Patents

Literature

120results about How to "Play a role in compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

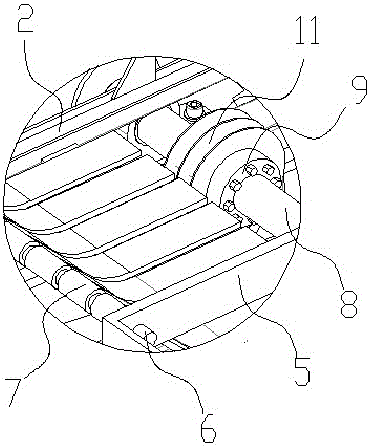

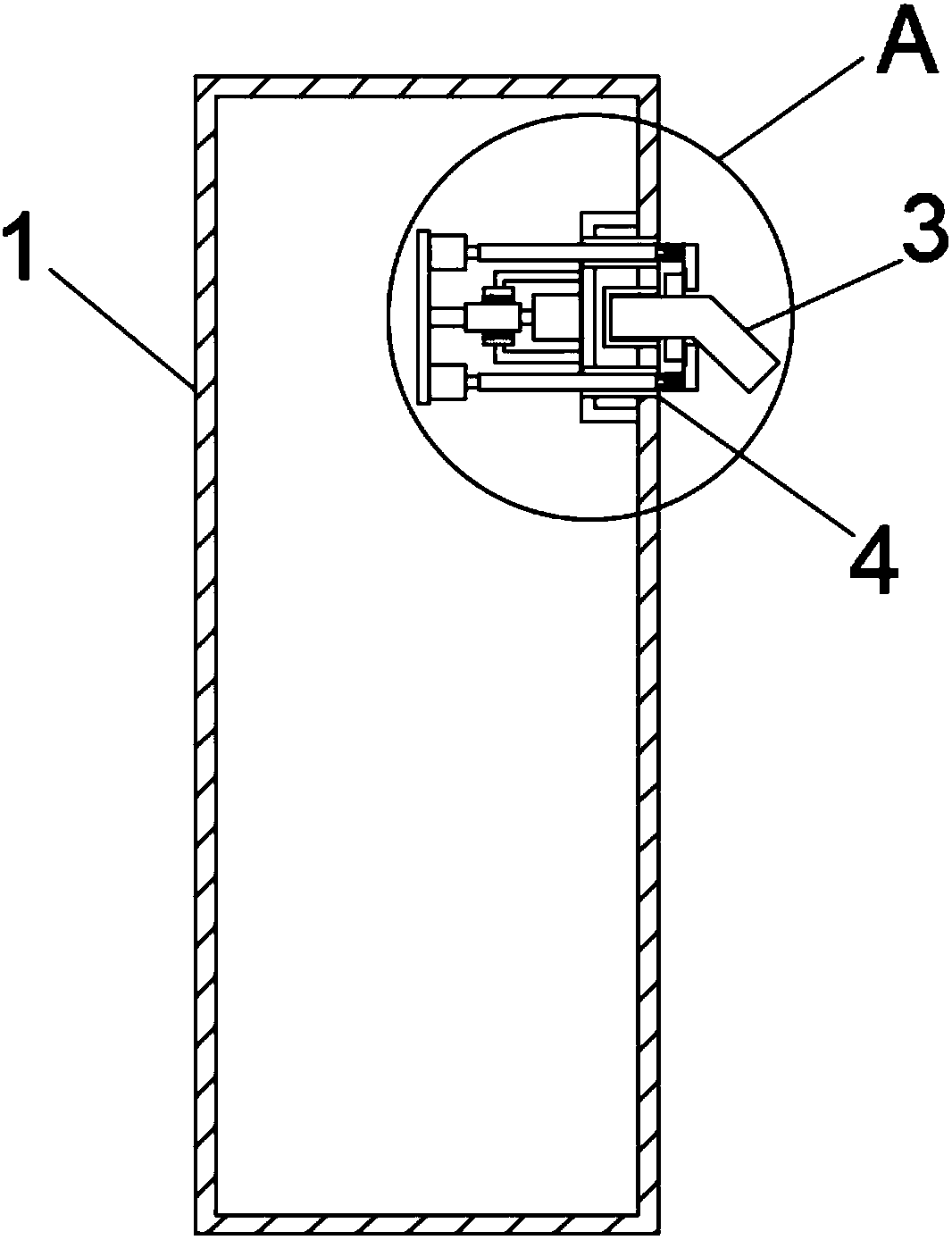

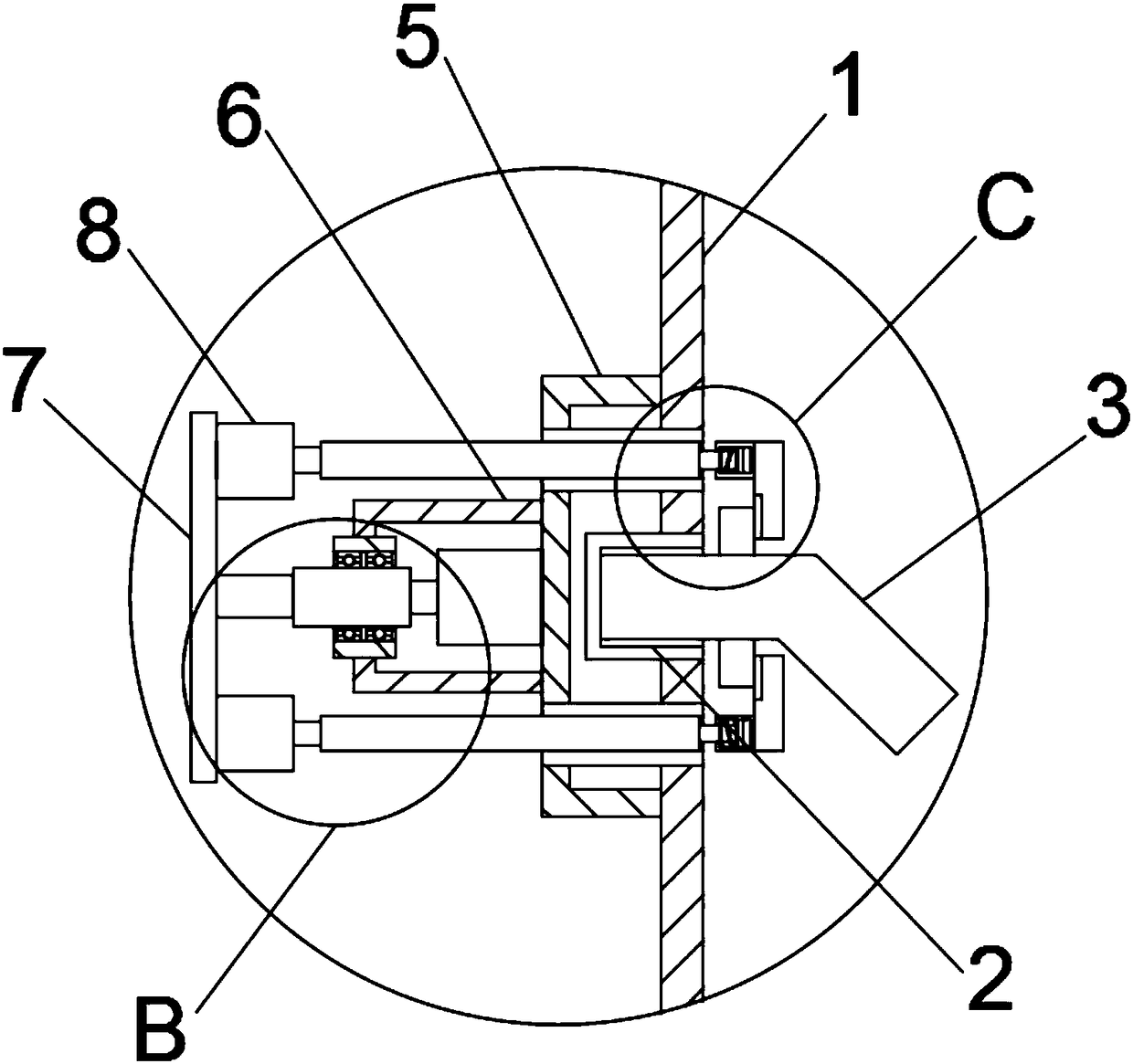

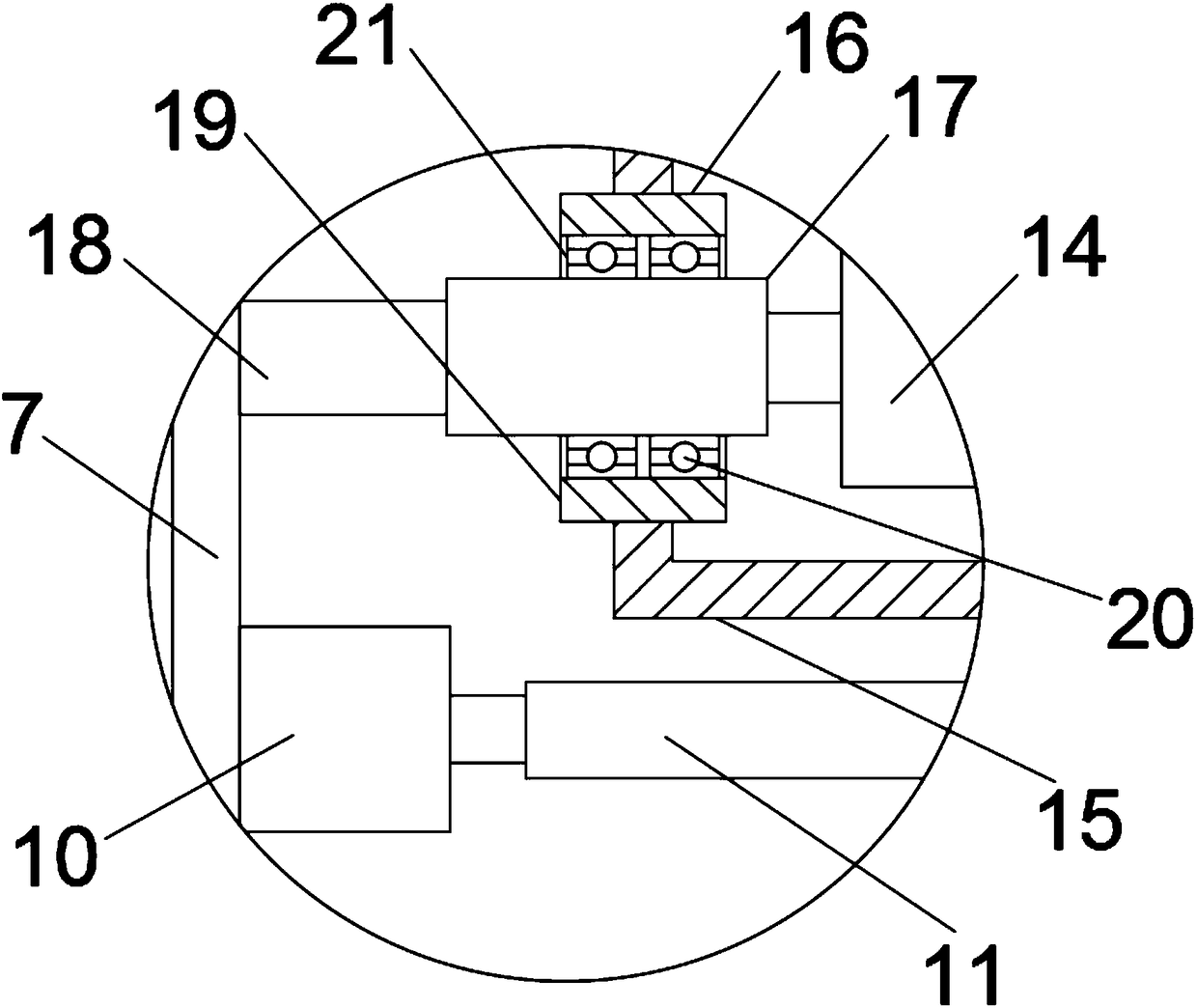

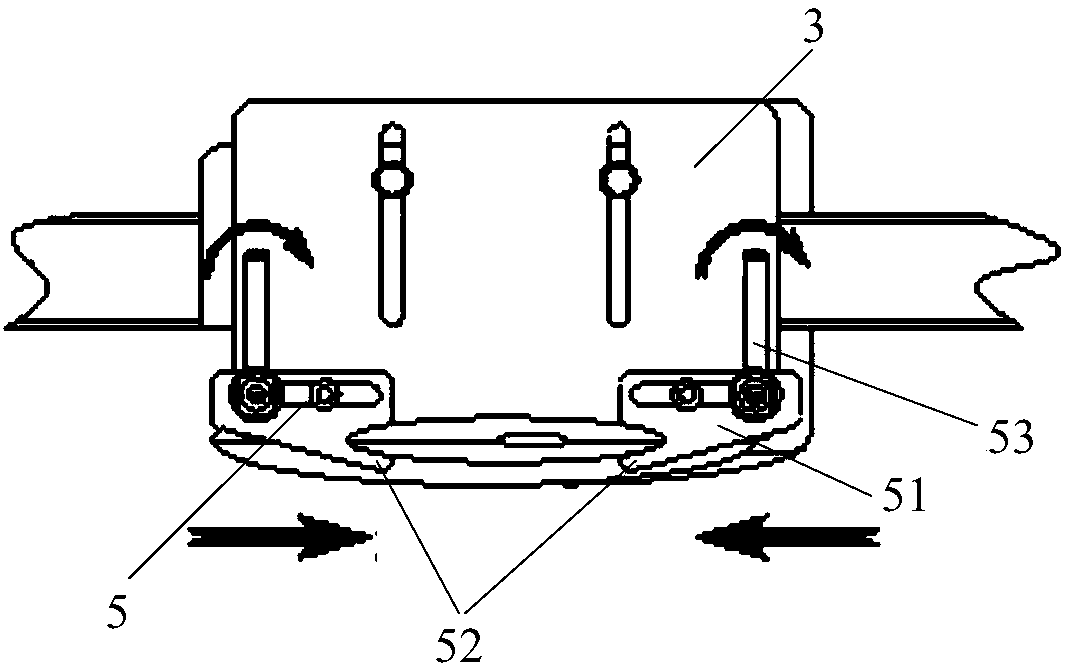

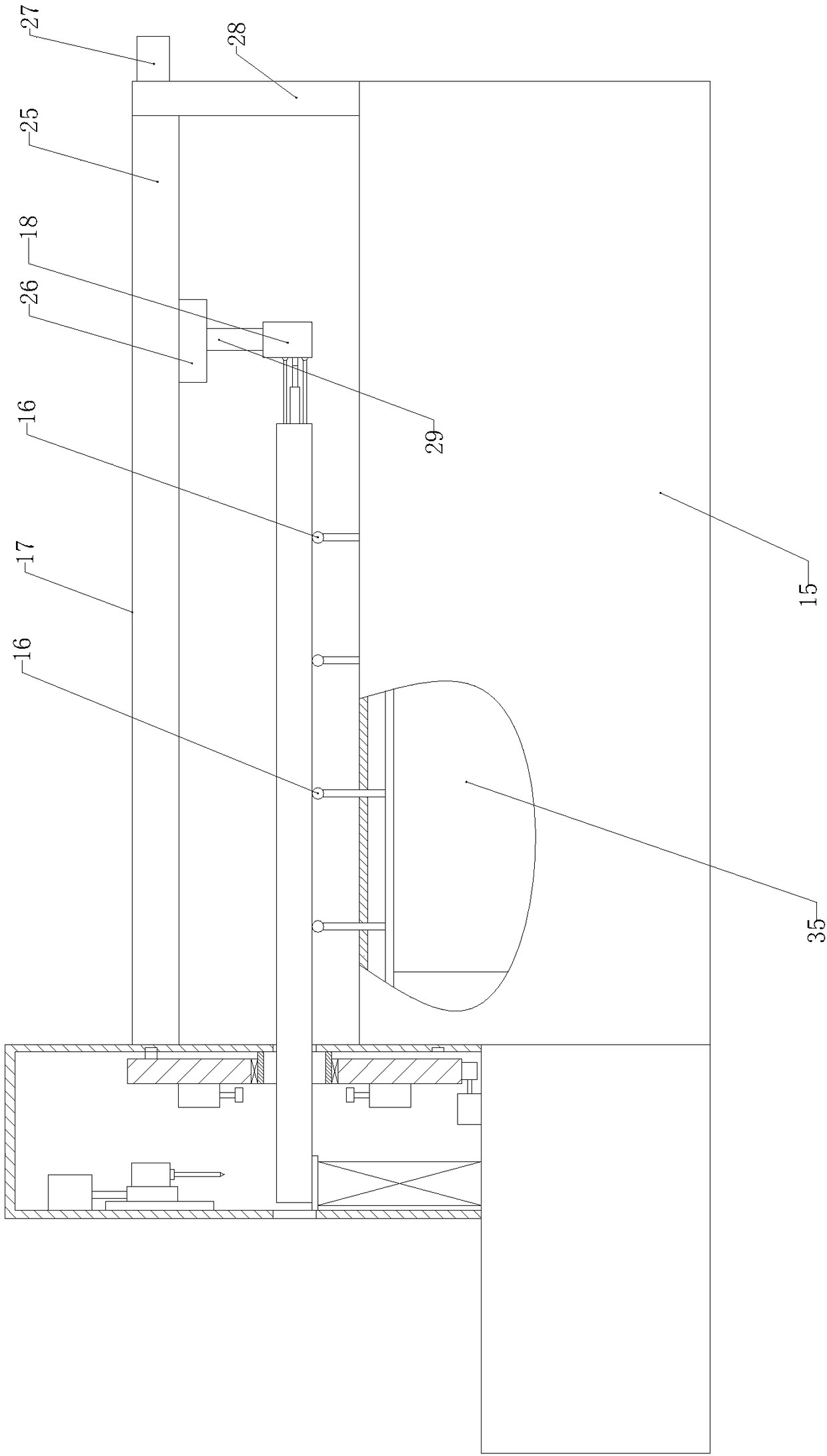

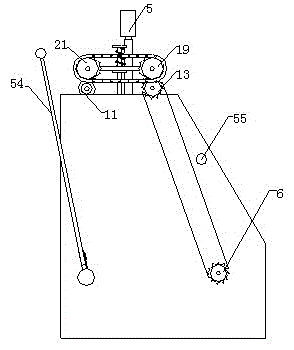

Temporary winding device with cleaning function and used for gauze production and machining

InactiveCN110626838AGood cleaning effectGuaranteed cleanlinessCleaning using toolsCleaning using gasesMachiningBlow out

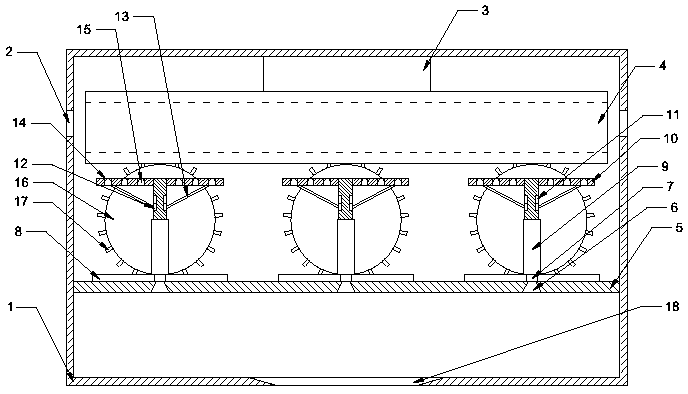

The invention relates to the field of gauze production and machining devices, and specifically relates to a temporary winding device with a cleaning function and used for gauze production and machining. The temporary winding device with the cleaning function and used for gauze production and machining comprises a bottom plate, a winding structure, a fixed plate, a compression structure, a flatly-laying structure, a guide structure, a cleaning structure and a side plate. The winding structure is capable of synchronously driving the cleaning structure to work during working, so that a better cleaning effect of the cleaning structure can be achieved; two oppositely-arranged brush plates are fixed into a cleaning sleeve, and cleaning working can be carried out on a gauze being wound, so that impurities on the surface of the gauze can be cleaned, and then the cleanliness of the wound gauze can be ensured; gas blowing holes communicate with the interior of a gas storage groove separately, and therefore, gas in the gas storage groove is blown out via the gas blowing holes, so that ash blowing cleaning working can be carried out before the gauze enters the two brush plates, and then the cleanliness of the wound gauze can be ensured.

Owner:LIXIN FUYA GAUZE CO LTD

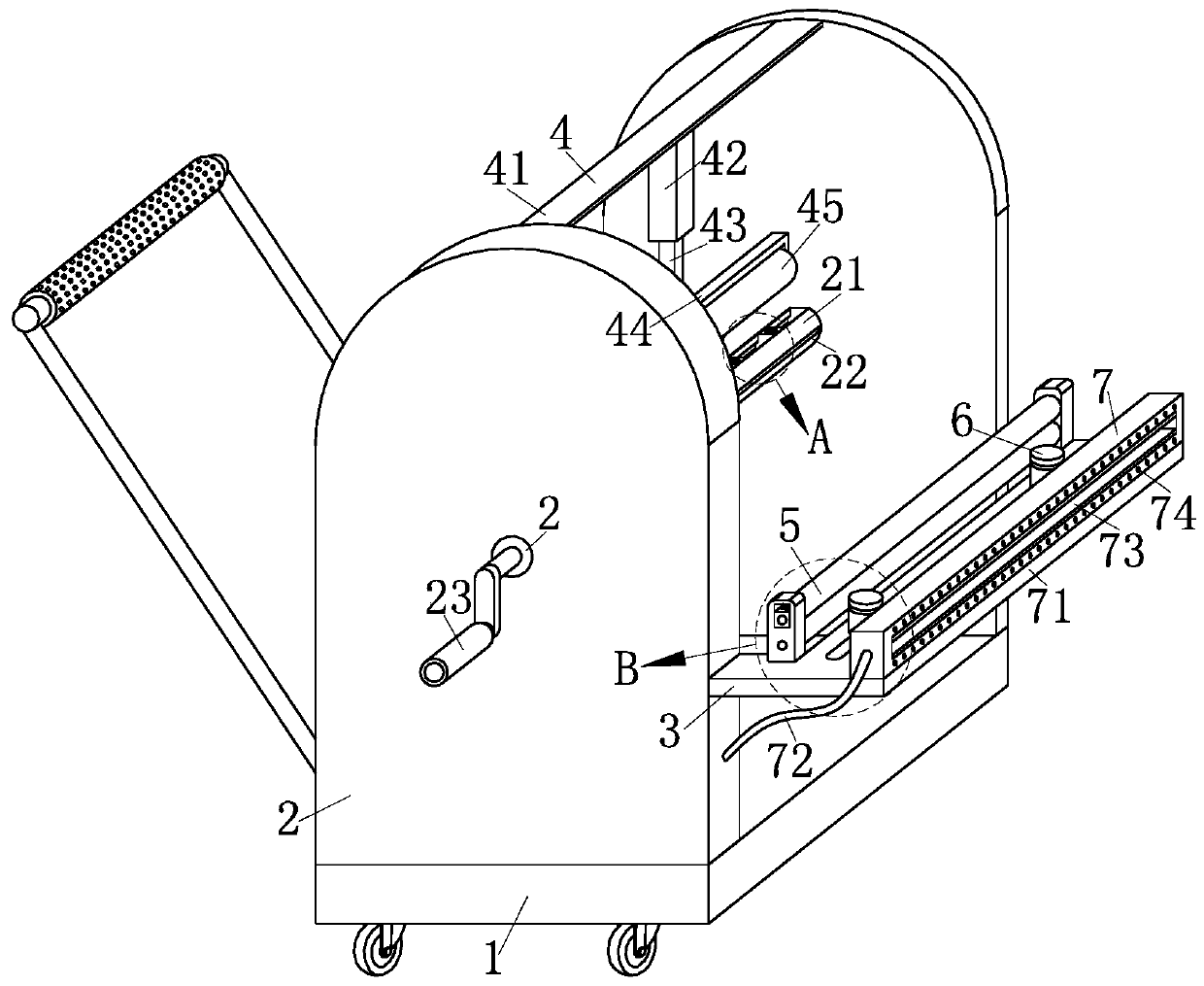

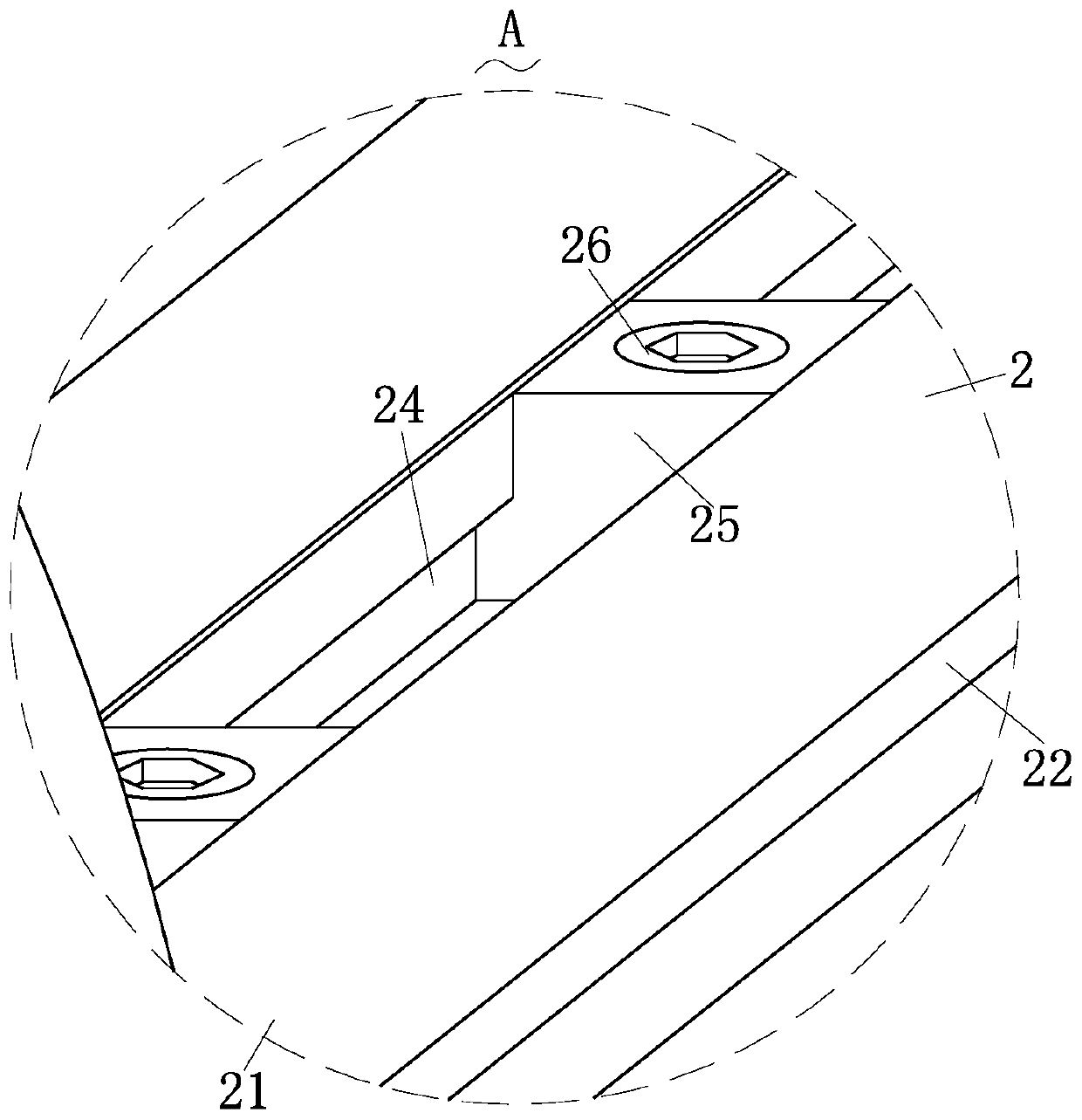

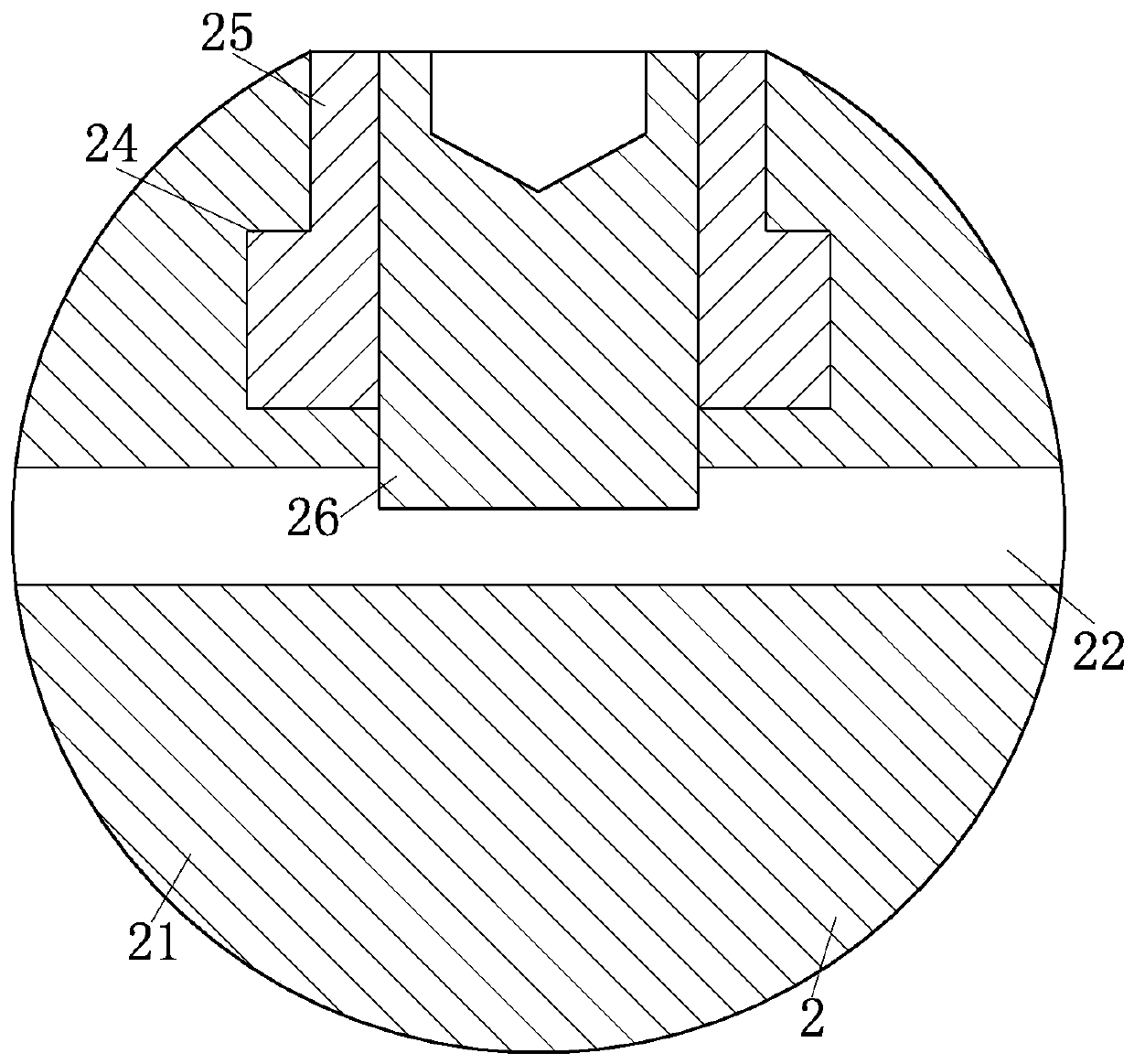

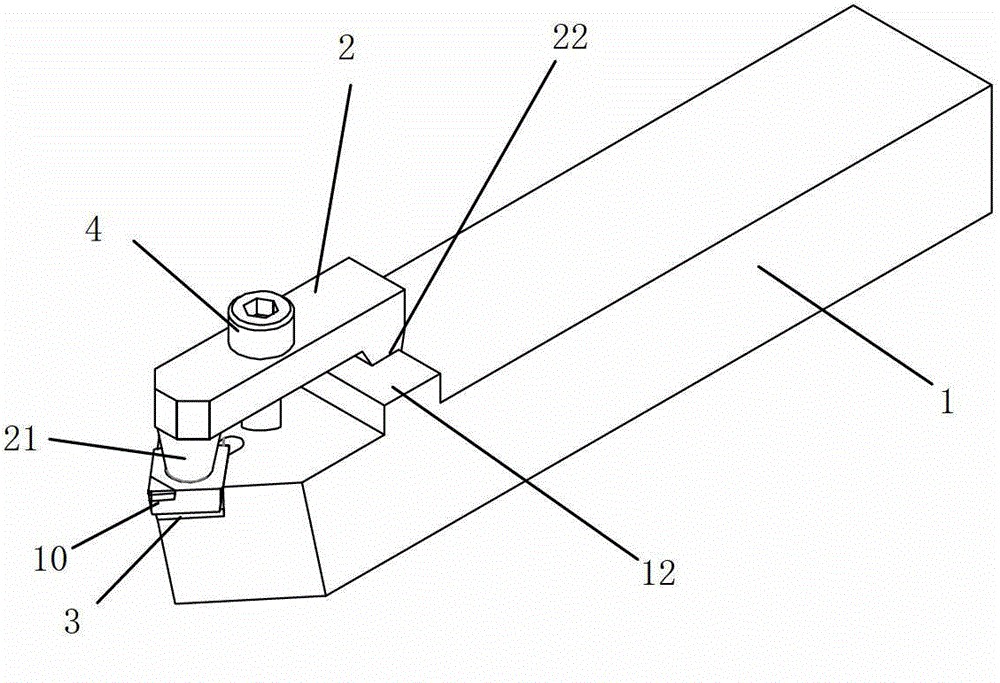

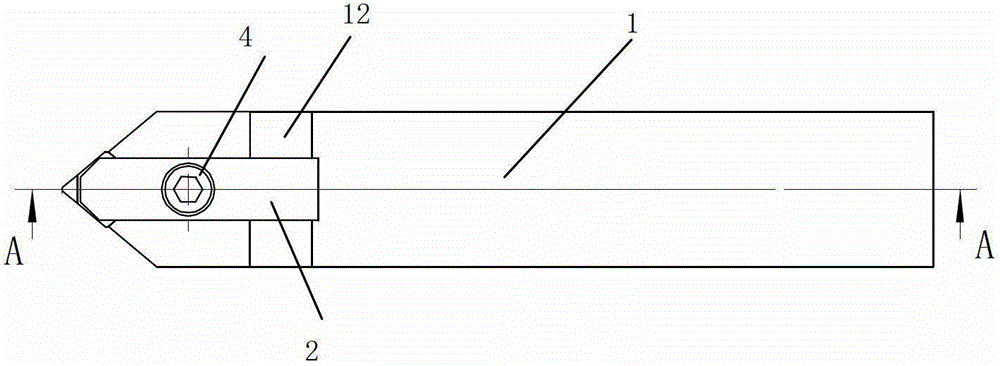

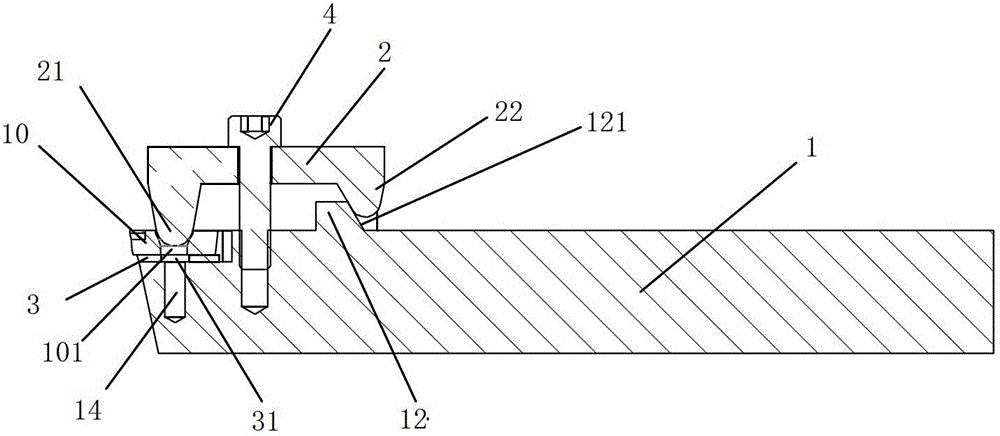

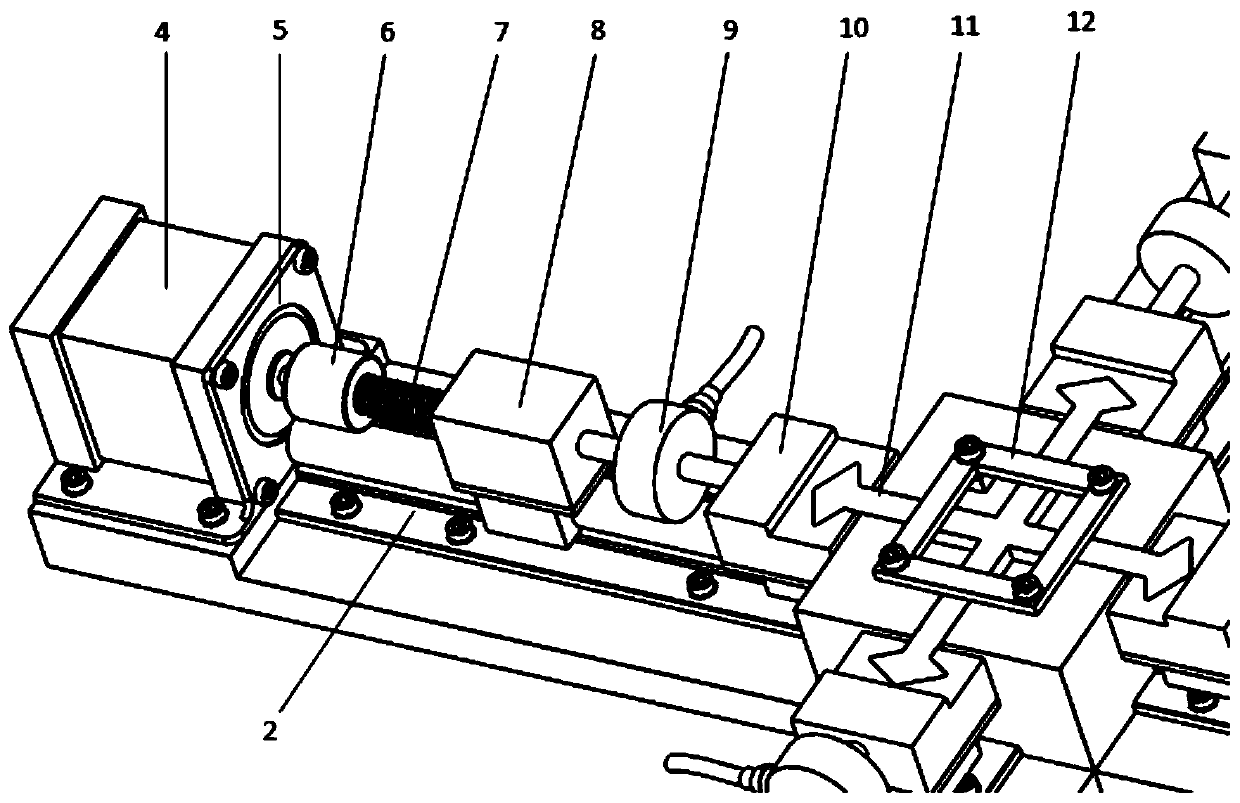

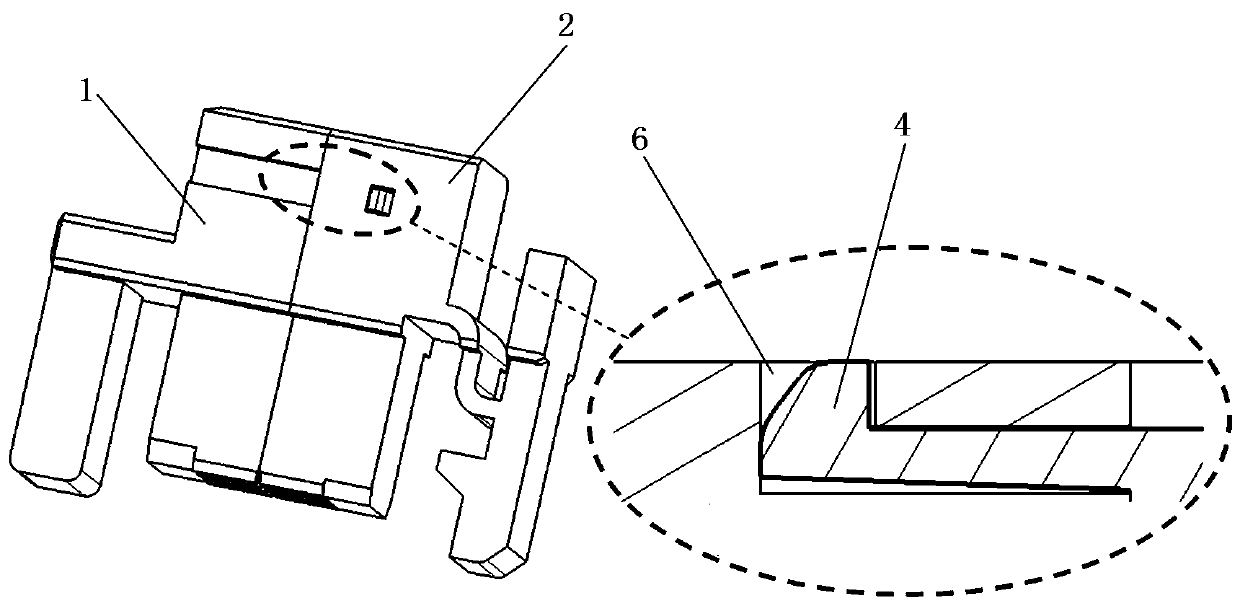

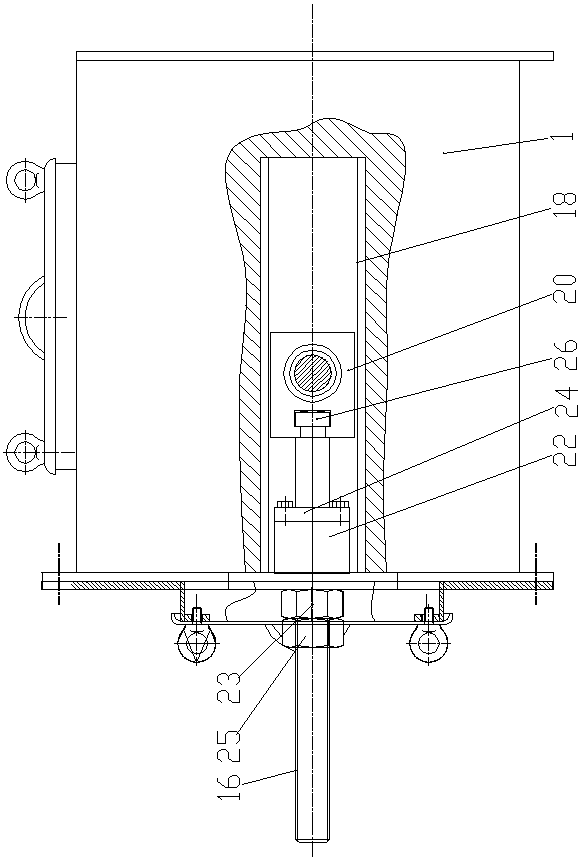

Dedicated jig for numerical control knife machine

InactiveCN102862099APlay a tensioning rolePlay a role in compressionOther manufacturing equipments/toolsNumerical controlEngineering

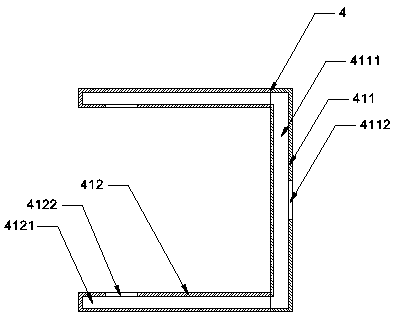

The invention discloses a dedicated jig for a numerical control knife machine. The dedicated jig comprises a lathe tool handle and a pressure plate; the pressure plate is in a door-frame shape; a cutter blade slot is formed at one end of the lathe tool handle, and the cutter blade slot has a vertical surface and a bottom surface; the middle of the pressure plate is fixed on the lathe tool handle by a screw, and one end of the pressure plate is pressed against a numerical control cutter blade which is placed in the cutter blade slot; a lug boss is arranged in the lathe tool handle, the internal end of the other end of the pressure plate is hooked on the lug boss of the lathe tool handle; one end of the pressure plate is designed into a ball structure; and one end of the pressure plate is pressed and adhered to the numerical control cutter plate which is placed into the cutter blade slot. The structure of the dedicated jig provided by the invention has the characteristics that the locking force is good, the repeated positioning precision is high, the wear resistance degree of the cutter blade slot is high, the flatness and the parallelism are easily ensured, and the sharpening angle of the numerical control cutter blade is easily ensured; and moreover, the consistency of shape and dimension for sharpening processing of the numerical control cutter blade of a super hard cutter tool can be ensured, and the sharpening efficiency and production yield are improved.

Owner:XIAMEN TUNGSTEN +1

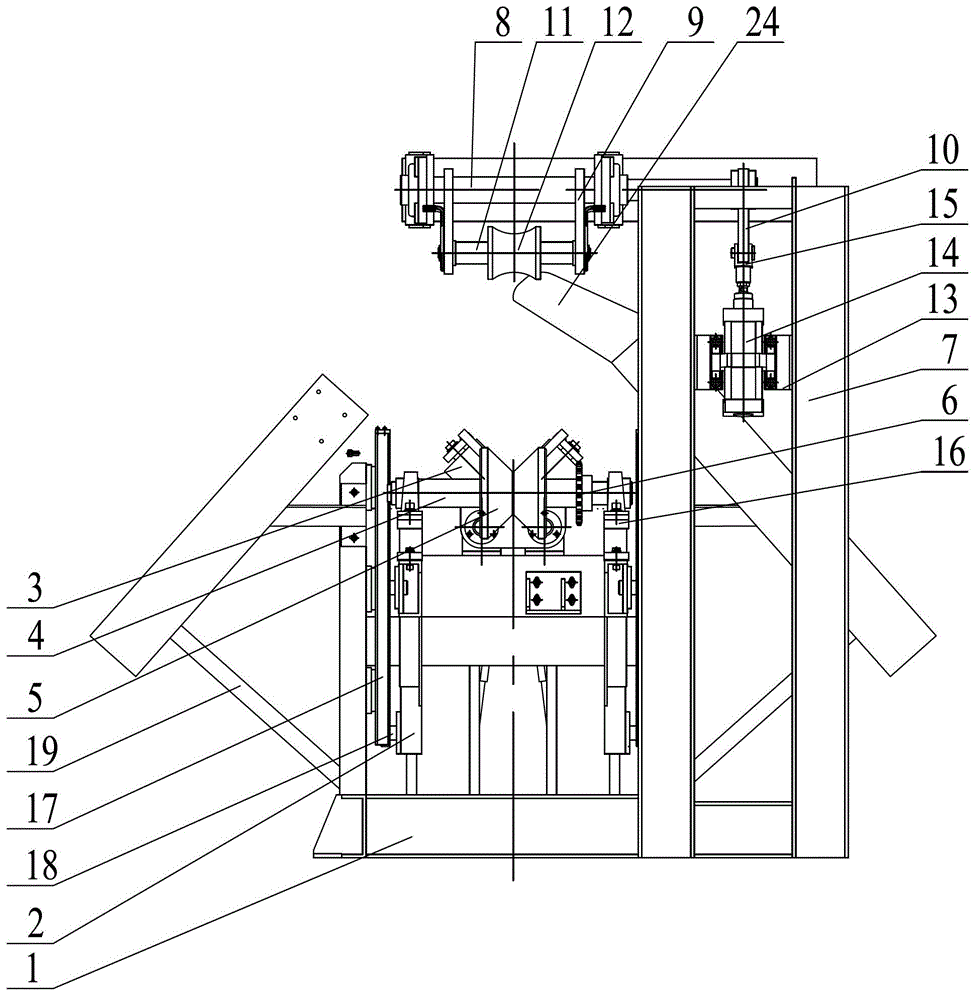

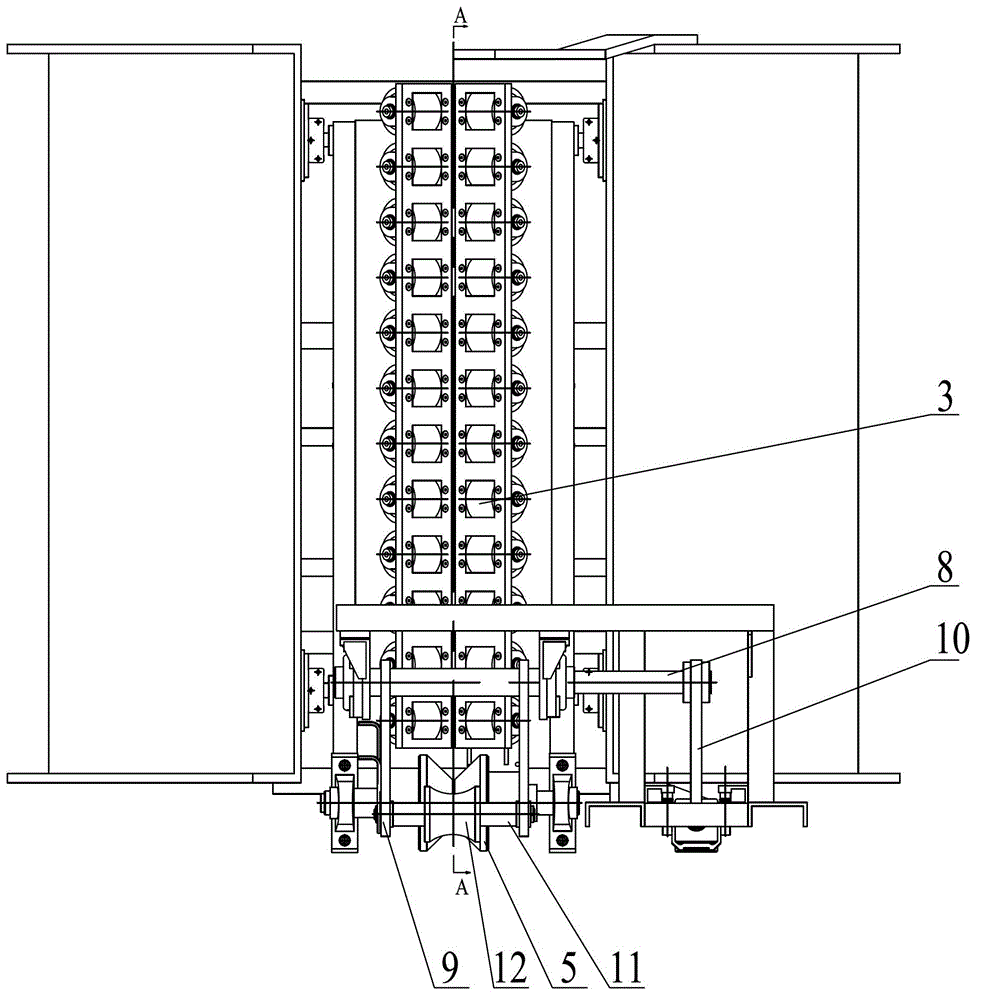

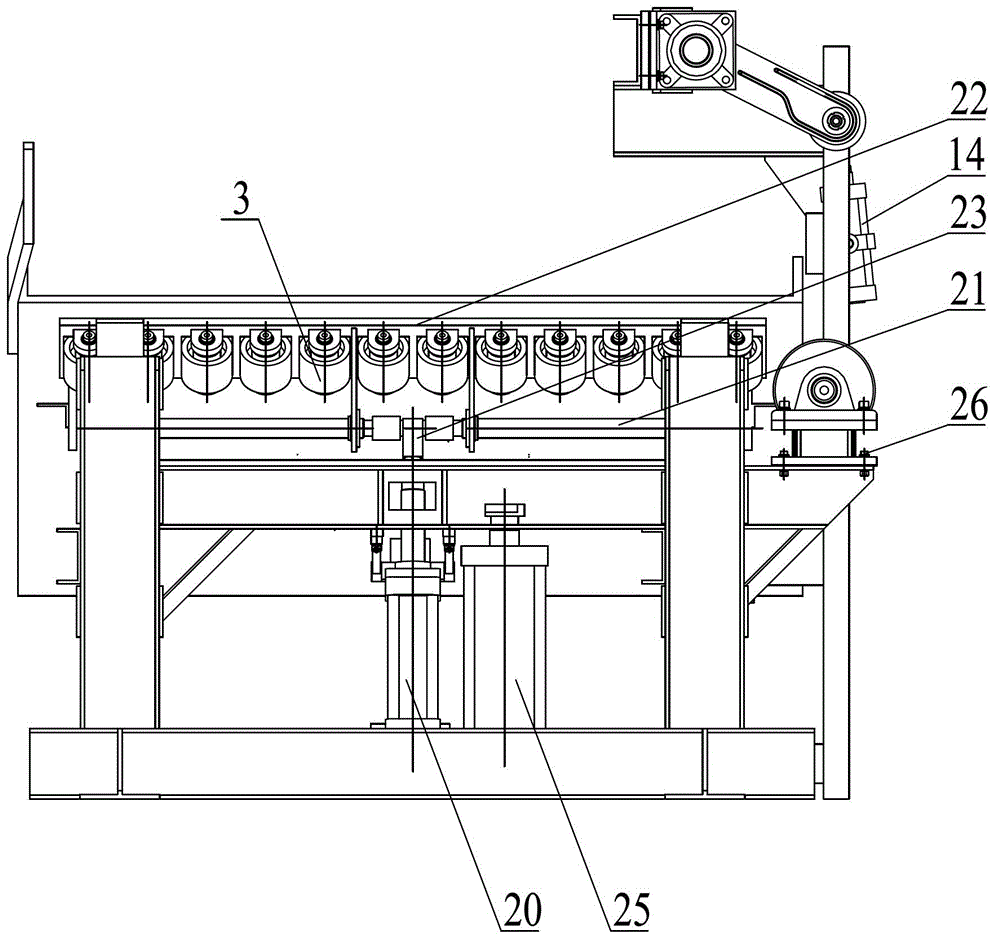

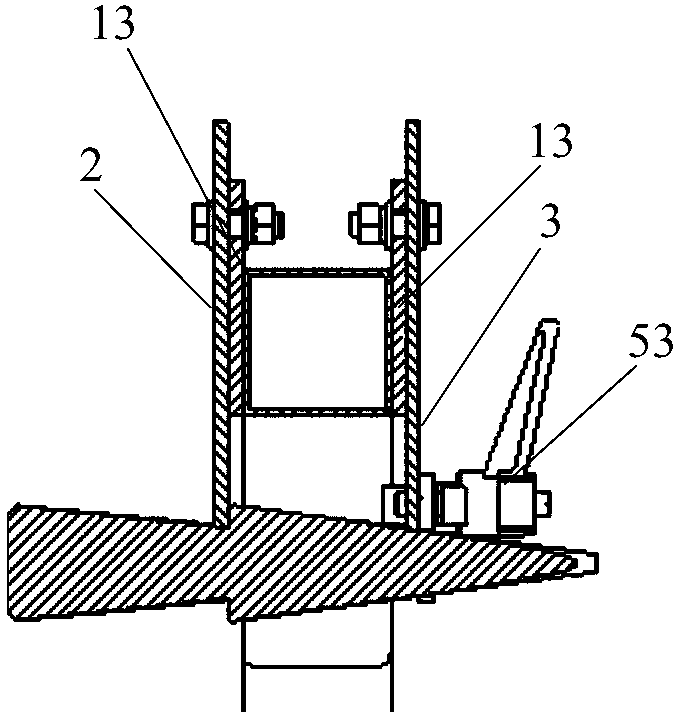

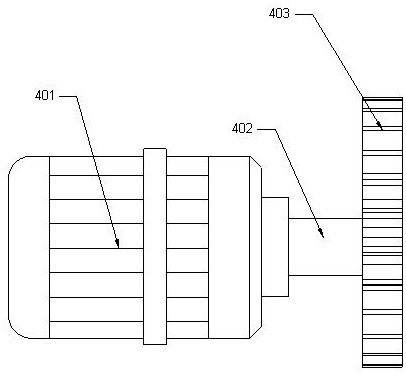

Pipe discharge mechanism

InactiveCN102910411ADelivery controlImprove discharge efficiencyConveyor partsRoller-waysDischarge efficiencyCylinder head

The invention relates to a pipe discharge mechanism. A lifting support is installed on an installation base in a vertically sliding mode, a roller shaft is rotatably erected on the lifting support, a conveying roller and a drive sprocket are fixed on the roller shaft, left and right rows of driven rollers are rotatably installed on the lifting support arranged on the rear side of the conveying roller, a compression support is fixed on the installation base, a compression pivot shaft is rotatably erected on the top end portion of the compression support, a pivot shaft frame and an air cylinder lever are fixed on a compression pivot shaft, a compression wheel shaft is rotatably installed on the pivot shaft frame, a compression wheel is fixed on the compression wheel shaft, an air cylinder base is fixed on the compression support, a compression air cylinder is installed on the air cylinder base in a hinged connection mode, and an air cylinder head is fixed on the end portion of a piston rod of the compression air cylinder. The pipe discharge mechanism has the advantages that the pipe discharging efficiency is improved and the usage is convenient and flexible.

Owner:WUXI HUALIAN SCI & TECH GROUP

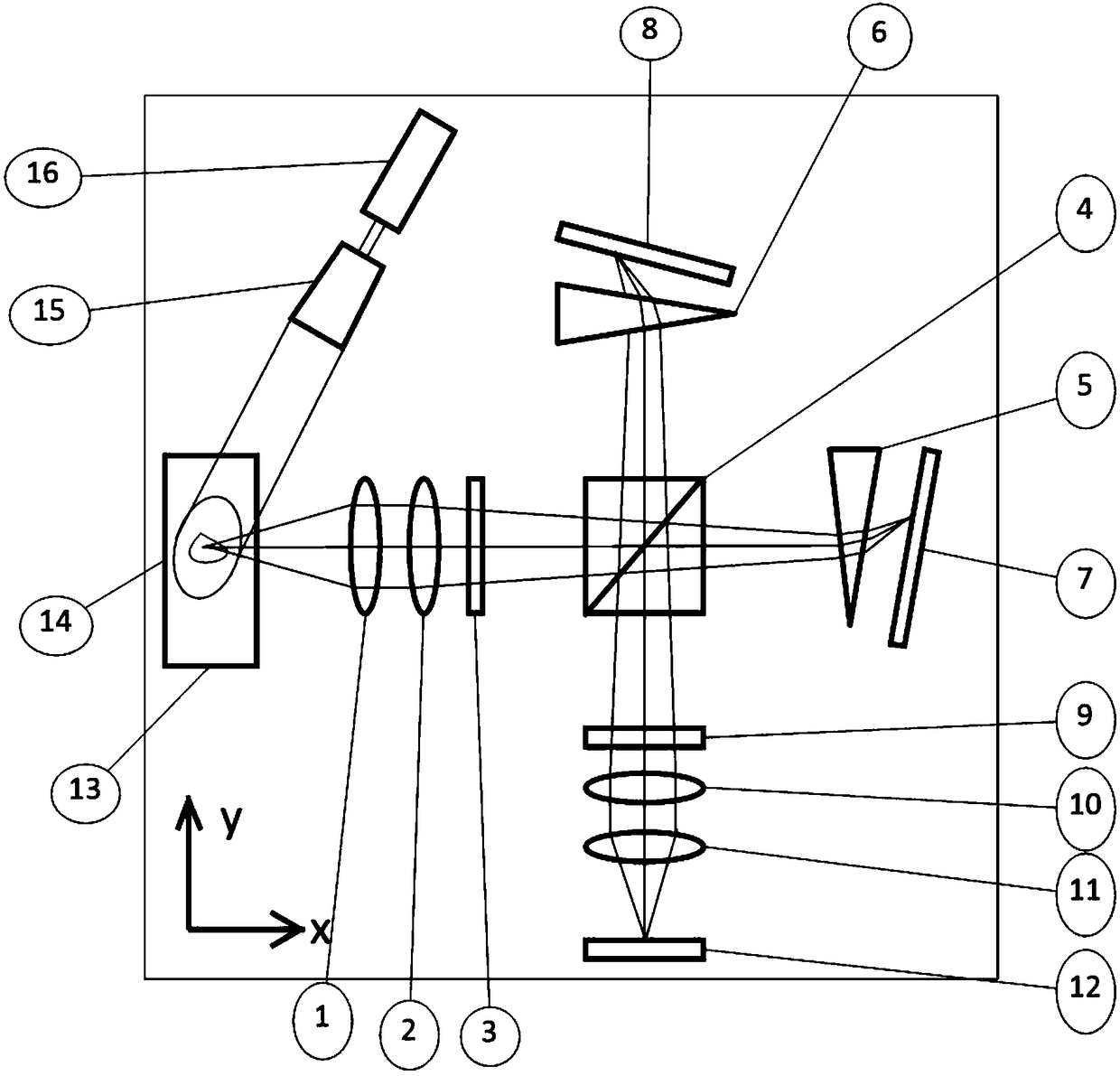

Optical path structure of spatial heterodyne Raman imaging spectrometer

The invention provides an optical path structure of a spatial heterodyne Raman imaging spectrometer. The optical path structure mainly comprises a collimating lens, a focusing lens, a first Raman light filter, a beam splitting prism, two wedged prisms, two blazed gratings, a second Raman light filter, an aspherical lens, an imaging lens set, an area array detector, an object stage, a beam expanderand a laser. Raman light emitted by a sample is focused on the blazed gratings on two arms of an interferometer after passing through the collimating lens, the focusing lens and the first Raman lightfilter, then combined again by the beam splitting prism to obtain spatial heterodyne Raman interference light, and finally received by the area array detector after passing through the second Raman light filter, the aspherical lens and the imaging lens set. Through adoption of the aspherical lens, the acquisition speed of each frame of the heterodyne Raman interference light acquired by the areaarray detector is effectively increased; through the optical path structure, rapid measurement of a Raman spectrum at each position on the surface of the sample to be detected is achieved; meanwhile,the optical path structure has the advantages of high resolution, large light flux, a wide measured waveband range and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

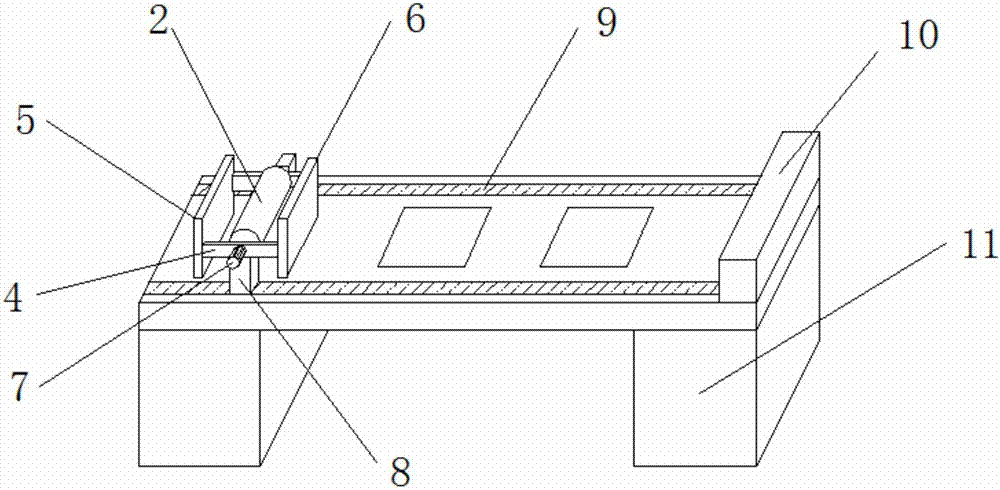

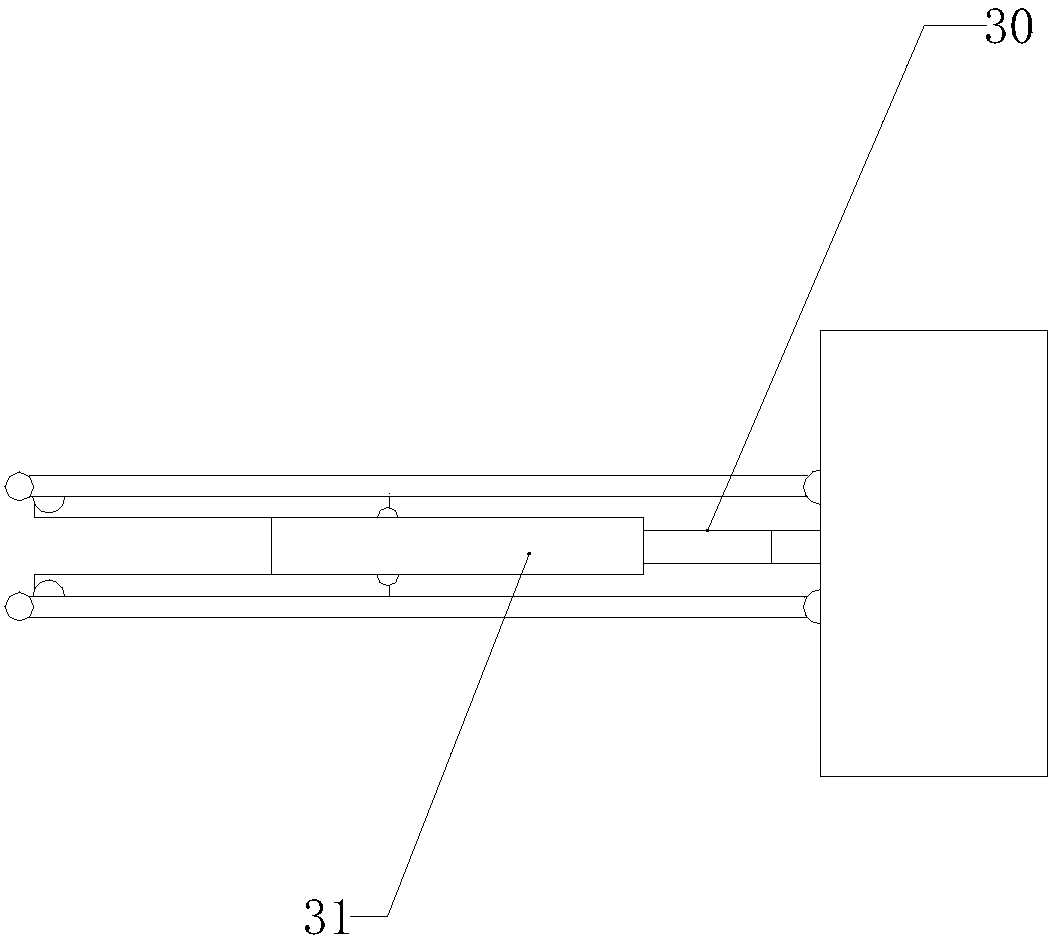

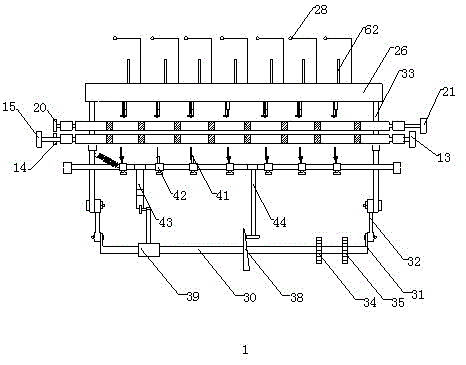

Powder paving device for quick forming equipment

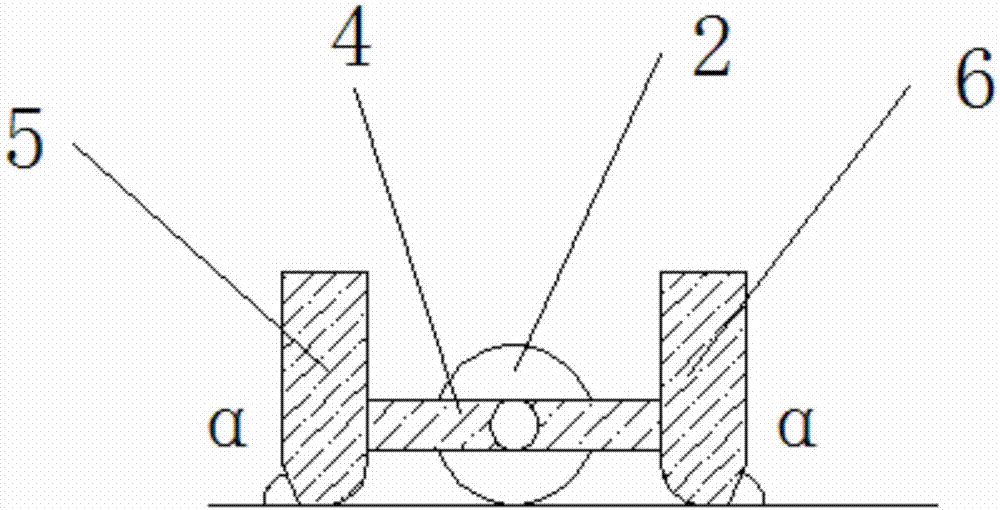

InactiveCN107150442AOvercoming the problem of easy unevennessPlay a role in compressionIncreasing energy efficiency3D object support structuresRapid prototypingAngle alpha

The invention discloses a powder paving device for quick forming equipment. The powder paving device comprises a worktable, a powder paving roller, a first pushing plate, a second pushing plate and a driving device; rotating shafts are respectively arranged at the two ends of the powder paving roller, and are horizontally connected with connecting plates; the first pushing plate and the second pushing plate are vertically fixed at the two ends of the connecting plates; motors are arranged on the connecting plates; output shafts of the motors penetrate through the connecting plates to be connected with the rotating shafts; two parallel slide rails are arranged on the upper surface of the worktable; the lower surfaces of the connecting plates are arranged in the slide rails through slide rods; the driving device is arranged on one side of the worktable; a connecting rod in the driving device is connected with the slide rods; one side part, far from the powder paving roller, of the first pushing plate is inwards inclined, and forms an included angle alpha with the horizontal plane; and one side part, far from the powder paving roller, of the second pushing plate is inwards inclined, and also forms the included angle alpha with the horizontal plane. The powder paving device overcomes the problems of incapability of uniformly paving raw material powder on the worktable and easy generation of irregularity of a paved powder machine of a powder paving device in the prior art.

Owner:安徽科元三维技术有限公司

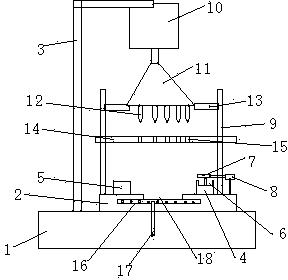

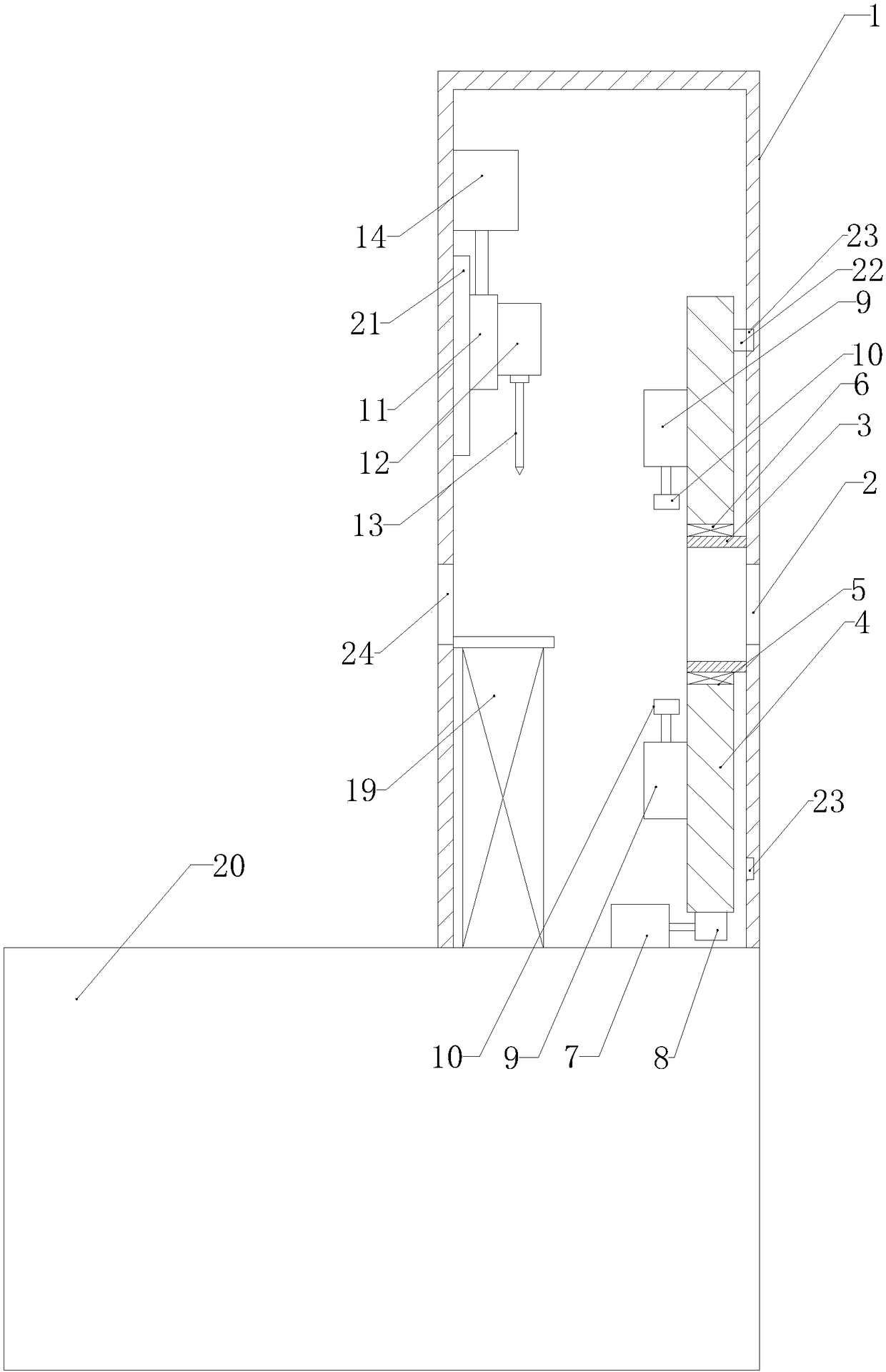

Automatic drilling machine for fan

InactiveCN103722209AEasy to moveSmooth shiftingFeeding apparatusPositioning apparatusSlide plateEngineering

The invention belongs to the technical field of motor fan machining tools, and particularly relates to an automatic drilling machine for a fan. The automatic drilling machine for the fan comprises a base, an output shaft is connected to the output end of a hydraulic oil cylinder, a drilling machine body is connected to the lower end of the output shaft, a plurality of drill bits are distributed at the bottom of the drilling machine body, the two lateral portions of the drilling machine body are provided with upper sliding plates, a lower sliding plate is connected to the upper sliding plates through springs, through holes corresponding to the drill bits in a one-to-one mode are formed in the lower sliding plate, and the upper sliding plates and the lower sliding plate are arranged on sliding rods in a sleeved mode. According to the automatic drilling machine, a fan groove is further formed, the fan can be initially positioned when being placed, and multiple times of adjustment are not required when the motor fan is initially placed.

Owner:德清县凌鹰电器有限公司

Tight bus duct

InactiveCN104269802APlay a role in compressionPrevent looseningTotally enclosed bus-bar installationsMechanical engineeringPower transmission

The invention relates to the technical field of electric transmission and transformation equipment, in particular to a tight bus duct. The tight bus duct comprises an upper cover plate, a lower cover plate, a left side plate and a right side plate, wherein the upper cover plate and the lower cover plate are connected to the two ends of the left side plate respectively and are connected to the two ends of the right side plate respectively, the inner side and the outer side of the upper cover plate are provided with a pressing plate and a wheel disc respectively, and the pressing plate is connected with the wheel disc through a screw rod. The inner side and the outer side of the upper cover plate are provided with the pressing plate and the wheel disc respectively, the pressing plate is connected with the wheel disc through the screw rod, in the using process, the height of the pressing plate can be adjusted by rotating the wheel disc, the pressing function is performed on a bus, loosening is prevented, so that the electric conductivity and the working stability of the bus are improved, and the safety of power transmission is greatly improved.

Owner:常州市武进南夏墅苏南锻造有限公司

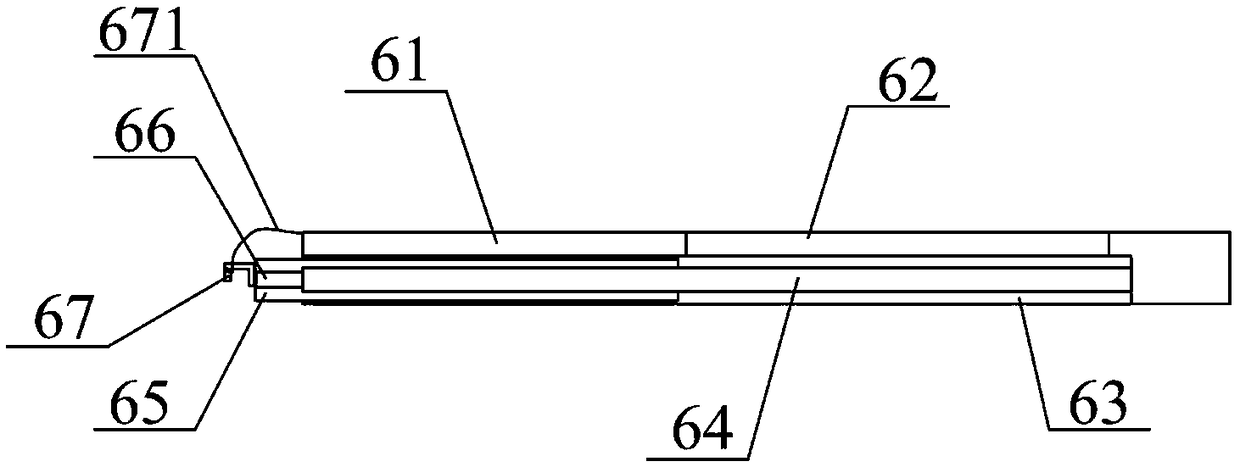

Scrap iron cleaning and collecting processing device for machinery works

InactiveCN109290294APlay a role in absorbingFunction as a collectionCleaning processes and apparatusPush pullMetal

The invention provides a scrap iron cleaning and collecting processing device for a machinery works. The scrap iron cleaning and collecting processing device comprises a lengthened sleeve pipe, a lengthened supporting rod, a push-pull handle, a tool hook, a bottom scrap iron sucking and collecting frame structure, a scrap iron crushing box structure, universal bottom wheels, a scrap iron production shovel bucket structure, a scrap iron extraction box structure, an illuminating lamp, a flange connecting disc, a sweeping extraction head structure, a bolt nut and a metal hose, wherein the lengthened sleeve is arranged on the upper portion of the left side of the scrap iron crushing box structure. According to scrap iron cleaning and collecting processing device, an electromagnet plate is arranged, so that scrap iron which is not cleaned or cleaned away from the bottom of the device can be absorbed; an inserting bucket slides to the right side and is placed at the lower part of the electromagnet plate, and meanwhile, the electromagnet plate is powered off, so that the scrap iron adsorbed on the electromagnet plate falls into the inserting bucket, and a collecting function is achievedon the scrap iron; and a sweeping brush is in key connection with the lower portion of a sweeping motor, so that when the scrap iron on the ground is extracted, the sweeping motor is electrified and can drive the sweeping brush to achieve a sweeping effect on the scrap iron adsorbed on the ground.

Owner:黄娥 +4

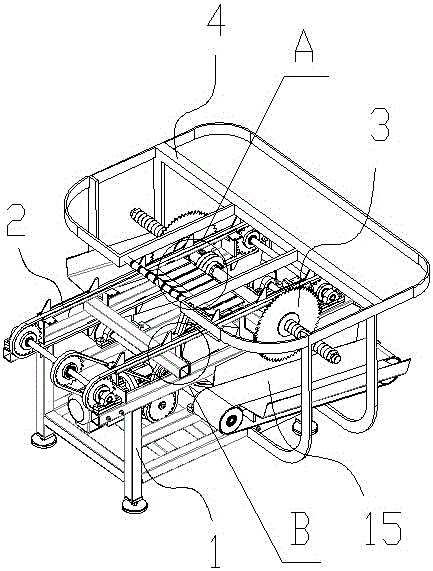

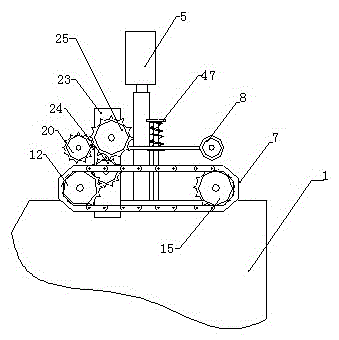

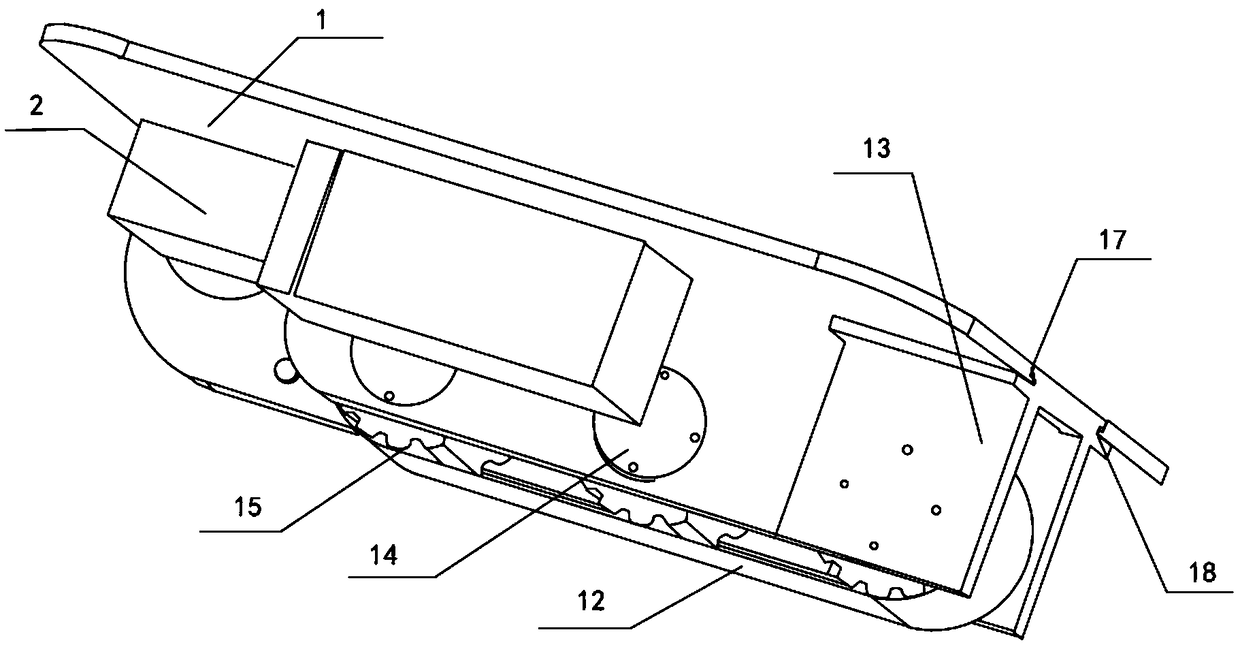

Two-sided trimmer for logs

InactiveCN106808530AImprove cutting efficiencyShorten the timeFeeding devicesGripping devicesTransmission beltEngineering

The invention relates to the field of log processing equipment and particularly relates to a two-sided trimmer for logs. The two-sided trimmer comprises a machine frame, wherein a cutting device is arranged on the machine frame and comprises a cutting knife shaft which is mounted on the machine frame through a bearing seat, the middle part of the cutting knife shaft is connected to a first motor through a first driving wheel and a first transmission belt, and cutting knives matched with log plates are arranged at the two ends of the cutting knife shaft. The two-sided trimmer for the logs, provided by the invention, has the aims that the cutting device is designed to have two parallel cutting knives, and meanwhile, the gap between the cutting knives is controlled to be consistent with a log required size, so that both sides of each log plate can be trimmed in one time, the cutting efficiency is greatly increased, the cutting time is saved, and the dimensional error of one-time cutting is reduced compared with that of two-time cutting.

PVC (Polyvinyl Chloride) profile laminator

ActiveCN103407272APlay a role in compressionCause damageLamination ancillary operationsLaminationPolyvinyl chlorideEngineering

The invention discloses a PVC (Polyvinyl Chloride) profile laminator comprising a rack, two groups of compression roller assemblies, an adjustable pressing mechanism, a fixed pressing mechanism and a film reel roller, wherein the film reel roller is fixed on the rack; the adjustable pressing mechanism and the fixed pressing mechanism are respectively arranged at two ends of the rack; the adjustable pressing mechanism is connected with one group of compression roller assembly; and the fixed pressing mechanism is connected with the other group of compression roller assembly. By using the PVC profile laminator disclosed by the invention, the upper surface and the lower surface can be simultaneously laminated; the laminating pressures on the surfaces of different profiles can be met through adjusting the pressure of the adjustable pressing mechanism; the fixed pressing mechanism is pressed by using a spring connecting rod so that little vibration is caused, and the laminating process is kept stable; and the film reel roller is made of elastic rubber, is in flexible contact with a protective film, can be used for playing a role in pressing the protective film and cannot damage the surfaces of the profiles. The PVC profile laminator is also provided with a cleaning brush for cleaning and pressing again, so that the laminating quality is improved. The laminator is firm and durable, little in vibration, low in fault rate and long in service life.

Owner:长春联塑实业有限公司

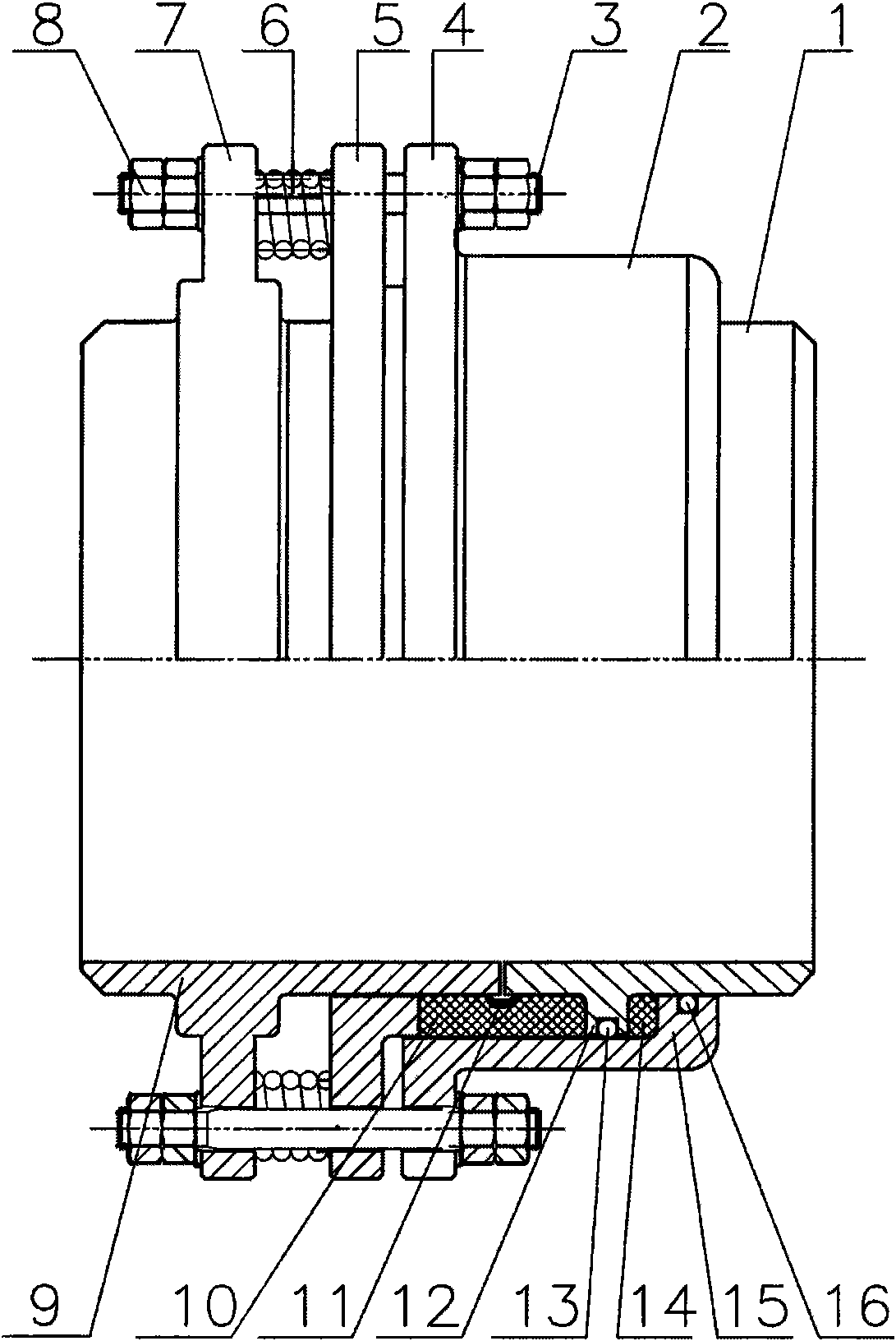

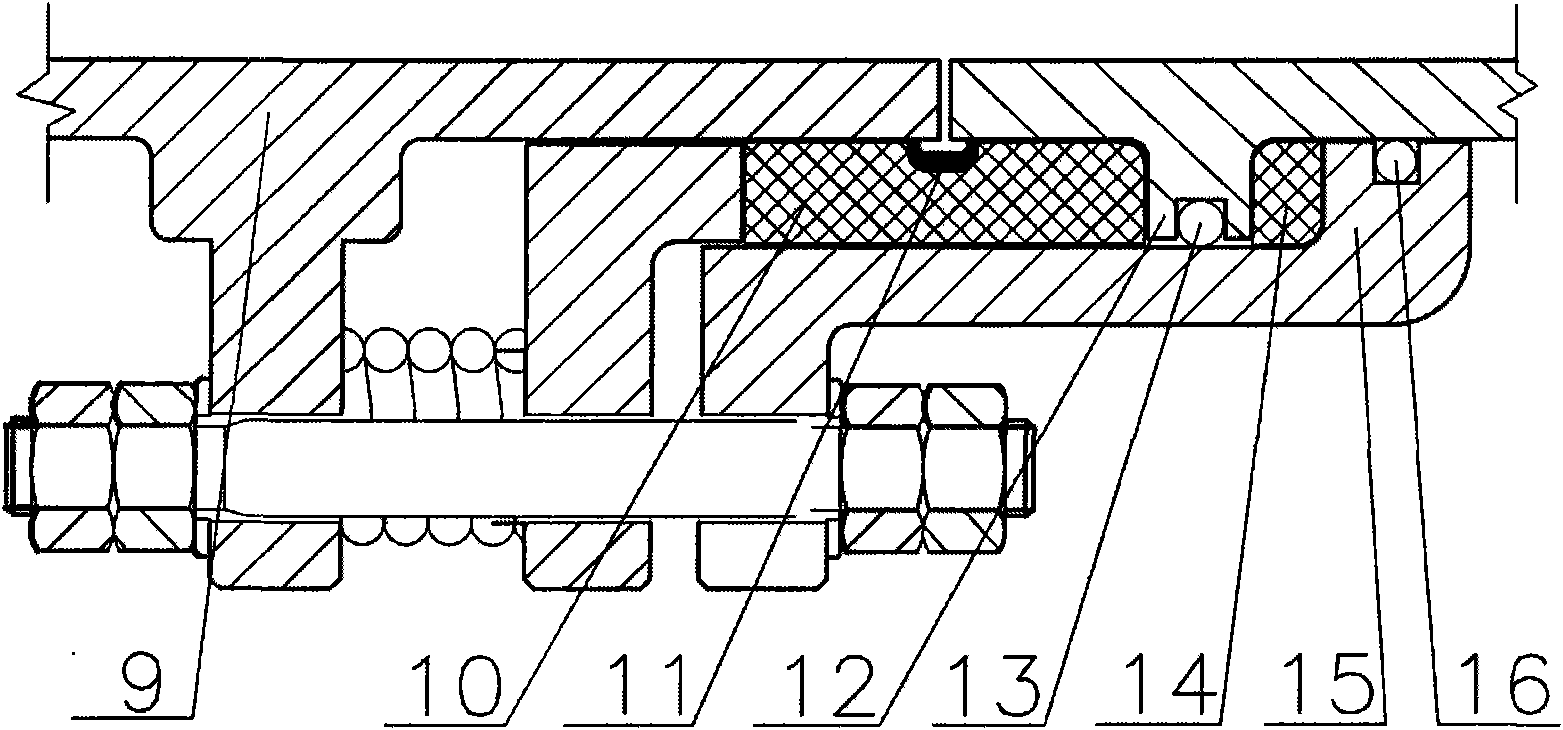

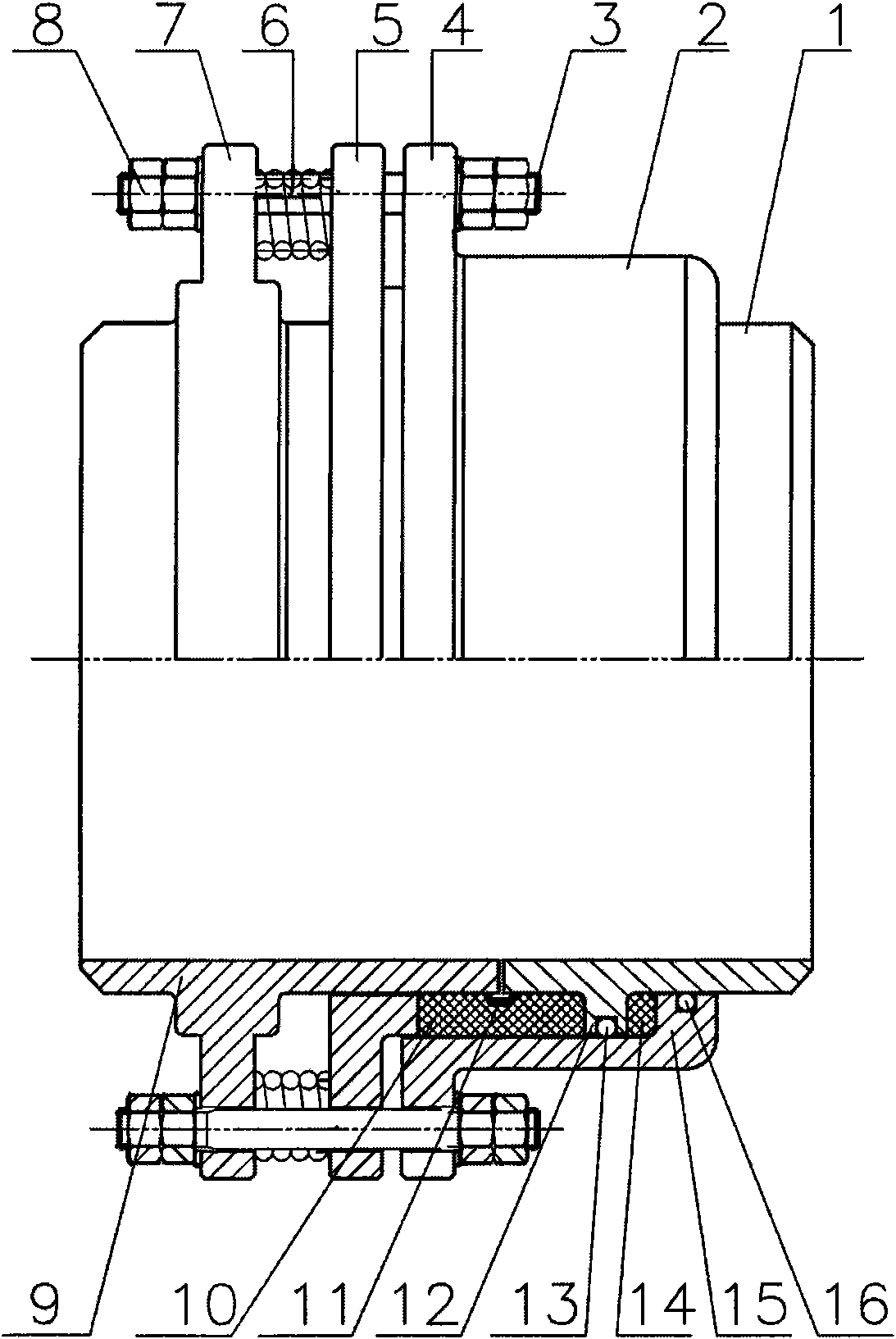

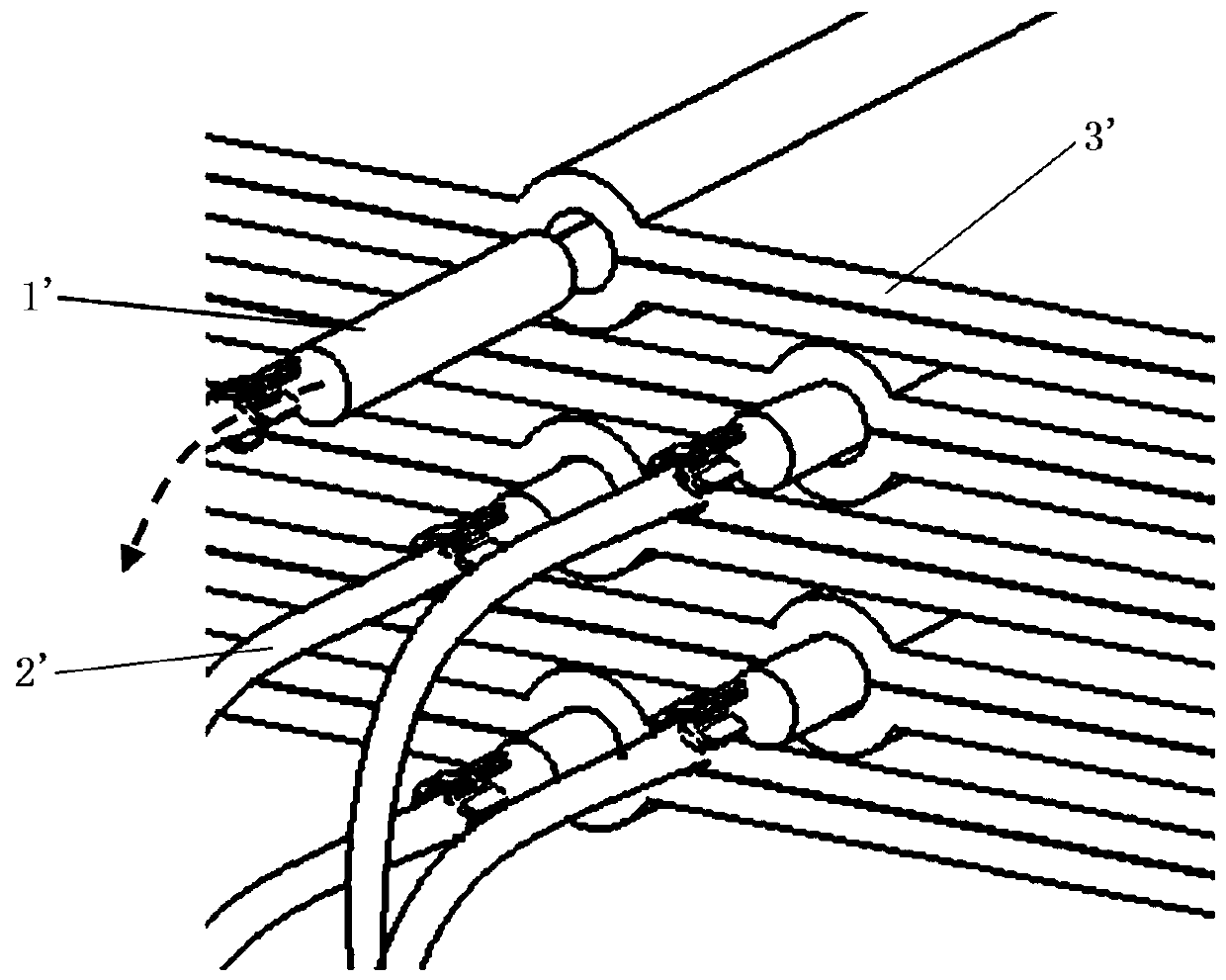

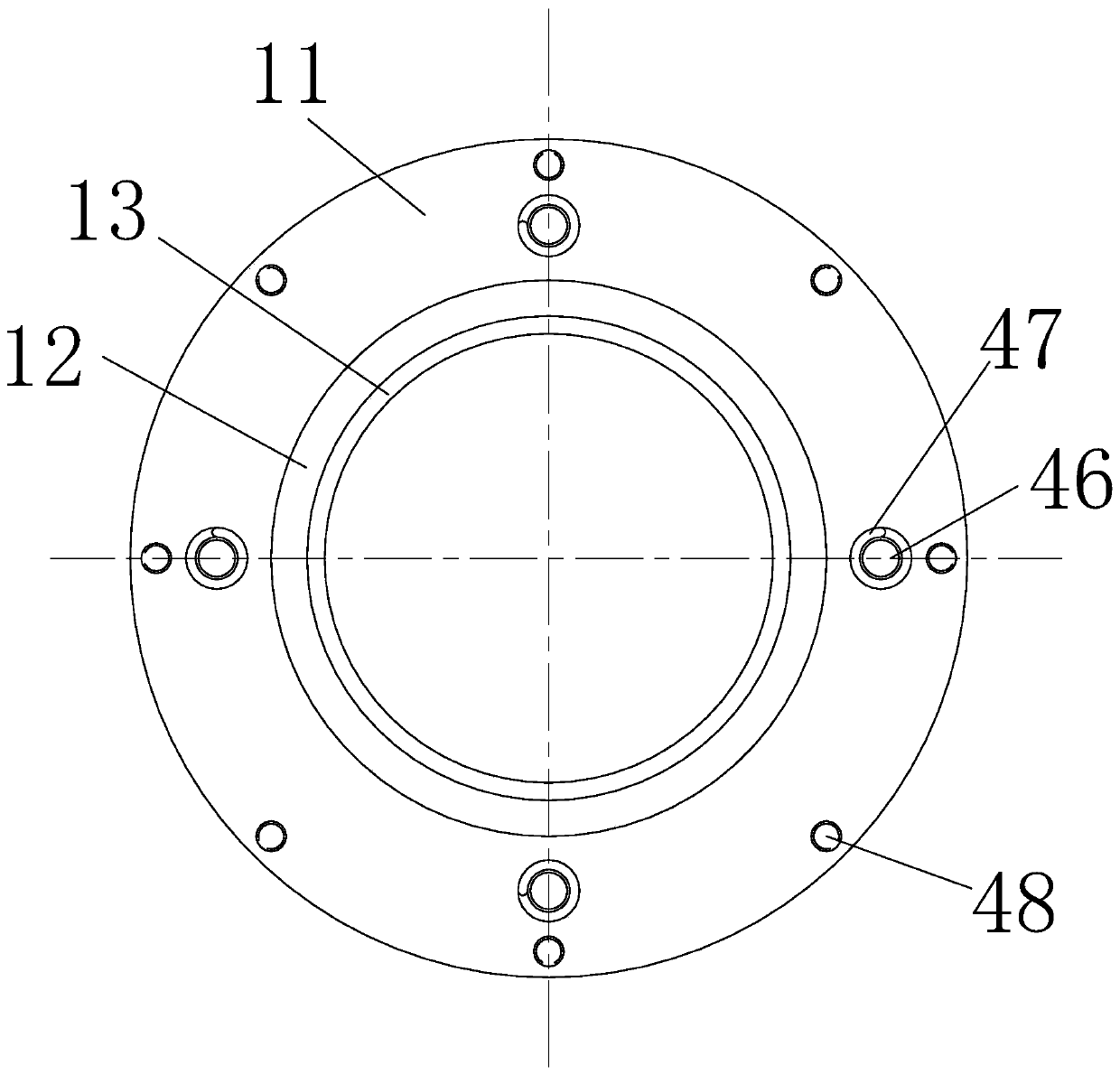

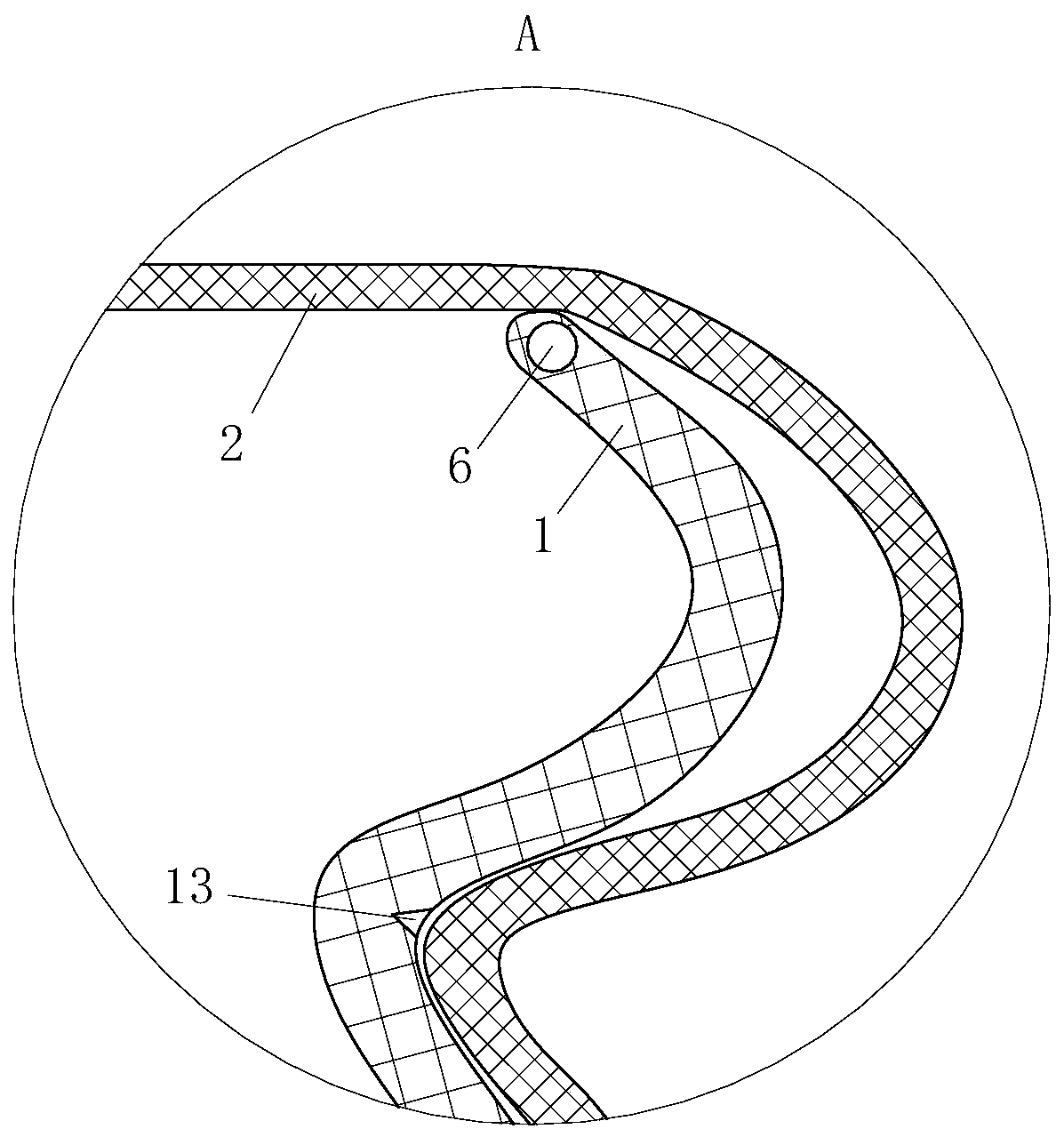

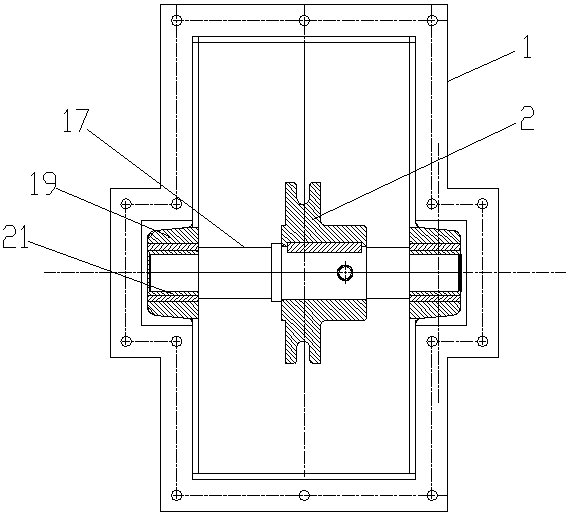

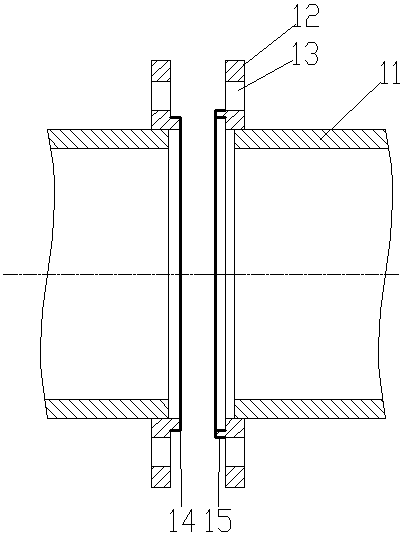

Novel high pressure-resistant maintenance-free rotary compensator

ActiveCN101852324ASmall seam gapImprove pressure capacityPipeline expansion-compensationEngineeringGraphite

The invention discloses a novel high pressure-resistant maintenance-free rotary compensator, which belongs to the technical field of thermodynamic piping compensators. The rotary compensator comprises an inner rotatable pipe (1), an outer sealing sleeve (2), a structural pipe flange (7), a structural pipe (9), flexible graphite packing (10), a U-shaped seal ring (11), an inner rotatable pipe boss (12), a graphite seal ring (14), an outer sealing sleeve base (15) and the like. The outer sealing sleeve (2) is sleeved on the outer circular surface of the inner rotatable pipe (1), and the inner rotatable pipe boss (12) is arranged on the inner rotatable pipe (1); the graphite seal ring (14) is arranged between the inner end surface of the outer sealing sleeve base (15) and the inner rotatable pipe boss (12); the U-shaped opening of the U-shaped seal ring (11) faces the port of the joint between the inner rotatable pipe (1) and the structural pipe (9), and the U-shaped seal ring (11) is embedded into the flexible graphite packing (10); and the structural pipe flange (7) is integrated with the structural pipe (9), which is an integrated straight pipe section. Since the structure is adopted, the quality of the connecting welds of a piping can be conveniently detected, and the rotary compensator is characterized by high precision, low friction coefficient, low torque, high bending resistance, high pressure-bearing capability, reliable sealing, little pressure loss, unlimited medium flow direction, excellent performance, safe and reliable piping operation and sealing material replaceability.

Owner:陈墅庚

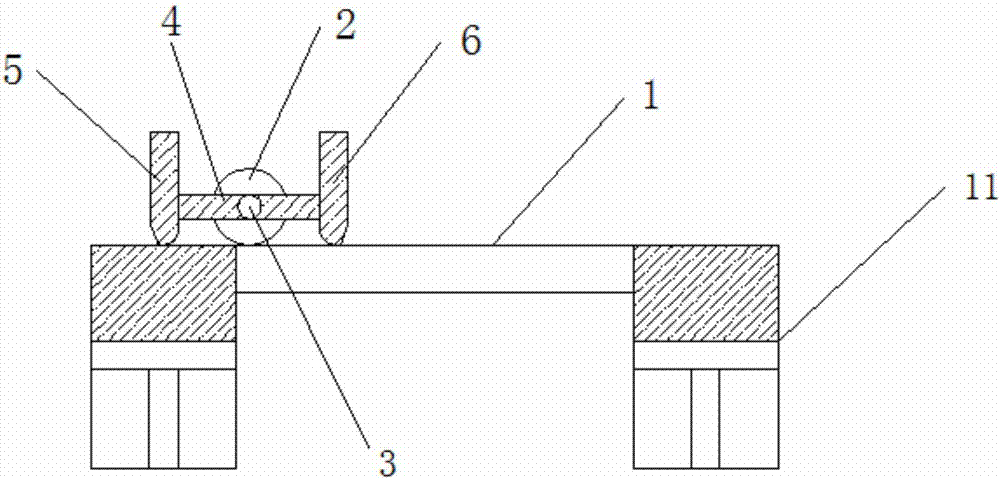

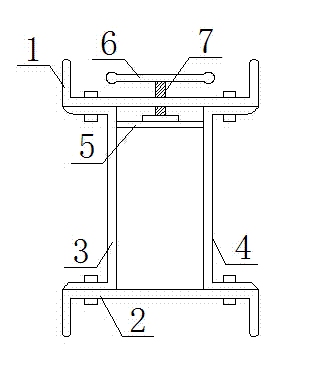

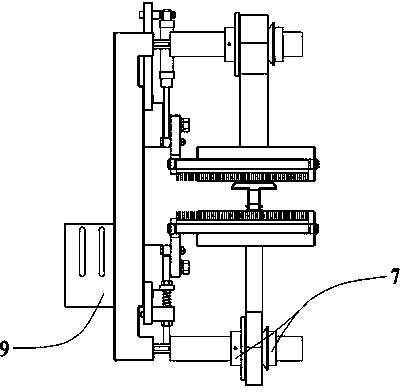

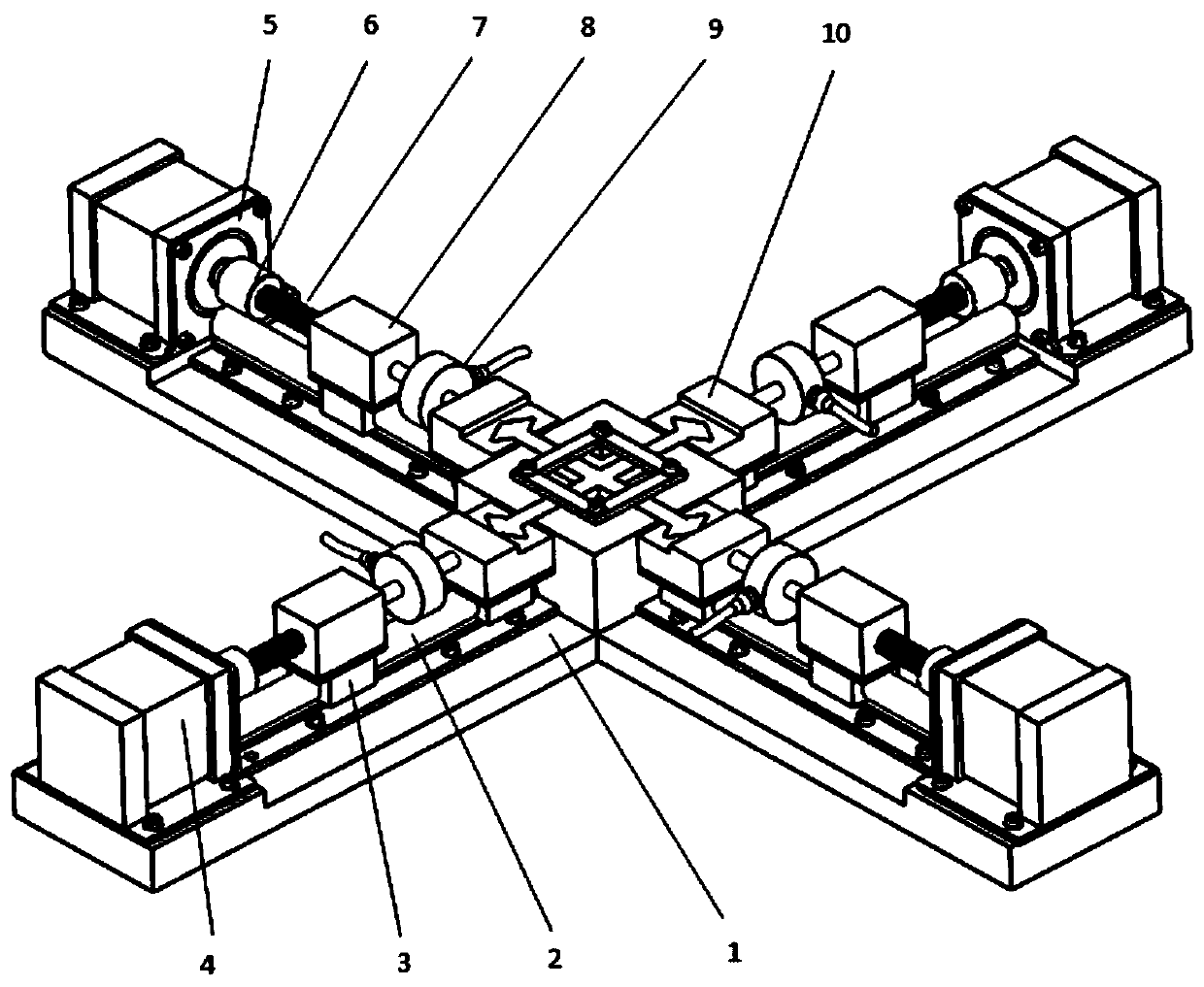

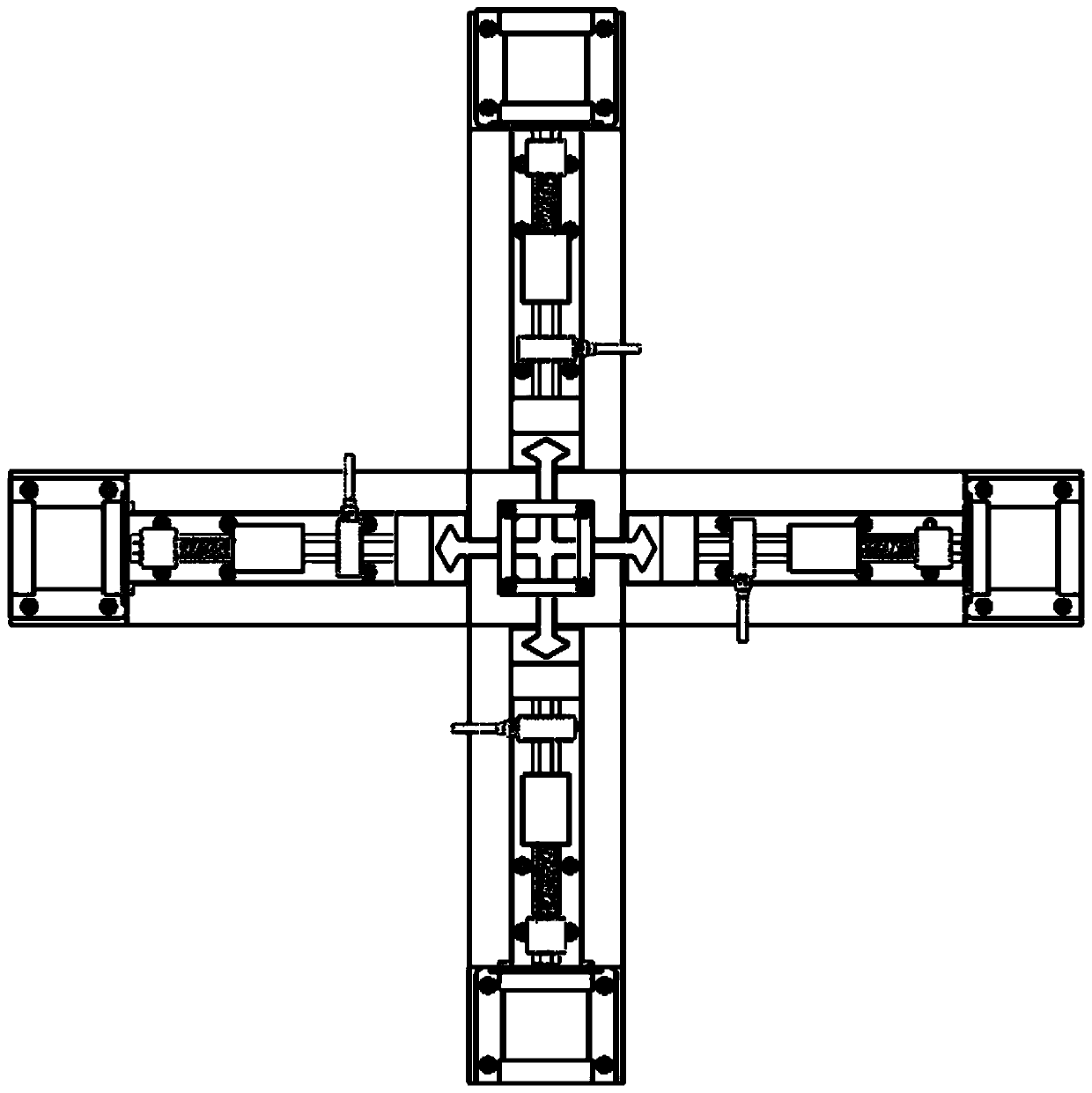

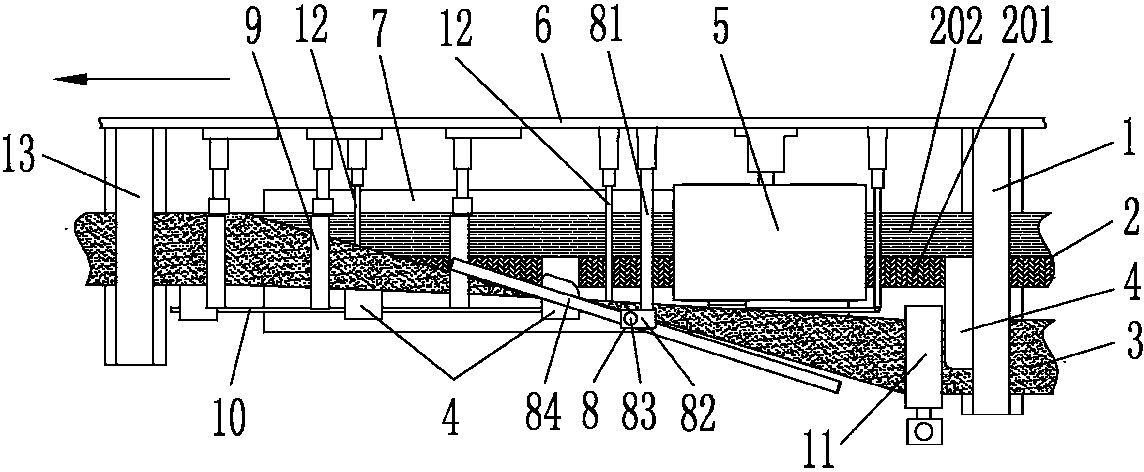

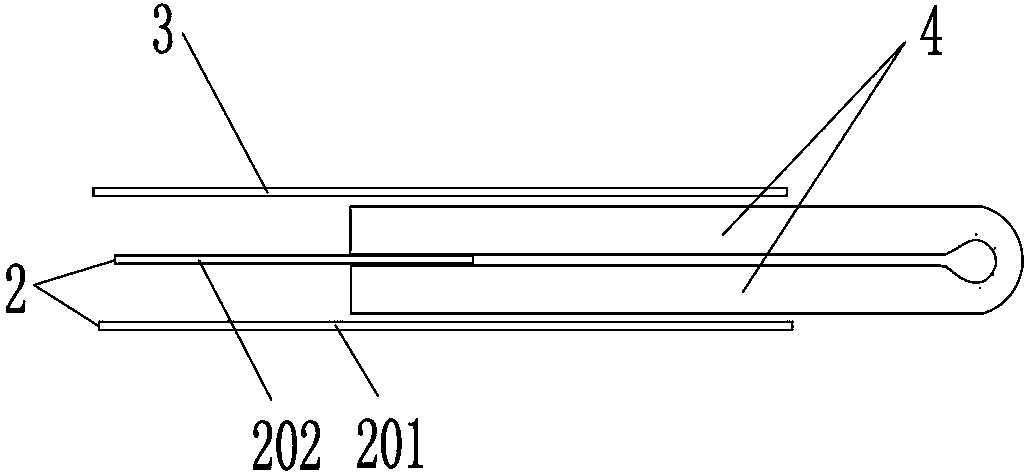

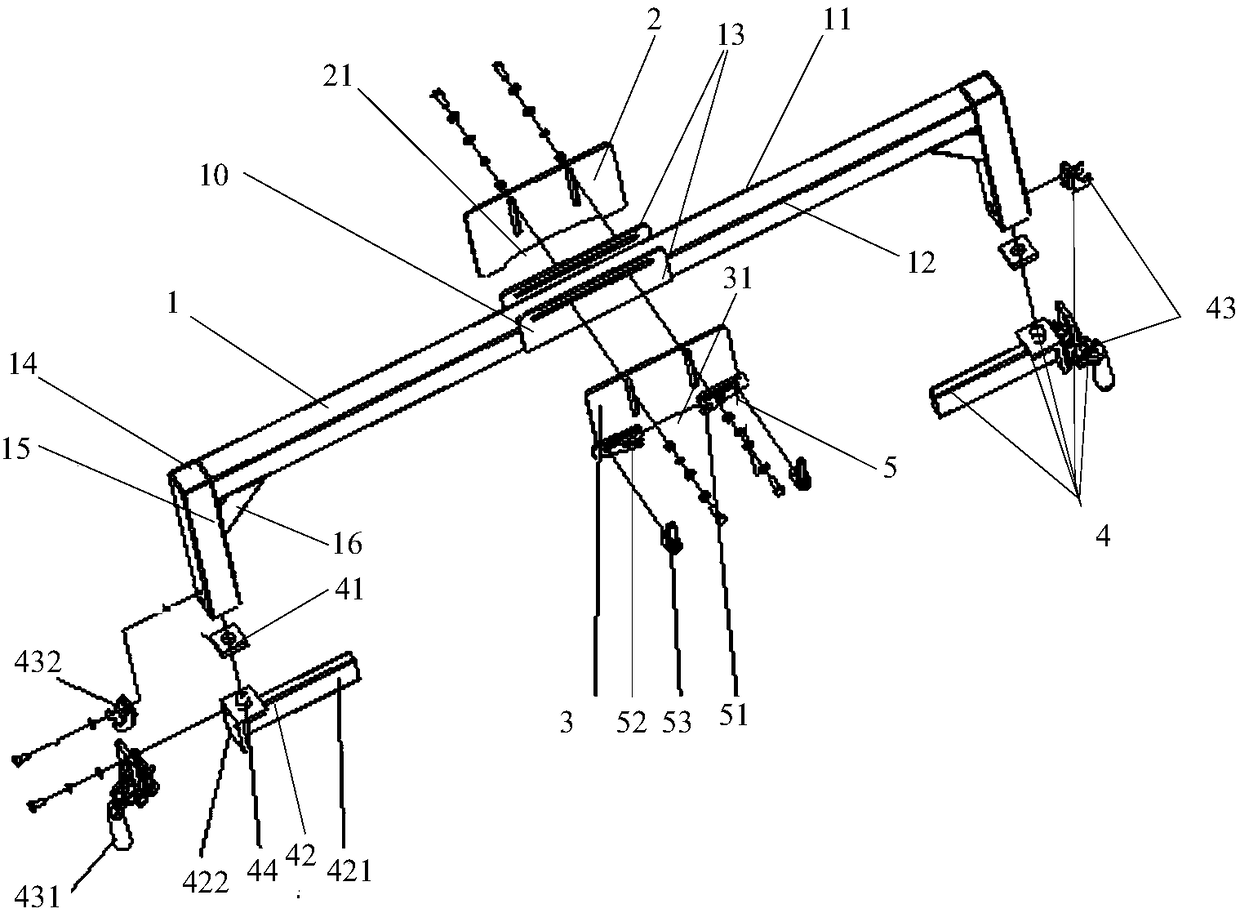

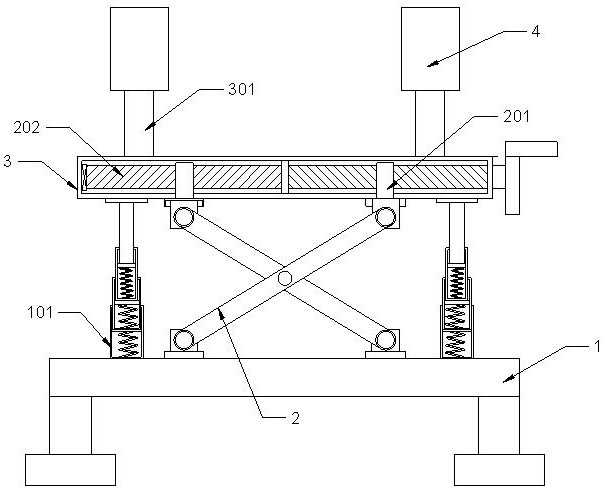

Residual stress introduction device keeping center position unchanged

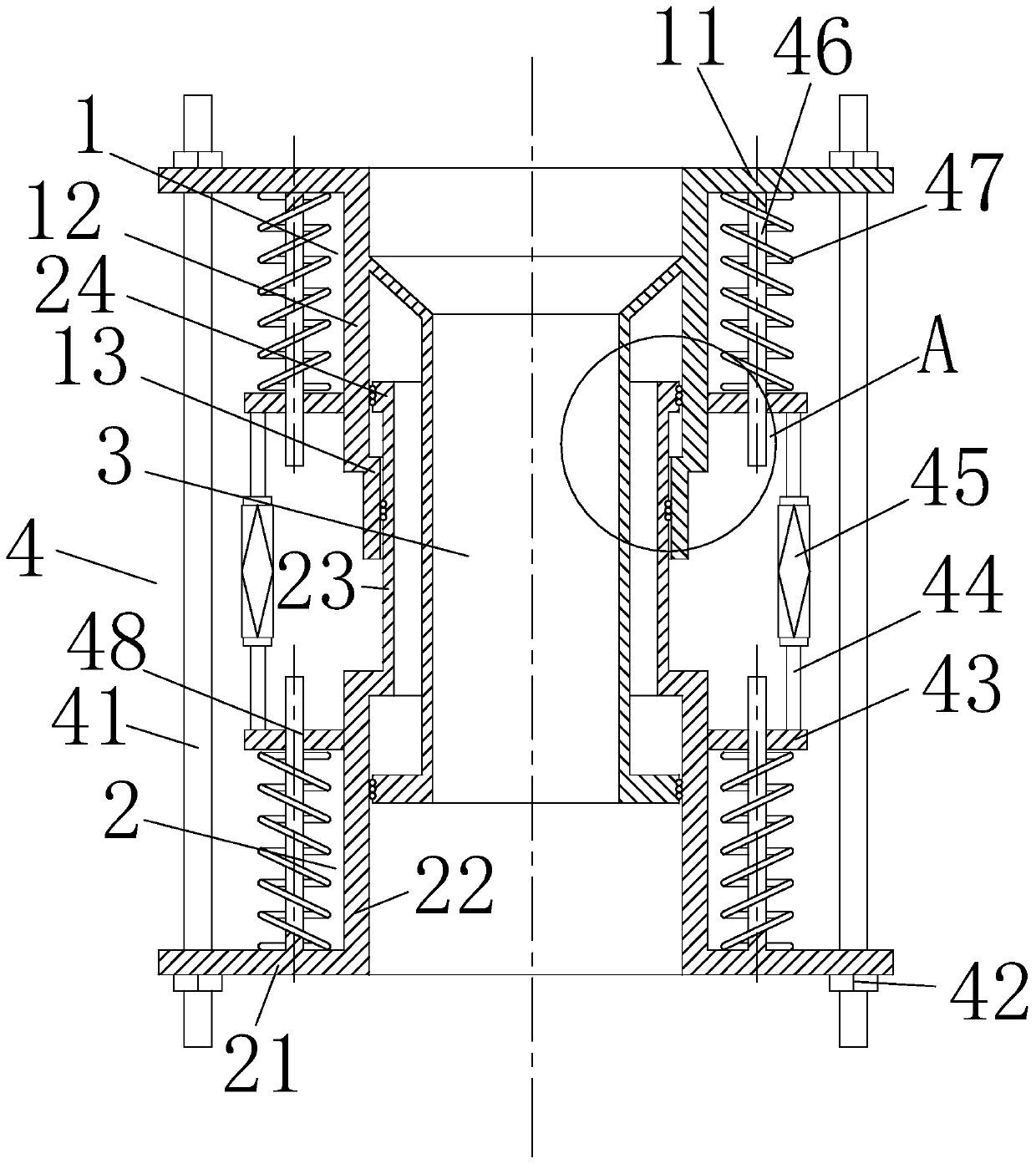

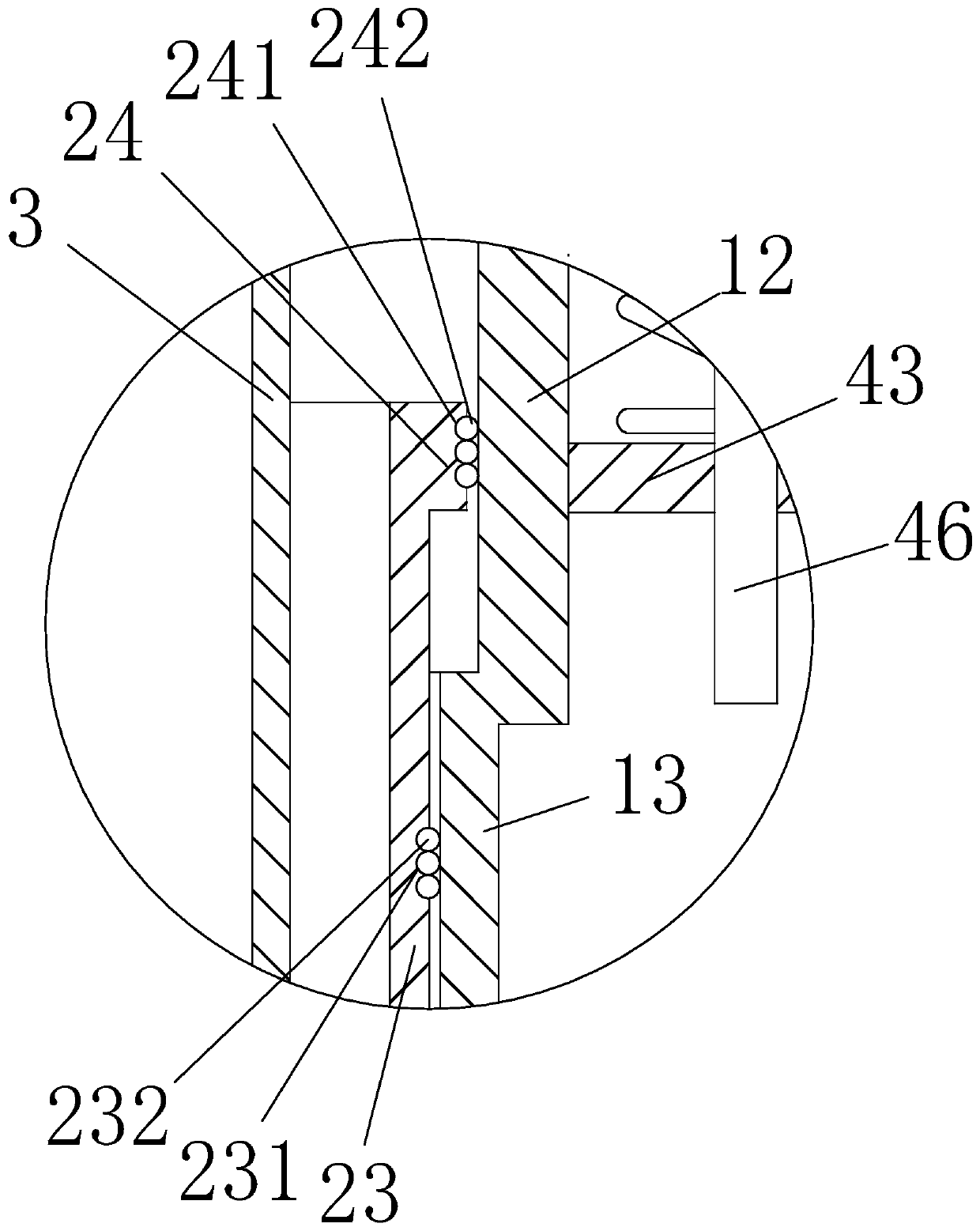

PendingCN110595658APlay a role in compressionAvoid warpingApparatus for force/torque/work measurementTest sampleDisplay device

The invention discloses a residual stress introduction device keeping a center position unchanged. The device includes a base seat, sliding rails, sliding blocks, stress applying components, load sensors, moving fixtures and pressing pieces. The base seat is cross-shaped. A concave platform with a slot is arranged in the middle of the base seat and is used to place a test sample. One end of a loadsensor is connected with a moving fixture, and the other end is connected with a stress applying component, and is connected with an equipped load displayer. A pressing piece is connected with the base seat by a fastening bolt, and is used to press the cross-shaped test sample. According to the device, the test sample is pulled or pressed through the stress applying components with two-end symmetry, uniform and arbitrary residual stress can be generated inside the test sample without introducing other stress, and the introduced residual stress is used as an agreed reference value. The devicecan be used to directly check accuracy and reliability of residual stress detection technology. A manner of applying pulling and pressing stress by the device is simple and convenient, frequent replacement of the stress applying components is not required, and working efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH

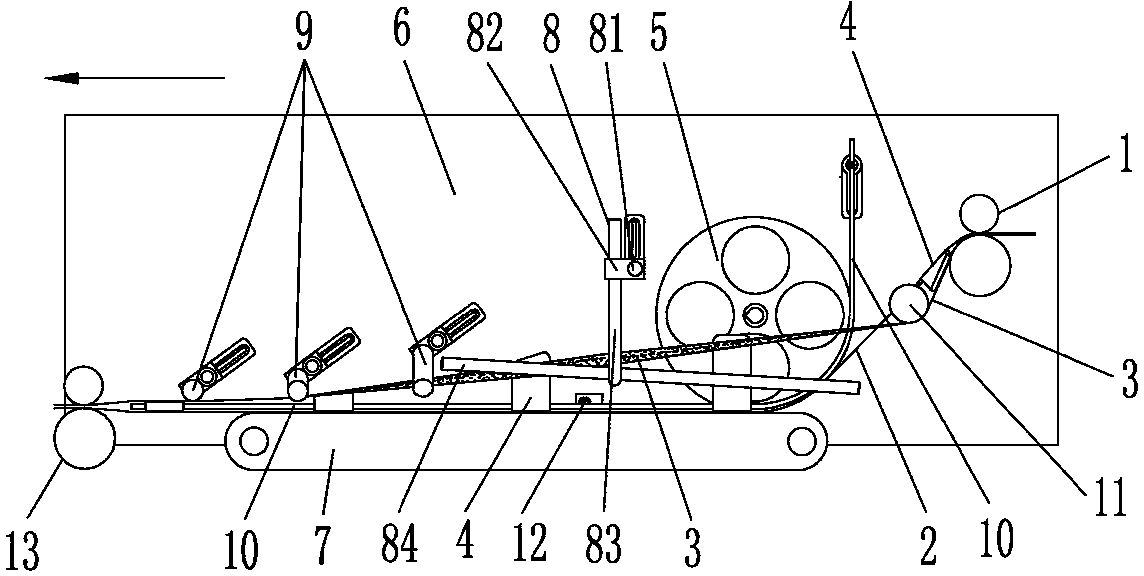

Unilateral fixation folding device for diapers

ActiveCN104337622ALow costSimple structureAbsorbent padsBaby linensEngineeringMechanical engineering

The invention aims to provide a unilateral fixation folding device for diapers. The device comprises a feeding component, a first conveying belt, a second conveying belt and a discharging component, wherein the first conveying belt and the second conveying are both arranged in the feeding component and the discharging component in a penetrating manner in sequence and are both wide belts; the second conveying belt and the first conveying belt at the position of the feeding component are arranged in parallel; viewed from the feeding component to the discharging component, the second conveying belt twists clockwise; the second conveying belt at the position of the discharging component is overlapped above the first conveying belt, and the back face of the second conveying belt faces upwards; a press roll for pressing the first conveying belt is arranged between the feeding component and the discharging component; a folding rod is arranged on the side of the first conveying belt. The device has a simple structure, continuous and stable folding of products can be realized, and good neatness of the folded products is guaranteed.

Owner:JINJIANG SHUNCHANG MACHINE MFG

Battery charging device of new energy electric car

InactiveCN108099684AInhibit sheddingImprove protectionCharging stationsElectric vehicle charging technologyBattery chargeNew energy

The invention discloses a battery charging device of a new energy electric car, which comprises a pile body and a charging gun; one side of the pile body is fixed with an insert opening, and an outputend of the charging gun is plugged in the insert opening; outside of the insert opening is provided with a fixing device, and the fixing device comprises an installing frame, a switch device, an installing plate, an adjusting device and a fixing plate; the installing frame is located at outside of the insert opening, and the installing frame is fixed with the inner wall of the pile body; the switch device is fixed at one side of the installing frame, the output end of the switch device is fixed with the installing plate; the adjusting device is fixed with one side of the installing plate closing to the installing frame; the adjusting device comprises an adjusting motor, a connecting shaft, a buffer device and a fixing head; the adjusting motor is fixed on the installing plate. Through thefixing device, the charging gun and the insert opening can be stably fixed, so as to prevent the charging gun from dropping from the insert opening; the charging gun can be well protected.

Owner:何钰

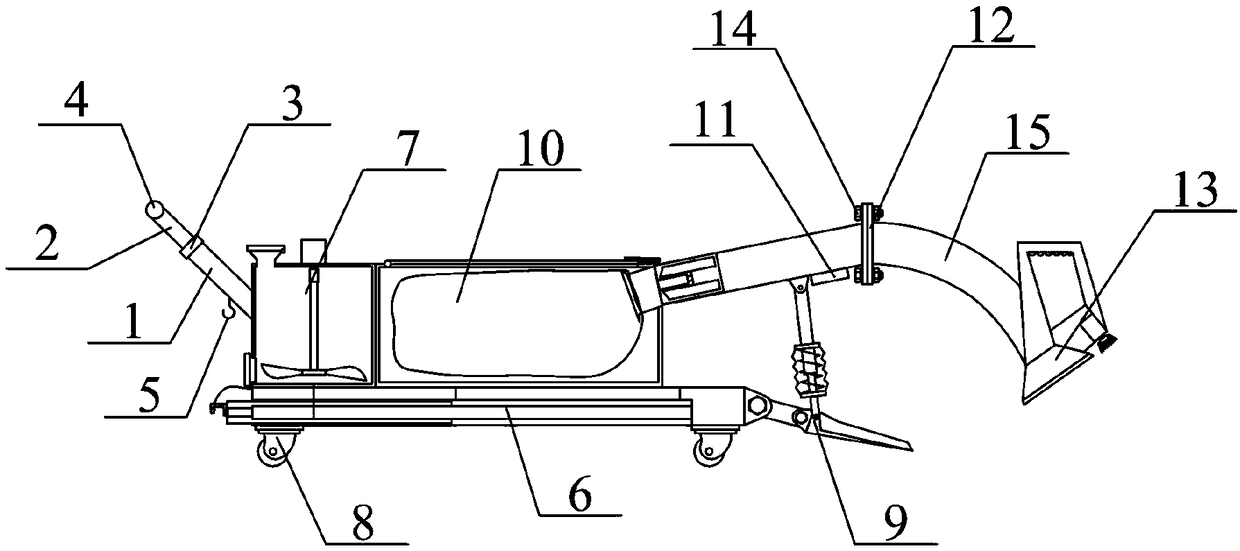

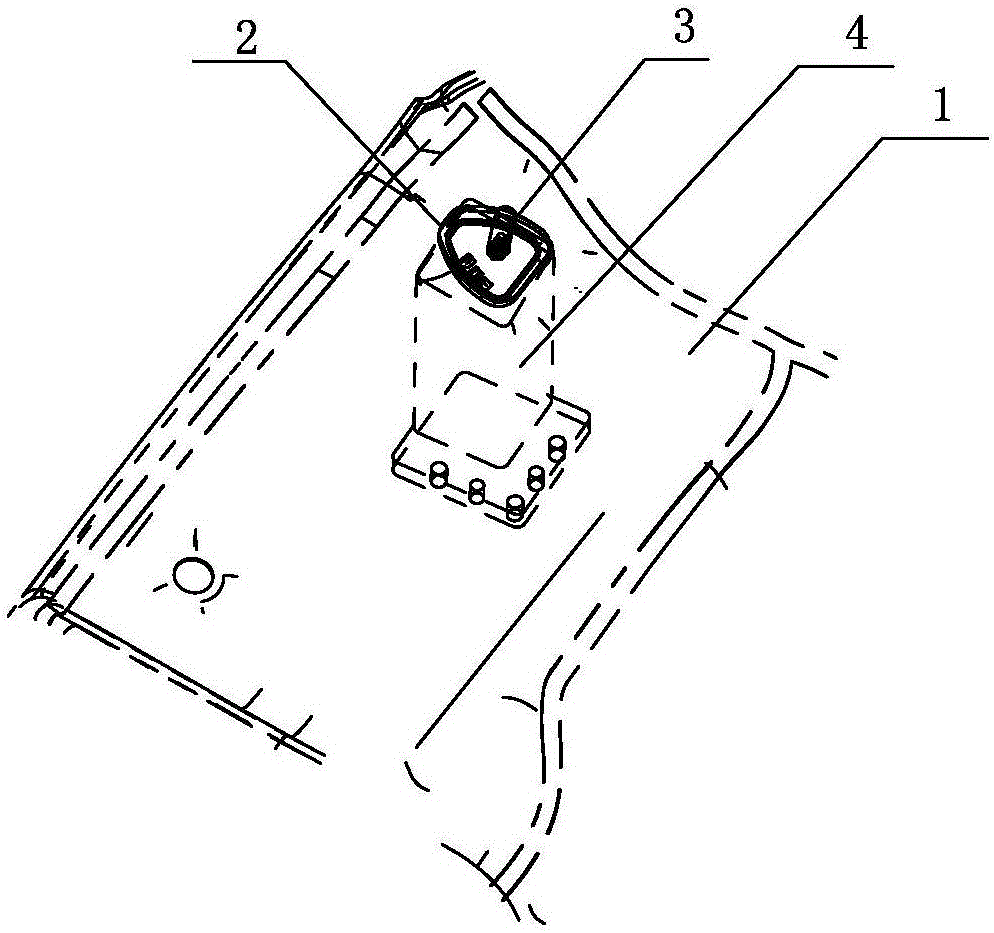

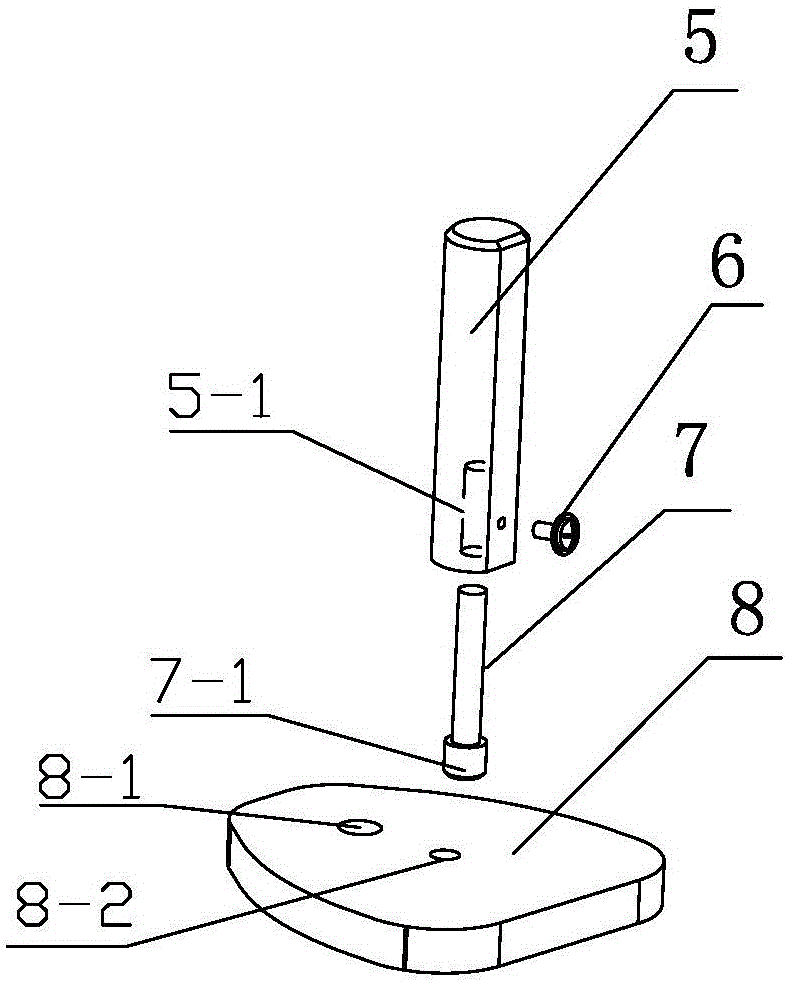

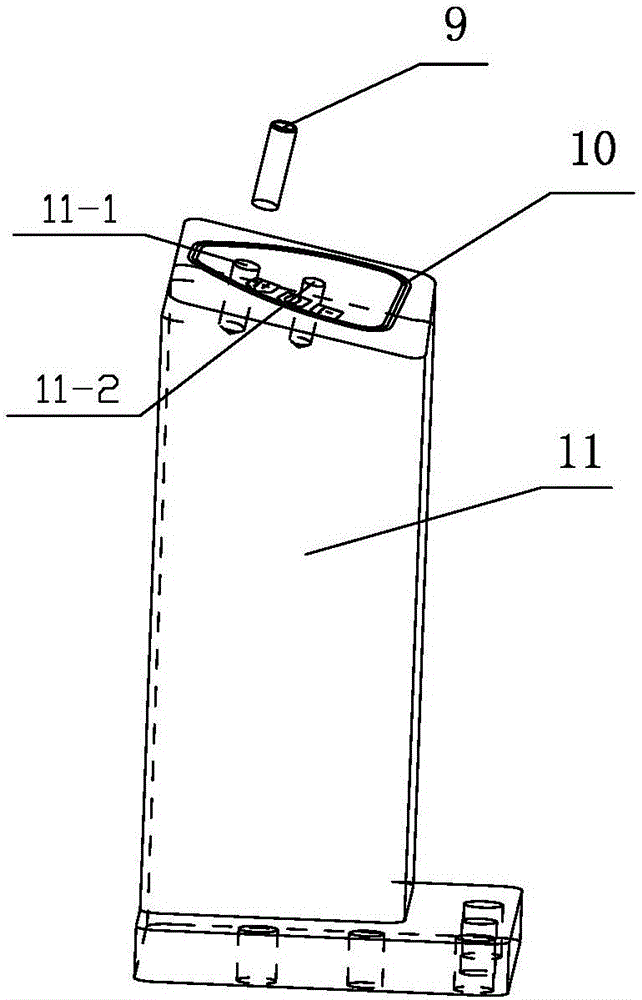

Wind power blade tip lightning arrester positioning tool

The invention provides a wind power blade tip lightning arrester positioning tool comprising a bracket, a root end limiting plate, a tip end limiting plate and a fixing device. A first side edge at the top of the bracket and a second side edge opposite to the first side edge are provided with installation plates for installing the root end limiting plate and the tip end limiting plate correspondingly. The root end limiting plate is provided with a part matched with a step surface of a blade tip lightning arrester, and the bottom of the root end limiting plate is provided with a positioning groove. The width of the positioning groove is the same as the chordwise width of the blade tip lightning arrester, and the positioning groove is provided with a part matched with the upper surface of the blade tip lightning arrester. The bottom of the tip end limiting plate is provided with an installation groove, the installation groove is provided with a part capable of being matched with the blade tip lightning arrester and the aluminum tip of a wind power blade, and the bottom of the tip end limiting plate is provided with a limiting device capable of fixing the aluminum tip of the wind power blade. Fixing devices are arranged at the bottom of the bracket oppositely. By means of the wind power blade tip lightning arrester positioning tool, the blade can be positioned in the axial direction, the chordwise direction and the vertical direction simultaneously.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

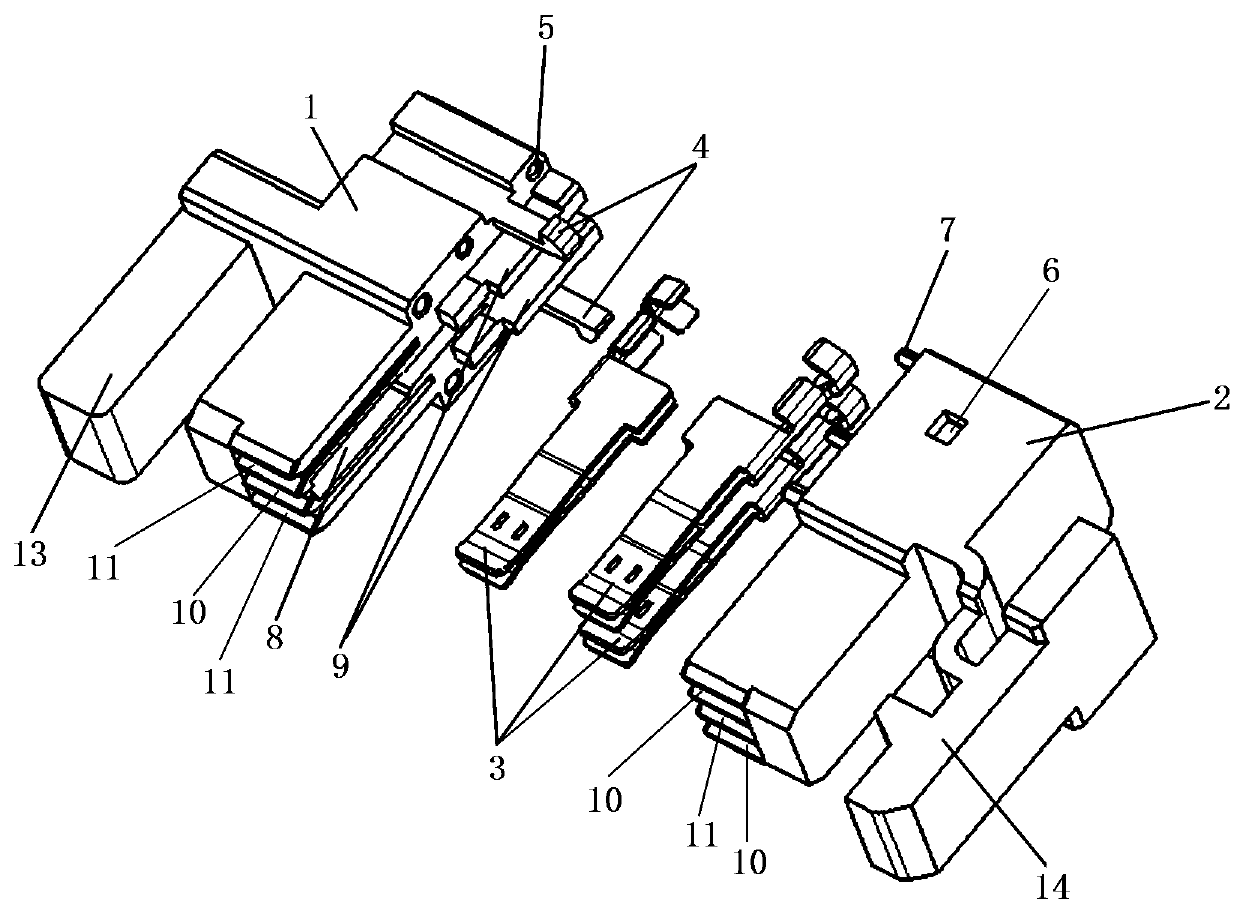

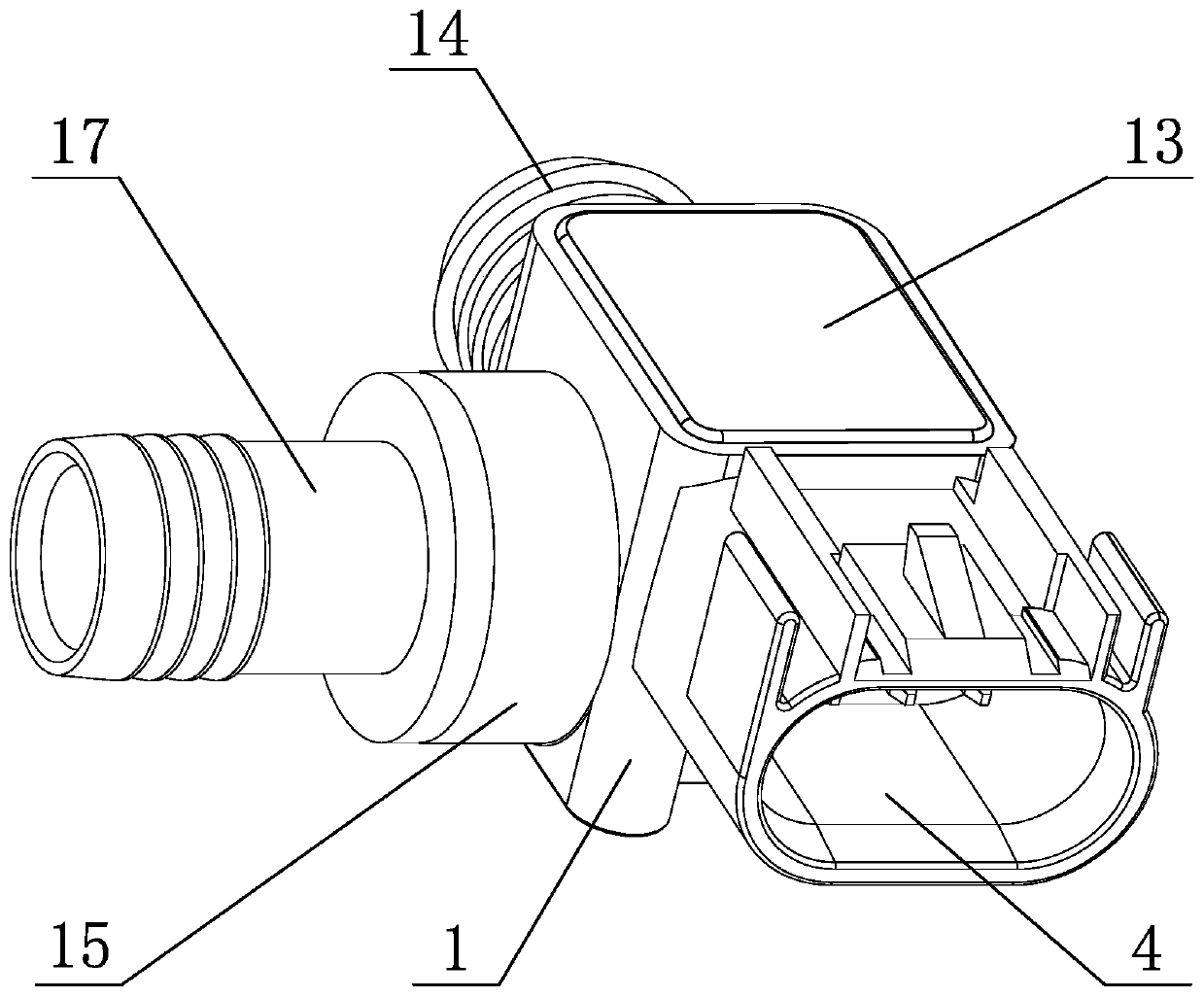

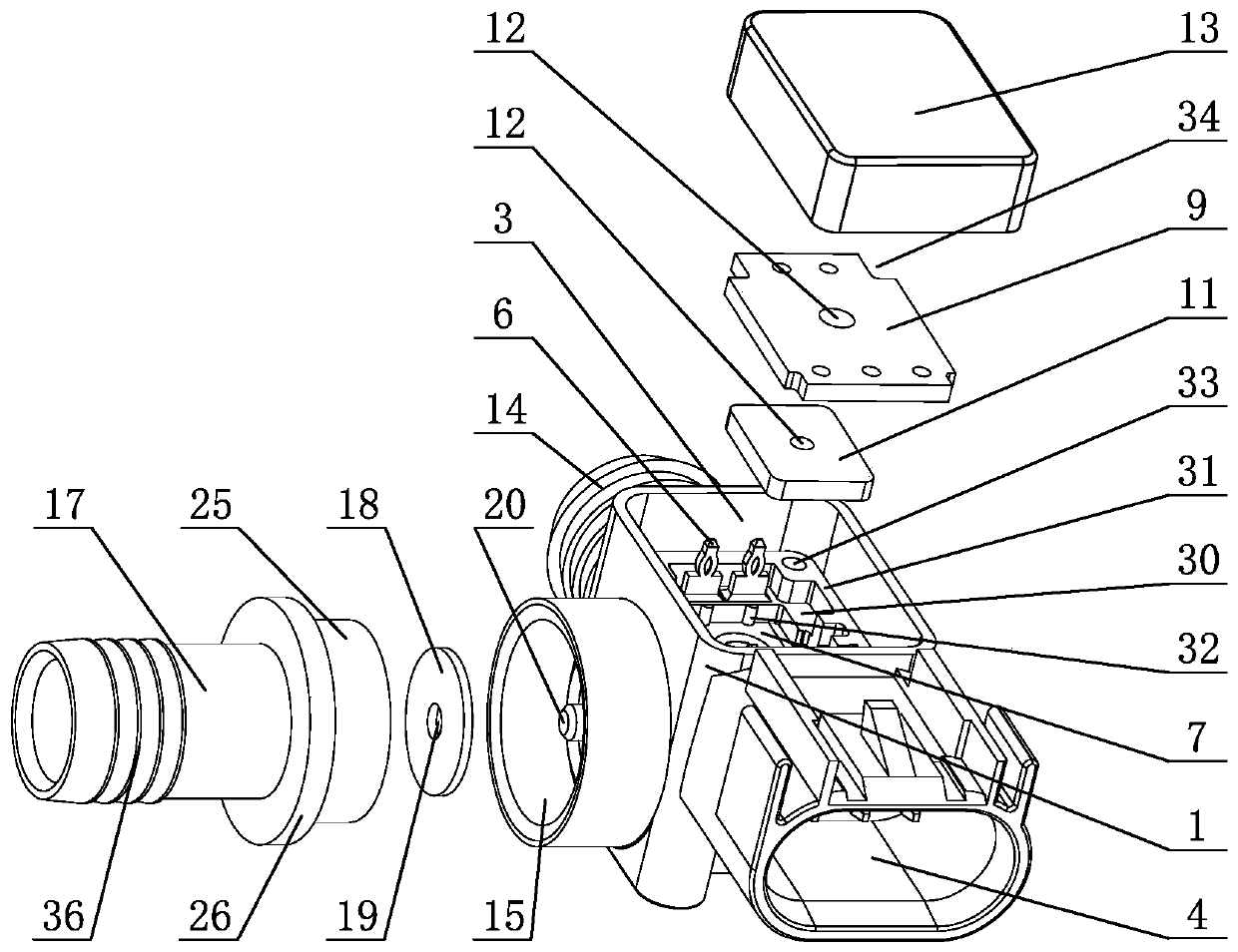

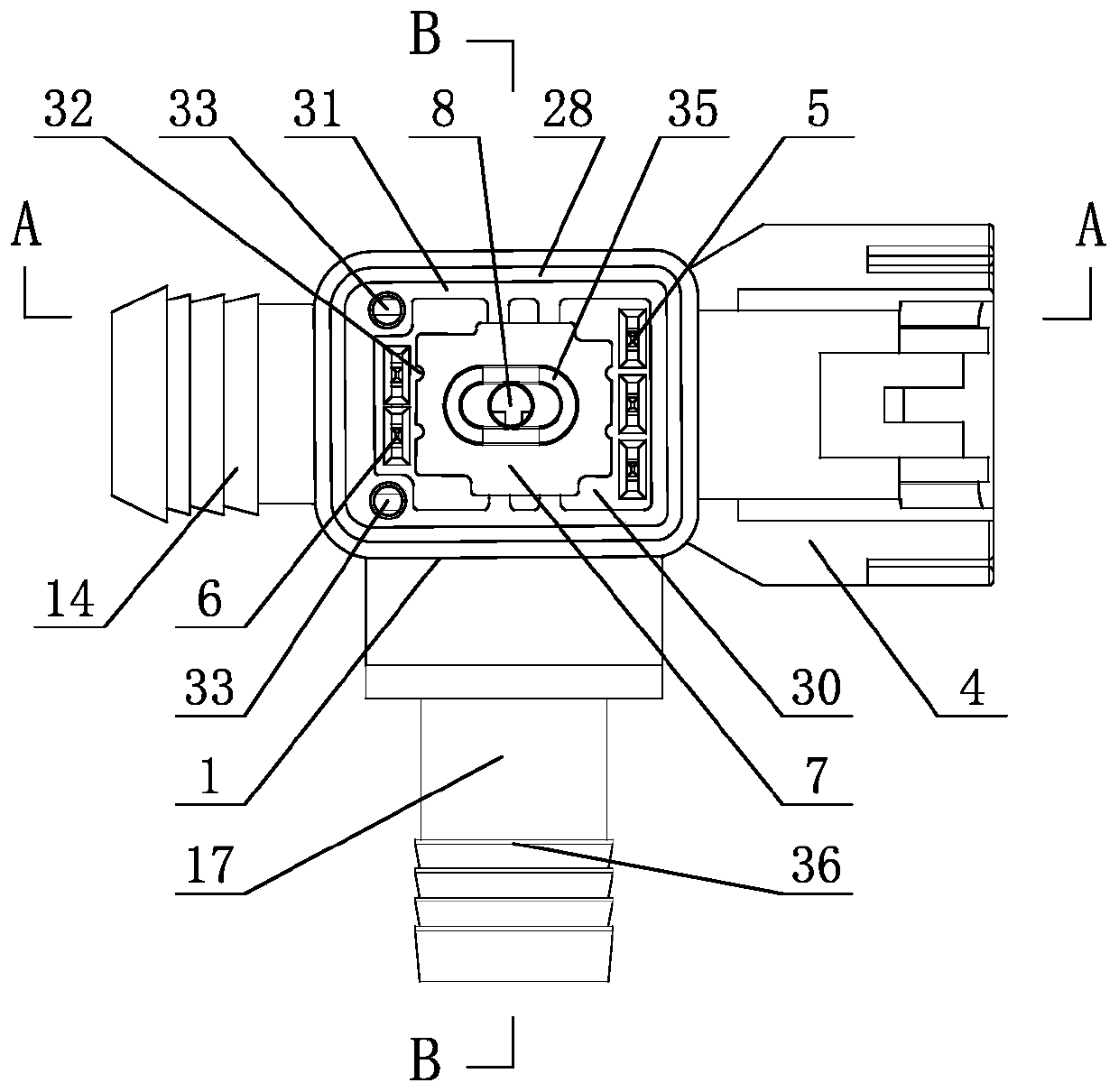

Integrated quick-plug device for voltage detection of metal bipolar plate of fuel cell

PendingCN110600923APlay a role in compressionAccurate and reliable connectionRelieving strain on wire connectionFinal product manufactureFuel cellsCantilever

The invention discloses an integrated quick-plug device for voltage detection of a metal bipolar plate of a fuel cell, which comprises a plastic shell and a metal reed, wherein a reed imbedding grooveis formed in the plastic shell, a fin connector and a fin inserting groove are formed in the front end, a wire connector is formed in the tail end, and the fin connector and the wire connector are both communicated with the reed imbedding groove; the metal reed is installed in the reed imbedding groove, the front end is in a clamping piece shape, the tail end is in a U shape, and a metal reed pressing structure is arranged on the plastic shell; and the two sides of the plastic shell are connected with a guide column and a cantilever buckle respectively. A plurality of detection units are integrated into one quick plug device to realize integrated detection; the plastic shell can be manufactured separately or integrally; the metal reed pressing structure not only has a pressing effect on the metal reed, but also has a pressing effect on an accessed wire; guiding is achieved when the guiding column and the metal bipolar plate are assembled, locking is achieved when the cantilever buckleand the metal bipolar plate are assembled, and reliable connection between the integrated quick-plug device and the metal bipolar plate is guaranteed.

Owner:SHANGHAI ZHIZHEN NEW ENERGY EQUIP CO LTD

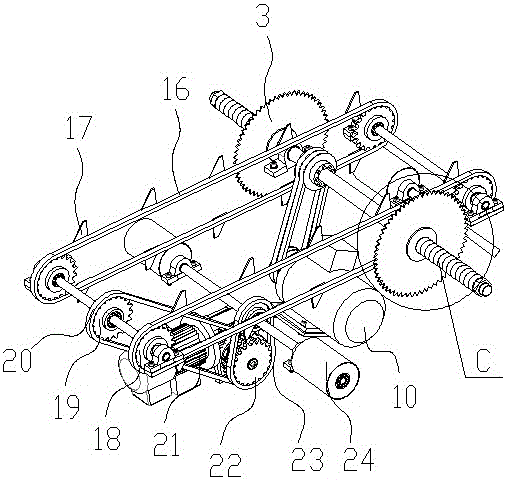

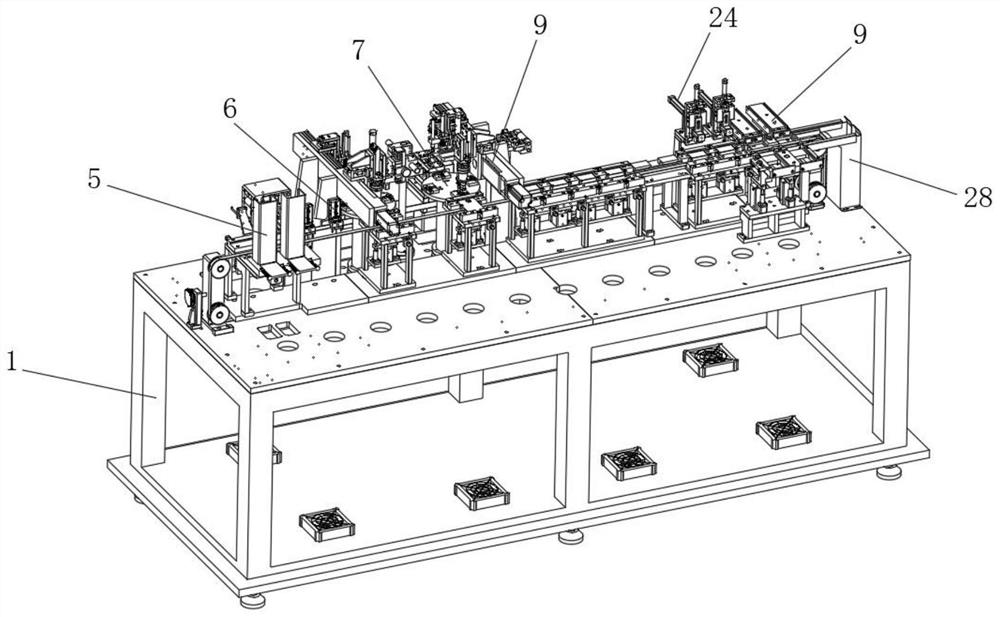

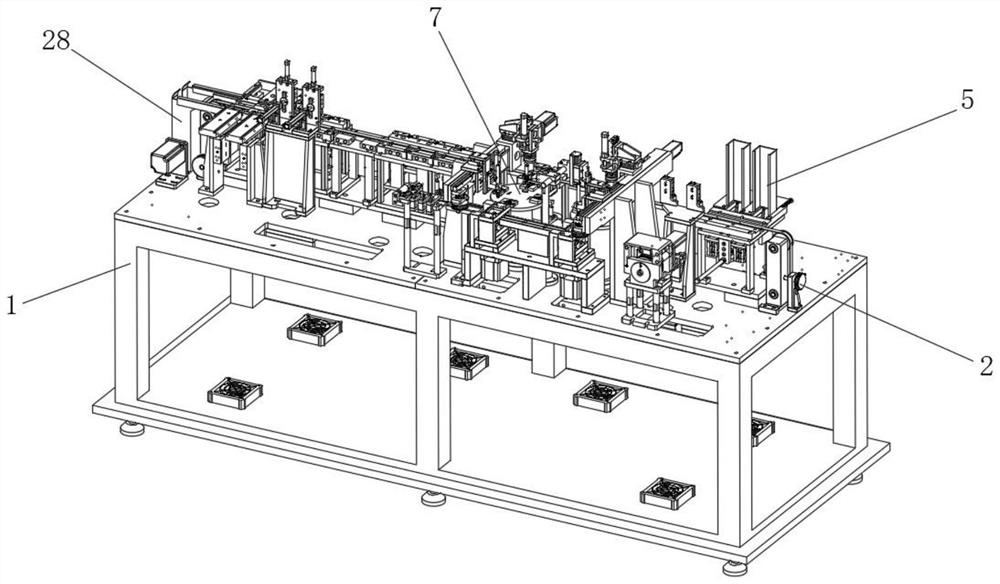

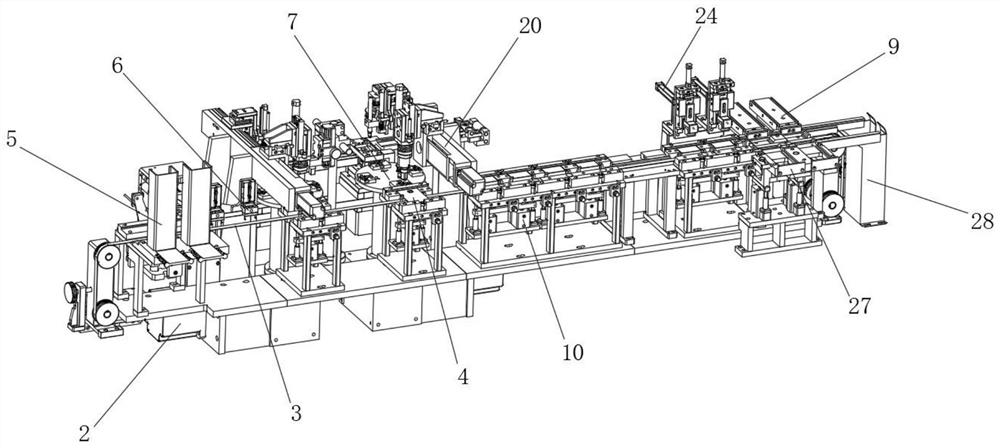

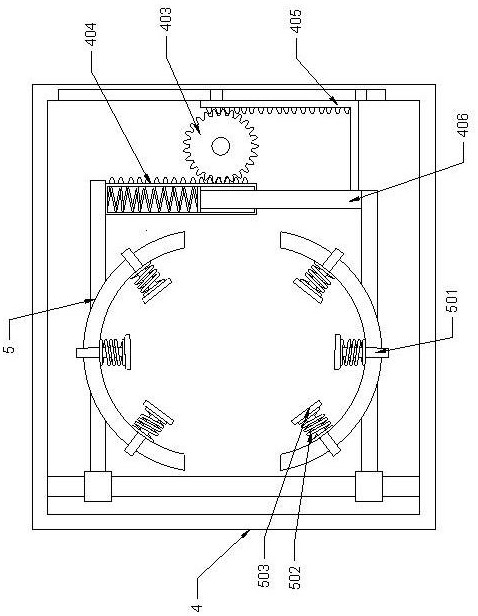

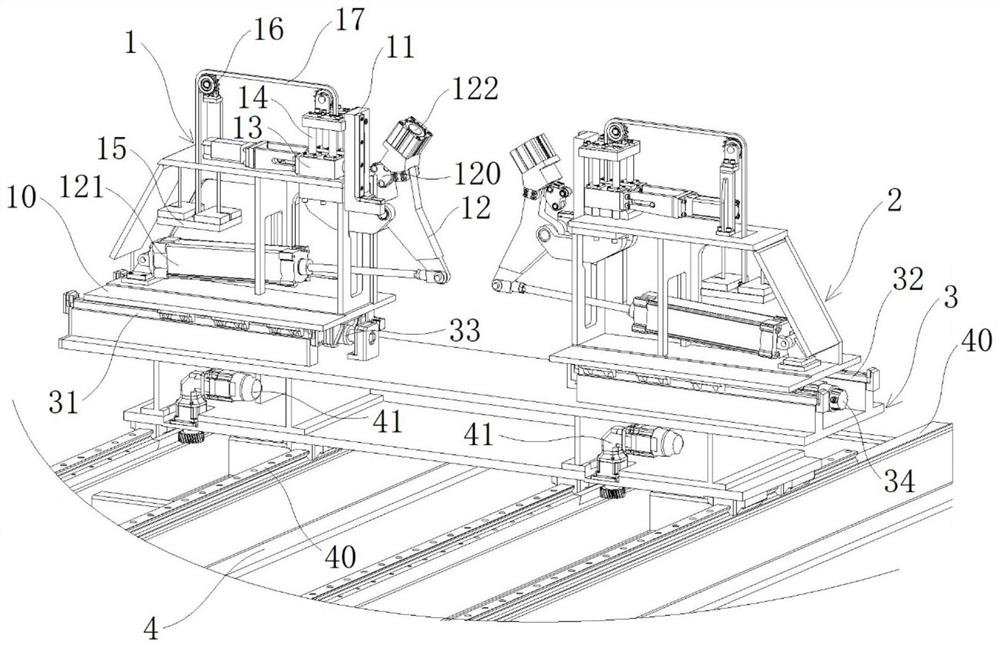

Efficient drilling production line

ActiveCN108581552APlay a role in compressionEasy to drillLarge fixed membersMetal working apparatusProduction lineGear wheel

The invention relates to an efficient drilling production line. The efficient drilling production line comprises an efficient drilling machine and an intelligent conveying device, wherein the efficient drilling machine comprises a housing; a mounting pipe is arranged on the inner side surface of the right sidewall of the housing; a compressing device and a drilling device are arranged in the housing; the compressing device comprises a mounting plate, and a mounting hole is formed in the middle part of the mounting plate; the left end of the mounting pipe is positioned in the mounting hole; a bearing is arranged between the mounting pipe and the mounting plate; teeth are arranged in the circumferential surface of the mounting plate; a gear is arranged below the mounting plate and is engagedwith the mounting plate; at least two compressing driving devices are arranged on the left side surface of the mounting plate; compressing plates are arranged at the output ends of the compressing driving devices; and the intelligent conveying device comprises a conveying platform which is positioned at the right side of the housing, a plurality of conveying rollers which are positioned above theconveying platform, and a pushing device which is positioned above each conveying roller. With the adoption of the efficient drilling production line, the work of drilling a pipe by any angles can beachieved; and the cost is low.

Owner:江苏国强兴晟能源科技有限公司

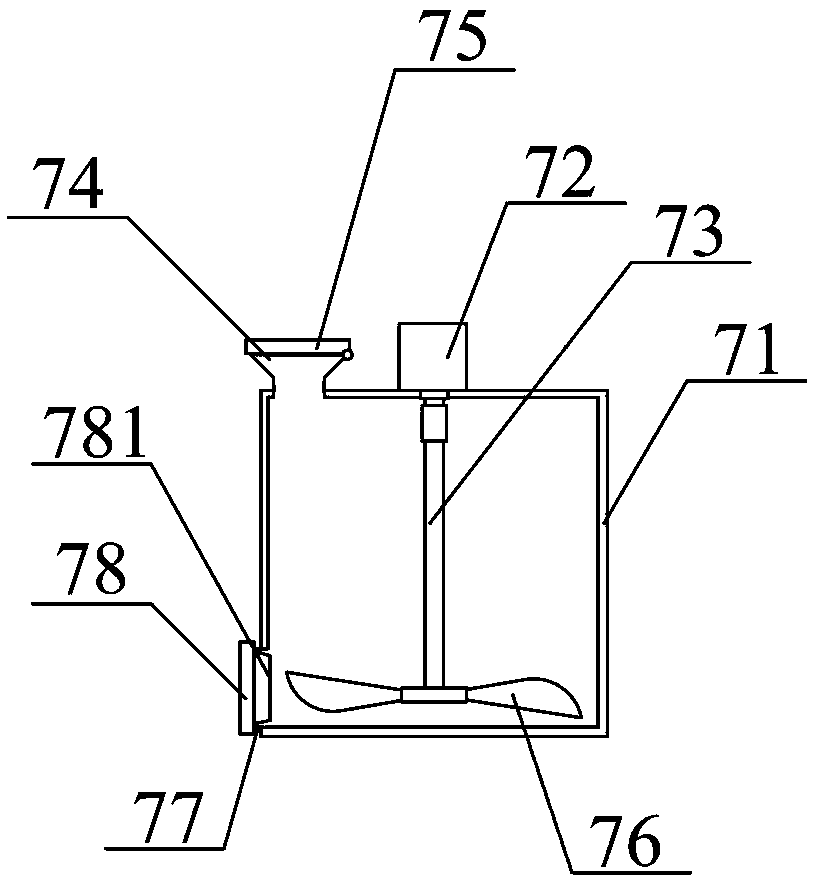

Finishing and ironing device for knitted fabrics

ActiveCN107641926AAchieve recyclingAvoid wrinklesLiquid/gas/vapor textile treatmentTextile shapingComputer engineering

The invention discloses a finishing and ironing device for knitted fabrics. The finishing and ironing device comprises a hollow processing tank, wherein a feeding hole is formed in the processing tank; limiting mechanisms are symmetrically arranged at the top of the processing tank; the limiting mechanisms comprise auxiliary arms and limiting blocks; vertical holes, first auxiliary holes, transverse holes and second auxiliary holes are formed in the limiting blocks; the processing tank is internally provided with a partition for partitioning the processing tank; a plurality of through holes are formed in the partition; a plurality of flattening mechanisms are also arranged on the partition; the flattening mechanisms comprise first support shafts, gears and telescopic rods; at least one transverse rod is hinged with each telescopic rod; at least one chute is formed in the side wall of each telescopic rod; sliding blocks are connected inside the chutes in a sliding manner; a moveable rodis hinged with each transverse rod; the moveable rods are fixedly connected with the sliding blocks; a plurality of air inlet holes are formed in the transverse rods; each air inlet hole is connectedwith an air charge bag; the processing tank is also internally provided with a plurality of transmission mechanisms; a steam inlet is formed in the bottom of the processing tank. By adopting the scheme of the invention, the problem that winkles can be formed when a knitted fabric garment is finished and ironed in a conventional mode is mainly solved.

Owner:宁波隆锐机械制造有限公司

Expansion joint

ActiveCN110440082AAvoid blockingGuaranteed tightnessPipeline expansion-compensationEngineeringExpansion joint

The invention relates to the technical field of pipeline accessories, and specifically relates to an expansion joint. The expansion joint comprises a first end pipe, a second end pipe, an inner sleevepipe and a sleeve connection structure, wherein the first end pipe is arranged at the outer side of the second end pipe in a sleeved manner; the inner sleeve pipe is arranged in the second end pipe;one end of the inner sleeve pipe is connected with the first end pipe; the first end pipe is connected with the second end pipe through the sleeve connection structure; the first end pipe comprises afirst connection plate, a first outer sleeve and a first extension sleeve; and the outer side of one end of the first outer sleeve is fixedly connected with the first connection plate. According to the expansion joint, through the arrangement for the inner sleeve pipe and three sealing rings, the first sealing ring is arranged between a second extension sleeve and the first extension sleeve, the second sealing ring is arranged between a first convex ring and a sleeve pipe main body, and the third sealing ring is arranged between a second convex ring and a second outer sleeve; and moreover, a wind-gathering cover is opposite to a fluid introduction direction, so that wind resistance is reduced.

Owner:泰州市通力机械有限公司

Direct-current direct-drive type driving chip with multiple packaging forms and packaging device and method

PendingCN113725193AHigh Efficiency Chip PackagingSolve balance problemsSemiconductor/solid-state device detailsSolid-state devicesAssembly lineStructural engineering

The invention relates to the technical field of chip packaging, and discloses a direct-current direct-drive type driving chip with multiple packaging forms and a packaging device and method. Stable and ordered blanking is completed through a simple mechanical structure by arranging an electric telescopic rod and the like, rapid heat fusion packaging is achieved by adopting a fluorescence labeling mode in cooperation with a hot melting gun, different chip packaging shells can be selected in a self-adaptive manner while precise packaging is realized, and the packaging efficiency is improved. Two clamping blocks at the corresponding positions are driven to rotate with the corresponding rotating shafts as the axes through the arrangement of clamping air cylinders and the like, then the clamping blocks on the two sides clamp the two sides of a to-be-packaged chip, the packaging stability is further improved, the displacement influence on the to-be-packaged chip caused by the operation of a conveying belt is avoided, a pushing plate pushes the corresponding to-be-packaged chip into a defective product groove through the operation of a material returning air cylinder, defective product collection is completed, and the packaging effect of an assembly line is ensured.

Owner:深圳市谦诚半导体技术有限公司

Passenger car inspection tool pressing mechanism

ActiveCN107179034ANovel structureEasy to operateMechanical measuring arrangementsEngineeringMechanical engineering

The invention relates to a passenger car inspection tool pressing mechanism, belonging to the technical field of passenger car inspection tools. The mechanism comprises a roof which is provided with a roof sunshade plate hole, a reference compression assembly and a reference block assembly. The reference compression assembly presses the roof sunshade plate hole in the roof to the reference block assembly. The mechanism has the advantages of a novel structure, simple operation and convenience in use. Through the inspection tool pressing mechanism, the outline of a bottom surface product can be clearly viewed after pressing the product by the inspection tool pressing mechanism, one reference can be used to detect precision in X, Y and Z directions simultaneously, and whether the roof is a qualified product is judged finally.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

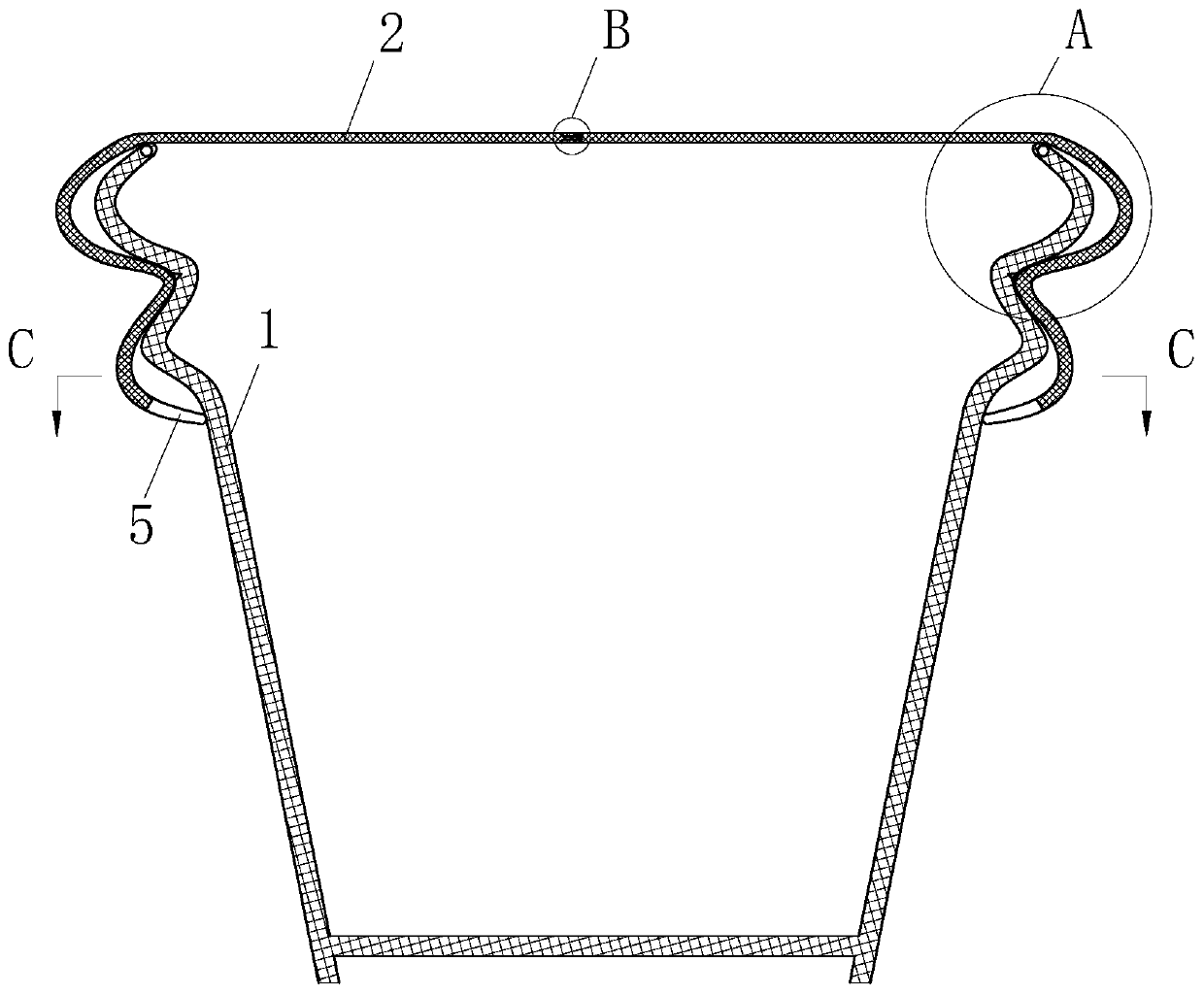

PP plastic meal delivery box

PendingCN110053860AImprove convenienceImprove efficiencyRemovable lids/coversLidsWave shapeEngineering

The invention belongs to the technical field of meal delivery boxes, and particularly relates to a PP plastic meal delivery box. The meal delivery box comprises a box body and a box cover, the upper portion cross section of the box body is of a wave-shaped structure, the box cover is also arranged into a wave-shaped structure corresponding to the wave-shaped structure of the box body, the box cover is connected with the box body through the wave-shaped structures, and the convex part of the box cover wave-shaped structure is arranged at the sunken part of the box body wave-shaped structure; the box cover is divided into two semicircular box covers symmetric about the circle center, the two semicircular box covers are hinged to each other, a convex block and a groove matched with each otherare arranged on the parting plane of the box cover, a buckle is hinged to the circumference of one semicircular box cover, and a clamping block matched with the buckle is arranged on the circumference of the other semicircular box cover. According to the box, the two semicircular box covers are hinged to each other to form the box cover, so that the packaging convenience is improved, forcibly pressing and fastening are not needed, trouble and labor consuming are omitted, and the packaging efficiency of the meal delivery box is improved.

Owner:王顺

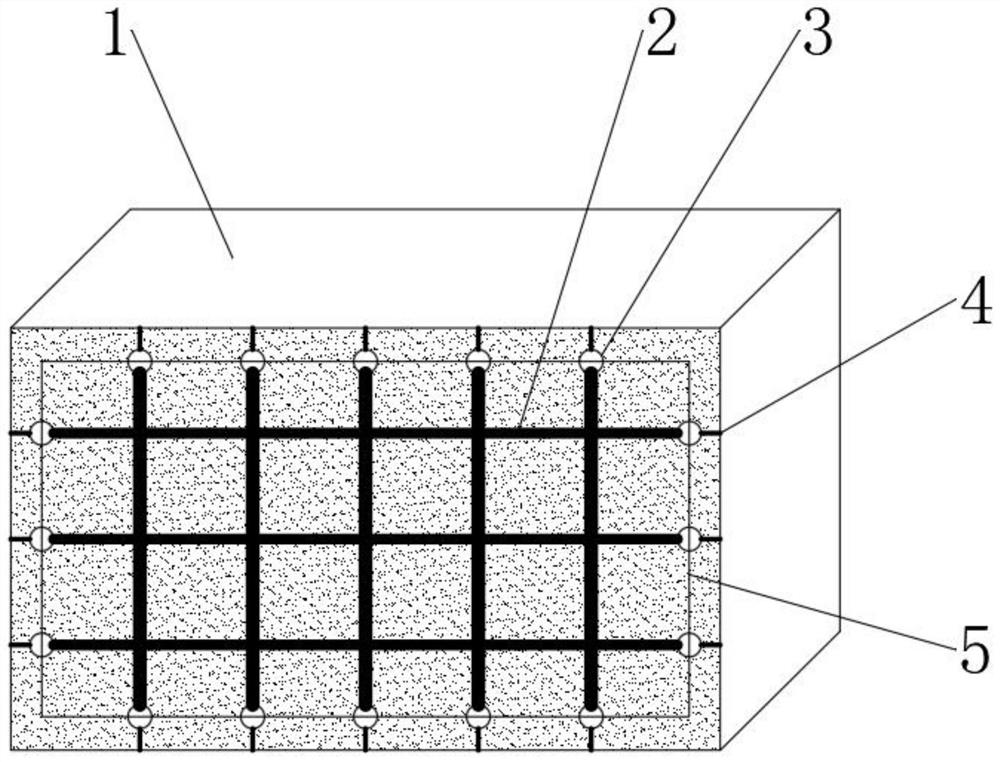

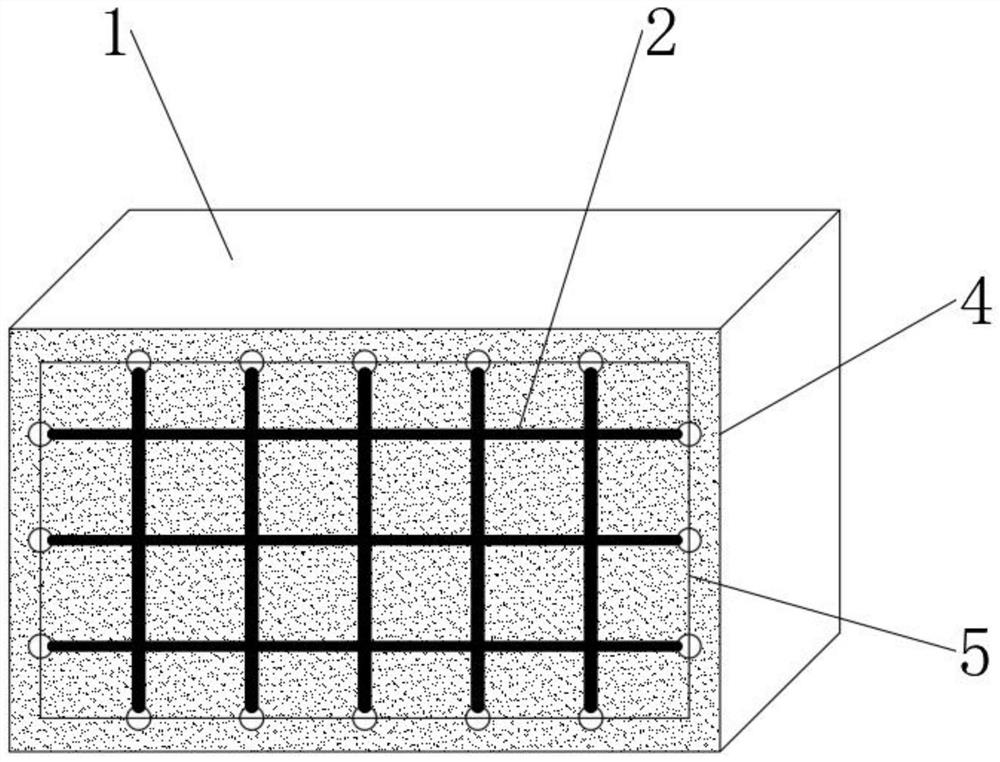

High-strength built reinforced concrete block and manufacturing mold thereof

InactiveCN112726938AHigh strengthImprove anti-seepage effectCeramic shaping apparatusBuilding componentsMagnetic tension forceFiber

The invention discloses a high-strength built reinforced concrete block and a manufacturing mold thereof, and belongs to the technical field of building materials. The high-strength built reinforced concrete block can be pre-buried in a building block body in advance by welding an anti-seepage ball on the end part of a steel bar net frame, the steel bar net frame is temporarily supported by an air compression rod during pouring forming, and when the steel bar net frame is close to curing after pouring is finished, a magnetic field is applied through the mold to force the air compression rod to move, so that the anti-seepage action of the anti-seepage ball is triggered, wherein the air compression rod can cause the internal air pressure to be increased when moving into the anti-seepage ball, so that an air sensing drum film is forced to extrude an isolation bag, and is punctured by a trigger needle to release internal blocking microspheres after transverse expansion, the blocking microspheres can actively get close to each other under the action of magnetic force so as to be in contact with a water guide fiber pipe, residual water is used for reacting, gas is released and carries an expansion material to be blown away into the building block body to realize hole blocking, the anti-seepage performance is improved, the internal steel bar net frame and the anti-seepage ball are protected, and good strength is maintained.

Owner:ZHEJIANG MEIKE CLEAN ENERGY

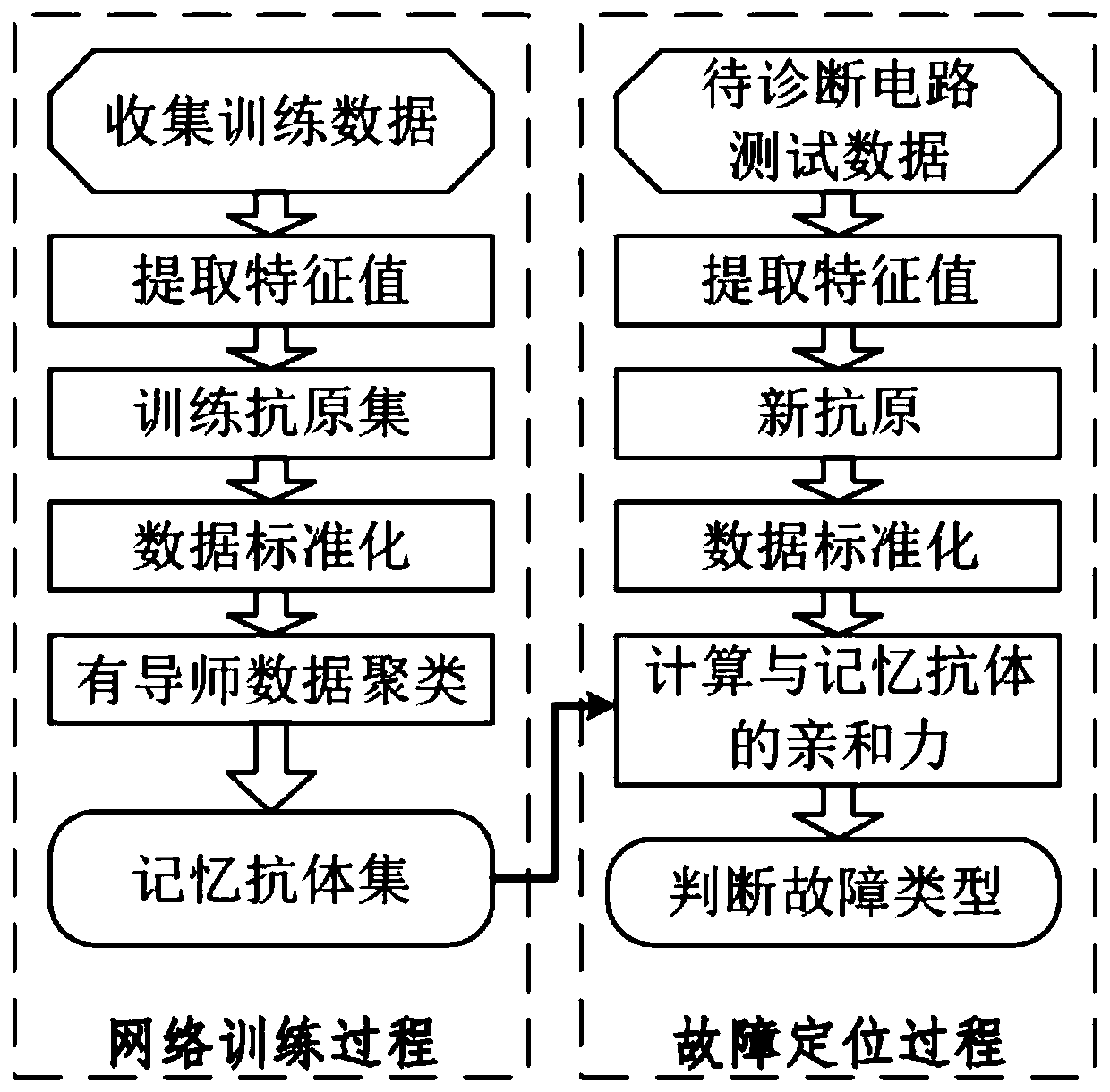

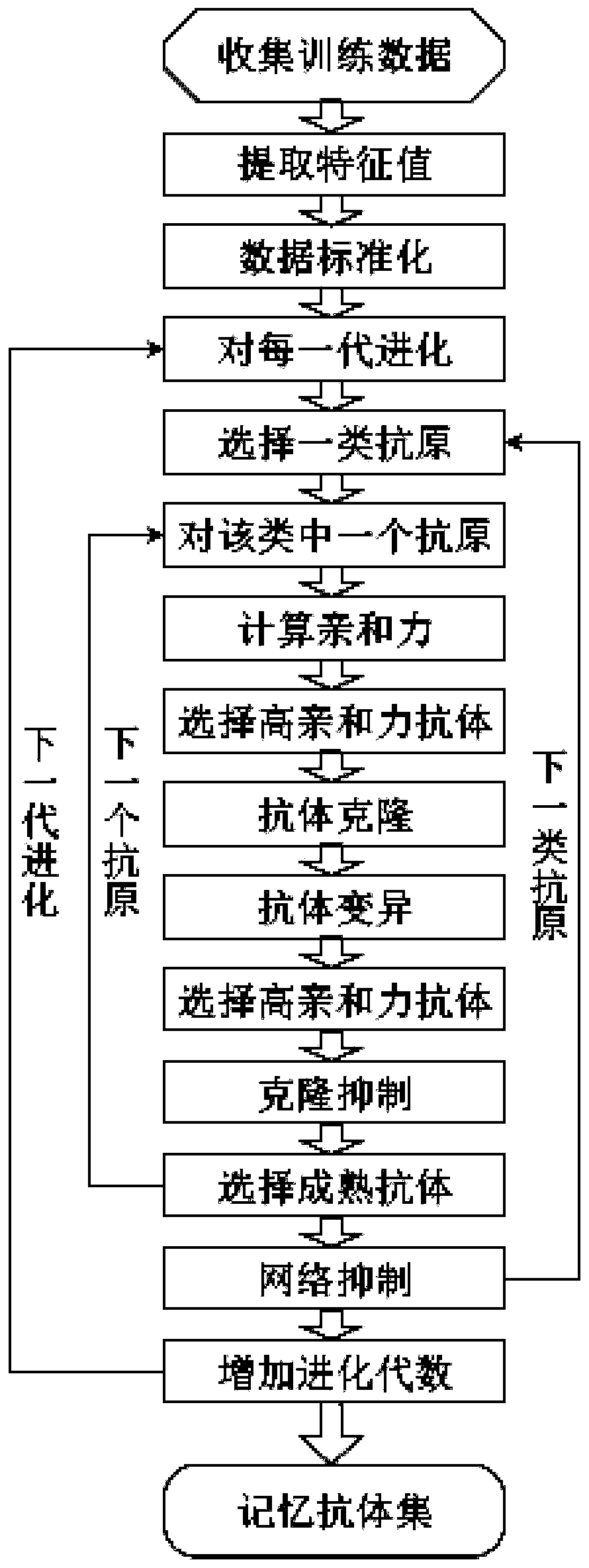

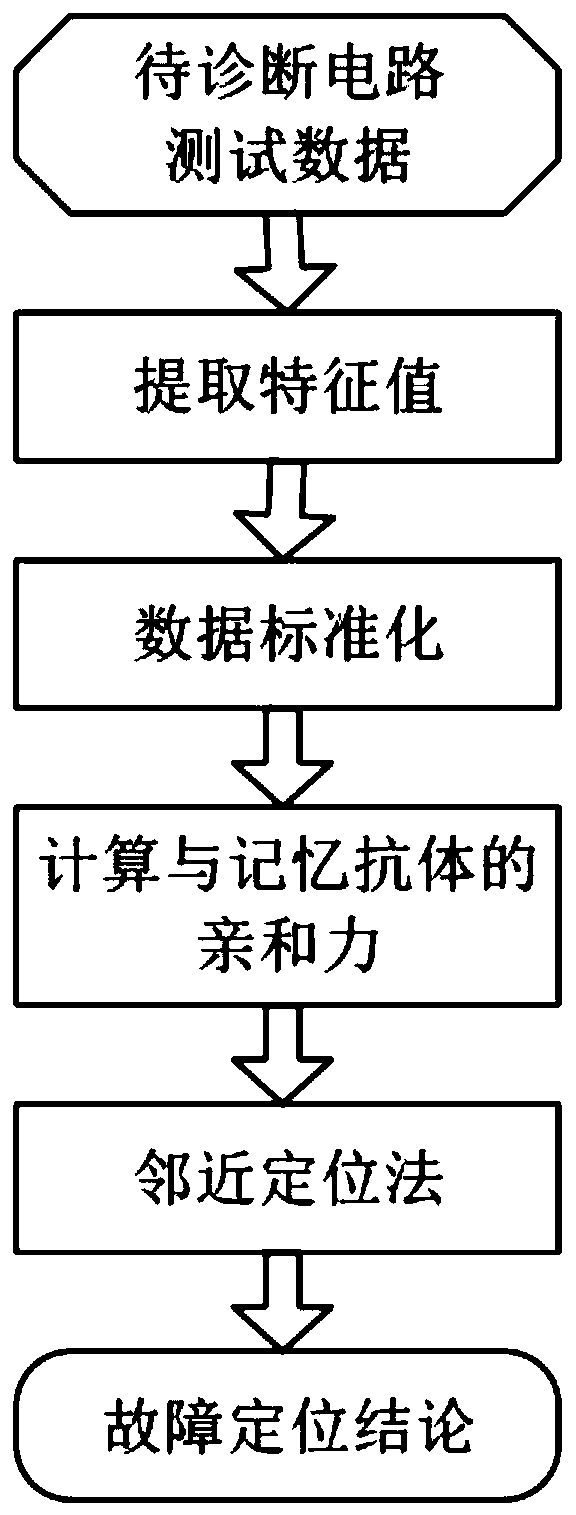

Analog circuit fault diagnosis method based on artificial immunity diagnosis network

ActiveCN109782156ATransparent structureSolving Modeling DifficultiesAnalog circuit testingBiological modelsAntigenMedicine

The invention provides an analog circuit fault diagnosis method based on an artificial immunity diagnosis network, which comprises the following steps of extracting a characteristic value of a circuitresponse signal in a training sample to form a training antigen set; performing data clustering with a director on the training antigen of each fault type to obtain a memory antibody set; acquiring aresponse signal of an actual circuit to be diagnosed, and extracting a characteristic value of the response signal to form a new antigen; activating a memory antibody in the artificial immunity diagnosis network by using the new antigen, and judging the specific fault type of the circuit to be diagnosed according to the total affinity of the new antigen and various fault type memory antibodies. According to the method, the fault type information of the circuit can be memorized after network training is completed, the fault recognition function is achieved, and the method has the advantages that influences of circuit tolerance can be effectively handled, and an analysis model does not need to be established.

Owner:NAVAL UNIV OF ENG PLA

Novel sealed type pipe chain conveyer

The invention discloses a novel sealed type pipe chain conveyer which comprises a driving box and a driven box; a material conveying pipeline is arranged between the driving box and the driven box; adriving motor is arranged in the driving box; a driving chain wheel is arranged on a main shaft of the driving motor; a driven chain wheel and a tensioning adjustment mechanism are arranged in the driven box; a chain located in the material conveying pipeline is connected between the driving chain wheel and the driven chain wheel; and a plurality of scraping plate assemblies are arranged on the chain. In conclusion, the novel sealed type pipe chain conveyer is novel in structure and low in manufacturing cost, the conveying chain runs stably, the sealability of the material conveying pipeline and a conveying box body is good, and the novel sealed type pipe chain conveyer adapts to material conveying operation in various fields.

Owner:三门峡高新机械有限公司

Automatic quilting machine

InactiveCN105887341APlay a supporting roleStep coordinationMattress sewingDrive shaftReciprocating motion

The invention relates to an automatic quilting machine. The machine comprises a rack, a stepping motor, a driving motor, a speed reducer and a sewing line rack, wherein a moving rack A and a moving rack B are arranged on the rack; dragging belts are arranged on the moving rack A and the moving rack B; the moving rack A and the moving rack B can be driven by gears to move in opposite directions; a lifting frame is arranged in the rack; the upper end of the lifting frame is connected with the moving rack B through an upper baffle plate and a lower baffle plate; an operating rod which is arranged at one side of the lifting frame can be rocked to lift the lifting frame up and down; line hooking shafts on which line hooking rulers are mounted are arranged in the rack. According to the machine, the line hooking shafts and sewing beams are used in match to sew a quilt; transmission shafts arranged at the bottom part of the sewing line rack can drive eccentric sheets at two ends so as to drive guide rods to feed a line and reciprocate, and as a result, the sewing beam can be driven to move up and down and matched with the line hooking shaft to sew.

Owner:HENAN XINPUFENG COTTON GIN TECH CO LTD

Treatment device for dismounting hydraulic oil cylinder guide sleeve

InactiveCN112320675AIncrease demandPlay a role in compressionWork holdersLifting framesGear wheelHydraulic ram

Owner:CHANGDE GEJIA MACHINERY

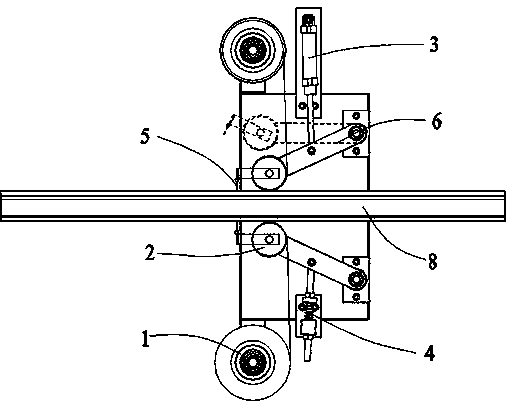

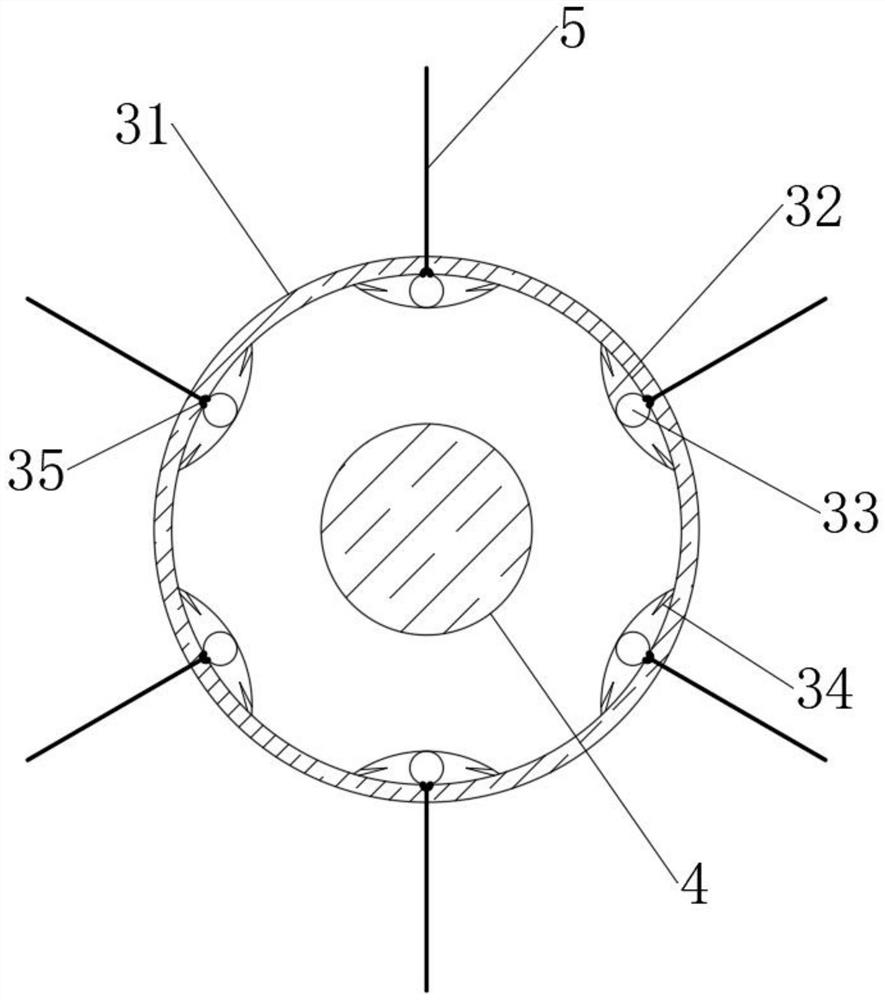

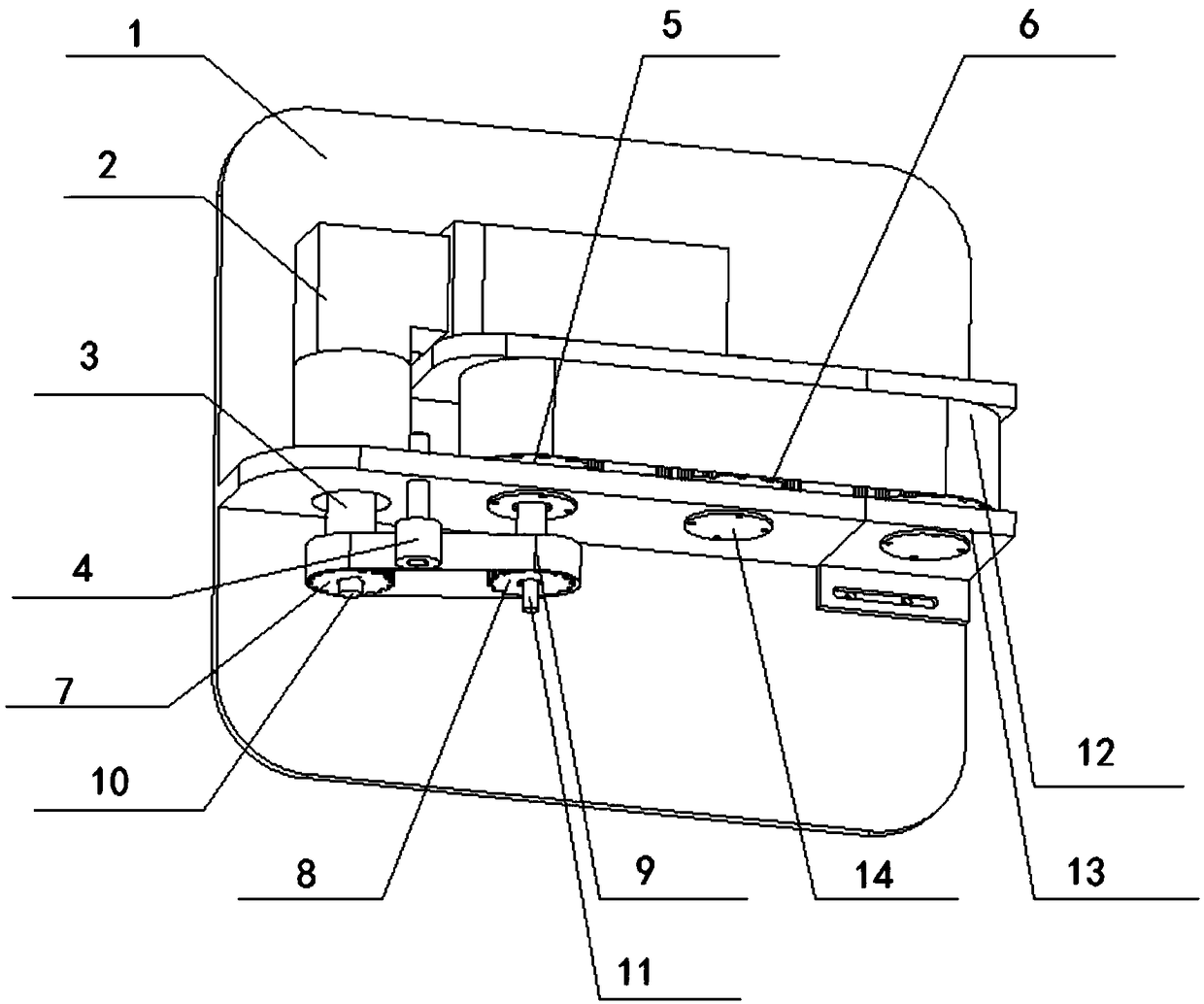

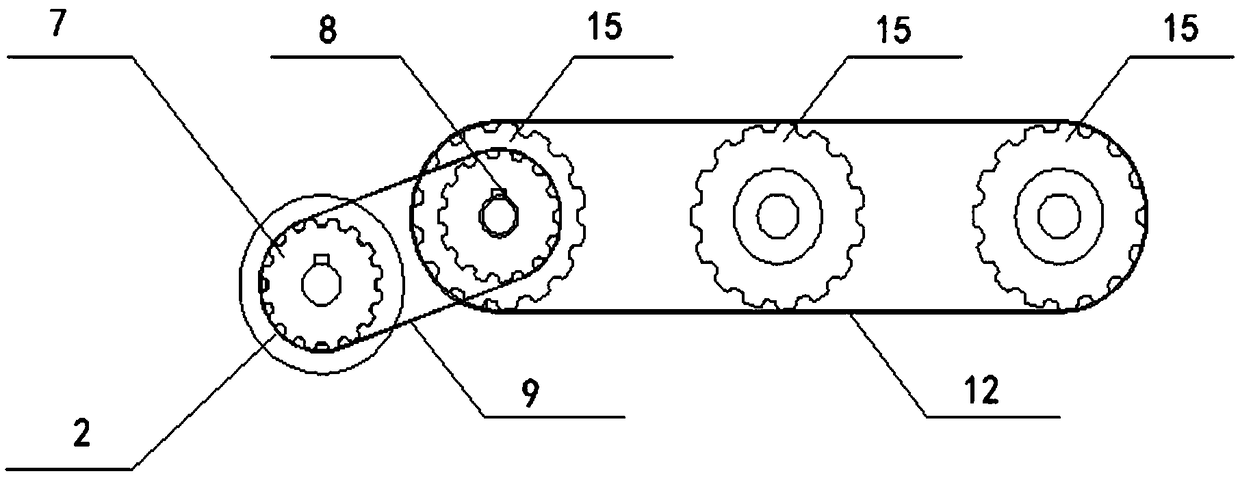

Multifunctional pipeline walking mechanism

The invention discloses a multifunctional pipeline walking mechanism comprising a base plate (1), a power motor assembly (2), a T-shaped sliding block, an L-shaped synchronous belt (9), a first transmission shaft (10), a driving rolling wheel assembly (5) and two driven rolling wheel assemblies (6). The T-shaped rolling wheel assembly (5) comprises a second transmission shaft (11) and a walking synchronous belt pulley (15). The first transmission shaft (10) and the second transmission shaft (11) are provided with a first transmission synchronous belt pulley (7) and a second transmission synchronous belt pulley (8) correspondingly. The L-shaped synchronous belt (9) is meshed with the first transmission synchronous belt pulley (7) and the second transmission synchronous belt pulley (8). TheT-shaped sliding block (13) comprises a sliding groove matched with a guide groove (17) and the driven rolling wheel assembly (6). The driving rolling wheel assembly (5) and the two driven rolling wheel assemblies (6) are sleeved with an H-shaped double-side staggered teeth synchronous belt (12) in a sleeved manner. The multifunctional pipeline walking mechanism can prevent slipping during walking.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

Vacuum degree sensing device

The invention discloses a vacuum degree sensing device. A lower chamber communicated with a vacuum chamber to be tested and an upper chamber communicated with the atmosphere are arranged in a main casing body. An output interface is arranged on one side of the upper chamber. An external pin is arranged on one side close to the output interface in the upper chamber, and a fixed pin is arranged on the other side. A partition plate is arranged between the lower chamber and the upper chamber. The partition plate is provided with a through hole communicated with the lower chamber and the upper chamber. A PCB board and a pressure sensing element are arranged in the upper chamber above the through hole. The PCB board is fixed in the upper chamber through the external pin and the fixed pin. The pressure sensing element is closely attached to the partition plate through a sealing pad. Air flow holes opposite to the through hole are arranged in the center of the PCB board and the sealing pad. Anupper cover is arranged at the top of the upper chamber. A pipe joint is arranged on the open side of the lower chamber. The vacuum degree sensing device provided by the invention has the characteristics of reasonable structure, high accuracy, high reliability and high practical value.

Owner:宁波拓普电器有限公司

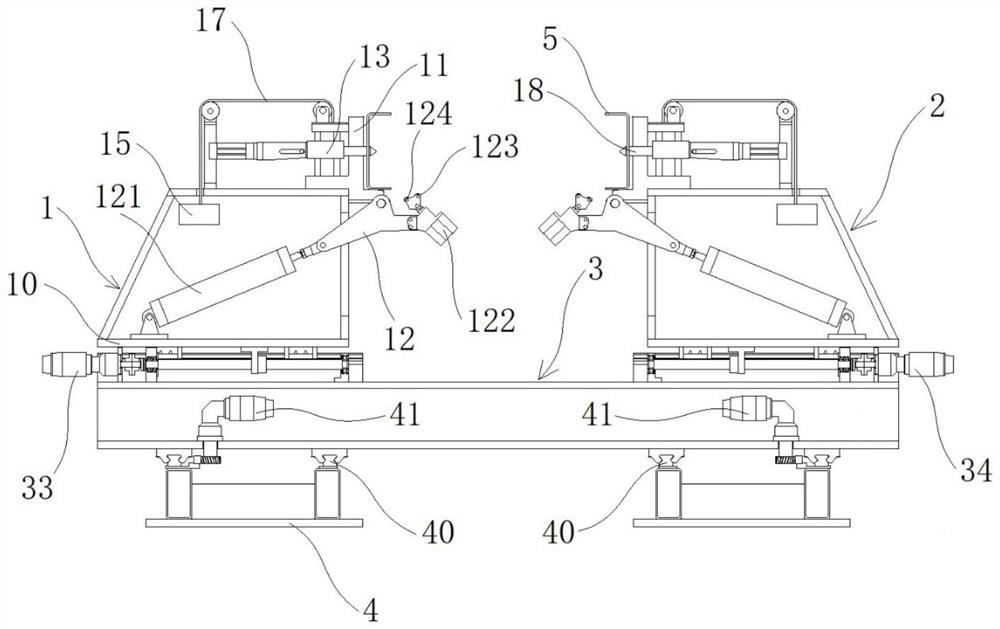

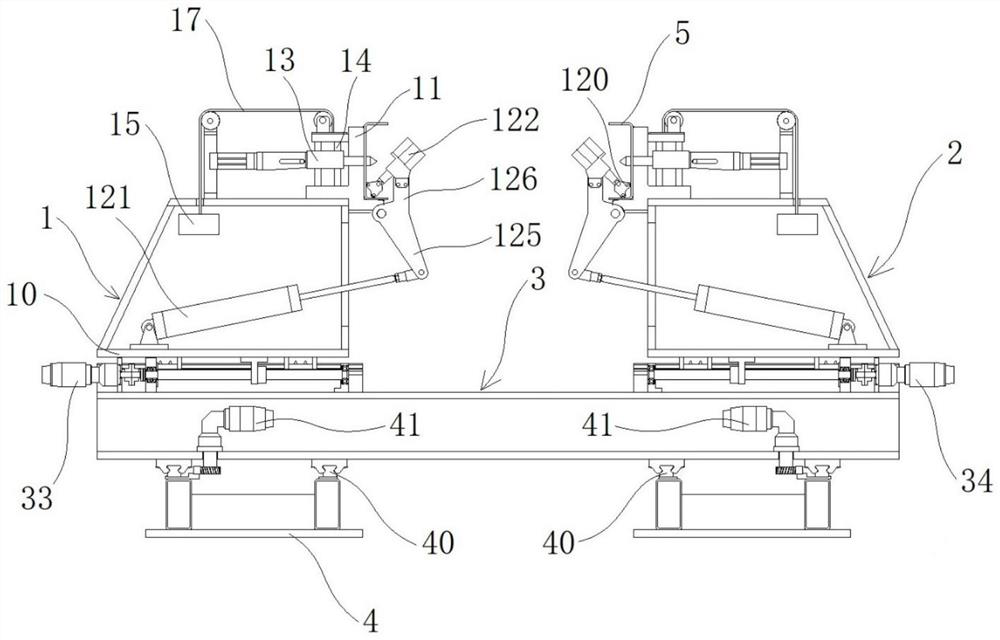

Positioning tool for frame longitudinal beam

ActiveCN113681220AFlexible adjustment of horizontal spacingTo achieve the purpose of automatic adaptationWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides a positioning tool for a frame longitudinal beam, and relates to the field of frame assembly. The positioning tool comprises a base, a first mounting seat and a second mounting seat, the first mounting seat and the second mounting seat are oppositely arranged at an interval, the first mounting seat comprises a support, a fixing block, a pressing mechanism and a first driving part, and a positioning angle facing the interval position is arranged on the fixing block; the first driving part is connected with the pressing mechanism, and the pressing direction of a pressing head of the pressing mechanism obliquely extends towards the positioning angle so as to press the lower inner angle of the longitudinal beam; and a positioning sliding block is vertically installed on the support in a guiding manner, and a positioning pin of the positioning sliding block is used for being matched with an auxiliary hole in the longitudinal beam ventral face in a positioning manner. According to the tool, the longitudinal beam ventral face is positioned and pressed, the longitudinal beam lower wing face is positioned and pressed, the longitudinal beam is accurately positioned in the length direction, and the positioning accuracy in the Z direction and the length direction is improved; and for frames of different specifications and models, the positions of the first mounting seat and the second mounting seat in the interval width direction and the interval length direction can be adjusted, and automatic adaptation is achieved.

Owner:DONGFENG LIUZHOU MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com