Patents

Literature

91results about How to "Avoid pipe burst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

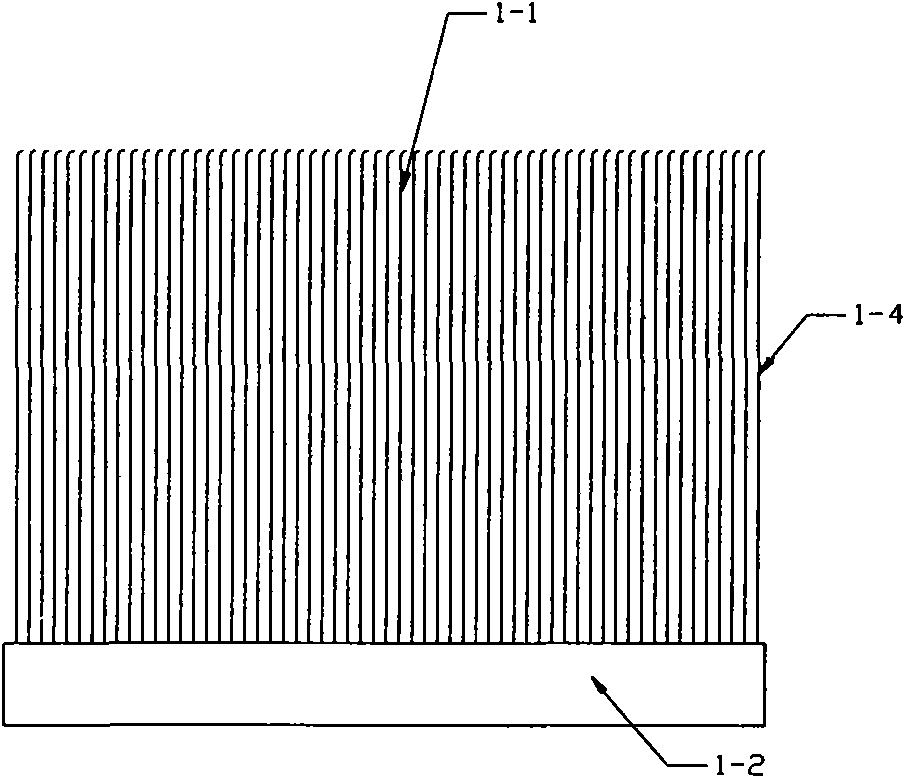

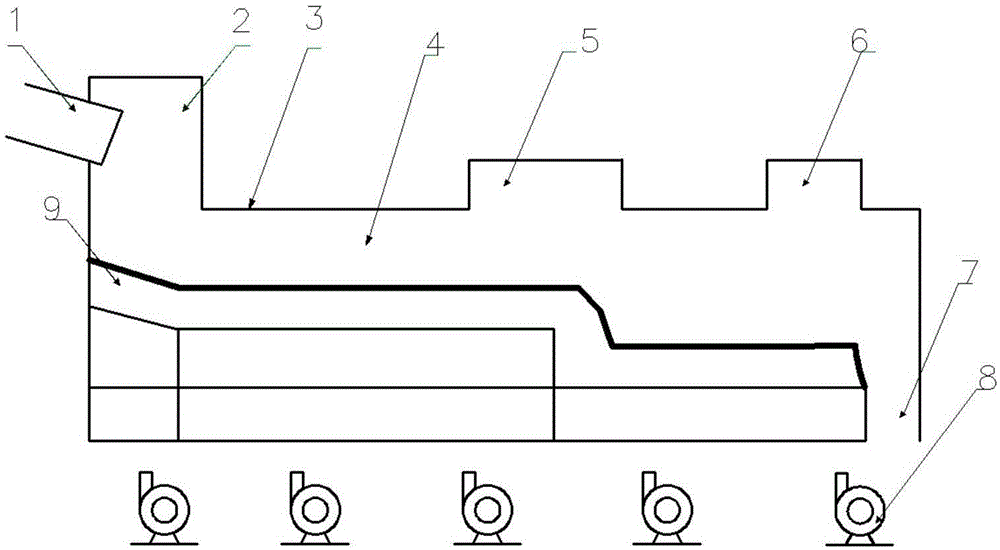

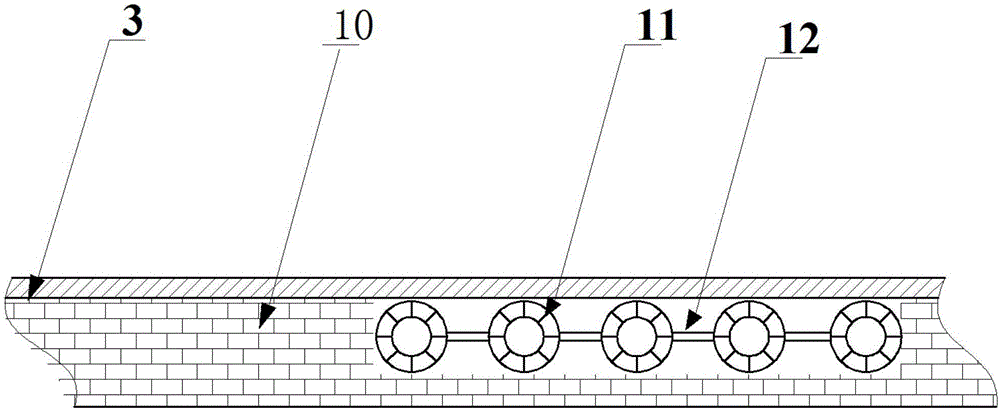

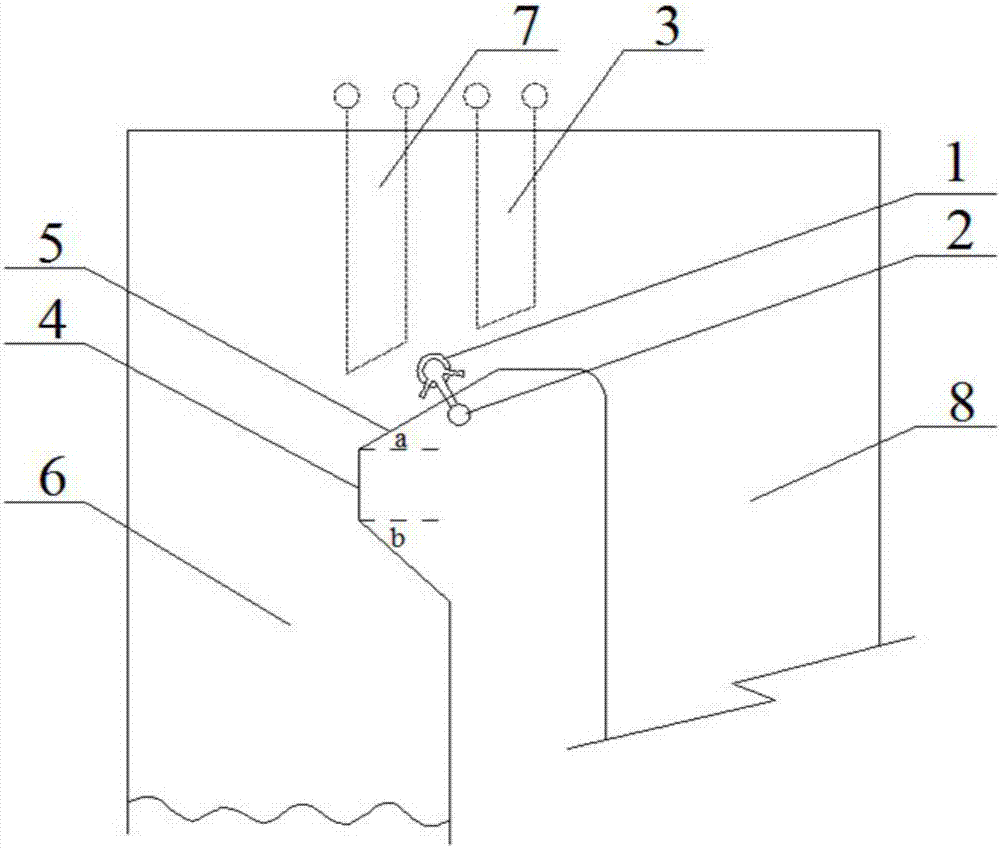

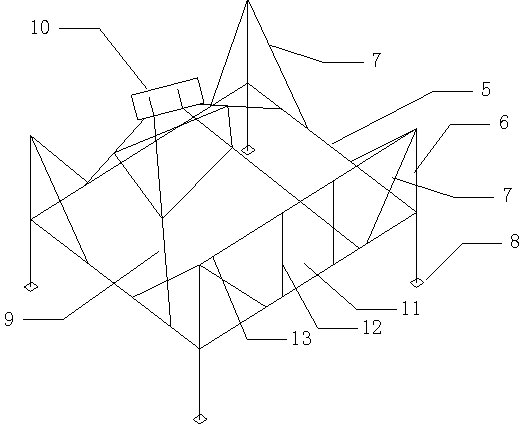

Oil and gas pipeline intelligent internal detection device based on multi-module combined location

ActiveCN103470959AReduce resistancePrevent pulling outPipeline systemsSpeed control systemElectromagnetic pulse

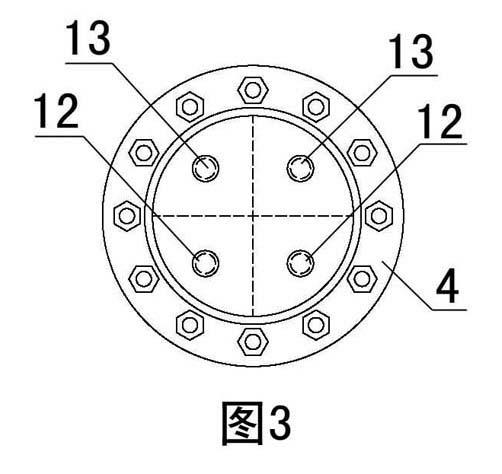

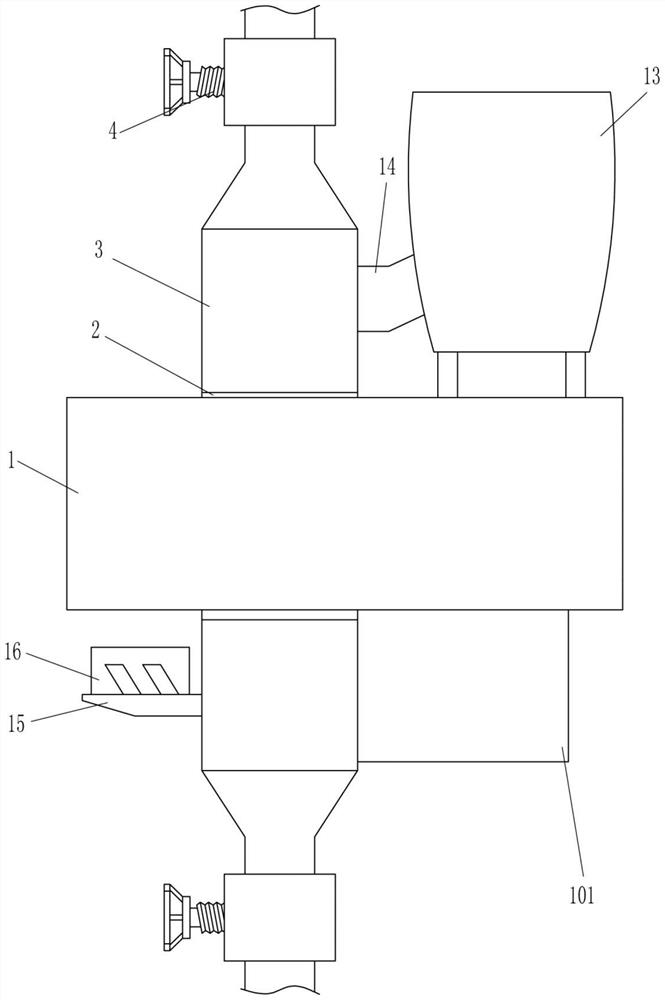

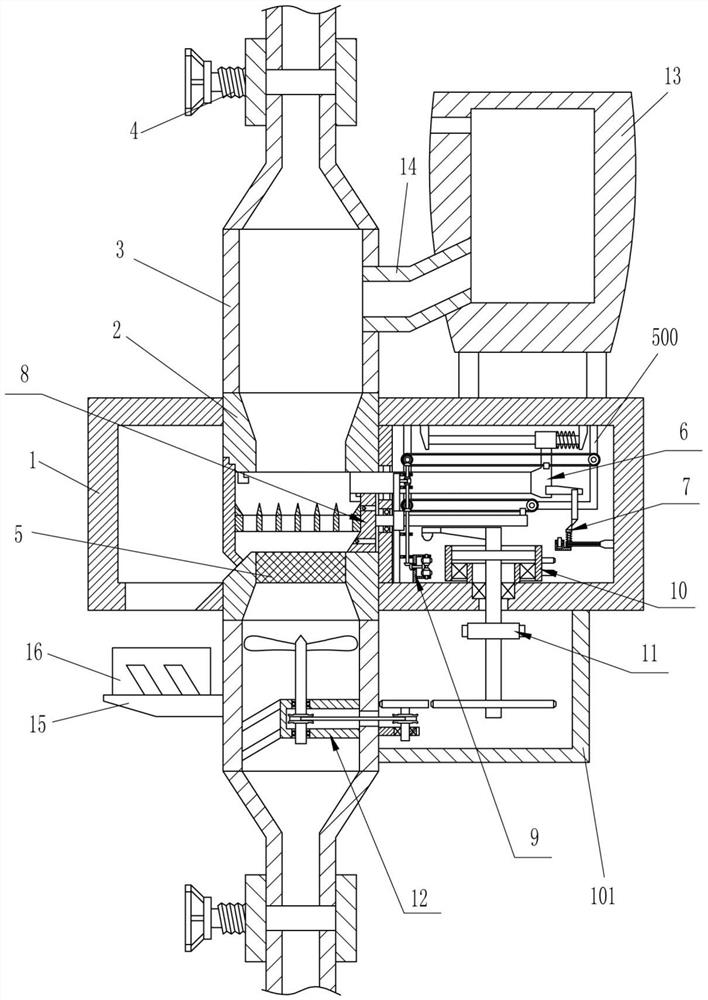

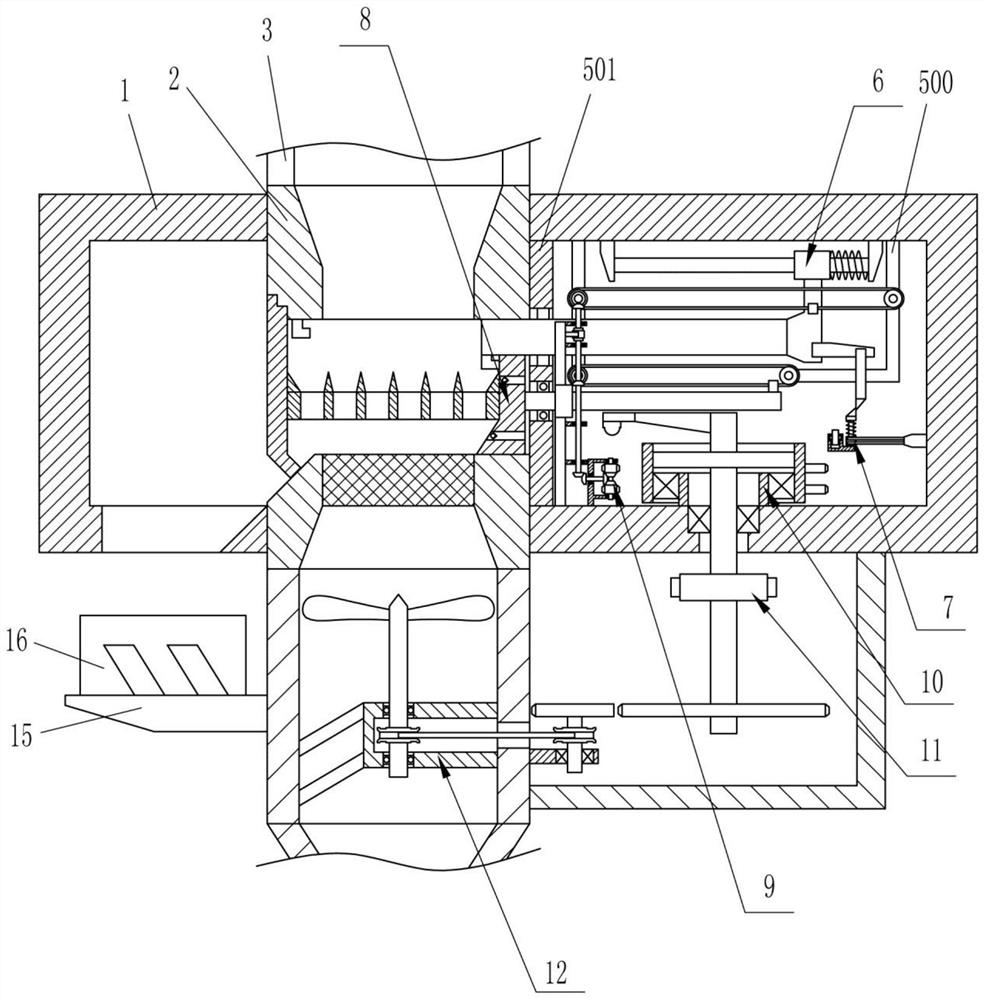

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

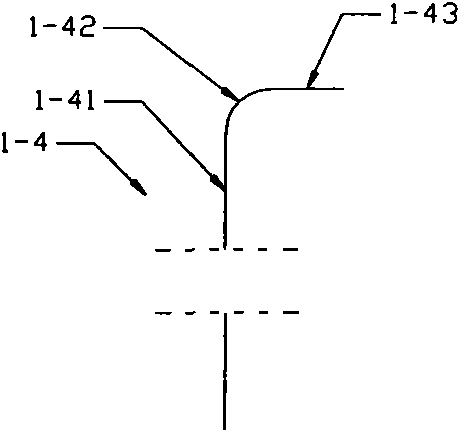

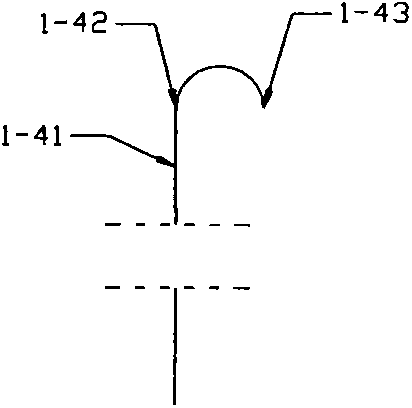

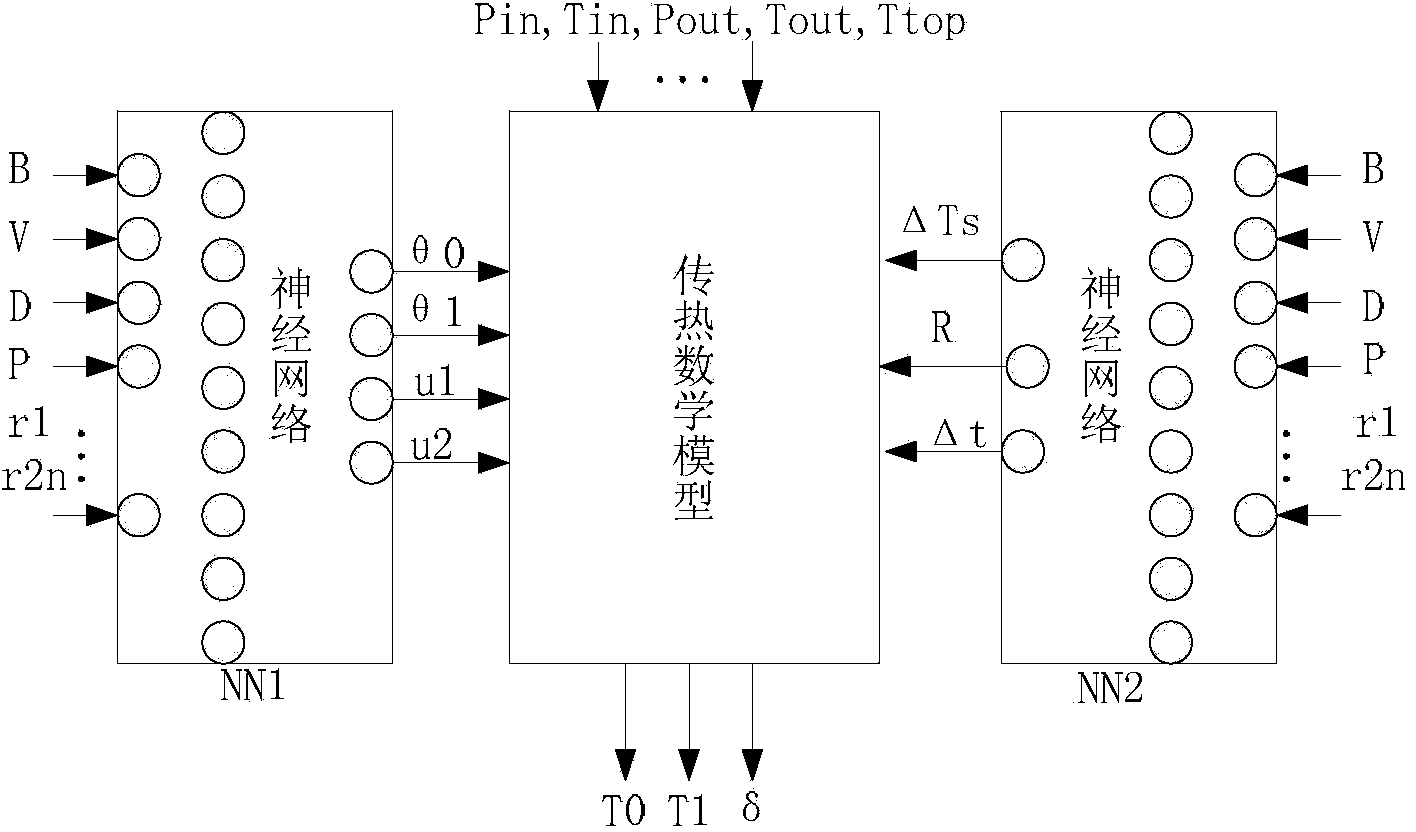

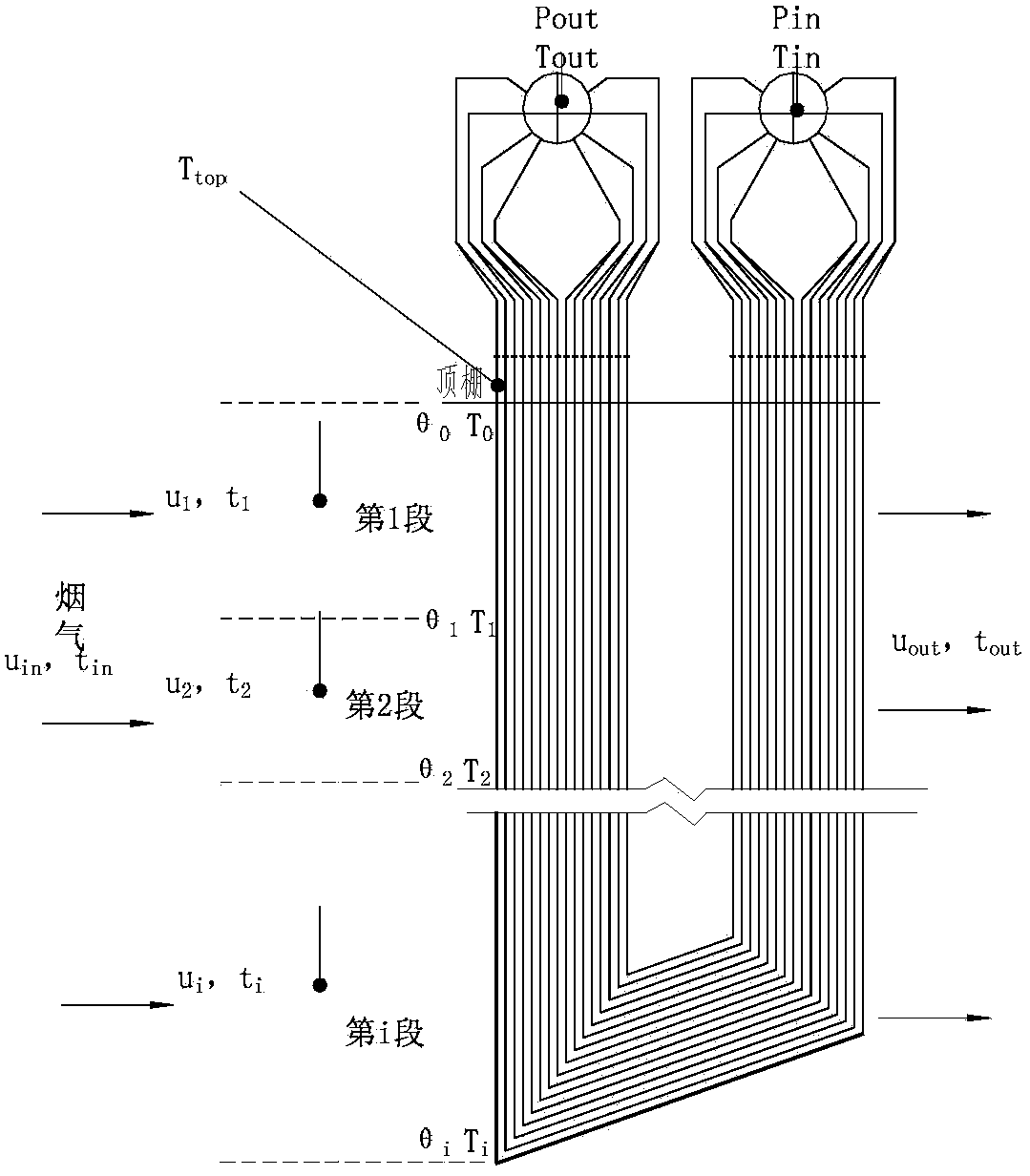

Method for monitoring wall temperature of heating surface and thickness of scale cinder of boiler superheater or reheater

The invention discloses a method for quantitatively and online monitoring the metal wall temperature of a heating surface and the thickness of a scale cinder (scale layer) of a boiler superheater or a reheater. The method includes the steps that according to operating parameters of a boiler, flue-gas temperature and speed of partition sections in the front of a pipe are predicted and monitored through a neutral network, and based on the flue-gas temperature and the speed, the distribution of the wall temperature of the heating surface and the thickness of the scale cinder (scale layer) of the superheater or the reheater are acquired according to a heat transfer mathematical model of the heating surface. The method has the advantages that the method is simple, rapid and capable of being continuously conducted, regular automatic learning can be achieved, the method can be used for quantitatively monitoring the wall temperature of the heating surface and the thickness of the scale cinder in the actual operating process of the pulverized coal boiler, and a quantitative basis is provided for preventing pipe explosion through optimizing, adjusting and controlling thermal deviation and for managing the service life of the heating surface of the boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

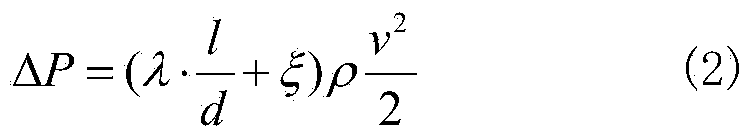

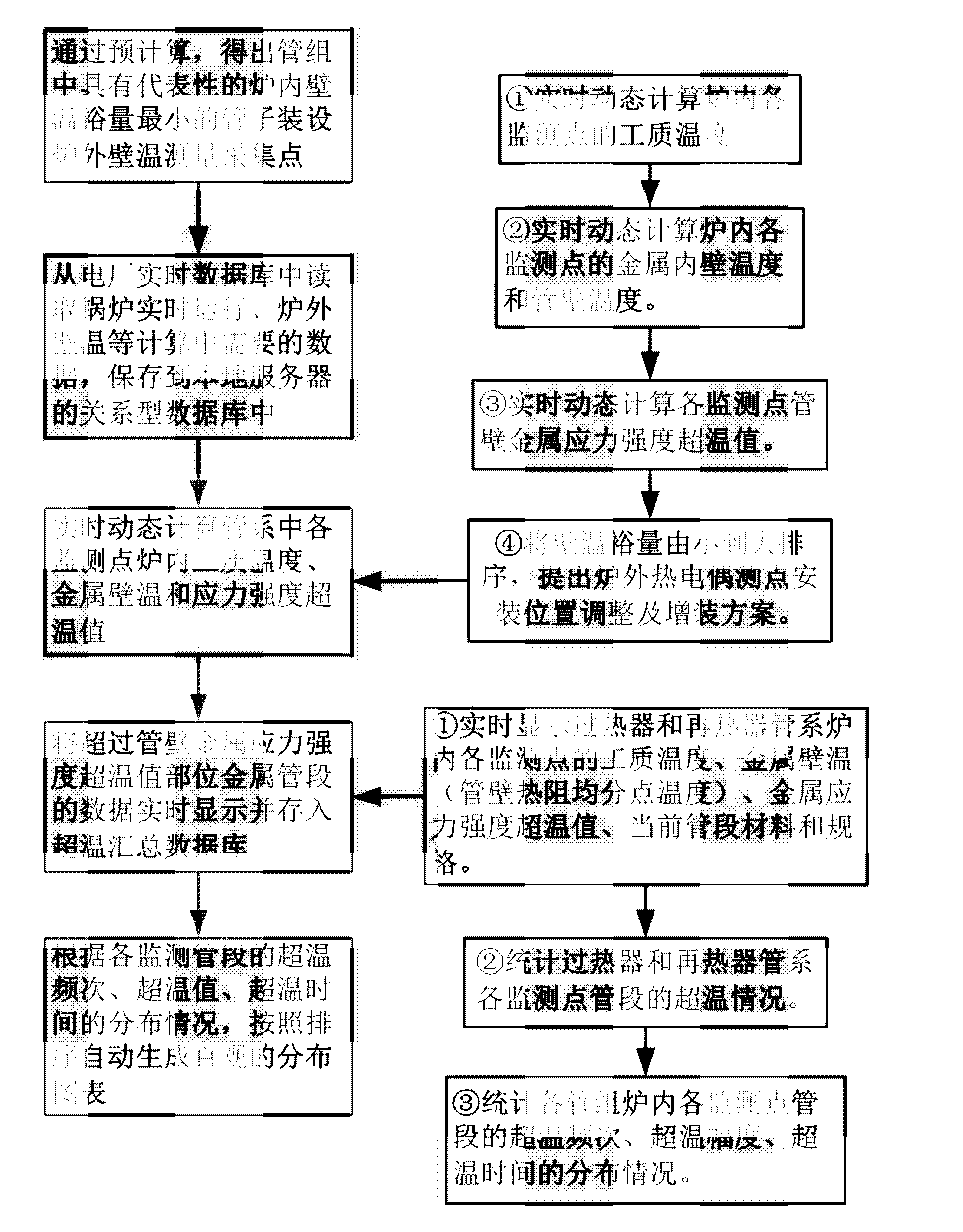

Method for monitoring intra-furnace dynamic wall temperature in high-temperature tube system of power station boiler

ActiveCN102494325AExtended service lifeReduce generationThermometer detailsBoiler indication operationsPower stationReal-time data

The invention discloses a method for monitoring intra-furnace dynamic wall temperature in a high-temperature tube system of a power station boiler in the technical field of the power station boilers. The method disclosed by the invention comprises the steps of: precomputing to obtain a representative tube with the minimal allowance of intra-furnace inner wall temperature in a tube group for installation of a furnace outer wall temperature measurement and collection point; reading data required for calculation of real-time operation of the boiler, the extra-furnace wall temperature and the like from a real-time database of a power plant, and storing the data in a relational database of a local server; generating real-time dynamic calculation of intra-furnace working medium temperature and intra-furnace metal wall temperature of a superheater and reheater tube system of the power station boiler according to real-time data of the real-time operation and the extra-furnace metal wall temperature; and separating the data of a metal tube section exceeding a tube wall metal stress intensity over-temperature value part and storing the data in an over-temperature summary database. The method disclosed by the invention effectively combines dynamic online calculation with dynamic online monitoring of practical working conditions so that the technical effect of prolonging the service life of the tube system is achieved and the technical problem on preventing over-temperature tube explosion of the tube system of the power station boiler is solved.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

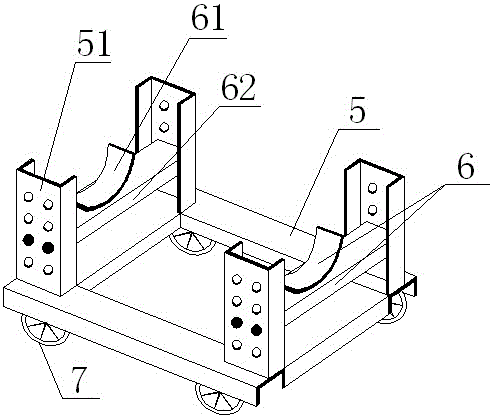

Pump pipe damping device

InactiveCN105114704AReduce pump tube vibrationAvoid pipe burstPipe supportsBuilding material handlingEngineeringFrictional resistance

The present invention discloses a pump pipe damping device. The device comprises a vertical pump pipe damping support and a horizontal sliding support seat. The vertical damping support is arranged a connection elbow part of a horizontal conveying pump pipe and a vertical conveying pump pipe at a first layer and is composed of a main support, a fixing pipe clamp and spring dampers. The horizontal sliding support seat is disposed on the first-layer horizontal conveying pump pipe and is composed of a support, pump pipe holders and a pulley system. The vertical pump pipe damping support realizes the aim of damping and noise reducing mainly through the spring dampers, and a pumping horizontal thrust is offset by frictional resistance generated by the pulley system of the horizontal sliding support seat and a terrace. The damping device is set up on a key position where pump pipes vibrate violently, and is used for preventing construction quality and safety accidents caused by pump pipe vibration damages, thereby bringing convenience for standardization management of construction sites and civilized construction. Meanwhile, the damping device is recyclable, and the cost is saved.

Owner:XIAN CONSTR ENG GENERAL CORP

Waste heat recovery system for circular cement production grate cooler

InactiveCN105066723AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyWaste heat recovery unitThermal insulation

The invention provides a waste heat recovery system for a circular cement production grate cooler. The grate cooler comprises a housing and a clinker channel, wherein a thermal insulation material is arranged between the housing and the clinker channel; waste heat recovery equipment is arranged in the thermal insulation material, and comprises a barrel; a heat exchange tube is arranged in the barrel; the barrel and the heat exchange tube are in a concentric circle structure. According to the grate cooler provided by the invention, sensible heat released by a clinker in a cooling machine in a fast cooling process can be fully absorbed; energy consumption of the clinker is reduced; the waste heat utilization quantity can also be effectively improved.

Owner:SHANDONG UNIV

Heat-absorbing material-coated grate cooler waste heat recycling device and system

InactiveCN105066722AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyEnergy consumptionWaste heat

The invention provides a heat-absorbing material-coated grate cooler waste heat recycling device and system. The device comprises barrels, wherein heat exchange tubes are arranged in the barrels; each barrel and the corresponding heat exchange tube are in a concentric circle structure; and a heat-absorbing material is coated on the outer surface of each barrel. According to the device and the system, the heat-absorbing material is arranged, so that the waste heat absorption can be further enhanced, the clinker energy consumption is reduced, and the utilization amount of waste heat also can be increased effectively.

Owner:SHANDONG UNIV

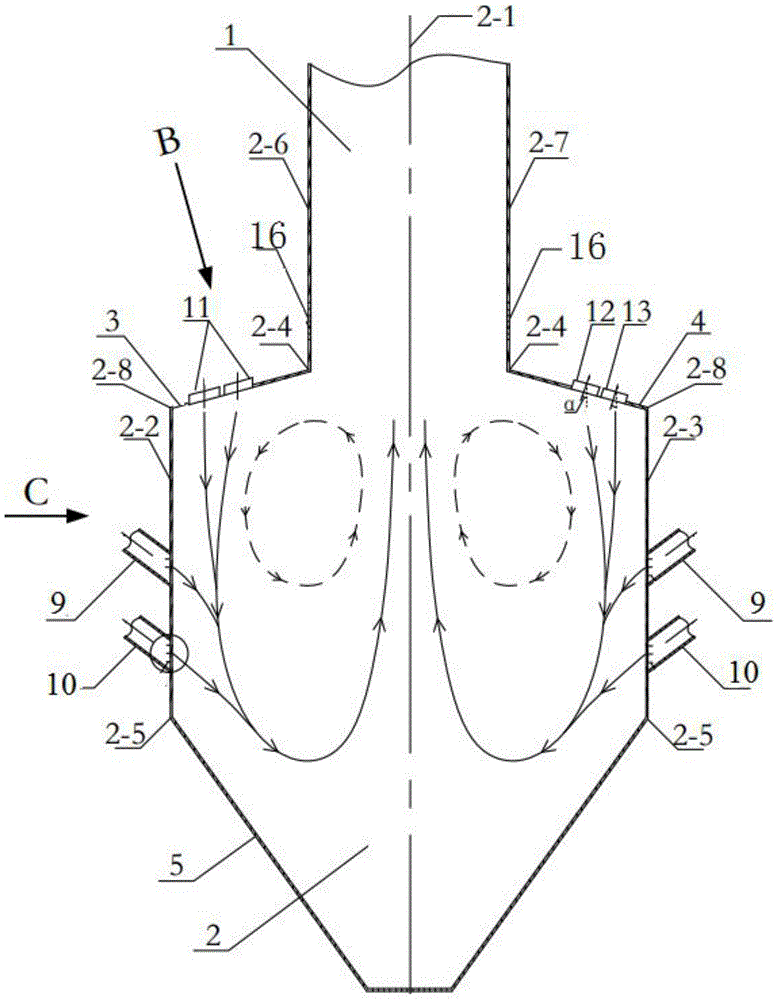

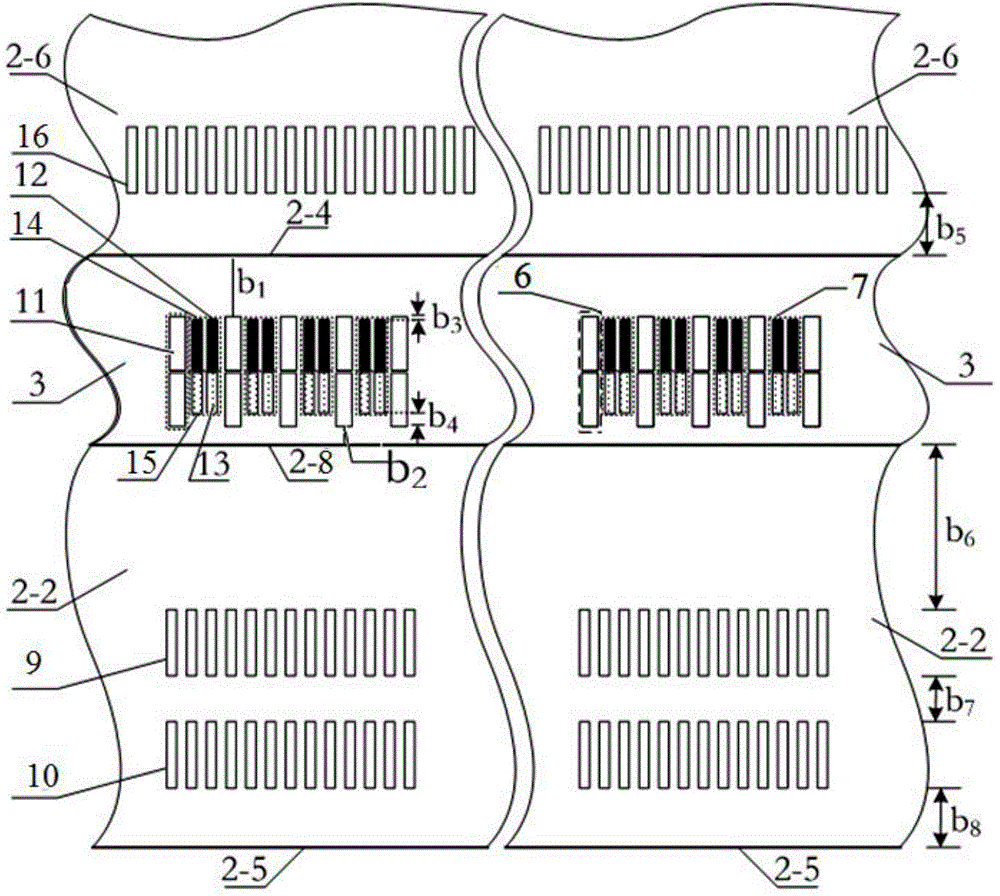

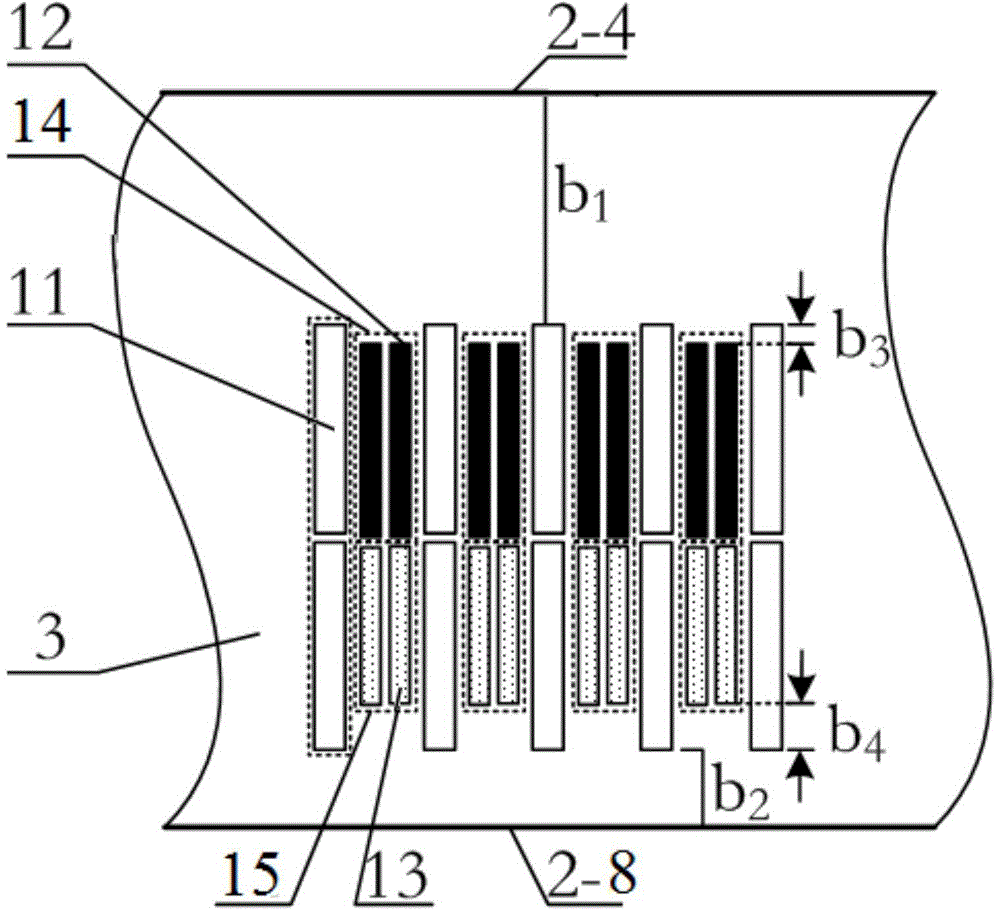

Ejecting staged combustion W flame boiler for improving ignition and combustion of pulverized coal

ActiveCN104595892AImprove combustion stabilityImprove burnout rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberSlag

The invention relates to an ejecting staged combustion W flame boiler for improving ignition and combustion of pulverized coal. The W flame boiler comprises a furnace hearth which is formed by an upper furnace hearth, a lower furnace hearth, a front furnace arch and a rear furnace arch, a plurality of secondary air nozzle groups which are arranged on the front furnace arch and the rear furnace arch, and a plurality of pulverized coal airflow nozzle groups, wherein the plurality of secondary air nozzle groups and the plurality of pulverized coal airflow nozzle groups are arranged side by side linearly, equidistantly and abreast along a width direction of a furnace, the plurality of pulverized coal airflow nozzle groups can be arranged on the furnace arches at fixed angles, an incident angle of secondary air can be adjusted, a plurality of over-fire air nozzles with adjustable incident angles can be formed in the upper furnace hearth, and two layers of tertiary air nozzles with the adjustable incident angles can be formed in water-cooled walls of front and rear walls of each furnace hearth. By adopting the W flame boiler disclosed by the invention, the combustion of the pulverized coal in the furnace can be effectively improved, the adaptive capacity of the boiler to coal types can be improved, the heat and reheat steam temperature can be effectively adjusted to reach a design value, the emission of NOx and the flue gas temperature can be reduced, slag bonding of the front and rear walls can be prevented, and the thermal fatigue existing in water-cooled walls of a combustion chamber hopper can be avoided.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

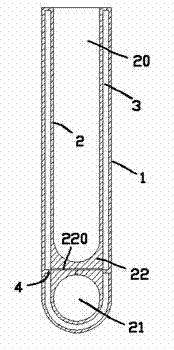

Straightthrough type double glazing vacuum solar heat collection tube

InactiveCN101256033AAvoid pipe burstGood effectSolar heating energySolar heat devicesGetterEngineering

Owner:SOUTHEAST UNIV

Waste heat recovery system for cement production grate cooler employing square equipment

InactiveCN105066724AReduce energy consumptionImprove utilizationEnergy industryIncreasing energy efficiencyWaste heat recovery unitThermal insulation

The invention provides a waste heat recovery system for a cement production grate cooler employing square equipment. The grate cooler comprises a housing and a clinker channel, wherein a thermal insulation material is arranged between the housing and the clinker channel; waste heat recovery equipment is arranged in the thermal insulation material, and comprises at least one barrel; a heat exchange tube is arranged in the at least one barrel; the barrel is a rectangle; a plane is arranged at the lower part of the barrel. According to the grate cooler provided by the invention, sensible heat released by a clinker in a cooling machine in a fast cooling process can be fully absorbed; energy consumption of the clinker is reduced; the waste heat utilization rate can also be effectively increased.

Owner:SHANDONG UNIV

Valve body with filtering function

ActiveCN110115868AQuality improvementEasy to useValve arrangementsFiltration separationReciprocating motionEngineering

The invention relates to the field of water control valves, in particular to a valve body with a filtering function. The valve body comprises a valve shell, wherein the left and right sides of the valve shell are fixedly provided with a water inlet connecting pipe and a water outlet connecting pipe respectively, the center of the inner portion of the valve shell is rotatably in fixed-axis connection with a rotating shaft, the rotating shaft is fixedly provided with a filter net, the water inlet connecting pipe is connected with an intermittent reciprocating mechanism and is connected with therotating shaft through the intermittent reciprocating mechanism, the lower side of the valve shell is fixedly provided with a discharge pipe, the joint of the discharge pipe and the valve shell is fixedly provided with a brush frame cleaning the filter net, and an outlet end of the discharge pipe is provided with an automatic discharge mechanism. The valve body with the filtering function can automatically perform cleaning, keep the stable discharge value of the filter net and improve the water delivery efficiency so that the water pressure in the valve body can be kept stable in time, therefore, structural parts in the valve body are not damaged by the excessive water pressure, the pipe is also prevented from being broken, automatic discharge can also be achieved, and the time and labor are saved.

Owner:浙江鑫泰阀门科技有限公司

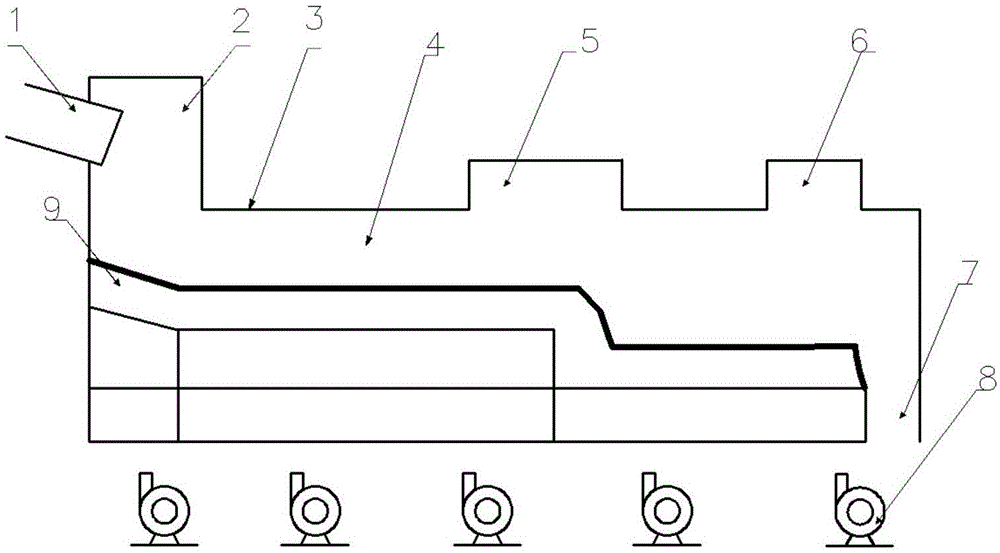

Soot blowing system and method for pi-shaped boiler furnace arch

The invention discloses a soot blowing system and method for a pi-shaped boiler furnace arch. The soot blowing system utilizes a pneumatic and steam-driven fluidization principle, and overcomes the friction of accumulated soot on the upper slope of the furnace arch, thus enabling the accumulated soot to separately flow to a hearth and a horizontal flue to be discharged. A hood-shaped soot blower is mounted on a diaphragm of the upper slope of the furnace arch, arranged between a high temperature superheater and a high temperature reheater, penetrates through the upper slope of the furnace arch, and is connected with a soot blowing media pipeline. The shapes of a first soot blowing pipe and a second soot blowing pipe of the hood-shaped soot blower are telescopic pipes, thereby improving thespeed of soot blowing airflow, and enhancing the soot blowing effect. During the soot blowing process, compressed air firstly blows the accumulated soot on the upper slope of the furnace arch, and then steam blows residual accumulated soot hard to clear, so that an excellent soot blowing effect can be achieved by a compound blowing mode. The soot blowing system can effectively clear the accumulated soot on the upper slope of the boiler furnace arch, avoids the occurrence of excessive blowing loss and pipe explosion of the furnace arch and the wall face of the superheater and saves the energyconsumption of blowing soot.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

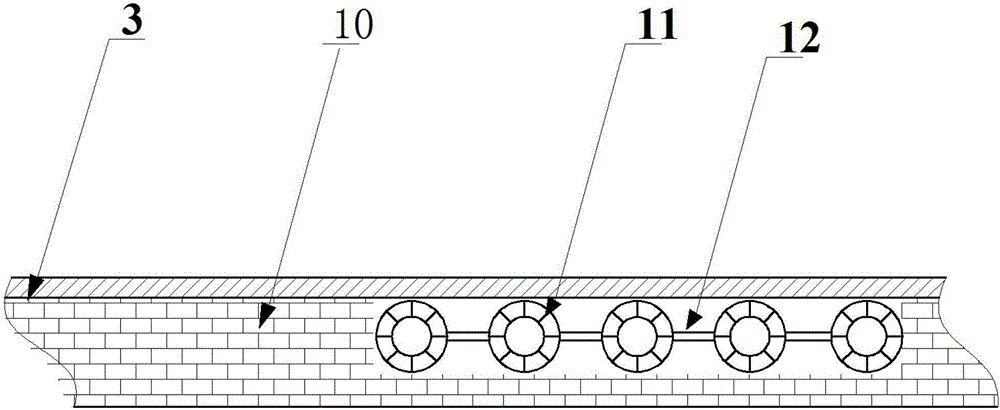

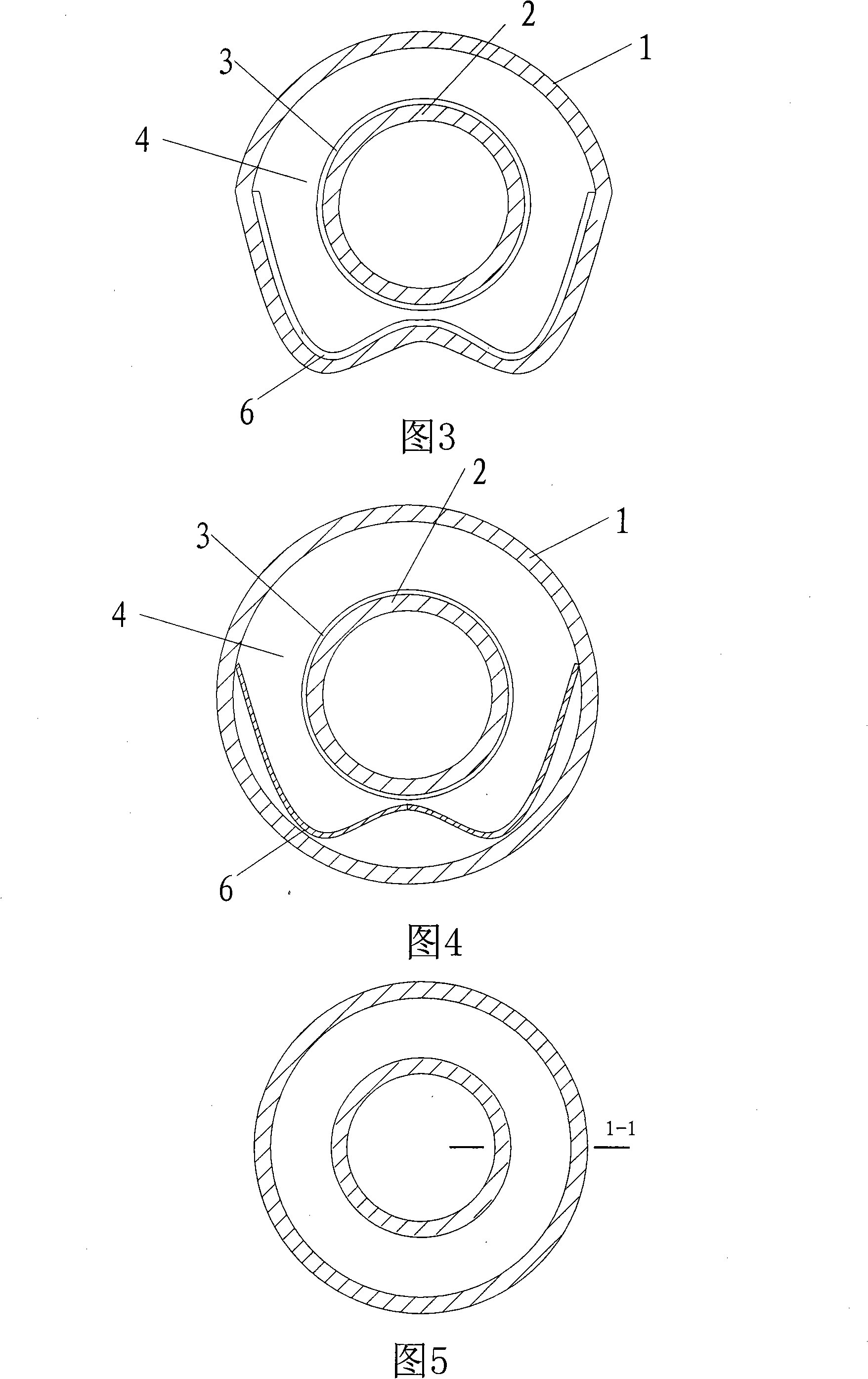

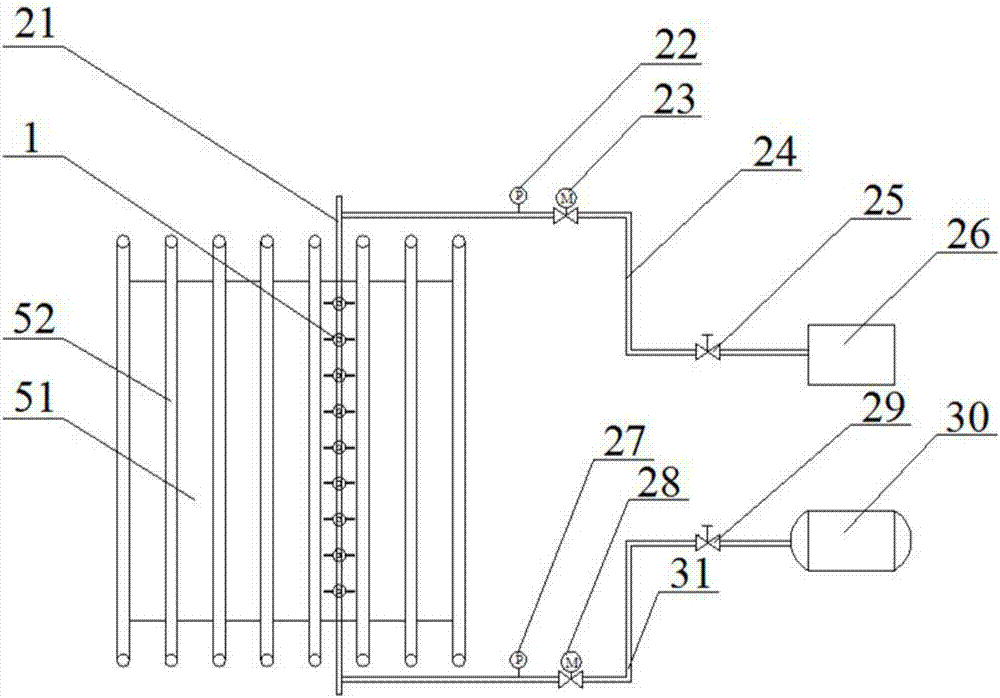

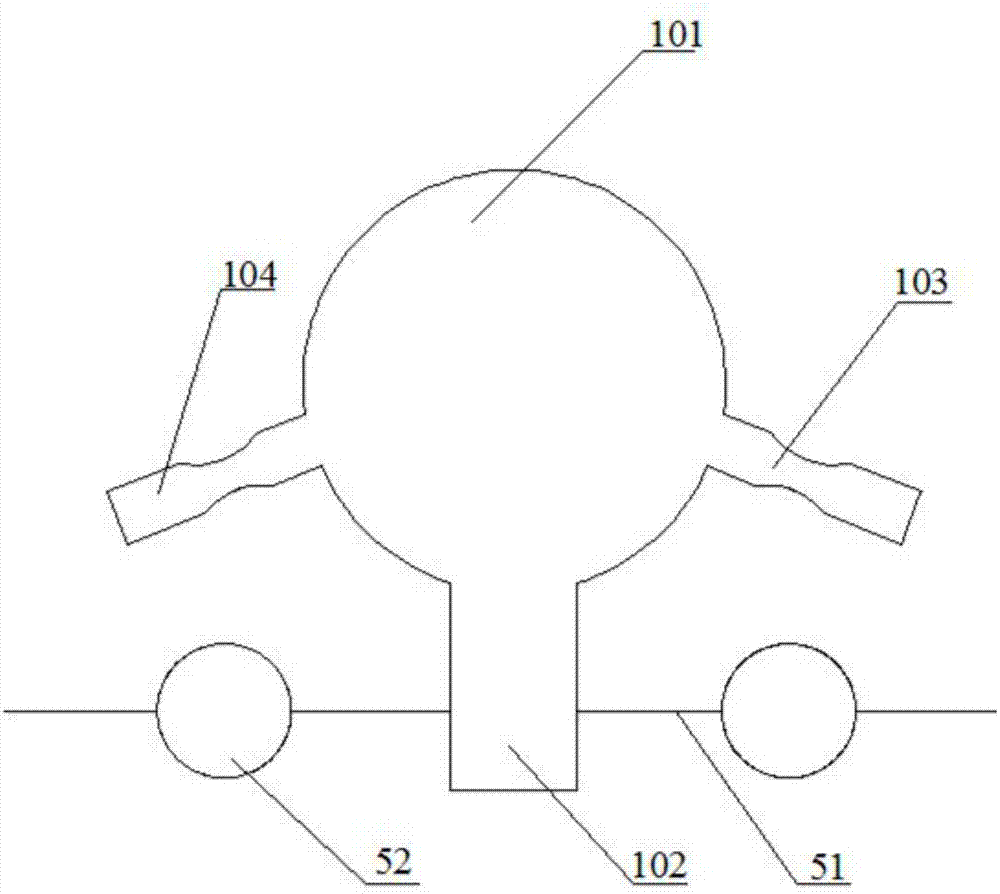

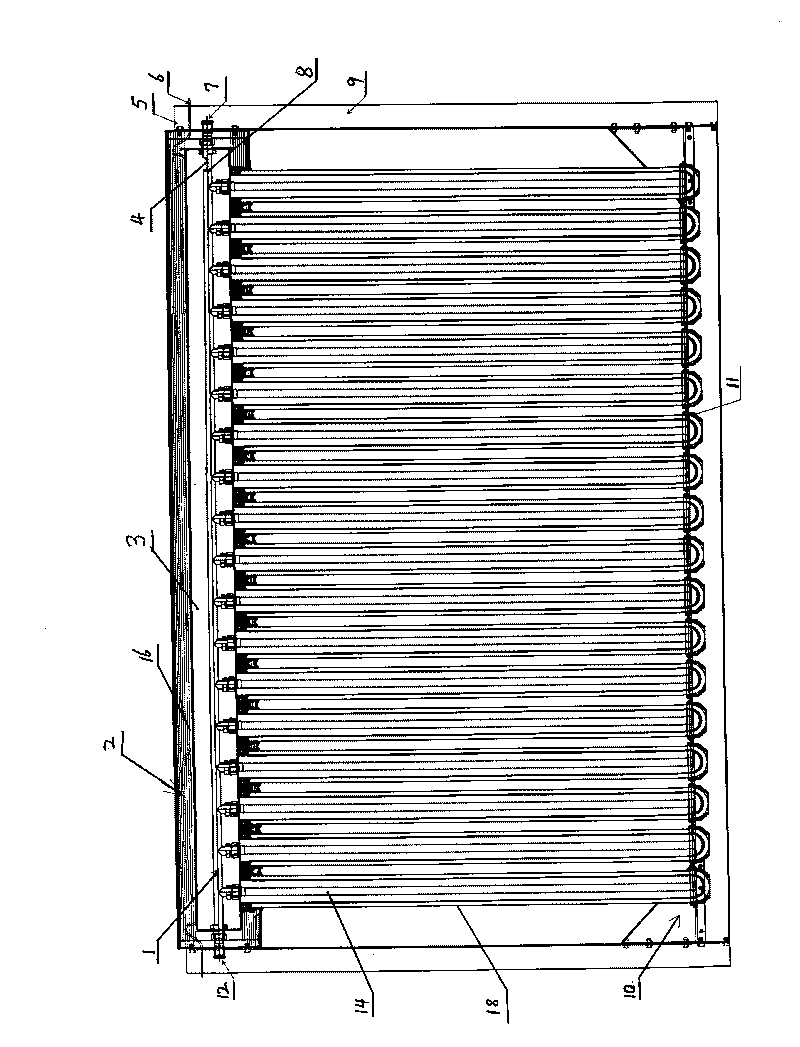

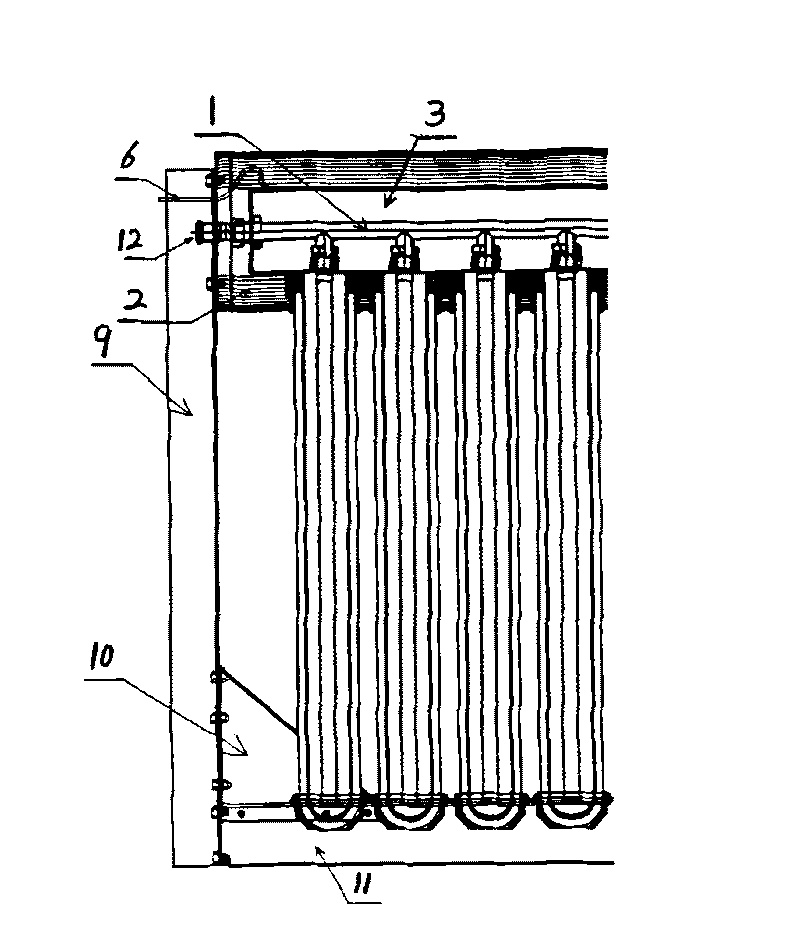

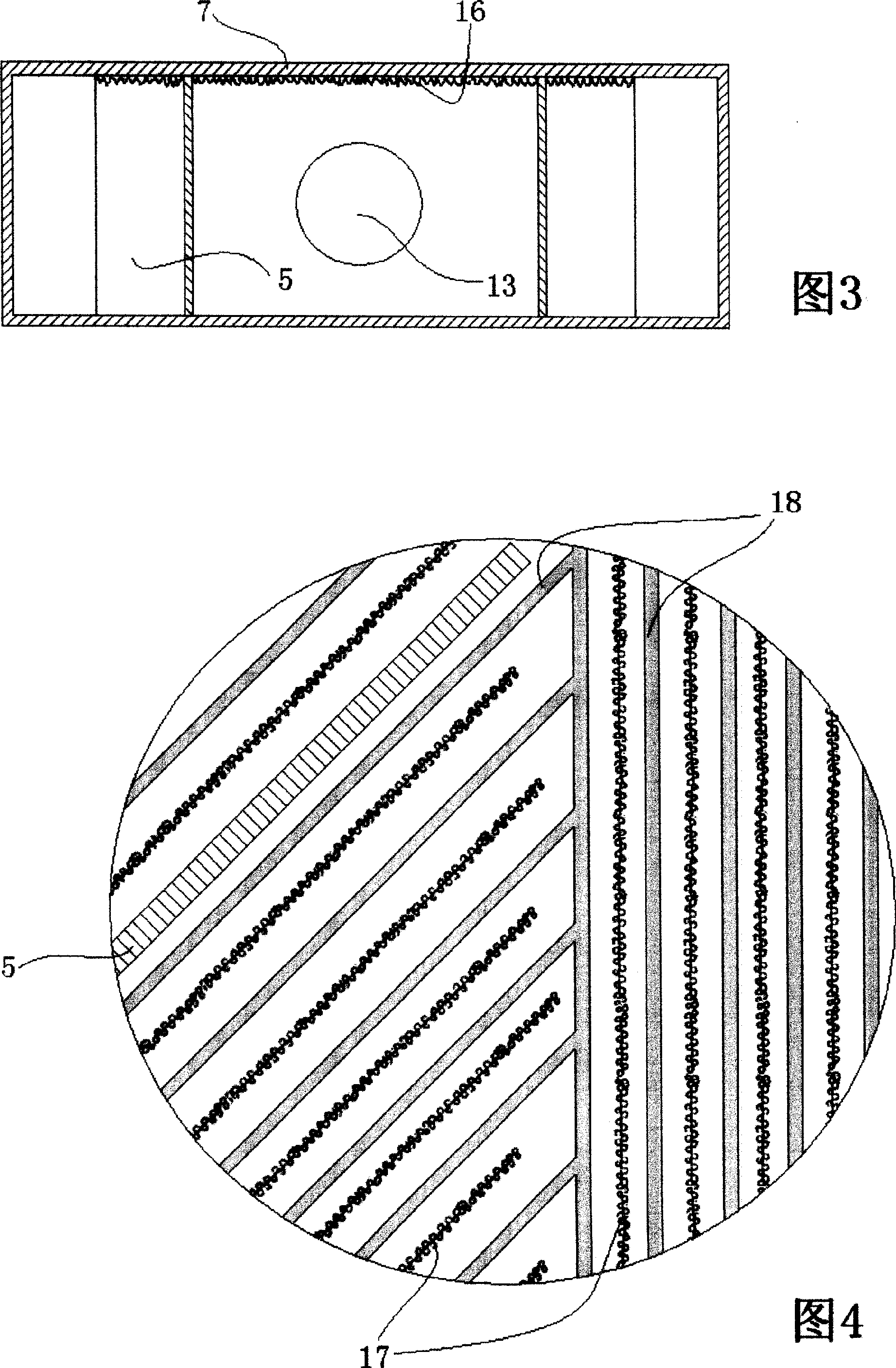

Heat collecting module of metal-glass sheathing heat collecting pipe

ActiveCN101762081AImprove pressure capacityImprove pressure bearing capacitySolar heating energySolar heat devicesCopper platingThermal energy

The invention discloses a heat collecting module of a metal-glass sheathing heat collecting pipe, belonging to the field of the solar thermal energy utilization technology. The current all-glass vacuum heat collecting pipe is not pressure-bearing, is easy to be explosive and is not anti-freezing, thereby being difficult to be applied to a heat collecting project; a selective heat absorption coating layer (a magnetron sputtering vacuum coating film) of the heat collecting pipe inner pipe outer surface of a vacuum heat pipe is easy to fall off under long-term basking. A vacuum glass pipe in the invention is the heat collecting module of the metal-glass suit heat collecting pipe, which does not contact working medium and is pressure-bearing and antiseptic and has high heat absorption efficiency and low heat emissivity. The heat collecting pipe comprises a glass vacuum heat preservation pipe and a metal heat collecting pipe, the heat collecting pipe is arranged in the glass vacuum heat preservation pipe, the outer surface of the heat collecting pipe is plated with copper chemically and a black nickel layer is electroplated after copper plating is carried out. Meanwhile, a flow channel blind plate is additionally arranged in a water filling circulating flow channel to separate cold and hot water working medium, and the water filling circulating flow channel is directly connected with a water filling pipe to guide cold water to directly reach the bottom part of the metal heating collecting pipe; and a new pressure-bearing connection type of connecting a collecting pipe and the heat collecting pipe is provided.

Owner:深圳市中装新能源科技有限公司

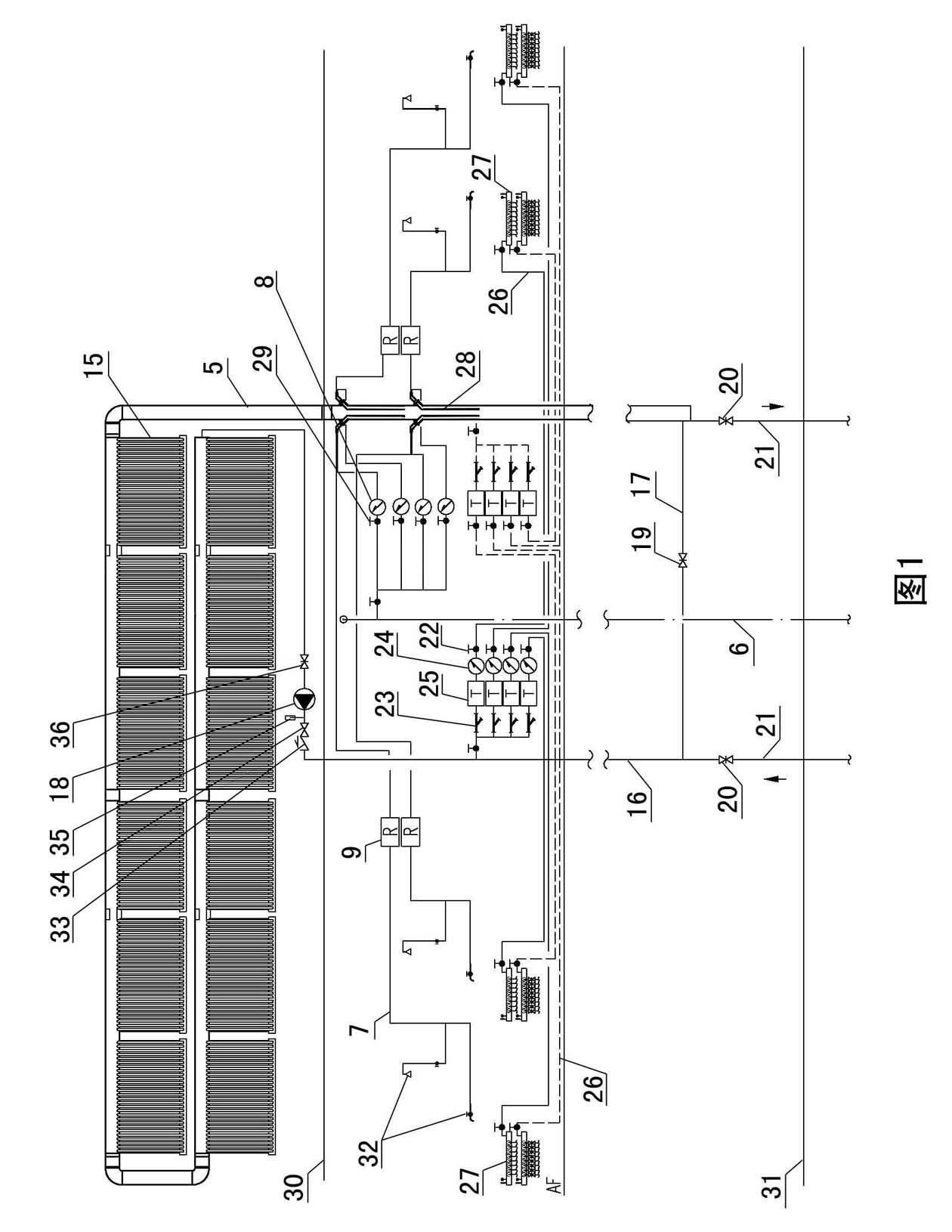

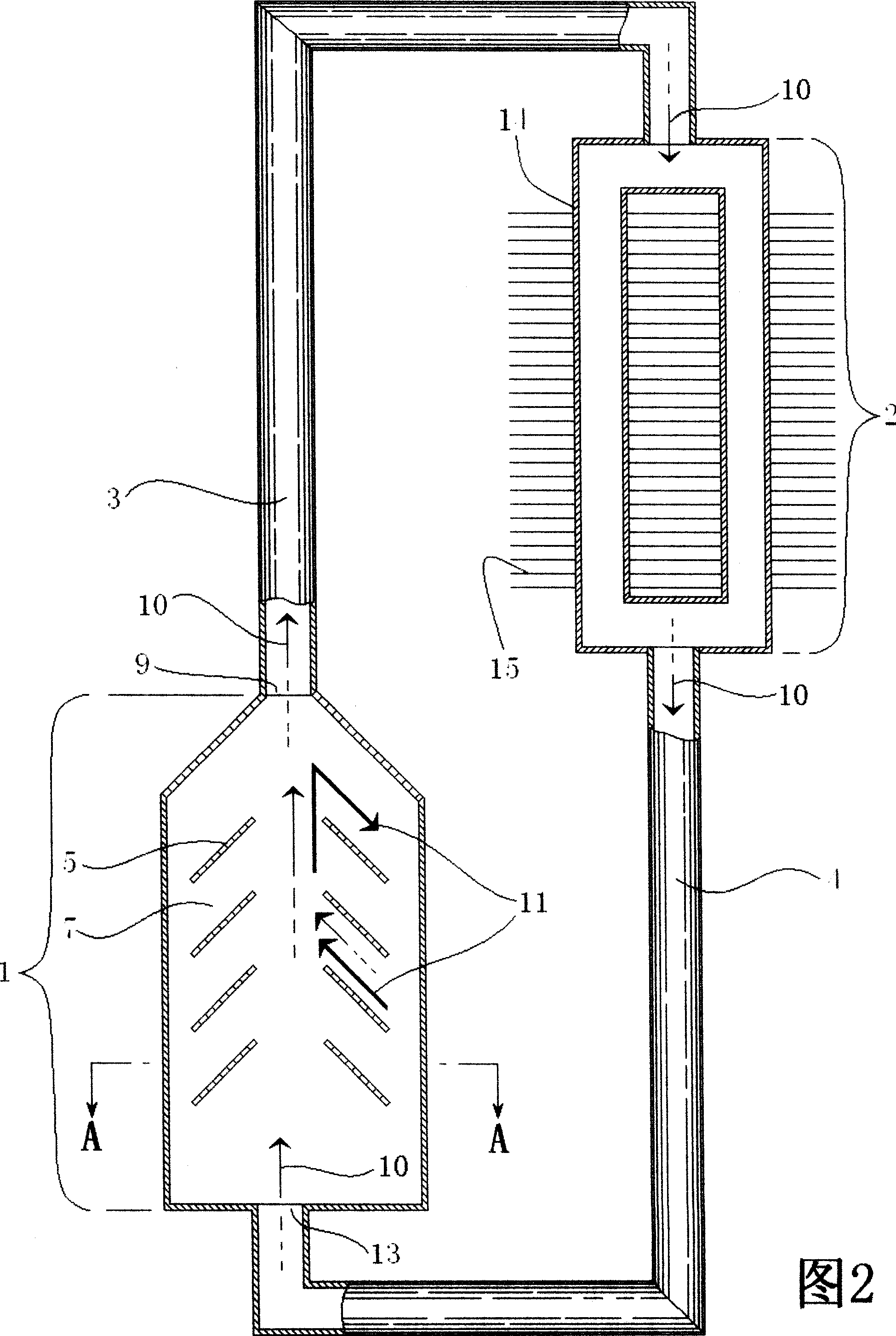

Solar comprehensive heating system capable of supplying heat and hot water integrally for house

ActiveCN102661615AAvoid pipe burstAvoid technical problems such as air blockageSolar heating energySolar heat devicesWater useCollector device

A solar comprehensive heating system capable of supplying heat and hot water integrally for a house comprises a vacuum tube solar collector, a collector water inlet pipe, a collector water outlet pipe, a heat storage pipeline, a heat exchanger, a domestic hot water pipe and a hot water use terminal. The collector water inlet pipe and the collector water outlet pipe are communicated with the solar collector. The collector water outlet pipe is communicated with the heat storage pipeline and is part of the heat storage pipeline. The heat storage pipeline is communicated with the collector water inlet pipe through connecting water pipes provides with switch valves. The collector water inlet pipe and the heat storage pipeline are connected with a low temperature radiation heating manifold through heating pipes so as to form water circulation. Water circulation between the vacuum tube solar collector and municipal heating hot water pipes are formed by the aid of the collector water inlet pipe and the heat storage pipeline. The solar comprehensive heating system is simple in structure, low in manufacture and maintenance cost, and low in maintenance difficulty.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

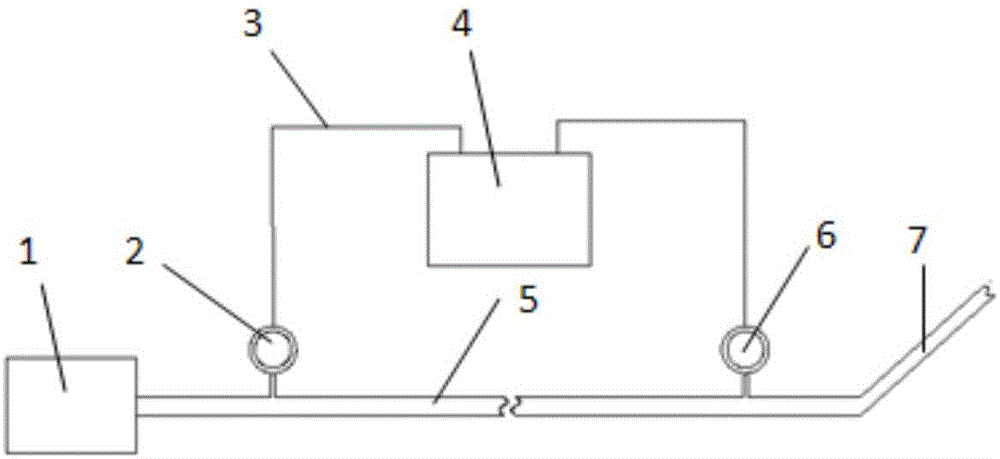

Erosion test device and method with capacity of controlling temperature, angle, flow velocity and time

ActiveCN106525628AHigh degree of automationAvoid errorsWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceCentrifugal pumpCheck valve

The invention discloses an erosion test device and method with capacity of controlling temperature, angle, flow velocity and time. An outlet of a reagent bottle is connected with a first inlet of a buffer bottle through a dosing pump and a check valve in sequence, an outlet of the buffer bottle is connected with a first inlet of a two-phase valve through a centrifugal pump, a second inlet of the two-phase valve is connected with outside atmosphere, an outlet of the two-phase valve is connected with an inlet of an erosion device through a first hydraulic sensor and a flow velocity sensor in sequence, an angle controller is connected and mounted on the erosion device, a temperature sensor is fixed on the inner side wall of the erosion device, an outlet of the erosion device is connected with an inlet of a diverter valve through a second hydraulic sensor, a first outlet of the diverter valve is connected with an inlet of the reagent bottle through a diversion pump, a fluid in a second outlet flows back to a second inlet of the buffer bottle; the reagent bottle, the dosing pump, the check valve and the buffer bottle are all placed in a constant-temperature bottle, and a heater is arranged in the constant-temperature bottle. With the adoption of the device and the method, erosion temperature, angle, flow velocity and time can be automatically regulated, labor cost is reduced, an operating process is simplified, reagents are recycled, and accordingly, resources are saved.

Owner:ZHEJIANG SCI-TECH UNIV

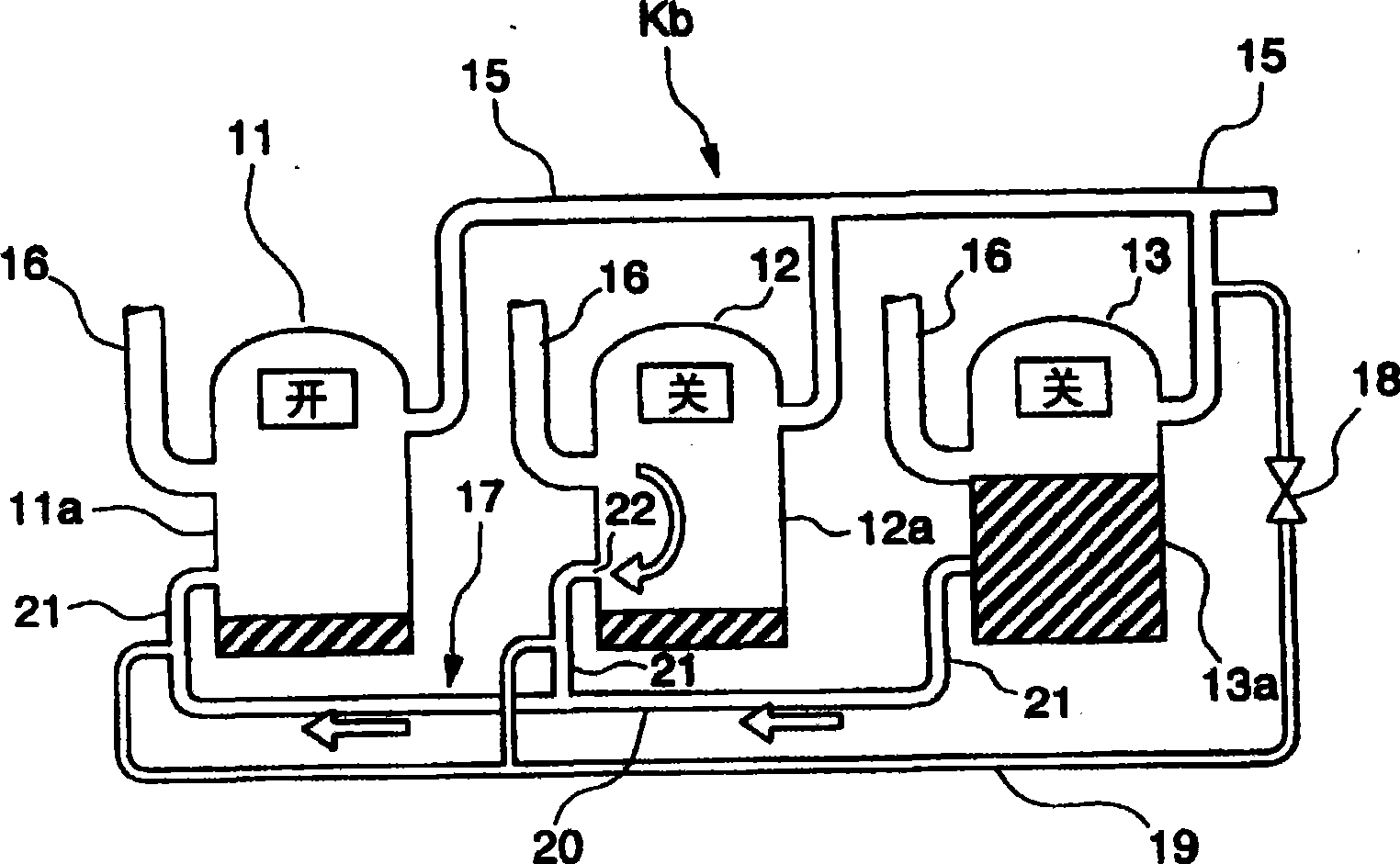

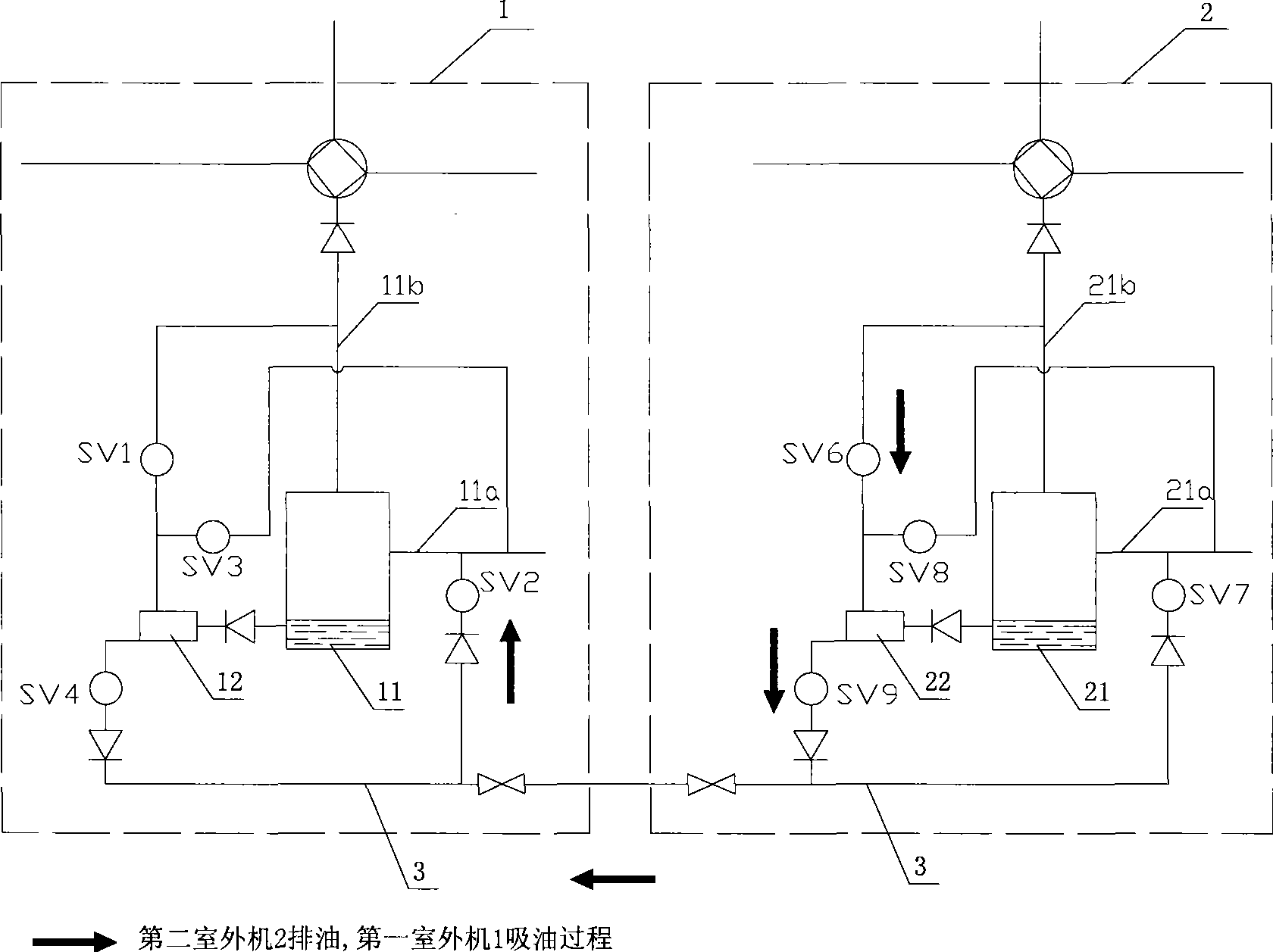

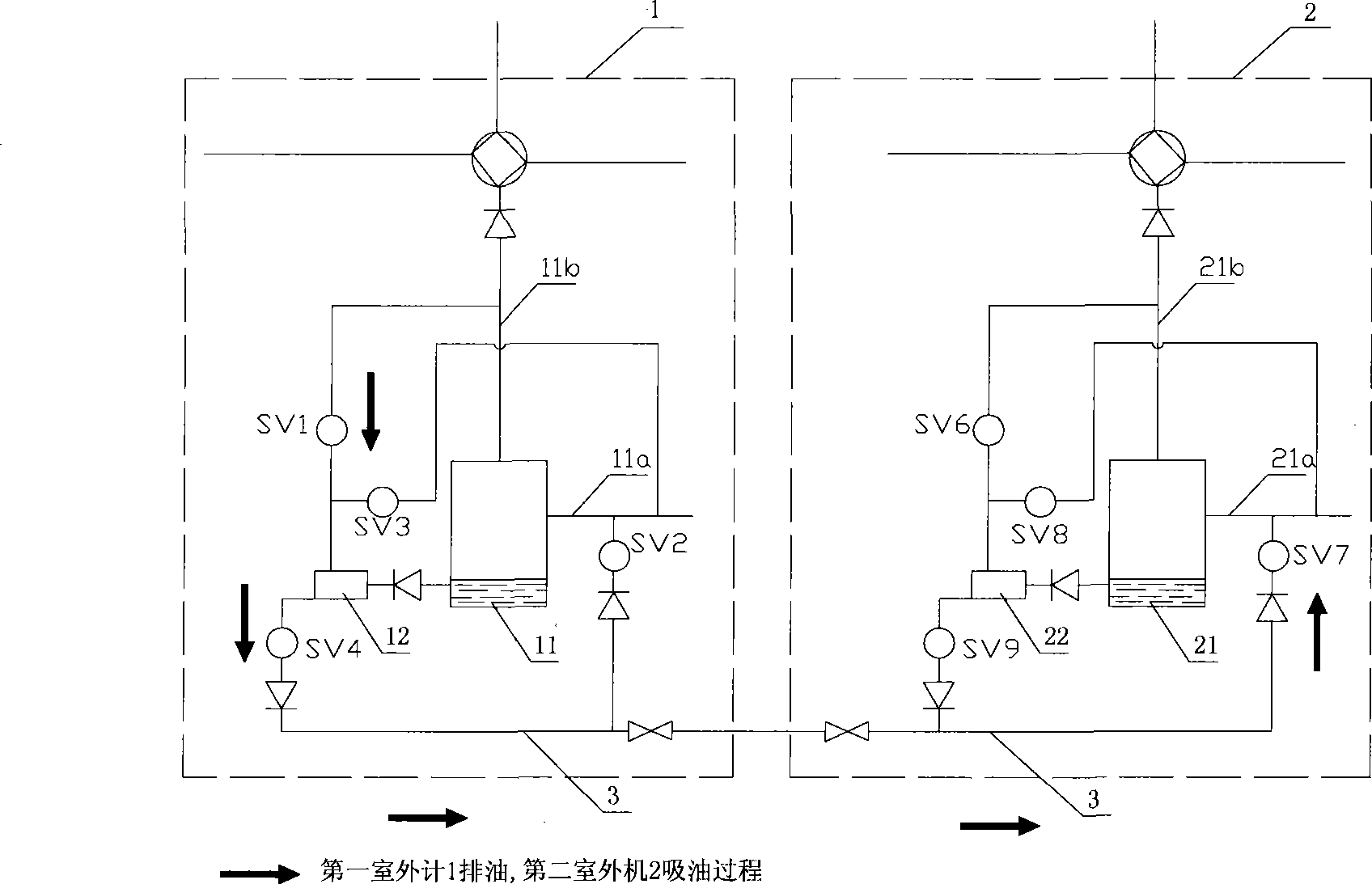

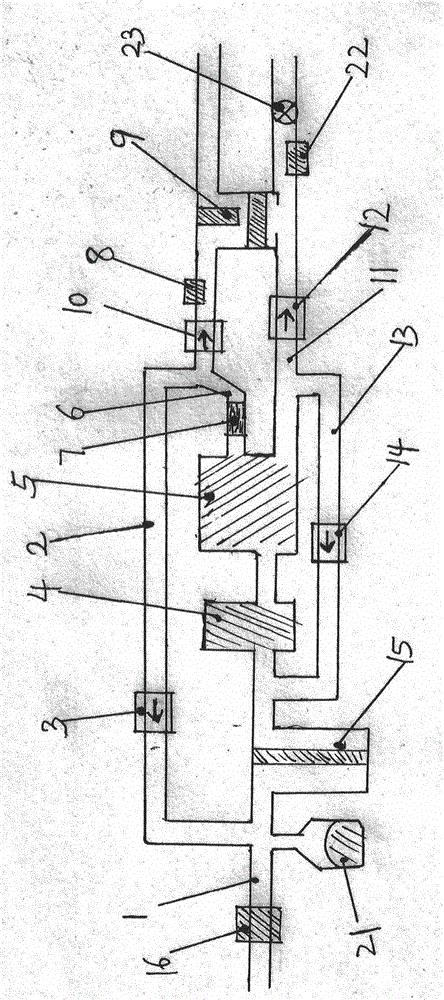

Multi-connection air conditioner oil balancing and gas balancing control device

InactiveCN101451757AAchieve oil leveling effectNo effect on operationSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEquilibrium controlElectromagnetic valve

The invention discloses an oil and gas balance controller of multi-connected air conditioner for the oil balance of compressors of at least two outdoor sets connected in parallel, wherein the oil balance controller comprises oil storage containers which communicate to the bottom of respective compressors of the plurality of outdoor sets, vent-pipes of respective compressors communicate to the oilstorage containers by an electromagnetic valve (1), every two oil storage containers communicate to one another by an oil balance connecting pipe to which each oil container communicates by an electromagnetic valve (4) and air suction pipes of respective compressors communicate by an electromagnetic valve (2), and each oil storage container communicates to the relative air suction pipes of respective compressors by an electromagnetic valve (3). The invention provides an oil and gas balance controller of multi-connected air conditioner for solving the problem of the oil balance of compressors in the various statuses.

Owner:HAIER GRP CORP +1

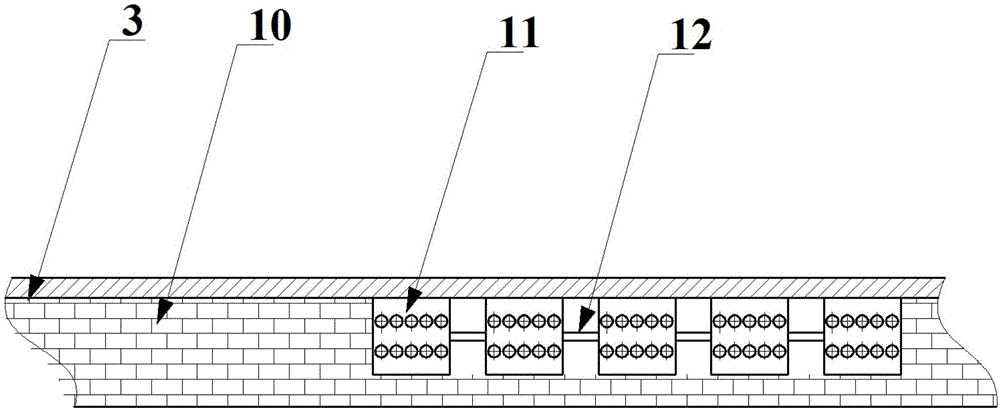

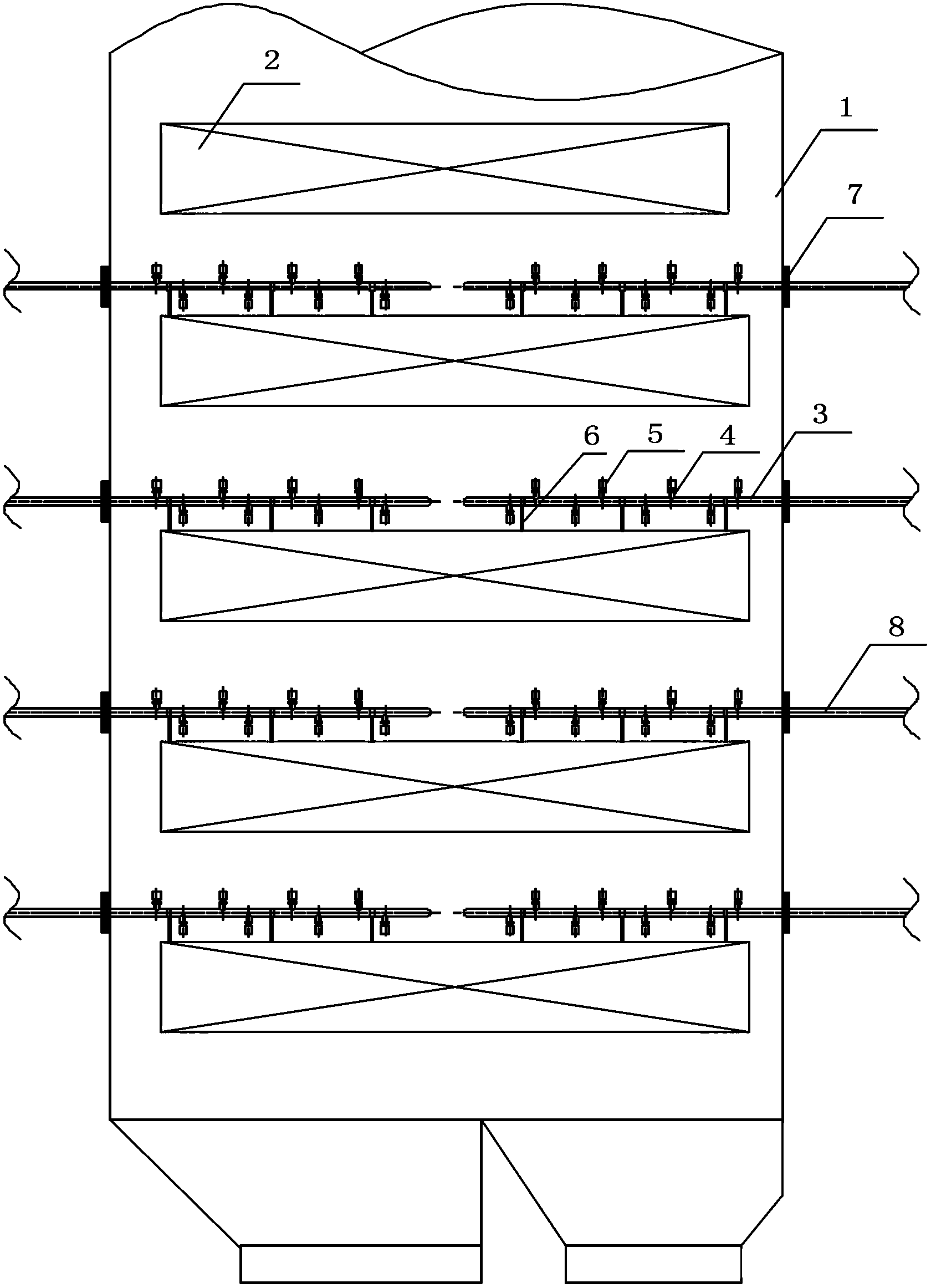

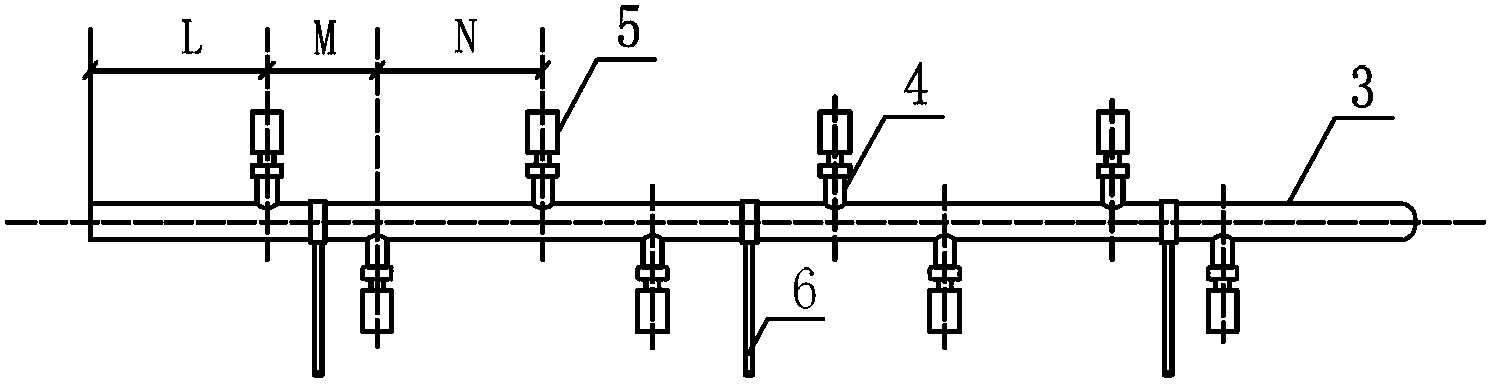

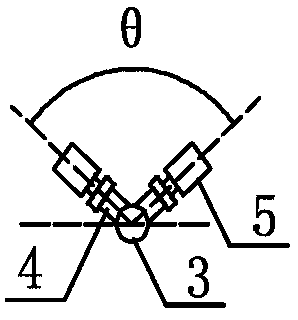

Coal-fired boiler shaft flue with sonic soot blowers

The invention relates to a coal-fired boiler shaft flue with sonic soot blowers and belongs to the technical field of coal-fired boilers. The coal-fired boiler shaft flue with the sonic soot blowers comprises heat exchangers, a plurality of pairs of primary pipes and the sonic soot blowers, wherein the pairs of primary pipes are evenly distributed along the cross section of a boiler, one end portions of each pair of primary pipes are opposite to each other and located in the center of the boiler, the other end portions of each pair of primary pipes extend out of the wall of the boiler respectively, and the end portions, extending out of the wall of the boiler, of the primary pipes are connected with steam supplying primary pipes outside the boiler in a welding mode. The heat exchangers and the pairs of primary pipes are installed in the shaft flue in a mutually spaced mode, and the primary pipes are fixed opposite to the heat exchangers through primary pipe supports. The sonic soot blowers are installed on the primary pipes through base pipes. The coal-fired boiler shaft flue has the advantages of being efficient, safe and energy-saving, promotes safety of the boiler, and can be free from daily tedious maintenance work. The sonic soot blowers are arranged in the boiler, and are free of rotating components and reliable in sealing.

Owner:张晨

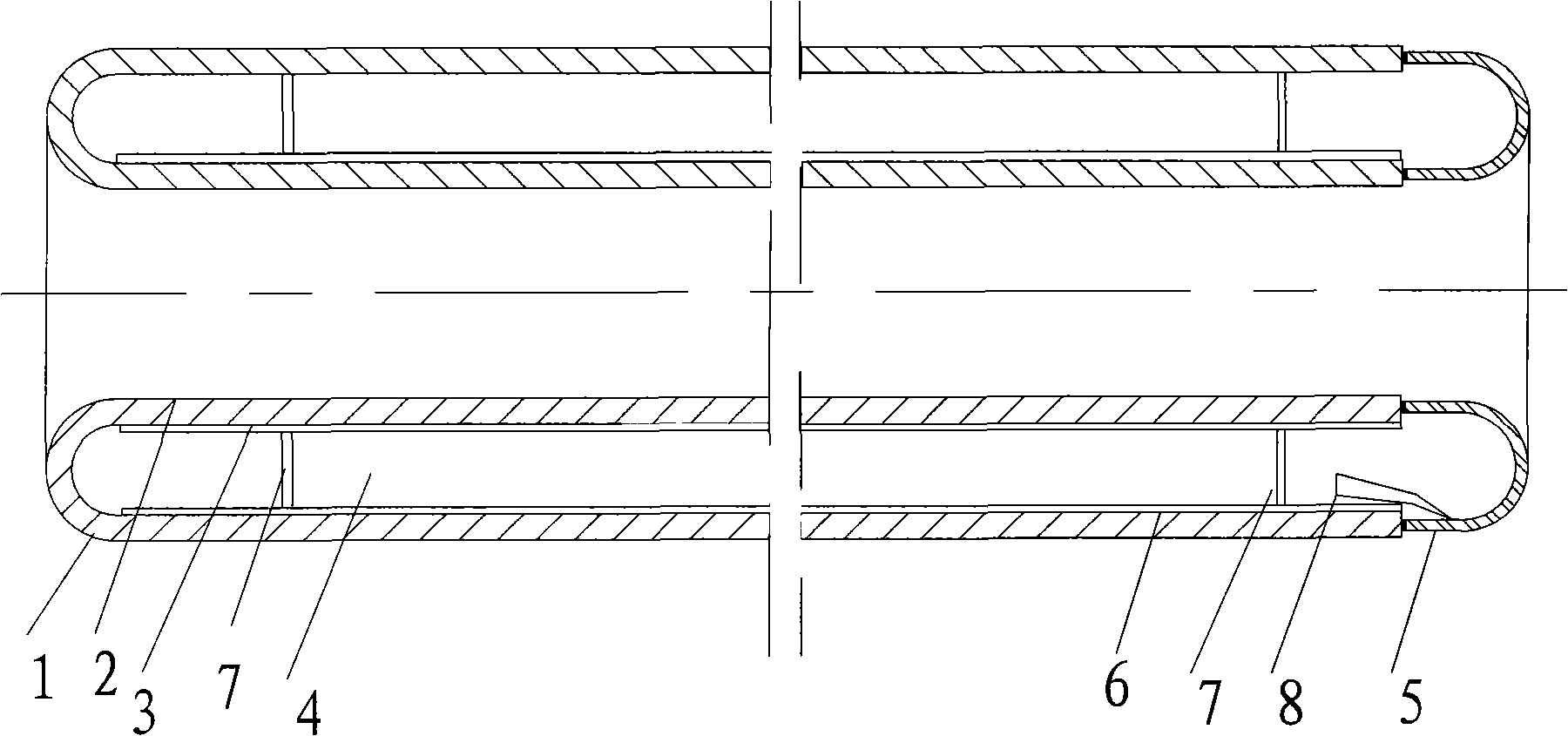

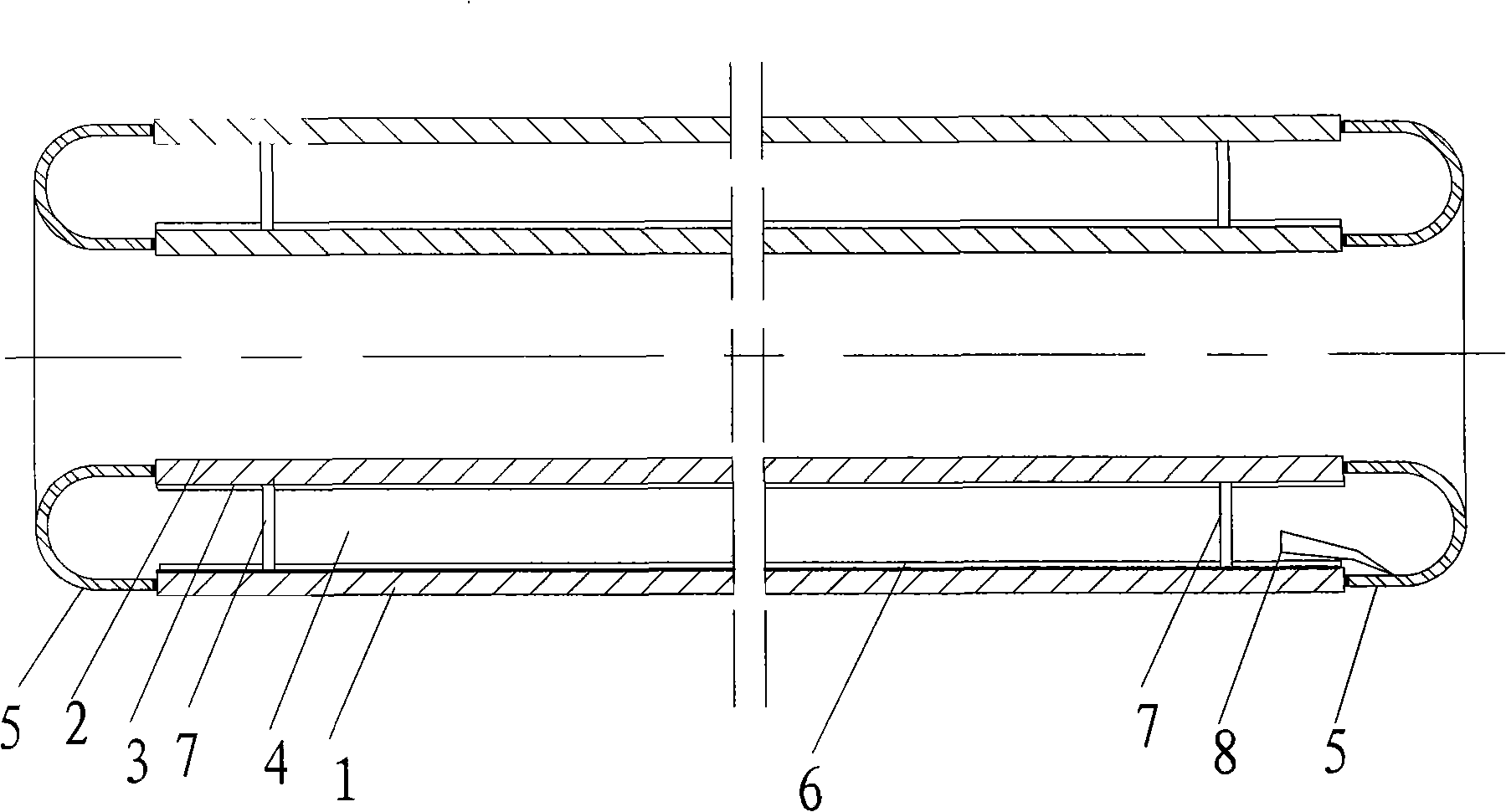

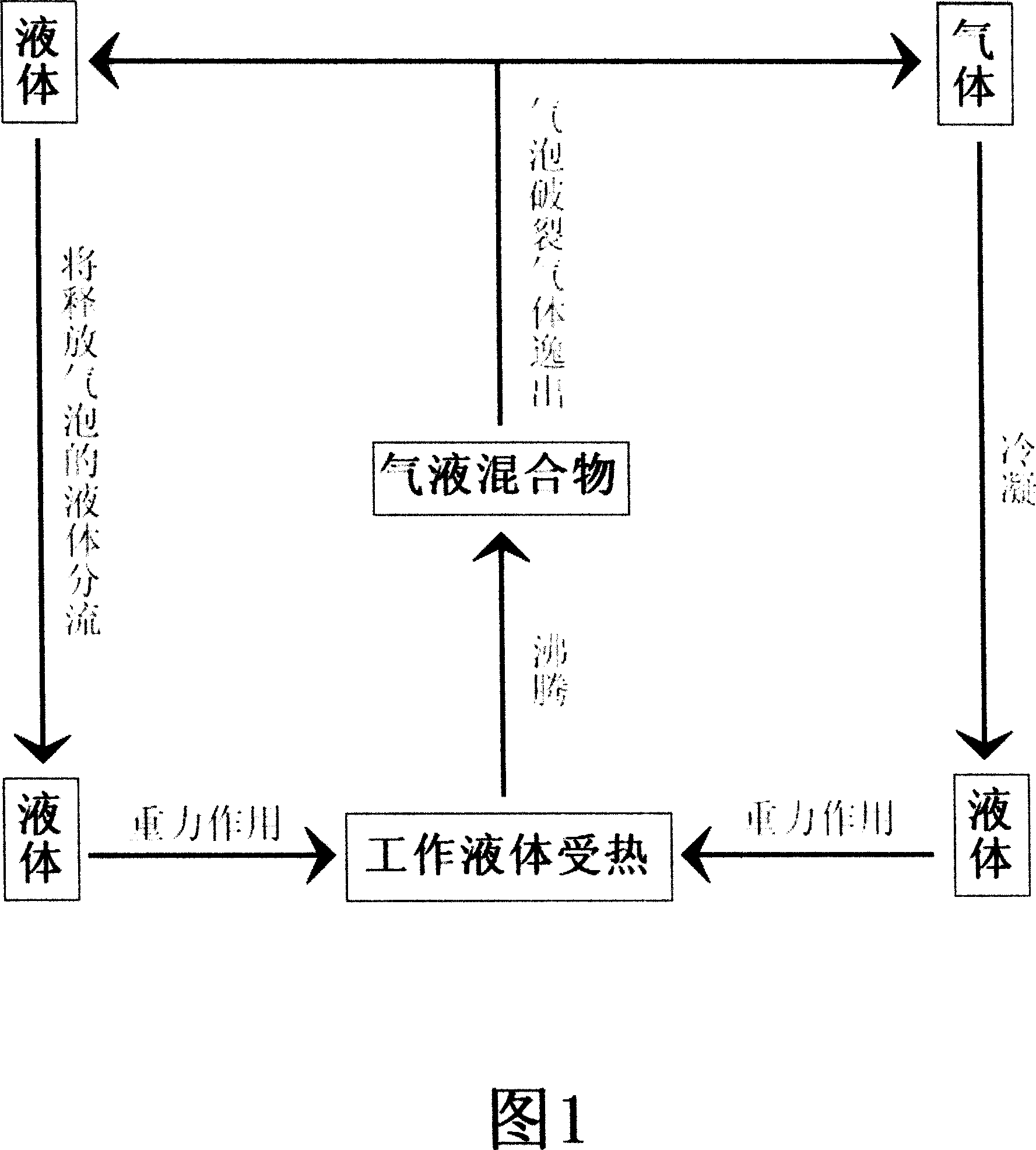

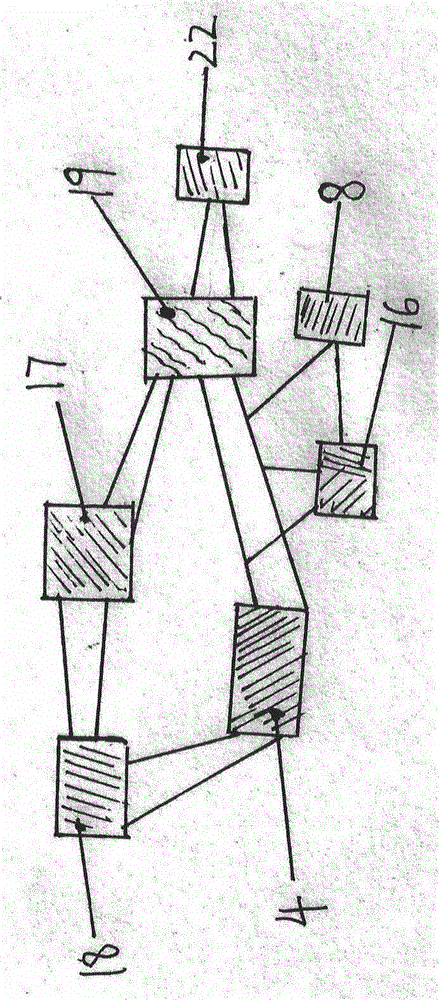

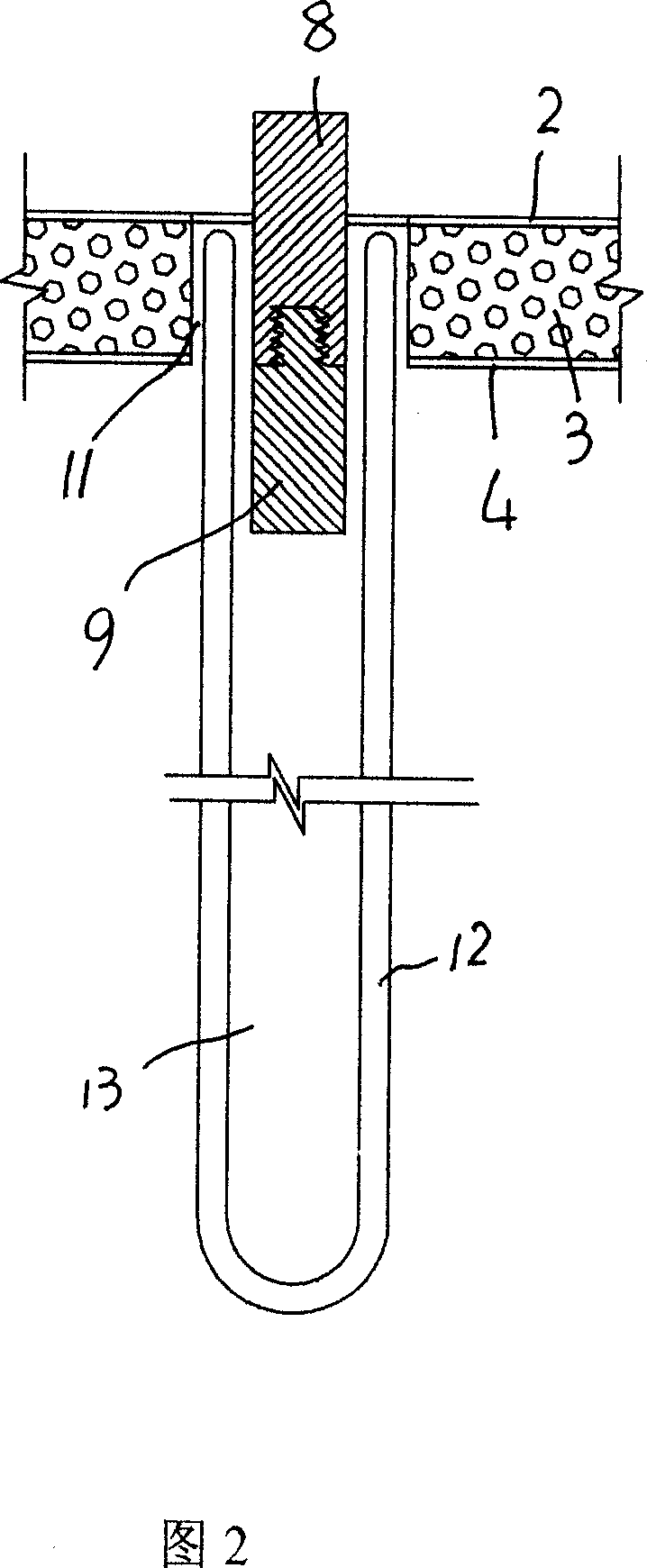

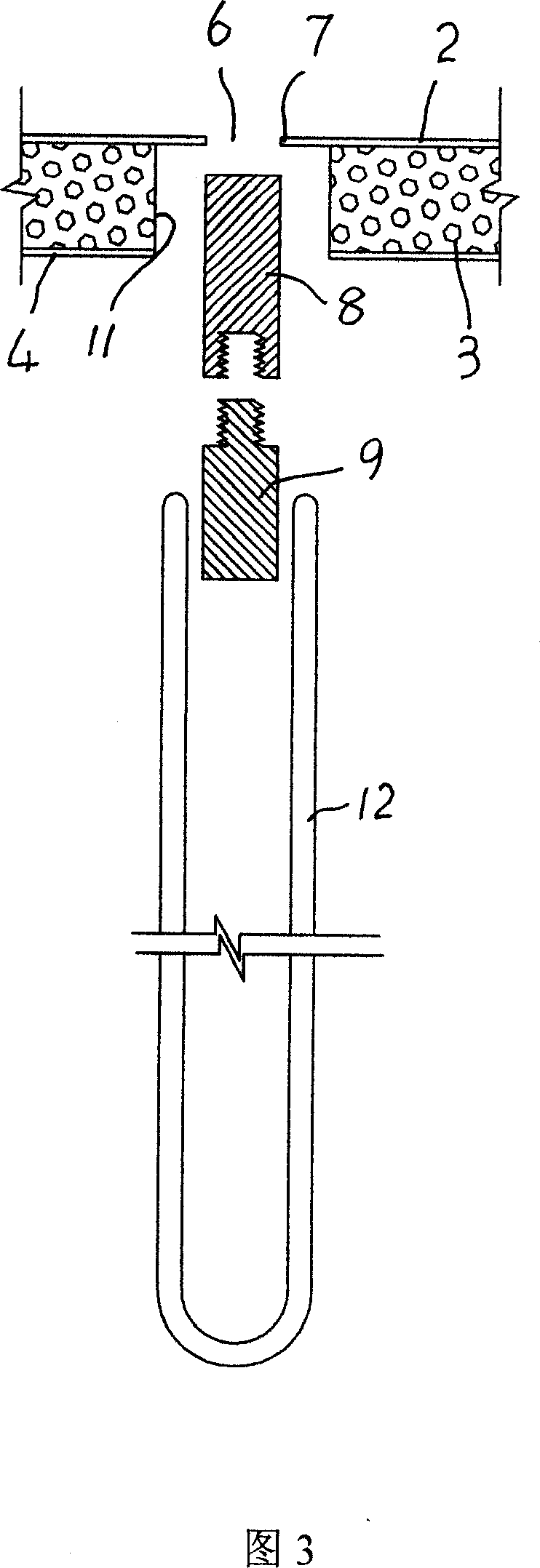

2D circulating gravity heat pipe

The invention relates to a two-dimensional cycling gravity heat pipe with guiding device. It is characterized in that guiding device, such as guiding plate, guiding pipe, drain pipe, impeller and collecting liquid cover so on is set in the heat pipe to make liquid in heat pipe flow on the setting route in cycling for promoting liquid steaming in evaporator, quickening gas-liquid cycling and improving heat conducting speed. Certain working material is injected in the closed cavity where the heat pipe is pumped in vacuum. When the heat pipe works, two setting cycling routes exist in the heat pipe. One is the cycling route with mutual transformation between working gas and working liquid and the other is the flowing cycling route in the working liquid.

Owner:刘海云

Fresh and pure water machine having water saving effect

ActiveCN106186188AAvoid cloggingProlong block timeWater/sewage treatment bu osmosis/dialysisWater savingFour-way valve

The invention discloses a fresh and pure water machine having water saving effect, which is composed of a primary filter core group, a water pump, and an RO membrane group. A pure water backflow pipe is connected to a water inlet pipe after the primary filter core group and before the water pump. Two output lines on a delay power cut control board are respectively connected to the water pump and a water inlet electromagnetic valve. The water inlet pipe after the water inlet electromagnetic valve is connected to a pressure-reduced micro pressure water storage barrel and a concentrated water backflow pipe which is provided with a concentrated water high pressure switch and a four-way valve. An input line of a 24-hour timing control board is connected to a power supply while an outlet line is connected to the water pump. When the fresh and pure water machine is switched on, TDS value of water quality of pure water can reach the standard quickly. The machine is free of waiting for water or has short waiting time, is free of or is less in waste on water, and is effectively prolonged in service life of the RO membrane.

Owner:正阳新地食品工业有限公司

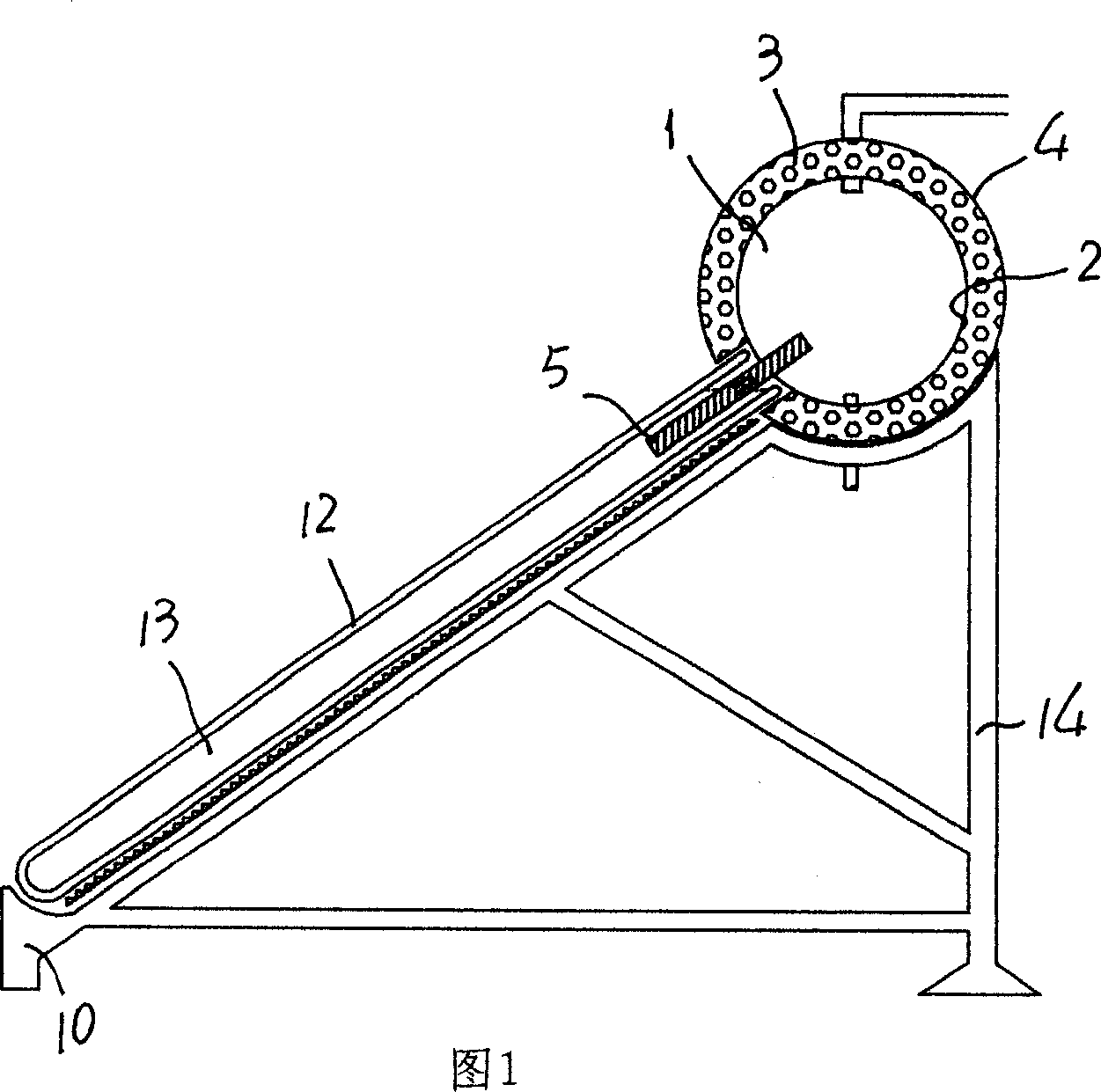

Rod insertion pressure bearing type solar energy water heater

InactiveCN1948859AAvoid pipe burstImprove heat transfer efficiencySolar heating energySolar heat devicesSolar waterEngineering

A solar water heater adopts a pressure-bearing water tank and a vacuum heat-collecting pipe and it is characterized by setting a metal heat-conducting bar. The insert section in the upper part of the metal heat-conducting bar is plugged in the inner container of the water tank and the extension section in the lower part of the metal heat-conducting bar is plugged in the vacuum heat-collecting pipe. The inserting mouth of the metal heat-conducting bar on the inner container of the water tank forms a plugging and the mouth of the vacuum heat-collecting pipe is disposed in the insulating layer of the pressure-bearing water tank and in the preset mouth of the casing.

Owner:尚诚德

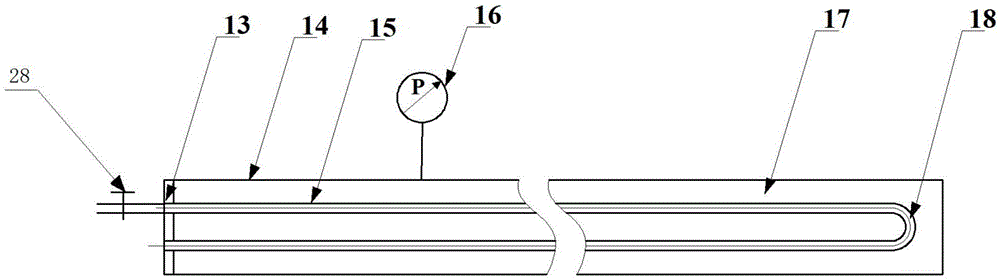

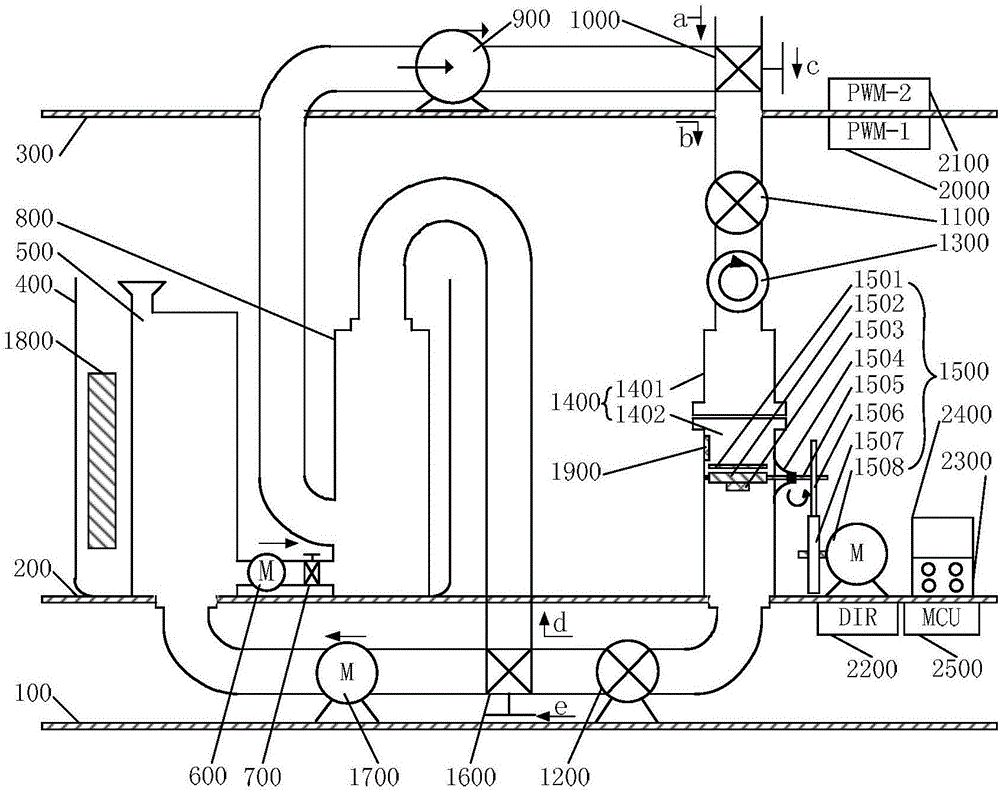

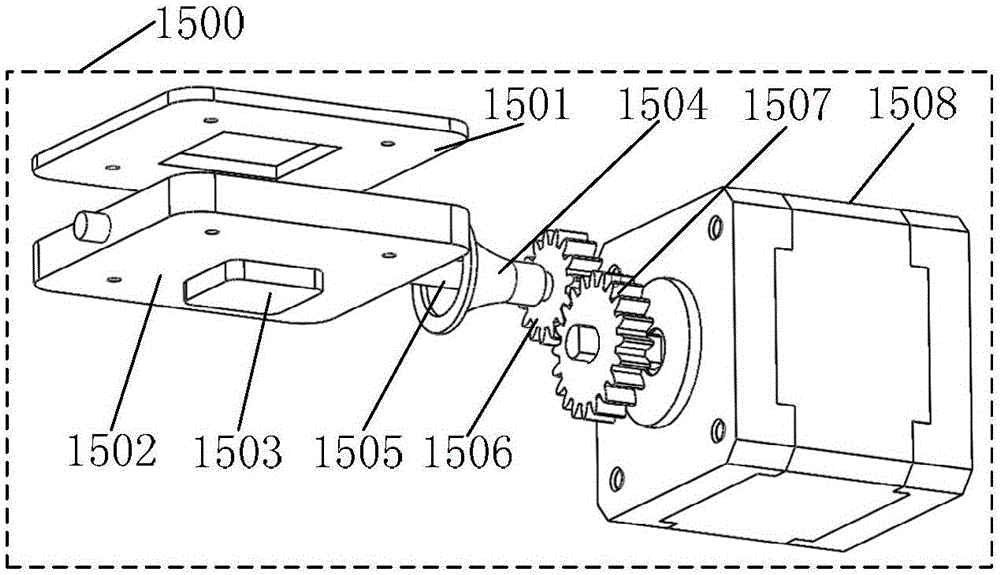

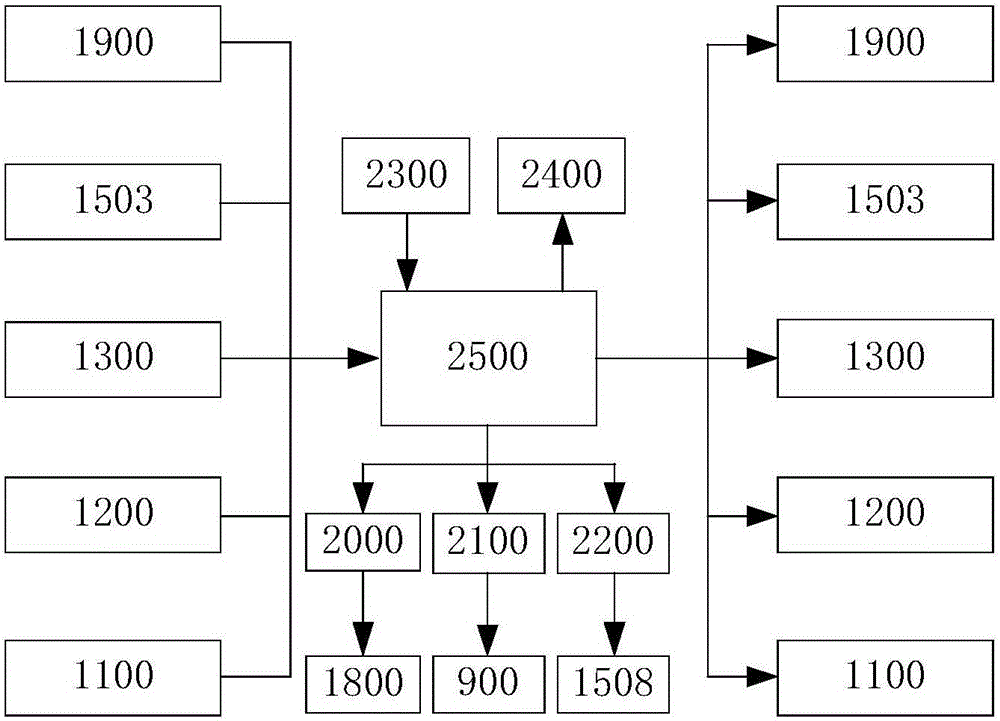

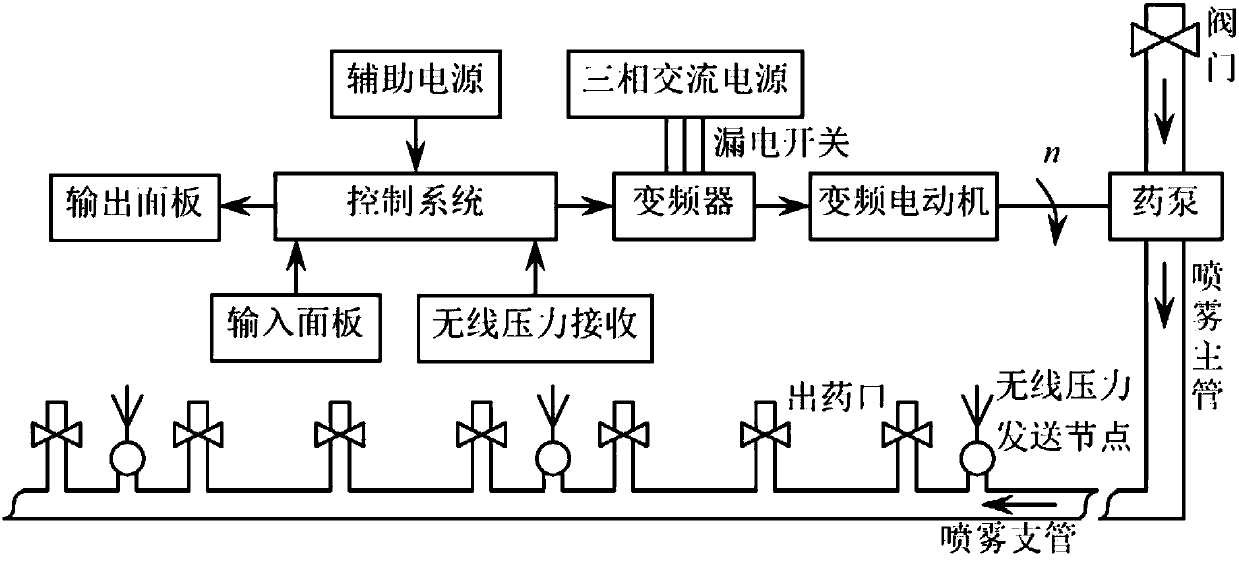

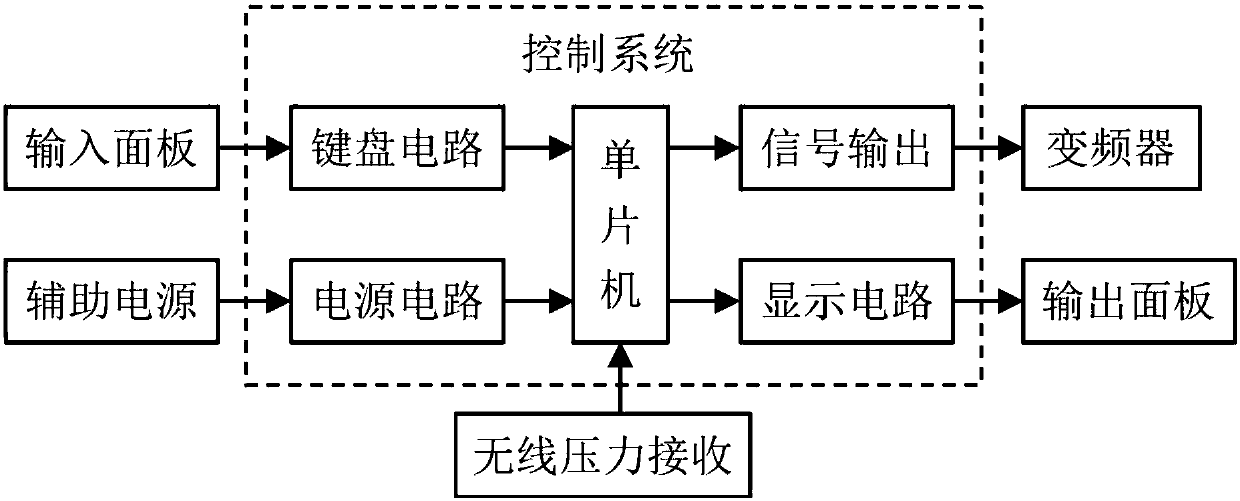

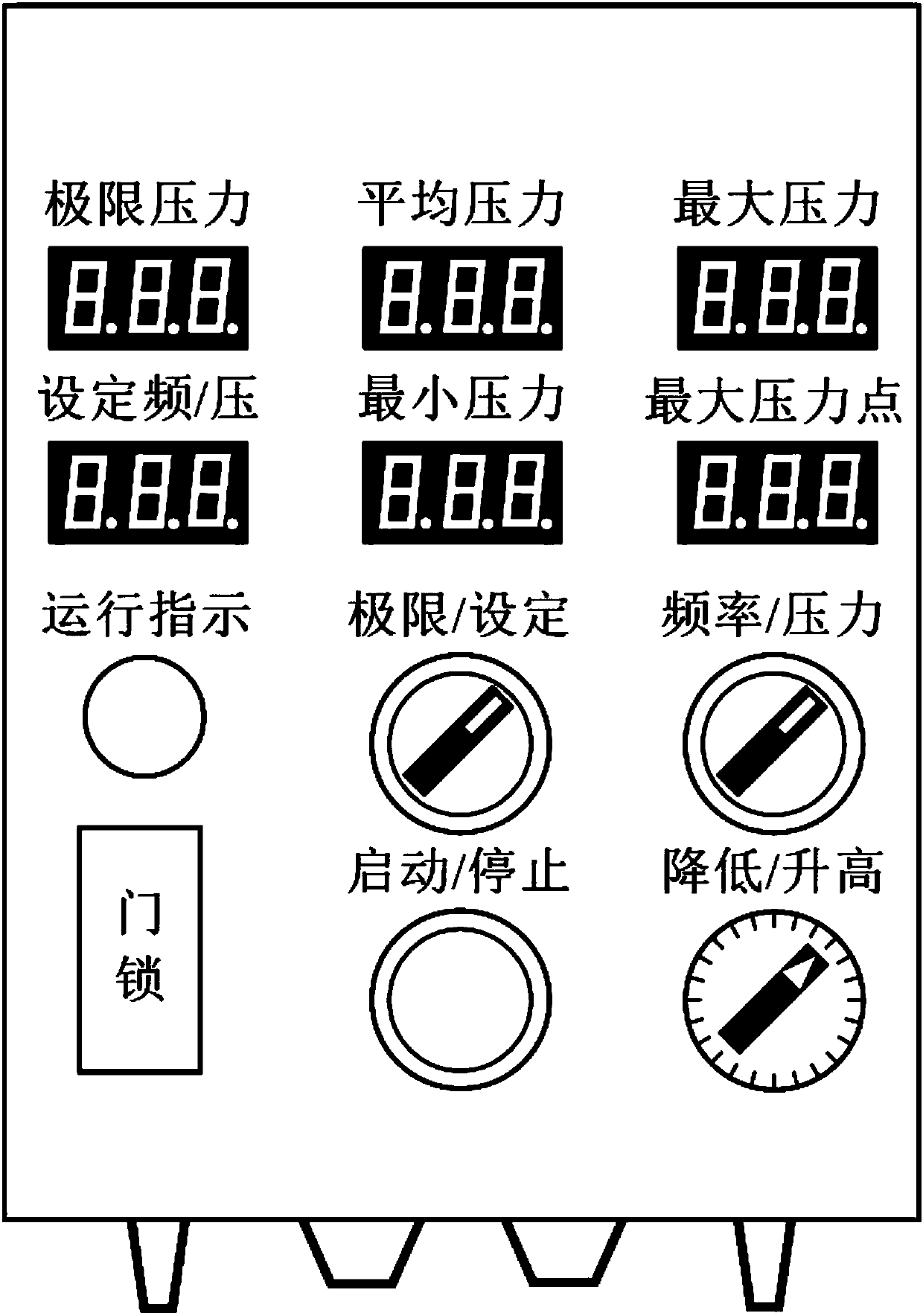

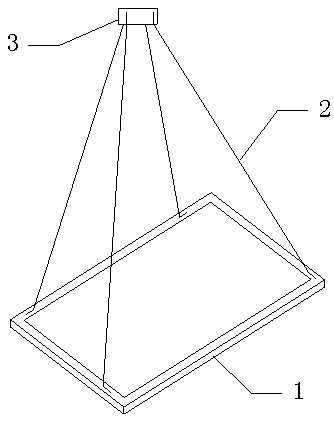

Pressure control device and method for spraying liquid medicine in pipeline of orchard

ActiveCN107943127AAvoid pipe burstLiquid pressure controlFluid pressure control using electric meansFrequency changerOrchard

The invention discloses a pressure control device and method for a spraying liquid medicine in a pipeline of an orchard. The device comprises a control system, an input panel, an output panel, a frequency converter, a frequency-conversion motor, a medicine pump, a wireless pressure receiving module and wireless pressure sending nodes; the control system is connected with the input panel, the output panel, the frequency converter and the wireless pressure receiving module, the frequency converter, the frequency-conversion motor and the medicine pump are connected successively, a medicine inputend of the medicine pump is connected with a medicine pool, and a medicine output end of the medicine pump is connected with the spraying pipeline; and the wireless pressure sending nodes are arrangedin the spraying pipeline, and connected with the wireless pressure receiving module. According to the invention, a control system can adjust the frequency of the frequency converter to control the rotating speed of the frequency-conversion motor and further control the medicine output amount of the medicine pump so as to control the liquid medicine pressure in the spraying pipeline, solve the problem that traditional pipeline spraying cannot control the liquid medicine pressure effectively, and improve the spraying effect.

Owner:SOUTH CHINA AGRI UNIV

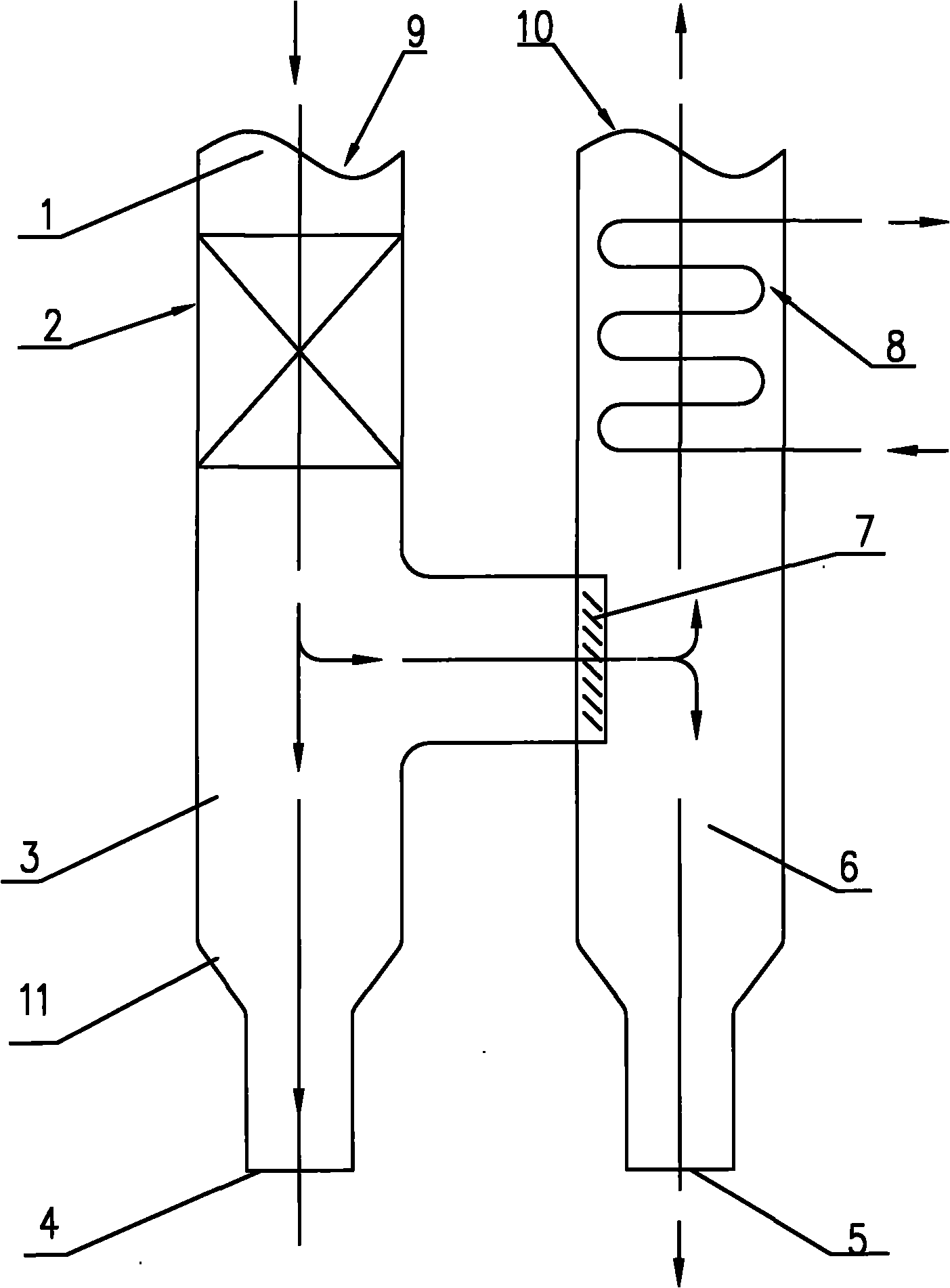

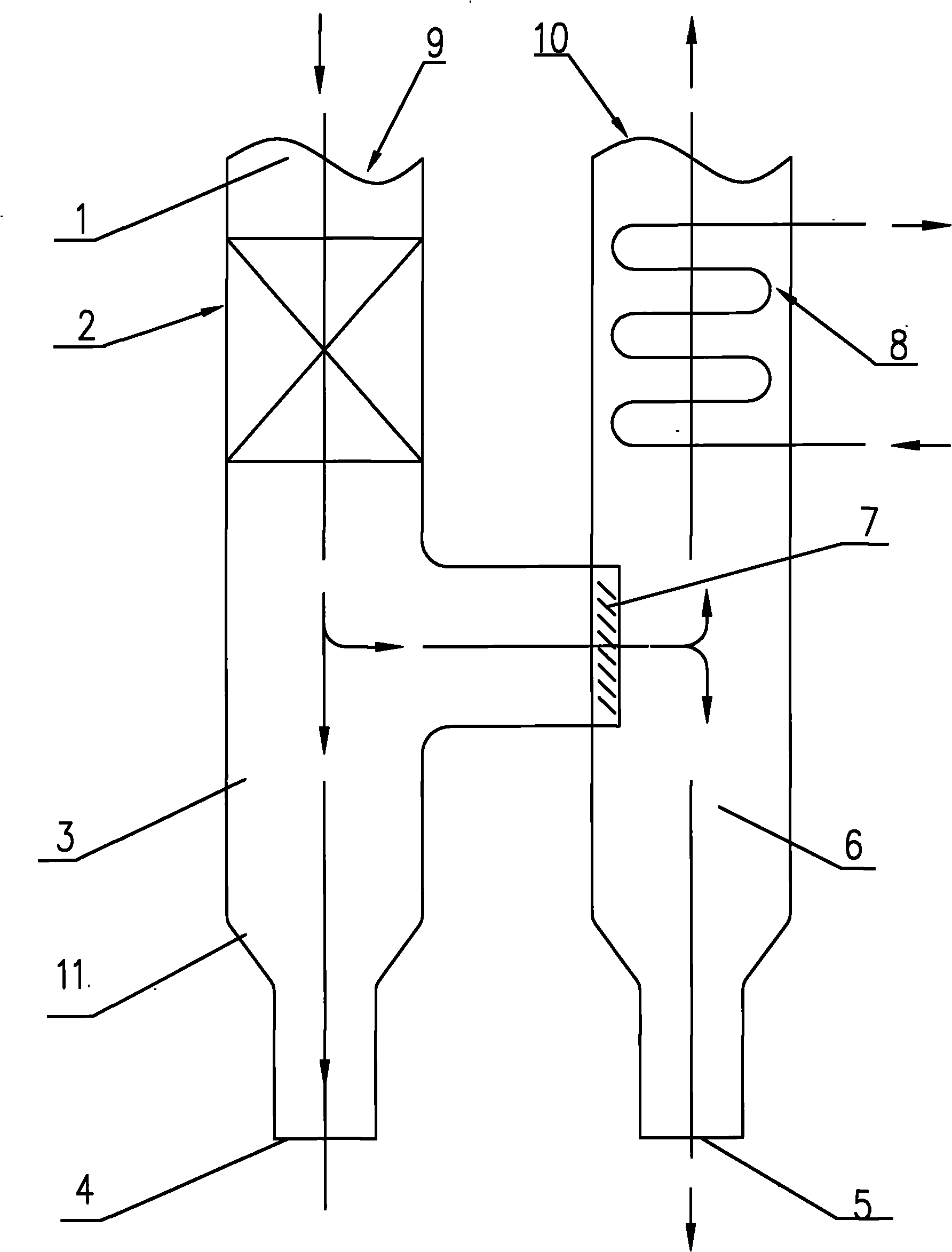

Waste heat recovery device

InactiveCN101963460AReduce mineral dust contentAutomatic temperature adjustmentEnergy industryWaste heat treatmentWaste heat recovery unitFlue gas

The invention discloses a waste heat recovery device. The device comprises a pre-evaporator, a primary ash settlement room, a secondary ash settlement room and a superheater, wherein the pre-evaporator and the primary ash settlement room are communicated with a flue; the secondary ash settlement room is communicated with the primary ash settlement room; the superheater is arranged in the secondary ash settlement room; the upper part of the primary ash settlement room is provided with a flue gas inlet; the lower part of the primary ash settlement room is provided with a primary ash discharge hole; the upper part of the secondary ash settlement room is provided with a flue gas outlet; the lower part of the secondary ash settlement room is provided with a secondary ash discharge hole; the superheater is arranged at the flue gas outlet; and an ash separator used for reducing a gas flow speed and separating ash is arranged between the primary ash settlement room and the secondary ash settlement room. The waste heat recovery device can separate ash from the flue gas very well, stabilize the temperature of the flue gas, and uniformize and stabilize a gas passing through the surface of the superheater so as to reduce local erosive wear of a heating surface of the superheater caused by the flue gas and avoid the explosion of a pipe.

Owner:JIANGNAN BOILERS & PRESSURE VESSELS ZHANGJIAGANG

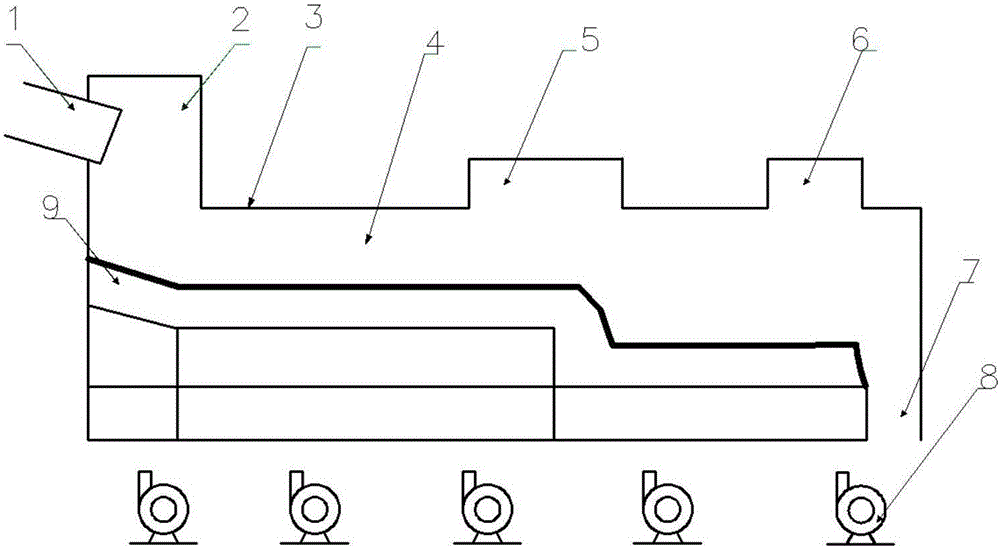

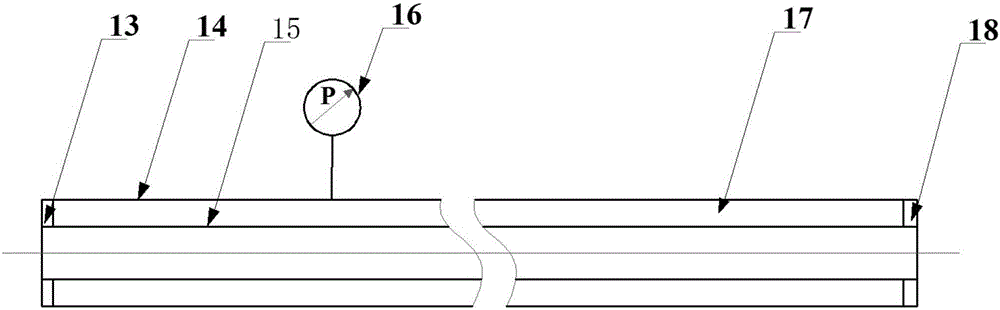

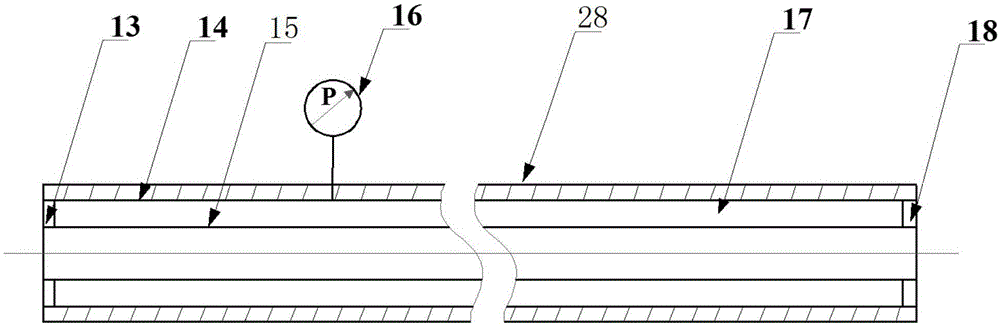

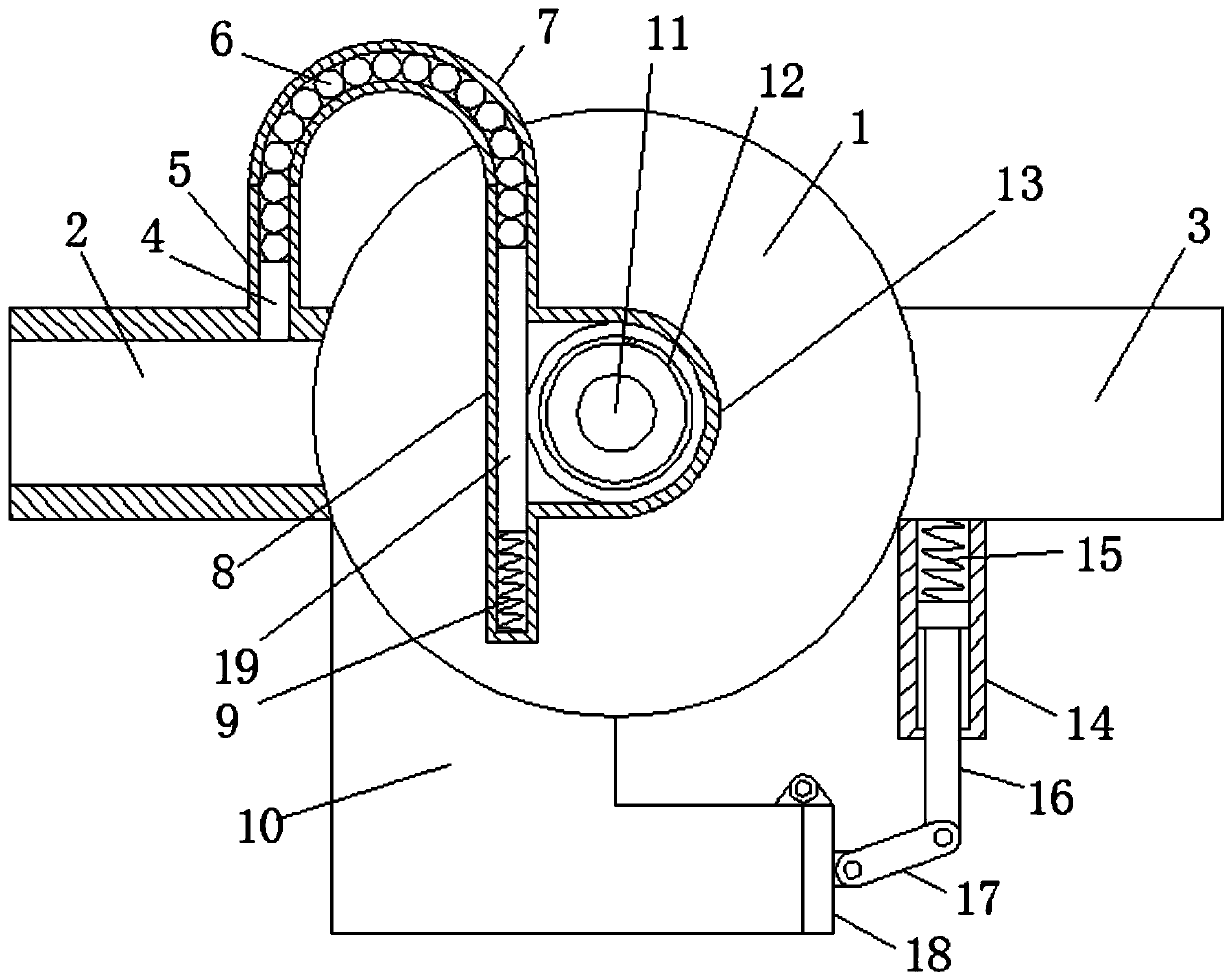

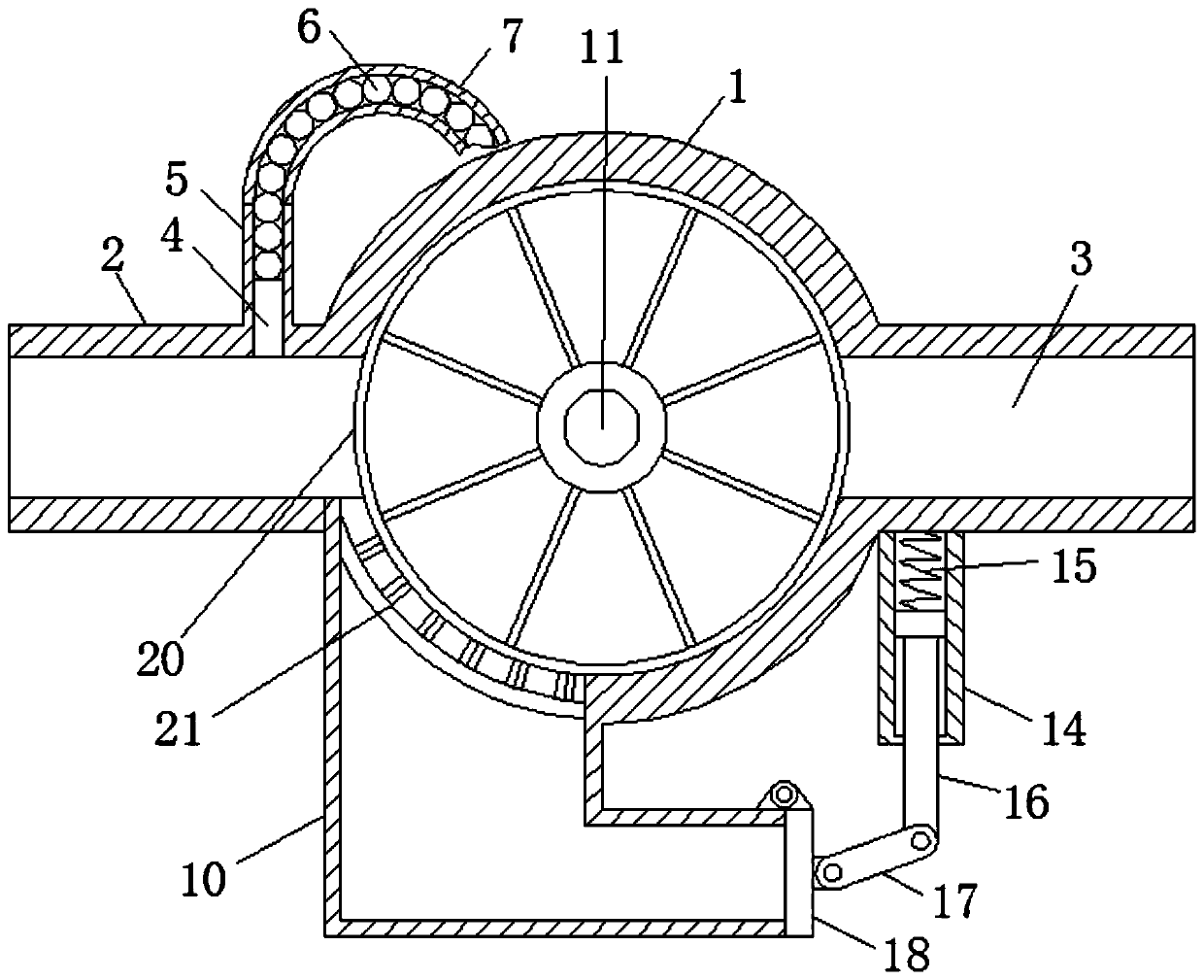

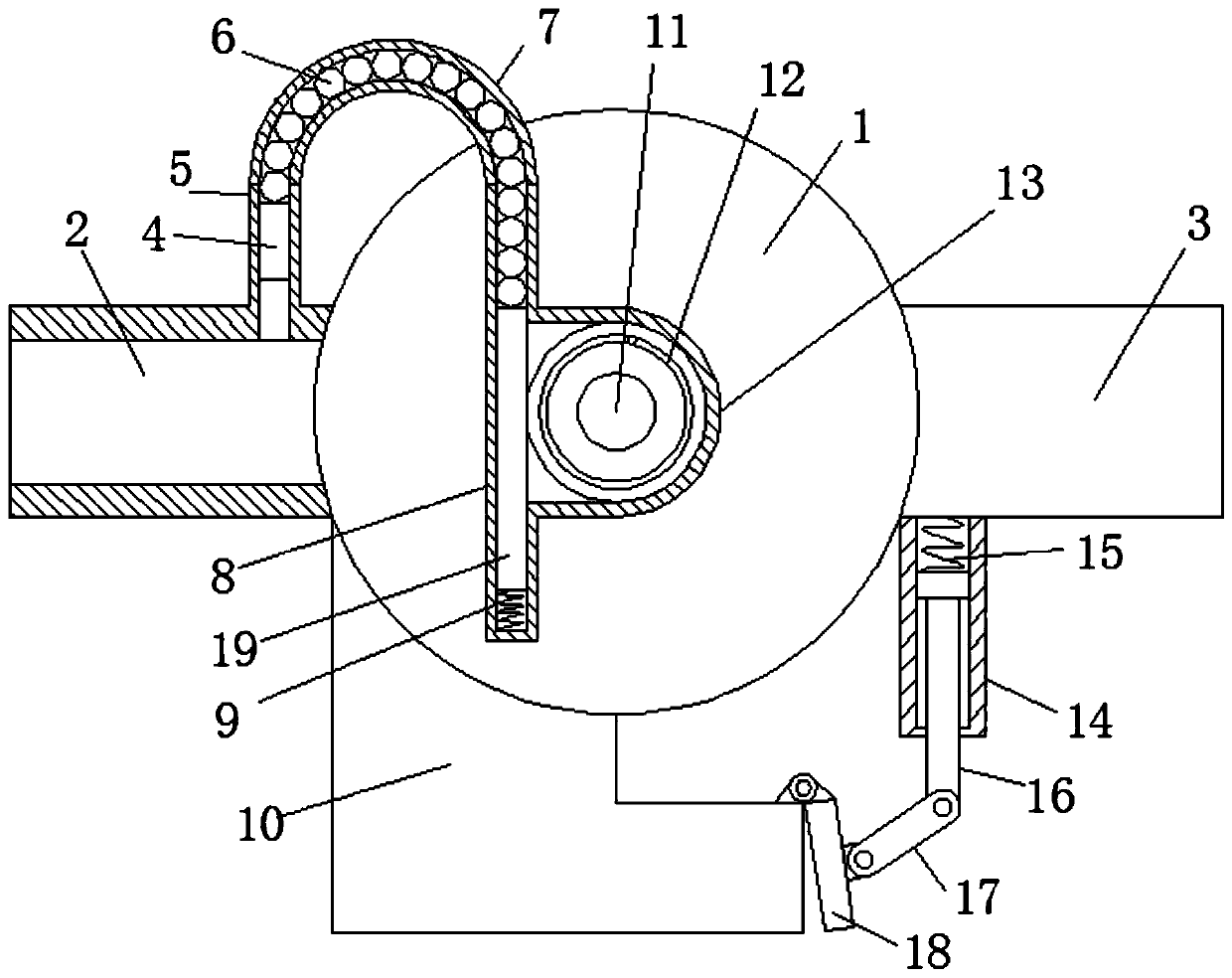

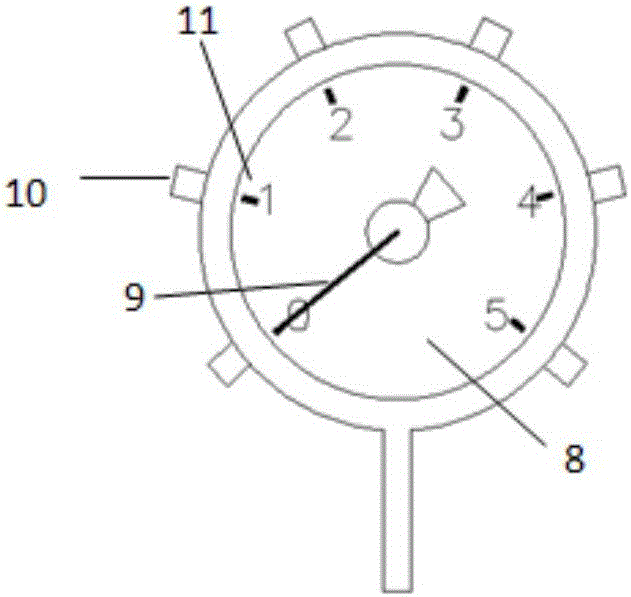

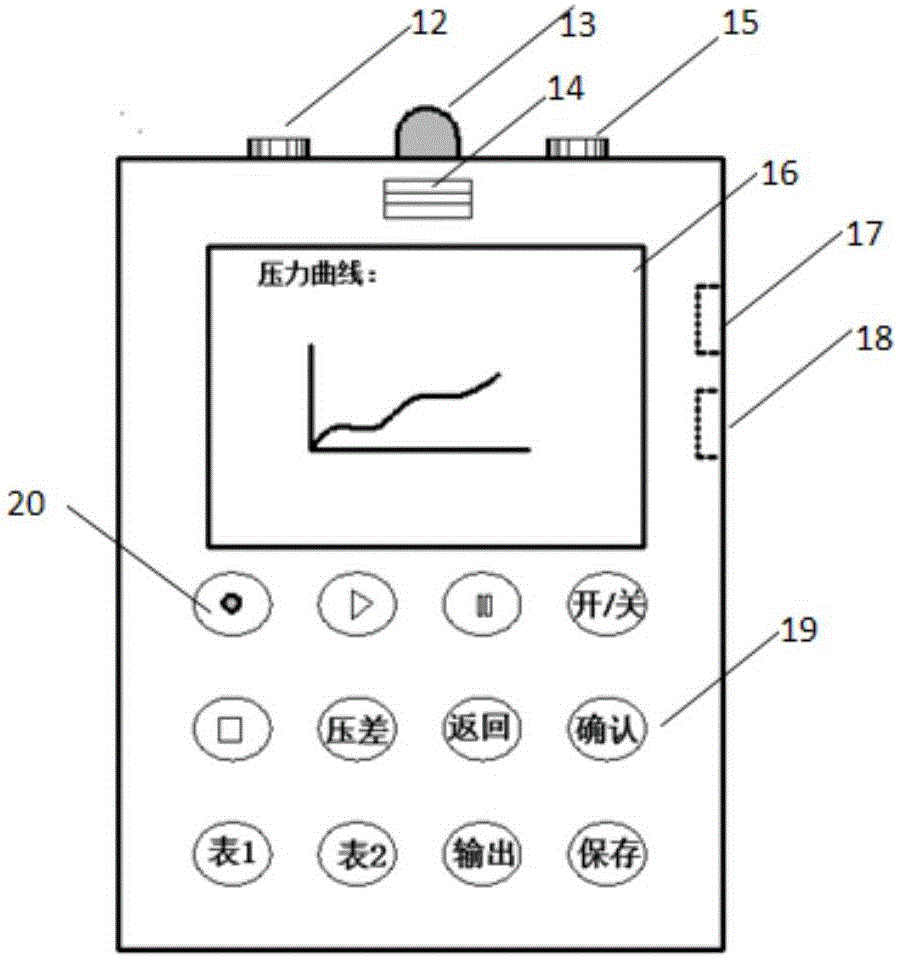

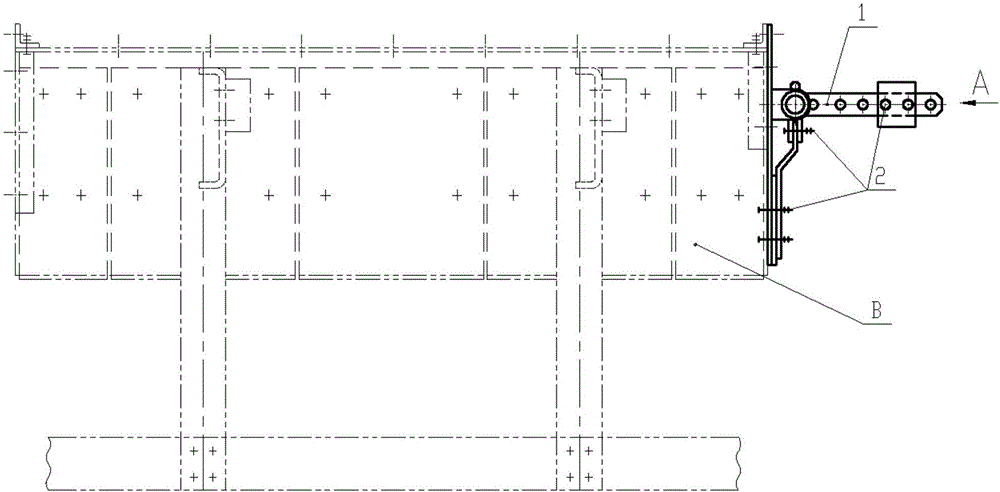

Anti-grouting-pipe-explosion monitoring and early warning system and using method thereof

ActiveCN106768601AReduce labor intensityImprove securityPressure difference measurement between multiple valvesEarly warning systemEngineering

The invention relates to an anti-grouting-pipe-explosion monitoring and early warning system and a using method thereof. The system comprises a first pressure measuring device which is arranged at the grout outlet of a grouting pump and used for measuring a first pressure value of grout at the outlet of the grouting pump, a second pressure measuring device which is arranged at the inlet of a grouting pipe and used for measuring a second pressure value of grout at the inlet of the grouting pipe, and an early warning device which has a shell for accommodating an early warning unit, wherein the first pressure measuring device and the second pressure measuring device are pressure gauges, each pressure gauge is equipped with a threshold input device, and the early warning device sounds an alarm when the first pressure value or the second pressure value is greater than a first threshold.

Owner:THE SECOND ENG CO LTD OF CHINA RAILWAY 14TH CONSTR BUREAU CO LTD +1

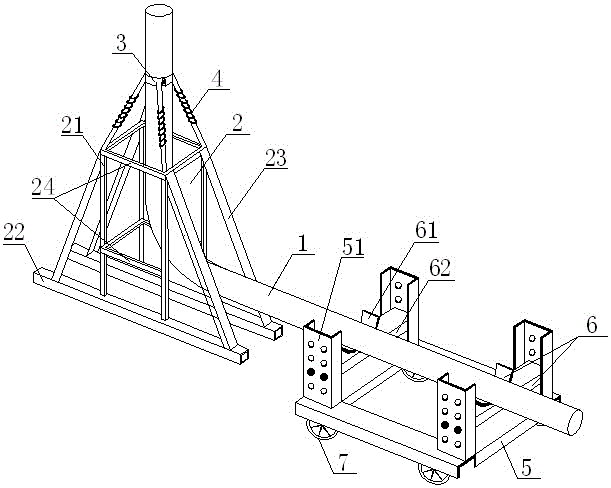

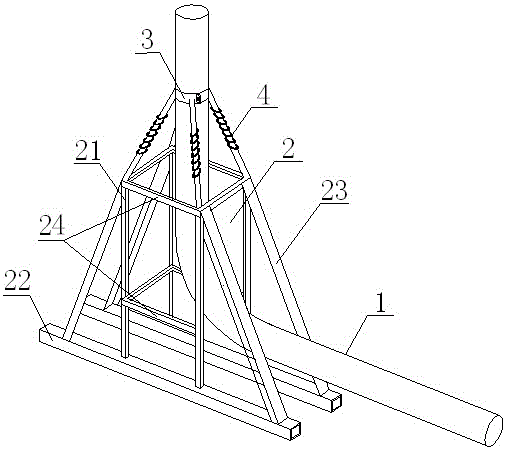

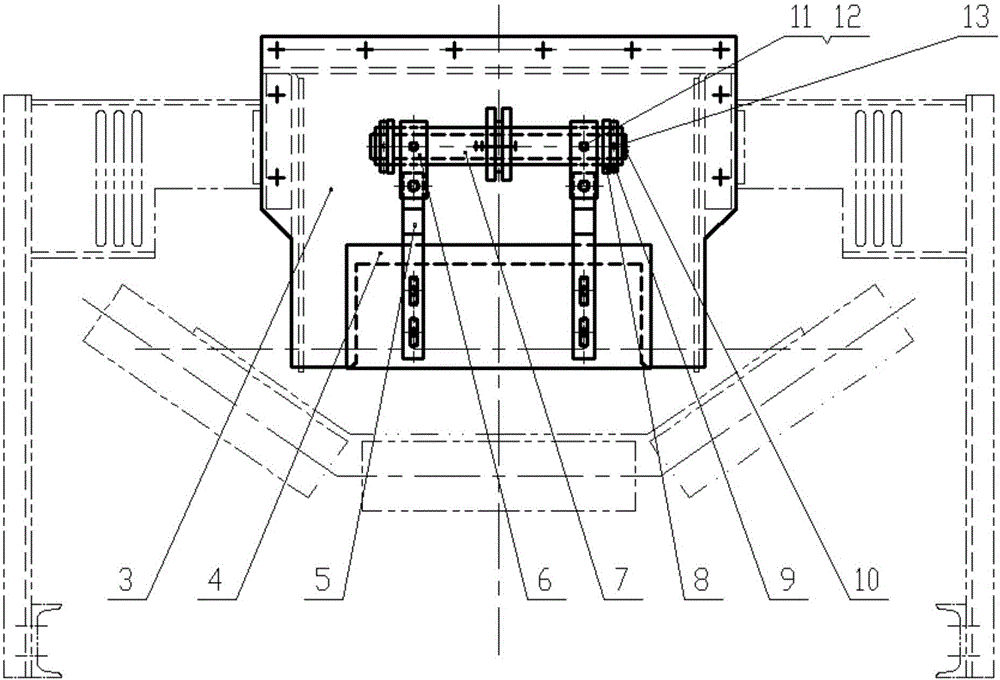

Concrete pouring pump pipe bracket

InactiveCN109518973ASimple structureEasy to manufactureBuilding material handlingDetonationConcrete pump

A concrete pouring pump pipe bracket includes a centralizing seat and a buffer frame, wherein the centralizing seat comprises a base, four first diagonal bracing rods and first clamps, and the bufferframe comprises a square frame, four first vertical rods, second clamps and a pipe stabilizing hole, wherein the buffer frame is fixed to the rectangular square steel plate base, and base plates of the four first vertical rods of the buffer frame are welded and fixed to the square steel plate base. The concrete pouring pump pipe bracket has the advantages that a concrete pouring pump pipe bracketdevice is simple in structure and convenient to manufacture, the concrete pouring pump pipe bracket is stable in structure and suitable for concrete pouring projects of various concrete pump pipes, the impact force of the concrete pump pipes during concrete conveying is effectively reduced, the phenomenon is avoided that the excessive impact force of concrete to cause pump pipe detonation, construction safety is improved, and engineering costs are reduced.

Owner:MCC5 GROUP CORP SHANGHAI

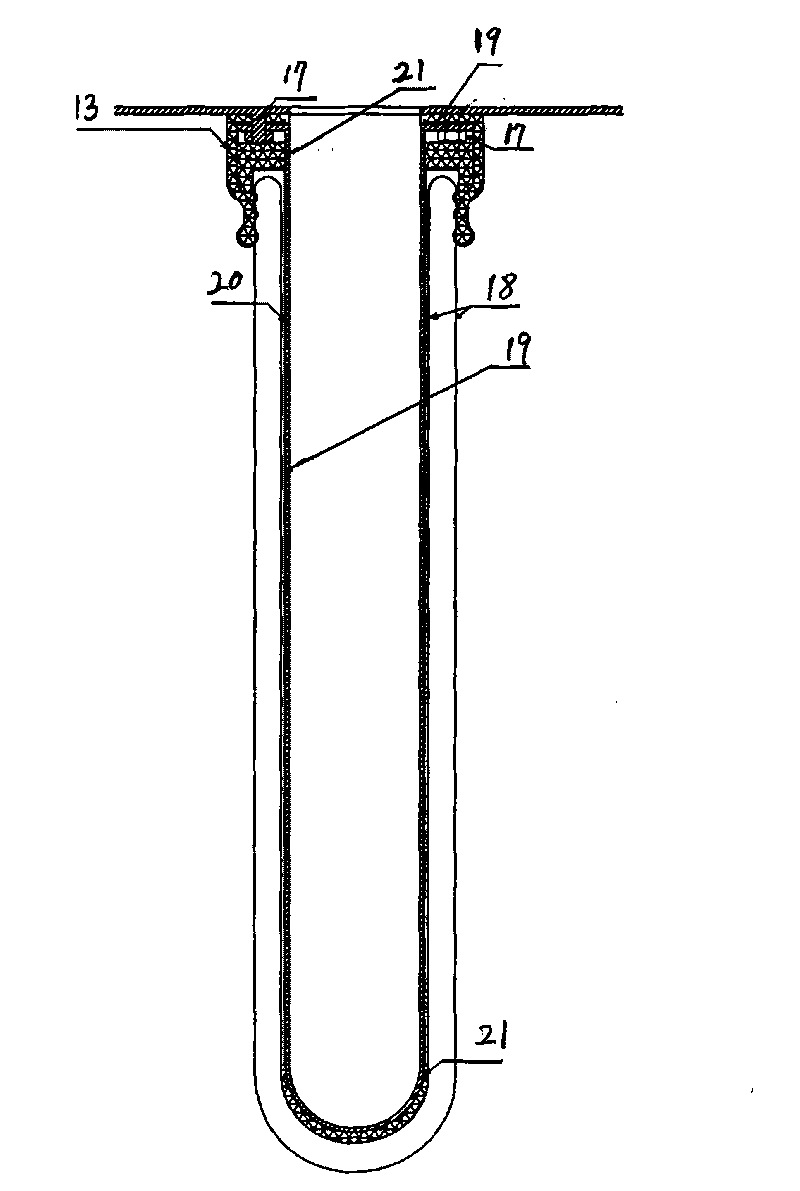

Solar evacuated collector tube

ActiveCN104748403AAvoid pipe burstQuickly disperseSolar heating energySolar heat devicesBoiling pointElectrical and Electronics engineering

The invention provides a solar evacuated collector tube which comprises an inner-layer glass tube and an outer-layer glass tube. A vacuum layer is arranged between the inner-layer glass tube and the outer-layer glass tube. A glass cavity is formed in the bottom of the inner-layer glass tube and communicated with the vacuum layer through a hole, an annular sealing board for connecting the inner-layer glass tube with the outer-layer glass tube is arranged in the vacuum layer, and the vacuum space below the port, in the vacuum layer, of the hole and the space above the vacuum space are isolated. The upper surface of the annular sealing board is not lower than the lower side of the port. The glass cavity contains mercury. When the temperature of the mercury is lower than 90% of the boiling point of liquid in the inner-layer glass tube at the standard atmospheric pressure, the volume of the mercury is smaller than the volume of the glass cavity; when the temperature of the mercury reaches the boiling point, mercury expands so that the glass cavity and the vacuum space above the annular sealing space are filled with the mercury. The solar evacuated collector tube has the excellent anti-explosion performance, and an explosion is not likely to happen even under the environment that a pressure relief hole is not available.

Owner:六安荣耀创新智能科技有限公司

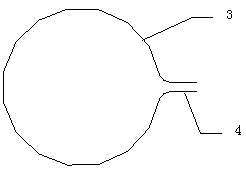

Circular tube conveyor material flow control device

A circular tube conveyor material flow control device comprises a pre-tensioning counterweight device, a fastener, a baffle, an adjusting plate, an adjusting linkage plate, a joint ring, a shaft, a fixing plate, a fixing ring, a sealing plate, a pin shaft, a first cotter pin and a second cotter pin. The circular tube conveyor material flow control device is installed at the end of a front section of a material guiding groove B to replace a front curtain of the material guiding groove B. The baffle is made of a steel plate with the thickness being 6 mm. The three faces of the upper portion are connected with an outlet of the front section of the material guiding groove B through a flange, a rectangular opening is formed in the lower portion of the baffle. The outer side of the rectangular opening of the baffle is covered with an adjusting plate assembly. The adjusting plate and the adjusting linkage plate are connected through a fastener. The pre-tensioning counterweight device is connected with the shaft. The adjusting linkage plate is connected with the shaft through the joint ring, the pin shaft and the first cotter pin. The shaft is connected to the baffle through the fixing plate. The two ends of the shaft are sealed and welded through sealing plates. The device can effectively control material flow, the materials can uniformly enter a circular tube, the filling rate is close to a theoretical filling rate, explosion of a circular tube conveyor is avoided, and the device is applied to the field of bulk material conveying devices.

Owner:NORTHERN HEAVY IND GRP CO LTD

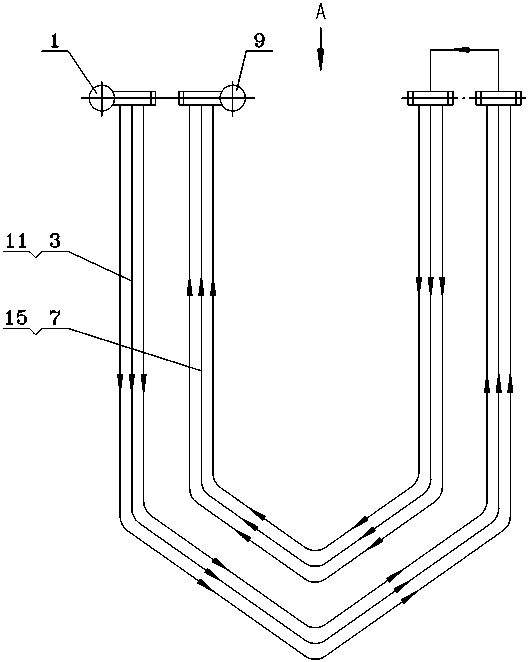

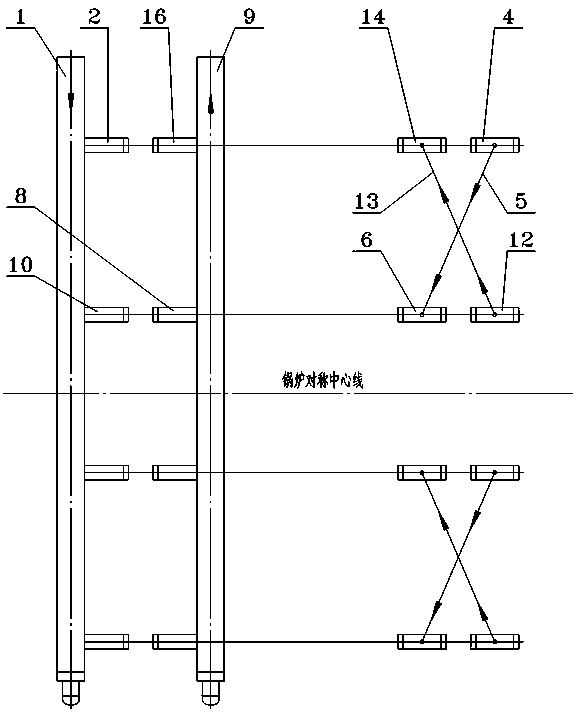

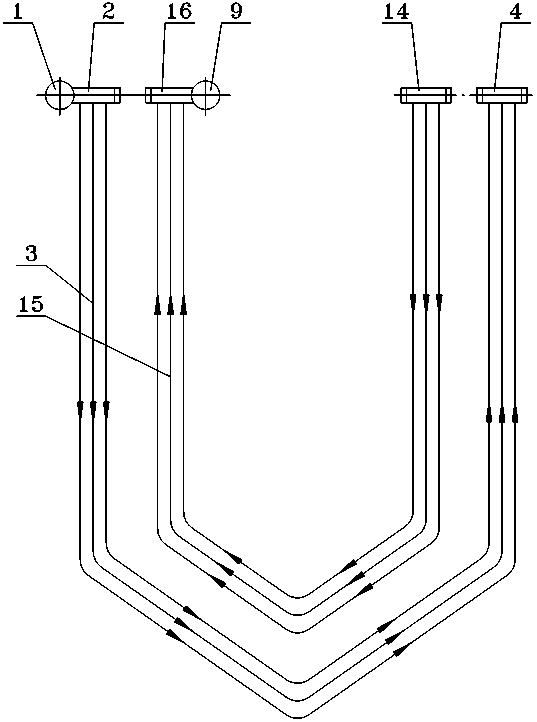

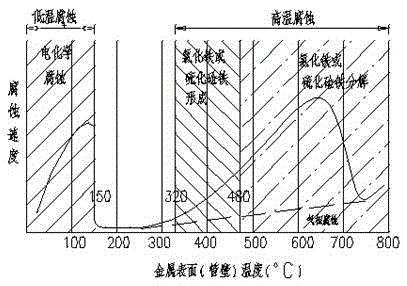

Cross mixed flow superheater

PendingCN109708096AReduce wall temperatureEliminate thermal deviation of working fluidSteam superheatersMixed flowCross connection

The invention discloses a cross mixed flow superheater. A superheater pipe screen comprises two sets of near center pipe screens and two sets of far center pipe screens separately arranged in a boilerin the boiler width direction; the two sets of near center pipe screens and the two sets of far center pipe screens are both connected with a superheater inlet header and a superheater outlet header;the near center pipe screens and the far center pipe screens approaching each other are connected through uniform temperature pipes; and near center pipe screen return headers with higher temperatures at the middle part of a hearth and far center pipe screen return headers with lower temperatures on two sides of the hearth are across connected, so that steam flows from the near center pipe screens to the far center pipe screens or from the far center pipe screens to the near center pipe screens for mixed flowing and mixed heating. The steam temperature of superheater pipe screen outlets separately arranged in the boiler width direction reaches the same parameters, so that the working medium heat deviation caused by different arrangement position temperature fields can be effectively eliminated, the wall temperature of superheated pipe screens in high-temperature areas is lowered, and the high-temperature corrosion in the areas is relieved and improved.

Owner:JINAN BOILER GRP

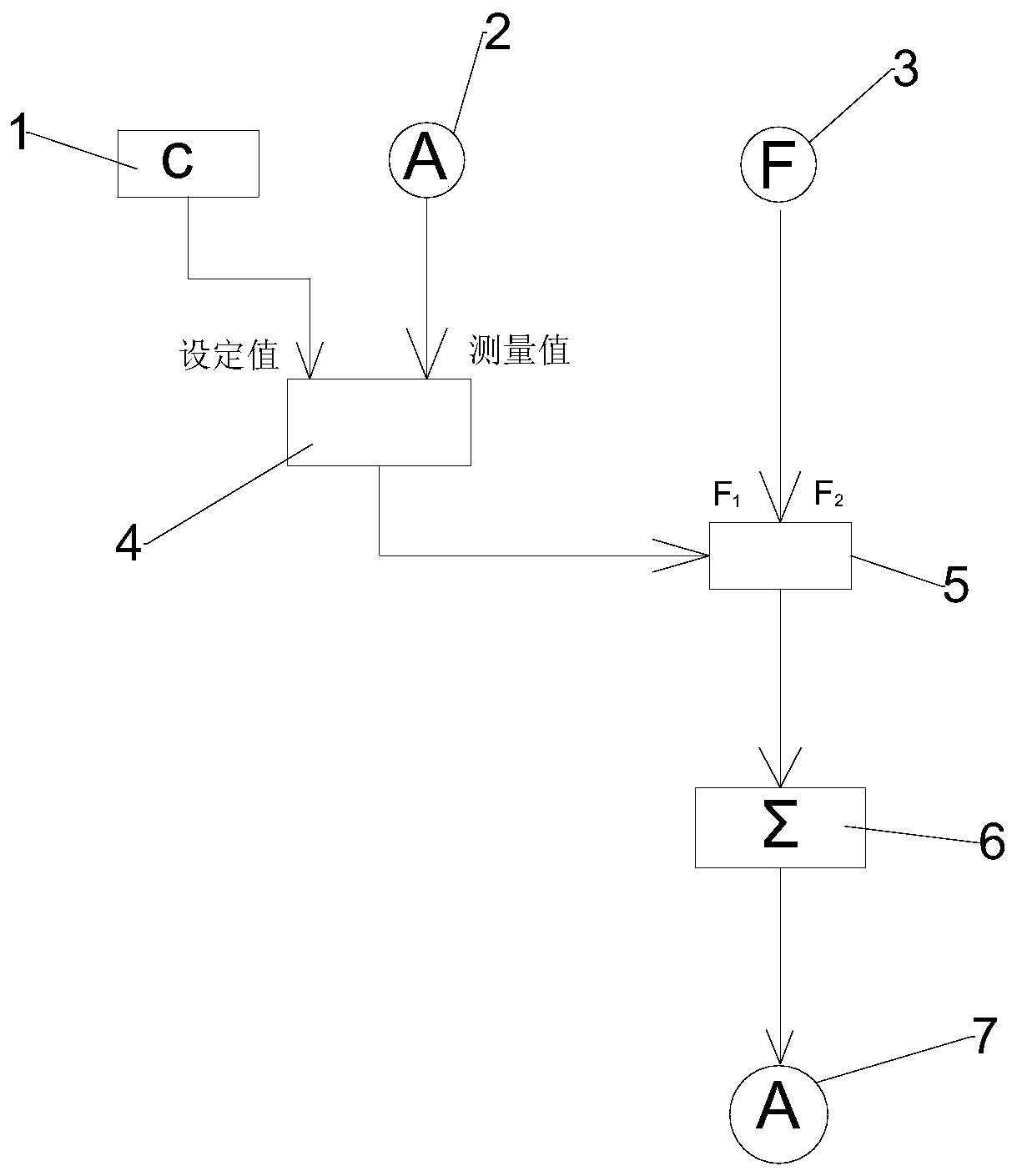

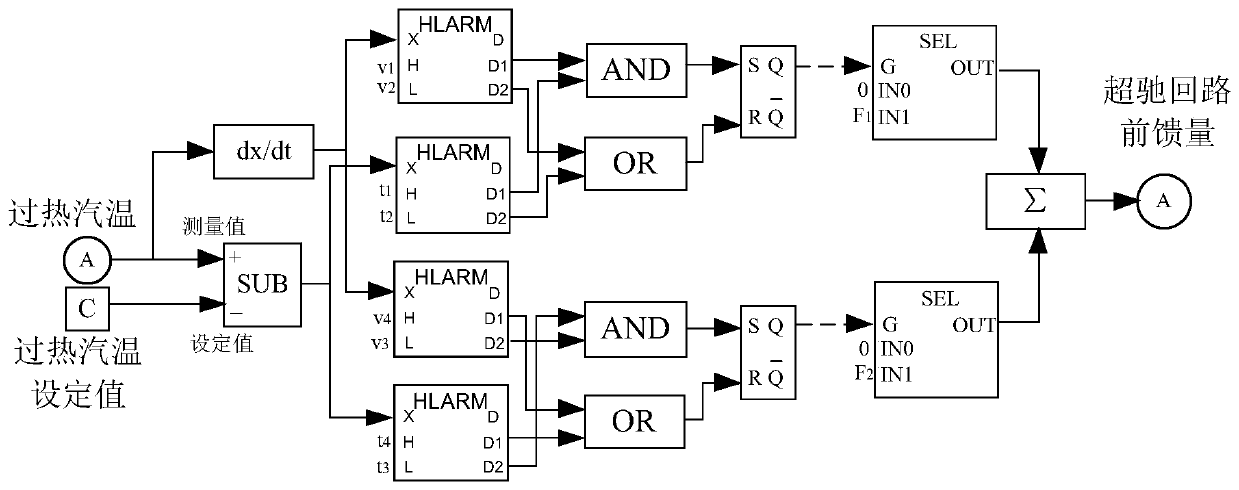

Override loop control method for superheated steam temperature of boiler

ActiveCN111486441ASmall temperature fluctuationsReduce labor intensitySuperheating controlTemperature controlLoop control

The invention provides an override loop control method for the superheated steam temperature of a boiler, and belongs to the technical field of boilers. An override loop control system is adopted forthe control method. The control system comprises a main controller, a feedforward controller, an override control module, a manipulator, a temperature sensor and a temperature control device. The temperature control device comprises a valve. The manipulator acts on the valve. The feedforward controller regards the real-time superheated steam temperature measured by the temperature sensor as a feedforward signal and feeds the signal back into the main controller, the main controller receives the information, and the override control module is rapidly started to control the increase and decreaseof the opening degree of the valve of the temperature control device, so that the superheated steam temperature is kept close to a set value. The control method can automatically, rapidly and accurately control the superheated steam temperature of the boiler, reduces the labor intensity of operators and reduces the fluctuation of the superheated steam temperature.

Owner:湛江电力有限公司

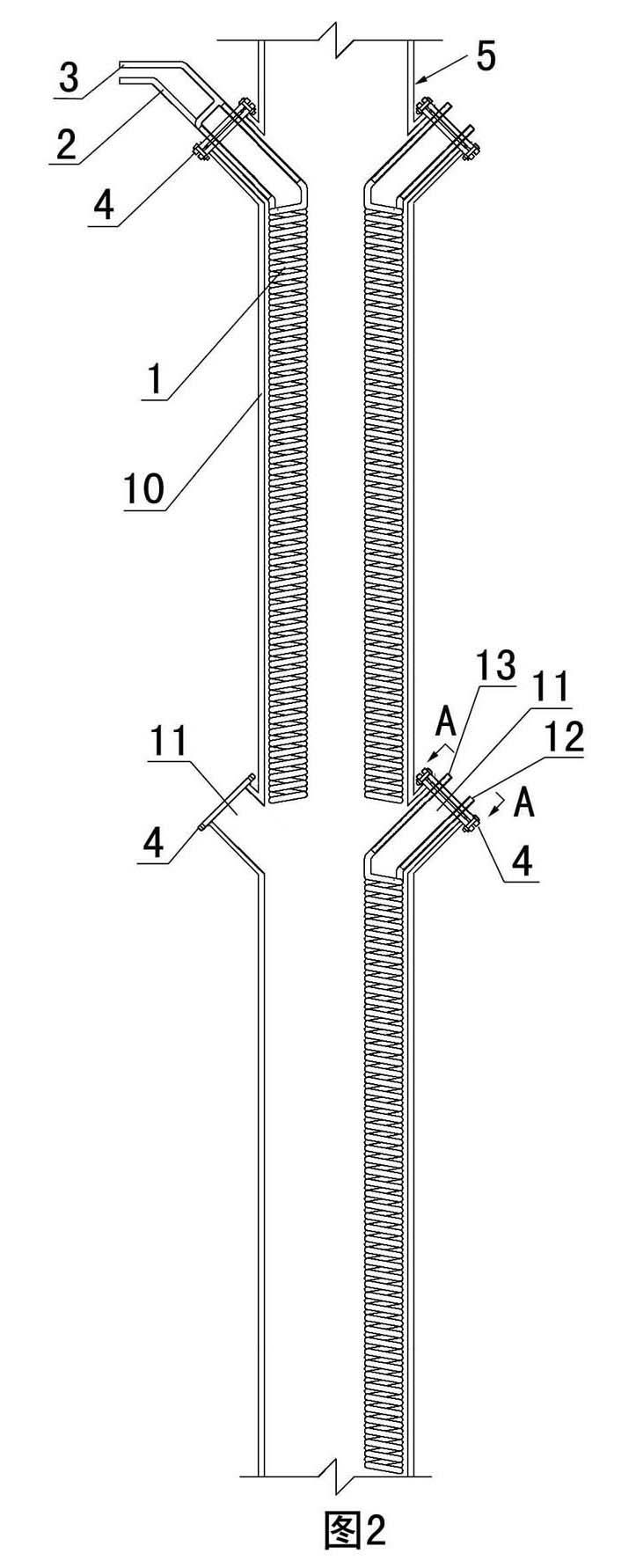

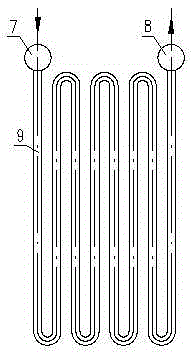

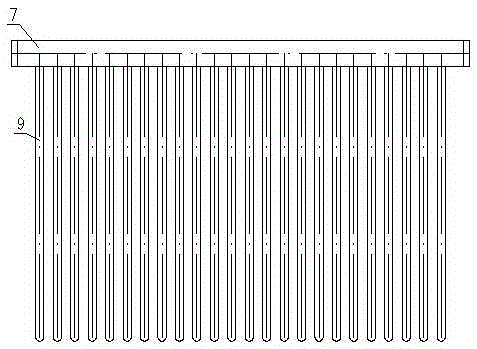

Uniform-temperature superheater for waste incineration boiler and superheated steam heating method

InactiveCN105299618AShort heating processImprove uniformitySteam superheatersIncinerator apparatusEngineeringSuperheater

The invention discloses a uniform-temperature superheater for a waste incineration boiler and a superheated steam heating method. The uniform-temperature superheater comprises a plurality of unit tube groups, wherein each unit tube group comprises an inlet mixer, an outlet mixer and a plurality of U-shaped superheating tubes which are connected between the inlet mixer and the outlet mixer in parallel; and the plurality of unit tube groups are sequentially arrayed, wherein the outlet mixer of the previous unit tube group is connected with the inlet mixer of the next unit tube group through a plurality of connection tubes which are connected in parallel. The uniform-temperature superheater disclosed by the invention is convenient to manufacture, short in tube pass, capable of improving the uniformity of the flow rate and the flow speed of steam in each section of tube and enabling the temperature of each section of tube to be balanced, and capable of preventing that the temperatures of the tubes are too high to accelerate corrosion to cause tube burst, thus benefiting to long-time stable running of the boiler.

Owner:CHINA WESTERN POWER INDAL

PPR plastic pipe with self-repairing function and preparation method thereof

The invention relates to a PPR plastic pipe with a self-repairing function and a preparation method thereof and belongs to the field of PPR pipe preparation. According to the preparation method of thePPR plastic pipe with the self-repairing function, the preparation method of the PPR plastic pipe includes the following steps that a, polyacrylic acid and poly allylamine hydrochloride are mixed uniformly into a mixed solution, the interlayer inner wall of an inner pipe body and an outer pipe body of the PPR plastic pipe are uniformly coated with the mixed solution, film forming is performed through thermal crosslinking, and the coated PPR pipe is obtained; and b, self-repairing micro capsules and light-blocking filler are mixed, an interlayer of the inner pipe body and the outer pipe body of the coated PPR pipe is filled with the mixed self-repairing micro capsules and light-blocking filler, and the PPR plastic pipe with the self-repairing function is prepared. After cracking happens tothe prepared the PPR plastic pipe, cracks can be fast repaired, pipe blasting is prevented, and the service life of the pipe is prolonged.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com