Pressure limiting type liquid column separation preventing air valve

A column separation and air valve technology, applied in the direction of balance valve, valve device, safety valve, etc., can solve the problems of increasing water pressure in the pipe, high water pressure of high-pressure gas in the pipeline, and inability to discharge quickly, so as to prevent water hammer when starting the pump. , The effect of reducing the pressure in the pipe and preventing the pipe from bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

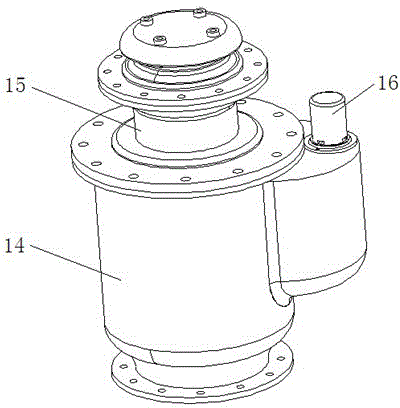

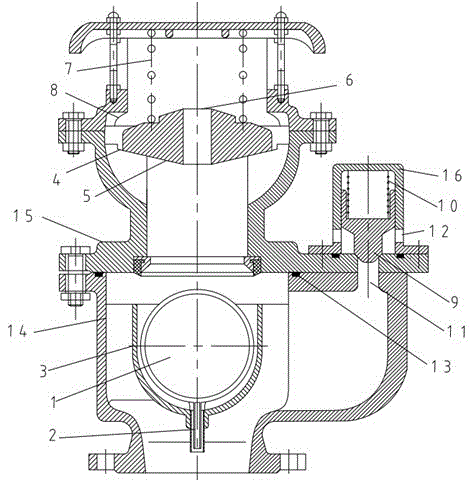

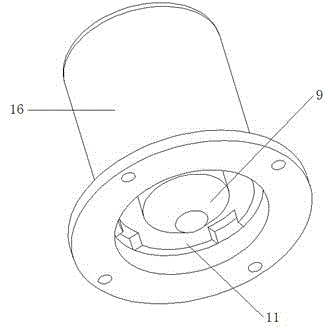

[0017] The present invention will be further explained below in conjunction with the drawings: Figure 1-4 As shown, a pressure-limiting anti-liquid column separation air valve includes a metal ball 1 that can move up and down by liquid buoyancy in the lower chamber, and the metal ball is controlled by controlling the movement of a shaft 2 connected to the lower end of the metal ball 1 The guide plate 3 in the moving direction has a large-diameter air inlet channel above the metal ball 1; the support plate 4 in the upper chamber supports the floating plate 5, wherein the center of the floating plate 5 is provided with an exhaust hole 6, which There is a pressure limiting spring 7 and a limiting valve body 8 on the upper side; a conical valve head 9 is provided on one side of the drain chamber, a pressure limiting spring 10 is provided on the upper side of the conical valve head 9 and a flow hole 11 is provided below, and a drain chamber The valve body is provided with an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com