Vacuum degree sensing device

A sensing device and technology of vacuum degree, applied in the field of vacuum degree sensing device, can solve problems such as unreasonable structure, poor sealing, easy entry of external water vapor, etc., and achieve high accuracy and reliability, high practical value, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

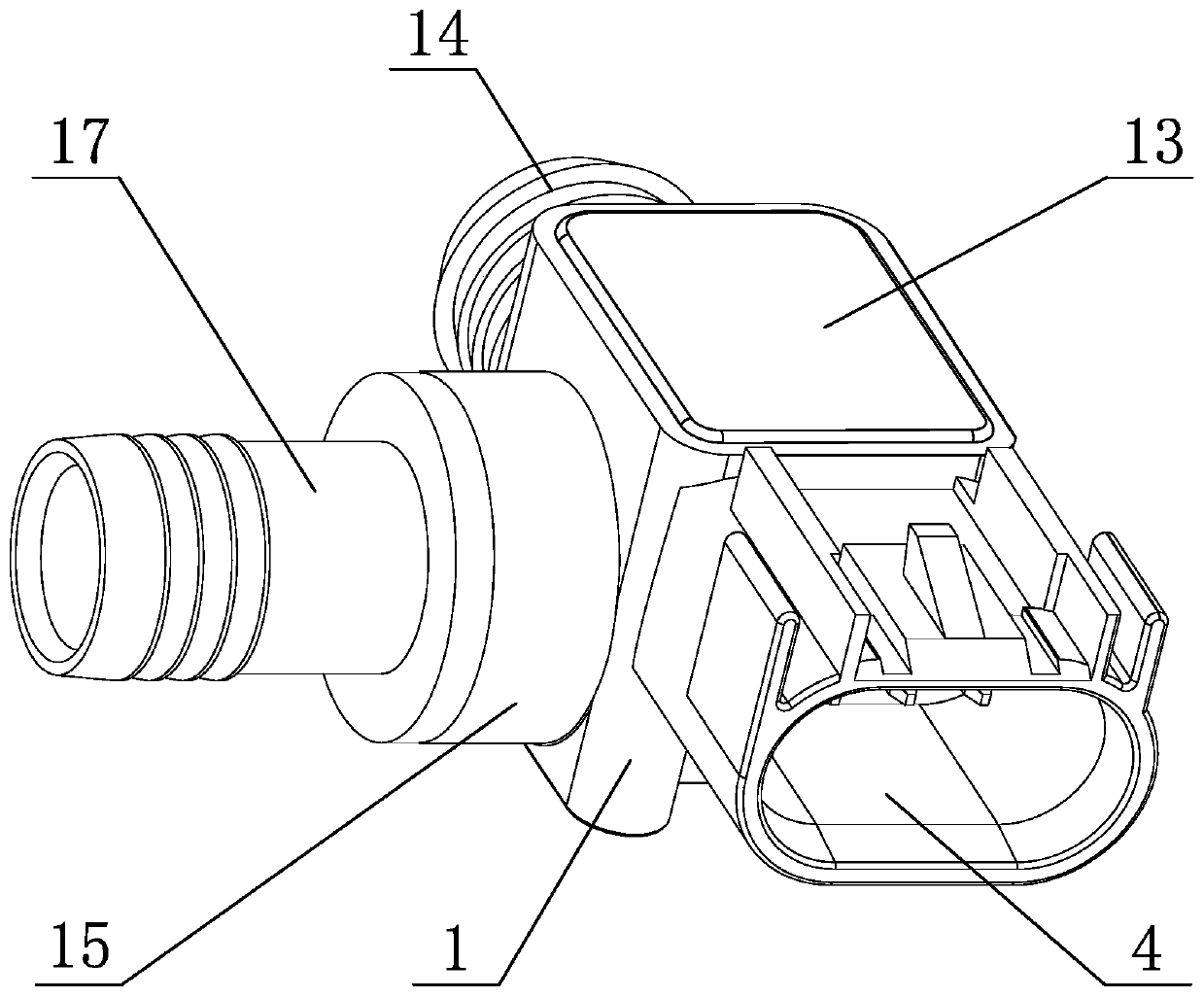

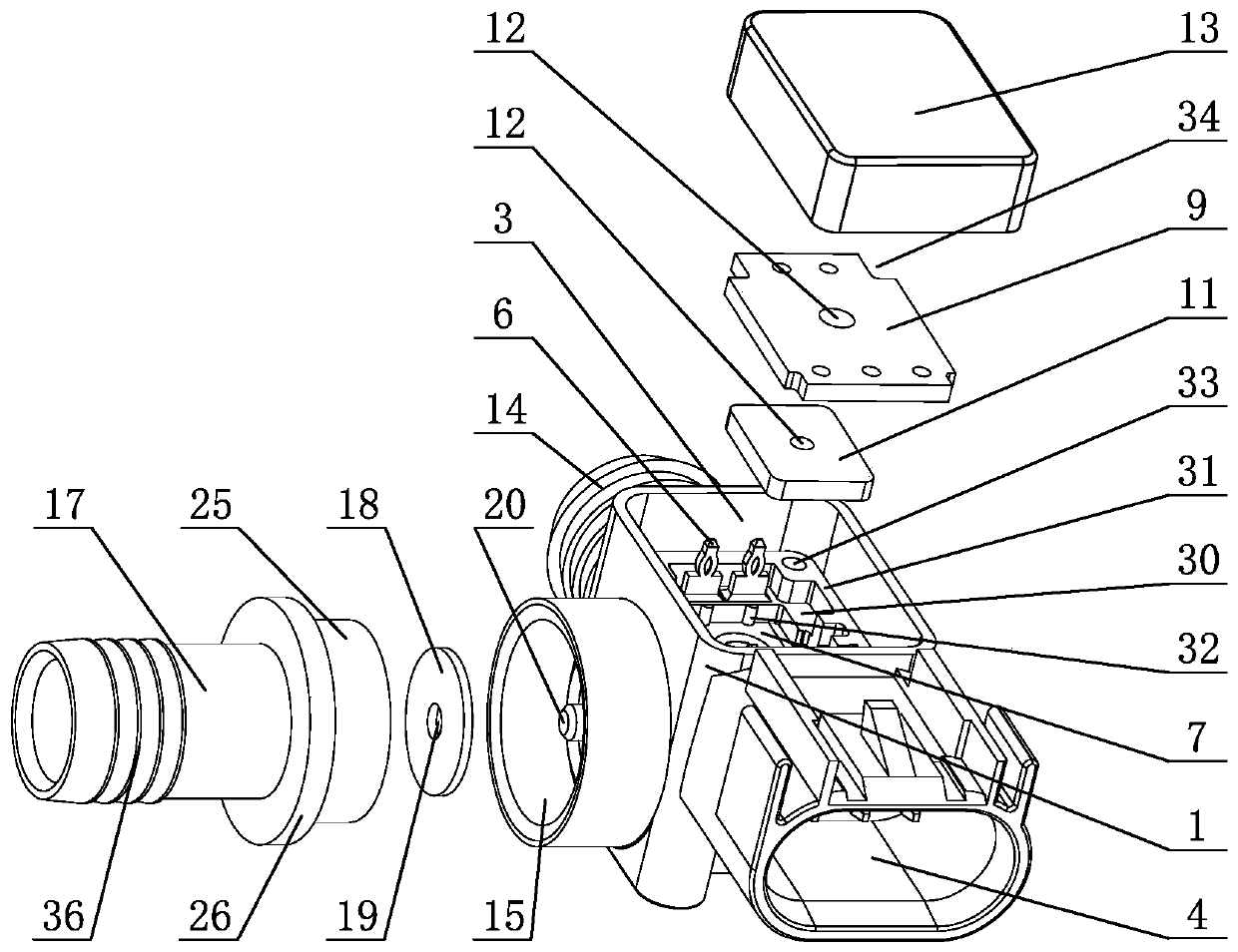

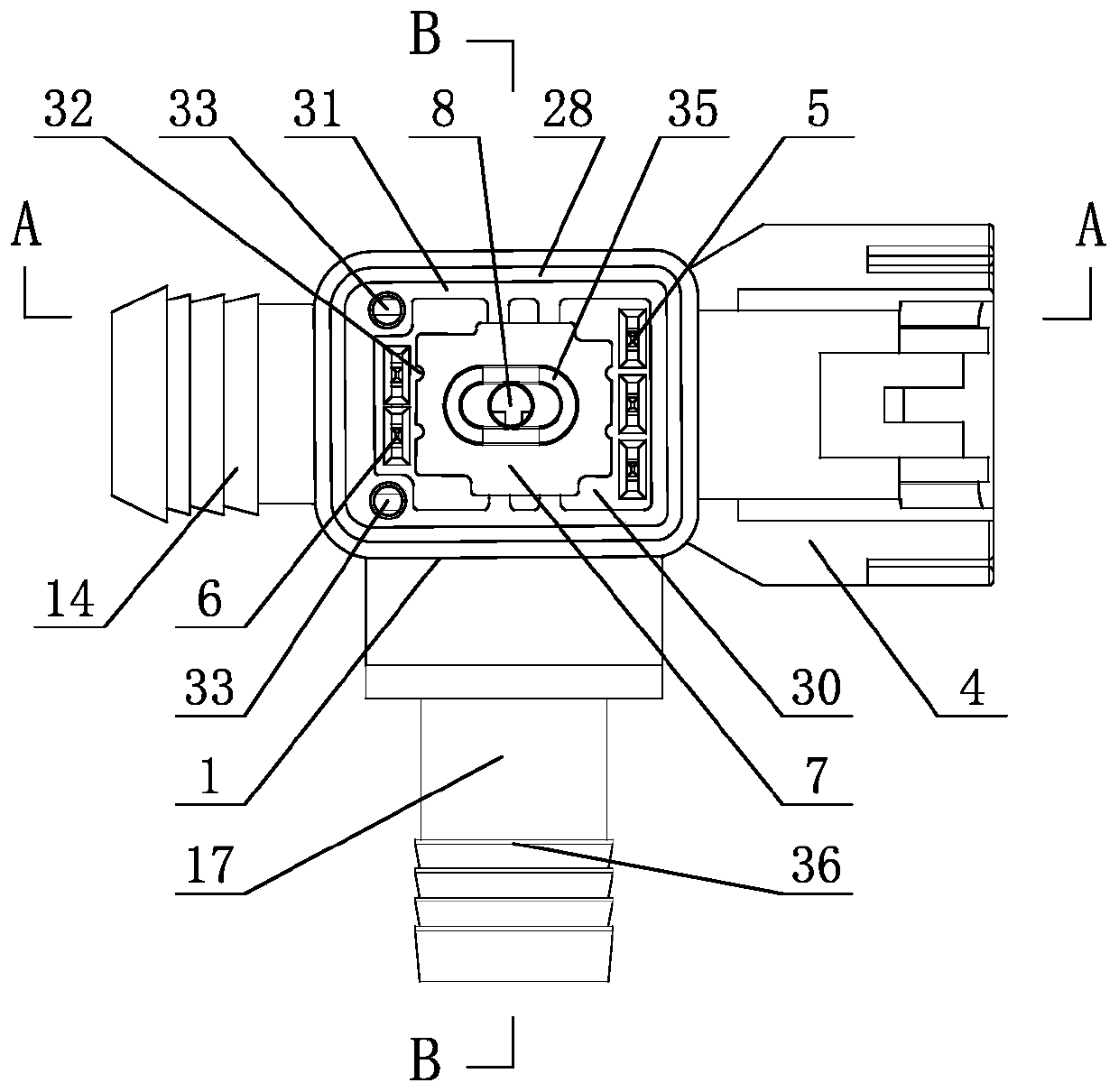

[0025] in such as figure 1 figure 2 In the shown embodiment 1, a vacuum degree sensing device includes a main housing 1, a lower chamber 2 communicating with the vacuum chamber to be tested and an upper chamber 3 communicating with the atmosphere are provided in the main housing, and the upper chamber is The whole is rectangular, one side of the upper cavity is provided with an output interface 4, and the side of the upper cavity close to the output interface is provided with three external pins 5 (see image 3 ), and the three external pins are power supply pins, ground pins and vacuum signal pins. The external pins are electrically connected to the output interface, two fixed pins 6 are arranged on the side away from the output interface in the upper cavity, a partition 7 is arranged between the lower cavity and the upper cavity, and a partition 7 is set on the partition. There is a through hole 8 connecting the lower cavity and the upper cavity, and a sealing rib 35 surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com