Residual stress introduction device keeping center position unchanged

A technology of residual stress and introducing devices, which is applied to measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of inability to introduce and low precision of prestress, achieve uniform stress state, ensure measurement accuracy, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

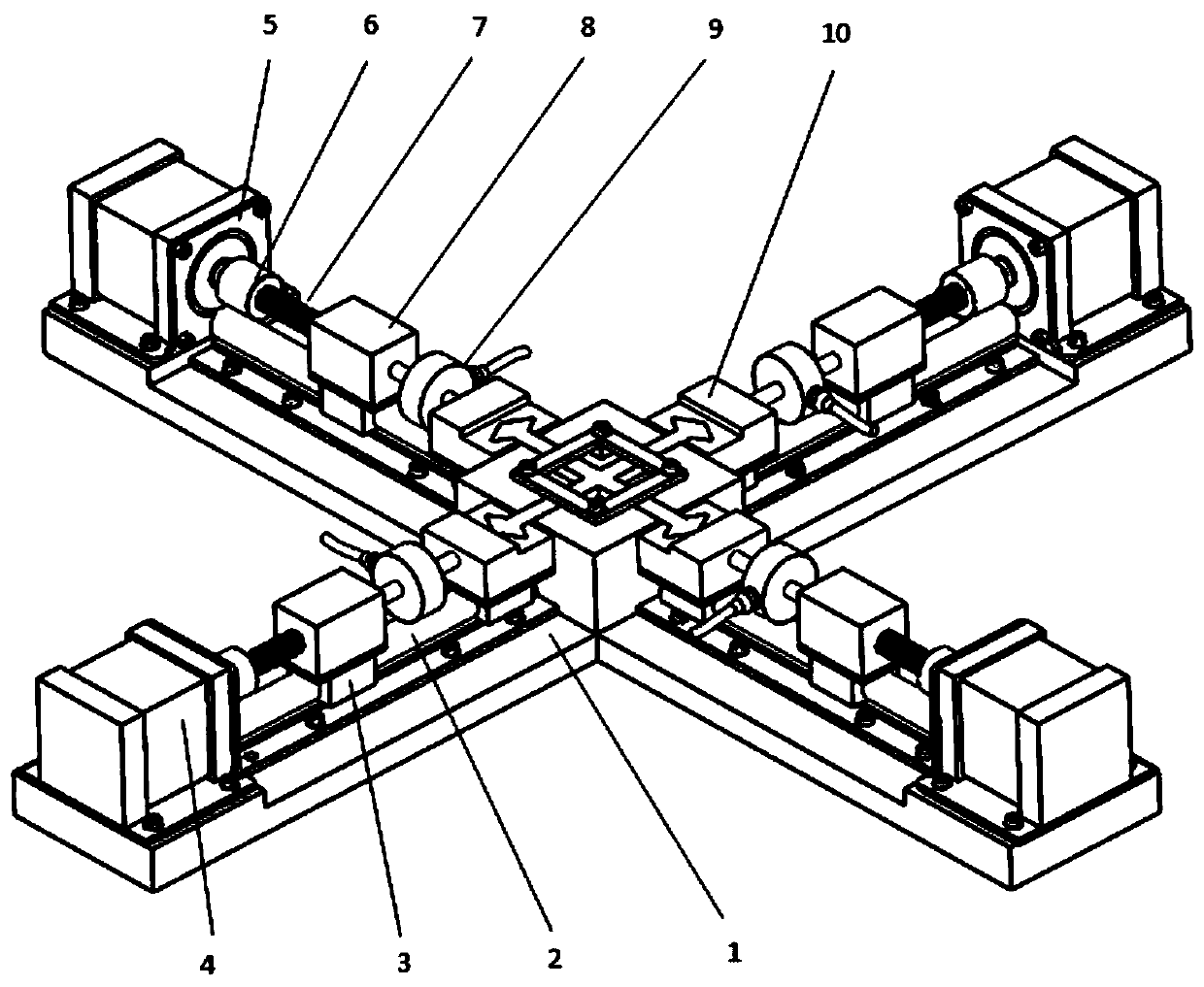

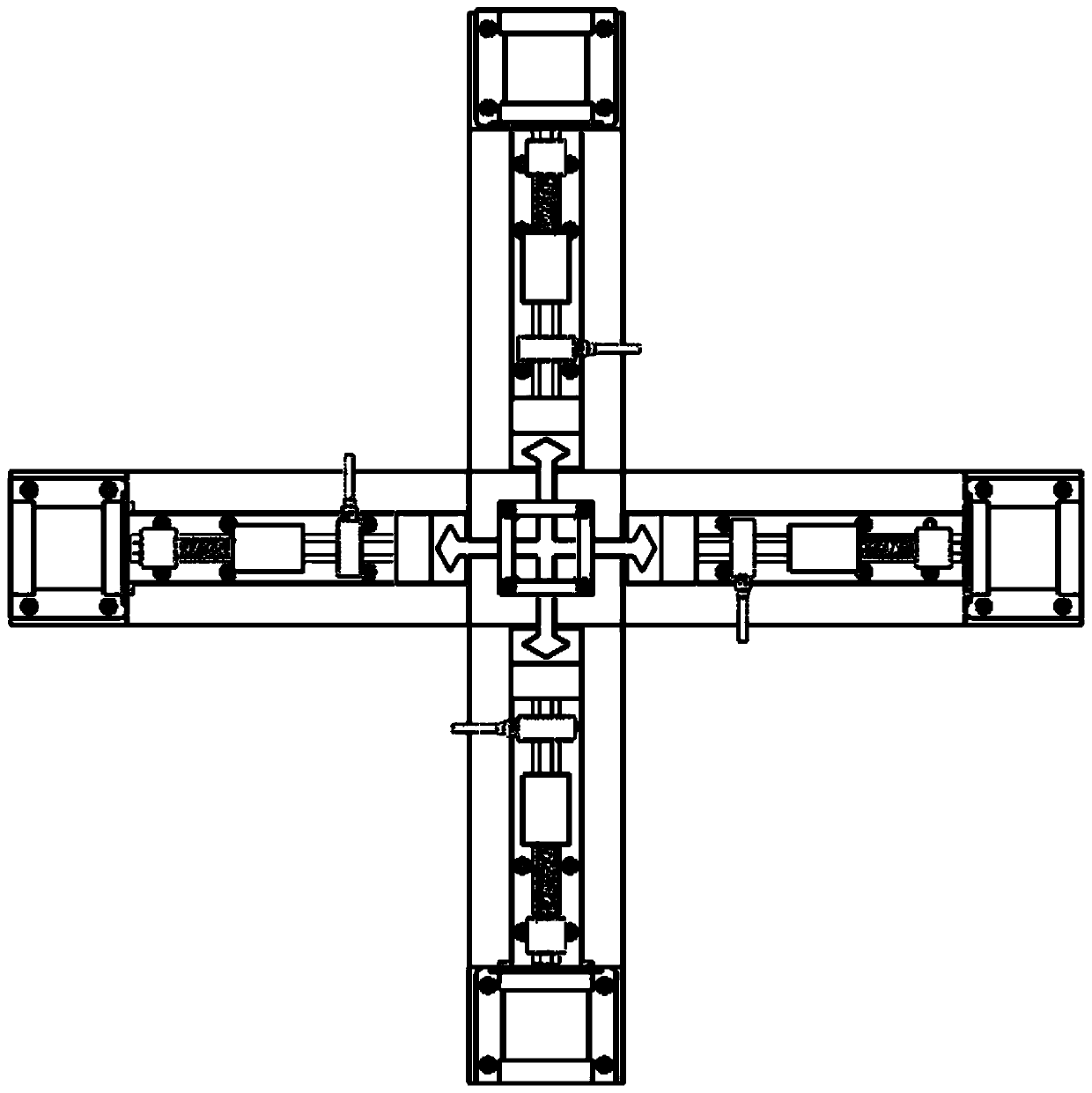

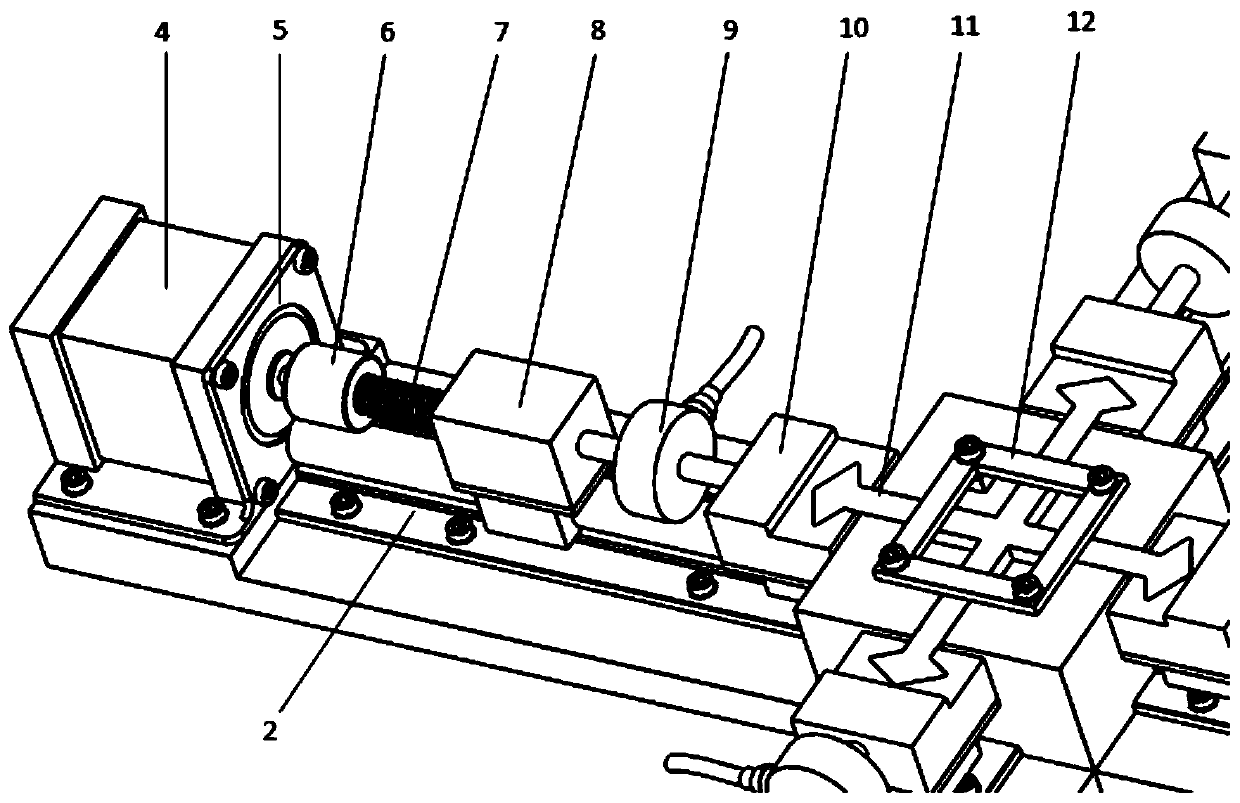

[0019] refer to Figure 1 ~ Figure 4 , a residual stress introduction device that keeps the central position fixed, including a base 1, a stress applying assembly, a load sensor 9, a movable fixture 10 and a pressure piece 12, the base 1 is designed as a cross, and a cross-shaped concave is arranged in the middle. The boss of the groove is used to place the sample 11 to be tested, and bosses are provided around it for fixing the motor support 5 and the driving motor 4 .

[0020] The stress applying assembly includes a driving motor 4 , a shaft coupling 6 , a lead screw 7 and a moving block 8 , the moving block is fixed to the slider 3 and moves on the slide rail 2 driven by the lead screw 7 . One end of the stress applying component is fixed to the base 1 , and the other end is connected to the load sensor 9 through threads, so as to apply tensile stress or compressiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com