Automatic quilting machine

A quilting machine and automatic technology, which is applied to sewing machines for sewing quilts, sewing equipment, textiles and papermaking, etc. It can solve the problems of complex design, uneven stitching, and high production costs, so as to reduce the input of control devices and improve overall quality. Reasonable design and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

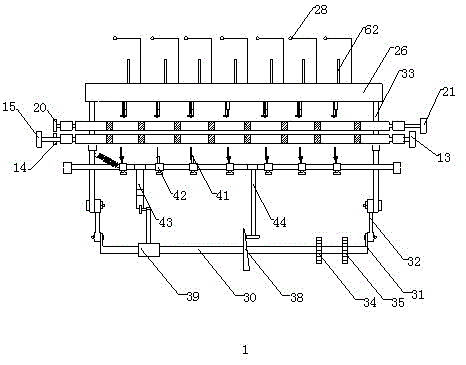

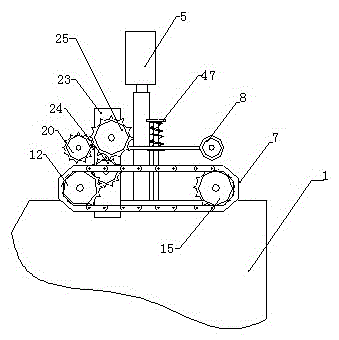

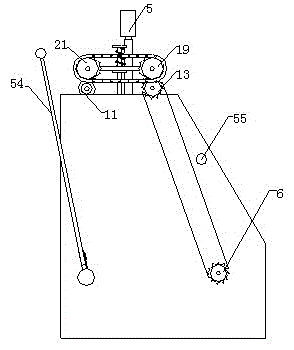

[0032] like figure 1 -shown in 13: a kind of automatic quilting machine, comprises frame 1, stepper motor 2, drive motor 3, speed reducer 4 and suture frame 5, and described stepper motor 2 is arranged on frame 1 inside, The stepper motor 2 is connected to the driving gear 6 arranged outside the frame 1 through a guide shaft, a walking frame A7 is installed on the upper part of the frame 1, and a walking frame is stacked on the walking frame A7 B8, the walking frame A7 is composed of an idler roller A9 and an idler roller B10, and the idler roller A9 is connected with the frame 1 through the shaft seats 11 arranged at both ends of the frame 1, and the right end of the idler roller A9 is set There is a gear A12, and a gear B13 is arranged at the left end thereof, and a transmission gear A14 is also arranged at the right end of the idler roller A9, and the idler roller B10 is connected with the frame 1 through the shaft seats 11 arranged at both ends of the frame 1 , the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com