Novel high pressure-resistant maintenance-free rotary compensator

A rotary compensator and high-pressure-resistant technology, which is used in expansion compensation devices for pipelines, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as increased pressure loss, restricted medium flow, and large friction coefficient. Achieve the effect of reducing pressure loss and improving pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings.

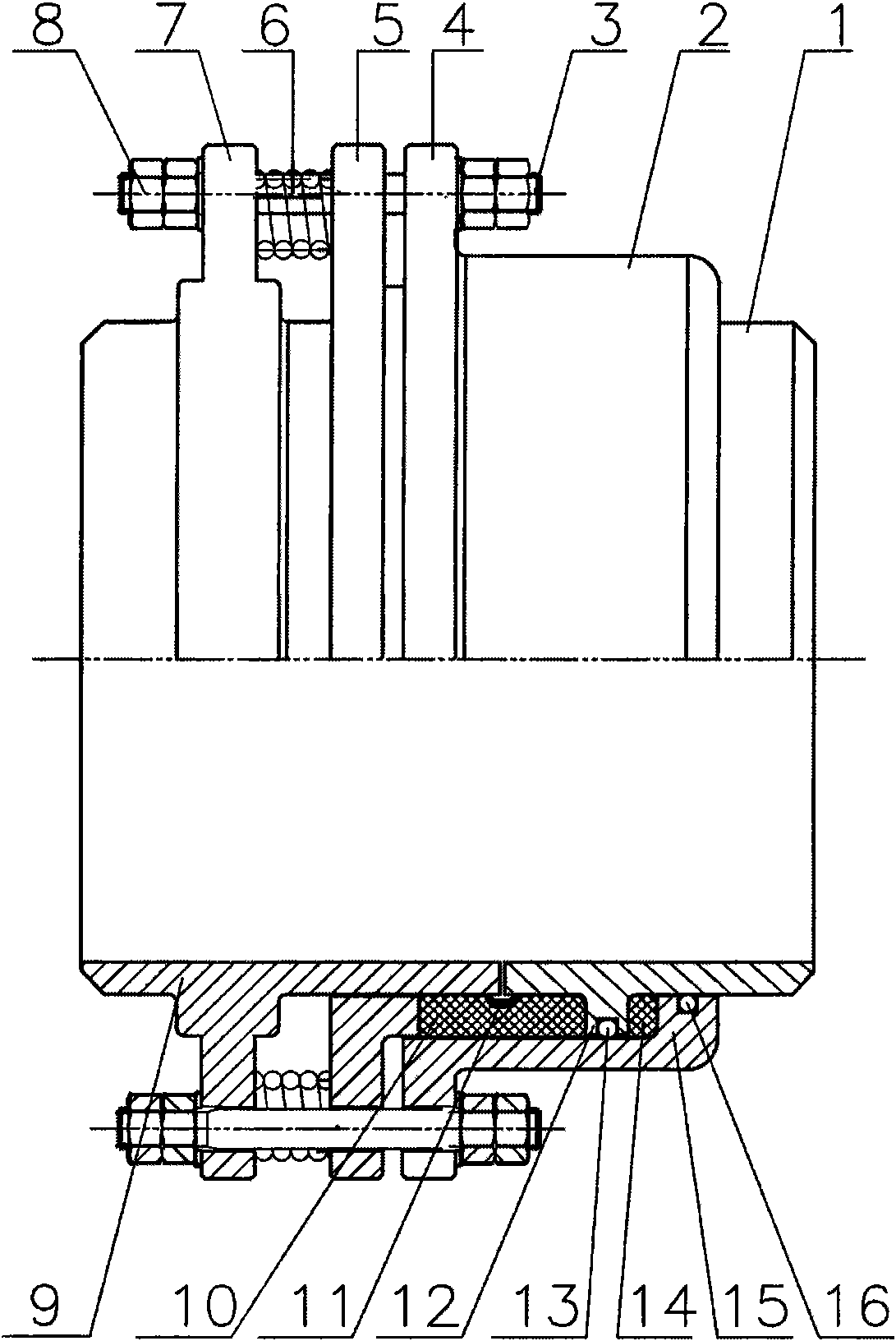

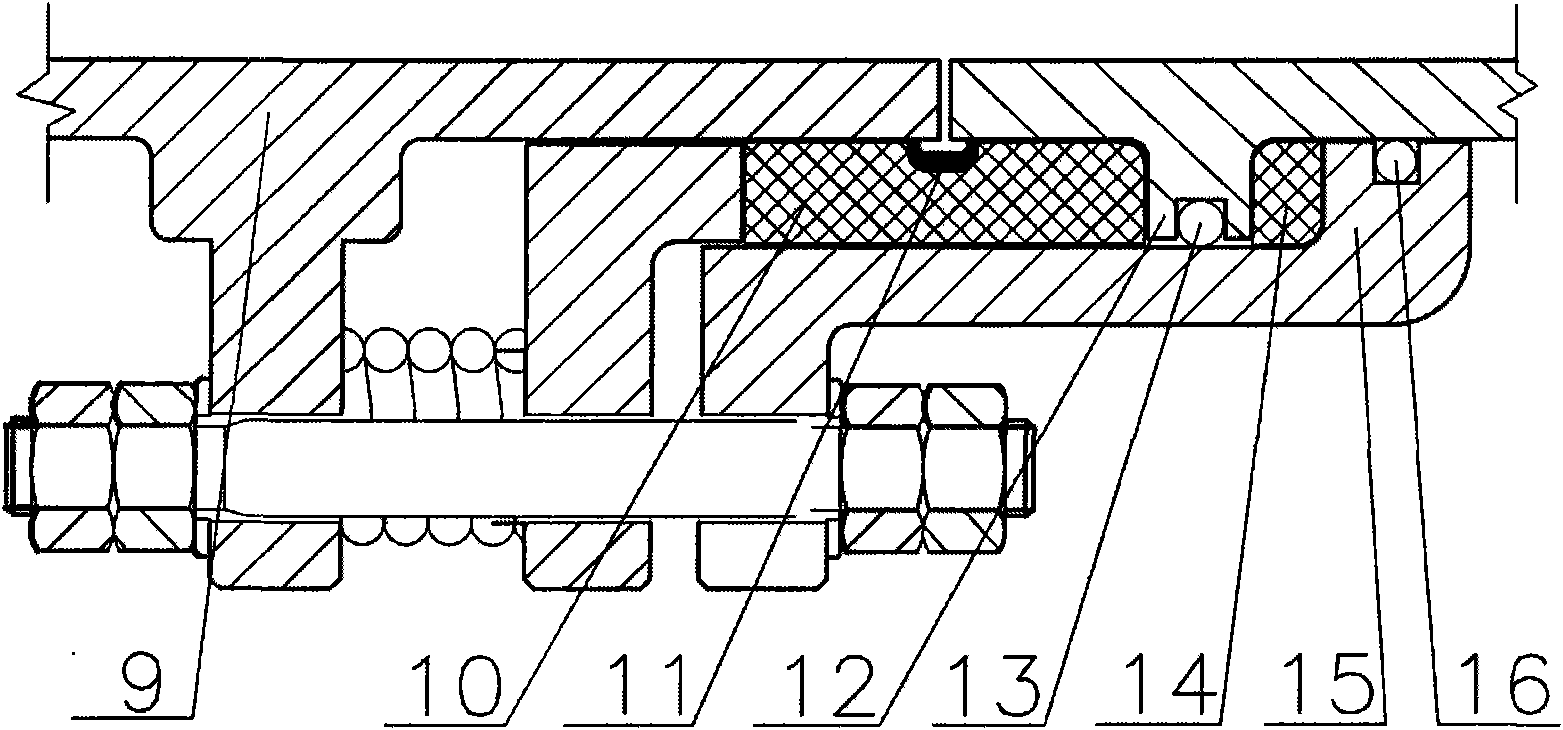

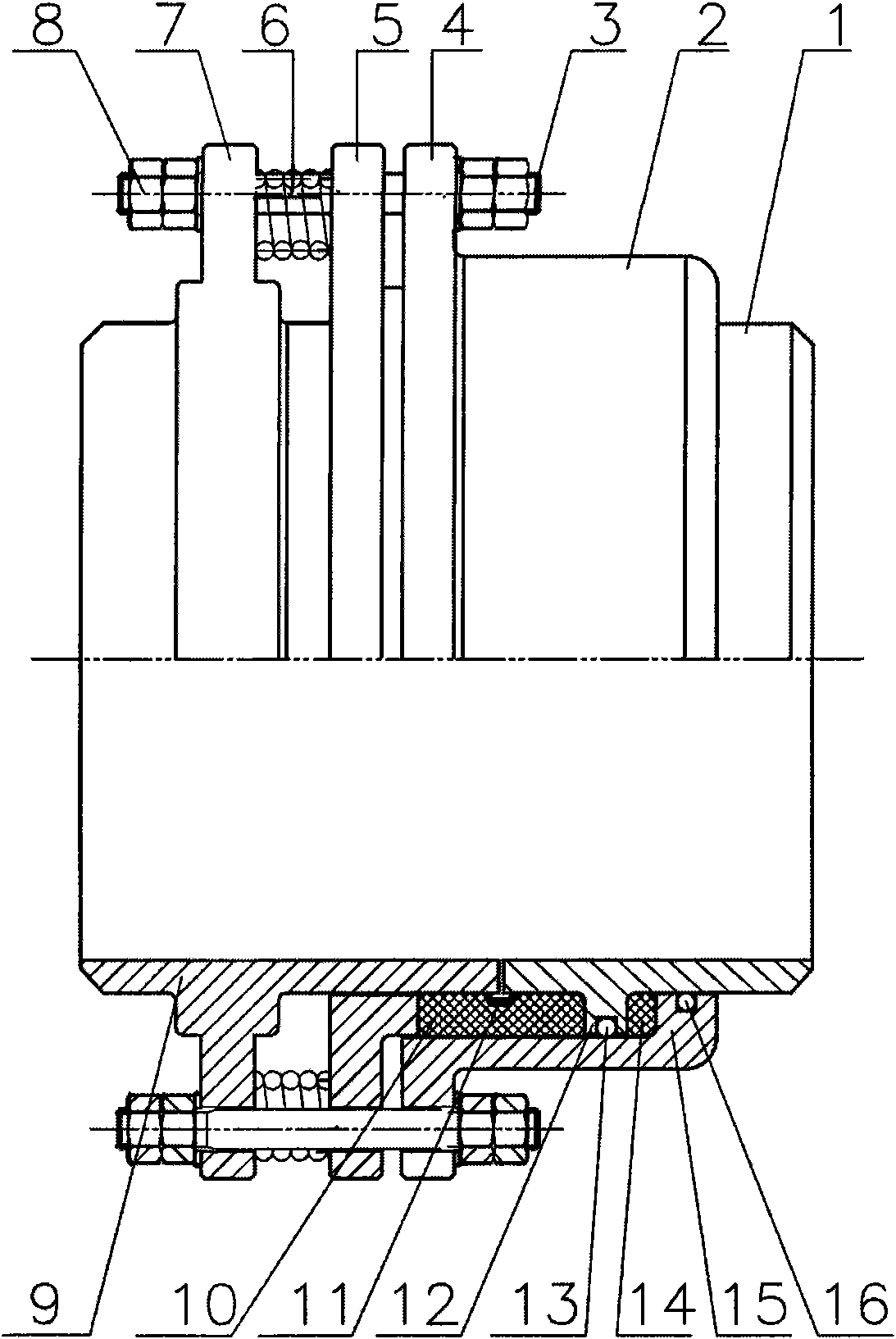

[0047] Such as figure 1 , figure 2 Shown is a schematic diagram of the structure of the present invention and a partially enlarged schematic diagram. It can be seen from the figure that the new high-pressure resistant and maintenance-free rotary compensator consists of a rotatable inner tube 1, a sealed outer sleeve 2, bolts 3, a sealed outer sleeve flange 4, and a pressing material. Cap 5, spring 6, structural pipe flange 7, nut 8, structural pipe 9, flexible graphite packing 10, U-shaped sealing ring 11, rotatable inner pipe boss 12, steel ball 13, graphite sealing ring 14, sealing outer sleeve The base 15 and the steel ball 16 are composed, wherein: the section of the sealing outer sleeve 2 is in an L-shaped transverse position and is looped on the outer ring surface of the rotatable inner tube 1, and the base 15 of the sealing outer sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com