Heat collecting module of metal-glass sheathing heat collecting pipe

A heat collecting module and heat collecting tube technology, applied in the field of solar thermal energy utilization, can solve the problems of complex process, air leakage failure, high cost, etc., and achieve the effect of improving the absorption efficiency of light radiation, strengthening the pressure bearing capacity, and improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

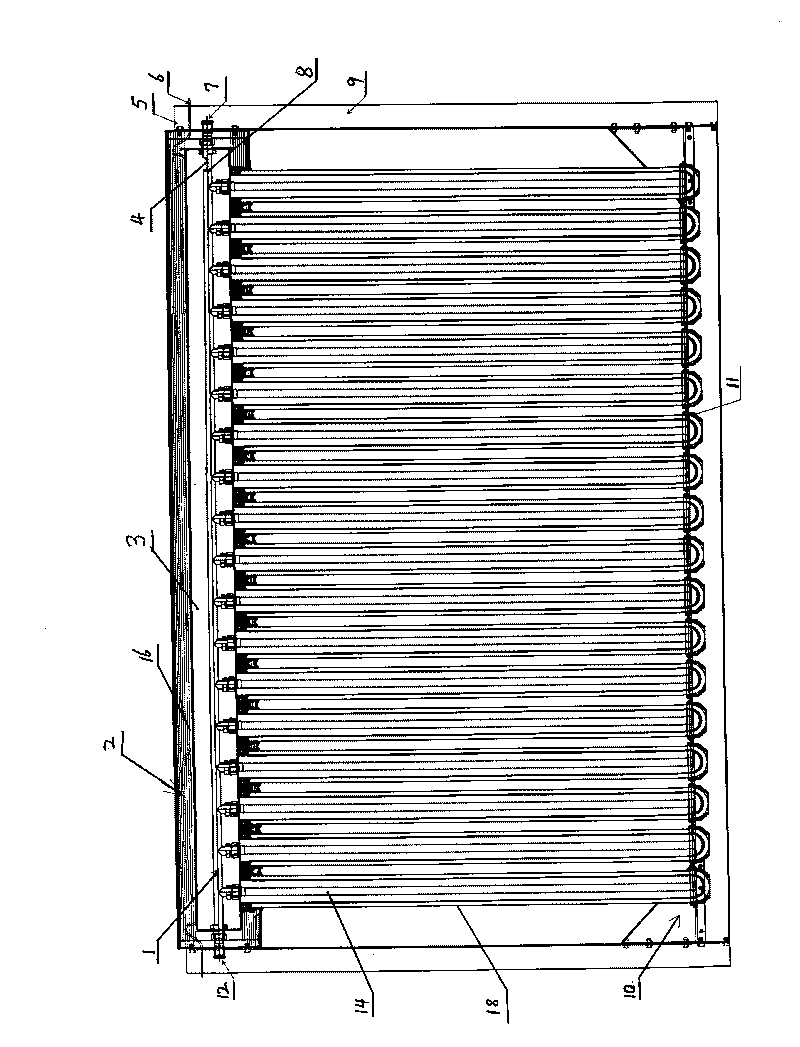

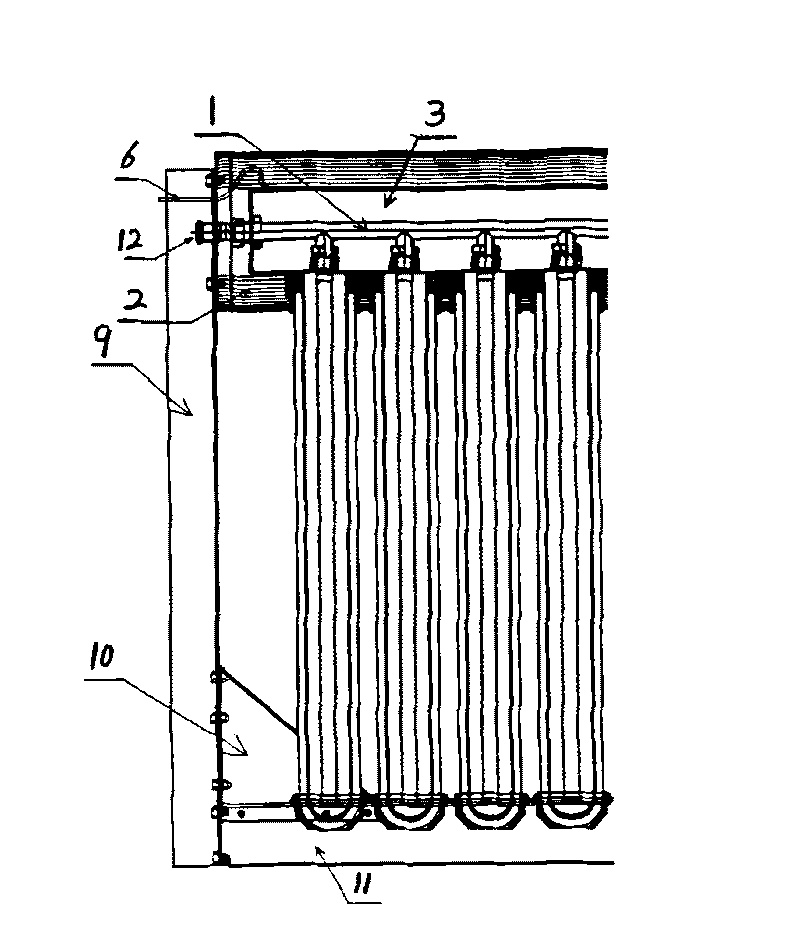

[0036] like figure 1 The shown metal-glass set collector tube collector module includes a collector tube, a connecting header 3, a temperature sensor 5, a collector tube tail 11, a collector connecting groove 9, a water injection pipe 14, and a water injection circulating flow channel 1.

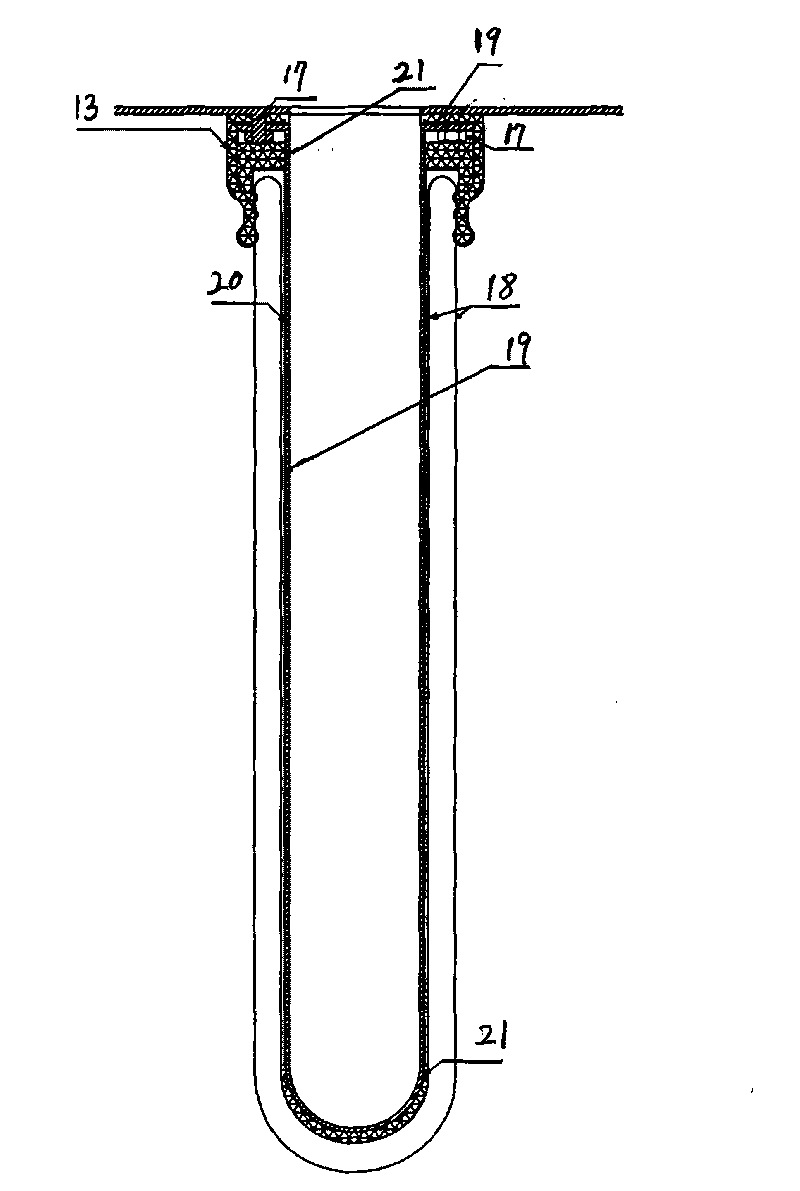

[0037] The heat collecting tube includes a glass vacuum heat preservation tube 18 and a metal heat collecting tube 19 . The metal heat collecting tube 19 is placed in the glass vacuum heat preservation tube 18 , and a silicone stop gasket 21 is filled between the tail of the glass vacuum heat preservation tube 18 and the metal heat collecting tube 19 .

[0038] The metal heat collector tube 19 is made of thin-walled polished stainless steel tube, electroless copper plating is used as the high infrared reflection film, and the electroplated black nickel layer is used as the high absorption outer layer. cm 2 , the optimum thickness of single-layer black nickel coating is 0.040~0.052mg / cm 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com