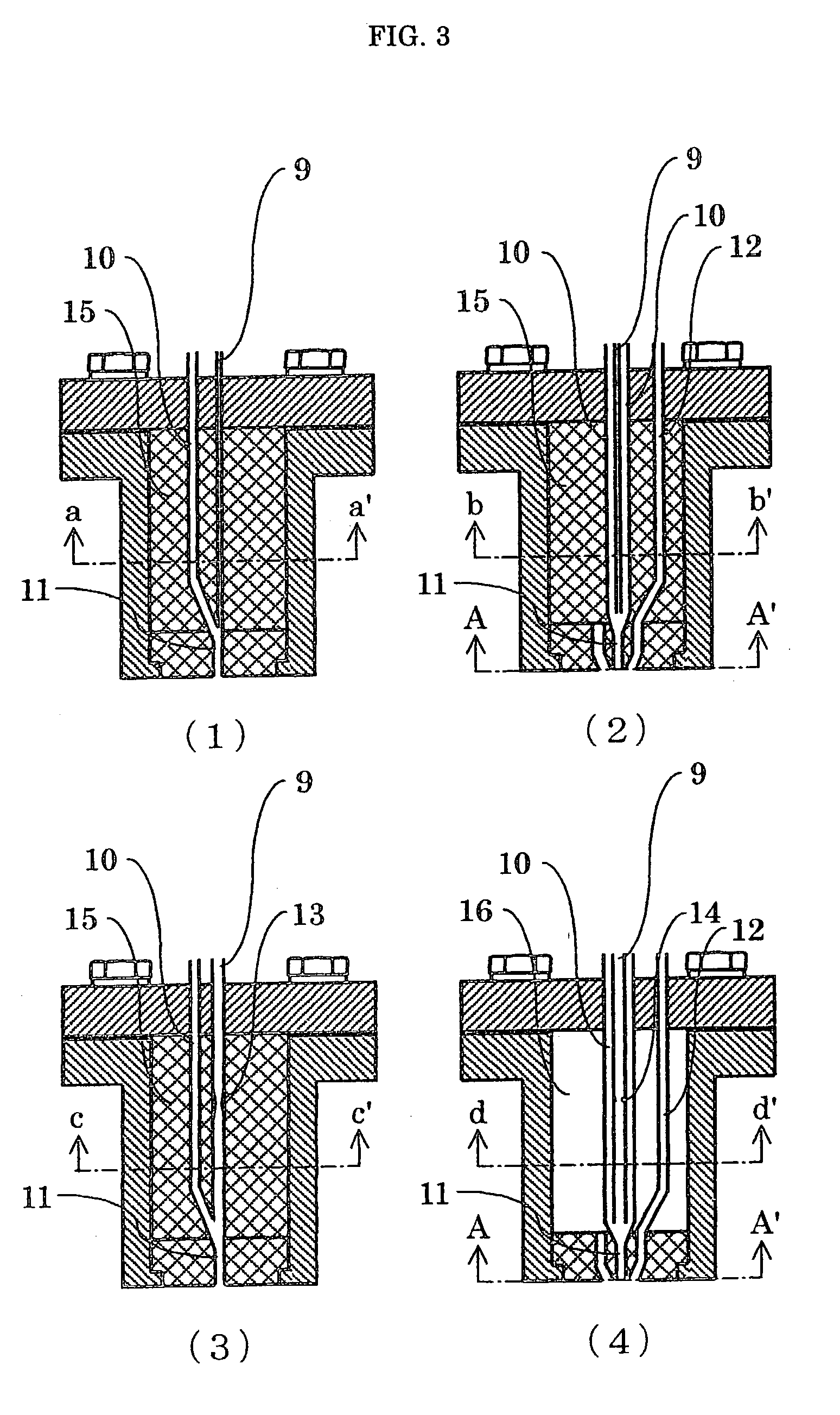

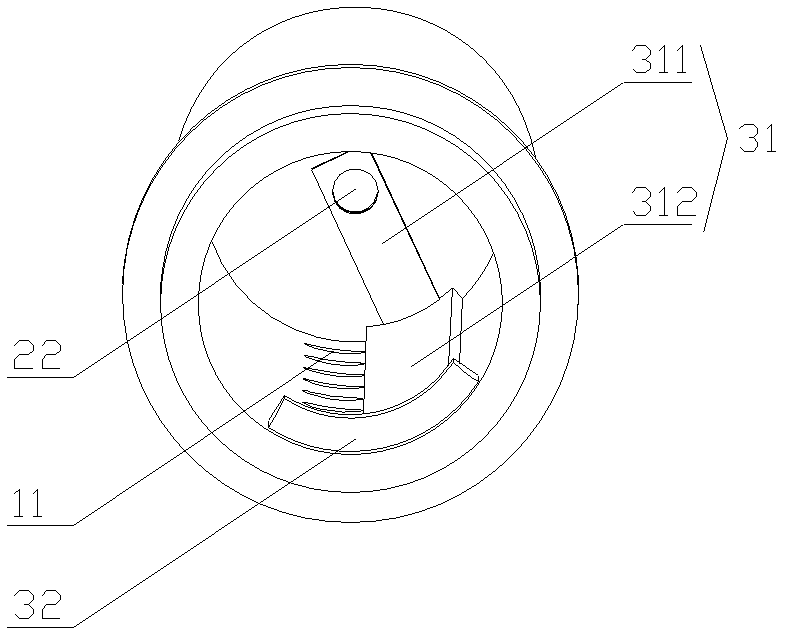

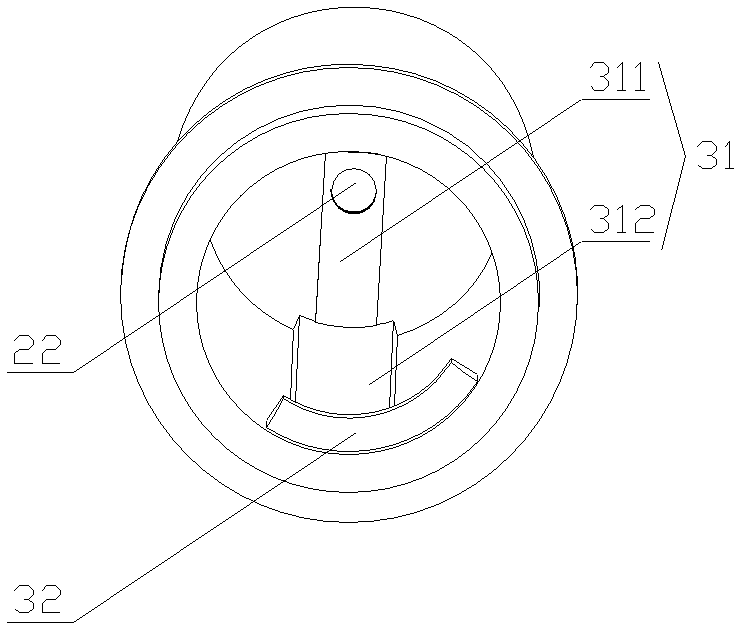

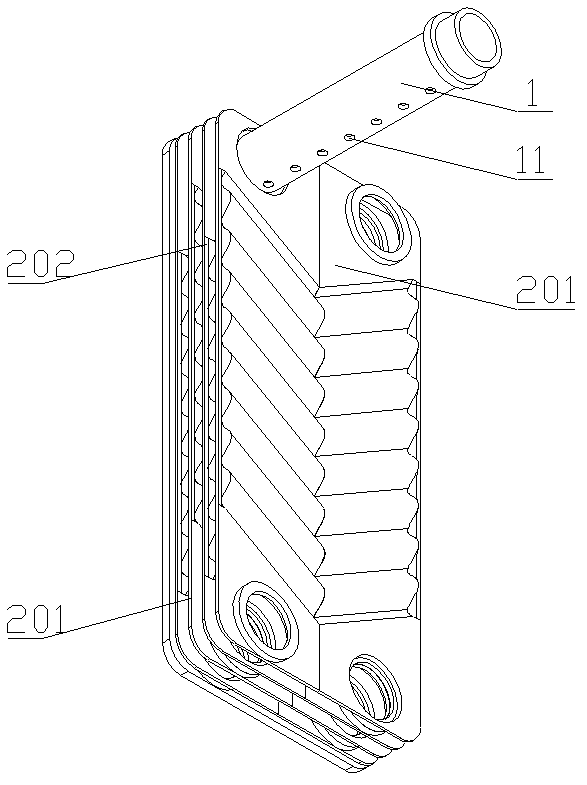

Plate heat exchanger and fluid distributor thereof and control method for plate heat exchanger

ActiveCN103363835AImprove heat transfer effectImprove stabilityHeat exchanger casingsEngineeringThermal stability

The invention discloses a fluid distributor for a plate heat exchanger. A distribution hole (11) for a refrigerant to flow into a refrigerant channel (202) is arranged at the position of the plate heat exchanger corresponding to the refrigerant channel (202) of the plate heat exchanger, and the fluid distributor comprises a driving component (2) and an execution component (3) for adjusting the size of an opening of the distribution hole (11) under the driving of the driving component (2). The plate heat exchanger can adjust pressure and temperature of the refrigerant, the refrigerant evenly enters a heat exchange channel, and heat exchange stability of the plate heat exchanger is improved. The invention further discloses the plate heat exchanger comprising the fluid distributor and a control method for the plate heat exchanger. The plate heat exchanger comprising the fluid distributor and the control method for the plate heat exchanger have identical effect.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

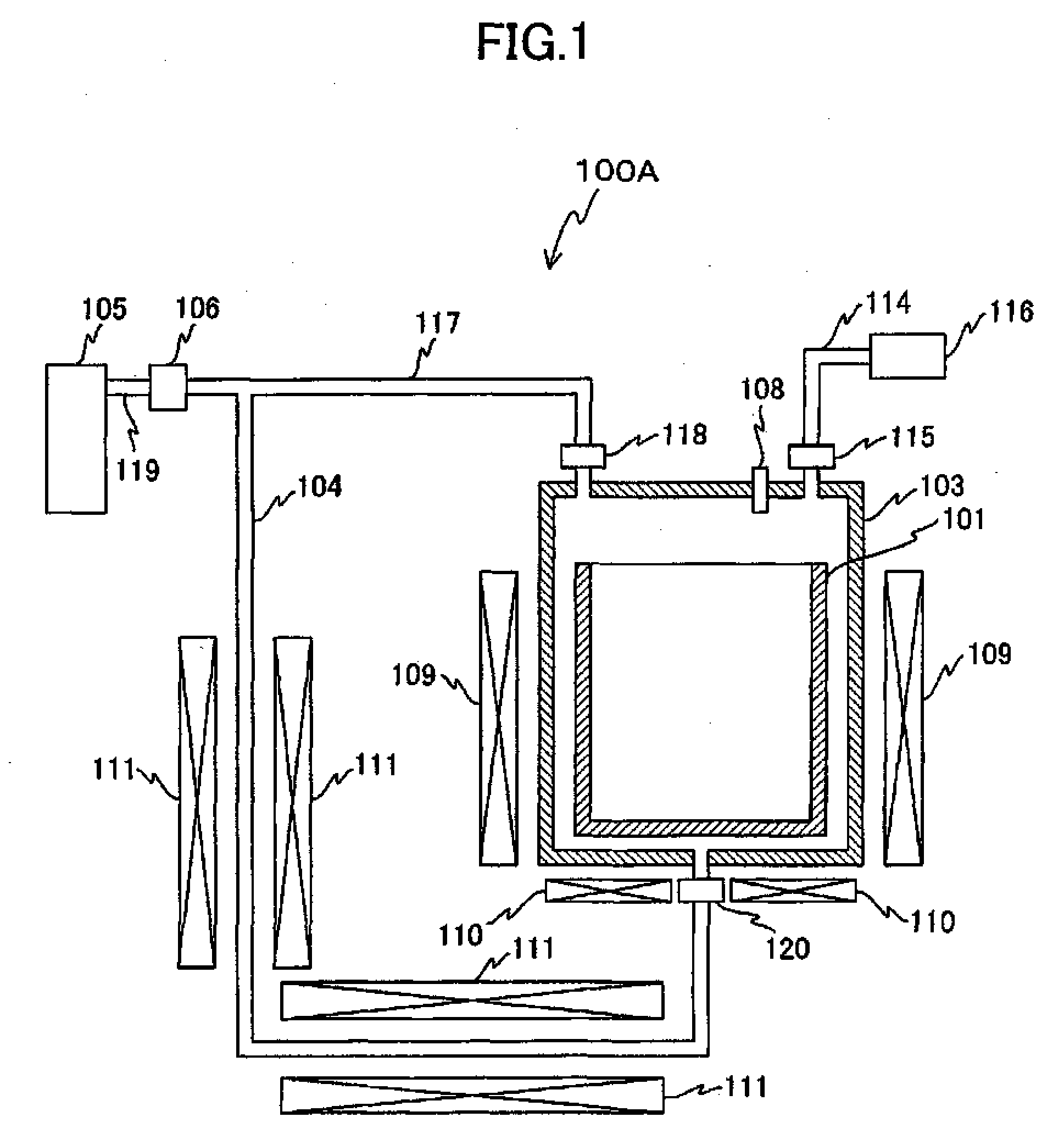

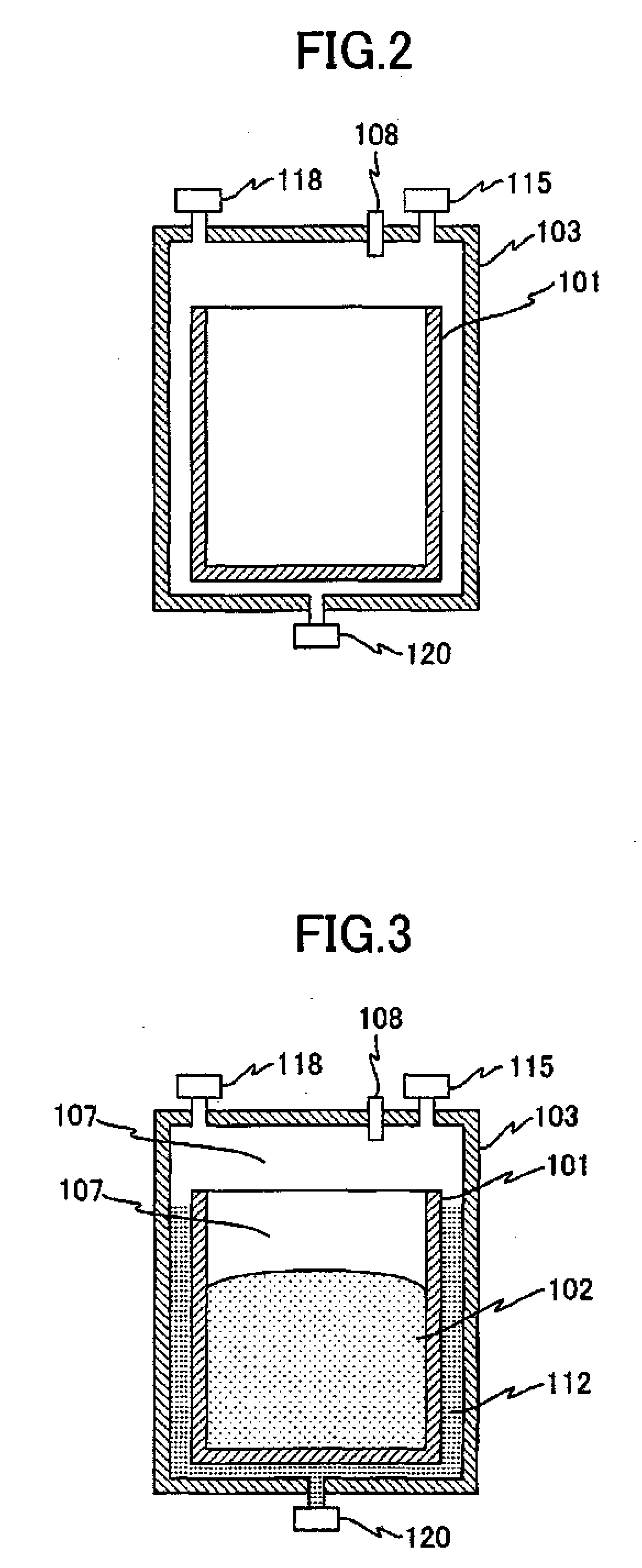

Method of producing group iii nitride crystal, apparatus for producing group iii nitride crystal, and group iii nitride crystal

InactiveUS20090249997A1Avoid vaporizationQuality improvementAfter-treatment apparatusPolycrystalline material growthNitrogenNitride

In a method of producing a group III nitride crystal in which a melt holding vessel where a melt containing a group III metal and flux is held is accommodated in a reaction vessel and a group III nitride crystal is produced as a substance containing nitrogen is supplied from an outside to the reaction vessel through a pipe, the method includes a step of forming an accumulated part of a liquid in the pipe to thereby temporarily close the pipe before growing the group III nitride crystal in the melt holding vessel.

Owner:RICOH KK

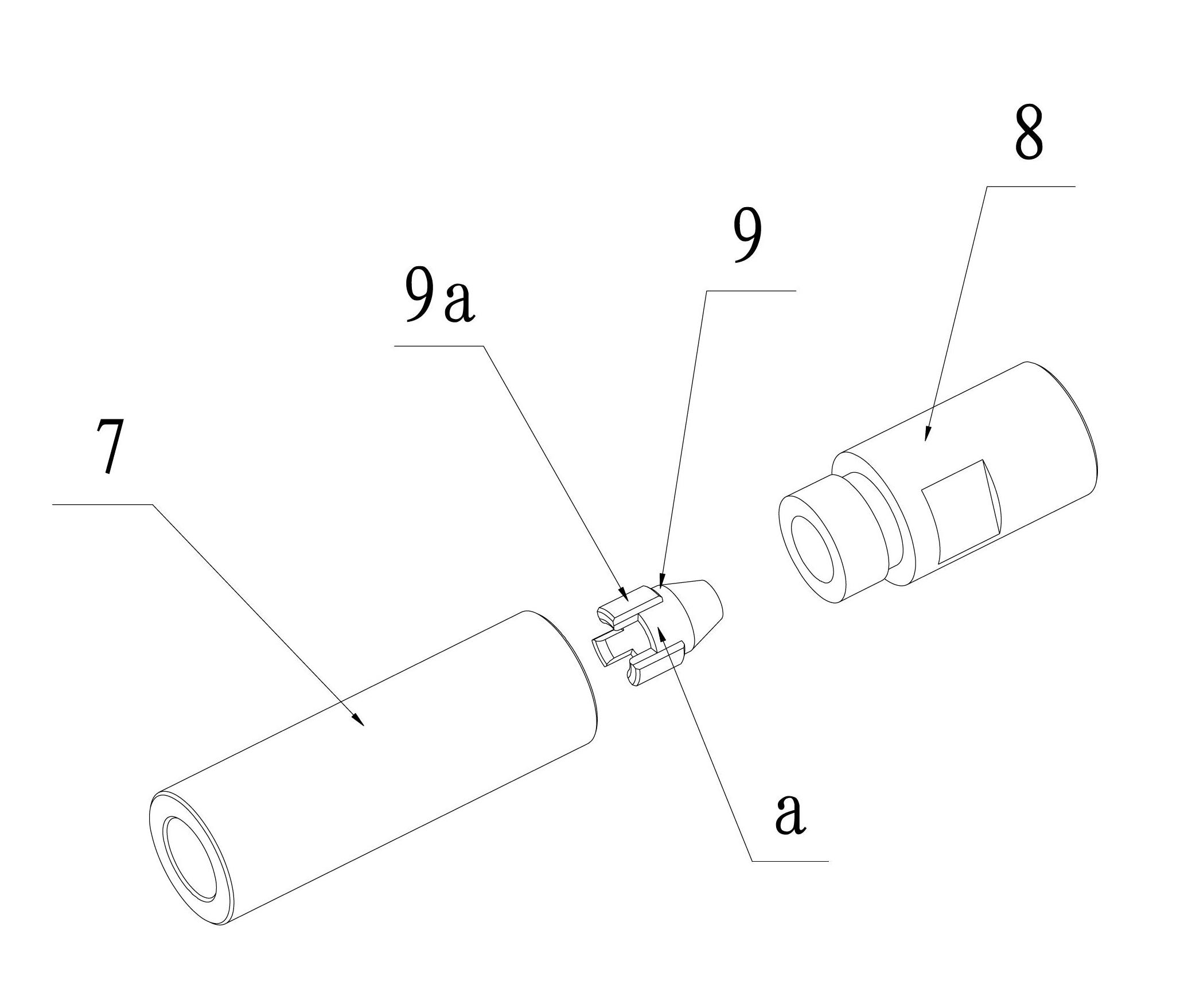

Throttling device for air conditioner check valve

InactiveCN102635986AImprove cooling effectReduce power consumptionCheck valvesFluid circulation arrangementFour-way valveLiquid state

The invention discloses a throttling device for an air conditioner check valve, which comprises a compressor, a four-way valve, a condenser and an evaporator, wherein the compressor, the four-way valve, the condenser and the evaporator are communicated circularly by pipelines, and a conveying pipeline for connecting the condenser and the evaporator is provided with a refrigeration throttling device close to the evaporator. The throttling device is characterized in that the refrigeration throttling device is one or more parallel check valve devices with a throttling device, and the conduction direction of the throttling device with the throttling function is appointed to the condenser. Therefore, the throttling device with the throttling function has the function and the advantage of a nozzle throttle and the check valve, so that the cooling capability of the condenser is improved when the air conditioner is under the refrigeration working state, the refrigeration amount of the air conditioner is increased, and the power consumption of the air conditioner is lowered; when the air conditioner is under the heating working state, high-pressure liquid refrigerant output by the evaporator is prevented from quickly vaporizing so as to lower heating amount to improve the heating capability of the air conditioner; and the air conditioner is guaranteed to avoiding two-phase flow noise in the refrigerating and heating process.

Owner:苏州恒兆空调节能科技有限公司

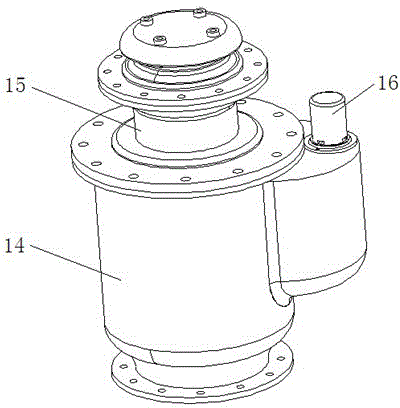

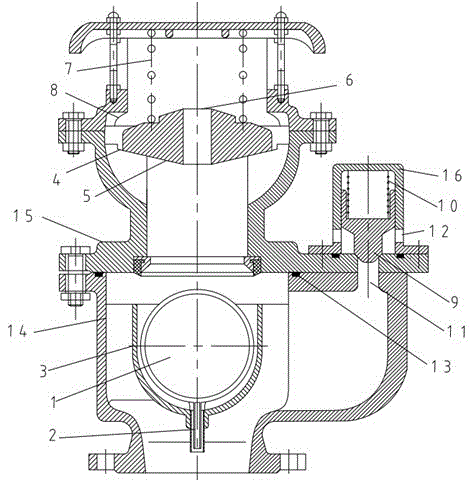

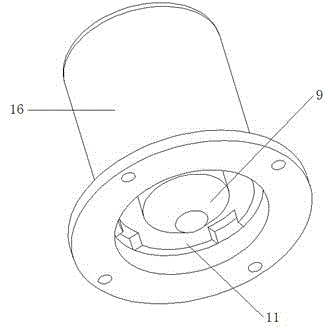

Pressure limiting type liquid column separation preventing air valve

InactiveCN104373742AImprove efficiencyPrevent pump water hammerEqualizing valvesPipe elementsEngineeringHigh pressure

Owner:WUHAN UNIV

Multifunctional cold-circulating bundling microwave treatment probe

ActiveCN102058428ALarge ablation volumeImprove the effect of treatmentSurgical needlesMedical devicesTemperature measurementTreatment effect

The invention discloses a multifunctional cold-circulating bundling microwave treatment probe comprising an operating handle and a bundle, wherein the bundle consists of two ore more than two liquid medium strengthened hollow cooling microwave probes; the center of the bundle is provided with a multifunctional passage used for infusing a liquid medium or embedding a solid medium into a target tissue or carrying out temperature measurement or tissue biopsy; and the multifunctional passage and the bundle are fixed on the operating handle. The invention can outstandingly enlarge the melting volume of a microwave tissue and has a function of enhancing the treatment effect by infusing the liquid medium or embedding the solid medium into the target tissue and multiple functions, i.e. the biopsy, the temperature measurement, and the like.

Owner:苗毅

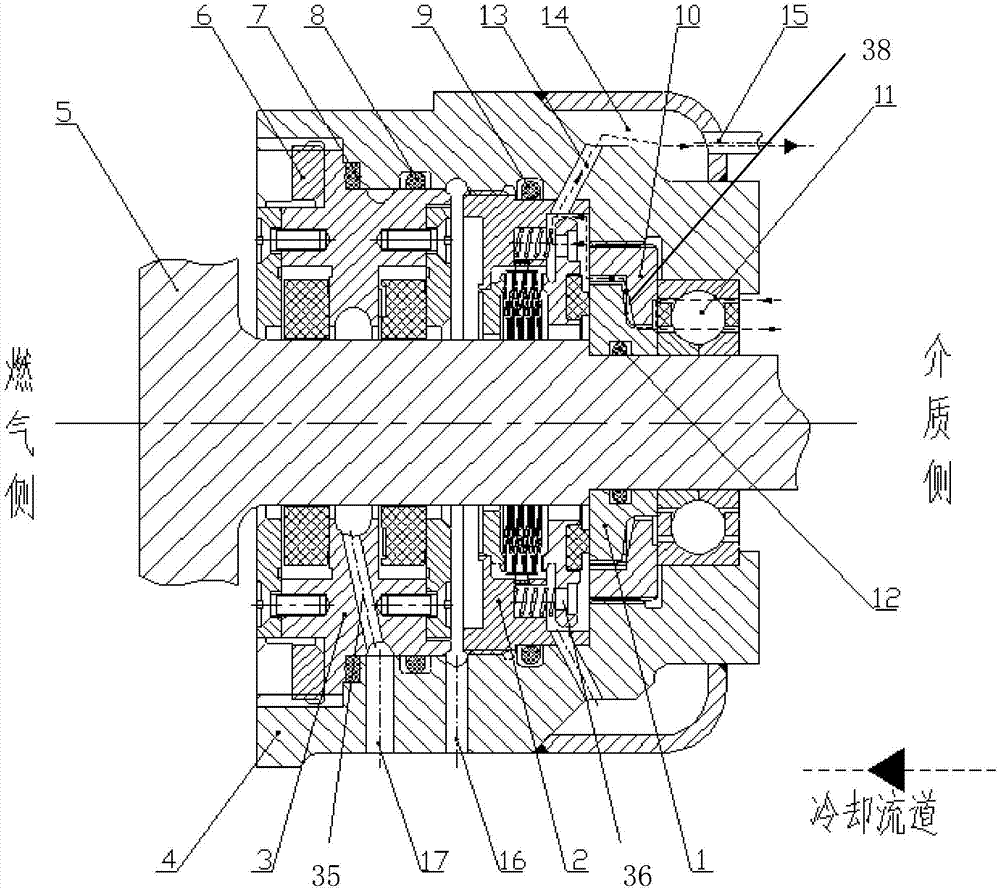

Combined mechanical seal device

ActiveCN107387261AAvoid meetingSimple systemPump componentsNuclear energy generationRubber ringEngineering

The invention particularly relates to a combined mechanical seal device which comprises a moving ring, a static ring assembly, a static ring housing, a floating ring assembly and an O-shaped rubber ring. The static ring assembly is arranged in the static ring housing and comprises an end face block assembly, a rotation-preventing pin, a spring and a damping belt. The end face block assembly comprises a static ring, a static ring seat, a film box assembly and a rear ring which are arranged in sequence. The damping belt is located in an annular groove of the inner surface of the static ring housing. The floating ring assembly comprises a floating ring, a cover plate and a floating ring housing, wherein the floating ring penetrates through a rotor to be arranged in the floating ring housing, and a cover plate penetrates through a rotor to be fixedly arranged on two sides of the floating ring housing respectively. A cooling backflow channel comprises a bearing axial gap, a gap between the moving ring and a pressing ring, a static ring seat balance hole gap, a radial gap between a static ring seat and the static ring housing, a backflow channel I, an accumulated liquid cavity and a backflow channel II which are communicated in sequence. The combined mechanical seal device achieves long-service-life, low-friction and zero-leakage work of a mechanical seal under the working conditions of high temperature and high pressure.

Owner:XIAN AEROSPACE PROPULSION INST

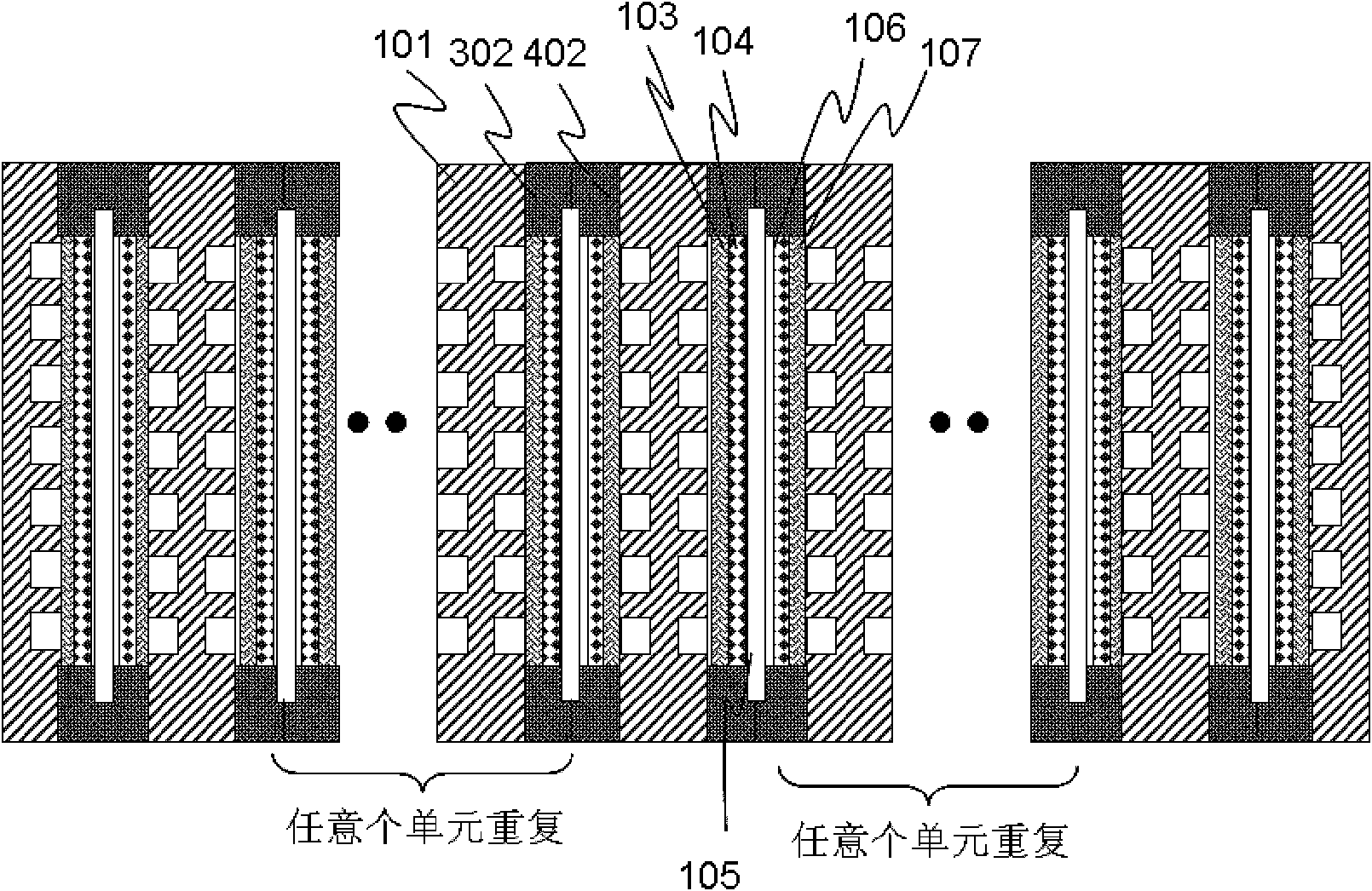

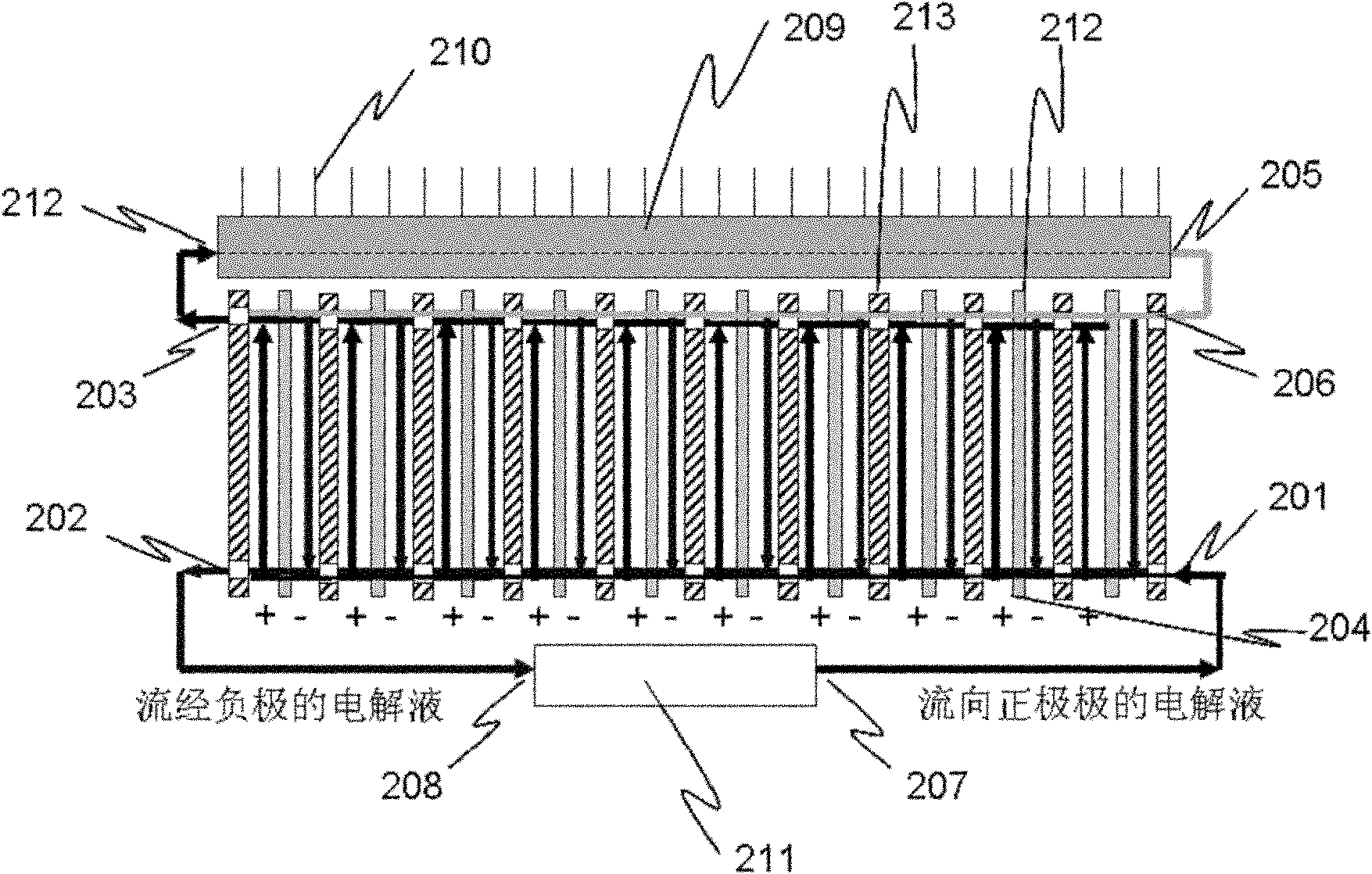

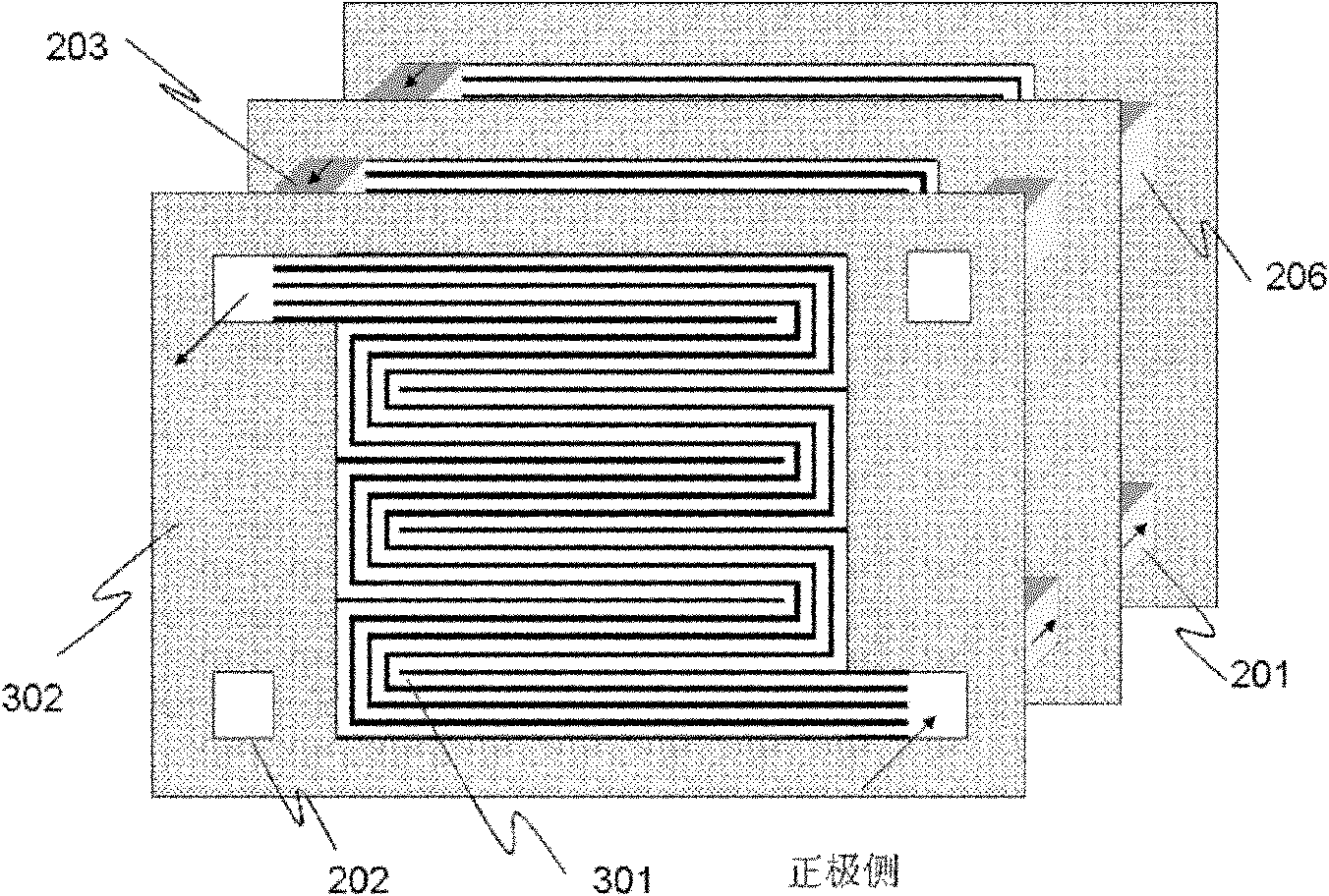

High-power lithium ion battery system with laminated battery structure

InactiveCN102064347AAvoid vaporizationControl temperature riseFinal product manufactureCell electrodesElectrical batteryEngineering

The invention relates to a lithium ion battery, and aims at providing a high-power lithium ion battery system with a laminated battery structure. The battery system comprises at least two single battery structures, adjacent single battery structures are separated by baffle plates, the laminated battery structure is formed by repeated arrangement of the single battery structures; electrolyte anodeand cathode outlet and inlet channels are respectively arranged on the baffle plates on two ends, two sides of the baffle plates arranged at the middle are both provided with an electrolyte flow path, and the flow paths arranged at the two sides are not communicated; and a piezoelectric pump and a radiating fin are respectively arranged between the electrolyte cathode outlet channel and electrolyte anode inlet channel and between the electrolyte anode outlet channel and the electrolyte cathode inlet channel, or the positions of the piezoelectric pump and the radiating fin are exchanged. By virtue of the battery system, the temperature rise of the lithium ion battery can be effectively suppressed during heavy current charging and discharging, the vaporization of an electrolyte is avoided, the explosion of the lithium ion battery duo to the rise of an internal pressure is effectively prevented, and the use safety of the lithium ion battery is improved.

Owner:ZHEJIANG UNIV

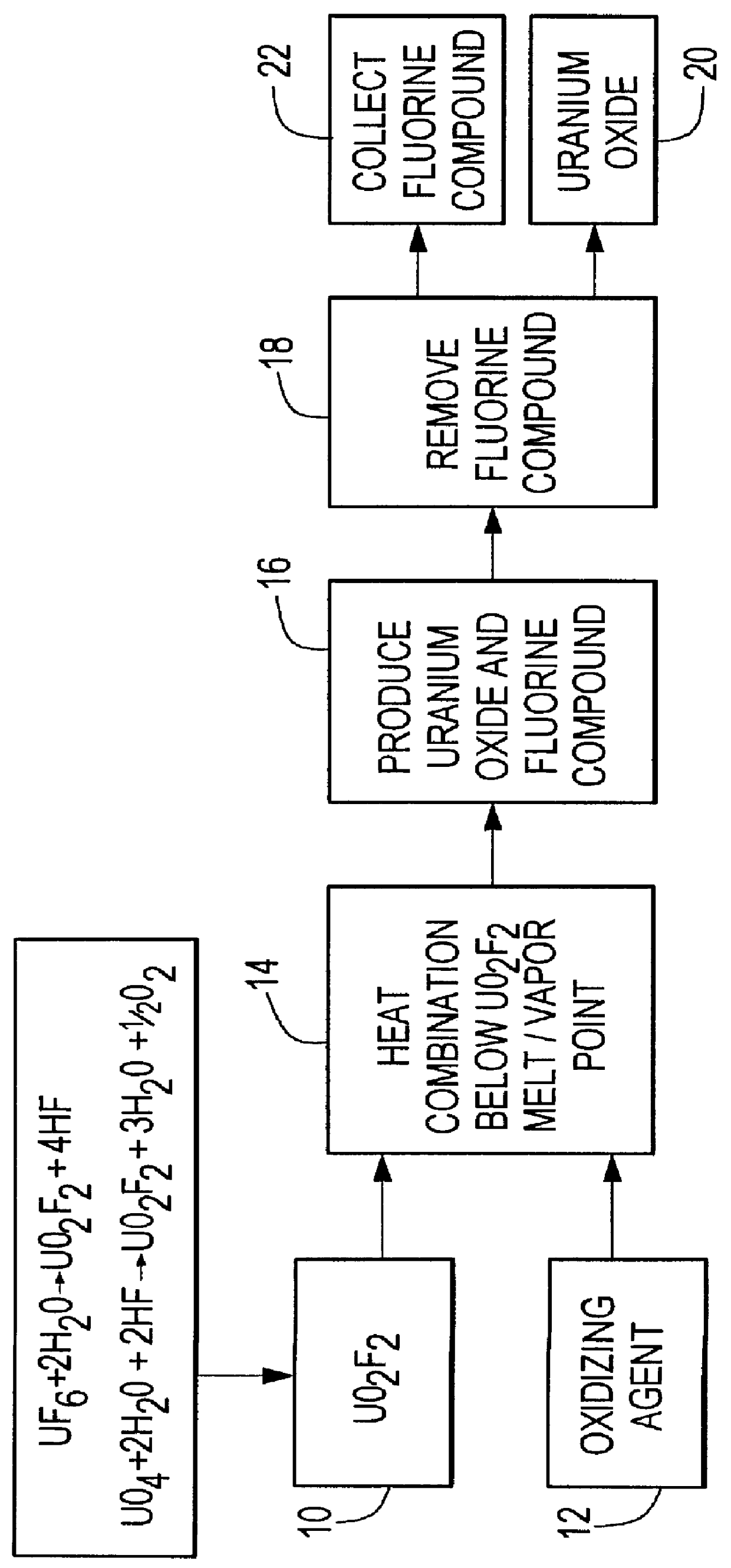

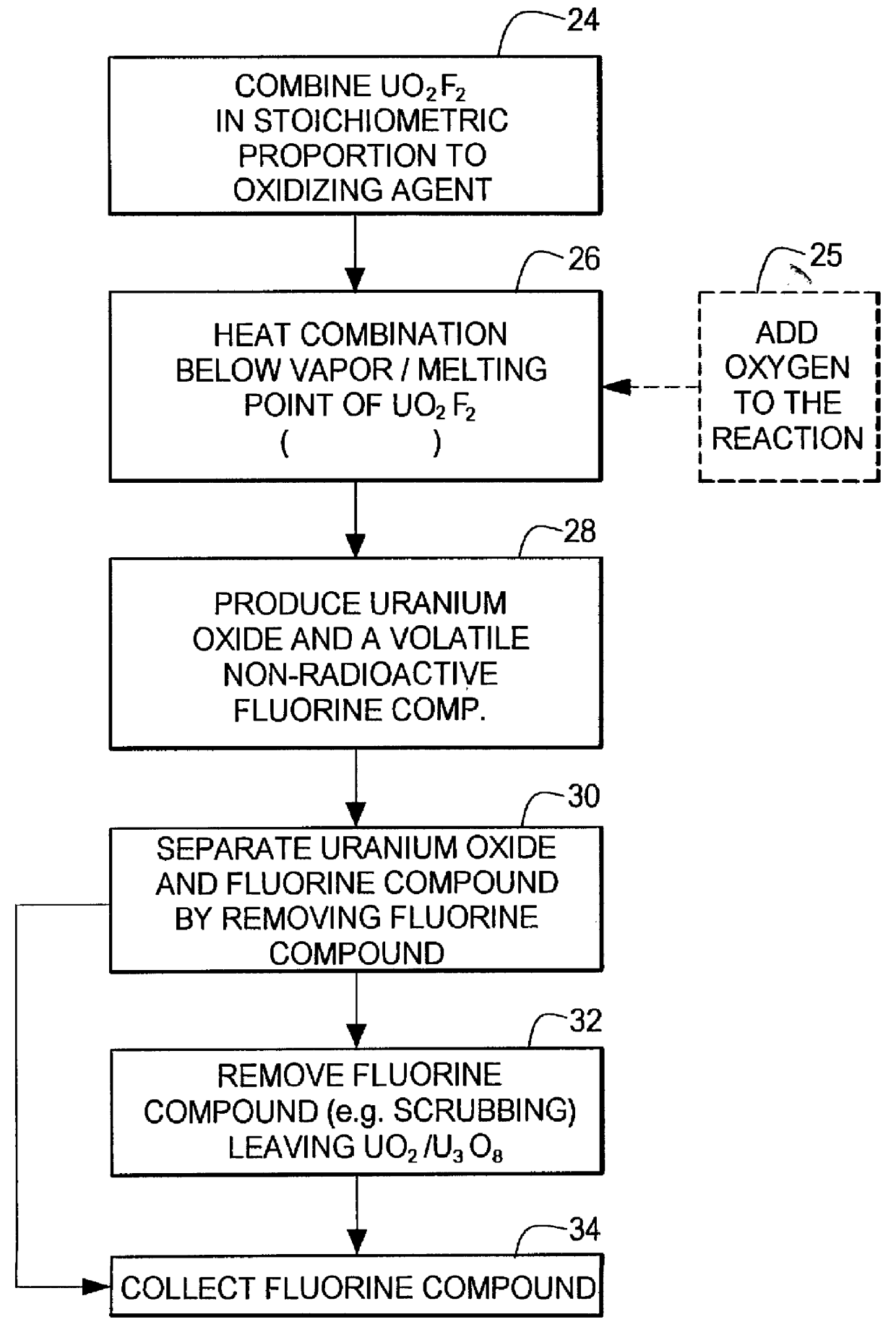

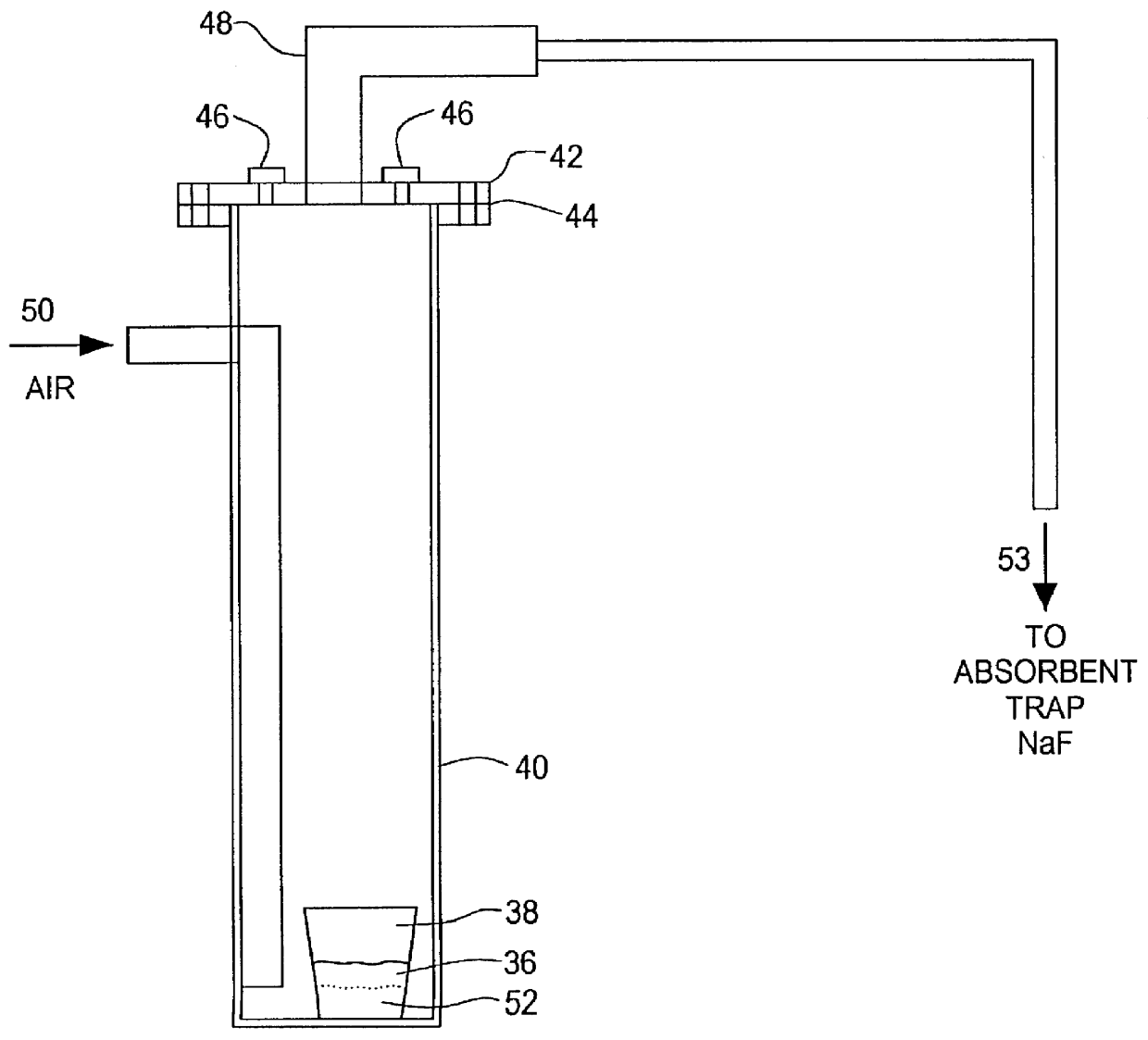

Method for producing uranium oxide from uranium oxyfluoride

InactiveUS6096281AReduced thermodynamic stabilityAvoid vaporizationPhosphorus halides/oxyhalidesFluoride preparationUranium oxideOxidizing agent

A method for producing uranium oxide includes combining uranium oxyfluoride and a solid oxidizing agent having a lower thermodynamic stability than the uranium oxide after "oxide"; heating the combination below the vapor point of the uranium oxyfluoride to sufficiently react the uranium oxyfluoride and the oxidizing agent to produce uranium oxide and a non-radioactive fluorine compound; and removing the fluorine compound after "compound".

Owner:INT ISOTOPES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com